Kupanga jekeseni Mould

Pulasitiki ndi zinthu zomwe zimagwiritsidwa ntchito kwambiri pazinthu zosiyanasiyana zamafakitale. Zoseweretsa, zida zamagalimoto, zida zamankhwala, zida, ndi zina zonse zimapangidwa kuchokera kupulasitiki. Zambiri mwazinthu zapulasitiki kapena zomwe timakumana nazo m'moyo wathu watsiku ndi tsiku zimapangidwa ndikusintha utomoni wosungunuka kukhala kapangidwe kake komwe kumatchedwa kupanga jakisoni wa pulasitiki. Njira yothandiza kwambiri imeneyi imatha kupanga ziwalo zazikulu ndi mawonekedwe ambiri ndipo zimatha kubwereza gawo lomwelo kangapo pogwiritsa ntchito nkhungu yomweyi. Pamtima pa njirayi ndi nkhungu, yomwe imatchedwanso tooling. Njira yopangira nkhungu yapamwamba ndiyofunikira kuti mupange magawo abwino ndikusunga magwiridwe antchito okwera mtengo. Gawo labwino lidzakwera ndipo ndalama zonse za polojekiti zidzatsika poika ndalama pakupanga nkhungu zapamwamba.

Masitepe opangira jakisoni

Kumangira jekeseni ndi imodzi mwazinthu zomwe zimagwiritsidwa ntchito popanga zinthu zapulasitiki. Ndi njira yofunidwa kwambiri yomwe imatha kuberekanso gawo lomwelo kambirimbiri. Njirayi imayamba ndi fayilo ya Computer Aided Design (CAD) yomwe ili ndi kopi ya digito ya gawolo. Fayilo ya CAD imagwiritsidwa ntchito ngati malangizo othandizira popanga nkhungu. Chikombole, kapena chida, chimapangidwa kuchokera ku zidutswa ziwiri zachitsulo. Mphepete mwa mawonekedwe a gawolo amadulidwa mbali iliyonse ya nkhungu. Nthawi zambiri nkhungu iyi imapangidwa kuchokera ku aluminiyamu, chitsulo, kapena aloyi.

Pambuyo popanga nkhungu, chotsatira ndikusankha zinthu zapulasitiki zoyenera. Kusankha zinthu kudzadalira mmene mbali yomaliza idzagwiritsiridwe ntchito. Zida za pulasitiki zili ndi makhalidwe osiyanasiyana oti aganizire. Izi zikuphatikizapo maonekedwe ndi maonekedwe onse, komanso kukana mankhwala, kutentha, ndi abrasion. Lankhulani ndi akatswiri a DJmolding kuti mudziwe zambiri za zipangizo zapulasitiki zomwe zilipo zopangira jekeseni.

Zomwe zasankhidwa zimayamba ngati pulasitiki ya pulasitiki yomwe imadyetsedwa mu hopper pamakina opangira jekeseni. Ma pellets amalowa m'chipinda chotentha momwe amasungunuka, kufinyidwa, ndiyeno amabayidwa m'bowolo. Gawolo likazizira, magawo awiri a nkhungu amatsegula kuti atulutse gawolo. Makinawo amayambiranso kuti ayambenso ntchitoyi.

Ndi Zinthu Zotani Zomwe Zimagwiritsidwa Ntchito Kupanga Nkhungu?

Kupanga nkhungu kumachitika ndi chitsulo, aluminiyamu, kapena aloyi. DJmolding amagwiritsa ntchito zitsulo zapamwamba kwambiri popanga nkhungu. Kupanga nkhungu yachitsulo ndikokwera mtengo pang'ono kuposa kugwiritsa ntchito aluminiyamu kapena aloyi. Mtengo wokwera umachepetsedwa ndi moyo wautali wa nkhungu zachitsulo. Zoumba za aluminiyamu, ngakhale zotsika mtengo kupanga, sizikhala nthawi yayitali ngati chitsulo ndipo ziyenera kusinthidwa pafupipafupi. Zoumba zachitsulo zimatha kupitilira ma XNUMX kuzungulira. Zoumba za aluminiyamu zimafunikira kusinthidwa pafupipafupi. Kupanga nkhungu zachitsulo kumatha kubweretsa mapangidwe ovuta kwambiri osatheka ndi aluminiyumu. Zoumba zachitsulo zimathanso kukonzedwa kapena kusinthidwa ndi kuwotcherera. Zoumba za aluminiyamu ziyenera kupangidwa kuchokera pachimake ngati nkhungu yawonongeka kapena kuti igwirizane ndi kusintha. Zoumba zachitsulo zapamwamba zimatha kugwiritsidwa ntchito masauzande, masauzande mazana, ndipo nthawi zina mpaka miliyoni imodzi.

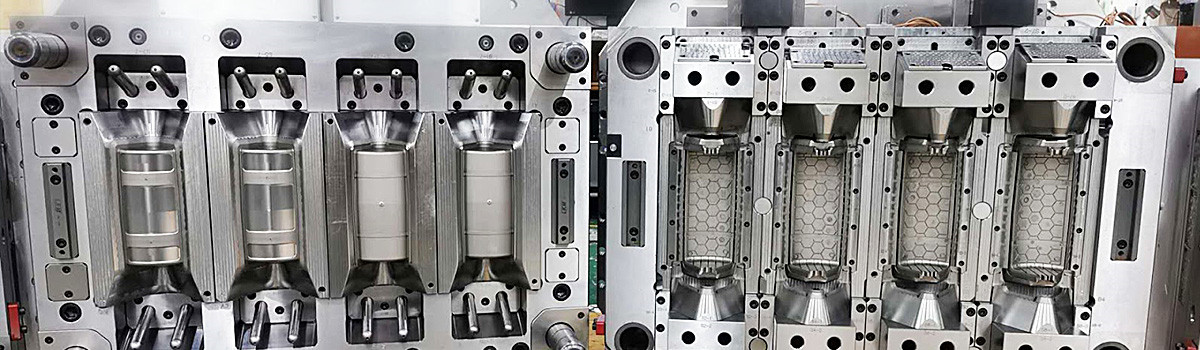

Jekeseni Mold zigawo

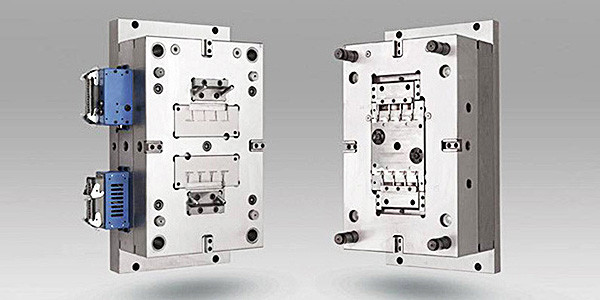

Mitundu yambiri ya jakisoni imapangidwa ndi magawo awiri - mbali A ndi B mbali, kapena patsekeke ndi pachimake. Mbali yapabowo nthawi zambiri imakhala yabwino kwambiri pomwe theka linalo, pachimake, limakhala ndi zolakwika zowoneka kuchokera pamapini a ejector omwe amakankhira mbali yomalizidwa kuchokera mu nkhungu. Chikombole cha jakisoni chidzaphatikizanso mbale zothandizira, bokosi la ejector, ejector bar, ejector pins, ejector plates, sprue bushing, ndi mphete yopezera.

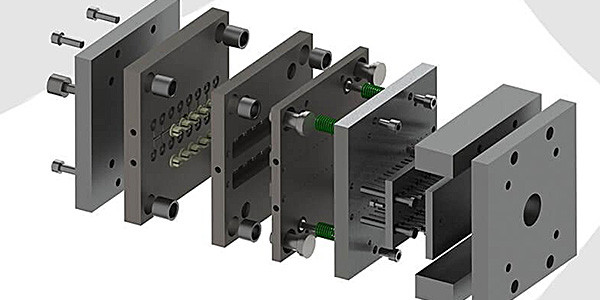

Kupanga jekeseni ndi njira yopangira yokhala ndi zidutswa zambiri zosuntha. M'munsimu muli mndandanda wa mawu omwe amafotokoza zambiri mwa zidutswa zofunika kupanga nkhungu ndi jekeseni. Zidazi zimakhala ndi mbale zingapo zachitsulo mkati mwa chimango. Chojambulachi chimayikidwa mu makina opangira jekeseni ndikugwiridwa ndi zingwe. Kudula kwa nkhungu ya jakisoni yomwe imawonedwa kumbali ingafanane ndi sangweji yokhala ndi magawo osiyanasiyana. Onani wathu Injection Molding Glossary kuti mumve zambiri za mawu.

Mtundu wa Mold kapena Mold Base: Mndandanda wazitsulo zachitsulo zomwe zimagwirizanitsa zigawo za nkhungu pamodzi, kuphatikizapo ma cavities, cores, runners system, cooling system, ndi ejection system.

A mbale: Theka limodzi la nkhungu zachitsulo. Mbaleyi ilibe zigawo zosuntha. Itha kukhala mkati kapena mkati.

B mbale: Theka lina la nkhungu zachitsulo. Mbaleyi imakhala ndi magawo osuntha kapena malo olola kuti magawo osuntha agwirizane ndi gawo lomalizidwa - makamaka zikhomo za ejector.

Zida Zothandizira: Zitsulo zachitsulo mkati mwa chimango cha nkhungu zomwe zimapereka bata panthawi yopangira.

Bokosi la Ejector: Muli ndi ejector system yomwe imagwiritsidwa ntchito kukankhira mbali yomalizidwa kuchoka mu nkhungu.

Ejector mbale: Chipinda chachitsulo chomwe chili ndi ejector bar. Mbale ya ejector imasuntha kuti itulutse chinthu chomalizidwa mutachipanga.

Ejector Bar: Gawo la mbale ya ejector. Zikhomo za ejector zimalumikizidwa ndi ejector bar.

Zikhomo za Ejector: Zikhomo zachitsulo zomwe zimalumikizana ndi gawo lomwe lamalizidwa ndikukankhira kunja kwa nkhungu. Zizindikiro za pini za ejector zimawonekera pazinthu zina zopangidwa ndi jakisoni, zomwe nthawi zambiri zimakhala zozungulira zomwe zimapezeka kumbuyo kwa gawolo.

Sprue Bushing: Chidutswa cholumikizira pakati pa nkhungu ndi makina opangira jakisoni pomwe utomoni wosungunuka umalowa m'bowo.

Sprue: Malo omwe ali pa chimango cha nkhungu pamene utomoni wosungunuka umalowa mu nkhungu.

mphete ya Locator: Mphete yachitsulo yomwe imatsimikizira kuti mphuno ya makina opangira jekeseni imalumikizana bwino ndi sprue bushing.

Cavity kapena Die Cavity: Kujambula kwa concave mu nkhungu, nthawi zambiri kumapanga kunja kwa gawo lopangidwa. Nkhungu zimasankhidwa kukhala pabowo limodzi kapena zibowo zambiri kutengera kuchuluka kwa zotupa zotere.

pakati: Mawonekedwe a convex mu nkhungu, nthawi zambiri amapanga mkati mwa gawo lopangidwa. Ichi ndi gawo lokwezeka la nkhungu. Ndilo chopinga cha pabowo. Utomoni wosungunula nthawi zonse umakankhidwa muzitsulo, kudzaza danga. Utomoni wosungunuka umapanga kuzungulira pachimake chokwera.

Runner kapena Runner System: Ngalande mkati mwa nkhungu yachitsulo yomwe imalola utomoni wosungunuka kuyenda kuchokera ku sprue-to-cavity kapena cavity-to-cavity.

Geti: Mapeto a wothamanga kumene utomoni wosungunuka umalowa mu nkhungu. Pali mitundu yosiyanasiyana ya zipata za ntchito zosiyanasiyana. Mitundu ya zipata zomwe zimagwiritsidwa ntchito kwambiri ndi pini, zolankhula, zimakupiza, m'mphepete, disk, fan, tunnel, nthochi kapena cashew, ndi chisel. Mapangidwe a zipata ndi kuyika kwake ndizofunikira kwambiri musanayambe kupanga nkhungu.

Njira Yozizira: Mndandanda wa ngalande mu chipolopolo chakunja cha nkhungu. Njirazi zimazungulira madzimadzi kuti zithandizire kuzirala. Ziwalo zosakhazikika bwino zimatha kuwonetsa zolakwika zosiyanasiyana pamtunda kapena mawonekedwe. Njira yozizira nthawi zambiri imapanga kuchuluka kwa jekeseni. Kuchepetsa nthawi yoziziritsa kumatha kuwongolera bwino nkhungu komanso kutsika mtengo. Fathom imapereka Kuzirala kwa Conformal pamapulogalamu ambiri opangira jakisoni omwe angawonjezere mphamvu ya nkhungu mpaka 60%

Kupanga nkhungu kwa DJ kwa Njira Zosiyanasiyana Zopangira

Njira yopangira jakisoni wa pulasitiki imatha kusinthidwa kuti igwirizane ndi zosowa zosiyanasiyana komanso zovuta. Ngakhale ndizoyenera kupanga zigawo zazikulu za pulasitiki zosavuta, zitha kugwiritsidwanso ntchito kupanga magawo ovuta kwambiri okhala ndi ma geometries ovuta kapena masukulu.

Multi-Cavity kapena Family Mold - Chikombole ichi chimakhala ndi ziboda zambiri mu nkhungu imodzi yomwe imapanga zigawo zingapo zofanana kapena zogwirizana ndi jekeseni iliyonse. Iyi ndi njira yabwino yowonjezerera ma voliyumu othamanga ndikutsitsa mtengo wagawo lililonse.

Kwambiri - Njira yopangira jakisoniyi imagwiritsidwa ntchito popanga magawo opangidwa ndi mitundu iwiri ya pulasitiki. Chitsanzo chabwino cha izi chingakhale chobowola chonyamula kapena chowongolera masewera chokhala ndi chipolopolo cholimba chakunja chokhala ndi zofewa zofewa, zokhala ndi rubberized. Mbali yopangidwa kale imalowetsedwanso mu nkhungu yopangidwa mwapadera. Chikombole chatsekedwa ndipo gawo lachiwiri la pulasitiki yosiyana limawonjezeredwa pa gawo loyambirira. Iyi ndi njira yabwino pamene mitundu iwiri yosiyana imafuna.

Ikani Kuumba - Njira yopangira jekeseni yomwe imalola kuti zitsulo, ceramic, kapena zidutswa zapulasitiki ziphatikizidwe mu gawo lomaliza. Zigawo zachitsulo kapena ceramic zimayikidwa mu nkhungu ndiyeno pulasitiki yosungunuka imalowetsedwa mu nkhungu kuti ipange chidutswa chopanda phokoso chopangidwa ndi zipangizo ziwiri zosiyana. Insert akamaumba ndi abwino kwa ntchito magalimoto chifukwa ndi njira nzeru kuchepetsa kulemera ndi kuchepetsa zinthu zodula ngati zitsulo. M'malo mopanga chidutswa chonsecho ndi chitsulo, zidutswa zogwirizanitsa zokha ziyenera kukhala zitsulo pamene zina zonse zidzapangidwa ndi pulasitiki.

Co-Injection Molding - Ma polima awiri osiyana amabayidwa motsatizana kapena nthawi imodzi m'bowo. Njirayi ingagwiritsidwe ntchito popanga ziwalo ndi khungu la mtundu umodzi wa pulasitiki wokhala ndi pakati pa wina.

Thin Wall Molding - Mapangidwe a jekeseni omwe amayang'ana nthawi zazifupi komanso zokolola zambiri kuti apange mapulasitiki owonda, opepuka komanso otsika mtengo.

Jekeseni wa Mpira - Labala amabayidwa mu nkhungu pogwiritsa ntchito njira yofanana ndi jekeseni wa pulasitiki. Zigawo za mphira zimafunikira kukakamiza kwambiri kuti apange jakisoni wopambana.

Jekeseni wa Ceramic - Njira yopangira jakisoni pogwiritsa ntchito zida za ceramic. Ceramic ndi chinthu cholimba mwachilengedwe, chomwe chimagwiritsidwa ntchito m'mafakitale osiyanasiyana. Jekeseni wa ceramic amafuna masitepe angapo owonjezera; kuphatikizapo sintering kapena kuchiritsa ziwalo zatsopano kuonetsetsa kuti khalidwe durability.

Kumangirira kwa jekeseni wa Pulasitiki Wotsika - Ziwalo za pulasitiki zomwe zimapangidwira pazovuta zochepa. Izi ndizothandiza makamaka pantchito zomwe zimafunikira kuyika magawo osalimba, monga zamagetsi.

Lumikizanani ndi DJmolding kuti mumve zambiri pakupanga jakisoni wapulasitiki. Gulu lathu la akatswiri litha kukuthandizani ndi polojekiti yanu yopangidwa ndi jakisoni wapulasitiki.