CNC Machining Service

Kodi CNC Machining ndi chiyani

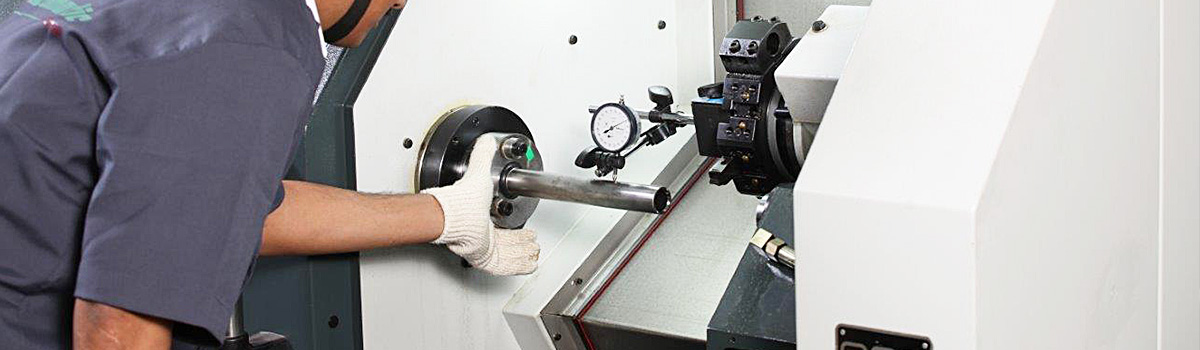

CNC imayimira kuwongolera manambala apakompyuta, yomwe ndiukadaulo wowongolera zida zamakina zokha pogwiritsa ntchito kompyuta yaying'ono yomwe imalumikizidwa pachidacho. Makina a CNC amatha kugwira ntchito motsatira malangizo omwe ali ndi coded, monga kayendedwe ka makina, kuchuluka kwa chakudya chamafuta, kuthamanga, ndi zina zotero. Palibe chifukwa choti oyendetsa aziwongolera makinawo pamanja, motero, CNC imathandizira kukonza bwino komanso kulondola kwambiri.

DJmolding CNC makina luso

Makina ofunikira a CNC opangira ma prototyping mwachangu ndi magawo opanga, odziwa bwino komanso oyesedwa bwino DJmolding CNC masitolo ogulitsa.

Timagwiritsa ntchito pafupifupi mtundu uliwonse wa mphero ya CNC ndi malo otembenukira, ndipo timanyadira kuti timatha kupanga makina aliwonse omwe mungafune, kuchokera ku zosavuta, zogwirira ntchito 'monga-makina' mpaka zovuta, ma geometries achilengedwe okhala ndi kulolerana kolimba. Tikapempha, tikhoza kupanganso magawo ndi EDM ndi grinders. Maenvulopu omanga, kukula kwake kocheperako ndi malangizo amapangidwe amasiyana pogaya ndi kutembenuza.

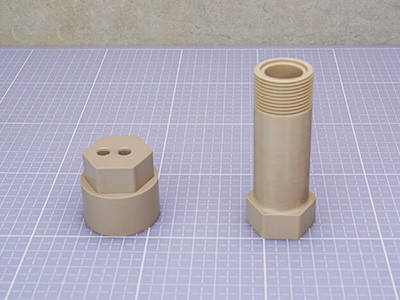

CNC kugaya Service

Malinga ndi mafayilo a CAD a kasitomala, landirani pompopompo CNC milling quote mu maola 24.

CNC Kutembenuza Service

Malinga ndi mafayilo a CAD a kasitomala, landirani pompopompo CNC yotembenuza mu maola 24.

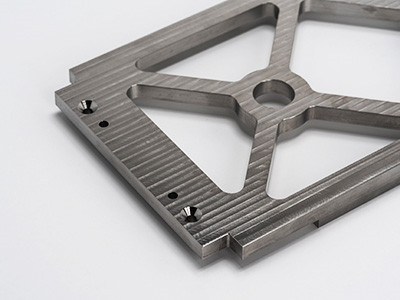

DJmolding CNC mphero ntchito luso

Kuchokera ku prototyping mpaka kupanga kwathunthu kumathamanga. Malo athu a 3 axis, 3+2 axis ndi full 5-axis mphero malo adzakuthandizani kuti mupange magawo olondola komanso abwino kwambiri kuti mukwaniritse zomwe mukufuna kwambiri.

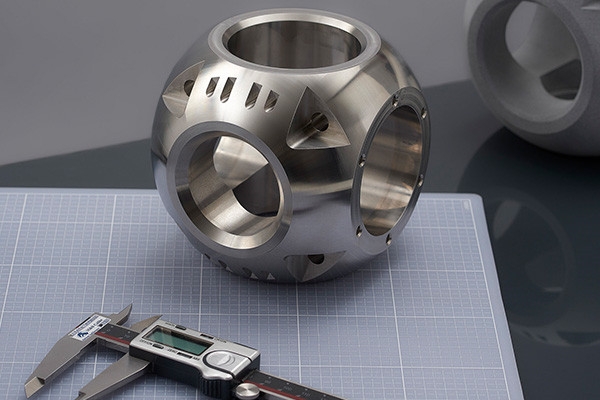

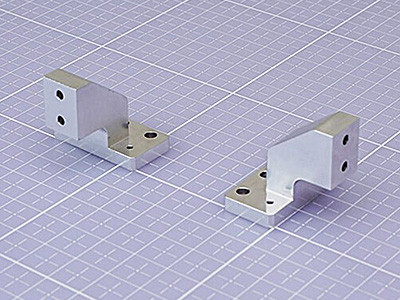

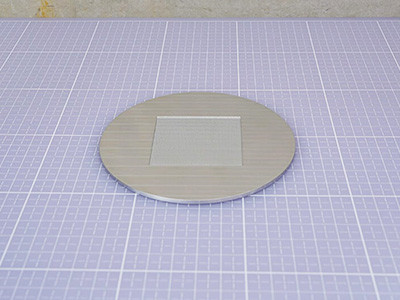

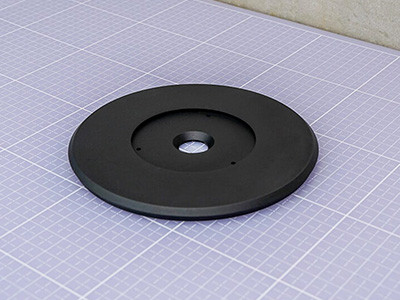

Gallery ya magawo opangidwa ndi makina a CNC

Timasindikiza ma prototypes othamanga kwambiri komanso madongosolo otsika otsika kwa makasitomala m'mafakitale angapo: zakuthambo, magalimoto, chitetezo, zamagetsi, zoyambira zamagetsi, makina opanga makina, makina, kupanga, zida zamankhwala, mafuta & gasi ndi robotic.

Aluminium 7075-T6

Aluminium 6061-T6

Aluminium 6082

Aluminium 6063

PeEK

Akatswiri aluso amagwiritsa ntchito makina a CNC pogwiritsa ntchito njira zopangira zida potengera ma geometry a magawo omaliza. Chidziwitso cha gawo la geometry chimaperekedwa ndi CAD (mapangidwe othandizidwa ndi makompyuta). Makina a CNC amatha kudula pafupifupi aloyi iliyonse yachitsulo ndi pulasitiki yolimba kwambiri komanso yobwerezabwereza, kupanga magawo opangidwa ndi makina oyenera pafupifupi makampani onse, kuphatikiza zakuthambo, zamankhwala, zama robotiki, zamagetsi, ndi mafakitale. DJmolding imapereka ntchito za CNC ndipo imapereka mawu a CNC pazida zopitilira 40 kuyambira pa aluminiyamu yamtengo wapatali ndi acetal mpaka titaniyamu yapamwamba ndi mapulasitiki opangidwa ngati PEEK ndi Teflon.

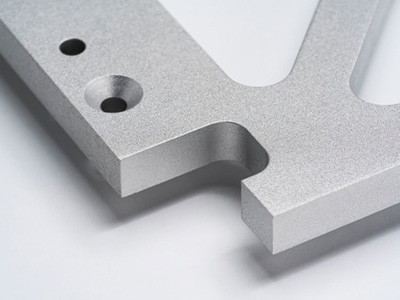

Zomaliza zopezeka pamwamba pa makina a CNC

Zomaliza zapamtunda zimagwiritsidwa ntchito pambuyo popanga makina ndipo zimatha kusintha mawonekedwe, kuuma kwapamtunda, kuuma komanso kukana kwazinthu zomwe zimapangidwa.

Monga makina (Ra 3.2μm / Ra 126μin)

Uku ndiye kumaliza kwathu kokhazikika. Magawo amapangidwa ndi makina ndipo amawongoleredwa, m'mbali zakuthwa ndi chamfered.

Makina osalala (Ra 1.6μm / Ra 63μin)

Makina osalala ali ngati kumaliza kwa 'Monga makina' koma okhala ndi zilembo zowoneka bwino zamakina. Magawo amapangidwa ndi chakudya chochepa, palibe kupukuta pamanja komwe kumayikidwa.

Mkanda Wophulika

Zigawo zake zimakhala ndi mikanda yowombedwa ndi mikanda yagalasi zomwe zimapangitsa kuti zisawonongeke.

Wopukutidwa + Electropolished (Ra 0.8μm / Ra 32μin)

Zigawozo ndi brushed ndi electropolished. Ndibwino kuti muchepetse kukula kwapang'onopang'ono kwa gawolo.

Okusayidi wakuda

Imagwiritsidwa ntchito pazitsulo, okusayidi wakuda ndi zokutira zosintha zomwe zimagwiritsidwa ntchito kuti zithandizire kukhazikika kwa dzimbiri ndikuchepetsa kuwunikira.

Brushed + Anodized Type II (Glossy)

Mbali ndi brushed ndiyeno anodized mtundu II. Zabwino pakuwonjezera kukana kwa dzimbiri kwa gawolo. Nthawi zambiri zimabweretsa mtundu wonyezimira.

Makina a CNC (Computer Numerical Control) ndiwo msana wa kupanga zamakono. Iwo asintha njira yopangira zinthu popereka kulondola, kuthamanga, ndi kusinthasintha kuti apange zigawo ndi zigawo zovuta. Komabe, kuonetsetsa kuti makina CNC ntchito pa mlingo wawo mulingo woyenera, iwo amafuna nthawi zonse kukonza, kukonza, ndi utumiki. Othandizira makina a CNC amapereka mautumiki osiyanasiyana kuti atsimikizire kuti makinawa akugwira ntchito bwino komanso moyenera. Mu positi iyi yabulogu, tikambirana mbali zosiyanasiyana zamakina a CNC komanso momwe zimapindulira mabizinesi opanga.

Kodi CNC Machine Service ndi chiyani?

CNC imayimira Computer Numerical Control, kutanthauza makina oyendetsedwa ndi pulogalamu ya pakompyuta. Makina a CNC amagwiritsidwa ntchito pazinthu zosiyanasiyana, kuphatikiza kudula, kubowola, mphero, ndi kutembenuza.

Ntchito zamakina a CNC zimaphatikizapo kugwiritsa ntchito makinawa kuti agwire ntchito zolondola kwambiri komanso zobwerezabwereza. Ntchitozi zimagwiritsidwa ntchito nthawi zambiri popanga, zomwe zimafuna magawo olondola komanso osasinthasintha.

Kuti mugwiritse ntchito makina a CNC, pulogalamu imapangidwa koyamba pogwiritsa ntchito pulogalamu yothandizidwa ndi makompyuta (CAD). Pulogalamuyi imakwezedwa pamakina, omwe amagwiritsa ntchito malangizowo kuti agwire ntchito yomwe akufuna pachinthu china.

CNC makina angagwiritsidwe ntchito ndi zipangizo zosiyanasiyana, kuphatikizapo zitsulo, pulasitiki, matabwa, ndi nsanganizo. Amapereka maubwino ambiri, kuphatikiza nthawi yopangira mwachangu, kulondola kwambiri, komanso kuthekera kopanga mawonekedwe ndi mawonekedwe ovuta.

Chifukwa chiyani CNC Machine Service Ndi Yofunika?

Makina a CNC (Computer Numerical Control) akhala ofunika kwambiri m’mafakitale opangira zinthu, makamaka pakupanga magalimoto, mlengalenga, ndi zipangizo zamankhwala. Makinawa ndi ongochita zokha, motero amatha kugwira ntchito kwa nthawi yayitali popanda kulowererapo kwa anthu. Makina a CNC amatha kupanga zida zovuta kwambiri komanso zolondola kwambiri, zomwe zimapangitsa kuti zikhale zofunika kwambiri popanga.

CNC makina utumiki n'kofunika pa zifukwa zingapo. Choyamba, zimatsimikizira kuti makinawo akugwira ntchito moyenera. Makina a CNC ali ndi magawo ambiri osuntha omwe amafunikira kukonza pafupipafupi kuti apewe kuwonongeka, zomwe zingayambitse kuwonongeka kwa makina ndi kutsika kwapang'onopang'ono. Kusamalira nthawi zonse kumathandiza kuzindikira ndi kuthetsa mavuto omwe angakhalepo asanakhale mavuto aakulu.

Kachiwiri, ntchito yamakina a CNC imathandizira kukonza moyo wamakina. Kuthandizira pafupipafupi kumawonetsetsa kuti zidazi zimagwira ntchito mkati mwazomwe zidapangidwira, kuchepetsa chiopsezo cha kutha msanga ndi kung'ambika. Izi zimatalikitsa moyo wa makinawo, kupulumutsa wopanga ndalama m'malo ndi kukonzanso.

Chachitatu, ntchito yamakina a CNC imathandizira kukhalabe ndi khalidwe losasinthika pakupanga. Makina a CNC amapangidwa kuti azitulutsa mbali zolondola kwambiri komanso zolondola kwambiri, zomwe ndizofunikira pakupanga zakuthambo ndi zida zamankhwala. Kugwira ntchito pafupipafupi kumapangitsa kuti makina azigwira ntchito moyenera, ndikupanga zidutswa zomwe zimakwaniritsa zofunikira ndikusunga zotulutsa zosasinthika.

Chachinayi, ntchito yamakina a CNC imathandizira kukonza chitetezo pantchito. Makina a CNC ndi zida zamphamvu zomwe zimafunikira kusamalira mosamala kuti mupewe ngozi. Kugwira ntchito pafupipafupi kumathandizira kuzindikira zoopsa zomwe zingachitike, zomwe zitha kuwongoleredwa zisanawononge ogwiritsa ntchito kapena kuwonongeka kwa makina.

Mitundu ya Makina a CNC

Makina a CNC (Computer Numerical Control) amagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana popanga molondola. Makinawa amagwiritsa ntchito makina owongolera apakompyuta kuti azitha kupanga makina ovuta komanso olondola kwambiri. Pali mitundu ingapo ya makina a CNC omwe alipo, omwe amapangidwira ntchito zinazake. Nayi mitundu yodziwika kwambiri:

CNC kugaya Makina

- Vertical Machining Centers (VMC):Makinawa ali ndi chopota cholunjika cholunjika ndipo ndi oyenera kudula ndi kupanga zida zolimba.

- Horizontal Machining Centers (HMC):Ma HMC ali ndi chopota chopingasa ndipo ndi abwino kukonza zida zazikulu ndi zolemetsa.

- Makina a 5-Axis:Makinawa amapereka kayendedwe ka nthawi imodzi mu nkhwangwa zisanu, zomwe zimathandiza kuti pakhale makina ovuta komanso ovuta.

Makina a CNC Lathe

Malo Otembenukira:Makinawa amagwiritsidwa ntchito potembenuza molondola, pomwe chogwirira ntchito chimazungulira pomwe zida zodulira zimapanga zinthuzo.

- Mitundu ya Swiss Lathes:Zopangira zamtundu waku Swiss zidapangidwa kuti zikhale zolondola kwambiri komanso zazing'ono zogwirira ntchito. Amakhala ndi mutu wotsetsereka komanso chitsamba chowongolera kuti chikhale cholondola kwambiri.

CNC Plasma Cutters

- Makina odulira plasma amagwiritsa ntchito jeti yothamanga kwambiri ya gasi wa ionized kudula zida zamagetsi monga chitsulo, aluminiyamu, ndi mkuwa. Amagwiritsidwa ntchito kwambiri popanga zitsulo komanso mafakitale.

CNC Laser Kudula Makina

- Makina odulira a laser amagwiritsa ntchito mtengo wokhazikika wa laser kuti asungunuke, kuwotcha, kapena kuumitsa zinthu, zomwe zimapangitsa mabala olondola komanso oyera. Ndiwokhazikika ndipo amatha kugwira ntchito zosiyanasiyana monga zitsulo, matabwa, acrylic, pulasitiki.

Makina a CNC rauta

- CNC routers makamaka ntchito kudula, kuumba, ndi chosema zipangizo monga matabwa, pulasitiki, ndi thovu. Amagwiritsidwa ntchito kwambiri pakupanga matabwa, kupanga zikwangwani, ndi prototyping.

Makina a CNC EDM

- Makina a Electrical Discharge Machining (EDM) amagwiritsa ntchito magetsi kuti achotse zinthu zomwe zimagwiritsidwa ntchito. Amagwiritsidwa ntchito popanga mawonekedwe ovuta komanso zinthu zolimba monga chitsulo cholimba ndi titaniyamu.

CNC Makina Akupera

- Makina opera amagwiritsidwa ntchito kuti akwaniritse zomaliza zapamwamba komanso miyeso yolondola. Amagwiritsa ntchito mawilo abrasive kuchotsa zinthu pa workpiece.

CNC Press mabuleki

- Mabuleki osindikizira amagwiritsidwa ntchito kupindika ndi kupanga zitsulo zachitsulo. Mabuleki a atolankhani olamulidwa ndi CNC amapereka kuwongolera kolondola panjira yopindika, zomwe zimapangitsa zotsatira zolondola komanso zobwerezabwereza.

Wamba CNC Machine Mavuto

Ngakhale makina a CNC ndi abwino kwambiri komanso odalirika, amatha kukumana ndi zinthu zina zomwe zingakhudze ntchito yawo ndi zokolola. Kumvetsetsa ndi kuthana ndi zovuta zomwe wambazi ndizofunikira kuti zitsimikizire kuti zikuyenda bwino. Nazi zina mwazovuta zamakina a CNC:

Zolakwika Zokonza Mapulogalamu

- Malangizo olakwika kapena osakwanira a pulogalamu amatha kuyambitsa zolakwika pamakina.

- Njira zosayenera za zida kapena kusankha kolakwika kwa zida kumatha kupangitsa kuti pakhale kusamalitsa bwino, kusawoneka bwino, kapena kusweka kwa zida.

Nkhani Zamakina

Zida zotha kapena zowonongeka monga ma bearing, malamba, kapena zomangira za mpira zimatha kuyambitsa kusewera mopitilira muyeso, zomwe zimapangitsa mabala olakwika ndikuchepetsa kulondola.

- Mafuta osakwanira kapena kusamalidwa bwino kungayambitse kugundana kwakukulu, kutentha kwambiri, komanso kutha msanga kwa zida zamakina.

Mavuto Amagetsi ndi Amagetsi

Kusinthasintha kwamagetsi kapena kusokoneza magetsi kungayambitse makina osasinthika, monga kuyimitsa mwadzidzidzi, kukonzanso, kapena kuyimitsa molakwika.

- Zomverera zolakwika kapena kusintha malire kungayambitse kusuntha kolakwika kwa makina kapena kuwerengera zolakwika zabodza.

Mavuto a Zida

- Zida zodulira zosawoneka bwino kapena zosayikika bwino zimatha kupangitsa kuti pakhale kusamalitsa bwino, macheza, kapena kuvala zida zambiri.

- Kusintha kwa zida zolakwika kapena kuyeza kutalika kwa zida kumatha kupangitsa kuti pakhale zolakwika.

Kuzizira ndi Kuchotsa Chip Nkhani

- Kusakwanira kozizira kozizira kapena kutulutsa kolakwika kwa chip kungayambitse kutentha, kutentha kwa zida, ndi kuchepa kwa moyo wa zida.

- Kusakwanira kwa chip kuchotsa kungayambitse kutsekeka kwa chip, komwe kumakhudza kutha kwa pamwamba ndipo kumatha kuwononga chogwirira ntchito kapena makina.

Zolakwika za Mapulogalamu ndi Zowongolera

- Kuwonongeka kwa mapulogalamu kapena zovuta zofananira zimatha kusokoneza makina ogwiritsira ntchito ndikubweretsa zolakwika zosayembekezereka kapena kuwonongeka.

- Kuwongolera kolakwika kapena zosintha zolakwika za parameter mkati mwa dongosolo lowongolera zitha kubweretsa zolakwika pakuyika kapena mitengo yolakwika ya chakudya.

Zinthu Zachilengedwe

- Kusiyanasiyana kwa kutentha, chinyezi, kapena fumbi zingakhudze magwiridwe antchito ndi kulondola kwa makina a CNC.

- Kuyika molakwika kapena kuyika makina molingana ndi zinthu zachilengedwe kungakhudze kukhazikika kwake ndi kudalirika kwake.

Kuteteza Kukonzekera kwa CNC Machines

Kukhazikitsa pulogalamu yodzitchinjiriza yodzitchinjiriza ndikofunikira kuti makina a CNC (Computer Numerical Control) azigwira bwino ntchito, odalirika, komanso moyo wautali. Kusamalira pafupipafupi kumathandizira kuzindikira zovuta zomwe zingachitike zisanakhale zovuta zazikulu, kumachepetsa nthawi yopumira, ndikuwonetsetsa kuti makina akugwira ntchito bwino. Nawa madera ena ofunika kuganizira pamene kuchita zodzitetezera kukonza makina CNC:

Kukonzekera

- Nthawi zonse thirirani mafuta pazinthu zamakina monga ma bearing, zomangira za mpira, ma slideways, ndi magiya malinga ndi malangizo opanga.

- Gwiritsani ntchito mafuta oyenerera ndikuwonetsetsa kuti pamakhala nthawi yokwanira yothira mafuta kuti muchepetse kugundana, kuchepetsa kutha, komanso kugwira ntchito bwino.

kukonza

- Sungani makina ndi malo ozungulira kukhala oyera kuchokera ku tchipisi, zotsalira zoziziritsa kukhosi, ndi zinyalala.

- Nthawi zonse yeretsani zosefera, matanki ozizirira, ndi ma thireyi a chip kuti muzizizira bwino komanso kuti musatseke.

Kuyang'ana ndi Kuwongolera

Yang'anani mwachizolowezi zinthu zofunika kwambiri monga zopota, zonyamula zida, ndi zokonzera kuti muzindikire zizindikiro za kuwonongeka kapena kuwonongeka.

- Yang'anirani ndikuwonetsetsa kulondola kwa nkhwangwa zamakina, zida zochotsera zida, ndi makina oyimilira kuti muwonetsetse kuti makinawo akulondola.

Zamagetsi ndi Zamagetsi

- Yang'anani maulumikizi amagetsi, zingwe, ndi mawaya kuti muwone ngati zawonongeka kapena zotayikira.

- Yang'anani ndi kuyesa masensa, kusintha malire, ndi zotchingira chitetezo kuti muwonetsetse kugwira ntchito moyenera.

Machitidwe Ozizira

- Sungani ndi kuyeretsa makina ozizirira pafupipafupi kuti apewe kuipitsidwa ndikuwonetsetsa kuti kuzizirira koyenera.

- Yang'anirani kuchuluka kwa zoziziritsa kukhosi, pH kukhazikika, ndi kukhazikika, ndikuwonjezeranso kapena m'malo ozizira ngati pakufunika.

Mapulogalamu ndi Control System

- Nthawi zonse sinthani ndikusunga pulogalamu yamakina a CNC ndi makina owongolera ndi mitundu yatsopano ndi zigamba.

- Tsimikizirani ndikuwongolera magawo owongolera, monga mitengo yazakudya ndi mathamangitsidwe, kuti muwonetsetse kukonza bwino.

Zida ndi Spindle

- Yang'anani ndikuyeretsa zosungira zida, makoleti, ndi ma spindle taper pafupipafupi kuti muwonetsetse kuti zida zikugwira bwino ndikuchepetsa kuthamanga.

- Yang'anani ndikusintha zida zodulira zakale kapena zowonongeka kuti mukhalebe ndi ntchito yabwino yodulira komanso kumaliza pamwamba.

Maphunziro a Opaleshoni ndi Zolemba

- Perekani maphunziro athunthu kwa ogwira ntchito pamakina ogwiritsira ntchito moyenera, njira zosamalira, ndi njira zotetezera.

- Sungani zolemba mwatsatanetsatane za ntchito yokonza, zoyendera, ndi kukonzanso kuti mufufuze ndi kusanthula.

Kuyang'ana Mwachizolowezi Makina a CNC

Kuyang'anira ndi kukonza makina a CNC (Computer Numerical Control) nthawi zonse ndikofunikira kuti awonetsetse kuti akugwira ntchito bwino komanso amakhala ndi moyo wautali. Pochita kuyendera mwachizolowezi, zinthu zomwe zingachitike zitha kudziwidwa msanga ndipo njira zodzitetezera zitha kuchitidwa kuti zisawonongeke komanso kuchedwa kupanga. Nazi mfundo zofunika kuziganizira panthawi yoyendera makina a CNC:

Kuyendera Kowoneka

- Yambani poyang'ana makinawo kuti muwone ngati akuwonongeka, kuwonongeka, kapena kutayikira.

- Yang'anani ngati pali kutuluka, monga mafuta kapena ozizira, zomwe zingasonyeze vuto ndi makina amadzimadzi a makina.

- Yang'anani phokoso lililonse lachilendo kapena kugwedezeka pakugwira ntchito kwa makina.

Kukonzekera

- Onetsetsani kuti malo onse opaka mafuta ndi odzola mokwanira kuti atsimikizire kuyenda bwino kwa zida zamakina.

- Yang'anani milingo yamafuta ndikuwonjezera ngati kuli kofunikira.

- Onetsetsani kuti zomangira za mpira zimapaka bwino, njanji zowongolera, ndi zinthu zina zofunika kwambiri.

Axis Calibration

Tsimikizirani kulondola kwa nkhwangwa zamakina poyesa ma calibration.

- Yang'anani zopatuka zilizonse kuchokera pazololera zomwe zatchulidwa ndikusintha ngati pakufunika.

- Yang'anirani makina oyesa, ngati kuli kotheka, kuti muwonetsetse kuti muyeso wolondola.

Kuyendera kwa Spindle

- Yang'anani chopondera ngati chili ndi zizindikiro zilizonse zakutha, kuwonongeka, kapena kusanja bwino.

- Yang'anani mayendedwe a spindle ndikusintha ngati kuli kofunikira.

- Tsimikizirani kutulutsa kwa spindle kuti muwonetsetse kukhazikika panthawi ya makina.

Zida ndi Kusintha kwa Zida

- Yang'anani zida zogwiritsira ntchito, kuphatikiza zosungira, makoleti, ndi zida zodulira, kuti muwone ngati zikuwonongeka kapena kuwonongeka.

- Yang'anani njira yosinthira zida kuti igwire bwino ntchito komanso kugwirizanitsa bwino.

- Yeretsani ndi kuthira mafuta zida zosinthira malinga ndi malangizo a wopanga.

Njira Yogwiritsira Ntchito

- Yang'anani gawo lowongolera la CNC ndikuwunika mauthenga aliwonse olakwika kapena zolakwika.

- Onetsetsani kuti zingwe zonse ndi zolumikizira zili zotetezeka komanso zili bwino.

- Sinthani mapulogalamu a makina, ngati kuli kotheka, ku mtundu waposachedwa kwambiri woperekedwa ndi wopanga.

Zinthu Zachitetezo

- Tsimikizirani magwiridwe antchito achitetezo, monga mabatani oyimitsa mwadzidzidzi ndi zotsekera.

- Yang'anani momwe zivundikiro zotetezera ndi zotchingira zilili kuti muwonetsetse chitetezo cha opareshoni.

- Yesani ma alarm a makina kuti mutsimikizire kugwira ntchito moyenera.

Zolemba:

Sungani mbiri yatsatanetsatane yamasiku oyendera, zomwe mwapeza, ndi kukonza kapena kukonza kulikonse komwe mwachitika.

- Tsatirani ndondomeko yokonza ndi malangizo a wopanga.

- Sungani chipika cha zida zilizonse zogwiritsidwa ntchito ndi manambala ake ofanana.

Kukonza Makina a CNC

Makina a CNC (Computer Numerical Control) akakumana ndi zovuta kapena zovuta, kukonza mwachangu ndikofunikira kuti muchepetse nthawi yopumira ndikusunga zokolola. Kukonza makina a CNC kumafuna ukatswiri ndi chidwi chatsatanetsatane kuonetsetsa kuti makinawo abwezeretsedwanso momwe amagwirira ntchito. Nazi mfundo zofunika kuziganizira pokonza makina a CNC:

Diagnostics

- Yambani pofufuza bwinobwino vutolo kuti muzindikire chimene chinayambitsa vutolo.

- Yang'anani zigawo za makinawo, monga ma motors, ma drive, masensa, ndi makina owongolera, kuti muone mbali yolakwika.

- Gwiritsani ntchito zida zowunikira komanso mapulogalamu othandizira kuzindikira vutolo molondola.

Kusintha kwa Zida Zolakwika

- Vuto likadziwika, sinthani zida zolakwika ndi zatsopano kapena zogwira ntchito bwino.

- Pezani magawo enieni kuchokera kwa ogulitsa odalirika kuti muwonetsetse kuti zikugwirizana komanso zodalirika.

- Tsatirani malangizo a wopanga kuti mulowe m'malo mwazinthu zinazake ndikuziyesa ngati zikufunika.

Kukonza Magetsi ndi Makina

- Kukonza magetsi, kuphatikizapo kukonza mawaya olakwika, zolumikizira, kapena matabwa owonongeka.

- Konzani kapena kusintha zida zowonongeka, monga malamba, magiya, ma pulleys, ndi ma bearings.

- Onetsetsani kuti makina amayendera bwino kuti akhale olondola komanso olondola.

Kusintha kwa Mapulogalamu ndi Kukonzekera

- Sinthani pulogalamu yamakina kukhala yaposachedwa kwambiri yoperekedwa ndi wopanga.

- Konzani magawo ndi makonda a CNC control system molingana ndi makina amakina.

- Yesani ndi kutsimikizira momwe makinawo akugwirira ntchito pambuyo pa zosintha zamapulogalamu kapena kusintha masinthidwe.

Calibration ndi Kuyanjanitsa

Sinthani nkhwangwa zamakina ndikuwonetsetsa kuti zalumikizidwa bwino kuti mukwaniritse makina olondola.

- Tsimikizirani kuthamanga kwa spindle ndi mayanidwe kuti muwonetsetse kukhazikika panthawi yogwira ntchito.

- Yang'anani ndikusintha zida zamakina ndi kubweza kutalika kwa chida kuti mudulidwe ndendende.

Kuyesa ndi Kutsimikizira

Yesetsani mozama makina okonzedwa kuti muwonetsetse kuti akugwira ntchito moyenera.

- Tsimikizirani kulondola kwa makinawo komanso kubwerezabwereza poyesa macheka kapena kugwiritsa ntchito zinthu zakale zoyeserera.

- Yang'anirani momwe makinawo amagwirira ntchito pamakina osiyanasiyana kuti muwonetsetse kukhazikika komanso kudalirika.

Ntchito Yokonzanso

Limbikitsani ndikuchita ntchito zodzitetezera mwachizolowezi kuti muchepetse kuwonongeka kwamtsogolo.

- Sambani ndi kuthira mafuta zida zamakina pafupipafupi kuti mupewe kuvala komanso kukhala ndi moyo wautali.

- Sungani mbiri ya ntchito yokonza, kuphatikizapo masiku, ntchito zomwe munachita, ndi zina zomwe zasinthidwa.

Maphunziro ndi Thandizo

Perekani maphunziro kwa ogwira ntchito pamakina pakugwiritsa ntchito moyenera ndi kukonza bwino kuti apewe zovuta zomwe zimafala.

- Perekani chithandizo chaukadaulo chopitilira ndi chitsogozo chothana ndi zovuta zazing'ono zomwe zingabuke.

- Limbikitsani chikhalidwe chosamalira makina mwachangu ndikulimbikitsa ogwira ntchito kuti afotokoze zolakwika zilizonse mwachangu.

Kusintha kwa Makina a CNC

Makina a CNC (Computer Numerical Control) adapangidwa kuti azikhala olimba komanso okhalitsa, koma ndi kupita patsogolo kwaukadaulo, kuwakweza kumatha kuwongolera magwiridwe antchito ndi luso lawo. Kukweza makina a CNC kumatha kukulitsa luso lawo, kuthamanga, ndi kulondola, kupatsa mabizinesi kukhala ndi mpikisano wopikisana. Nazi mfundo zofunika kuziganizira pamene kukweza makina CNC:

Kuwunika Dziko Lino

Yambani ndikuwunika momwe makinawo alili, kuphatikiza zida zake ndi mapulogalamu ake.

- Unikani zaka za makinawo, momwe alili, komanso ngati akugwirizana ndi zosintha zaposachedwa.

- Dziwani zotsatira zomwe mukufuna pakukwezako, monga kuwongolera liwiro, kulondola, kapena magwiridwe antchito owonjezera.

Kuzindikira Zokonda Zokwezera

- Fufuzani zaukadaulo waposachedwa ndi kupita patsogolo kuti muwone kukweza koyenera kwamakina.

- Funsani ndi wopanga makinawo kapena mavenda a chipani chachitatu kuti mudziwe kukweza kwabwino kwachitsanzo cha makinawo.

- Ganizirani zosankha monga zowongolera bwino, makina ozungulira, zosinthira zida, ndi masensa.

Kusintha kwa Hardware Components

- Sinthani zida zamagetsi monga ma mota, zoyendetsa, ndi makina owongolera kuti muwongolere liwiro komanso kulondola.

- Ikani masensa atsopano ndi ma probes kuti muwongolere kulondola kwa muyeso ndikusintha ntchito zina.

- Sinthani zida zakale kapena zakale ndi zatsopano kuti makina azikhala olimba komanso kuti azikhala ndi moyo wautali.

Kukweza Mapulogalamu

- Sinthani pulogalamu yamakina kukhala yaposachedwa kwambiri kuti muwongolere magwiridwe antchito ndi magwiridwe antchito.

- Ikani ma module atsopano apulogalamu kuti muthe kugwira ntchito zina kapena kukonza zomwe zilipo kale.

- Konzani pulogalamuyo kuti igwirizane ndi zofunikira zamakina enieni.

Kuyesa ndi Kutsimikizira

- Yesani makina okwezedwa kuti muwonetsetse kuti akugwira ntchito moyenera ndikukwaniritsa zomwe mukufuna.

- Tsimikizirani kulondola kwa makinawo ndi kubwerezabwereza poyesa macheka kapena kugwiritsa ntchito zinthu zakale zoyeserera.

- Yang'anirani momwe makinawo amagwirira ntchito pamakina osiyanasiyana kuti muwonetsetse kukhazikika komanso kudalirika.

Maphunziro ndi Thandizo

- Perekani maphunziro kwa ogwira ntchito pamakina pazinthu zatsopano ndi magwiridwe antchito a makina okwezedwa.

- Perekani chithandizo chaukadaulo chopitilira ndi chitsogozo kuti muthane ndi zovuta zilizonse zomwe zingabuke.

- Limbikitsani chikhalidwe chosamalira makina mwachangu ndikulimbikitsa ogwira ntchito kuti afotokoze zolakwika zilizonse mwachangu.

CNC Machine Calibration

Calibration ndi njira yofunika kwambiri kuti makina a CNC (Computer Numerical Control) akhale olondola komanso olondola. Kuwongolera pafupipafupi kumawonetsetsa kuti nkhwangwa, zopota, ndi zida zamakina zimalumikizidwa bwino, zomwe zimapangitsa kuti makina azigwira bwino ntchito. Nazi mfundo zofunika kuziganizira mukamayesa makina a CNC:

Axis Calibration

- Sanjani mbali iliyonse yamakina kuti muwonetsetse kuyika bwino ndi kuyenda.

- Gwiritsani ntchito zida zoyezera molondola, monga ma laser interferometers kapena ma bar bar system, kuti muyeze zopatuka ndikusintha.

- Tsimikizirani kuti mayendedwe amtundu wa makinawo ndi aang'ono amagwirizana ndi kulolerana komwe kwatchulidwa.

Kuyeza kwa Spindle Runout:

- Yezerani kuthamanga kwa spindle kuti muwonetsetse kukhazikika pakugwira ntchito kwa makina.

- Gwiritsani ntchito chizindikiro choyimba kapena chida chozikidwa ndi laser kuti muyeze kupendekera kulikonse kapena kugwedezeka kwa spindle.

- Sinthani ma spindle kapena sinthani zida zakale kuti muchepetse kuthamanga ndikuwonjezera kulondola.

Kutalika kwa Chida ndi Kuwongolera kwa Chida

- Sanjani chida choyezera kutalika kwa chida kuti muwonetsetse kuti chida chili cholondola.

- Gwiritsani ntchito zida zoyeserera kapena zoyezera kutalika kuti muyeze kutalika kwa chida ndikuyerekeza ndi miyeso ya makinawo.

- Sinthani kutalika kwa zida zomwe mumagwiritsa ntchito pamakina owongolera kuti mukwaniritse zosemphana zilizonse.

Tool Diameter Malipiro

- Chitani zowerengera zolipirira zida kuti muwerengere kusiyana kwa ma diameter a zida.

- Yezerani kukula kwa chida chenichenicho pogwiritsa ntchito micrometer kapena caliper ndikuyerekeza ndi zomwe makinawo amapangira.

- Sinthani zida zochotsera zida kapena zolipirira zida kuti mubwezere kusiyana kulikonse ndikupeza mabala olondola.

Kuyesa System Calibration

- Ngati makinawo ali ndi makina oyesa, yesani kuti muwonetsetse kuti muyeso wagawo ndi wolondola.

- Chitani machitidwe oyesa kuti muwonetsetse kulondola kwa dongosolo lofufuzira ndikusintha ngati kuli kofunikira.

- Tsimikizirani kuti makina ofufuzira amazindikira malo ndi kukula kwake.

Spindle Speed Calibration

- Sinthani liwiro la spindle kuti muwonetsetse kuti likugwirizana ndi RPM yotchulidwa (Kuzungulira Pa Minute).

- Gwiritsani ntchito tachometer kapena spindle speed sensor kuti muyese kuthamanga kwenikweni kwa spindle panthawi yogwira ntchito.

- Sinthani magawo owongolera liwiro pamakina owongolera makina kuti mukwaniritse RPM yomwe mukufuna.

Zolemba ndi Zolemba

- Sungani mbiri yatsatanetsatane ya zochitika za kasinthidwe, kuphatikiza masiku, ntchito zomwe zidachitika, ndi zosintha zilizonse zomwe zachitika.

- Tsatirani ndondomeko ndi malangizo a wopanga.

- Sungani chipika chazinthu zilizonse zoyeserera zomwe zimagwiritsidwa ntchito ndi ziphaso zofananira.

Kusintha kwa Makina a CNC

Kuyanjanitsa koyenera ndikofunikira kuti makina a CNC (Computer Numerical Control) azigwira ntchito molondola komanso mwandondomeko. Kusalongosoledwa bwino kwa zigawo za makina, monga mphira, makina opangira zida, ndi nkhwangwa, zimatha kubweretsa zolakwika ndi kusagwirizana pamakina. Nazi mfundo zofunika kuziganizira pogwirizanitsa makina a CNC:

Kuyang'ana Mkhalidwe Wamakina

Musanayambe kugwirizanitsa makinawo, fufuzani mkhalidwe wake, kuphatikizapo momwe zigawo zake zilili.

- Yang'anani njira zamakina, otsogolera, ndi zida zina zamakina kuti ziwonongeke komanso kuwonongeka.

- Tsimikizirani momwe ma spindle ndi zida zogwirira ntchito zilili.

Kulumikizana kwa Spindle

- Spindle ndi gawo lofunikira lomwe liyenera kulumikizidwa molondola.

- Gwiritsani ntchito zida zoyezera mwatsatanetsatane, monga cholozera kapena chida chozikidwa ndi laser, kuti muyeze momwe spindle ikuyendera.

- Sinthani malo a spindle ndi zigawo zake, monga ma fani, kuti mugwirizane bwino.

Kuyang'ana Axes

- Yang'anani momwe makinawo amayendera kuti muwonetsetse kusuntha ndi kuyika bwino.

- Gwiritsani ntchito zida zoyezera molondola kuti muyeze kupotoka mumzere uliwonse ndikusintha.

- Onetsetsani kuti nkhwangwa zikuyenda molunjika ndikugwirizana ndi kulolerana komwe kwatchulidwa.

Kugwirizana kwa Zida Zopangira

- Njira zopangira zida, kuphatikiza zosungira zida ndi zosintha zida, ziyenera kulumikizidwa bwino kuti zitsimikizire kuti zida zili zolondola.

- Gwiritsani ntchito zida zoyezera molondola kuti muyese momwe zidazo zikugwirizanirana ndikusintha ngati kuli kofunikira.

- Onetsetsani kuti makina opangira zida akugwirizana ndi nkhwangwa ndi spindle za makina.

Kuyesa ndi Kutsimikizira

- Mukagwirizanitsa makinawo, yesetsani kuyesa kuti muwonetsetse kuti ndi yolondola komanso yolondola.

- Gwiritsani ntchito zinthu zakale zoyeserera kapena zida zina zoyezera kuti mutsimikizire kulondola kwa makinawo.

- Yang'anirani momwe makinawo amagwirira ntchito pamakina osiyanasiyana kuti muwonetsetse kukhazikika kwake komanso kudalirika kwake.

Kusamalira ndi Kusamalira

- Yang'anani nthawi zonse ndikusunga zida zamakina kuti mupewe kusokoneza komanso kuvala.

- Phunzitsani ogwira ntchito pamakina kuti afotokoze zovuta zilizonse nthawi yomweyo ndikugwira ntchito zokonza nthawi zonse.

- Tsatirani ndondomeko yokonza ndi malangizo a wopanga.

Kuyanjanitsa koyenera kwa makina a CNC ndikofunikira kuti tikwaniritse magwiridwe antchito olondola komanso olondola. Potsatira njira zoyendetsera bwino komanso kukonza nthawi zonse, ogwira ntchito amatha kuonetsetsa kuti makina awo nthawi zonse amatulutsa zida zapamwamba zokhala ndi zolakwika zochepa komanso kukonzanso.

Kupaka mafuta a CNC Machines

Kupaka mafuta moyenera ndikofunikira kuti makina a CNC (Computer Numerical Control) azigwira bwino ntchito. Mafuta amachepetsa kugundana, amachepetsa kutha, amachotsa kutentha, komanso amateteza zida zamakina kuti zisawonongeke. Kusamalira mafuta nthawi zonse kumathandizira kutalikitsa moyo wa makina ndikuwonetsetsa kuti ntchitoyo ikuyenda bwino. Nazi mfundo zofunika kuziganizira pamene mafuta CNC makina:

Kusankhidwa kwa Mafuta

- Sankhani mafuta omwe amavomerezedwa ndi wopanga makina pazigawo zina ndi machitidwe.

- Ganizirani zinthu monga kutentha, liwiro, katundu, ndi chilengedwe posankha mafuta.

- Gwiritsani ntchito mafuta oyenerera pazigawo zosiyanasiyana zamakina, monga zitsulo zopindika, njanji zowongolera, ndi zomangira za mpira.

Lubrication Ndandanda

- Tsatirani ndondomeko ya mafuta opangira mafuta pagawo lililonse la makina.

- Khazikitsani njira yothira mafuta pafupipafupi potengera momwe makina amagwiritsidwira ntchito komanso momwe amagwirira ntchito.

- Ganizirani zinthu monga maola ogwirira ntchito, kuchuluka kwa ntchito, komanso momwe chilengedwe chikuyendera.

Mafuta Opaka

- Dziwani ndikuyika chizindikiro pamakina onse opaka mafuta, kuphatikiza madoko amafuta, zopaka mafuta, ndi malo osungira.

- Onetsetsani kuti malo onse opaka mafuta akupezeka mosavuta komanso owoneka bwino kuti azipaka mafuta.

Njira Zothirira

- Gwiritsani ntchito njira zoyenera zoyatsira pagawo lililonse, monga malo osambira amafuta, makina opangira mafuta, kapena kuthira mafuta pamanja.

- Tsatirani njira zoyenera zoyatsira mafuta, monga kuyika mafuta oyenera ndikuwonetsetsa kuti agawidwe.

- Gwiritsani ntchito makina opangira mafuta, ngati alipo, kuti azipaka mafuta mosasinthasintha komanso moyenera.

Kugwiritsa Ntchito Lubricant

- Chotsani malo opaka mafuta musanagwiritse ntchito mafuta kuti muchotse litsiro, zinyalala, ndi zotsalira zakale zamafuta.

- Gwiritsani ntchito zopaka mafuta zovomerezeka, monga maburashi, mfuti zamafuta, kapena zitini zamafuta, kuti muzipaka mafuta molondola.

- Onetsetsani kuti mafutawo afika pamalo onse ofunikira, monga ma bearing, magiya, ndi malo otsetsereka.

Lubricant Kuchuluka

- Ikani mafuta oyenera monga momwe wopanga makinawo akunenera.

- Pewani mafuta ochulukirapo, chifukwa mafuta ochulukirapo angayambitse kuipitsidwa ndi kutsekereza zinthu zofunika kwambiri.

- Yang'anirani kuchuluka kwa mafuta nthawi zonse ndikuwonjezeranso ngati pakufunika kuti mafutawo azikhala ofunikira.

Lubricant Quality

- Gwiritsani ntchito mafuta opangira mafuta apamwamba kwambiri omwe amakwaniritsa miyezo yamakampani ndi zomwe amafunikira.

- Yang'anirani momwe mafuta opangira mafuta, monga mamachulukidwe akayendedwe, ukhondo, ndi kuchuluka kwa okosijeni, ndikusintha ngati kuli kofunikira.

- Sungani mafuta odzola moyenera kuti akhale abwino komanso ogwira mtima.

Kujambula Kusunga

- Sungani mbiri yatsatanetsatane ya ntchito zothira mafuta, kuphatikiza masiku, mafuta ogwiritsidwa ntchito, ndi malo opaka mafuta omwe adayankhulidwa.

- Onetsetsani momwe mafuta amagwiritsidwira ntchito, kuphatikizapo kuchuluka kwa mafuta omwe amagwiritsidwa ntchito ndi kusungidwa.

- Gwiritsani ntchito zolembedwazo ngati cholozera pakukonza zodzoladzola zam'tsogolo ndikuthetsa mavuto.

Kusintha Magawo a Makina a CNC

M’kupita kwa nthawi, makina a CNC (Computer Numerical Control) angafunike kusinthidwa mbali zina chifukwa cha kutha, kuwonongeka, kapena kufunikira kokonzanso. Kusintha mwachangu komanso molondola kwa zida zamakina a CNC ndikofunikira kuti makinawo azigwira ntchito komanso kuchepetsa nthawi yopumira. Nazi mfundo zofunika kuziganizira posintha magawo a makina a CNC:

Dziwani Vuto

- Dziwani bwino makinawo kuti muzindikire gawo lolakwika kapena lowonongeka.

- Unikani zizindikiro, mauthenga olakwika, kapena machitidwe olakwika a makina kuti muwone vuto.

- Gwiritsani ntchito zida zowunikira ndikuwona zolemba zamakina kapena malangizo a wopanga kuti athetse mavuto.

Source Genuine Part

- Gulani zida zolowa m'malo kuchokera kwa ogulitsa odalirika kapena mwachindunji kwa opanga makinawo.

- Onetsetsani kuti zigawozo ndi zenizeni ndipo zikugwirizana ndi zomwe zidalizo poyamba.

- Ganizirani zinthu monga mtundu, kugwirizana, ndi chitsimikizo posankha zina.

Disassembly ndi Unsembe

- Tsatirani njira ndi malangizo oyenera ochotsa makinawo ndikuchotsa gawo lolakwika.

- Tengani njira zodzitetezera kuti muteteze zida zodziwikiratu ndikuwonetsetsa chitetezo chaumwini panthawi ya disassembly.

- Mosamala ikani cholowa m'malo, kutsatira malangizo opanga ndi analimbikitsa makokedwe specifications.

Calibration ndi Kuyesa

- Mukasintha gawolo, sinthani makinawo kuti muwonetsetse kuti akugwira ntchito moyenera komanso moyenera.

- Chitani zosintha zofunikira kapena masinthidwe kuti muwonetsetse kulondola komanso kulondola.

- Yesetsani mokwanira kuti muwonetsetse kuti gawo lolowa m'malo lathana ndi vutolo ndipo makinawo akugwira ntchito moyenera.

Zolemba ndi Kusunga Zolemba

- Sungani zolemba mwatsatanetsatane za magawo omwe asinthidwa, kuphatikizapo tsiku, nambala ya gawo, ndi zambiri za ogulitsa.

- Sungani mbiri yakale yokonza makinawo, kuphatikiza zonse zosinthidwa, kukonzanso, ndi kukweza.

- Gwiritsani ntchito zolembedwazo ngati cholozera pakukonza mtsogolo ndi kuthetsa mavuto.

Ntchito Yokonzanso

- Yang'anani ndikuwongolera makina nthawi zonse kuti muzindikire zovuta zomwe zingachitike zisanachitike.

- Tsatirani ndondomeko yotetezedwa yotetezedwa ndi wopanga makina ndi zigawo zake.

- Sinthani magawo mosamalitsa potengera kagwiritsidwe ntchito, nthawi yomwe amayembekezeka, kapena zovuta zomwe zimadziwika.

Maphunziro ndi Thandizo

- Perekani maphunziro kwa oyendetsa makina ndi ogwira ntchito yokonza njira zoyenera zosinthira.

- Perekani chithandizo chaukadaulo chopitilira ndi chitsogozo kuti muthane ndi zovuta zilizonse zomwe zingabuke panthawi yosintha kapena pambuyo pake.

- Limbikitsani chizoloŵezi chokonzekera mosamala ndikulimbikitsa ogwira ntchito kuti afotokoze zolakwika zilizonse nthawi yomweyo.

Potsatira mfundo zazikuluzikuluzi ndikugwira ntchito ndi ogulitsa odalirika komanso akatswiri odziwa bwino ntchito, kusintha magawo a makina a CNC kungathe kuchitidwa bwino. Kusintha magawo munthawi yake komanso molondola kumathandiza kuwonetsetsa kuti makinawo akugwira ntchito bwino, amatalikitsa moyo wake, komanso kuchepetsa kusokonezeka kwa madongosolo opanga.

Kutumikira kwa CNC Machine Spindles

Makina opangira makina a CNC (Computer Numerical Control) amagwira ntchito yofunikira pakulondola komanso magwiridwe antchito a makina. Kuonetsetsa magwiridwe antchito ndi moyo wautali, kutumikiridwa pafupipafupi kwa ma spindles a makina a CNC ndikofunikira. Nazi mfundo zofunika kuziganizira pankhani ya kutumikira CNC makina spindles:

Ntchito Yokonzanso

- Kukonzekera kokonzekera n'kofunika kwambiri kuti tipewe kutsika kosayembekezereka komanso kukonza zodula.

- Pangani ndondomeko yokonza yomwe imaphatikizapo kuyang'anitsitsa nthawi zonse ndi ntchito zothandizira.

- Tsatirani malingaliro a wopanga pa nthawi yokonza ndi njira.

Kuyeretsa ndi Kupaka mafuta

- Tsukani ulusi nthawi zonse kuti muchotse zinyalala, fumbi, ndi zotsalira zoziziritsa kukhosi zomwe zingasokoneze kugwira ntchito.

- Gwiritsani ntchito zoyeretsera zoyenera ndi njira zomwe wopanga amapangira.

- Onjezani zida za spindle molingana ndi malangizo omwe aperekedwa kuti muwonetsetse kuti zikuyenda bwino komanso kupewa kuvala.

Kuyang'ana kwa Belt ndi Bearing

- Yang'anani momwe malamba alili ngati zizindikiro zatha, ming'alu, kapena kuwonongeka. M'malo mwake ngati kuli kofunikira.

- Yang'anirani ma bearing a phokoso lambiri, kugwedezeka, kapena kuchuluka kwa kutentha, zomwe zingasonyeze kufunika kosintha kapena kusintha.

- Moyenera agwirizane ndi kumangika malamba kukhalabe mulingo woyenera kwambiri kufala mphamvu.

Kusamalira System Yozizira

- Nthawi zonse yeretsani ndikusunga zoziziritsa kukhosi kuti mupewe kuipitsidwa ndi kutsekeka.

- Onani milingo yozizirira, zosefera, ndi mapampu kuti mugwire bwino ntchito.

- Yang'anirani mtundu wa zoziziritsa kukhosi ndikusintha ngati kuli kofunikira kuti mukhale ndi nthawi yabwino yodulira ndikupewa kuwonongeka kwa spindle.

Spindle Runout ndi Balance

- Yezerani kuthamanga kwa spindle pogwiritsa ntchito zida zolondola kuti muwonetsetse kukhazikika komanso kulondola.

- Yendetsani nsongayo ngati kugwedezeka kwakukulu kapena kudula kosafanana kukuwoneka.

- Yang'anirani zovuta zilizonse mwachangu kuti mupewe kuwonongeka kwa spindle kapena workpiece.

Kuwunika kwa Magetsi

- Yang'anani zolumikizira magetsi, mawaya, ndi masensa kuti muwone ngati zawonongeka kapena sizikuyenda bwino.

- Yesani injini ya spindle ndikuyendetsa kuti muwonetsetse kuti ikugwira ntchito bwino.

- Sinthani makina owongolera liwiro kuti mukhale ndi RPM yolondola.

Thandizo la Katswiri

- Phatikizani akatswiri oyenerera kapena oyimilira opanga kuti athandize kapena kukonza zovuta.

- Nthawi zonse phunzitsani ogwira ntchito ndi ogwira ntchito yokonza njira zoyendetsera bwino ndi kukonza.

- Funsani upangiri wa akatswiri kuti athetse mavuto opitilira kukonza nthawi zonse.

CNC Machine Electrical System Inspection

Dongosolo lamagetsi la makina a CNC ndi gawo lofunikira lomwe limakhudza mwachindunji magwiridwe ake ndi kudalirika kwake. Kuwunika pafupipafupi kwamagetsi ndikofunikira kuti zitsimikizire kuti zikugwira ntchito bwino komanso magwiridwe antchito abwino. Nazi mfundo zofunika kuziganizira poyang'anira makina a CNC:

Kuyendera Kowoneka

- Yambani poyang'ana mbali zonse zamagetsi kuti muwone ngati zawonongeka, monga mawaya otayika, zingwe zophwanyika, kapena zolumikizira zowotchedwa.

- Yang'anani zolumikizira zilizonse zotayirira kapena zotengera zomwe zingakhudze madulidwe amagetsi.

- Yang'anani umboni wa kutentha kwambiri, monga kusinthika kapena kusungunuka kwa zigawo zikuluzikulu.

mphamvu Wonjezerani

- Onetsetsani kuti makina akulandira voteji yoyenera komanso kuti magetsi ndi okhazikika komanso okhazikika bwino.

- Yang'anani zingwe zazikulu zamagetsi ndi zolumikizira kuti muwone ngati zatha kapena kuwonongeka.

- Yesani magwiridwe antchito a ophwanya ma circuit ndi ma fuse kuti muwonetsetse kuti akupereka chitetezo chokwanira.

Zokambirana Zadongosolo

- Tsegulani kabati yowongolera ndikuyang'ana zigawo zamkati, monga ma board ozungulira, ma relay, ndi ma contactor.

- Yang'anani zizindikiro za kutentha kwambiri, monga zipsera zopsereza kapena fungo lamphamvu la kutentha kwa moto.

- Onetsetsani kuti zingwe zonse ndi zolumikizira zili zomangika bwino komanso zolembedwa bwino.

Motor ndi Drive Systems

- Yang'anani ma motors ndi ma drive kuti muwone ngati zawonongeka, monga mawaya otayika kapena maburashi otha.

- Yesani kugwira ntchito kwa ma drive amagalimoto ndikuwonetsetsa kuti akupereka zowongolera zoyenda bwino komanso zolondola.

- Yezerani mphamvu yamagetsi kuti muwonetsetse kuti ili mkati mwazomwe mwasankha kuti igwire bwino ntchito.

Emergency Stop System

- Yesani mabatani oyimitsa mwadzidzidzi kuti muwonetsetse kuti akugwira ntchito moyenera ndipo mutha kuyimitsa makinawo nthawi yomweyo pakagwa ngozi.

- Yang'anani mawaya ndi maulumikizidwe a pulogalamu yoyimitsa mwadzidzidzi pazovuta zilizonse kapena kulumikizana kotayirira.

Communication Interfaces

- Yang'anani njira zoyankhulirana, monga Ethernet kapena ma serial ports, kuti muwonetsetse kuti zikuyenda bwino.

- Yesani maulalo olumikizirana ndi zida zakunja, monga makompyuta kapena ma programmable logic controllers (PLCs), kuti muwonetsetse kusamutsa deta moyenera.

Grounding System

- Tsimikizirani kuti makina oyambira amayikidwa bwino ndikulumikizidwa.

- Yang'anani kukhulupirika kwa mawaya oyika pansi ndi maulumikizidwe kuti muteteze kuopsa kwa magetsi ndikuwonetsetsa kuchepetsa phokoso lamagetsi.

Kusamalira Nthawi Zonse

- Khazikitsani ndondomeko yanthawi zonse yokonza magetsi, kuphatikizapo kuyeretsa, kukhwimitsa zolumikizira, ndi kuyang'anira zingwe.

- Tsatirani malangizo a wopanga pamayendedwe oyenera kukonza ndi nthawi zina.

- Phunzitsani ogwira ntchito ndi ogwira ntchito yokonza pachitetezo chamagetsi komanso kusamalira bwino makina a CNC.

Kukonzekera Kozizira kwa Makina a CNC

Makina ozizira a makina a CNC (Computer Numerical Control) amagwira ntchito yofunika kwambiri pakusunga kutentha kwabwino, kutalikitsa moyo wa zida, ndikuwonetsetsa kuti makinawa akulondola. Kukonzekera koyenera kwa makina ozizirira ndikofunikira kuti tipewe kutentha kwambiri, kukhalabe ndi mpweya wabwino, komanso kupewa kuwonongeka kwa makina. Nazi mfundo zofunika kuziganizira pankhani yozizira dongosolo kukonza makina CNC:

Kuyeretsa zonse

- Tsukani thanki yozizirira, zosefera, ndi ngalande zozizirira pafupipafupi kuti muchotse zinyalala, tchipisi, ndi zinyalala.

- Gwiritsani ntchito zoyeretsera zoyenera ndi njira zomwe wopanga makinawo amapangira.

- Yambani makina nthawi ndi nthawi kuonetsetsa kuti madzi ozizira sakutsekereza.

Kukhazikika Kozizira

- Yang'anirani ndikusunga kuchuluka kwa zoziziritsa kukhosi mudongosolo molingana ndi zomwe wopanga akufuna.

- Yesani zoziziritsa kukhosi nthawi zonse pogwiritsa ntchito ma refractometer kapena zida zoyesera kuti muwonetsetse kuti zikukwaniritsa milingo yoyenera.

- Sinthani ndendeyo powonjezera madzi ozizira kapena madzi ngati kuli kofunikira.

Njira Zosintha

- Yang'anani ndikuyeretsa zosefera zoziziritsa nthawi zonse kuti muchotse zowononga ndikupewa kutsekeka.

- Bwezerani zosefera molingana ndi nthawi zovomerezeka kapena zitakhala zakuda kwambiri kapena zowonongeka.

- Lingalirani kugwiritsa ntchito zosefera zapamwamba kwambiri kapena zolekanitsa maginito kuti muwongolere bwino kusefera.

Coolant Quality

- Yang'anirani mulingo wa pH ya choziziritsira, kukhuthala kwake, ndi kapangidwe kakemiko kuonetsetsa kuti chikukhalabe m'njira yovomerezeka.

- Yesani kukula kwa bakiteriya kapena kuipitsidwa komwe kungayambitse fungo loipa kapena kuwonongeka kwa ntchito yoziziritsa.

- Bwezerani zoziziritsa kukhosi ngati zikuwonetsa kunyozeka kapena zikulephera kukwaniritsa miyezo yofunikira.

Pampu ndi Mtengo Woyenda

- Yang'anani pampu yozizirira kuti igwire bwino ntchito, kuyang'ana ngati ikutha, phokoso lachilendo, kapena kuchepa kwa madzi.

- Chotsani kapena sinthani chopondera chopopera ngati chatha kapena kuwonongeka.

- Tsimikizirani kuti kuzirala kwa madzi ozizira kuli mkati mwa mulingo wovomerezeka kuti mutsimikizire kuziziritsa kogwira mtima.

Kuwongolera Kutentha Kozizira

- Yang'anani makina owongolera kutentha, monga chozizira kapena chotenthetsera kutentha, kuti musunge kutentha kwaziziritsira mkati mwanthawi yomwe mwatchulidwa.

- Yang'anani masensa, mavavu, ndi njira zowongolera kuti muwonetsetse kuwongolera kolondola kwa kutentha.

- Tsukani kapena sinthani zipsepse zotenthetsera ngati zatsekedwa ndi dothi kapena zinyalala.

Maphunziro Oyendetsa

- Perekani maphunziro kwa ogwira ntchito pamakina pakugwiritsa ntchito bwino zoziziritsa kukhosi, kuphatikiza kudzazanso, kusintha ndende, ndi kupereka lipoti zokhudzana ndi kuzizira.

- Funsani ogwira ntchito kuti azindikire zizindikiro za kuwonongeka kwa zida zoziziritsa kuziziritsa kapena kuwonongeka kwa dongosolo ndi momwe angayankhire moyenera.

- Limbikitsani chikhalidwe chaukhondo ndi kukonza makina oziziritsira mwachangu pakati pa ogwira ntchito.

Kutumikira CNC Machine Controls ndi mapulogalamu

Kuthandizira pafupipafupi makina a CNC ndi mapulogalamu ndikofunikira kuti zitsimikizire kuti zikuyenda bwino ndikupewa zovuta zomwe zingachitike. Nazi mfundo zofunika kuziganizira pankhani kutumikira CNC amazilamulira makina ndi mapulogalamu:

Zosintha Zamakono

- Nthawi zonse sinthani pulogalamu yamakina a CNC kuti mupindule ndi zinthu zaposachedwa, kukonza zolakwika, komanso kukonza magwiridwe antchito.

- Tsatirani malangizo a wopanga ndi malingaliro ake pakukonzanso pulogalamuyo.

- Pangani zosunga zobwezeretsera za pulogalamu yamakono yamakina musanawonjezere zosintha.

Calibration ndi Kuyanjanitsa

- Nthawi ndi nthawi sinthani ndikuwongolera makina a CNC kuti mukhale olondola komanso olondola.

- Yang'anani ndikusintha makulidwe a ma ax, zida zochotsera zida, ndi magawo a zero.

- Tsimikizirani kulondola kwa kachitidwe ka kafukufuku, ngati kuli kotheka, ndikukonzanso ngati kuli kofunikira.

Kusunga ndi Kubwezeretsa

- Nthawi zonse sungani magawo ofunikira a makina, zoikamo, ndi mapulogalamu kuti muteteze kutayika kwa data.

- Sungani ma backups angapo pazida zakunja kapena kusungirako mitambo kuti muwonjezere chitetezo.

- Yesani njira yobwezeretsa nthawi ndi nthawi kuti muwonetsetse kuti zosunga zobwezeretsera ndizodalirika komanso zopezeka.

Control Panel Inspection

- Yang'anani mowonekera gulu lowongolera kuti muwone ngati pali zisonyezo zowonongeka, monga mabatani osweka, zolumikizira zotayirira, kapena zizindikiro zosagwira ntchito.

- Tsukani zowongolera ndi mabatani pafupipafupi kuti muchotse fumbi kapena zinyalala zomwe zingakhudze ntchito.

- Yesani magwiridwe antchito a gulu lowongolera potsimikizira batani lililonse, kusinthana, ndikuwonetsa.

Kugwirizana kwa Magetsi

- Yang'anani momwe magetsi akulumikizira mkati mwa kabati yowongolera ngati pali mawaya otayirira kapena ochita dzimbiri.

- Limbitsani zolumikizira zilizonse zotayirira ndikusintha zingwe kapena zolumikizira zowonongeka.

- Yesetsani kuyang'anitsitsa dongosolo lamagetsi kuti muwonetsetse malo oyenera ndikuchepetsa chiopsezo cha kuwonongeka kwa magetsi.

Kusamalira Zida Zolowetsa

- Yang'anani magwiridwe antchito a zida zolowetsa, monga kiyibodi, mbewa, kapena zowonera.

- Yeretsani zida zolowetsa kuti muchotse zinyalala kapena zotsalira zomwe zingasokoneze kugwira ntchito kwake.

- Bwezerani zida zotha kapena zosagwira ntchito kuti muzitha kuyang'anira bwino.

Maphunziro Oyendetsa

- Apatseni ogwira ntchito maphunziro athunthu pazowongolera makina a CNC ndi mapulogalamu.

- Dziwitsani ogwira ntchito ndi ntchito zosiyanasiyana, menyu, ndi magawo a mawonekedwe owongolera.

- Phunzitsani ogwira ntchito kugwiritsa ntchito moyenera mawonekedwe apulogalamu ndi njira zothetsera mavuto.

Kufufuza Kwanthawi Zonse

- Chitani macheke a periodic system kuti muzindikire zomwe zingachitike pa mapulogalamu kapena zowongolera.

- Yang'anirani zolemba zolakwika, ma alarm, ndi mauthenga owunikira pazovuta zilizonse.

- Chitani zoyezetsa zamakina ndikutsatira malangizo a wopanga pakuthana ndi mavuto.

CNC Machine Safety Checks

Kuwonetsetsa chitetezo cha ogwira ntchito ndi malo ogwirira ntchito ndikofunikira kwambiri mukamagwira ntchito ndi makina a CNC (Computer Numerical Control). Nazi mfundo zofunika kuziganizira pofufuza chitetezo cha makina a CNC:

Makina Ozungulira

- Yang'anani malo otchingidwa ndi makinawo kuti muwonetsetse kuti palibe ming'alu kapena kuwonongeka kulikonse.

- Onetsetsani kuti zitseko zonse, mapanelo, ndi zotchingira chitetezo zikuyenda bwino.

- Yang'anani mawonekedwe oyenera a machenjezo, zilembo, ndi mabatani oyimitsa mwadzidzidzi.

Emergency Stop System

- Yesani mabatani oyimitsa mwadzidzidzi kuti muwonetsetse kuti ayimitsa makinawo nthawi yomweyo akakanikizidwa.

- Tsimikizirani kuti njira yoyimitsa mwadzidzidzi ili m'malo oyenera ogwira ntchito komanso kuti ogwira ntchito amatha kupezeka mosavuta.

- Phunzitsani oyendetsa ntchito moyenera mabatani oyimitsa mwadzidzidzi ndi malo awo.

Kuteteza Magetsi

- Yang'anani zida zamagetsi za mawaya aliwonse owonekera, zolumikizira zotayirira, kapena zotchingira zowonongeka.

- Onetsetsani kuti magetsi akhazikika bwino kuti achepetse kugwedezeka kwamagetsi.

- Onetsetsani nthawi zonse kuti zowononga ma circuit ndi ma fuse zikuyenda bwino.

Zida ndi Chitetezo cha Workpiece

- Yang'anani zida, monga zida zodulira kapena zomangira, kuti ziwonongeko, zawonongeka, kapena kuyika kolakwika.

- Yang'anani zogwirira ntchito kuti zikhazikike motetezeka komanso kutsekereza koyenera kuti musasunthike pakupanga makina.

- Yang'anirani zida zogwiritsira ntchito ndikusintha zida ngati kuli kofunikira kuti mukhale osamala komanso osamala.

Kuwala Kwadzidzidzi

- Onetsetsani kuti malo ogwirira ntchito ali ndi kuyatsa koyenera ngati magetsi azimitsidwa kapena pachitika ngozi zina.

- Yesani kuyatsa kwadzidzidzi pafupipafupi kuti muwonetsetse kuti kumagwira ntchito moyenera ndikuwunikira bwino dera.

Chitetezo Kumoto

- Tsimikizirani kupezeka ndi magwiridwe antchito a zozimitsa moto pafupi ndi makina a CNC.

- Phunzitsani ogwira ntchito pakugwiritsa ntchito moyenera zozimitsira moto ndi njira zopulumutsira moto pakakhala moto.

- Chotsani malo ozungulira makina a CNC azinthu zilizonse zoyaka kapena zinyalala.

Maphunziro Othandizira ndi Kudziwitsa

- Perekani maphunziro athunthu kwa ogwira ntchito pamayendedwe otetezeka komanso zoopsa zomwe zingachitike pamakina a CNC.

- Limbikitsani chikhalidwe chodziwitsa anthu zachitetezo ndikulimbikitsa ogwira ntchito kuti anene zachitetezo chilichonse mwachangu.

- Chitani misonkhano yachitetezo pafupipafupi kapena nkhani za m'bokosi la zida kuti mukambirane zachitetezo ndikulimbikitsa machitidwe otetezeka.

Kutsata Miyezo ya Chitetezo

- Onetsetsani kuti makina a CNC akukwaniritsa miyezo ndi malamulo otetezeka omwe akugwira ntchito.

- Khalani odziwitsidwa pazosintha zilizonse kapena zosintha pamiyezo yachitetezo ndikuziphatikiza muzowunika zachitetezo.

- Lankhulani ndi akatswiri achitetezo kapena alangizi, ngati kuli kofunikira, kuti muwonetsetse kuti mukutsatiridwa ndi njira zabwino.

Kuyeretsa Makina a CNC

Kuyeretsa nthawi zonse ndi kukonza makina a CNC ndikofunikira pakuchita bwino, kulondola, komanso moyo wonse. Potsatira njira zoyeretsera izi, ogwira ntchito angathe kuonetsetsa kuti makina awo a CNC amakhalabe mumkhalidwe wabwino, kuchepetsa nthawi yopuma komanso kukulitsa zokolola.

- Kusunga makina aukhondo a CNC (Computer Numerical Control) ndikofunikira kuti agwire bwino ntchito komanso kukhala ndi moyo wautali. Kuyeretsa makina nthawi zonse kumathandiza kupewa kupangika kwa zinyalala, fumbi, ndi tchipisi zomwe zingayambitse zovuta zamakina ndi zolakwika pakukonza.

- Yambani ndikuzimitsa makinawo ndikuchotsa kugwero lamagetsi kuti mutsimikizire chitetezo panthawi yoyeretsa.

- Yambani ndikuchotsa tchipisi totayirira, zinyalala, kapena madzi odula pamalo ogwirira ntchito pogwiritsa ntchito vacuum kapena burashi. Samalani kumadera ovuta kufikako, monga ming’alu ndi ngodya, kumene zinyalala zimaunjikana.

- Pukutani pansi pa makinawo ndi nsalu yoyera, yopanda lint ndi njira yochepetsera yochepetsera. Pewani kugwiritsa ntchito zotsukira zomwe zingawononge kumaliza kwa makina. Onetsetsani bwino malo onse owonekera, kuphatikizapo tebulo, zopota, zosungira zida, ndi mpanda.

- Tsukani thanki yozizirira ndikusintha madzi odulira pafupipafupi. Madzi odulira odetsedwa kapena oipitsidwa amatha kusokoneza magwiridwe antchito a makina komanso mtundu wazinthu zomwe zamalizidwa.

- Yang'anani zosefera ndi zowonera mu pulogalamu yozizirira, makina osefera mpweya, ndi makina opaka mafuta. Yeretsani kapena m'malo mwa zigawozi ngati kuli kofunikira kuti muwonetsetse kusefedwa koyenera ndi kutuluka kwamadzimadzi.

- Samalani kwambiri ndi makina opota ndi makina osinthira zida. Chotsani zinyalala zilizonse kapena zomanga zomwe zingasokoneze kugwira ntchito kwawo bwino. Mafuta azigawozi molingana ndi malangizo a wopanga kuti azigwira bwino ntchito.

- Yang'anani chivundikiro ndi mvuvu ngati zizindikiro zilizonse zowonongeka kapena zowonongeka. M'malo mwawo ngati kuli kofunikira kuteteza makina amkati kuti asaipitsidwe.

- Pomaliza, yang'anani zolumikizira zamagetsi, zingwe, ndi mawaya. Onetsetsani kuti ndi otetezeka komanso osawonongeka. Yeretsani zowongolera ndi mabatani ndi chotsukira pang'ono kuti muchotse zinyalala zilizonse.

- Sungani ndondomeko yoyeretsa nthawi zonse ndi ntchito yokonza zolemba. Izi zimathandizira kutsata pafupipafupi kuyeretsa ndikuzindikira zovuta zilizonse zomwe zingachitike koyambirira.

CNC Machine Training ndi Thandizo

Popereka maphunziro athunthu ndi chithandizo chopitilira, ogwira ntchito amatha kukhala ndi luso lofunikira komanso chidaliro chogwiritsa ntchito makina a CNC moyenera. Ogwira ntchito ophunzitsidwa bwino amathandizira kuti pakhale zokolola zambiri, kuchepetsa nthawi yopumira, komanso zotulukapo zapamwamba.

- Maphunziro oyenerera ndi chithandizo chokhazikika ndizofunikira kuti ogwira ntchito agwiritse ntchito bwino makina a CNC (Computer Numerical Control) ndikukulitsa zomwe angathe. Mapulogalamu ophunzitsira amapatsa ogwiritsa ntchito chidziwitso ndi luso lofunikira kuti agwiritse ntchito, kukonza, ndikuthetsa makina a CNC.

- Yambani popereka maphunziro athunthu pazoyambira zaukadaulo wa CNC, kuphatikiza kumvetsetsa zigawo zamakina, zida, ndi zoyambira zamapulogalamu. Maziko awa amathandiza ogwira ntchito kumvetsetsa mfundo zazikuluzikulu ndi mawu okhudzana ndi makina a CNC.

- Yambitsani ogwiritsira ntchito pulogalamu ya CAD/CAM yomwe imagwiritsidwa ntchito popanga magawo amitundu ndi kupanga mapulogalamu amakina. Kuphunzitsa pazida zamapulogalamuwa kumathandizira ogwiritsa ntchito kukonza makina a CNC moyenera ndikuwongolera njira zamakina.

- Perekani magawo ophunzitsira omwe ogwira ntchito amatha kuyeserera kukhazikitsa makina, kutsitsa zida, komanso kuyendetsa makina. Chochitika chothandizachi chimathandizira kukhala ndi chidaliro komanso kudziwa bwino momwe makinawo amagwirira ntchito.

- Tsindikani ndondomeko zachitetezo ndi machitidwe abwino pamaphunziro. Ogwira ntchito akuyenera kuphunzitsidwa njira zoyenera zoyambira ndi kuzimitsa makina, kagwiridwe ka zida zodulira, komanso kugwiritsa ntchito zida zodzitetezera (PPE) kuwonetsetsa kuti malo ogwirira ntchito ali otetezeka.

- Perekani maphunziro pa kukonza makina ndi chisamaliro chodzitetezera. Oyendetsa galimoto aphunzire momwe angayang'anire ndi kusamalira zinthu zofunika kwambiri, monga zopota, zotchingira njira, ndi makina opaka mafuta, kuti makina aziyenda bwino.

- Perekani chithandizo chokhazikika kudzera m'mabuku, zolemba, ndi zothandizira pa intaneti. Buku lathunthu la ogwiritsa ntchito lomwe limakhudza momwe makina amagwirira ntchito, zitsanzo zamapulogalamu, maupangiri othetsera mavuto, ndi njira zokonzetsera zitha kukhala ngati kalozera wofunikira kwa ogwiritsa ntchito.

- Khazikitsani dongosolo lothandizira pomwe ogwira ntchito angapeze thandizo ndi chitsogozo akakumana ndi zovuta kapena zovuta. Izi zitha kukhala ngati gulu lodzipereka lothandizira, nambala yothandizira paukadaulo, kapena mabwalo apaintaneti pomwe ogwiritsira ntchito amatha kulumikizana ndi ogwiritsa ntchito a CNC odziwa zambiri.

- Chitani maphunziro otsitsimula nthawi ndi nthawi kuti mulimbikitse chidziwitso ndi luso. Ukadaulo wa CNC umasintha pakapita nthawi, kotero kupangitsa ogwiritsa ntchito kukhala anthawi zonse ndi kupita patsogolo ndi njira zaposachedwa kumatsimikizira kuti amatha kugwiritsa ntchito bwino makinawo.

- Limbikitsani ogwira ntchito kuti atenge nawo mbali pazochitika zamakampani, ziwonetsero zamalonda, ndi zokambirana kuti awonjezere chidziwitso chawo ndikulumikizana ndi akatswiri ena pantchitoyo. Zochitika izi zimapereka mwayi wophunzirira matekinoloje atsopano, kugawana zokumana nazo, ndi kuzindikira machitidwe abwino kwambiri.

Mtengo wapatali wa magawo CNC

Kumvetsetsa mtengo wokhudzana ndi makina a CNC ndikofunikira pakukonza bajeti ndikukonzekera.

- Mtengo wamakina a CNC (Computer Numerical Control) ungasiyane kutengera zinthu zingapo, kuphatikiza mtundu wa ntchito yofunikira, zovuta zamakina, komanso mitengo ya opereka chithandizo. Kumvetsetsa zinthu izi ndikofunikira pakukonza bajeti ndikuwonetsetsa kuti dongosolo lokonzekera bwino ndi lotsika mtengo.

- Kukonza zodzitetezera chizolowezi ndi ntchito wamba CNC makina. Nthawi zambiri zimakhala ndi ntchito monga kuyang'anira, kuyeretsa, kuthira mafuta, ndi kuwongolera. Mtengo wokonza zodzitetezera ukhoza kuchoka pa mazana angapo mpaka madola zikwi zingapo pachaka, malingana ndi kukula kwa makina ndi zovuta zake.

- Kukonzekera kwadzidzidzi kapena kosakonzekera ndi mbali ina ya utumiki wa makina a CNC omwe angakhudze ndalama. Kukonzekera kumeneku nthawi zambiri kumakhala kosayembekezereka ndipo kumafuna chisamaliro chamsanga kuti kuchepetsa nthawi yopuma. Mtengowo udzadalira kuopsa kwa nkhaniyo, kupezeka kwa zida zosinthira, komanso ukatswiri wofunika kuthetsa vutoli. Kukonza mwadzidzidzi kumatha kuchoka pa mazana angapo mpaka madola masauzande angapo.

- Ena opereka chithandizo amapereka makontrakitala a ntchito kapena mapulani okonza omwe amakhudza zonse zachizoloŵezi zodzitetezera komanso kukonza mwadzidzidzi. Makontrakitalawa atha kupulumutsa ndalama komanso mtendere wamumtima powonetsetsa kuti athandizidwe mwachangu komanso kuchepetsa chiwopsezo cha zowonongera zosayembekezereka. Mtengo wamakontrakitala amasiyanasiyana malinga ndi zaka zamakina, zovuta zake, komanso kuchuluka kwa zomwe zimaperekedwa.

- Ziwalo zosinthira ndi consumables ndi ndalama zina kuganizira potumikira makina CNC. Zinthu monga ma motors, masensa, malamba, ndi ma bearings angafunike kusinthidwa pakapita nthawi. Mtengo wa magawowa udzatengera mtundu wa makinawo, mtundu wake, komanso kupezeka kwake. Ndikoyenera kusunga mndandanda wa zida zomwe zimagwiritsidwa ntchito nthawi zambiri kuti muchepetse nthawi yochepetsera komanso kuchepetsa ndalama zotumizira.

- Kuyendera malo ochezera a pawebusaiti kungawononge ndalama zina, monga ndalama zoyendera, malo ogona, ndi malipiro a akatswiri. Ndalamazi zimatha kusiyanasiyana malinga ndi komwe kuli makina komanso mfundo za opereka chithandizo. Zowunikira zakutali ndi njira zothetsera mavuto zitha kukhalapo, zomwe zingathandize kuchepetsa kufunikira koyendera malo ndi ndalama zomwe zimagwirizana.

- Ndikoyenera kupeza ndalama kuchokera kwa opereka chithandizo angapo kuti mufananize mtengo ndi ntchito zomwe zimaperekedwa. Ganizirani za mbiri, zochitika, ndi ukatswiri wa opereka chithandizo, komanso nthawi yawo yoyankhira komanso kupezeka pazochitika zachangu.

- Kuyika ndalama pakukonza nthawi zonse komanso kukonza nthawi yake kungathandize kuchepetsa ndalama zomwe zimatenga nthawi yayitali. Kunyalanyaza kukonza kungayambitse kuwonongeka pafupipafupi, kuchepetsa moyo wa makina, komanso kuchuluka kwa ndalama zokonzera.

Kutsiliza

Utumiki wa makina a CNC ndi wofunikira kuti makinawa agwire ntchito bwino komanso moyenera. Othandizira makina a CNC amapereka ntchito zingapo zosamalira, kukonza, ndi kukweza makinawa kuti atsimikizire kuti akwaniritsa zofunikira zamabizinesi opanga. Kusamalira nthawi zonse, kuyang'anitsitsa, ndi kukonzanso n'kofunika kwambiri kuti tipewe nthawi yopuma komanso kuchepetsa chiopsezo cha kukonzanso kwamtengo wapatali. Mwa kuyika ndalama muutumiki wamakina a CNC, mabizinesi amatha kuwonetsetsa kuti akukulitsa kuthekera kwa makina awo a CNC ndikuwongolera zokolola zawo zonse.