Tšebeletso ea CNC Machining

CNC Machining ke Eng?

CNC e emetse taolo ea linomoro tsa komporo, e leng thekenoloji ea ho laola lisebelisoa tsa machining ka ho sebelisa komporo e nyane e hoketsoeng sesebelisoa. Mechini ea CNCs e ne e tla sebetsa ho latela litaelo tse hlophisitsoeng tse hlophisitsoeng, joalo ka motsamao oa mechini, sekhahla sa phepelo ea thepa, lebelo, joalo-joalo. Ha ho na tlhoko ea hore basebelisi ba laole mochini ka letsoho, ka hona, CNC e thusa ho ntlafatsa ts'ebetso le ho nepahala ho isa tekanyong e kholo.

DJmolding CNC bokhoni ba ho etsa mochini

Mechine ea CNC e batloang haholo bakeng sa likarolo tse potlakileng tsa prototyping le likarolo tsa tlhahiso, mabenkele a mochini a CNC a nang le boiphihlelo a bile a hlahlojoa ka botlalo.

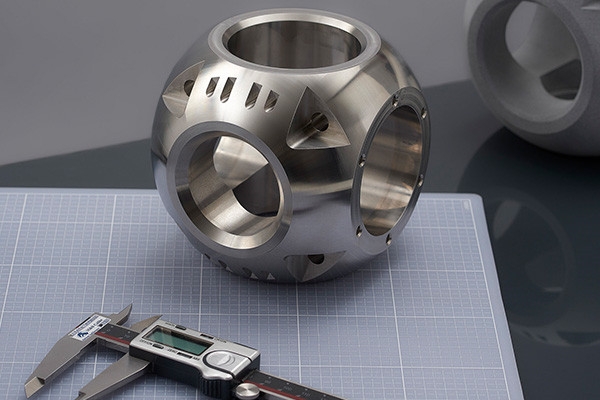

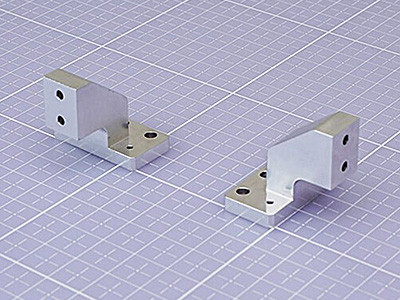

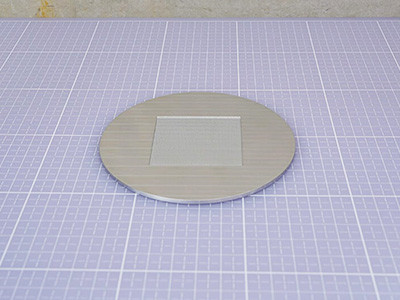

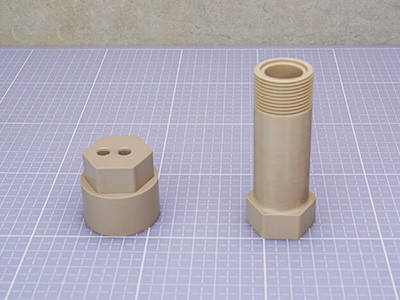

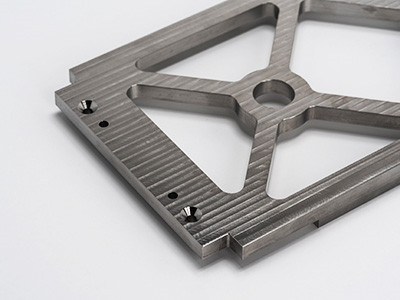

Re sebetsa hoo e batlang e le mofuta o mong le o mong oa leloala la CNC le setsi sa ho fetolela, 'me re motlotlo ka ho khona ho etsa mochini o mong le o mong oo o o hlokang, ho tloha ho mesebetsi e bonolo, e "sebetsang" ho isa ho lijeometri tse rarahaneng, tse nang le mamello e thata. Ka kopo, re ka boela ra hlahisa likarolo tse nang le EDM le li-grinders. Haha lienfelopo, boholo ba likarolo le litataiso tsa moralo li fapana bakeng sa ho sila le ho phethola.

CNC siloa Service

Ho latela lifaele tsa CAD tsa moreki, fumana quote ea CNC milling hang ka mor'a lihora tse 24.

Tšebeletso ea CNC Turning

Ho latela lifaele tsa CAD tsa moreki, fumana quote ea CNC hang hang ka lihora tse 24.

DJmolding CNC matla a ts'ebeletso ea ho sila

Ho tloha ho prototyping ho isa tlhahiso e felletseng e sebetsa. Litsi tsa rona tsa 3 axis, 3+2 le litsi tse felletseng tsa 5-axis li tla u lumella ho hlahisa likarolo tse nepahetseng haholo le tsa boleng ho fihlela litlhoko tsa hau tse thata.

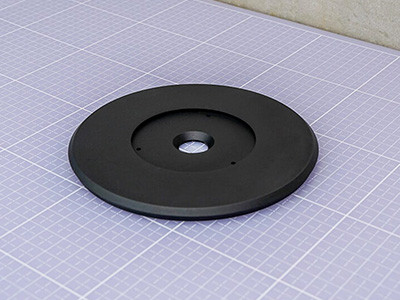

Gallery ea likarolo tsa mochini oa CNC

Re etsa li-prototypes tse potlakileng le litaelo tsa tlhahiso ea boleng bo tlase bakeng sa bareki ba liindasteri tse ngata: sefofane, likoloi, ts'ireletso, lisebelisoa tsa elektroniki, li-hardware tse qalang, li-automation tsa indasteri, mechini, tlhahiso, lisebelisoa tsa bongaka, oli & khase le liroboto.

Aluminium 7075-T6

Aluminium 6061-T6

Aluminium 6082

Aluminium 6063

TS'ELISO

Bo-machini ba nang le litsebo ba sebelisa mochine oa CNC ka litsela tsa lisebelisoa tse thehiloeng ho geometry ea likarolo tsa ho qetela tse entsoeng. Lintlha tsa karolo ea geometry li fanoa ke mohlala oa CAD (moqapi o thusoang ke khomphutha). Mechini ea CNC e ka khaola hoo e batlang e le motsoako ofe kapa ofe oa tšepe le polasetiki e thata ka ho nepahala le ho pheta-pheta, ho etsa likarolo tse tloaelehileng tsa mochini tse loketseng hoo e batlang e le indasteri e 'ngoe le e' ngoe, ho kenyeletsoa sefofane, bongaka, liroboto, lisebelisoa tsa elektroniki le indasteri. DJmolding e fana ka lits'ebeletso tsa CNC 'me e fana ka mantsoe a qotsitsoeng a CNC ho lisebelisoa tse fetang 40 ho tloha ho aluminium ea thepa le acetal ho isa ho titanium e tsoetseng pele le lipolasetiki tse entsoeng ka boenjiniere tse kang PEEK le Teflon.

Lisebelisoa tse fumanehang ka holim'a mochini oa CNC

Lisebelisoa tsa holim'a metsi li sebelisoa ka mor'a ho sebetsa ka mochine 'me li ka fetola ponahalo, boima ba bokaholimo, boima le khanyetso ea lik'hemik'hale ea likarolo tse hlahisoang.

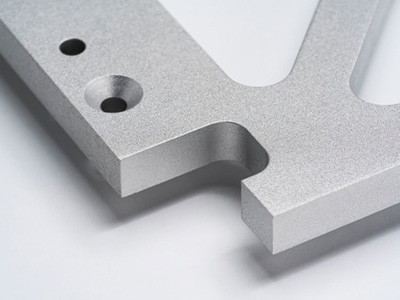

Joalo ka mochini (Ra 3.2μm / Ra 126μin)

Ena ke pheletso ea rona e tloaelehileng. Likarolo li entsoe ka mochini 'me li hlakotsoe, litšepe tse bohale lia chesoa.

Ho sebetsa ka boreleli (Ra 1.6μm / Ra 63μin)

Machining a boreleli a tšoana le 'As Machined' empa a na le matšoao a sa bonahaleng hanyane. Likarolo li entsoe ka lijo tse tlase, ha ho na polishing ea letsoho e sebelisoang.

Bead Blasted

Likarolo tse ling ke lifaha tse phatlohileng ka lifaha tsa khalase tse etsang hore ho be le thollo.

Brushed + Electropolished (Ra 0.8μm / Ra 32μin)

Likarolo li entsoe ka brushed le electropolished. E loketse ho fokotsa micro-roughness ea karolo.

oxide e ntšo

E sebetsa ho li-steels, black oxide ke seaparo sa phetoho se sebelisetsoang ho ntlafatsa ho hanyetsa ha kutu le ho fokotsa khanya ea leseli.

Brushed + Anodized type II (Glossy)

Likarolo tse ling lia hlatsuoa ebe li na le anodized mofuta oa II. E loketse ho eketsa khanyetso ea kutu ea karolo. Hangata e hlahisa 'mala o benyang.

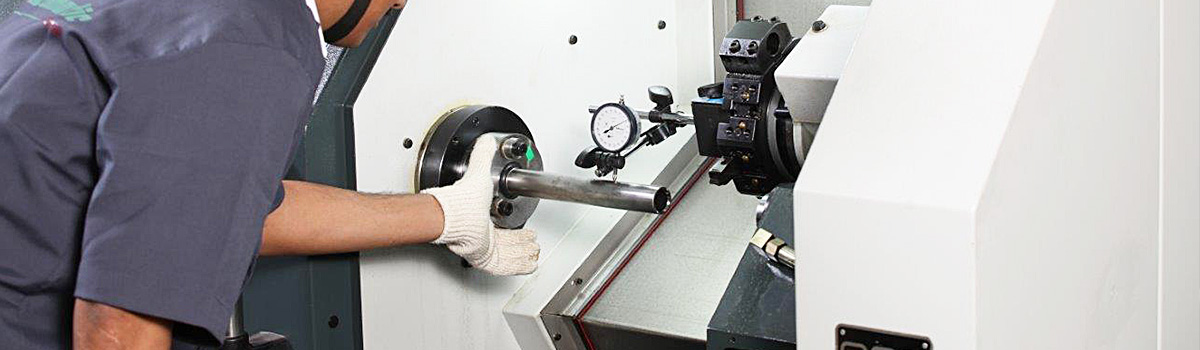

Mechini ea CNC (Computer Numerical Control) ke mokokotlo oa tlhahiso ea sejoale-joale. Ba fetotse mokhoa oa ho etsa lintho ka ho fana ka ho nepahala, lebelo, le ho tenyetseha ho hlahisa likarolo le likarolo tse rarahaneng. Leha ho le joalo, ho etsa bonnete ba hore mechini ea CNC e sebetsa ka mokhoa o nepahetseng, e hloka ho lokisoa, ho lokisoa le ho hlakisoa khafetsa. Bafani ba lits'ebeletso tsa mochini oa CNC ba fana ka lits'ebeletso tse fapaneng ho netefatsa hore mechini ena e sebetsa hantle le ka nepo. Ka poso ena ea blog, re tla tšohla likarolo tse fapaneng tsa ts'ebeletso ea mochini oa CNC le hore na e thusa likhoebo tsa tlhahiso joang.

Tšebeletso ea Mochini oa CNC ke eng?

CNC e emetse Computer Numerical Control, e bolelang mochine o laoloang ke lenaneo la k'homphieutha. Mechini ea CNC e sebelisoa bakeng sa mesebetsi e fapaneng, ho kenyelletsa ho seha, ho cheka, ho sila le ho phethola.

Litšebeletso tsa mochini oa CNC li kenyelletsa ho sebelisa mechini ena ho etsa mesebetsi e nepahetseng haholo le e pheta-phetoang. Litšebeletso tsena hangata li sebelisoa ho etsa tlhahiso, tse hlokang likarolo tse nepahetseng le tse tsitsitseng.

Ho sebelisa mochini oa CNC, lenaneo le qala ka ho sebelisa software ea komporo e thusoang ke komporo (CAD). Joale lenaneo le kenngoa mochineng, o sebelisang litaelo ho etsa mosebetsi o lakatsehang holim'a sekhechana sa thepa.

Mechini ea CNC e ka sebelisoa ka lisebelisoa tse fapaneng, ho kenyeletsoa tšepe, polasetiki, lehong le likhomphutha. Ba fana ka melemo e mengata, ho kenyelletsa le linako tse potlakileng tsa tlhahiso, ho nepahala ho phahameng, le bokhoni ba ho theha libopeho le likarolo tse rarahaneng.

Hobaneng ha Tšebeletso ea Mochini oa CNC e le Bohlokoa?

Mechini ea CNC (Computer Numerical Control) e se e le ea bohlokoa indastering ea tlhahiso, haholo-holo tlhahisong ea likoloi, sefofane le lisebelisoa tsa bongaka. Mechini ena ke ea boiketsetso, kahoo e khona ho sebetsa nako e telele ntle le ho kenella ha motho. Mechini ea CNC e ka hlahisa likarolo tse rarahaneng ka ho nepahala le ho nepahala ho phahameng, ho etsa hore e be tsa bohlokoa tlhahisong.

Ts'ebeletso ea mochini oa CNC e bohlokoa ka mabaka a 'maloa. Pele ho tsohle, e netefatsa hore mechini e sebetsa maemong a eona a nepahetseng. Mechini ea CNC e na le likarolo tse ngata tse tsamaeang tse hlokang ho lokisoa khafetsa ho thibela ho senyeha le ho taboha, e leng se ka lebisang ho putlama ha mochini le ho fokotsa nako ea tlhahiso. Tlhokomelo ea kamehla le litšebeletso li thusa ho lemoha le ho rarolla mathata a ka bang teng pele e ka ba mathata a maholo.

Taba ea bobeli, ts'ebeletso ea mochini oa CNC e thusa ho ntlafatsa bophelo ba mochini. Ho fana ka litšebeletso khafetsa ho netefatsa hore lisebelisoa li sebetsa ka har'a li-parameter tse entsoeng, ho fokotsa kotsi ea ho senyeha le ho taboha pele ho nako. Sena se lelefatsa nako ea bophelo ba mochini, ho boloka chelete ea moetsi bakeng sa litšenyehelo tse ncha le tsa ho lokisa.

Taba ea boraro, tšebeletso ea mochini oa CNC e thusa ho boloka boleng bo tsitsitseng tlhahisong. Mechini ea CNC e hlophiselitsoe ho hlahisa likarolo tse nepahetseng le tse nepahetseng, e leng ntho ea bohlokoa molemong oa ho hlahisa lifofo le lisebelisoa tsa bongaka. Ts'ebeletso ea khafetsa e netefatsa hore mechini e sebetsa ka nepo, e theha likotoana tse fihlelang litlhoko tse hlokahalang le ho boloka boleng bo tsitsitseng ba tlhahiso.

Ntlha ea bone, ts'ebeletso ea mochini oa CNC e thusa ho ntlafatsa polokeho mosebetsing. Mechini ea CNC ke lisebelisoa tse matla tse hlokang ho tšoaroa ka hloko ho thibela likotsi. Ho fana ka litšebeletso khafetsa ho thusa ho tseba likotsi tse ka bang teng tsa polokeho, tse ka rarolloang pele li baka kotsi ho basebelisi kapa ho senya mechini.

Mefuta ea Mechini ea CNC

Mechini ea CNC (Computer Numerical Control) e sebelisoa haholo liindastering tse fapaneng bakeng sa tlhahiso e nepahetseng. Mechini ena e sebelisa litsamaiso tsa taolo ea komporo ho iketsetsa le ho etsa ts'ebetso e rarahaneng ea machining ka nepo le ts'ebetso e phahameng. Ho na le mefuta e 'maloa ea mechini ea CNC e fumanehang, e' ngoe le e 'ngoe e etselitsoe lits'ebetso tse ikhethileng. Mona ke mefuta e meng e tsebahalang haholo:

Mechine ea CNC ea ho betla

- Vertical Machining Centers (VMC):Mechini ena e na le mokokotlo o otlolohileng 'me e loketse ho seha le ho etsa thepa e tiileng.

- Horizontal Machining Centers (HMC):Li-HMC li na le li-spindle tse tšekaletseng 'me li loketse ho sebetsa lisebelisoa tse kholo le tse boima.

- Mechini ea 5-Axis:Mechini ena e fana ka motsamao ka nako e le 'ngoe ka lilepe tse hlano, e nolofalletsang ts'ebetso e rarahaneng le e rarahaneng ea machining.

Mechini ea Lathe ea CNC

Litsi tsa Phetoho:Mechini ena e sebelisoa bakeng sa ts'ebetso e nepahetseng ea ho fetola, moo mosebetsi o potolohang ha lisebelisoa tsa ho seha li etsa sebopeho.

- Litsela tsa Mofuta oa Switzerland:Li-lathe tsa mofuta oa Switzerland li etselitsoe lisebelisoa tsa ho sebetsa tsa boleng bo holimo le tse bophara bo nyane. Li na le hlooho e thellang le bushing ea tataiso bakeng sa ho nepahala ho ntlafalitsoeng.

CNC Plasma Cutters

- Mechini e sehang ea plasma e sebelisa jete ea lebelo le phahameng ea khase ea ionized ho seha lisebelisoa tse tsamaisang motlakase tse kang tšepe, aluminium le koporo. Hangata li sebelisoa ho etsa tšepe le lits'ebetsong tsa indasteri.

Mechini ea ho Seha Laser ea CNC

- Mechini ea ho itšeha ka laser e sebelisa lebone la laser le tsepamisitsoeng ho qhibilihisa, ho chesa, kapa ho etsa mouoane, e leng se bakang maqeba a nepahetseng le a hloekileng. Li na le mekhoa e mengata 'me li khona ho sebetsana le lisebelisoa tse fapaneng tse kang tšepe, lehong, acrylic le polasetiki.

Mechini ea router ea CNC

- Li-routers tsa CNC li sebelisoa haholo-holo bakeng sa ho seha, ho betla le ho betla lisebelisoa tse kang lehong, polasetiki le foam. Li sebelisoa haholo ho betla mapolanka, tlhahiso ea matšoao le prototyping.

Mechini ea CNC EDM

- Mechini ea Motlakase ea Phallo ea Motlakase (EDM) e sebelisa lisebelisoa tsa motlakase ho tlosa thepa ho tloha mosebetsing. Hangata li sebelisoa bakeng sa libopeho tse rarahaneng le lisebelisoa tse thata joaloka tšepe e thata le titanium.

Mechini ea ho Sila ea CNC

- Mechini ea ho sila e sebelisoa ho fihlela litekanyo tse nepahetseng tsa boleng bo holimo le litekanyo tse nepahetseng. Ba sebelisa mabili a abrasive ho tlosa thepa ho tloha workpiece.

CNC Press Brakes

- mariki a tobetsa a sebelisoa bakeng sa ho kobeha le ho bopa lakane tšepe. Li-brake tsa khatiso tse laoloang ke CNC li fana ka taolo e nepahetseng holim'a mokhoa oa ho kobeha, e leng se hlahisang liphello tse nepahetseng le tse ka phetoang.

Mathata a Tloaelehileng a Mochini oa CNC

Le hoja mechine ea CNC e sebetsa hantle haholo ebile e tšepahala, e ntse e ka ba le mathata a itseng a ka amang ts'ebetso le tlhahiso ea eona. Ho bohlokoa ho utloisisa le ho rarolla mathata ana a tloaelehileng bakeng sa ho etsa bonnete ba hore ts'ebetso e sebetsa hantle. Mona ke a mang a mathata a tloaelehileng a mochini oa CNC:

Liphoso tsa Lenaneo

- Litaelo tse fosahetseng kapa tse sa phethahalang tsa mananeo li ka baka liphoso ts'ebetsong ea machining.

- Litsela tse sa nepahalang tsa lisebelisoa kapa khetho e fosahetseng ea lisebelisoa li ka fella ka ho se sebetse hantle holimo, ho se nepahale ha litekanyo, kapa ho senyeha ha lisebelisoa.

Litaba tsa Mechini

Likarolo tse tsofetseng kapa tse senyehileng joalo ka li-bearings, mabanta kapa li-screws tsa bolo li ka baka papali e feteletseng, e lebisang ho sehoeng ho sa nepahalang le ho fokotsa ho nepahala.

- Mafura a fosahetseng kapa tlhokomelo e sa lokelang ho ka baka khohlano e eketsehileng, ho futhumala ho feteletseng le ho senyeha ha likarolo tsa mochini pele ho nako.

Mathata a Motlakase le Elektronike

Ho feto-fetoha ha motlakase kapa tšitiso ea motlakase ho ka baka boits'oaro bo sa tsitsang ba mochini, joalo ka ho ema ka tšohanyetso, ho seta bocha, kapa ho beha sebaka se fosahetseng.

- Li-sensor tse fosahetseng kapa li-switch switch li ka lebisa metsamaong e fosahetseng ea mochini kapa ho bala liphoso tse fosahetseng.

Mathata a Lisebelisoa

- Lisebelisoa tsa ho itšeha tse lerootho kapa tse kentsoeng ka mokhoa o sa nepahalang li ka baka botlaaseng bo bobe, ho qoqa kapa ho roaloa ha lithulusi tse ngata.

- Litokiso tse fosahetseng tsa lithulusi kapa litekanyo tsa bolelele ba lisebelisoa li ka fella ka ho se nepahale ho itseng.

Mathata a ho Pholisa le ho Tlosa Chip

- Phallo e sa lekaneng ea ho pholisa kapa ho ntšoa ha chip ka tsela e sa lokelang ho ka baka mocheso o mongata, mocheso o feteletseng oa lisebelisoa, le ho fokotsa bophelo ba lisebelisoa.

- Ho tlosoa ha chip e sa lekaneng ho ka baka ho koala ha chip, e leng ho amang ho qeta holimo 'me ho ka senya mosebetsi kapa mochine.

Liphoso tsa Sisteme ea Software le Taolo

- Litšitiso tsa software kapa litaba tsa tšebetso li ka sitisa ts'ebetso ea mochini mme tsa baka liphoso kapa likotsi tse sa lebelloang.

- Tekanyetso e fosahetseng kapa litlhophiso tse fosahetseng tsa paramethara ka har'a sistimi ea taolo li ka lebisa ho liphoso tsa maemo kapa litefiso tse fosahetseng tsa phepelo.

Lintho tsa Tikoloho

- Ho fapana ha mocheso, mongobo, kapa lerole ho ka ama ts'ebetso le ho nepahala ha mechini ea CNC.

- Ho kenya mochine kapa ho beha mochine ka tsela e fosahetseng mabapi le maemo a tikoloho ho ka ama botsitso le ho tšepahala ha oona.

Tlhokomelo e Thibelang bakeng sa Mechini ea CNC

Ho kenya ts'ebetsong lenaneo la tlhokomelo ea thibelo e matla ho bohlokoa bakeng sa ho eketsa ts'ebetso, botšepehi, le nako ea bophelo ea mechine ea CNC (Computer Numerical Control). Tlhokomelo ea kamehla e thusa ho tseba mathata a ka bang teng pele e e-ba mathata a maholo, ho fokotsa nako, le ho netefatsa ts'ebetso e nepahetseng ea mochini. Mona ke lintlha tse ling tsa bohlokoa tseo u lokelang ho tsepamisa maikutlo ho tsona ha u etsa tlhokomelo ea thibelo bakeng sa mechini ea CNC:

Lubrication

- Lumella lisebelisoa tsa mochini khafetsa joalo ka li-bearings, likurufu tsa bolo, li-slideways le likere ho latela tataiso ea moetsi.

- Sebelisa mafura a loketseng 'me u netefatse hore ho na le linako tse nepahetseng tsa ho lubrication ho fokotsa khohlano, ho fokotsa ho senyeha le ho boloka ts'ebetso e sebetsa hantle.

Cleaning

- Boloka mochini le libaka tse o potileng li hloekile ho tsoa ho li-chips, masalla a pholiso le litšila.

- Hloekisa lihloela khafetsa, litanka tse pholisang, le literei tsa chip ho boloka tšebetso e nepahetseng ea ho pholisa le ho thibela ho koala.

Ho hlahloba le ho lekanya

Etsa tlhahlobo ea ka mehla ea likaroloana tsa bohlokoa joalo ka li-spindle, li-thulusi, le li-fixtures ho bona matšoao a ho tsofala kapa tšenyo.

- Lekola le ho lekola ho nepahala ha lilepe tsa mochini, li-offsets tsa lisebelisoa, le lits'ebetso tsa ho beha maemo ho netefatsa machining a nepahetseng.

Lisebelisoa tsa Motlakase le Elektronike

- Lekola likhokahano tsa motlakase, lithapo, le likhoele bakeng sa matšoao leha e le afe a tšenyo kapa likhokello tse hlephileng.

- Sheba le ho lekola lisensara, li-switches tse fokolang, le li-interlock tsa polokeho ho netefatsa hore li sebetsa hantle.

Mekhoa ea ho Pholisa

- Boloka le ho hloekisa lisebelisoa tsa ho pholisa khafetsa ho thibela tšilafalo le ho netefatsa hore ho pholisoe hantle.

- Lekola maemo a pholiso, ho leka-lekana ha pH, le ho tsepamisa maikutlo, 'me u tlatse kapa u nke sebaka se pholisang ha ho hlokahala.

Software le Sistimi ea Taolo

- Kamehla ntlafatsa le ho boloka software le tsamaiso ea mochini oa CNC ka liphetolelo tsa morao-rao le lipache.

- Netefatsa le ho lekanya liparamente tsa sistimi ea taolo, joalo ka litefiso tsa phepelo le ho potlakisa, ho netefatsa ts'ebetso e nepahetseng ea mochini.

Lisebelisoa le Spindle

- Hlahloba 'me u hloekise litšepe tsa lisebelisoa, li-collets le li-spindle taper khafetsa ho netefatsa hore lisebelisoa li tlamelloa hantle le ho fokotsa ho tsoa.

- Sheba 'me u nke sebaka sa lisebelisoa tsa ho itšeha tse tsofetseng kapa tse senyehileng ho boloka ts'ebetso e nepahetseng ea ho itšeha le ho qeta bokaholimo.

Koetliso ea Basebetsi le Litokomane

- Fana ka koetliso e felletseng ho basebetsi ba mechini mabapi le ts'ebetso e nepahetseng, mekhoa ea tlhokomelo, le liprothokholo tsa polokeho.

- Boloka lirekoto tse qaqileng tsa mesebetsi ea tlhokomelo, tlhahlobo, le litokiso bakeng sa litšupiso le tlhahlobo.

Tlhahlobo e Tloaelehileng ea Mechini ea CNC

Tlhahlobo le tlhokomelo ea khafetsa ea mechini ea CNC (Computer Numerical Control) e bohlokoa ho netefatsa ts'ebetso ea eona e nepahetseng le bophelo bo bolelele. Ka ho etsa litlhahlobo tse tloaelehileng, mathata a ka bang teng a ka tsejoa esale pele, 'me mehato ea thibelo e ka nkoa ho qoba ho senyeha ha litšenyehelo le tieho ea tlhahiso. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang nakong ea tlhahlobo e tloaelehileng ea mechini ea CNC:

Tlhahlobo e bonoang

- Qala ka ho hlahloba mochine ka mahlo bakeng sa matšoao leha e le afe a ho senyeha, ho senyeha kapa likarolo tse hlephileng.

- Hlahloba ho dutla ho kang oli kapa se phodisang, ho ka bontshang hore ho na le bothata ka tsamaiso ya mokelikeli wa mochini.

- Sheba lerata leha e le lefe le sa tloaelehang kapa ho thothomela nakong ea ts'ebetso ea mochine.

Lubrication

- Netefatsa hore lintlha tsohle tsa lubrication li tlositsoe ka mokhoa o lekaneng ho netefatsa hore likarolo tsa mochini li tsamaea hantle.

- Sheba maemo a lubricant 'me u a phahamise ha ho hlokahala.

- Netefatsa ho tlotsoa ka nepo ha li-screws tsa bolo, liporo tsa tataiso, le likarolo tse ling tsa bohlokoa.

Axis Calibration

Netefatsa bonnete ba lilepe tsa mochini ka ho etsa liteko tsa calibration.

- Sheba ho kheloha leha e le hofe ho tsoa ho mamello e boletsoeng 'me u lokise ha ho hlokahala.

- Lekanya mokhoa oa ho hlahloba oa mochine, haeba ho hlokahala, ho netefatsa tekanyo e nepahetseng.

Tlhahlobo ea Spindle

- Lekola spindle bakeng sa matšoao leha e le afe a ho tsofala, ho senyeha, kapa ho sa tsamaee hantle.

- Sheba li-bearings tsa spindle 'me u li nkele sebaka ha ho hlokahala.

- Netefatsa ho phalla ha spindle ho netefatsa hore ho tsepamisitsoe maikutlo nakong ea ts'ebetso ea mochini.

Lisebelisoa le ho fetola lisebelisoa

- Lekola sistimi ea lisebelisoa, ho kenyeletsoa litšepe, li-collets, le lisebelisoa tsa ho itšeha, bakeng sa matšoao leha e le afe a ho senyeha kapa ho senyeha.

- Sheba mochine oa ho fetola lisebelisoa bakeng sa ho sebetsa hantle le ho tsamaisana hantle.

- Hloekisa le ho tlotsa lisebelisoa tsa ho fetola lisebelisoa ho latela litataiso tsa moetsi.

Tsamaiso ea Tsamaiso

- Lekola yuniti ea taolo ea CNC 'me u behe leihlo bakeng sa melaetsa efe kapa efe ea liphoso kapa ho se sebetse hantle.

- Netefatsa hore lithapo tsohle le likhokelo li bolokehile ebile li maemong a matle.

- Nchafatsa software ea mochini, haeba ho hlokahala, ho mofuta oa morao-rao o fanoeng ke moetsi.

Litšobotsi tsa polokeho

- Netefatsa ts'ebetso ea likarolo tsa polokeho, joalo ka likonopo tsa ho emisa le li-interlock.

- Lekola boemo ba likoahelo tse sireletsang le litšitiso ho netefatsa polokeho ea opareitara.

- Lekola sistimi ea alamo ea mochini ho netefatsa ts'ebetso e nepahetseng.

Litokomane:

Boloka rekoto e felletseng ea matsatsi a tlhahlobo, lintho tse fumanoeng, le tokiso efe kapa efe e entsoeng.

- Latela kemiso ea tlhokomelo e khothaletsoang ke moetsi le litataiso.

- Boloka tlaleho ea likarolo life kapa life tse setseng tse sebelisitsoeng le linomoro tsa tsona tse tsamaisanang le tsona.

Litokiso tsa Mochini oa CNC

Ha mochini oa CNC (Computer Numerical Control) o na le mathata kapa o sa sebetse hantle, ho lokisoa ka potlako ho bohlokoa ho fokotsa nako le ho boloka tlhahiso. Ho lokisa mechini ea CNC ho hloka boiphihlelo le ho ela hloko lintlha tse qaqileng ho netefatsa hore mechini e khutlisetsoa maemong a eona a ho sebetsa hantle. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u lokisa mochini oa CNC:

tlhathoba

- Qala ka ho hlahloba bothata ka botlalo ho fumana sesosa sa ho se sebetse hantle.

- Lekola likarolo tsa mochini, joalo ka lienjineri, li-drive, lisensara, le sistimi ea taolo, ho supa karolo e phoso.

- Sebelisa lisebelisoa tsa tlhahlobo le software ho thusa ho tseba bothata ka nepo.

Ho Fetola Likarolo Tse Fosahetseng

- Hang ha bothata bo se bo lemohuoe, tlosa likarolo tse fosahetseng ka tse ncha kapa tse sebetsang hantle.

- Fumana likarolo tsa 'nete ho tsoa ho barekisi ba tšepahalang ho netefatsa hore lia lumellana le ho tšepahala.

- Latela litataiso tsa moetsi bakeng sa ho fetola likarolo tse itseng 'me u li lekanye ha ho hlokahala.

Litokiso tsa Motlakase le Mechini

- Etsa litokiso tsa motlakase, ho kenyelletsa le ho lokisa lithapo tse fosahetseng, likhokahano, kapa liboto tsa potoloho tse senyehileng.

- Lokisa kapa u nke sebaka sa lisebelisoa tse senyehileng, joalo ka mabanta, likere, li-pulley le li-bearings.

- Etsa bonnete ba ho lumellana hantle ha likarolo tsa mochine ho boloka ho nepahala le ho nepahala.

Lintlafatso tsa Software le Tlhophiso

- Ntlafatsa software ea mochini ho mofuta oa morao-rao o fanoeng ke moetsi.

- Lokisa liparamente le litlhophiso tsa sistimi ea taolo ea CNC ho latela litlhaloso tsa mochini.

- Lekola le ho netefatsa ts'ebetso ea mochini ka mor'a lintlafatso tsa software kapa liphetoho tsa tlhophiso.

Tekanyetso le Ho tsamaisana

Lekola lilepe tsa mochini 'me u netefatse hore li hokahane hantle ho fihlela mochini o nepahetseng.

- Netefatsa runout ea spindle le alignment ho netefatsa concentricity nakong ea ts'ebetso.

- Sheba le ho lokisa lisebelisoa tsa mochini le puseletso ea bolelele ba lisebelisoa bakeng sa ho itšeha hantle.

Teko le netefatso

Etsa tlhahlobo e felletseng ea mochini o lokisitsoeng ho netefatsa hore o sebetsa ka nepo.

- Netefatsa ho nepahala le ho pheta-pheta ha mochini ka ho fokotsa liteko kapa ho sebelisa li-artifact tsa calibration.

- Lekola ts'ebetso ea mochini nakong ea ts'ebetso e fapaneng ea machining ho netefatsa botsitso le ts'epahalo.

Thibelo ea Thibelo

Khothaletsa le ho etsa mesebetsi ea tloaelo e thibelang ho lokisoa ho fokotsa ho senyeha ha nako e tlang.

- Hloekisa le ho tlotsa likarolo tsa mochini khafetsa ho thibela ho senyeha le ho ntlafatsa bophelo bo bolelele.

- Boloka rekoto ea mesebetsi ea tlhokomelo, ho kenyeletsoa matsatsi, mesebetsi e entsoeng, le likarolo tse ling tse nchafalitsoeng.

Koetliso le Tšehetso

Fana ka koetliso ho basebetsi ba mochini mabapi le tšebeliso e nepahetseng le tlhokomelo ho thibela mathata a tloaelehileng.

- Fana ka tšehetso e tsoelang pele ea tekheniki le tataiso ho rarolla mathata a manyane a ka hlahang.

- Khothaletsa moetlo oa tlhokomelo ea mochini o sebetsang le ho khothaletsa basebelisi ho tlaleha lintho tse sa tloaelehang hang hang.

Lintlafatso tsa mochini oa CNC

Mechini ea CNC (Computer Numerical Control) e etselitsoe ho tšoarella le ho tšoarella nako e telele, empa ka tsoelo-pele ea theknoloji, ho e ntlafatsa ho ka ntlafatsa ts'ebetso le bokhoni ba eona. Ho ntlafatsa mechini ea CNC ho ka ntlafatsa ts'ebetso ea bona, lebelo le ho nepahala, ho fa likhoebo monyetla oa tlholisano. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u ntlafatsa mechini ea CNC:

Ho Lekola Boemo ba Hona Joale

Qala ka ho lekola boemo ba hajoale ba mochini, ho kenyeletsoa lisebelisoa tsa ona le software.

- Lekola lilemo tsa mochini, boemo, le ho lumellana le lintlafatso tsa morao-rao.

- Fumana liphetho tse lakatsehang tsa ntlafatso, joalo ka lebelo le ntlafalitsoeng, ho nepahala, kapa ts'ebetso e eketsehileng.

Ho Khetholla Likhetho tsa Ntlafatso

- Batlisisa theknoloji ea morao-rao le tsoelo-pele ho fumana lintlafatso tse loketseng mochini.

- Buisana le moetsi oa mochini kapa barekisi ba mokhatlong oa boraro ho fumana lintlafatso tse ntle bakeng sa mofuta o itseng oa mochini.

- Nahana ka likhetho tse kang li-controller tse ntlafalitsoeng, li-spindle system, li-changer tsa lisebelisoa le li-sensor.

Ho ntlafatsa likarolo tsa Hardware

- Ntlafatsa likarolo tsa lisebelisoa tse kang li-motor, li-drive, le litsamaiso tsa taolo ho ntlafatsa lebelo le ho nepahala.

- Kenya lisensara tse ncha le li-probes ho ntlafatsa ho nepahala ha tekanyo le ho iketsetsa mesebetsi e itseng.

- Fetola likarolo tse tsofetseng kapa tse siiloeng ke nako ka tse ncha ho ntlafatsa ho tšoarella ha mochini le bophelo bo bolelele.

Ho ntlafatsa Software

- Ntlafatsa software ea mochini ho mofuta oa morao-rao ho ntlafatsa ts'ebetso le ts'ebetso.

- Kenya li-module tse ncha tsa software ho nolofalletsa mesebetsi e meng kapa ho ntlafatsa tse seng li ntse li le teng.

- Hlophisa software hore e lumellane le litlhoko tse khethehileng tsa mochine.

Teko le netefatso

- Lekola mochini o ntlafalitsoeng ho netefatsa hore o sebetsa ka nepo mme o fihlela liphetho tse lakatsehang.

- Netefatsa ho nepahala le ho pheta-pheta ha mochini ka ho fokotsa liteko kapa ho sebelisa li-artifacts tsa calibration.

- Lekola ts'ebetso ea mochini nakong ea ts'ebetso e fapaneng ea machining ho netefatsa botsitso le ts'epahalo.

Koetliso le Tšehetso

- Fana ka koetliso ho basebetsi ba mochini mabapi le likarolo tse ncha le ts'ebetso ea mochini o ntlafalitsoeng.

- Fana ka tšehetso e tsoelang pele ea tekheniki le tataiso ho rarolla mathata afe kapa afe a ka hlahang.

- Khothaletsa moetlo oa tlhokomelo ea mochini o sebetsang le ho khothaletsa basebelisi ho tlaleha lintho tse sa tloaelehang hang hang.

Tekanyo ea Mochini oa CNC

Calibration ke ts'ebetso ea bohlokoa ho boloka ho nepahala le ho nepahala ha mechini ea CNC (Computer Numerical Control). Tekanyetso ea kamehla e netefatsa hore lilepe tsa mochini, spindle, le lisebelisoa tsa lisebelisoa li hokahantsoe ka nepo, e leng se etsang hore ho be le ts'ebetso e nepahetseng ea mochini. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u etsa calibration ea mochini oa CNC:

Axis Calibration

- Lekanya axis e 'ngoe le e' ngoe ea mochini ho netefatsa boemo bo nepahetseng le ho sisinyeha.

- Sebelisa lisebelisoa tsa ho metha ka mokhoa o nepahetseng, joalo ka laser interferometer kapa ball bar system, ho lekanya ho kheloha le ho etsa liphetoho.

- Netefatsa hore metsamao ea mochini le likhutlo li tsamaisana le mamello e boletsoeng.

Tekanyo ea ho Runout ea Spindle:

- Lekanya ho phalla ha spindle ho etsa bonnete ba ho tsepamisa maikutlo nakong ea ts'ebetso ea mochini.

- Sebelisa lets'oao la ho daela kapa sesebelisoa se thehiloeng ho laser ho lekanya ho tšoana hofe kapa ho sisinyeha ho spindle.

- Fetola likarolo tsa spindle kapa u nke sebaka sa likarolo tse tsofetseng ho fokotsa ho tsoa le ho holisa ho nepahala.

Bolelele ba Tool le Tool Offset Calibration

- Lekanya mokhoa oa ho metha bolelele ba sesebelisoa ho netefatsa hore lisebelisoa li behiloe ka nepo.

- Sebelisa li-artifact tsa calibration kapa li-gauge tsa bophahamo ho metha bolelele ba sesebelisoa le ho bo bapisa le litekanyo tsa mochini.

- Fetola boleng ba sesebelisoa sa bolelele ba sesebelisoa tsamaisong ea taolo ea mochini ho lefella liphapang life kapa life.

Tool Diameter Puseletso

- Etsa tlhahlobo ea puseletso ea bophara ba sesebelisoa ho ikarabella bakeng sa phapang ea li-diameter tsa lisebelisoa.

- Lekanya bophara ba sesebelisoa u sebelisa micrometer kapa caliper 'me u e bapise le litekanyetso tse hlophisitsoeng tsa mochine.

- Fetola mats'eliso a lisebelisoa kapa mats'eliso a lisebelisoa ho lefella liphapang leha e le life 'me u fihlele ho fokotsa ho nepahetseng.

Ho lekola Sisteme ea ho lekanya

- Haeba mochini o na le sistimi ea ho hlahloba, e lekanye ho netefatsa tekanyo e nepahetseng ea karolo le ho tsamaisana.

- Etsa litloaelo tsa ho lekanya ho netefatsa bonnete ba sistimi ea ho hlahloba le ho lokisa ha ho hlokahala.

- Netefatsa hore sistimi ea ho hlahloba ka nepo e lemoha libaka le boholo ba sebaka sa mosebetsi.

Spindle Speed Calibration

- Lekanya lebelo la spindle ho netefatsa hore le lumellana le RPM e boletsoeng (Rotations Per Minute).

- Sebelisa sensor ea lebelo la tachometer kapa spindle ho lekanya lebelo la 'nete la spindle nakong ea ts'ebetso.

- Fetola liparamente tsa taolo ea lebelo tsamaisong ea taolo ea mochini ho fihlela RPM e lakatsehang.

Litokomane le Lirekoto

- Boloka rekoto e felletseng ea mesebetsi ea tlhophiso, ho kenyeletsoa matsatsi, mesebetsi e entsoeng, le liphetoho life kapa life tse entsoeng.

- Latela kemiso le litataiso tse khothaletsoang ke moetsi.

- Boloka tlaleho ea lintho tsa khale tsa calibration tse sebelisitsoeng le litifikeiti tse tsamaellanang le tsona.

Khokahano ea Mochini oa CNC

Ho tsamaisana hantle ho bohlokoa hore mochini oa CNC (Computer Numerical Control) o sebetse ka nepo le ka nepo. Ho se tsamaisane hantle ha likarolo tsa mochine, tse kang seluloana, lisebelisoa tsa ho sebetsa le lilepe, ho ka baka liphoso le ho se lumellane ha mochine o etsoa. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u hokahanya mechini ea CNC:

Ho hlahloba Boemo ba Mochini

Pele o hokahanya mochine, hlahloba boemo ba oona, ho kenyelletsa le boemo ba likarolo tsa oona.

- Lekola litsela tsa mochini, basebetsi ba etellang pele, le lisebelisoa tse ling tsa mochini hore na li senyehile kapa li senyehile.

- Netefatsa boemo ba litsamaiso tsa spindle le lisebelisoa.

Ho tsamaisana ha Spindle

- The spindle ke karolo ea bohlokoa e lokelang ho lumellana hantle.

- Sebelisa lisebelisoa tsa ho metha ka nepo, joalo ka sesupo sa ho daela kapa sesebelisoa sa laser-based, ho metha tsela eo spindle e leng ka eona.

- Fetola boemo ba spindle le likarolo tsa eona, joalo ka li-bearings, ho fihlela tlhophiso e nepahetseng.

Ho hlahloba Lilepe

- Lekola ho tsamaisana ha axis e 'ngoe le e' ngoe ea mochini ho netefatsa motsamao o nepahetseng le boemo.

- Sebelisa lisebelisoa tsa ho metha ka nepo ho lekanya ho kheloha axis ka 'ngoe le ho etsa liphetoho.

- Netefatsa hore lilepe li tsamaea ka tsela e otlolohileng 'me li ikamahanya le mamello e boletsoeng.

Ho hokahanya Sisteme ea Lisebelisoa

- Litsamaiso tsa lisebelisoa, ho kenyeletsoa ba tšoereng lithulusi le ba chencheng lithulusi, li tlameha ho nyallana ka nepo ho netefatsa boemo bo nepahetseng ba lisebelisoa.

- Sebelisa lisebelisoa tsa ho metha ka nepo ho lekanya tekano ea sistimi ea lisebelisoa le ho etsa liphetoho ha ho hlokahala.

- Netefatsa hore lisebelisoa tsa lisebelisoa li hokahana le lilepe tsa mochini le spindle.

Teko le netefatso

- Kamora ho hokahanya mochini, etsa likheo tsa liteko ho netefatsa ho nepahala le ho nepahala ha ona.

- Sebelisa li-artifact tsa calibration kapa lisebelisoa tse ling tsa ho lekanya ho netefatsa tepo le ho nepahala ha mochini.

- Lekola ts'ebetso ea mochini nakong ea ts'ebetso e fapaneng ea mochini ho netefatsa botsitso le ts'epahalo ea eona.

Tlhokomelo le Tlhokomelo

- Kamehla hlahloba le ho boloka likarolo tsa mochini oa mochini ho thibela ho se tsamaisane le ho senyeha.

- Koetlisa basebetsi ba mechini ho tlaleha lintho tse sa tloaelehang hang-hang le ho etsa mesebetsi e tloaelehileng ea ho lokisa.

- Latela kemiso ea tlhokomelo e khothaletsoang ke moetsi le litataiso.

Ho tsamaisana hantle ha mechini ea CNC ho bohlokoa bakeng sa ho fihlela ts'ebetso e nepahetseng le e nepahetseng ea mochini. Ka ho khomarela mekhoa e nepahetseng ea ho lumellana le ho etsa tlhokomelo e tloaelehileng, basebetsi ba ka etsa bonnete ba hore mechine ea bona e lula e hlahisa likarolo tsa boleng bo phahameng tse nang le liphoso tse fokolang le ho sebetsa hape.

Lubrication ea Mechini ea CNC

Ho tlotsa ka mokhoa o nepahetseng ho bohlokoa bakeng sa ts'ebetso e bonolo le e sebetsang ea mechini ea CNC (Computer Numerical Control). Lisebelisoa li fokotsa likhohlano, li fokotsa ho khathala le ho taboha, li tlosa mocheso le ho sireletsa likarolo tsa mochini hore li se ke tsa senyeha. Tlhokomelo ea kamehla ea lubrication e thusa ho lelefatsa bophelo ba mochini le ho netefatsa ts'ebetso e nepahetseng. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u tlotsa mechini ea CNC:

Khetho ea Lisebelisoa

- Khetha mafura a khothaletsoang ke moetsi oa mochini bakeng sa likarolo le litsamaiso tse itseng.

- Nahana ka lintlha tse kang mocheso, lebelo, mojaro le tikoloho ha u khetha mafura.

- Sebelisa mafura a loketseng bakeng sa likarolo tse fapaneng tsa mochini, joalo ka li-spindle bearings, liporo tsa tataiso, le likurufu tsa bolo.

Kemiso ea Lubrication

- Latela kemiso e khothaletsoang ea moetsi ea ho tlotsa bakeng sa karolo ka 'ngoe ea mochini.

- Theha mokhoa o tloaelehileng oa ho tlotsa o ipapisitse le ts'ebeliso ea mochini le maemo a ts'ebetso.

- Ela hloko lintlha tse kang lihora tsa ts'ebetso, matla a ts'ebeliso le maemo a tikoloho.

Lintlha tsa Lubrication

- Tseba le ho tšoaea libaka tsohle tsa ho tlotsa mochining, ho kenyeletsoa likou tsa oli, lisebelisoa tsa mafura le matamo.

- Netefatsa hore libaka tsohle tsa lubrication li fumaneha habonolo le ho bonahala bakeng sa ho tlotsa hantle.

Mekhoa ea ho Lubrication

- Sebelisa mekhoa e nepahetseng ea ho tlotsa bakeng sa karolo ka 'ngoe, joalo ka libate tsa oli, lisebelisoa tsa moholi oa oli, kapa ho sebelisa mafura ka letsoho.

- Latela mekhoa e nepahetseng ea ho tlotsa, joalo ka ho sebelisa mafura a lekaneng le ho etsa bonnete ba hore o ajoa.

- Sebelisa lisebelisoa tse itirisang tsa lubrication, haeba li le teng, bakeng sa ho tlotsa ka mokhoa o tsitsitseng le o nepahetseng.

Tšebeliso ea Lubricant

- Hloekisa libaka tsa ho tlotsa pele u sebelisa setlolo ho tlosa litšila, maloanlahla le masalla a khale a lubricant.

- Sebelisa lisebelisoa tse tlotsang mafura tse khothalelitsoeng, tse kang borashe, lithunya tsa mafura, kapa makotikoti a oli, ho tlotsa litlolo ka nepo.

- Netefatsa hore mafura a fihla libakeng tsohle tse hlokahalang, joalo ka li-bearings, likere le libaka tse thellang.

Lubricant Bongata

- Kenya mafura a lekaneng joalo ka ha a hlalositsoe ke moetsi oa mochini.

- Qoba ho tlotsa haholo, kaha mafura a feteletseng a ka baka tšilafalo le ho koala likarolo tsa bohlokoa.

- Lekola maemo a lubricant khafetsa 'me u tlatse hape ha ho hlokahala ho boloka mafura a hlokahalang.

Lubricant Quality

- Sebelisa mafura a boleng bo holimo a kopanang le maemo a indasteri le litlhaloso.

- Lekola boemo ba mafura, joalo ka viscosity, bohloeki, le boemo ba oxidation, 'me u li nkele sebaka ha ho hlokahala.

- Boloka mafura ka nepo ho boloka boleng le katleho ea ona.

Rekota Ho boloka

- Boloka rekoto e felletseng ea mesebetsi ea ho tlotsa, ho kenyeletsoa matsatsi, lilubricant tse sebelisitsoeng, le lintlha tsa ho tlotsa tse boletsoeng.

- Boloka tlaleho ea tšebeliso ea lubricant, ho kenyeletsoa le bongata bo sebelisitsoeng le ho khutlisoa.

- Sebelisa rekoto e le tšupiso bakeng sa tlhokomelo ea nakong e tlang ea lubrication le ho rarolla mathata.

Phetoho ea Likarolo tsa Mochini oa CNC

Ha nako e ntse e ea, mechine ea CNC (Computer Numerical Control) e ka ’na ea hloka ho nkeloa sebaka ke likarolo tse itseng ka lebaka la ho tsofala, ho senyeha, kapa tlhokahalo ea ho ntlafatsoa. Phetoho e potlakileng le e nepahetseng ea likarolo tsa mochini oa CNC ke ea bohlokoa ho boloka ts'ebetso ea mochini le ho fokotsa nako ea ho theoha. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u fetola likarolo tsa mochini oa CNC:

Khetholla Bothata

- Hlahloba ka ho feletseng mochine ho khetholla karolo e fosahetseng kapa e senyehileng.

- Sekaseka matšoao, melaetsa ea liphoso, kapa boitšoaro bo sa tloaelehang ba mochini ho supa bothata.

- Sebelisa lisebelisoa tsa tlhahlobo 'me u shebe litokomane tsa mochini kapa litataiso tsa moetsi bakeng sa ho rarolla mathata.

Mohloli oa Likarolo tsa 'Nete

- Reka likarolo tse ncha ho tsoa ho barekisi ba tšepahalang kapa ka kotloloho ho tsoa ho moetsi oa mochini.

- Etsa bonnete ba hore likarolo ke tsa 'nete 'me li lumellana le litlhaloso tsa likarolo tsa pele.

- Nahana ka lintlha tse kang boleng, ho lumellana, le tiisetso ha u khetha likarolo tse ling.

Ho qhaqha le ho kenya

- Latela mekhoa le litataiso tse nepahetseng bakeng sa ho qhaqha mochine le ho tlosa karolo e fosahetseng.

- Nka mehato e hlokahalang ea ho sireletsa likarolo tse hlokolosi le ho netefatsa polokeho ea botho nakong ea ho qhaqhoa.

- Kenya ka hloko karolo e ncha, ho latela litaelo tsa moetsi le litlhaloso tse khothalletsoang tsa torque.

Teko le Teko

- Ka mor'a ho fetola karolo, lekanya mochine ho netefatsa hore o sebetsa hantle le ho lumellana.

- Etsa liphetoho tse hlokahalang kapa li-alignments ho netefatsa ho nepahala le ho nepahala.

- Etsa tlhahlobo e felletseng ho netefatsa hore karolo e ncha e rarollotse bothata le hore mochini o sebetsa ka nepo.

Litokomane le ho Boloka Rekoto

- Boloka lirekoto tse felletseng tsa likarolo tse nchafalitsoeng, ho kenyeletsoa letsatsi, nomoro ea karolo le tlhaiso-leseling ea mofani oa thepa.

- Boloka tlaleho ea nalane ea tokiso ea mochini, ho kenyeletsoa tse nchafalitsoeng, litokiso le lintlafatso.

- Sebelisa litokomane e le tšupiso ea ho lokisa le ho rarolla mathata nakong e tlang.

Thibelo ea Thibelo

- Kamehla hlahloba le ho hlokomela mochini ho tseba mathata a ka bang teng pele a baka ho hloleha ho itseng.

- Latela kemiso e khothaletsoang ea moetsi ea ho boloka mochini le likarolo tsa eona.

- Fetola likarolo ka mokhoa o hlakileng ho latela ts'ebeliso, nako e lebelletsoeng ea bophelo, kapa bofokoli bo tsejoang.

Koetliso le Tšehetso

- Ho fana ka koetliso ho basebetsi ba mochini le basebetsi ba tlhokomelo mabapi le mekhoa e nepahetseng ea ho nchafatsa karolo.

- Fana ka tšehetso e tsoelang pele ea tekheniki le tataiso ho rarolla mathata afe kapa afe a ka hlahang nakong kapa ka mor'a karolo e 'ngoe.

- Khothaletsa tloaelo ea ho lokisa ka potlako 'me u khothalletse basebelisi ho tlaleha lintho tse sa tloaelehang hang-hang.

Ka ho latela lintlha tsena tsa bohlokoa le ho sebetsa le barekisi ba tšepahalang le litsebi tse nang le boiphihlelo, phetolo ea likarolo tsa mochini oa CNC e ka etsoa ka nepo. Ho fetola karolo ka nako le ka nepo ho thusa ho netefatsa hore mochini o sebetsa hantle, ho lelefatsa bophelo ba oona, le ho fokotsa litšitiso ho linako tsa tlhahiso.

Ts'ebeletso ea li-spindle tsa mochini oa CNC

Li-spindle tsa mochini oa CNC (Computer Numerical Control) li bapala karolo ea bohlokoa ho nepahaleng le ts'ebetsong ea ts'ebetso ea mochini. Ho netefatsa ts'ebetso e nepahetseng le bophelo bo bolelele, ts'ebeletso e tloaelehileng ea li-spindle tsa mochini oa CNC e bohlokoa. Mona ke lintlha tsa bohlokoa tse lokelang ho nahanoa ha ho tluoa ts'ebeletso ea li-spindle tsa mochini oa CNC:

Thibelo ea Thibelo

- Tlhokomelo e hlophisitsoeng e bohlokoa ho qoba ho theoha ho sa lebelloang le ho lokisoa ho theko e boima.

- Etsa kemiso ea tlhokomelo e kenyeletsang tlhahlobo ea kamehla le mesebetsi ea litšebeletso.

- Latela litlhahiso tsa moetsi bakeng sa linako le mekhoa ea tlhokomelo.

Ho Hloekisa le ho Lubrication

- Hloekisa seluloana khafetsa ho tlosa lithōle, lerōle, le masalla a pholiso a ka amang tšebetso.

- Sebelisa lisebelisoa tse nepahetseng tsa ho hloekisa le mekhoa e khothaletsoang ke moetsi.

- Tlotsa likarolo tsa spindle ho latela litataiso tse boletsoeng ho netefatsa ts'ebetso e boreleli le ho thibela ho roala.

Tlhahlobo ea lebanta le Bearing

- Sheba boemo ba mabanta bakeng sa matšoao a ho senyeha, mapetsong, kapa ho senyeha. Li nkele sebaka ha ho hlokahala.

- Hlahloba li-bearings bakeng sa lerata le feteletseng, ho thothomela, kapa ho eketseha ha mocheso, tse ka 'nang tsa bontša tlhokahalo ea ho fetola kapa ho lokisoa.

- Lokisa hantle le mabanta a tsitsipano ho boloka phetiso e nepahetseng ea matla.

Tlhokomelo ea Sistimi ea Pholiso

- Hloekisa kamehla 'me u boloke mochini o pholisang ho thibela tšilafalo le ho koala.

- Sheba maemo a pholiso, lihloela le lipompo bakeng sa ts'ebetso e nepahetseng.

- Ela hloko boleng ba sepholi 'me u bo nkele sebaka ha ho hlokahala ho boloka maemo a nepahetseng a ho itšeha le ho thibela tšenyo ea spindle.

Spindle Runout le Balance

- Lekanya ho phalla ha spindle u sebelisa lisebelisoa tse nepahetseng ho netefatsa boteng le ho nepahala.

- Leka-lekanya spindle haeba ho thothomela ho feteletseng kapa ho seha ho sa tšoaneng ho bonoa.

- Rarolla mathata afe kapa afe ka potlako ho qoba tšenyo e ka bang teng ho spindle kapa workpiece.

Tlhahlobo ea Tsamaiso ea Motlakase

- Lekola likhokahano tsa motlakase, likhoele, le lisensara bakeng sa matšoao a tšenyo kapa ho se sebetse hantle.

- Lekola mochini oa spindle le ts'ebetso ea koloi ho netefatsa ts'ebetso e nepahetseng.

- Beakanya litsamaiso tsa taolo ea lebelo ho boloka spindle RPM e nepahetseng.

Thuso ea Litsebi

- Kopana le litsebi tse koetlisitsoeng kapa baemeli ba bahlahisi bakeng sa litšebeletso tse rarahaneng kapa litokiso.

- Kamehla koetlisa basebetsi le basebeletsi ba tlhokomelo mabapi le mekhoa e nepahetseng ea ho sebetsana le tlhokomelo.

- Batla keletso ea litsebi bakeng sa ho rarolla mathata ka ntle ho tlhokomelo e tloaelehileng.

Tlhahlobo ea Tsamaiso ea Motlakase oa Mochini oa CNC

Sistimi ea motlakase ea mochini oa CNC ke karolo ea bohlokoa e amang ts'ebetso le ts'epo ea eona ka kotloloho. Ho hlahlojoa khafetsa tsamaiso ea motlakase hoa hlokahala ho netefatsa ts'ebetso e bolokehileng le ts'ebetso e nepahetseng. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u etsa tlhahlobo ea sistimi ea motlakase bakeng sa mechini ea CNC:

Tlhahlobo e bonoang

- Qala ka ho hlahloba ka mahlo likarolo tsa motlakase bakeng sa matšoao a ts'enyehelo, joalo ka lithapo tse hlephileng, likhoele tse robehileng, kapa likhokello tse cheleng.

- Hlahloba likhokahano leha e le life tse hlephileng kapa li-terminals tse ka amang tsamaiso ea motlakase.

- Batla bopaki ba ho chesa haholo, joalo ka ho fifala kapa ho qhibiliha ha likaroloana.

Phepelo ea motlakase

- Netefatsa hore mochini o fumana motlakase o nepahetseng le hore phepelo ea motlakase e tsitsitse ebile e theiloe hantle.

- Lekola lithapo tse kholo tsa motlakase le likhokahano bakeng sa matšoao leha e le afe a ho senyeha kapa ho senyeha.

- Lekola tšebetso ea li-circuit breaker le fuse ho netefatsa hore li fana ka tšireletso e lekaneng.

Lekhotla la Tsamaiso

- Bula khabinete ea taolo 'me u hlahlobe likarolo tsa kahare, joalo ka liboto tsa potoloho, li-relay, le likhokahano.

- Sheba matšoao a ho chesa haholo, joalo ka matšoao a cheleng kapa monko o matla oa ho chesa.

- Etsa bonnete ba hore lithapo tsohle le likhokahano li tlanngoe ka mokhoa o sireletsehileng 'me li ngotsoe hantle.

Litsamaiso tsa makoloi le likoloi

- Lekola lienjene le li-drive bakeng sa matšoao leha e le afe a senyehileng, joalo ka lithapo tse hlephileng kapa borashe bo tsofetseng.

- Lekola ts'ebetso ea likoloi tsa makoloi 'me u netefatse hore li fana ka taolo e bonolo le e nepahetseng ea motsamao.

- Lekanya motlakase oa motlakase ho netefatsa hore o ka har'a sebaka se boletsoeng bakeng sa ts'ebetso e nepahetseng.

Emergency Stop System

- Lekola likonopo tsa ho emisa ts'ohanyetso ho netefatsa hore li sebetsa ka nepo, 'me u ka emisa mochini hang hang ha ho ka ba le ts'ohanyetso.

- Sheba lithapo le likhokahano tsa sistimi ea ho emisa ts'ohanyetso bakeng sa liphoso kapa likhokahano tse hlephileng.

Libaka tsa Puisano

- Lekola likhokahano tsa puisano, joalo ka Ethernet kapa li-serial ports, ho netefatsa hore li sebetsa ka nepo.

- Lekola likhokahano le lisebelisoa tsa kantle, joalo ka likhomphutha kapa li-programmable logic controllers (PLCs), ho netefatsa phetisetso ea data e nepahetseng.

Sistimi ea ho Grounding

- Netefatsa hore sistimi ea mochini e kentsoeng hantle ebile e hokahantsoe.

- Lekola botšepehi ba lithapo tsa fatše le likhokahano ho thibela likotsi tsa motlakase le ho netefatsa ho fokotsa lerata la motlakase.

Tlhokomelo ea Kamehla

- Theha kemiso ea kamehla ea tlhokomelo ea tsamaiso ea motlakase, ho kenyelletsa ho hloekisa, ho tiisa likhokahano le ho hlahloba lithapo.

- Latela litataiso tsa moetsi bakeng sa mekhoa e khothaletsoang ea tlhokomelo le linako.

- Koetlisa basebetsi le basebetsi ba tlhokomelo mabapi le polokeho ea motlakase le ts'ebetso e nepahetseng ea mochini oa CNC.

Tlhokomelo ea Mokhoa oa ho Pholisa bakeng sa Mechini ea CNC

Sistimi ea ho pholisa ea mechini ea CNC (Computer Numerical Control) e bapala karolo ea bohlokoa ho bolokeng mocheso o nepahetseng oa ts'ebetso, ho lelefatsa bophelo ba lisebelisoa, le ho netefatsa ho nepahala ha mochini. Tlhokomelo e nepahetseng ea sistimi ea ho pholisa e bohlokoa ho thibela mocheso o feteletseng, ho boloka boleng ba pholiso, le ho qoba tšenyo e ka bang teng mochining. Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha ho tluoa tabeng ea ho lokisa tsamaiso ea pholileng bakeng sa mechine ea CNC:

Ho Hloekisa Kamehla

- Hloekisa tanka e pholisang, lihloela le likanale tse pholileng khafetsa ho tlosa lithōle, li-chips le litšila.

- Sebelisa lisebelisoa tse nepahetseng tsa ho hloekisa le mekhoa e khothaletsoang ke moetsi oa mochini.

- Hlakola sisteme nako le nako ho netefatsa hore pholiso ha e sitisoe.

Motsoako o Phodileng

- Lekola le ho boloka moea o nepahetseng oa sepholisa tsamaisong ho latela litlhaloso tsa moetsi.

- Lekola sepholisa khafetsa u sebelisa li-refractometer kapa lisebelisoa tsa tlhahlobo ho netefatsa hore se kopana le maemo a khothaletsoang.

- Fetola motsoako ka ho eketsa sepholi kapa metsi ha ho hlokahala.

Sesebelisoa sa ho hlatsoa

- Sheba le ho hloekisa lihloela tse pholisang khafetsa ho tlosa litšila le ho thibela ho koala.

- Fetola li-filters ho latela linako tse khothaletsoang kapa ha li silafala haholo kapa li senyehile.

- Nahana ka ho sebelisa lihloela tsa boleng bo holimo kapa li-separators tsa makenete ho ntlafatsa ts'ebetso ea ho sefa hantle.

Coolant Quality

- Lekola boemo ba pH ba sepholisa, viscosity, le sebopeho sa lik'hemik'hale ho netefatsa hore se lula ka har'a mefuta e amohelehang.

- Teko bakeng sa kholo ea baktheria kapa tšoaetso e ka lebisang monkong o mobe kapa ho senyeha ha tšebetso ea pholiso.

- Ntsha se phodisang haeba se bontsha matshwao a ho theoha kapa se hloleha ho fihlella maemo a hlokahalang a tshebetso.

Sekhahla sa Pompo le Phallo

- Lekola pompo e pholisang bakeng sa ts'ebetso e nepahetseng, lekola hore na ha e lutle, lerata le sa tloaelehang, kapa sekhahla sa phallo e fokotsehileng.

- Hloekisa kapa u nke sebaka sa pompo ea pompo haeba e senyehile kapa e senyehile.

- Netefatsa hore sekhahla sa phallo ea pholiso e ka har'a sebaka se khothalelitsoeng ho netefatsa hore pholile e sebetsa hantle.

Taolo ea Mocheso o Phodileng

- Lekola sistimi ea taolo ea mocheso, joalo ka chiller kapa mochini o futhumatsang mocheso, ho boloka thempereichara ea pholileng ka har'a sebaka se boletsoeng.

- Hlahloba li-sensor, li-valve, le mekhoa ea ho laola ho netefatsa taolo e nepahetseng ea mocheso.

- Hloekisa kapa u nke sebaka sa mapheo a futhumatsang mocheso haeba a koaletsoe ke litšila kapa maloanlahla.

Koetliso ea Basebetsi

- Fana ka koetliso ho basebetsi ba mechini mabapi le ho tšoara lipholisa hantle, ho kenyeletsoa ho tlatsa hape, ho lokisa mahloriso, le ho tlaleha litaba tse amanang le pholiso.

- Laela basebetsi ho lemoha matšoao a ho senyeha ha pholiso kapa ho se sebetse hantle ha sistimi le mokhoa oa ho arabela ka nepo.

- Khothaletsa moetlo oa bohloeki le tlhokomelo e tsoelang pele ea mochini o pholisang har'a basebetsi.

Ho sebeletsa Litaolo tsa Mochini oa CNC le Software

Ts'ebeletso ea khafetsa ea taolo ea mochini oa CNC le software e bohlokoa ho netefatsa ts'ebetso e nepahetseng le ho qoba mathata a ka bang teng. Mona ke lintlha tse ling tsa bohlokoa tseo u ka li nahanang ha ho tluoa tabeng ea ho sebeletsa li-control tsa mochini oa CNC le software:

Lisebelisoa tsa Software

- Kamehla ntlafatsa software ea mochini oa CNC ho rua molemo ho tsoa ho likarolo tsa morao-rao, litokiso tsa liphoso, le ntlafatso ea ts'ebetso.

- Latela litataiso le likhothaletso tsa moetsi bakeng sa ho nchafatsa software.

- Etsa li-backups tsa software ea hajoale ea mochini pele o etsa lintlafatso.

Tekanyetso le Ho tsamaisana

- Nako le nako, lekanya le ho hokahanya taolo ea mochini oa CNC ho boloka ho nepahala le ho nepahala.

- Lekola 'me u lokise litekanyo tsa li-axes, li-exsets tsa lisebelisoa, le maemo a zero a workpiece.

- Netefatsa bonnete ba litsamaiso tsa lipatlisiso, haeba ho hlokahala, 'me u lokise bocha ha ho hlokahala.

Bekapo le Khutlisa

- Kamehla boloka li-parameter tsa bohlokoa tsa mochini, litlhophiso le mananeo ho thibela tahlehelo ea data.

- Boloka likopi tse ngata tsa li-backups lisebelisoa tsa kantle kapa polokelo ea leru bakeng sa ts'ireletso e eketsehileng.

- Lekola ts'ebetso ea ho khutlisa nako le nako ho netefatsa hore li-backups lia tšepahala ebile lia fumaneha.

Control Panel Tlhahlobo

- Lekola phanele ea taolo ka mahlo bakeng sa matšoao afe kapa afe a tšenyo, joalo ka likonopo tse robehileng, lihokelo tse hlephileng, kapa matšoao a sa sebetseng hantle.

- Hloekisa phanele ea taolo le likonopo khafetsa ho tlosa lerōle kapa litšila tse ka amang ts'ebetso.

- Lekola tšebetso ea phanele ea taolo ka ho netefatsa konopo ka 'ngoe, switjha le ponts'o.

Likhoebo tsa Motlakase

- Lekola likhokahano tsa motlakase ka har'a khabinete ea taolo bakeng sa lithapo life kapa life tse hlephileng kapa tse holang.

- Tiisa likhokahano life kapa life tse hlephileng 'me u nkele lithapo tse senyehileng kapa lihokelo.

- Etsa tlhahlobo e phethahetseng ea tsamaiso ea motlakase ho netefatsa ho theoa ho nepahetseng le ho fokotsa kotsi ea liphoso tsa motlakase.

Tlhokomelo ea lisebelisoa tsa ho kenya

- Lekola tšebetso ea lisebelisoa tse kentsoeng, joalo ka likonopo, litoeba, kapa li-touchscreens.

- Hloekisa lisebelisoa tsa ho kenya ho tlosa litšila kapa masalla a ka sitisang tšebetso ea tsona.

- Kenya sebaka sa lisebelisoa tse khathetseng kapa tse sa sebetseng hantle ho boloka taolo e bonolo le e nepahetseng.

Koetliso ea Basebetsi

- Fana ka lithupelo tse felletseng mabapi le taolo ea mochini oa CNC le software.

- Tseba basebedisi ka mesebetsi e fapaneng, dimenu, le liparamente tsa sebopeho sa taolo.

- Laela basebetsi ka tšebeliso e nepahetseng ea likarolo tsa software le mekhoa ea ho rarolla mathata.

Licheke tsa Kamehla tsa Tsamaiso

- Etsa licheke tsa nako le nako ho fumana lintlha tse ka bang teng tsa software kapa taolo.

- Lekola litlaleho tsa liphoso, lialamo, le melaetsa ea tlhahlobo bakeng sa mathata afe kapa afe.

- Etsa liteko tsa tlhahlobo ea sistimi 'me u latele litataiso tsa moetsi bakeng sa ho rarolla mathata le ho rarolla mathata.

Litlhahlobo tsa Tšireletso ea Mochini oa CNC

Ho netefatsa polokeho ea basebetsi le sebaka sa mosebetsi ho bohlokoa haholo ha o sebetsa le mechini ea CNC (Computer Numerical Control). Mona ke lintlha tsa bohlokoa tseo u ka li nahanang ha u etsa liteko tsa polokeho ea mochini oa CNC:

Sekoahelo sa Mochini

- Lekola sebaka sa mochini ho etsa bonnete ba hore se tiile, se sirelelitsoe hantle, 'me ha se na mapetsong kapa tšenyo.

- Netefatsa hore menyako eohle ea ho kena, liphanele le li-interlock tsa polokeho li sebetsa ka nepo.

- Lekola ponahalo e nepahetseng ea matšoao a tlhokomeliso, lileibole le likonopo tsa ho emisa boemo ba tšohanyetso.

Emergency Stop System

- Lekola likonopo tsa ho emisa ts'ohanyetso ho netefatsa hore li emisa ts'ebetso ea mochini hang hang ha o tobetse.

- Netefatsa hore sistimi ea ho emisa ts'ohanyetso e maemong a nepahetseng a ts'ebetso 'me e fumaneha habonolo ho basebelisi.

- Koetlisa basebetsi ka tšebeliso e nepahetseng ea likonopo tsa ho emisa boemo ba tšohanyetso le libaka tsa bona.

Tšireletso ea Motlakase

- Lekola likarolo tsa motlakase bakeng sa lithapo life kapa life tse pepeneneng, likhokello tse hlephileng, kapa litšupiso tse senyehileng.

- Netefatsa hore tsamaiso ea motlakase e theiloe ka nepo ho fokotsa kotsi ea ho tsukutloa ha motlakase.

- Kamehla hlahloba hore li-circuit breaker le fuse li sebetsa hantle.

Tooling le Workpiece Safety

- Hlahloba lisebelisoa, joalo ka lithulusi tsa ho seha kapa li-clamp, bakeng sa tšenyo, ho senyeha kapa ho kenngoa ho fosahetseng.

- Sheba lisebelisoa tsa mosebetsi bakeng sa boemo bo sireletsehileng le ho koala ka nepo ho qoba ho falla nakong ea machining.

- Lekola moaparo oa lisebelisoa 'me u nke sebaka sa lisebelisoa ha ho hlokahala ho boloka seha se bolokehile ebile se sebetsa hantle.

Leseli la Emergency

- Netefatsa hore sebaka sa mosebetsi se na le mabone a lekaneng a ts'ohanyetso ha motlakase o khaoha kapa maemong a mang a tšohanyetso.

- Lekola mabone a tšohanyetso khafetsa ho netefatsa hore a sebetsa hantle le ho bonesa sebaka hantle.

Polokeho ea Mollo

- Netefatsa boteng le tšebetso ea litima-mollo sebakeng sa mochini oa CNC.

- Koetlisa basebetsi ka tšebeliso e nepahetseng ea litima-mollo le mekhoa ea ho ntša batho ha ho ka cha.

- Hlakola sebaka se potolohileng mochine oa CNC oa thepa leha e le efe e tukang kapa lithōle.

Koetliso ea Basebetsi le Tlhokomeliso

- Fana ka koetliso e felletseng ho basebetsi mabapi le mekhoa e bolokehileng ea ts'ebetso le likotsi tse ka bang teng ho mochini oa CNC.

- Khothaletsa moetlo oa tlhokomeliso ea polokeho le ho khothaletsa basebelisi ho tlaleha matshwenyeho afe kapa afe a polokeho.

- Etsa liboka tsa kamehla tsa polokeho kapa lipuisano tsa lebokose la lithulusi ho sebetsana le lihlooho tsa polokeho le ho matlafatsa mekhoa e sireletsehileng.

Ho lumellana le Melao ea Tšireletseho

- Netefatsa hore mochini oa CNC o kopana le litekanyetso le melaoana ea ts'ireletso sebakeng sa ts'ebetso.

- Lula u le haufi le liphetoho leha e le life kapa lintlafatso tsa litekanyetso tsa polokeho 'me u li kenye litlhahlobong tsa polokeho.

- Kopana le litsebi tsa tšireletso kapa baeletsi, haeba ho hlokahala, ho netefatsa hore ho latela melao le mekhoa e metle.

Ho Hloekisa Mochini oa CNC

Ho hloekisa khafetsa le ho lokisoa ha mechini ea CNC ho bohlokoa bakeng sa ts'ebetso ea bona, ho nepahala le nako ea bophelo ka kakaretso. Ka ho latela mekhoa ena ea ho hloekisa, basebetsi ba ka etsa bonnete ba hore mechine ea bona ea CNC e lula e le boemong bo botle, ho fokotsa nako ea ho theoha le ho eketsa tlhahiso.

- Ho boloka mochine o hloekileng le o hlokometsoeng hantle oa CNC (Computer Numerical Control) ho bohlokoa bakeng sa ts'ebetso ea oona e nepahetseng le bophelo bo bolelele. Ho hloekisa mochini khafetsa ho thusa ho thibela ho bokellana ha lithōle, lerōle le li-chips tse ka bakang mathata a mochini le ho se nepahale ha machining.

- Qala ka ho tima mochine le ho o khaola mohloling oa matla ho netefatsa polokeho nakong ea ho hloekisa.

- Qala ka ho tlosa li-chips leha e le life tse hlephileng, lithōle, kapa metsi a sehang sebakeng sa mosebetsi u sebelisa vacuum kapa borashe. Ela hloko libaka tseo ho leng thata ho fihla ho tsona, joalo ka maphao le likhutlong, moo maloanlahla a atisang ho bokellana.

- Hlakola bokaholimo ba mochini ka lesela le hloekileng, le se nang letlapa le motsoako o bonolo oa sesepa. Qoba ho sebelisa li-abrasive cleaners tse ka senyang karolo ea mochini. Hloekisa libaka tsohle tse pepeneneng ka botlalo, ho kenyeletsoa tafole, selulo, litšepe tsa lisebelisoa le sebaka se kampetsoeng.

- Hloekisa tanka e pholisang 'me u nkele maro a sehang sebaka khafetsa. Mekelikeli a sehang a litšila kapa a silafetseng a ka ama ts'ebetso ea mochini le boleng ba lihlahisoa tse felileng.

- Lekola lihloela le li-skrini ho sistimi e pholisang, sisteme ea tlhoekiso ea moea, le sistimi ea lubrication. Hloekisa kapa u nke sebaka sa likarolo tsena ha ho hlokahala ho etsa bonnete ba ho sefa hantle le ho phalla ha mokelikeli.

- Ela hloko ka ho khethehileng mekhoa ea mochini ea spindle le ea ho fetola lisebelisoa. Tlosa lithōle leha e le life kapa lintho tse ka 'nang tsa kena-kenana le ts'ebetso ea tsona e bonolo. Lubricate likarolo tsena ho latela litataiso tsa moetsi ho boloka ts'ebetso e nepahetseng.

- Sheba sekoahelo le melumo bakeng sa matšoao leha e le afe a ho senyeha kapa ho senyeha. Li nkele sebaka ha ho hlokahala ho sireletsa batho ba ka hare ho mochine hore ba se ke ba silafala.

- Qetellong, hlahloba likhokahano tsa motlakase, likhoele le likhoele. Netefatsa hore li bolokehile ebile ha li na tšenyo. Hloekisa karolo ea taolo le likonopo ka sehloekisi se bonolo ho tlosa litšila kapa litšila.

- Boloka kemiso ea kamehla ea ho hloekisa le mesebetsi ea ho lokisa litokomane. Sena se thusa ho lekola makhetlo a ho hloekisa le ho tseba mathata afe kapa afe a ka bang teng esale pele.

Koetliso le Tšehetso ea Mochini oa CNC

Ka ho fana ka koetliso e felletseng le tšehetso e tsoelang pele, basebetsi ba ka hlaolela litsebo tse hlokahalang le boitšepo ba ho sebetsa mechini ea CNC ka katleho. Basebetsi ba koetlisitsoeng hantle ba kenya letsoho ho ntlafatseng tlhahiso, nako e fokotsehileng ea nako, le liphetho tsa boleng bo holimo.

- Koetliso e nepahetseng le tšehetso e tsoelang pele ke tsa bohlokoa bakeng sa basebetsi ho sebelisa mechine ea CNC (Computer Numerical Control) ka katleho le ho eketsa bokhoni ba bona. Mananeo a koetliso a fa basebetsi tsebo le litsebo tse hlokahalang ho sebetsa, ho hlophisa le ho rarolla mathata ka mechini ea CNC.

- Qala ka ho fana ka koetliso e felletseng mabapi le metheo ea theknoloji ea CNC, ho kenyeletsoa ho utloisisa likarolo tsa mochini, lisebelisoa, le metheo ea mananeo. Motheo ona o thusa basebetsi ho utloisisa mehopolo ea mantlha le mantsoe a amanang le mechini ea CNC.

- Tsebisa basebetsi ho software ea CAD/CAM e sebelisetsoang ho theha likarolo tsa meralo le ho hlahisa mananeo a machining. Koetliso ea lisebelisoa tsena tsa software e thusa basebelisi ho hlophisa mechini ea CNC hantle le ho ntlafatsa lits'ebetso tsa mochini.

- Fana ka lithupelo tsa ho sebetsa moo basebetsi ba ka ikoetlisetsang ho seta mochini, ho kenya lisebelisoa, le ho tsamaisa ts'ebetso ea mochini. Boiphihlelo bona bo sebetsang bo thusa ho aha boits'epo le ho tloaelana le ts'ebetso ea mochini.

- Hatisa liprothokholo tsa polokeho le mekhoa e metle nakong ea koetliso. Basebelisi ba lokela ho koetlisoa mabapi le mekhoa e nepahetseng ea ho qala le ho koala mochini, ho sebetsana le lisebelisoa tsa ho itšeha, le ts'ebeliso ea lisebelisoa tsa ts'ireletso (PPE) ho netefatsa tikoloho e bolokehileng ea ts'ebetso.

- Fana ka koetliso mabapi le tlhokomelo ea mochine le tlhokomelo ea thibelo. Basebelisi ba lokela ho ithuta ho hlahloba le ho boloka likarolo tsa bohlokoa, joalo ka li-spindle, li-way covers, le lisebelisoa tsa ho tlotsa, ho boloka mochini o sebetsa hantle.

- Fana ka tšehetso e tsoelang pele ka libuka, litokomane le lisebelisoa tsa marang-rang. Bukana e felletseng ea mosebelisi e sebetsanang le ts'ebetso ea mochini, mehlala ea mananeo, litataiso tsa ho rarolla mathata, le mekhoa ea ho lokisa e ka sebetsa e le litšupiso tsa bohlokoa bakeng sa basebelisi.

- Theha mokhoa oa ts'ehetso moo basebetsi ba ka batlang thuso le tataiso ha ba kopana le mathata kapa mathata. Sena e ka ba ka sebopeho sa sehlopha sa ts'ehetso se inehetseng, mohala oa thuso oa tekheniki, kapa liforamu tsa marang-rang moo basebelisi ba ka hokahanang le basebelisi ba CNC ba nang le boiphihlelo.

- Etsa lithupelo tsa ho nchafatsa nako le nako ho matlafatsa tsebo le bokhoni. Theknoloji ea CNC e fetoha ha nako e ntse e ea, kahoo ho boloka basebetsi ba ntse ba le morao-rao ka tsoelo-pele le mekhoa ea morao-rao ho netefatsa hore ba ka sebelisa bokhoni ba mochine ka botlalo.

- Khothalletsa basebetsi ho kenya letsoho liketsahalong tsa indasteri, lipontšo tsa khoebo, le lithupelo ho atolosa tsebo ea bona le marang-rang le litsebi tse ling tšimong. Liketsahalo tsena li fana ka menyetla ea ho ithuta ka mahlale a macha, ho arolelana liphihlelo, le ho fumana leseli mabapi le mekhoa e metle.

Litsenyehelo tsa CNC Machine Service

Ho utloisisa lintlha tsa litšenyehelo tse amanang le ts'ebeletso ea mochini oa CNC ho bohlokoa bakeng sa tekanyetso le moralo.

- Litšenyehelo tsa tšebeletso ea mochine oa CNC (Computer Numerical Control) li ka fapana ho itšetlehile ka lintlha tse 'maloa, ho kenyelletsa le mofuta oa tšebeletso o hlokahalang, ho rarahana ha mochine, le litefiso tsa mofani oa litšebeletso. Ho utloisisa lintlha tsena ho bohlokoa bakeng sa ho etsa moralo oa tšebeliso ea chelete le ho etsa bonnete ba hore ho na le moralo o bolokang litšenyehelo.

- Tlhokomelo ea kamehla ea thibelo ke tšebeletso e tloaelehileng bakeng sa mechine ea CNC. Hangata e kenyelletsa mesebetsi e kang ho hlahloba, ho hloekisa, ho tlotsa le ho lekanya. Litsenyehelo tsa tlhokomelo ea thibelo li ka tloha ho makholo a seng makae ho ea ho liranta tse likete tse 'maloa ka selemo, ho itšetlehile ka boholo ba mochine le ho rarahana.

- Litokiso tsa maemo a tšohanyetso kapa tse sa reroang ke karolo e 'ngoe ea ts'ebeletso ea mochini oa CNC e ka amang litšenyehelo. Hangata litokiso tsena ha li lebeletsoe 'me li hloka tlhokomelo e potlakileng ho fokotsa nako ea ho theoha. Litšenyehelo li tla itšetleha ka ho teba ha taba, ho fumaneha ha likarolo tse ncha, le botsebi bo hlokahalang ho rarolla bothata. Litokiso tsa maemo a tšohanyetso li ka tloha ho liranta tse makholo a seng makae ho isa ho tse likete tse 'maloa.

- Bafani ba bang ba litšebeletso ba fana ka likonteraka tsa litšebeletso kapa merero ea tlhokomelo e koahelang ka bobeli tlhokomelo e tloaelehileng ea thibelo le tokiso ea tšohanyetso. Likontraka tsena li ka fana ka phokotso ea litšenyehelo le khotso ea kelello ka ho netefatsa tšebeletso e potlakileng le ho fokotsa kotsi ea litšenyehelo tse sa lebelloang. Litsenyehelo tsa likonteraka tsa litšebeletso li fapana ho latela lintlha tse kang lilemo tsa mochini, ho rarahana, le boemo ba ts'ireletso e fanoeng.

- Likarolo tsa lisebelisoa le lisebelisoa ke litšenyehelo tse ling tse lokelang ho nahanoa ha u sebeletsa mechini ea CNC. Likarolo tse kang li-motor, li-sensor, mabanta le li-bearings li ka hloka ho nkeloa sebaka ha nako e ntse e ea. Litsenyehelo tsa likarolo tsena li tla itšetleha ka mofuta oa mochini, mohlala le ho fumaneha ha ona. Ho kgothaletswa ho boloka lethathamo la lisebelisoa tse sebelisoang hangata ho fokotsa nako ea ho theoha le ho fokotsa litšenyehelo tsa ho romela thepa.

- Ho etela sebaka sa marang-rang ho ka baka litšenyehelo tse ling, joalo ka litšenyehelo tsa maeto, bolulo le litefiso tsa litsebi. Litšenyehelo tsena li ka fapana ho latela sebaka sa mochini le maano a mofani oa litšebeletso. Mekhoa ea ho hlahloba le ho rarolla mathata e ka 'na ea e-ba teng, e ka thusang ho fokotsa tlhokahalo ea ho etela setšeng le litšenyehelo tse amanang le tsona.

- Ho eletsoa ho fumana litheolelo ho tsoa ho bafani ba litšebeletso tse ngata ho bapisa litšenyehelo le lits'ebeletso tse fanoang. Nahana ka botumo, boiphihlelo, le boitseanape ba mofani oa litšebeletso, hammoho le nako ea bona ea karabelo le boteng ba maemo a tšohanyetso.

- Ho tsetela tlhokomelong ea kamehla le ho lokisa ka nako ho ka thusa ho fokotsa litšenyehelo tsa nako e telele. Ho hlokomoloha tlhokomelo ho ka lebisa ho senyeha khafetsa, ho fokotsa nako ea bophelo ba mochini, le litšenyehelo tse eketsehileng tsa tokiso.

fihlela qeto e

Ts'ebeletso ea mochini oa CNC e bohlokoa ho netefatsa hore mechini ena e sebetsa hantle le ka nepo. Bafani ba litšebeletso tsa mochini oa CNC ba fana ka lits'ebeletso tse fapaneng ho hlokomela, ho lokisa, le ho ntlafatsa mechini ena ho netefatsa hore e fihlela litlhoko tsa likhoebo tsa tlhahiso. Tlhokomelo ea kamehla, tlhahlobo, le litokiso li bohlokoa ho thibela ho theoha le ho fokotsa kotsi ea litokiso tse theko e boima. Ka ho tsetela ho ts'ebeletso ea mochini oa CNC, likhoebo li ka etsa bonnete ba hore li eketsa bokhoni ba mochini oa bona oa CNC le ho ntlafatsa tlhahiso ea bona ka kakaretso.