Kupukutira kwa pulasitiki

Kumangira jekeseni wa pulasitiki ndi njira yopangira yomwe imaphatikizapo kusungunula mapepala apulasitiki ndikuwalowetsa mu nkhungu kuti apange chinthu chamagulu atatu. Izi zimayamba ndi zinthu zambiri, kuchokera ku tizigawo tating'onoting'ono tolondola kwambiri mpaka zida zazikulu zamagalimoto. Kumangira jekeseni wa pulasitiki kumapereka maubwino ambiri kuposa njira zina zopangira, kuphatikiza mitengo yayikulu yopangira, kusinthasintha kwa mapangidwe, komanso kutsika mtengo. Bukhuli liyang'ana mozama pakupanga jekeseni wa pulasitiki ndikuwunika ntchito zake zosiyanasiyana, maubwino, ndi zolephera.

Mbiri ya Pulasitiki Jakisoni Woumba

Kuumba jekeseni wa pulasitiki ndi njira yopangira yomwe imaphatikizapo kubaya pulasitiki yosungunuka mu nkhungu kuti apange mawonekedwe enieni. Mbiri yakuumba jekeseni wa pulasitiki imatha kuyambika chakumapeto kwa zaka za m'ma 1800 pomwe celluloid, mtundu wa pulasitiki, idapangidwa koyamba. Komabe, munali m'ma 1940 pamene kuumba jekeseni wa pulasitiki kunagwiritsidwa ntchito kwambiri ngati njira yopangira.

M’kati mwa nkhondo yachiŵiri ya padziko lonse, kufunikira kwa mapulasitiki opangidwa mochuluka kunawonjezereka, ndipo opanga anayamba kufunafuna njira zatsopano ndi zogwirira ntchito zopangira zimenezo. Mu 1946, James Watson Hendry, wotulukira ku America, adapanga makina opangira jekeseni woyamba, omwe adasintha makampani opanga jakisoni wapulasitiki. Makinawa amalola kuwongolera kolondola komanso kosasinthika kwa jekeseni, kupangitsa kupanga zigawo zazikulu zapulasitiki kukhala zofikirika komanso zogwira mtima.

M'zaka zonse za m'ma 1950 ndi 1960, kupita patsogolo kwaukadaulo wamapulasitiki kunapitilira kukonza njira yopangira jakisoni wapulasitiki. Kukhazikitsidwa kwa zinthu zatsopano, monga polystyrene ndi polyethylene, zidapanga zida zapulasitiki zovuta komanso zolimba. Kuphatikiza apo, kusintha kwaukadaulo wamakina omangira, kuphatikiza kugwiritsa ntchito ma hydraulic system, kunapangitsa njira yopangira jakisoni kukhala yabwino komanso yotsika mtengo.

Masiku ano, kuumba jekeseni wa pulasitiki ndi njira yodzipangira yokha yomwe imagwiritsidwa ntchito popanga zinthu zambiri zamapulasitiki, kuyambira zoseweretsa ndi katundu wa ogula kupita ku zida zamagalimoto ndi zida zamankhwala. Pakupangidwa kwa zida zatsopano ndi matekinoloje, njira yopangira jakisoni wapulasitiki ikupitilizabe kusinthika ndikuwongolera, kuwonetsetsa kuti ikhalabe njira yofunika kwambiri yopanga zaka zambiri.

Zoyambira za Pulasitiki jakisoni Kumangira

Kumangira jekeseni wa pulasitiki ndi njira yopangira kupanga magawo ndi zinthu zopangidwa kuchokera kuzinthu zapulasitiki. Ntchitoyi imaphatikizapo kubaya pulasitiki yosungunuka mu nkhungu, yomwe imazizira ndi kulimba kuti ipange mawonekedwe ofunikira.

Njira zoyambira zomwe zimakhudzidwa pakuumba jekeseni wa pulasitiki ndi izi:

- Mapangidwe a nkhungu: Chinthu choyamba pakupanga nkhungu yomwe idzagwiritsidwe ntchito kupanga gawo lomwe mukufuna. Chikombolecho chimapangidwa kuchokera kuchitsulo ndipo chiyenera kukhala chokonzekera kuwerengera chifukwa cha shrinkage pamene pulasitiki imazizira ndi kulimba.

- Kukonzekera kwazinthu: Zinthu zapulasitiki zomwe zimagwiritsidwa ntchito popanga jakisoni zimabwera ngati ma pellets kapena ma granules, omwe ayenera kusungunuka ndikukonzekera jekeseni mu nkhungu. Izi nthawi zambiri zimachitika mu hopper, pomwe pulasitiki imatenthedwa mpaka kutentha kwina ndikusungunuka kukhala madzi.

- Jekeseni: Pulasitiki ikasungunuka, imabayidwa mu nkhungu pogwiritsa ntchito makina apadera opangira jakisoni. Makinawa amagwiritsa ntchito kukakamiza kwa pulasitiki yosungunuka, kukakamiza kulowa mu nkhungu, komwe kumatenga mawonekedwe a nkhungu.

- Kuziziritsa ndi kulimbitsa: pulasitiki ikatha kubayidwa mu nkhungu, imatha kuziziritsa ndikulimbitsa. Izi zitha kutenga paliponse kuyambira masekondi angapo mpaka mphindi zingapo, kutengera kukula ndi zovuta za gawolo.

- Kutulutsa: Pulasitiki ikakhazikika ndikukhazikika, nkhungu imatsegulidwa, ndipo gawolo limatulutsidwa. Udindowu ungafunike ntchito yomaliza yomaliza, monga kudula kapena kusenda mchenga, kuchotsa pulasitiki yochulukirapo kapena m'mphepete mwazovuta.

Kumangira jakisoni wa pulasitiki ndi njira yeniyeni komanso yobwerezabwereza, kupangitsa kuti ikhale yabwino pazigawo zopanga kwambiri ndi zinthu zokhala ndi mtundu wokhazikika. Komanso ndi yosinthasintha kwambiri, chifukwa imatha kupanga zidutswa ndi zinthu zosiyanasiyana kukula kwake, mawonekedwe, ndi zovuta. Zina mwazinthu zomwe zimagwiritsidwa ntchito kwambiri pakuumba jekeseni wa pulasitiki ndi monga kupanga zoseweretsa, zinthu zogula, zida zamagalimoto, ndi zida zamankhwala.

Njira Yopangira jekeseni wa pulasitiki: Pang'onopang'ono

Kuumba jekeseni wa pulasitiki ndi njira yovuta yomwe imaphatikizapo masitepe angapo. Nayi kalozera watsatane-tsatane wa njira yopangira jakisoni wa pulasitiki:

- Kupanga Nkhungu: Chinthu choyamba ndi kupanga nkhungu yomwe imagwiritsidwa ntchito popanga gawolo. Nthawi zambiri nkhungu imapangidwa kuchokera ku chitsulo kapena aluminiyamu ndipo iyenera kukonzedwa kuti igwirizane ndi shrinkage ya pulasitiki ikazizira.

- Kupanga Nkhungu: Kapangidwe ka nkhungu kakamalizidwa, amapangidwa pogwiritsa ntchito pulogalamu yothandizidwa ndi makompyuta (CAD) ndi makina opangira makompyuta (CAM). Chikombolecho chiyenera kusanjidwa bwino ndi kupukutidwa kuti chinthu chomalizacho chikhale cholondola komanso chatha.

- Kusankha Kwazinthu: Zinthu zapulasitiki zomwe zimagwiritsidwa ntchito popanga jakisoni ziyenera kusankhidwa kutengera zomwe gawolo likufuna, monga mphamvu yake, kusinthasintha, mtundu, ndi kapangidwe kake.

- Kukonzekera Kwazinthu: Zinthu zapulasitiki zomwe zasankhidwa zimatenthedwa mpaka kutentha kwina ndikusungunuka kukhala madzi. Zinthuzo zimalowetsedwa mu hopper ya makina omangira.

- Kumangirira Jakisoni: Zinthu zapulasitiki zosungunula zimabayidwa mu nkhungu pogwiritsa ntchito makina apadera opangira jakisoni. Makinawa amagwiritsa ntchito kukakamiza pazinthu zapulasitiki, kuzikakamiza kulowa mu nkhungu, komwe zimatengera mawonekedwe a nkhungu.

- Kuziziritsa: Mphepete mwa nkhungu ikadzazidwa ndi pulasitiki, imatha kuziziritsa ndi kulimba. Nthawi yozizira imatsimikiziridwa ndi mawonekedwe a pulasitiki, kukula ndi makulidwe a gawolo, ndi kutentha kwa nkhungu.

- Ejection: Pulasitiki ikakhazikika, nkhungu imatsegulidwa, ndipo gawolo limatulutsidwa mu nkhungu pogwiritsa ntchito zikhomo za ejector.

- Kumaliza: Gawo lomwe latulutsidwa lingafunike ntchito yomaliza, monga kudula, kusenda mchenga, kapena kupenta, kuti muchotse pulasitiki kapena m'mphepete mwake.

- Kuwongolera Ubwino: Gawo lomalizidwa limawunikiridwa bwino kuti likwaniritse zofunikira komanso miyezo yapamwamba.

Kumangira jakisoni wa pulasitiki kumatha kupanga magawo osiyanasiyana ndi zinthu zazikulu, mawonekedwe, ndi zovuta. Njirayi imagwiritsidwa ntchito kwambiri m'mafakitale angapo, kuphatikiza zamagalimoto, zamankhwala, zogula, ndi zamagetsi.

Mitundu ya Pulasitiki Yomwe Amagwiritsidwa Ntchito Popanga Jakisoni

Mitundu yambiri ya pulasitiki ingagwiritsidwe ntchito popanga jekeseni. Kusankhidwa kwa zinthu zapulasitiki kumatengera zofunikira za chinthu kapena gawo lomwe likupangidwa, monga mphamvu, kusinthasintha, kulimba, ndi mawonekedwe. Nayi mitundu yodziwika bwino ya pulasitiki yomwe imagwiritsidwa ntchito popanga jakisoni:

- Polyethylene (PE): PE ndi pulasitiki yogwiritsidwa ntchito kwambiri yomwe imadziwika ndi mphamvu zake komanso kusinthasintha. Amagwiritsidwa ntchito popanga zinthu zosiyanasiyana, kuphatikiza zida zonyamula, zoseweretsa, ndi zida zamankhwala.

- Polypropylene (PP): PP ndi pulasitiki yopepuka komanso yolimba yomwe imagwiritsidwa ntchito kwambiri pamagalimoto amkati, monga ma dashboards ndi mapanelo a zitseko. Amapanganso zinthu zopakira, monga zotengera ndi mabotolo.

- Polycarbonate (PC): PC ndi pulasitiki yolimba komanso yowonekera yomwe imagwiritsidwa ntchito popanga zida zamagetsi, monga makompyuta ndi mafoni. Amagwiritsidwanso ntchito ngati ma lens akumutu ndi zida zapa dashboard mumakampani amagalimoto.

- Acrylonitrile Butadiene Styrene (ABS): ABS ndi pulasitiki yosunthika yomwe imadziwika ndi mphamvu zake, kulimba, komanso kukana kutentha. Amagwiritsidwa ntchito kwambiri kupanga zida zamagalimoto, monga ma dashboard, ma fender flares, zoseweretsa, ndi zinthu zogula.

- Polyamide (PA): PA, yomwe imadziwikanso kuti nayiloni, ndi pulasitiki yolimba komanso yopepuka yomwe imagwiritsidwa ntchito popanga zida zamagalimoto, monga zovundikira injini ndi makina otengera mpweya. Amapanganso zida zamasewera, monga nsapato za ski ndi ma racket a tennis.

- Polystyrene (PS): PS ndi pulasitiki yopepuka komanso yolimba yomwe imagwiritsidwa ntchito popanga zinthu monga makapu, mathireyi, ndi zotengera zakudya. Amapanganso katundu wogula, monga zoseweretsa ndi zida zamagetsi.

- Polyethylene Terephthalate (PET): PET ndi pulasitiki yolimba komanso yowonekera yomwe imagwiritsidwa ntchito popanga zida zonyamula, monga mabotolo ndi zotengera. Amagwiritsidwanso ntchito m'makampani opanga nsalu kupanga ulusi ndi nsalu.

Awa ndi ochepa mwa mitundu yodziwika bwino ya pulasitiki yomwe imagwiritsidwa ntchito popanga jakisoni. Mitundu ina yambiri ya zipangizo zapulasitiki zilipo, iliyonse ili ndi katundu ndi makhalidwe apadera. Kusankhidwa kwa zinthu zapulasitiki kumatengera zofunikira za gawo kapena chinthu chomwe chikupangidwa.

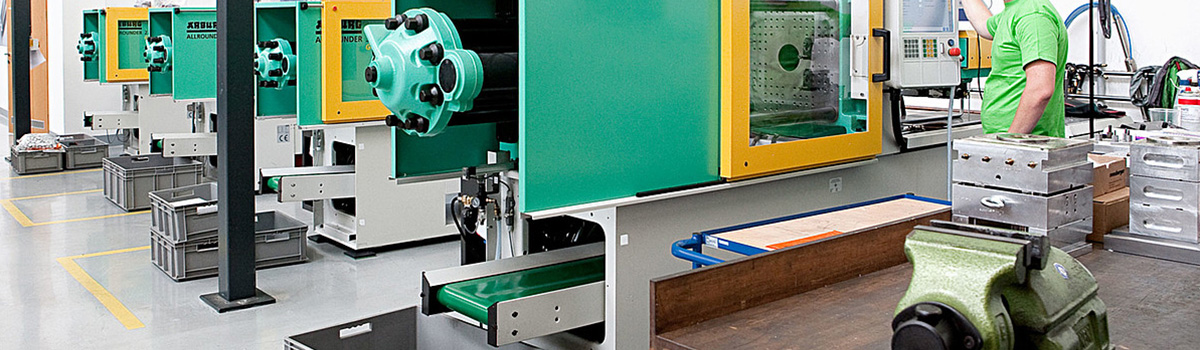

Mitundu Yamakina Omangira Majekeseni

Makina omangira jakisoni amabwera m'mitundu ndi makulidwe osiyanasiyana, iliyonse idapangidwa kuti ikwaniritse zofunikira zopanga. Nayi mitundu yodziwika bwino yamakina omangira jakisoni:

- Makina Opangira Ma Hydraulic: Makinawa amagwiritsa ntchito mphamvu ya hydraulic kuti apange kukakamiza kubaya pulasitiki mu nkhungu. Makina a Hydraulic nthawi zambiri amagwiritsidwa ntchito pazinthu zofunika kwambiri zomwe zimafunikira mphamvu yolimba kwambiri.

- Makina Omangira Jakisoni Wamagetsi: Makina amagetsi amagwiritsa ntchito ma motors amagetsi kuti apangitse jekeseni ndi makina ochepetsa. Amadziwika ndi kulondola kwambiri komanso kugwiritsa ntchito mphamvu zamagetsi, zomwe zimawapangitsa kukhala otchuka popanga tizigawo tating'ono tating'ono tating'ono tating'ono.

- Hybrid Injection Molding Machine: Makina a Hybrid amaphatikiza ubwino wa zida za hydraulic ndi magetsi, pogwiritsa ntchito mphamvu zonse za hydraulic ndi magetsi kuti apange mphamvu ndi mphamvu zofunikira. Makina a Hybrid amapereka liwiro labwino, kulondola, komanso kugwiritsa ntchito mphamvu.

- Makina Omangirira Oyima: Makina oyima amatulutsa zida zomwe zimafunikira kuumba kapena kuumba mopitilira muyeso. Amakhala ndi vertical clamping unit yomwe imalola mwayi wofikira nkhungu, kuwapangitsa kukhala abwino kupanga magawo ang'onoang'ono kapena ovuta.

- Makina Opangira Majekeseni Awiri: Makina owombera awiri amapanga magawo okhala ndi zida kapena mitundu yosiyanasiyana. Chipangizocho chili ndi mayunitsi awiri a jakisoni, iliyonse imatha kubaya zinthu zakunja mu nkhungu. Makina amtunduwu amagwiritsidwa ntchito kwambiri popanga zida zamagalimoto, monga zogwirira ndi makono.

- Multi-Shot Injection Molding Machine: Makina owombera angapo amapanga magawo okhala ndi zida zopitilira ziwiri kapena mitundu. Chipangizocho chili ndi mayunitsi angapo a jakisoni, iliyonse imatha kubaya zinthu zosiyanasiyana mu nkhungu. Makina amtunduwu amagwiritsidwa ntchito kwambiri popanga zinthu zogula, monga misuwachi ndi malezala.

- Makina Omangirira Amagetsi Onse: Makina amagetsi onse amagwiritsa ntchito ma motors amagetsi kuti apange jekeseni, makina otchingira, ndi nkhungu. Amadziwika ndi kulondola kwambiri, kuthamanga, komanso kugwiritsa ntchito mphamvu, zomwe zimawapangitsa kukhala otchuka popanga tizigawo tating'ono tating'ono tambiri.

Izi ndi zochepa chabe mwa mitundu yodziwika bwino ya makina opangira jekeseni. Makina aliwonse ali ndi mawonekedwe apadera komanso ubwino wake, zomwe zimapangitsa kuti pakhale kofunika kusankha chipangizo choyenera pazomwe zimapangidwira.

Zigawo za Makina Opangira Jakisoni

Makina opangira jekeseni ali ndi magawo angapo omwe amapanga zigawo zapulasitiki kuchokera kuzinthu zopangira. Nazi zigawo zofunika kwambiri zamakina omangira jekeseni:

Hopper: Malo osungiramo madzi amakhala ndi pulasitiki yaiwisi isanadyedwe mu makina opangira jakisoni. Zinthuzo nthawi zambiri zimakhala ngati ma pellets kapena ufa.

Mgolo: Mgolo ndi gawo lalitali, lacylindrical la makina omangira jekeseni omwe amakhala ndi zomangira, zomwe zimasungunuka ndikusakaniza zinthu zapulasitiki.

Screw: Chomangira ndi chipangizo chozungulira mkati mwa mbiya chomwe chimakankhira zinthu zapulasitiki patsogolo ndikuzisungunula ndi kugunda ndi kutentha.

Jekiseni jekeseni: Gawo la jakisoni limaphatikizapo chopondera, mbiya, ndi wononga ndipo imayang'anira kusungunula ndi kubaya pulasitiki mu nkhungu.

Clamping unit: Chigawo cha clamping chimakhala ndi udindo wosunga nkhunguyo mosamala ndikugwiritsa ntchito kukakamiza kofunikira panthawi yopangira jakisoni.

Nkhungu: Chikombole ndi chida chomwe chimapanga mawonekedwe ndi kukula kwa gawo la pulasitiki. Nthawi zambiri nkhungu imapangidwa ndi chitsulo ndipo imakhala ndi magawo awiri omwe amalumikizana.

Nozzle: Nozzle ndi gawo la jakisoni lomwe limalumikiza makina opangira jakisoni ndi nkhungu. Pulasitiki yosungunuka imalowetsedwa kudzera mumphuno ndi mu nkhungu.

Dongosolo lozizira: Makina ozizirira amakhala ndi udindo woziziritsa gawo la pulasitiki likangobayidwa mu nkhungu. Izi zimatsimikizira kuti chidutswacho ndi cholimba ndipo chikhoza kuchotsedwa mu nkhungu popanda kuwonongeka.

Control Panel: Gulu lowongolera ndi mawonekedwe omwe amalola wogwiritsa ntchito kuyang'anira ndikusintha makonzedwe a makina opangira jakisoni, monga kutentha, kupanikizika, ndi nthawi yozungulira.

Chilichonse mwa zigawozi chimakhala ndi gawo lofunikira pakuumba jekeseni, ndipo ndikofunikira kusunga ndikuwongolera gawo lililonse kuti zitsimikizire kuti zida zapamwamba zimapangidwa bwino.

Jekeseni Woumba Zida: Kupanga ndi Kupanga

Kupanga jekeseni kumatanthauza kupanga ndi kupanga nkhungu zomwe zimagwiritsidwa ntchito m'makina opangira jekeseni kuti apange zigawo zapulasitiki. Ubwino ndi luso la zisankho zimakhudza mwachindunji ubwino ndi zokolola za njira yopangira jekeseni. Nawa njira zofunika kwambiri pakupanga ndi kupanga zida zomangira jakisoni:

Kapangidwe kazinthu: Gawo loyamba la zida zopangira jakisoni ndikupanga zinthu zomwe ziyenera kupangidwa. Mapangidwe azinthu amaphatikizanso kukula kwa gawo, mawonekedwe, ndi zinthu, komanso mawonekedwe kapena zofunikira zilizonse.

Mapangidwe a nkhungu: Njira yopangira nkhungu imayamba pomwe kapangidwe kazinthu kakamalizidwa. Wopanga nkhunguyo ndiye adzadziwa mtundu wabwino kwambiri wa nkhungu, kuchuluka kwa zibowo zofunika, kukula ndi mawonekedwe a nkhunguyo.

Kupanga nkhungu: Chikombolecho chimapangidwa potengera kapangidwe ka nkhungu, pogwiritsa ntchito zida zapamwamba monga chitsulo kapena aluminiyamu. Nthawi zambiri nkhungu imapangidwa m'mahalofu awiri, iliyonse imakhala ndi mphako imodzi kapena zingapo.

Msonkhano wa nkhungu: Chikombolechi chikapangidwa, chimasonkhanitsidwa ndikuyesedwa kuti chikhale cholondola komanso chogwira ntchito. The nkhungu ayenera kupirira kuthamanga ndi kutentha jekeseni akamaumba ndondomeko.

Kuyesa ndi kutsimikizira nkhungu: Pambuyo posonkhanitsa nkhungu, imayesedwa ndikutsimikiziridwa kuti iwonetsetse kuti imapanga zigawo zapamwamba zomwe zimakwaniritsa zofunikira za mankhwala. Chikombolecho chingafunikire kusinthidwa kapena kusinthidwa kuti chikhale bwino.

Kusamalira nkhungu: Kukonzekera ndi kukonza nkhungu nthawi zonse ndikofunika kwambiri kuti zitsimikizidwe kuti zikhale ndi moyo wautali komanso ntchito. Izi zikuphatikizapo kuyeretsa, kuthira mafuta, ndi kuchotsa mbali zonse zowonongeka kapena zowonongeka.

Zida zomangira jakisoni zimafunikira kulondola komanso ukadaulo kuti apange zida zapamwamba nthawi zonse komanso moyenera. Potsatira dongosolo lathunthu ndi kupanga, opanga amatha kupanga nkhungu zomwe zimakwaniritsa zofunikira zamagulu awo ndikuwongolera njira zawo zopangira jakisoni.

Mitundu ya Injection Molding Tooling

Kumangira jekeseni ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga magawo ambiri. Kumaphatikizapo kubaya pulasitiki wosungunuka m'bowolo ndikulola kuti izizizire ndi kulimba mumpangidwe womwe ukufunidwa. Jekeseni akamaumba tooling ndi njira yopangira nkhungu zomwe zimagwiritsidwa ntchito popanga jakisoni. Pali mitundu ingapo ya jekeseni akamaumba tooling, aliyense ndi ubwino wake ndi kuipa.

- Mitundu Yambiri-Plate Moulds yokhala ndi mbale ziwiri ndi njira yosavuta kwambiri yopangira jekeseni. Amakhala ndi mbale ziwiri zomangika pamodzi kuti apange nkhungu. Pulasitiki yosungunuka imalowetsedwa mu dzenje kudzera pachipata ndikuloledwa kuziziritsa ndi kulimba. Gawolo likapangidwa, mbale ziwirizo zimalekanitsidwa, ndipo ndalamazo zimatulutsidwa. Mitundu yamitundu iwiri imagwiritsidwa ntchito kwambiri pazinthu zazing'ono mpaka zapakatikati zokhala ndi ma geometries osavuta.

- Mitundu itatu ya matabwa Mapangidwe a mapepala atatu amafanana ndi mapepala awiri, koma ali ndi mbale yowonjezera, yotchedwa stripper plate, yomwe imalekanitsa gawo lopangidwa ndi othamanga. Dongosolo lothamanga ndi netiweki yamakina yomwe imapereka pulasitiki yosungunuka ku nkhungu. Kuumba kwa mbale zitatu kumagwiritsidwa ntchito pazinthu zofunika kwambiri komanso ma geometri ovuta kwambiri.

- Nkhungu Zothamanga Zotentha M'makoko othamanga, pulasitiki yosungunula imabayidwa mwachindunji mu nkhungu kudzera munjira zotenthetsera zambiri m'malo modutsa pachipata. Izi zimachepetsa zinthu zomwe zawonongeka mu dongosolo lothamanga, zomwe zimapangitsa kuti pakhale njira yabwino kwambiri. Zoumba zothamanga zotentha zimagwiritsidwa ntchito popanga zida zambiri zamagulu ovuta.

- Nkhungu za Banja Zoumba zapabanja zimatulutsa magawo angapo mu nkhungu imodzi. Amakhala ndi ma cavities osiyanasiyana okonzedwa mwanjira yomwe imalola kupanga madera ambiri nthawi imodzi. Zoumba zamabanja zimagwiritsidwa ntchito kwambiri popanga magawo ang'onoang'ono mpaka apakatikati.

- Insert Molds Ikani nkhungu zimapanga zigawo zomwe zimafuna kuyika zitsulo kapena pulasitiki. Zoyikapo zimayikidwa mu nkhungu musanabaya pulasitiki yosungunuka. Pulasitiki ikazizira ndi kulimba, gawolo ndi choyikapo zimamangiriridwa kosatha. Zopangira zoyika zimagwiritsidwa ntchito ngati malo omwe amafunikira mphamvu, kulimba, kapena kukongola.

- Overmolding Overmolding ndi njira yomwe gawo limawumbidwa kuposa lina. Nthawi zambiri amagwiritsidwa ntchito pamaudindo omwe amafunikira kukhudza kofewa kapena kugwira bwino. Kuchulukitsa kumaphatikizapo kukhazikitsa gawo laling'ono kapena gawo loyambira kenako ndikuwumba chinthu chachiwiri pamwamba pake. Chinthu chachiwiri chikhoza kukhala pulasitiki yamtundu wina, mphira, kapena thermoplastic elastomer.

Pomaliza, kusankha kwa zida zomangira jakisoni kumatengera mtundu wa gawo lomwe likupangidwa, kuchuluka kofunikira, komanso kuchuluka kwa zovuta zomwe zimakhudzidwa ndi kapangidwe ka gawolo. Kusankha zida zoyenera ndikofunikira kuti zitsimikizire kuti ntchitoyi ndi yabwino komanso yotsika mtengo.

Mapangidwe Opangira Majekeseni

Kumangira jekeseni ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga zida zapulasitiki. Kupanga magawo opangira jekeseni kumafuna kumvetsetsa bwino njira, zipangizo, ndi ndondomeko zopangira zomwe ziyenera kutsatiridwa kuti tsatanetsataneyo apangidwe bwino. Nawa malangizo opangira ma jakisoni omwe muyenera kukumbukira:

Makulidwe a khoma, makulidwe a khoma la gawolo ayenera kukhala yunifolomu komanso woonda momwe angathere ndikusunga mphamvu ndi magwiridwe antchito. Izi zimathandizira kuchepetsa nthawi yozizirira komanso yozungulira komanso kuchepetsa chiwopsezo cha zopindika ndi zozama.

Nthiti ndi Mabwana Nthiti ndi mabwana angagwiritsidwe ntchito kuonjezera mphamvu ndi kuuma kwa gawolo. Nthiti zisapitirire 60% ya makulidwe a khoma, ndipo mabwana akuyenera kukhala 1.5 kuwirikiza mwadzina.

Draft Angle, Kujambula koyenera kwa madigiri osachepera 1-2 kuyenera kugwiritsidwa ntchito pamalo onse oyimirira kuti athandizire kutulutsa gawo ndikupewa kuwonongeka kwa nkhungu.

Fillets ndi Radii Sharp ngodya ndi m'mphepete ziyenera kupewedwa kuti mupewe kupsinjika maganizo, zomwe zingayambitse kusweka ndi kulephera. M'malo mwake, ma fillets ndi ma radii ayenera kugawa kupsinjika ndikuwongolera mphamvu ya gawolo.

Ma Gates ndi Othamanga Malo ndi mapangidwe a zipata ndi othamanga ndizofunikira kwambiri kuti akwaniritse mbali yabwino. Zolowera ziyenera kukhala zazing'ono momwe zingathere mu gawo lakuda kwambiri la gawolo. Othamanga ayenera kupangidwa kuti achepetse kutsika kwa kuthamanga ndikuwonjezera kuthamanga.

Kumaliza Pamwamba Kumapeto kwa gawoli kuyenera kufotokozedwa kutengera zomwe mukufuna. Kutsirizitsa kwapamwamba kungafunike pazidutswa zowoneka, pamene mapeto apansi apansi angakhale ovomerezeka pazigawo zobisika.

Kusankha Zinthu Zomwe zasankhidwa pagawoli ziyenera kukhala zoyenera kuumba jekeseni ndikukwaniritsa zofunikira zamakina, zotentha, komanso zamankhwala.

Ntchito Zachiwiri mu Kumangirira Jakisoni

Kumangira jekeseni ndi njira yosinthika yomwe imagwiritsidwa ntchito popanga magawo osiyanasiyana apulasitiki. Kuphatikiza pa kuumba koyambirira, maudindo ambiri amafunikira ntchito zachiwiri kuti akwaniritse mawonekedwe omwe akufuna, kumaliza, kapena magwiridwe antchito. Nawa machitidwe achiwiri a tsiku ndi tsiku poumba jekeseni:

- Kucheka ndiko kuchotsa zinthu zochulukirapo pagawo lowumbidwa zitatulutsidwa mu nkhungu. Izi zimachitidwa pogwiritsa ntchito makina osindikizira kapena makina a CNC. Kudula kumafunika kuti mukwaniritse mawonekedwe omaliza ndi kukula kwa gawolo.

- Kuwotcherera kumaphatikiza magawo awiri apulasitiki kapena kupitilira apo pogwiritsa ntchito kutentha, kukakamiza, kapena kuphatikiza zonse ziwiri. Izi nthawi zambiri zimagwiritsidwa ntchito popanga zinthu zazikulu kapena zovuta kwambiri zomwe sizingapangidwe mu nkhungu imodzi.

- Kukongoletsa ndi njira yowonjezerapo zinthu zowoneka kapena zogwira ntchito pamwamba pa gawo lopangidwa. Izi zingaphatikizepo kujambula, kusindikiza, kulemba zilembo, kapena kugwiritsa ntchito kapangidwe kake kapena pateni.

- Assembly ndi njira yolumikizira magawo angapo kuti mupange chinthu chathunthu. Izi zitha kuchitika pogwiritsa ntchito zomangira, zomatira, kapena njira zina zolumikizirana.

- Insert Molding Insert ndikumangira pulasitiki kuzungulira chitsulo chopangidwa kale kapena pulasitiki. Izi nthawi zambiri zimagwiritsidwa ntchito popanga magawo okhala ndi mphamvu yayikulu kapena kulimba.

- Overmolding Overmolding ndi njira yopangira chinthu chachiwiri pagawo lomwe linapangidwa kale. Izi zitha kuwonjezera kukhudza kofewa, kuwongolera kugwira, kapena kupanga chidutswa chamitundu iwiri kapena chamitundu yambiri.

- Chophimbacho chimagwiritsa ntchito chingwe chopyapyala pamwamba pa gawolo kuti liwoneke bwino, likhale lolimba, kapena zina. Izi zingaphatikizepo zokutira monga chrome, nickel, kapena zokutira za ufa.

Ubwino Pulasitiki jekeseni akamaumba

Kumangira jakisoni wa pulasitiki ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga zida zapulasitiki zolondola kwambiri, zosasinthika, komanso zabwino. Kumaphatikizapo kubaya pulasitiki wosungunuka m'bowolo ndikulola kuti izizizire ndi kulimba. Nawa maubwino ena opangira jakisoni wa pulasitiki:

- Kuchita Bwino Kwambiri ndi Kupanga Majekeseni a Pulasitiki ndi njira yabwino kwambiri komanso yodzipangira yokha yomwe imatha kupanga magawo ambiri osasinthika komanso abwino. Ndi ukadaulo wapamwamba wopanga, nthawi yozungulira yopangira imatha kuchepetsedwa kukhala masekondi, zomwe zimalola kupanga kwapamwamba kwambiri kwa magawo ovuta komanso ovuta.

- Kukonzekera Kwapamwamba Kwambiri ndi Kumangirira Jakisoni kumawonjezera kulondola komanso kulondola pakupanga magawo ovuta komanso ovuta. Makina oyendetsedwa ndi makompyuta ndi mapulogalamu apamwamba amathandizira kulolerana kolimba ndikubwerezabwereza komanso kulondola.

- Versatility jekeseni akamaumba ndi njira yosunthika yomwe imatha kupanga magawo osiyanasiyana apulasitiki amitundu yosiyanasiyana, mawonekedwe, ndi zovuta. Njirayi ingagwiritsidwe ntchito kupanga chirichonse kuchokera ku tizidutswa tating'ono tating'onoting'ono tokhala ndi zambiri mpaka zazikulu ndi ma geometries ovuta.

- Material Flexibility jekeseni akamaumba akhoza kugwiritsa ntchito zipangizo zosiyanasiyana pulasitiki, kuphatikizapo thermoplastics, thermosets, ndi elastomers. Izi zimalola kupanga magawo okhala ndi makina osiyanasiyana, matenthedwe, ndi mankhwala.

- Low Waste Production Injection molding ndi njira yopangira zinyalala zochepa chifukwa imatulutsa zinyalala zochepa panthawi yopanga. Zinthu zilizonse zochulukirapo zitha kusinthidwanso mosavuta ndikugwiritsiridwanso ntchito popanga, kupangitsa kuti ikhale yogwirizana ndi chilengedwe.

- Kuchepetsa Mtengo Wogwira Ntchito Kuchuluka kwa makina opangira jakisoni kumachepetsa kufunikira kwa njira zovutirapo, kumachepetsa kwambiri ndalama zogwirira ntchito. Izi zimachepetsanso chiwopsezo cha zolakwika za anthu, kuwongolera mtundu wa chinthu chomaliza komanso kusasinthika.

- Kuchepetsa Kumayambiriro kwa Ntchito Kuumba jekeseni kumapanga mbali zolondola kwambiri komanso zosasinthasintha, kuchepetsa kufunika kwa ntchito zopanga pambuyo pakupanga monga kudula, kubowola, kapena mphero. Izi zimachepetsa nthawi yopangira komanso mtengo wa chinthu chomaliza.

- Consistency ndi Quality jakisoni akamaumba kumapanga mbali ndi mkulu mlingo kugwirizana ndi khalidwe. Ukadaulo wapamwamba kwambiri komanso makina oyendetsedwa ndi makompyuta amawonetsetsa kuti chilichonse chikhale chofanana m'mawonekedwe, kukula, ndi mtundu.

- Design Flexibility jakisoni woumba amapereka kusinthasintha kwakukulu kwa mapangidwe, chifukwa amalola kupanga magawo okhala ndi ma geometries ovuta, mafupipafupi, ndi tsatanetsatane wovuta. Izi zidzathandiza opanga kupanga zidutswa zokhala ndi mawonekedwe apadera ndi ntchito zomwe sizingapangidwe pogwiritsa ntchito njira zina zopangira.

- Zotsika mtengo pakuumba jekeseni wa High-Volume Production ndi njira yotsika mtengo popanga zida zapulasitiki. Mtengo woyambira wopangira zida ukhoza kukhala wokwera, koma mtengo wagawo lililonse umachepa pamene kuchuluka kwa zopanga kumawonjezeka. Izi zimapangitsa kukhala njira yabwino yopangira magawo ambiri.

Kumangira jakisoni wa pulasitiki kumapereka zabwino zambiri, zomwe zimapangitsa kukhala chisankho chodziwika bwino popanga zida zapulasitiki. Kuchita kwake kwakukulu, kulondola, kusinthasintha, kusinthasintha kwa zinthu, kutsika kwa zinyalala, kuchepetsa ndalama zogwirira ntchito, komanso kusasinthasintha ndi khalidwe zimapangitsa kuti ikhale njira yabwino yogwiritsira ntchito zosiyanasiyana. Kukhoza kupanga magawo ovuta komanso ovuta kwambiri omwe ali ndi mapangidwe apamwamba komanso okwera mtengo pakupanga kwapamwamba kwambiri kumapangitsa kuti pakhale njira yopangira kwambiri.

Kuipa kwa Pulasitiki jakisoni Kumangira

Kumangira jekeseni wa pulasitiki ndi njira yopangira yomwe imagwiritsidwa ntchito kwambiri yomwe imaphatikizapo kubaya pulasitiki yosungunuka mu nkhungu kuti ipange pulasitiki ndi zinthu zambiri. Ngakhale kuumba jekeseni wa pulasitiki kuli ndi ubwino wambiri, palinso zovuta zingapo. Nazi zina mwazovuta zazikulu pakuumba jekeseni wa pulasitiki:

- Mtengo wapamwamba wopangira zida: Mtengo wopangira ndi kupanga nkhungu yopangira jakisoni wapulasitiki ukhoza kukhala wokwera kwambiri. Izi ndichifukwa choti nkhungu iyenera kupangidwa kuchokera kuzinthu zapamwamba kwambiri ndikumangidwa bwino kuti ipange gawo lomwe mukufuna. Kuonjezera apo, mtengo wopangira ndi kupanga nkhungu ukhoza kukhala woletsedwa pamayendedwe ang'onoang'ono, zomwe zimapangitsa kuti jekeseni wa pulasitiki ukhale wochepa kwambiri pakupanga ndalama zochepa.

- Nthawi yayitali: Njira yopangira ndi kupanga nkhungu yopangira jakisoni wa pulasitiki imatha kutenga nthawi yayitali, yomwe ingachedwetse kupanga zida zapulasitiki. Izi zitha kukhala zovuta makamaka kwa mabizinesi omwe akufunika kuyankha mwachangu kusintha kwa msika kapena kupanga zinthu zatsopano.

- Kusinthasintha kwapang'onopang'ono: Chikombolechi chikapangidwa ndikupangidwa, zimakhala zosavuta komanso zotsika mtengo kusintha mapangidwe kapena kusintha njira yopangira. Izi zitha kuchepetsa kusinthasintha kwa jekeseni wa pulasitiki ndikupangitsa kuti ikhale yosayenerera kupanga zinthu zamtundu kapena zamtundu umodzi.

- Zokhudza chilengedwe: Kuumba jekeseni wa pulasitiki kumadalira mapulasitiki ambiri, omwe angakhale ndi zotsatira zoipa pa chilengedwe. Zinyalala za pulasitiki ndizovuta kwambiri zachilengedwe, ndipo kuumba jekeseni wa pulasitiki kungayambitse vutoli. Kuphatikiza apo, njira yopangira zinthu zapulasitiki imafuna kugwiritsa ntchito mphamvu ndi zinthu zachilengedwe, zomwe zitha kusokoneza chilengedwe.

- Kukwera kwa zinyalala: Kuumba jekeseni wa pulasitiki kumatha kutulutsa zida zazikulu, zomwe zingakhale zodula kutaya kapena kuzikonzanso. Kuonjezera apo, kupanga zinthu zowonongeka kungathe kuonjezera mtengo wonse wopangira ndikuchepetsa mphamvu ya kupanga.

- Zosankha zazing'ono: Kumangira jekeseni wa pulasitiki kumagwiritsidwa ntchito kwambiri popanga magawo ndi zinthu kuchokera ku zida za thermoplastic, zomwe zimakhala ndi zochepa poyerekeza ndi zida zina monga zitsulo kapena zoumba. Izi zitha kupangitsa kuumba kwa jekeseni wa pulasitiki kukhala kosayenera kwa mapulogalamu omwe amafunikira mphamvu zambiri, kukana kutentha, kapena zinthu zina zapamwamba.

Zochepera pa Pulasitiki jakisoni Kumangira

Ngakhale kuumba jekeseni wa pulasitiki kumapereka ubwino wambiri, zolepheretsa zina zimagwirizanitsidwa ndi ndondomekoyi. Nawa zolephera za jekeseni wa pulasitiki:

Mtengo Wokwera Kwambiri Wopangira Zida: Mtengo woyambira wopanga ndi kupanga nkhungu ukhoza kuwonjezeka. Chikombolecho chimayenera kukhala chokhazikika komanso cholimba kuti chisasunthike mobwerezabwereza, ndipo izi zingafunike ndalama zambiri zam'tsogolo, makamaka za nkhungu zovuta kapena zazikulu.

Nthawi Yotsogolera: Nthawi yotsogolera yopanga nkhungu ikhoza kukhala yofunikira, kuyambira masabata mpaka miyezi, malingana ndi zovuta ndi kukula kwa nkhungu. Izi zitha kuchedwetsa nthawi yopanga, makamaka pama projekiti omwe amakhudzidwa ndi nthawi.

Zopinga Zopanga: Kupanga jakisoni kumakhala ndi zoletsa zina zomwe ziyenera kuganiziridwa. Mwachitsanzo, kukwaniritsa makulidwe a khoma lofanana mbali zonse ndikofunikira kuti mutsimikizire kudzazidwa koyenera komanso kuziziritsa. Kuphatikiza apo, ma angles olembera amafunikira pamalo oyima kuti athe kutulutsa mosavuta nkhungu.

Kuchepetsa Kukula Kwagawo: Kujambula kwa jekeseni ndikoyenera kwambiri kupanga magawo ang'onoang'ono mpaka apakatikati. Zigawo zazikulu zingafunike zida zapadera ndi nkhungu zazikulu, zomwe zimawonjezera mtengo ndi zovuta.

Kusankha Zinthu: Ngakhale kuumba jekeseni kumalola zipangizo zapulasitiki zambiri, kusankha kwazinthu kumakhalabe kochepa poyerekeza ndi njira zina zopangira. Zipangizo zomwe zimakhala ndi malo osungunuka kwambiri kapena makhalidwe abwino othamanga sizingakhale zoyenera kuumba jekeseni.

Kumaliza Pamwamba: Njira yopangira jakisoni imatha kupangitsa kuti mizere yolumikizana iwoneke kapena mizere yolekanitsa pagawolo. Kukwaniritsa kutha kwapamwamba kumatha kukhala kovuta, ndipo njira zina, monga kupukuta kapena zokutira, zingafunike.

Zochepa Zochepa: Ma Undercuts ndi mawonekedwe kapena tsatanetsatane wa gawo lomwe limalepheretsa kuchotsedwa mosavuta mu nkhungu. Ma undercuts amatha kusokoneza njira yotulutsa ndipo amafuna mawonekedwe owonjezera a nkhungu kapena ntchito zachiwiri kuti mukwaniritse gawo lomwe mukufuna.

Zosankha Zokonza Zochepa: Ngati nkhungu yawonongeka kapena ikufunika kusinthidwa, ikhoza kukhala yodula komanso yowononga nthawi kukonza kapena kusintha nkhungu yomwe ilipo. Nthawi zina, nkhungu yatsopano ingafunike kupangidwa, zomwe zimapangitsa kuti pakhale ndalama zowonjezera komanso kuchedwa.

Ngakhale pali zolephera izi, kuumba jekeseni wa pulasitiki kumakhalabe njira yosunthika komanso yogwiritsidwa ntchito kwambiri popanga zida zapulasitiki. Poganizira mozama zolepheretsa izi panthawi yokonzekera ndi kupanga, ndizotheka kuchepetsa mphamvu zawo ndikugwiritsa ntchito bwino ubwino wa jekeseni.

Kugwiritsa Ntchito Plastic Injection Molding

Kumangira jekeseni wa pulasitiki ndi njira yopangira zinthu zambiri zomwe zimatha kupanga magawo ambiri apulasitiki. Nazi zina mwazogwiritsa ntchito popanga jakisoni wa pulasitiki:

- Consumer Products: jekeseni akamaumba chimagwiritsidwa ntchito kupanga zinthu zosiyanasiyana, monga zoseweretsa, kitchenware, ndi zamagetsi. Njirayi imatha kupanga magawo apamwamba kwambiri okhala ndi ma geometries ovuta komanso miyeso yolondola, ndikupangitsa kuti ikhale yabwino pazinthu zomwe zimafunikira kulolerana kolimba komanso mawonekedwe ovuta.

- Zigawo Zagalimoto: Zida zambiri zamapulasitiki zamagalimoto, monga zida za dashboard, zogwirira zitseko, ndi kuyatsa, zimapangidwa pogwiritsa ntchito jekeseni. Njirayi imalola kupanga ma voliyumu apamwamba komanso mtundu wokhazikika, ndikupangitsa kuti ikhale njira yotsika mtengo kwa opanga magalimoto.

- Zipangizo Zachipatala: Kumangira jekeseni kumagwiritsidwa ntchito popanga zida zamankhwala, monga ma syringe, ma inhalers, ndi zida zowunikira. Njirayi imatha kupanga zigawo zolondola kwambiri komanso zosasinthika, kuonetsetsa kuti zidazo ndi zodalirika komanso zodalirika.

- Kupaka: Kumangira jekeseni kumagwiritsidwa ntchito kwambiri popanga zotengera zapulasitiki, monga zotengera, zivindikiro, ndi zipewa. Njirayi imatha kukhala ndi magawo omwe ali ndi miyeso yofananira komanso kumaliza kwapamwamba, zomwe zimapangitsa kuti zikhale zoyenera kulongedza ndi mawonekedwe owoneka bwino komanso otetezeka.

- Zamlengalenga ndi Chitetezo: Kumangirira jekeseni kumapanga zinthu zosiyanasiyana zakuthambo ndi chitetezo, monga zamkati mwa ndege, kuyatsa, ndi njira zoyankhulirana. Njirayi imatha kukhala ndi magawo okhala ndi zinthu zopepuka, zolimba, zomwe zimawapangitsa kukhala oyenera kugwiritsa ntchito zomwe zimafunikira mphamvu zolimbitsa thupi kwambiri.

- Kumanga: Kumangira jekeseni kumatha kupanga zinthu zosiyanasiyana zomangira, monga matailosi apulasitiki, denga, ndi mphepete. Njirayi imatha kukhala ndi magawo omwe ali ndi miyeso yofananira komanso kumaliza kwapamwamba, zomwe zimapangitsa kukhala njira yabwino kwamakampani omanga.

- Masewera ndi Kusangulutsa: Kumangira jakisoni kumagwiritsidwa ntchito kwambiri popanga zida zamasewera, monga makalabu a gofu, ma racket a tennis, ndi zida zanjinga. Njirayi imatha kupanga magawo okhala ndi zida zopepuka komanso ma geometries enieni, kuwonetsetsa kuti zida zake zimagwira ntchito komanso kulimba.

Ponseponse, kuumba jekeseni wa pulasitiki ndi njira yosunthika komanso yogwiritsidwa ntchito kwambiri yomwe imatha kupanga zida zapulasitiki zapamwamba pazogwiritsa ntchito zosiyanasiyana. Njirayi imatha kukonzedwa kuti ikwaniritse zofunikira zapangidwe ndi kupanga, ndikupangitsa kuti ikhale njira yosangalatsa kwa opanga m'mafakitale angapo.

Makampani Opangira Magalimoto ndi Pulasitiki Jakisoni Wopanga

Makampani opanga magalimoto ndiwogwiritsa ntchito kwambiri ukadaulo wopangira jakisoni wapulasitiki. Njira yopangira jekeseni wa pulasitiki yasintha kupanga mbali zamagalimoto ndi zigawo zake, ndikupangitsa kuti zitheke kupanga mawonekedwe ovuta kwambiri komanso olondola kwambiri. Nazi zina mwa njira zomwe jekeseni wa pulasitiki amagwiritsidwa ntchito popanga magalimoto:

- Zigawo zamkati: Kujambula kwa pulasitiki kumapanga zinthu zambiri zamkati, kuphatikizapo zida za dashboard, mapanelo a zitseko, zidutswa zochepetsera, ndi zina. Zigawozi zitha kupangidwa ndi mawonekedwe otsogola ndi mawonekedwe ake ndikusinthidwa kuti zigwirizane ndi mtundu uliwonse wagalimoto ndi momwe zimagwirira ntchito.

- Ziwalo Zakunja: Kumangira jekeseni wa pulasitiki kumagwiritsidwanso ntchito kupanga zinthu zosiyanasiyana zakunja, kuphatikiza ma bumpers, ma grilles, magalasi am'mbali, ndi zina zambiri. Zigawozi zitha kupangidwa kuti zizitha kupirira nyengo yoipa ndipo zimapangidwa ndi mitundu ingapo komanso zomaliza.

- Zigawo za pansi pa hood: Kumangira jekeseni wa pulasitiki kumapanga zinthu zambiri za pansi pa hood, kuphatikizapo zophimba injini, makina opangira mpweya, ndi zida zoziziritsa. Zigawozi zimafuna kutentha kwakukulu ndi kukana kwa mankhwala, zomwe zingatheke ndi zipangizo za thermoplastic.

- Zida zamagetsi ndi zamagetsi: Kumangira jekeseni kwa pulasitiki kumapanga zinthu zosiyanasiyana zamagetsi ndi zamagetsi, kuphatikizapo zolumikizira, nyumba, ndi masensa. Zigawozi zimafuna kulondola kwambiri komanso kudalirika, zomwe zingatheke ndi kulondola komanso kusasinthasintha kwa jekeseni wa pulasitiki.

- Kupepuka: Kumangira jekeseni wa pulasitiki nthawi zambiri kumagwiritsidwa ntchito popanga zida zopepuka zomwe zimathandiza kuchepetsa kulemera kwagalimoto, kukonza bwino mafuta komanso kuchepetsa mpweya. Kuchepetsa kungathenso kuwongolera kagwiridwe ndi kachitidwe kagalimoto.

Makampani Opanga Zamankhwala ndi Pulastiki jakisoni

Kumangira jekeseni wa pulasitiki kumagwiritsidwa ntchito kwambiri m'makampani azachipatala kuti apange zida ndi zida zosiyanasiyana zamankhwala. Njira yopangira jakisoni wa pulasitiki imalola kupanga mawonekedwe ovuta kwambiri komanso olondola kwambiri, ndikupangitsa kuti ikhale njira yabwino yopangira ntchito zambiri zamankhwala. Nazi zina mwa njira zomwe jekeseni wa pulasitiki amagwiritsidwa ntchito m'makampani azachipatala:

- Zipangizo zachipatala: Kujambula kwa pulasitiki kumapanga zipangizo zamankhwala zosiyanasiyana, kuphatikizapo zida zopangira opaleshoni, zida zowunikira, machitidwe operekera mankhwala osokoneza bongo, ndi zina zotero. Zidazi nthawi zambiri zimafuna kulondola kwambiri komanso kulondola, ndipo jekeseni wa pulasitiki akhoza kukwaniritsa zofunikirazi.

- Implants: Kumangira jekeseni wa pulasitiki kumagwiritsidwanso ntchito popanga mitundu yosiyanasiyana ya implants, kuphatikizapo zolowa m'malo, zoikamo mano, ndi zina. Ma implants awa atha kupangidwa kuti agwirizane ndi thupi la wodwalayo ndikupangidwa ndi zinthu zomwe zimayenderana ndi biocompatible.

- Zida za labotale: Kumangira jekeseni kwa pulasitiki kumapanga ma pipette, ma microplates, ndi machubu oyesera. Zigawozi zimafuna kulondola kwambiri komanso kulondola kuti zitsimikizire zotsatira zodalirika.

- Kupaka: Kumangira jekeseni wa pulasitiki kumagwiritsidwa ntchito popanga zida zachipatala, kuphatikiza makina osabala otchinga ndi kuyika kwazinthu zamtundu uliwonse. Njira zopakirazi zitha kuthandizira kuti chida chachipatala chikhale cholimba komanso chokhazikika.

- Zipangizo zogwiritsira ntchito kamodzi: Kuumba jekeseni wa pulasitiki kaŵirikaŵiri kumapanga zipangizo zogwiritsira ntchito kamodzi monga majakisoni, singano, ndi ma catheter. Zipangizozi zitha kupangidwa mokweza kwambiri pamtengo wotsika ndipo zitha kuthandiza kupewa kufalikira kwa matenda m'malo azachipatala.

Consumer Products ndi Plastic Injection Molding

Kumangira jekeseni wa pulasitiki kumagwiritsidwa ntchito kwambiri popanga zinthu za ogula chifukwa cha kusinthasintha kwake, kuchita bwino, komanso kutsika mtengo. Njira yopangira jakisoni wa pulasitiki imalola kupanga mawonekedwe ovuta kwambiri komanso olondola kwambiri, ndikupangitsa kuti ikhale njira yabwino yopangira ntchito zambiri za ogula. Nazi zina mwa njira zomwe jekeseni wa pulasitiki amagwiritsidwa ntchito popanga zinthu za ogula:

- Zoseweretsa: Kumangira jekeseni wa pulasitiki kumapanga zoseweretsa zosiyanasiyana, kuchokera pazithunzi zazing'ono mpaka zazikulu zosewerera. Njirayi imalola kupanga mapangidwe ovuta komanso tsatanetsatane ndikupanga zoseweretsa zamitundu yosiyanasiyana ndi zida.

- Katundu wapakhomo: Kumangira jakisoni wa pulasitiki kumapanga zinthu zosiyanasiyana zapakhomo, kuphatikiza ziwiya zakukhitchini, zotengera zosungira, ndi zoyeretsera. Zogulitsazi zitha kupangidwa kuti zikhale zolimba, zopepuka komanso zosavuta kugwiritsa ntchito.

- Zamagetsi: Kumangira jakisoni wa pulasitiki kumapanga zinthu zambiri zamagetsi, kuphatikiza nyumba zamakompyuta, ma foni, ndi ma charger. Kulondola ndi kulondola kwa ndondomekoyi kumatsimikizira kuti zigawozi zimapangidwa ndipamwamba kwambiri komanso zodalirika.

- Zinthu zosamalira munthu: Kuumba jekeseni wa pulasitiki kumapanga zinthu zosamalira mwapadera, kuphatikizapo misuwachi, malezala, ndi maburashi. Zogulitsazi zimafuna kulondola kwambiri komanso kulondola kuti zitsimikizire kugwiritsa ntchito mosavuta komanso chitetezo.

- Zida zamagalimoto: Kumangirira kwa pulasitiki kumapanga zida zamagalimoto zosiyanasiyana, kuphatikiza zida zapa dashboard, zonyamula makapu, ndi zina zambiri. Zigawozi zitha kupangidwa kuti zikhale zopepuka, zolimba, komanso zosagwirizana ndi kuwonongeka kwa ntchito tsiku ndi tsiku.

Zolinga Zachilengedwe mu Pulasitiki jakisoni Woumba

Kumangira jekeseni wa pulasitiki ndi njira yomwe imagwiritsidwa ntchito kwambiri popanga koma imakhala ndi tanthauzo lalikulu la chilengedwe. Nazi zina mwazachilengedwe pakuumba jakisoni wa pulasitiki:

- Kusankha kwazinthu: Kusankha zinthu zapulasitiki zomwe zimagwiritsidwa ntchito popanga jakisoni zitha kukhudza kwambiri chilengedwe. Zida zina zimatha kuwonongeka kapena kubwezeretsedwanso, pomwe zina sizitha. Kugwiritsa ntchito zinthu zowola kapena zobwezerezedwanso kungathandize kuchepetsa kuwonongeka kwa chilengedwe cha jekeseni wa pulasitiki.

- Kugwiritsa ntchito mphamvu: Kuumba jekeseni wa pulasitiki kumafuna mphamvu zambiri kuti asungunuke pulasitiki ndikuyibaya mu nkhungu. Zida ndi njira zogwiritsira ntchito mphamvu, monga makina amagetsi ndi makina otsekedwa, amatha kuchepetsa kugwiritsa ntchito mphamvu komanso kuwononga chilengedwe.

- Kasamalidwe ka zinyalala: Kuumba jekeseni wa pulasitiki kumatulutsa zinyalala kuchokera ku zinthu zochulukira, zosokonekera, ndi zoyikapo. Njira zoyenera zoyendetsera zinyalala, monga kukonzanso ndikugwiritsanso ntchito zinyalala, zingathandize kuchepetsa kuwonongeka kwa chilengedwe cha jekeseni wa pulasitiki.

- Kugwiritsa ntchito mankhwala: Mankhwala ena opangira jakisoni wa pulasitiki, monga zotulutsa nkhungu ndi zosungunulira, zimatha kuwononga chilengedwe. Kugwiritsa ntchito njira zina zowononga chilengedwe kapena kuchepetsa kugwiritsa ntchito mankhwalawa kungathandize kuchepetsa kuwonongeka kwa chilengedwe.

- Zoganizira za mapeto a moyo: Zinthu za pulasitiki zopangidwa ndi jekeseni nthawi zambiri zimakhala zotayira, zomwe zingatenge zaka mazana ambiri kuti ziwonongeke. Kupanga zinthu kuti zitha kubwezeretsedwanso kapena kuwonongeka kwachilengedwe kumatha kuchepetsa kukhudzidwa kwa chilengedwe ndi jekeseni wa pulasitiki.

Tsogolo la Pulasitiki jakisoni Kumangira

Tsogolo la jekeseni wa pulasitiki likuwoneka bwino, chifukwa kupita patsogolo kwa teknoloji ndi zipangizo zikuyembekezeka kuti ntchitoyi ikhale yogwira mtima, yotsika mtengo, komanso yokhazikika. Nazi zina mwazomwe zikuchitika komanso zomwe zingapangitse tsogolo la jekeseni wa pulasitiki:

- Kupanga zowonjezera: Kupanga kowonjezera, komwe kumadziwikanso kuti kusindikiza kwa 3D, ndiukadaulo womwe ukubwera womwe ungathe kusintha jekeseni wa pulasitiki. Pogwiritsa ntchito kusindikiza kwa 3D kuti apange zisankho, opanga amatha kuchepetsa kwambiri nthawi ndi mtengo wokhudzana ndi njira zamakono zopangira nkhungu.

- Kupanga mwanzeru: Kupanga mwanzeru, komwe kumaphatikizapo zodzichitira, kusanthula deta, ndi kuphunzira pamakina, kukuyembekezeka kusinthira jekeseni wa pulasitiki. Opanga amatha kukonza bwino, kuchepetsa zinyalala, ndikuwonjezera zokolola pogwiritsa ntchito masensa ndi kusanthula deta kuti akwaniritse bwino njira.

- Zipangizo zokhazikika: Zida zokhazikika, monga bioplastics ndi mapulasitiki obwezerezedwanso, zikuchulukirachulukira mumakampani opanga jakisoni wapulasitiki. Zida zimenezi zimapereka ubwino wa chilengedwe ndipo zingathandize opanga kukwaniritsa zolinga zokhazikika.

- Micro molding: Micro molding, yomwe imaphatikizapo kupanga tizigawo ting'onoting'ono mwatsatanetsatane kwambiri, ikukhala yofunika kwambiri m'mafakitale monga zaumoyo ndi zamagetsi. Kupita patsogolo kwaukadaulo ndi zida zikuyembekezeka kupangitsa kuumba kwapang'ono kukhala kosavuta komanso kotsika mtengo.

- Kusintha Mwamakonda: Pamene ogula amafuna zinthu zambiri zamunthu, jekeseni wa pulasitiki akuyembekezeka kukhala wosinthika komanso wosinthika. Kupita patsogolo kwaukadaulo, monga kuyankha kwanthawi yeniyeni ndi kuphunzira pamakina, kumathandizira opanga kupanga zinthu zomwe zimakonda mwachangu komanso moyenera.

Kutsiliza:

Kumangira jekeseni wa pulasitiki ndi njira yosinthika komanso yothandiza kwambiri yopangira zinthu zomwe zasintha kwambiri kupanga zinthu zambiri. Kuchokera pazida zamankhwala kupita ku zida zamagalimoto, kuumba jekeseni wa pulasitiki kumapereka maubwino ambiri kuposa njira zina zopangira, kuphatikiza mitengo yokwera kwambiri, kusinthasintha kwa mapangidwe, komanso kutsika mtengo. Ndi kupita patsogolo kosalekeza kwaukadaulo ndi zida, tsogolo la jekeseni wa pulasitiki likuwoneka lowala, ndipo izi zitha kukhala ndi gawo lofunikira kwambiri pamakampani opanga zaka zikubwerazi.