Nyeoe Jeremane:

Tšebeliso ea Mould ea Ente ho Tlhahiso ea Likarolo Tsa Likoloi

Jeremane, ho etsa ente ke e 'ngoe ea mekhoa e sebelisoang haholo ea tlhahiso ea polasetiki. Sena se nepahetse kaha se fana ka tharollo e sebetsang bakeng sa tlhahiso e kholo ea likarolo tsa koloi tsa boleng bo holimo tse tsoang mefuteng e mengata ea li-polymers. Indastering ea likoloi, moo botsitso, polokeho le boleng li leng bohlokoa haholo, ho bopa ente ea polasetiki ea likoloi ke ts'ebetso ea bohlokoa ea tlhahiso.

Ho na le bahlahisi ba 'maloa ba indasteri ea likoloi ba tsoang Jeremane, ba sebelisanang le DJmolding, ba reka likarolo tsa polasetiki tsa makoloi ho tsoa lits'ebeletso tsa mochini oa ente ea DJmolding, ho kenyeletsoa li-fenders, grilles, bumpers, mamati a mamati, liporo tsa fatše, matlo a bobebe le tse ling.

Ho DJmolding, re fana ka lits'ebeletso tsa ho bopa ente, ho isa likarolo tsa koloi ea polasetiki e entsoeng ka bongata ho bareki ba indastering ea likoloi le tse ling. Litšebeletso tsa rona li kenyelletsa ho bopa ente ea thermoplastic, ho bopa ho feta tekano, ho kenya mochini, le ho etsa hlobo. Tabeng ea ho qetela, litsebi tsa rona li sebetsa le bareki ba Jeremane ho hlahisa hlobo ea boleng bo phahameng bakeng sa prototyping kapa lihlahisoa tse kholo tsa tlhahiso.

DJmolding e boetse e sebetsa ka mefuta e mengata ea lisebelisoa tsa ente ea polasetiki, ho kenyelletsa le li-thermoplastics tse matla, tse thibelang mocheso le tse thata; tenyetsehang, ka potlako phekola thermoplastics; le lipolasetiki tsa rabara tse tšoarellang nako e telele, tse nang le mocheso o phahameng. Litšebeletso tsa rona tsa profeshenale tsa ho bopa ente ea polasetiki ea likoloi li thusa bareki ba rona ba likoloi ho fumana likarolo tsa makoloi tsa boleng bo holimo tse fihlelang litlhoko tsa bona tsa kopo, haholo-holo bakeng sa linaha tse matla tsa indasteri ea likoloi, joalo ka Gemany, USA, Japan.

Likopo tsa Tlhahiso bakeng sa Molding ea Ente ea Likoloi

Lefapheng la likoloi, ho etsa ente ke e 'ngoe ea mekhoa e sebelisoang haholo ke baetsi ho etsa likarolo tsa polasetiki. Leha ho le joalo, ho ka ba thata ho etsa lethathamo la likarolo tsa polasetiki ka koloing e hlahisoang ka ho bōptjoa ha ente, kahoo re tla sheba tse ling tsa tse ka sehloohong.

1. Likaroloana tse ka tlas'a-hood

Lilemong tse mashome a mabeli tse fetileng, likarolo tse ngata tse ka tlas'a-hood tseo baetsi ba pele ba neng ba li etsa ka tšepe li fetotsoe ho polasetiki. Bakeng sa lits'ebetso tsena, li-polymer tse matla tse kang ABS, Nylon, le PET li tloaelehile. Leha ho le joalo, hona joale bahlahisi ba etsa likarolo tse kang li-cylinder head covers le lipane tsa oli ba sebelisa ente. Mokhoa ona o fana ka litekanyo tse tlase le litšenyehelo ha li bapisoa le likarolo tsa tšepe.

2. Likaroloana tsa Kantle

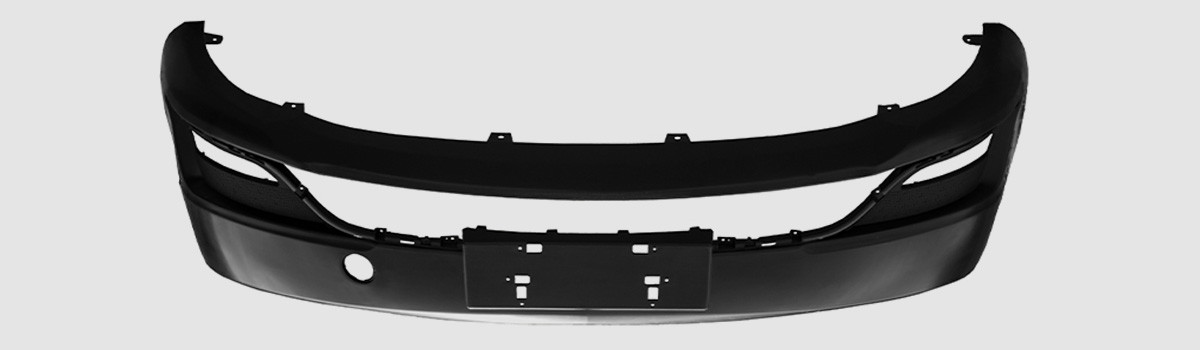

Ho bopa ka ente ke ts'ebetso e thehiloeng bakeng sa likarolo tse ngata tsa likoloi tsa kantle, ho kenyeletsoa li-fenders, grilles, bumpers, liphanele tsa mamati, liporo tsa fatše, matlo a bobebe, le tse ling. Balebeli ba Splash ke mohlala o motle oa ho bontša ho tšoarella ha likarolo tse entsoeng ka ente. Ho phaella moo, likaroloana, tse sireletsang koloi ho tloha litšila tsa litsela le ho fokotsa ho phatloha, hangata li entsoe ka rabara kapa lisebelisoa tse ling tse tšoarellang le tse tenyetsehang.

3. Likaroloana tsa ka Hare

Baetsi ba boetse ba hlahisa likarolo tse ngata tsa ka hare tsa likoloi ba sebelisa mochini oa ente ea polasetiki ea likoloi. Li kenyeletsa lisebelisoa tsa lisebelisoa, bokaholimo ba ka hare, li-faceplates tsa dashboard, li-handle handles, li-glove compartments, li-air vents, le tse ling. Ho feta moo, ba boetse ba sebelisa ente ea ente bakeng sa ho hlahisa likarolo tsa polasetiki tse khabisitsoeng.

Mekhoa e meng ea ho Enta Mould bakeng sa Mefuta ea Likoloi tsa theko e tlase

Maemong a mangata, polasetiki e bōpiloeng e sebetsa e le mokhoa o mong oa tšepe. Nakong e fetileng, bahlahisi ba etsa lintho tse kang li-brackets, li-trunk lids, li-modules tsa lebanta la setulo, le lijana tsa mekotla ea moea feela ka tšepe. Matsatsing ana, ho etsa ente ke mokhoa o ratoang oa tlhahiso bakeng sa lipolasetiki tsena.

Ka lehlakoreng le leng, ka linako tse ling bahlahisi ba ka nkela likarolo tsa polasetiki tse bōpiloeng sebaka ka likarolo tsa koloi ea polasetiki e hatisitsoeng ea 3D. Sena se etsahala haholo-holo ho prototyping, moo ho nang le tlhokahalo e fokolang ea ho tšoarella ho feteletseng kapa qetello e boreleli. Li-plastiki tse ngata tse ka bōptjoang li ka sebetsa e le li-filament tsa khatiso tsa FDM 3D kapa e le li-powders tsa khatiso tsa SLS 3D bakeng sa li-nylon. Bahatisi ba bang ba litsebi le ba mocheso o phahameng ba 3D ba ka boela ba hatisa likarolo tse matlafalitsoeng bakeng sa likarolo tse matla haholo.

Bakeng sa li-prototypes tsa nako e le 'ngoe, haholo-holo likarolo tseo e seng tsa mochini, khatiso ea 3D e ka fana ka mefuta e meng e theko e boima ea ho bopa. Ka lebaka la ho ba sieo ha litšenyehelo tsa lisebelisoa, litheko tsa tlhahiso ha li phahame haholo.

Maemong a mang, bahlahisi ba ka ba ba sebelisa khatiso ea 3D bakeng sa likarolo tse seng kae tsa likoloi tse sebelisoang qetellong. Ba ka 'na ba sebelisa khatiso ea SLM 3D ho etsa likarolo tsa ho tšoara metsi joaloka li-valve (ha hangata li entsoe ka ente). Leha ho le joalo, khetho e 'ngoe ke ho sebelisa khatiso ea SLS 3D ho etsa likarolo tse kang li-bumpers, trim, le li- windbreaker, tseo ka linako tse ling li entsoeng ka ente.

Baetsi ba ka sebelisa tlhahiso ea tlatsetso bakeng sa mefuta e mengata e pharalletseng ea likarolo tsa koloi tsa ente nakong e tlang e seng hole haholo. Sena se ka tloha ho mamati le liphanele tsa 'mele (SLM) ho isa ho powertrain le likarolo tsa drivetrain (EBM).

DJmolding e ntle haholo ho bopeng ente ea polasetiki bakeng sa likarolo tsa likoloi, haeba u batla ho qala morero oa hau oa ho hlahisa likarolo tsa likoloi, ka kopo ikopanye le rona, re tla ba le corperation e ntle.