Thermoplastic Injection Molding

Thermoplastic jakisoni woumba ndi njira yotchuka yomwe imagwiritsidwa ntchito popanga magawo osiyanasiyana apulasitiki pamafakitale angapo. Kuchita zimenezi kumaphatikizapo kusungunula mapepala apulasitiki ndi kuwabaya mu nkhungu kuti apange mawonekedwe atatu. Kumangira jakisoni wa Thermoplastic ndikothandiza kwambiri komanso kotsika mtengo popanga zigawo zazikulu zapulasitiki zapamwamba zololera zolimba. Kalozera watsatanetsataneyu awunika mbali zosiyanasiyana za jekeseni wa thermoplastic, kuphatikiza zabwino ndi zovuta zake, mitundu ya ma thermoplastics omwe amagwiritsidwa ntchito, njira yopangira jakisoni, malingaliro amapangidwe, ndi zina zambiri.

Mbiri ya Thermoplastic Injection Molding

Mbiri yakuumba jekeseni wa thermoplastic imatenga zaka zambiri zakupita patsogolo kwaukadaulo, kupita patsogolo kwazinthu, komanso kugwiritsa ntchito mafakitale. Kuyambira pachiyambi chake chocheperako monga njira yopangira ma celluloid kupita kuukadaulo wamakono wamakono, kuumba jekeseni kumakhalabe njira yofunikira yopangira, kuyendetsa zinthu zatsopano komanso kupanga mafakitale osiyanasiyana.

- Zoyamba Zoyambirira:John Wesley Hyatt ndi mchimwene wake Yesaya adapanga makina oyamba opangira jakisoni, kutsata magwero a jekeseni wa thermoplastic mpaka kumapeto kwa zaka za zana la 19. Mu 1872, adapanga chipangizo chomwe chimagwiritsa ntchito plunger kulowetsa celluloid mu nkhungu, kupanga zinthu zolimba. Kupambana kumeneku kunayala maziko a njira yamakono yopangira jakisoni.

- Kupititsa patsogolo kwa Zida:Kumayambiriro kwa zaka za m'ma 20, kubweretsa ma polima opangidwa atsopano kunatsegula njira zatsopano zopangira jakisoni. Bakelite, phenolic resin, idakhala chinthu chodziwika bwino pakuwumba chifukwa champhamvu zake zotchingira magetsi. M'zaka zonse za m'ma 1930 ndi 1940, kupita patsogolo kwa chemistry ya polima kudapangitsa kuti pakhale zida zina zopangira thermoplastics, monga polystyrene ndi polyethylene, zomwe zidakulitsanso mitundu ingapo ya zida zoyenera kuumba jekeseni.

- Kutengera kwa Industrial: Kutengera kofala kwa jekeseni wa thermoplastic kunayamba m'ma 1950 pomwe opanga adazindikira kukwera mtengo kwake komanso kusinthasintha kwake. Kuyambitsa makina othamanga kwambiri amalola nthawi yozungulira mwachangu komanso kuchuluka kwazinthu zopanga. Zotsatira zake, mitundu yosiyanasiyana ya zinthu zomwe zimagwiritsidwa ntchito pawekha komanso mafakitale zidakhalapo. Izi zinaphatikizapo zigawo za galimoto, zipangizo zapakhomo, ndi masewera.

- Zaukadaulo:Kwa zaka zambiri, teknoloji yopangira jekeseni ikupitirizabe kusintha. M'zaka za m'ma 1960, makina oyendetsedwa ndi makompyuta adatuluka, zomwe zinapangitsa kuti aziwongolera bwino momwe amawumba. Kuyambitsidwa kwa makina othamanga otentha m'zaka za m'ma 1980 kunachepetsa zinyalala ndikuwongolera bwino pakuchotsa kufunikira kwa othamanga ndi ma sprues. M'zaka zaposachedwa, ma automation, ma robotics, ndi kupita patsogolo kwa 3D kusindikiza kwasintha kwambiri ntchito yopanga jakisoni, kupangitsa mapangidwe ovuta komanso kuchepetsa nthawi yopanga.

- Kukhazikika ndi Kubwezeretsanso:Ndi zovuta zachilengedwe zomwe zikuchulukirachulukira, makampani opanga ma jakisoni atenga njira zokhazikika. Opanga apanga bio-based and recycled thermoplastics, kuchepetsa kudalira mafuta opangira mafuta. Kuphatikiza apo, matekinoloje okonzanso obwezeretsanso athandizira kukonzanso zinyalala zomwe zabwera pambuyo pa ogula komanso pambuyo pa mafakitale, kuchepetsa kuwononga chilengedwe cha jekeseni wa thermoplastic.

- Zam'tsogolo:Tsogolo la jekeseni wa thermoplastic likuwoneka ngati labwino. Makampaniwa akuyang'ana zatsopano monga jekeseni ya micro-injection ya tinthu tating'onoting'ono, njira zamitundu yambiri komanso zowonjezera pazigawo zovuta, ndikuphatikiza matekinoloje anzeru pakuwunika ndi kukhathamiritsa. Kuphatikiza apo, ofufuza amayembekeza kupita patsogolo kwa zinthu zomwe zimatha kuwonongeka komanso kupanga zowonjezera kuti zisinthe gawo, ndikupangitsa kuti jekeseni ikhale yokhazikika komanso yosinthika.

Ubwino wa Thermoplastic Injection Molding

Kumangira jakisoni wa Thermoplastic kumapereka zabwino zambiri kwa opanga. Amapereka kusinthasintha kwapangidwe, kulola kuti pakhale mapangidwe ovuta komanso ovuta okhala ndi zinthu zosiyanasiyana. Njirayi ndiyotsika mtengo, imachepetsa zinyalala zakuthupi ndikuchepetsa mtengo wamagulu. Kumangira jakisoni wa Thermoplastic kumathandizira zida zingapo, kumapereka kusinthasintha kwamagwiritsidwe osiyanasiyana.

- Kusinthasintha Kwapangidwe:Kumangirira jakisoni wa thermoplastic kumapangitsa kuti pakhale mapangidwe ovuta komanso ovuta okhala ndi mawonekedwe ngati mafupi, makoma opyapyala, ndi makulidwe osiyanasiyana, kupatsa opanga ufulu waukulu.

- Kuchita Mtengo: Njirayi ndiyothandiza kwambiri, imachepetsa zinyalala zakuthupi ndikuchepetsa mtengo wamagulu. Kupanga nthawi imodzi kwa magawo angapo komanso kupanga mwachangu kumathandizira kupulumutsa ndalama.

- Zinthu Zosiyanasiyana: Kumangira jakisoni wa Thermoplastic kumathandizira zida zosiyanasiyana, zomwe zimapangitsa opanga kusankha njira yoyenera kwambiri pakugwiritsa ntchito kulikonse, kuphatikiza zolimba kapena zosinthika, zowonekera kapena zowoneka bwino, komanso zida zolimbana ndi mankhwala.

- Mphamvu ndi Kukhalitsa:Ma jekeseni opangidwa ndi thermoplastics amatha kuwonetsa zinthu zabwino zamakina, monga kulimba kwambiri, kulimba, komanso kukana kukhudzidwa. Zosankha zolimbikitsira, monga magalasi kapena ulusi wa kaboni, zimawonjezera izi.

- Kusasinthasintha ndi Ubwino:Kumangirira jekeseni kumatsimikizira kusasinthika kwapang'onopang'ono komanso kulondola kwapang'onopang'ono, kumapereka kulolerana kolimba ndi zinthu zodalirika. Njirayi imaperekanso mawonekedwe osalala komanso ofananira pamwamba, kuchotsa kufunikira kwa ntchito zina zomaliza.

- Scalability ndi Mass Production:Jekeseni akamaumba ndi scalable kuchokera otsika kwambiri voliyumu, kuti akhale oyenera kupanga ambiri. Opanga akapanga nkhungu, amatha kupanga magawo ambiri ofanana ndi kusiyana kochepa.

- Kuphatikiza ndi Msonkhano:Ziwalo zopangidwa ndi jekeseni zimatha kuphatikizira zigawo zingapo mugawo limodzi, kuchepetsa kufunikira kwa njira zowonjezera zowonjezera. Kuphatikiza uku kumawonjezera magwiridwe antchito, kumachepetsa nthawi yophatikizira, ndikuchepetsa mtengo.

- Kukhazikika:Makampani opanga ma jakisoni akuwonetsa chidwi kwambiri pakukhazikika. Kupezeka kwa zinthu zochokera ku bio ndi zobwezerezedwanso kumathandizira kupanga zinthu zoteteza chilengedwe. Kugwiritsa ntchito bwino zinthu komanso kubwezeretsedwanso kwa ma thermoplastics kumathandizira kupanga njira yobiriwira.

Zopindulitsa izi zapangitsa kuti ikhale njira yopangira zogwiritsiridwa ntchito kwambiri m'mafakitale osiyanasiyana, kupereka njira zapamwamba, zotsika mtengo, komanso zosamalira zachilengedwe pazofunikira zovuta zazinthu.

Kuipa kwa Thermoplastic Injection Molding

Ngakhale kuumba jekeseni wa thermoplastic kumapereka zabwino zambiri, palinso zovuta zingapo. Opanga amayenera kuwunika mosamala zinthuzi ndikuziyesa molingana ndi phindu kuti adziwe kuyenera kwa jekeseni wa thermoplastic pakugwiritsa ntchito kwawo.

- Ndalama Zoyamba Kwambiri: Kukhazikitsa makina opangira jakisoni wa thermoplastic kumafuna ndalama zoyambira pakupangira nkhungu ndi kupanga ndikugula makina apadera. Mtengo wokhudzana ndi kupanga nkhungu ndi zida zitha kukhala zokulirapo, makamaka pamapangidwe ovuta komanso ovuta.

- Zolepheretsa Mapangidwe: Ngakhale kuumba kwa jekeseni wa thermoplastic kumapereka kusinthasintha kwa mapangidwe, zofooka zina zilipo. Mwachitsanzo, kukwaniritsa makulidwe a khoma lofanana mbali zonse kungakhale kovuta, zomwe zimapangitsa kuti pakhale kusiyana kwa kagawidwe kazinthu komanso zofooka zomwe zingachitike. Kuphatikiza apo, kukhalapo kwa ma undercuts kapena ma geometri ovuta kungafunike kugwiritsa ntchito mawonekedwe owonjezera a nkhungu kapena ntchito zachiwiri, kuchulukitsa mtengo ndi nthawi yopanga.

- Nthawi Yotsogola Kwambiri:Njira yopangira ndi kupanga nkhungu zopangira jakisoni zitha kutenga nthawi, zomwe zimapangitsa kuti pakhale nthawi yayitali yotsogolera pakupanga zinthu. Mapangidwe obwerezabwereza, kupanga nkhungu, ndi kuyesa kungawonjezere nthawi yofunikira pa nthawi yonse yopanga nthawi, yomwe singakhale yoyenera mapulojekiti omwe ali ndi nthawi yolimba.

- Zoletsa Kusankha Zinthu:Ngakhale kuumba jekeseni wa thermoplastic kumathandizira zida zosiyanasiyana, pali zolepheretsa komanso zopinga zina. Zida zina zitha kukhala ndi zofunikira pakukonza kapena kupezeka pang'ono, zomwe zimakhudza zosankha zamapangidwe ndi kusankha kwazinthu zantchito inayake.

- Mbali Zochepa Zochepa:Makina opangira jekeseni ali ndi malire a kukula, potengera kukula kwa chipangizocho komanso kukula kwa zisankho zomwe angakwanitse. Kupanga zigawo zazikulu kungafune zida zapadera kapena njira zina zopangira.

- Zachilengedwe:Pomwe makampaniwa akugwira ntchito kuti akhazikike, njira yopangira jakisoni wa thermoplastic imapangabe zinyalala, kuphatikiza zinyalala ndi sprues. Kutaya koyenera ndi kukonzanso zinthuzi ndikofunikira kuti muchepetse kuwonongeka kwa chilengedwe.

- Kuvuta kwa Process Optimization:Kukwaniritsa magawo oyenera a jekeseni wa thermoplastic kungakhale kovuta komanso kuwononga nthawi. Opanga amayenera kuwongolera mosamala ndikuwongolera kutentha, kuthamanga, kuzizira, ndi nthawi yozungulira kuti atsimikizire kusasinthasintha kwa gawo ndikuchepetsa kuwonongeka.

Mitundu ya Thermoplastics Yomwe Amagwiritsidwa Ntchito Popanga Jakisoni

Izi ndi zitsanzo zochepa chabe za thermoplastics zomwe zimagwiritsidwa ntchito popanga jakisoni. Chilichonse chimakhala ndi zinthu zapadera, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsira ntchito potengera mphamvu, kusinthasintha, kukana mankhwala, kuwonekera, ndi mtengo. Opanga ayenera kuganizira za izi ndi zofunikira posankha thermoplastic yoyenera pama projekiti awo opangira jakisoni.

- Polypropylene (PP):Polypropylene ndi thermoplastic yosunthika yomwe imagwiritsidwa ntchito popanga jakisoni. Amapereka kukana kwamankhwala kwabwino kwambiri, kachulukidwe kakang'ono, komanso mphamvu yabwino. PP (polypropylene) imakhala ndi ntchito zosiyanasiyana pakuyika, zida zamagalimoto, zida zapakhomo, ndi zida zamankhwala.

- Polyethylene (PE):Polyethylene ndi ina yogwiritsidwa ntchito kwambiri thermoplastic popanga jakisoni. Amapezeka m'mitundu yosiyanasiyana, monga polyethylene yapamwamba kwambiri (HDPE) ndi polyethylene yotsika kwambiri (LDPE). PE imapereka kukana kwamankhwala kwabwino, kulimba, komanso kusinthasintha, ndikupangitsa kuti ikhale yoyenera mabotolo, zotengera, ndi mapaipi.

- Polystyrene (PS):Polystyrene ndi thermoplastic yosunthika yomwe imadziwika chifukwa chomveka bwino, yokhazikika komanso yotsika mtengo. Imapeza kugwiritsidwa ntchito kofala pakuyika, katundu wogula, ndi zinthu zotayidwa. PS (polystyrene) imalola kukonzedwa mwachangu komanso imapereka kukhazikika kwa mawonekedwe, koma imatha kukhala yolimba komanso yotha kusokonezeka ndi kupsinjika kwa chilengedwe.

- Acrylonitrile Butadiene Styrene (ABS): ABS ndi thermoplastic yotchuka yomwe imadziwika chifukwa cha kukana kwake komanso kulimba kwake. Zimaphatikiza zinthu za acrylonitrile, butadiene, ndi styrene kuti apange zinthu zosunthika zoyenera zida zamagalimoto, nyumba zamagetsi, ndi zidole.

- Polyvinyl Chloride (PVC): PVC ndi thermoplastic yomwe imagwiritsidwa ntchito kwambiri yomwe imadziwika chifukwa cha kukana kwake kwamankhwala, kulimba, komanso kutsika mtengo. Ikhoza kukhala yolimba kapena yosinthika kutengera mapangidwe ndi zowonjezera zomwe zimagwiritsidwa ntchito. PVC (polyvinyl chloride) imapezeka nthawi zambiri pomanga, kutchinjiriza magetsi, zinthu zachipatala, ndi kulongedza.

- Polycarbonate (PC): Polycarbonate ndi thermoplastic yowoneka bwino yokhala ndi mphamvu yodabwitsa komanso kukana kutentha kwambiri. Imapeza kugwiritsidwa ntchito kofala pamapulogalamu omwe amafunikira kumveka bwino, monga zida zamagalimoto, zipewa zachitetezo, ndi zowonera zamagetsi.

- Nayiloni (Polyamide):Nylon ndi thermoplastic yamphamvu komanso yolimba yomwe imadziwika chifukwa cha makina ake abwino komanso kukana mankhwala. Imapeza kugwiritsidwa ntchito kofala m'mapulogalamu omwe amafunikira mphamvu zambiri, monga zida zamagalimoto, zida zamafakitale, ndi zinthu zogula.

- Polyethylene Terephthalate (PET):PET ndi thermoplastic yotchuka popanga mabotolo, zotengera, ndi zida zonyamula. Imapereka kumveka bwino, kukana kwa mankhwala, ndi zotchinga, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsa ntchito zakudya ndi zakumwa.

Makhalidwe a Thermoplastics Omwe Amagwiritsidwa Ntchito Popanga Jakisoni

Izi zamafuta a thermoplastics zimagwira ntchito yofunika kwambiri pakuzindikiritsa kuyenerera kwawo pamakina opangira majekeseni. Opanga ayenera kuganizira mozama za zinthuzi ndikusankha thermoplastic yoyenera kutengera momwe akufunira, momwe chilengedwe chimakhalira, komanso mtengo wake.

- Mawotchi Katundu:Ma thermoplastics omwe amagwiritsidwa ntchito popanga jakisoni amatha kuwonetsa mawonekedwe osiyanasiyana amakina, kuphatikiza kulimba kwamphamvu, kukana kukhudzidwa, komanso mphamvu yosinthika. Zinthu izi zimatsimikizira kuthekera kwazinthu kupirira mphamvu zogwiritsidwa ntchito komanso kulimba kwake pazonse zosiyanasiyana.

- Kukaniza Chemical:Ma thermoplastics ambiri omwe amagwiritsidwa ntchito popanga jakisoni amatha kukana mankhwala, zosungunulira, ndi mafuta. Katunduyu ndi wofunikira kwambiri pamagwiritsidwe omwe amakhudzana ndi malo ovuta kapena zinthu zowononga.

- Kutentha Kwambiri:Kukhazikika kwa kutentha kwa thermoplastics kumatanthawuza kutha kwawo kupirira kutentha kwapamwamba popanda kuwonongeka kwakukulu. Ma thermoplastics ena amawonetsa kukana kutentha kwambiri, kuwalola kukhalabe ndi makina awo ngakhale kutentha kwambiri.

- Zamagetsi:Ma thermoplastics omwe amagwiritsidwa ntchito popanga jakisoni amatha kukhala ndi mphamvu zenizeni zamagetsi, kuphatikiza kutsekereza magetsi, ma conductivity, kapena mphamvu ya dielectric. Zinthu izi ndizofunikira pakugwiritsa ntchito m'mafakitale amagetsi ndi zamagetsi, pomwe zida ziyenera kupereka magwiridwe antchito odalirika amagetsi.

- Kuwonekera ndi Kumveka:Ma thermoplastics ena, monga polycarbonate ndi PET, amapereka kuwonekera bwino komanso kumveka bwino, kuwapangitsa kukhala oyenera kugwiritsa ntchito zomwe zimafunikira mawonekedwe owoneka bwino. Opanga nthawi zambiri amagwiritsa ntchito zinthuzi pazinthu monga mawindo owonekera, magalasi, ndi zowonetsera.

- Kusinthasintha ndi Kulimba: Kusinthasintha ndi kulimba ndizofunikira kwambiri za thermoplastics zomwe zimagwiritsidwa ntchito pazinthu zomwe zimafunikira kukana komanso kulimba. Ma thermoplastics ena, monga ABS ndi nayiloni, amapereka kulimba kwambiri, kuwalola kupirira zovuta zobwereza popanda kusweka.

- Dimensional Kukhazikika:Kukhazikika kwa dimensional kumatanthauza kuthekera kwa thermoplastic kukhalabe ndi mawonekedwe ndi kukula kwake mosiyanasiyana, kuphatikiza kusintha kwa kutentha. Zipangizo zokhazikika bwino zimatsimikizira kukula kwa magawo, kuchepetsa chiopsezo cha kugwedezeka kapena kupotoza.

- Kugwirizana kwa Chemical:Kugwirizana kwa mankhwala a thermoplastics kumatanthawuza kutha kwawo kukana kuwonongeka kapena kuyanjana ndi mankhwala osiyanasiyana, kuphatikiza ma acid, maziko, ndi zosungunulira. Kuti muwonetsetse kuti ikugwira ntchito bwino, kusankha thermoplastic yomwe imatha kupirira malo enaake amankhwala omwe angakumane nawo pazomwe akufunira ndikofunikira.

- Kusakanikirana: Thermoplastics ali ndi makulidwe osiyanasiyana, omwe amatha kukhudza kulemera kwawo komanso mbali zake zonse. Zida zotsika kwambiri, monga polyethylene, zimapereka njira zopepuka, pomwe zida zolimba kwambiri, monga polypropylene, zimapereka mphamvu komanso kulimba.

Njira Yopangira Jekeseni: Pang'onopang'ono

Njira yopangira jakisoni imatsata njira izi, zomwe zimapangitsa kuti pakhale bwino komanso molondola magawo apamwamba a thermoplastic. Gawo lirilonse limafuna kuwongolera ndi kuyang'anira mosamala kuti zitsimikizidwe kuti zikugwirizana ndi magawo, katundu wakuthupi, ndi khalidwe lonse.

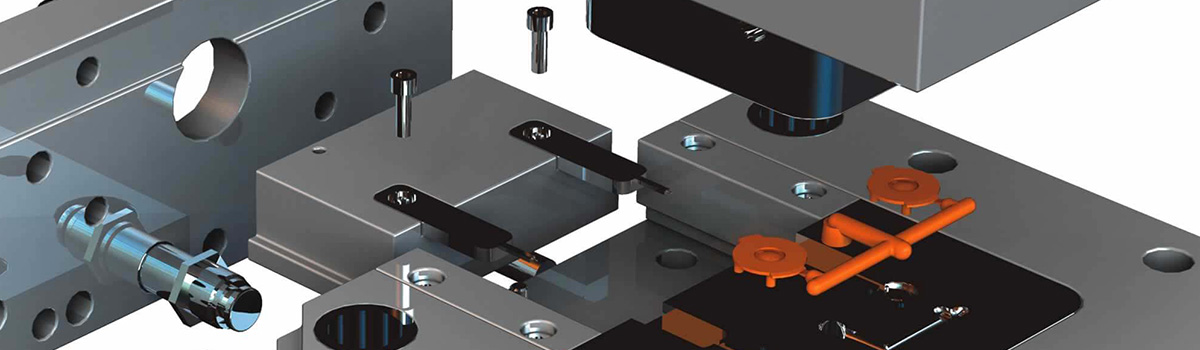

- Kupanga ndi Kupanga Mold: Chinthu choyamba pakupanga jekeseni ndikujambula ndi kupanga nkhungu. Opanga ayenera kupanga mawonekedwe olondola komanso atsatanetsatane kuti akwaniritse zomwe akufunidwa. Opanga amapanga nkhunguyo pogwiritsa ntchito njira zosiyanasiyana, monga CNC kapena Electric discharge Machining (EDM).

- Kukonzekera Kwazinthu: Chotsatira ndikukonzekera pamene nkhungu yakonzeka. Ma pellets a thermoplastic kapena ma granules amasankhidwa kutengera zomwe amafunikira ndikusungunuka mu hopper. Oyendetsa ndiye amadyetsa zinthuzo mu mbiya yamakina opangira jakisoni, pomwe amasungunuka ndi homogenization.

- Jekeseni:Pa gawo la jekeseni, ogwira ntchito amabaya thermoplastic yosungunuka mu nkhungu chifukwa cha kupanikizika kwakukulu. Makina a jakisoni amakankhira zinthu zosungunuka kudzera pamphuno ndi kulowa mu nkhungu. Zinthuzo zimadzaza nkhungu, kutenga mawonekedwe a gawo lomwe mukufuna.

- Kuzizira ndi Kulimbitsa:Pambuyo podzaza nkhungu, ogwira ntchito amalola pulasitiki yosungunuka kuti ikhale yozizira komanso yolimba. Kuziziritsa ndikofunikira kuti muzitha kukhazikika komanso kuti magawo apangidwe moyenera. Othandizira amatha kuwongolera kuziziritsa pozungulira zoziziritsa kukhosi kudzera munjira zomwe zili mkati mwa nkhungu kapena kugwiritsa ntchito mbale zozizirira.

- Kutsegula ndi Kutulutsa Mold:Ogwira ntchito amatsegula nkhungu ndikutulutsa gawolo kuchokera mu nkhungu pulasitikiyo ikakhazikika. Dongosolo la ejection mkati mwa makinawo limagwiritsa ntchito mapini, ma ejector plate, kapena kuphulika kwa mpweya kuti achotse chigawochi ku nkhungu. Chikombolecho chimakhala chokonzekera jekeseni wotsatira.

- Pambuyo pokonza: Pambuyo pa ejection, gawolo likhoza kuchitidwa pambuyo pokonza, monga kudula, kuchotsa, kapena kumaliza pamwamba. Masitepewa amathandizira kuchotsa zinthu zochulukirapo, zosalala m'mphepete, ndikuwongolera mawonekedwe omaliza a gawolo.

- Kuyendera Bwino: Gawo lomaliza limakhudzanso kuyang'ana magawo omwe adabadwira kuti akhale abwino ndikuwonetsetsa kuti akukwaniritsa zofunikira. Njira zosiyanasiyana zowongolera khalidwe, kuphatikizapo kuyeza kwa dimensional, kuyang'ana maso, ndi kuyesa kachitidwe ka ntchito, zingagwiritsidwe ntchito kutsimikizira kuti gawolo ndi labwino komanso kukhulupirika kwake.

- Kubwezereranso ndi Kugwiritsiridwanso Ntchito Zinthu:Zinthu zilizonse zowonjezera kapena zotsalira zomwe zimapangidwa panthawi yopangira jakisoni zitha kubwezeretsedwanso ndikugwiritsidwanso ntchito. Kuchepetsa kugwiritsa ntchito zinthu zatsopano za thermoplastic kumathandizira kuchepetsa zinyalala ndikuwongolera kukhazikika.

Zida Zogwiritsidwa Ntchito Pomanga Jakisoni

Zidazi zimathandizira kupanga jekeseni, kuchokera kusungunuka ndi kubaya zinthu za thermoplastic mpaka kupanga, kuziziritsa, ndi kutulutsa gawo lomaliza. Kugwira ntchito moyenera ndi kukonza zidazi ndizofunikira kwambiri kuti zitheke kupanga jekeseni wapamwamba kwambiri.

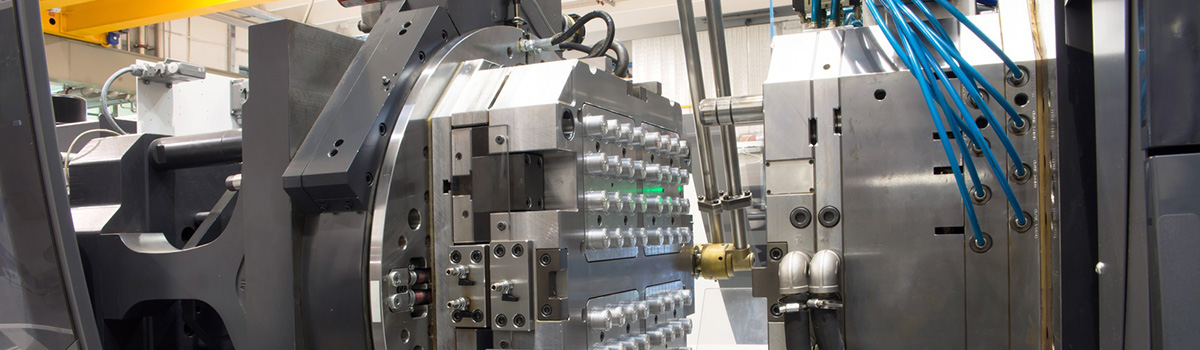

- Makina opangira jakisoni:Zida zoyambira pakuumba jekeseni zimakhala ndi udindo wosungunula zinthu za thermoplastic, kuzibaya mu nkhungu, ndikuwongolera njirayo.

- Mold: Nkhungu, yopangidwa mwachizolowezi kuti ipange mawonekedwe ofunikira ndi mawonekedwe a pulasitiki, imakhala ndi magawo awiri, patsekeke ndi pachimake. Othandizira amachiyika pagawo lotsekera la makina omangira jakisoni.

- Hopper:Chidebe chomwe chimasungira zinthu za thermoplastic mu pellet kapena granular ndikuzidyetsa mumgolo wa makina omangira jekeseni kuti asungunuke ndi kubayidwa.

- Barel ndi Screw: Mgolo, chipinda cha cylindrical, chimasungunula ndikupangitsa kuti zinthu za thermoplastic zisinthe momwe piritsi limazungulira mkati mwake kuti lisungunuke, kusakaniza, ndikusintha zinthuzo.

- Njira Zotenthetsera ndi Kuziziritsa:Makina opangira jekeseni ali ndi zinthu zotenthetsera, monga zotenthetsera zamagetsi kapena zotenthetsera pogwiritsa ntchito mafuta otentha, kukweza kutentha kwa mbiya, ndi njira zoziziritsira, monga kufalikira kwa madzi kapena mafuta, kuziziritsa nkhungu ndikulimbitsa gawo la pulasitiki.

- Ejector System:Imachotsa gawo lopangidwa kuchokera ku nkhungu pambuyo pokhazikika, pogwiritsa ntchito ma ejector pin, mbale, kapena kuphulika kwa mpweya potsegula nkhungu.

- Njira Yogulitsa:Amayang'anira ndikuwongolera magawo osiyanasiyana a jekeseni wopangira jekeseni, kulola ogwira ntchito kukhazikitsa ndi kusintha magawo monga kuthamanga kwa jekeseni, kutentha, kuthamanga, ndi nthawi yozizira.

Makina Omangira Jakisoni: Mitundu ndi Makhalidwe

Mtundu uliwonse wa makina opangira jekeseni uli ndi makhalidwe ake ndi ubwino wake, zomwe zimalola opanga kusankha chipangizo choyenera kwambiri pazomwe akufuna kupanga.

- Makina Opangira Ma Hydraulic: Makinawa amagwiritsa ntchito makina a hydraulic kuti apange mphamvu yofunikira yobaya pulasitiki yosungunuka mu nkhungu. Amadziwika ndi mphamvu yawo yolimba kwambiri, kuwongolera bwino, komanso kusinthasintha pogwira ma thermoplastics osiyanasiyana. Makina a Hydraulic ndi oyenera kupanga zazikulu ndipo amatha kukhala ndi nkhungu zovuta.

- Makina Omangira Jakisoni Wamagetsi:Makina amagetsi amagwiritsa ntchito ma servo motors amagetsi pamakinawa, kuphatikiza jakisoni, ma clamping, ndi ejector system. Amapereka kuwongolera kolondola, kuyendetsa bwino mphamvu, komanso nthawi yoyankha mwachangu kuposa makina a hydraulic. Makina amagetsi ndi abwino popanga makina olondola omwe amafunikira kubwereza komanso kulondola kwambiri.

- Makina Omangira Ma Hybrid:Makina osakanizidwa amaphatikiza ubwino wa zida zonse za hydraulic ndi magetsi. Amagwiritsa ntchito makina ophatikizika a hydraulic ndi magetsi servo kuti akwaniritse kulondola kwambiri, kuwongolera mphamvu, komanso kutsika mtengo. Makina a Hybrid ndi oyenera kugwiritsa ntchito zosiyanasiyana, kupereka malire pakati pa magwiridwe antchito ndi ndalama zogwirira ntchito.

- Makina Omangira Mapulani Awiri: Makina a matabwa awiri ali ndi mapangidwe apadera omwe ali ndi mbale ziwiri zosiyana zomangira nkhungu. Kapangidwe kameneka kamapereka kukhazikika kokhazikika, kulumikizana bwino kwa nkhungu ndikuloleza kukula kwa nkhungu ndi mphamvu zolimba kwambiri. Makina a matabwa awiri ndi oyenera zigawo zazikulu ndi zovuta zomwe zimafuna kuumba mwatsatanetsatane.

- Makina Omangira Magawo Osiyanasiyana:Opanga amapanga makinawa kuti apange magawo okhala ndi zida zingapo kapena mitundu mumkombero umodzi woumba. Amakhala ndi mayunitsi osiyanasiyana a jakisoni ndi nkhungu, zomwe zimathandiza jekeseni wanthawi imodzi wazinthu zosiyanasiyana. Makina amitundu yambiri amapereka kusinthasintha komanso kuchita bwino popanga magawo ovuta okhala ndi mawonekedwe osiyanasiyana.

- Makina Opangira Majekeseni a Micro:Opangidwa makamaka kuti apange tizigawo tating'ono komanso olondola, makina omangira ma jakisoni ang'onoang'ono amapereka kulondola kwambiri komanso kulondola. Amatha kupanga tsatanetsatane wololera molimba komanso kuwononga zinthu zochepa. Zamagetsi, zida zamankhwala, ndi ma micro-optics nthawi zambiri amagwiritsa ntchito makina opangira jakisoni ang'onoang'ono.

Zolinga Zopangira Mold Pakuumba jekeseni

Kuganizira mozama kamangidwe ka nkhungu ndikofunikira pakupanga bwino jekeseni.

- Kapangidwe kagawo:Mapangidwe a nkhungu ayenera kutengera zofunikira za gawolo, kuphatikiza mawonekedwe ake, miyeso yake, ndi magwiridwe antchito. Opanga akuyenera kuganizira moyenerera ma angles ojambulidwa, makulidwe a khoma, mafupipafupi, ndi zinthu zilizonse zofunika kuti awonetsetse kuti kutulutsa kosavuta komanso mtundu wina wake.

- Zinthu za Mold: Kusankhidwa kwa zinthu za nkhungu ndikofunikira kuti zitheke kukhazikika, kukhazikika kwa dimensional, komanso kukana kutentha. Zida zodziwika bwino za nkhungu zimaphatikizapo ma aloyi achitsulo, ma aloyi a aluminiyamu, ndi zitsulo zamagetsi. Kusankhidwa kwa zinthu kumatengera zinthu monga kuchuluka kwa zinthu zomwe zimapangidwa, zovuta zina, komanso moyo wa zida zomwe zikuyembekezeka.

- Njira Yozizira:Kuziziritsa koyenera ndikofunikira kuti mbali yokhazikika ikhale yolimba komanso kuchepetsa nthawi yozungulira. Mapangidwe a nkhungu ayenera kukhala ndi mayendedwe ozizirira kapena zoyika bwino kuti zitsimikizire kuzizirira kofanana. Kuziziritsa koyenera kumachepetsa chiopsezo cha ma warpage, kuchepa, ndi zina zolakwika.

- Kubowola:Kutulutsa mpweya kokwanira ndikofunikira kuti mpweya ndi mpweya uzituluka panthawi yobaya. Kusatulutsa mpweya wokwanira kungayambitse misampha ya gasi, zizindikiro zoyaka, kapena kusadzaza mbali zonse. Opanga amatha kupeza mpweya wabwino pophatikiza mipope, mapini, kapena njira zina pamapangidwe a nkhungu.

- Ejection System:Mapangidwe a nkhungu ayenera kukhala ndi njira yabwino yotulutsira madzi kuti achotse bwino komanso moyenera gawo lopangidwa kuchokera ku nkhungu. Dongosolo la ejection litha kukhala ndi ma ejector pin, manja, kapena njira zina, zoyikidwa bwino kuti zipewe kusokoneza ntchito kapena zofunikira.

- Mapangidwe a Gate:Pachipata ndi pamene pulasitiki yosungunuka imalowa mu nkhungu. Mapangidwe a zipata akuyenera kuwonetsetsa kudzazidwa koyenera, kuchepetsa mizere yoyenda, komanso kupewa kuzizira kwa zinthu zomwe zisanakwane. Mapangidwe a zipata zokhazikika amaphatikizapo zipata zam'mphepete, zipata za ngalande, ndi makina othamanga otentha, malingana ndi zofunikira za gawo ndi katundu.

- Mzere Wogawanika:Mapangidwe a nkhungu ayenera kufotokozera mzere woyenera wogawanika, womwe ndi mzere umene magawo awiri a nkhungu amasonkhana. Kuyika koyenera kwa mzere wolekanitsa kumawonetsetsa kuti kung'anima pang'ono ndi kusagwirizana kwa mzere wolekanitsa kumathandizira kukonza bwino nkhungu.

- Kusamalira Nkhungu ndi Kugwira Ntchito: Opanga akuyenera kuganizira za kumasuka pakukonza, kukonza, ndi kukonza nkhungu. Zigawo za nkhungu ziyenera kupezeka mosavuta kuti ziyeretsedwe, kuziwona, ndi kuzisintha. Kuphatikizira zinthu monga zoyika zosintha mwachangu kapena mapangidwe ang'onoang'ono atha kupititsa patsogolo magwiridwe antchito a nkhungu.

Zida Zakukhungu Zogwiritsidwa Ntchito Popanga jekeseni

Kugwirizana ndi akatswiri azinthu za nkhungu ndikuganiziranso zosowa zenizeni za ntchito yowumba kungathandize kudziwa zinthu zoyenera kwambiri kuti mukwaniritse ntchito yabwino ya nkhungu ndi gawo la mtundu.

- Zida Zachitsulo: Ma aloyi achitsulo, monga zitsulo zachitsulo (mwachitsanzo, P20, H13) ndi zitsulo zosapanga dzimbiri, zimagwiritsidwa ntchito kwambiri popanga ma jekeseni akamaumba chifukwa cha kulimba kwawo, kukana kutentha, komanso kukana kuvala. Zidazi zimatha kupirira kutentha kwambiri komanso kupsinjika munjira yopangira jakisoni ndikupereka kukhazikika kwapang'onopang'ono popanga magawo apamwamba kwambiri.

- Aluminiyamu Aloyi:Ma aluminiyamu aloyi, monga 7075 ndi 6061, ndi opepuka ndipo amapereka ma conductivity abwino a matenthedwe, kuwapanga kukhala oyenera nkhungu zomwe zimafuna kuziziritsa bwino. Opanga nthawi zambiri amagwiritsa ntchito nkhungu za aluminiyamu popanga ma prototyping, kupanga pang'ono, kapena kugwiritsa ntchito komwe kuchepetsa kulemera ndikofunikira. Komabe, nkhungu za aluminiyamu zimatha kukhala ndi mphamvu zochepa poyerekeza ndi ma alloys achitsulo.

- Zida za Copper:Ma alloys amkuwa, monga mkuwa wa beryllium, amawonetsa matenthedwe apamwamba komanso machinability abwino. Amapeza kugwiritsidwa ntchito mu nkhungu zomwe zimafuna kutentha kwambiri kuti ziziziziritsa bwino. Ma alloys amkuwa angathandize kuchepetsa nthawi yozungulira pochotsa kutentha mwachangu kuchokera pagawo lowumbidwa, zomwe zimapangitsa kulimba mwachangu.

- Zida Zitsulo:Zida zopangira zida, kuphatikiza H13, S7, ndi D2, zidapangidwa kuti zizigwiritsidwa ntchito kwambiri. Zitsulo izi zimapereka kuphatikiza kwamphamvu kwambiri, kuuma, ndi kukana kuvala. Zitsulo za zida zimagwirizana ndi nkhungu zokhala ndi ma voliyumu ambiri opanga, zida zonyezimira, kapena zovuta zomangira.

- Nickel Aloyi:Ma aloyi a Nickel, monga Inconel ndi Hastelloy, amadziwika ndi kukana kwapadera kwa dzimbiri, mphamvu zotentha kwambiri, komanso kukhazikika kwamafuta. Opanga amagwiritsa ntchito ma aloyiwa mu nkhungu zomwe zimagwira zinthu zowononga kapena zimafuna kukana kutentha kwambiri komanso malo owumba mwaukali.

- Zophatikiza:Zida zophatikizika, monga mapulasitiki olimbikitsidwa kapena zophatikizika zokhala ndi zitsulo, nthawi zina zimagwiritsidwa ntchito popanga zinthu zina. Zipangizozi zimapereka zinthu zofananira, monga mphamvu zambiri, kukhazikika kwamafuta, komanso kuchepa kwa thupi. Zoumba zophatikizika zimatha kukhala njira zotsika mtengo pazofunikira zinazake zopanga.

Mitundu ya Jekeseni Moulds

Kumangira jekeseni ndi njira yosinthika komanso yogwiritsidwa ntchito kwambiri popanga zida zapulasitiki.

- Mitundu Yambiri:Kuumba kwa mbale ziwiri ndi mtundu wofala kwambiri wa jekeseni. Amakhala ndi mbale ziwiri, mbale yamkati, ndi core plate, zomwe zimalekanitsa kuti zitheke kutulutsa gawo lopangidwa. Chipinda chamkati chimakhala ndi mbali ya nkhungu, pomwe mbale yayikulu imakhala ndi mbali yapakati. Opanga amagwiritsa ntchito nkhungu za mbale ziwiri popanga magawo osiyanasiyana chifukwa cha kapangidwe kake kosavuta.

- Nkhungu Zitatu:Chikombole chamagulu atatu ndi mtundu wapamwamba wa nkhungu ya mbale ziwiri. Zimaphatikizapo mbale yowonjezera, wothamanga, kapena mbale ya sprue. Mbalame yothamanga imapanga njira yosiyana ya sprue, othamanga, ndi zipata, zomwe zimathandiza kuchotsa mosavuta gawo lopangidwa. Opanga nthawi zambiri amagwiritsa ntchito nkhungu za mbale zitatu kuti zidziwitse zambiri zokhala ndi zovuta zotsekera kapena popewa zitseko zachipata pamtengowo ndi zofunika.

- Hot Runner Mold:Njira yothamanga ndi zipata imatenthedwa muzitsulo zothamanga zotentha, kuchotsa kufunikira kwa kulimbitsa ndi kusungunukanso kwa zinthu panthawi iliyonse. Makina othamanga otentha amakhala ndi manifolds otentha ndi ma nozzles omwe amasunga kusungunuka kwa pulasitiki. Zoumba zothamanga zotentha zimapereka zabwino monga kuchepetsedwa kwa nthawi yozungulira, kuwononga zinthu zochepa, komanso kuwongolera mbali zina pochepetsa zipata.

- Cold Runner Mold: Zozizira zozizira zimakhala ndi othamanga achikhalidwe ndi dongosolo lachipata kumene pulasitiki yosungunuka imayenda mwa othamanga ozizira omwe amalimbitsa ndi kuzungulira kulikonse. Oyendetsa pambuyo pake amachotsa othamanga olimba, zomwe zimapangitsa kuti ziwonongeke. Opanga nthawi zambiri amagwiritsa ntchito nkhungu zothamanga kuti apange voliyumu yocheperako kapena ngati ndalama zakuthupi sizikhala zovuta kwambiri chifukwa cha kapangidwe kawo kowongoka.

- Ikani Mold:Ikani zisankho zomwe zimayika zitsulo kapena pulasitiki mu nkhungu panthawi yopangira jakisoni. Zolowetsa zimatha kukhazikitsidwa kale mu nkhungu kapena kulowetsedwa ndi njira zodzichitira. Chikombole ichi chimalola kugwirizanitsa zigawo zina zowonjezera kapena kulimbikitsa zinthu mu gawo lopangidwa, kupititsa patsogolo ntchito yake kapena mphamvu zake.

- Overmold: Kupanga mochulukira kumaphatikizapo kuumba chinthu chimodzi pamwamba pa chinzake, nthawi zambiri kumangiriza gawo lapulasitiki lolimba ndi elastomer yofewa kapena thermoplastic. Njirayi imalola kuti pakhale magawo okhala ndi zida zingapo kapena mawonekedwe mu nkhungu imodzi, zomwe zimapangitsa kuti pakhale kugwirira bwino, kuwongolera, kapena kukongoletsa.

Zomwe Zimakhudza Mtengo Wopangira Majekeseni

Kuganizira zinthu izi kungathandize opanga kuyerekezera ndi kukhathamiritsa mtengo wa jekeseni, kuonetsetsa kuti pali kusiyana pakati pa ubwino, kuchita bwino, ndi kutsika mtengo kwa zomwe akufuna kupanga.

- Kuvuta Kwambiri:Kuvuta kwa kapangidwe ka gawo kumagwira ntchito yofunika kwambiri pozindikira mtengo wa jekeseni. Ma geometri, mafupi, makoma opyapyala, kapena mawonekedwe ovuta angafunike zida zowonjezera, nkhungu zapadera, kapena mizungulire yayitali, kukulitsa mtengo wonse wopanga.

- Kusankha Zinthu:Kusankhidwa kwa zinthu za thermoplastic kumakhudza mtengo wopangira jakisoni. Zida zosiyanasiyana zimakhala ndi mitengo yosiyana pa kilogalamu, ndipo zinthu monga kupezeka kwa zinthu, katundu, ndi zofunikira pakukonza zimatha kukhudza mtengo wazinthu zonse.

- Kupanga Zida ndi Mold: Ndalama zoyamba zopangira zida ndi nkhungu ndizofunika kwambiri pamitengo yopangira jakisoni. Zinthu monga kuchulukitsitsa kwa nkhungu, kuchuluka kwa zibowo, kukula kwa nkhungu, ndi zinthu za nkhungu zimathandizira pakupanga zida ndi ndalama zopangira nkhungu. Zoumba zovuta kwambiri kapena zoumba zomwe zimafunikira zida zapamwamba zitha kukulitsa ndalama zam'tsogolo.

- Voliyumu Yopanga: Voliyumu yopanga imakhudza mwachindunji mtengo pagawo lililonse pakuumba jekeseni. Mabuku apamwamba nthawi zambiri amabweretsa chuma chambiri, kuchepetsa mtengo pagawo lililonse. Mosiyana ndi izi, kutsika kwamphamvu kumatha kubweretsa ndalama zambiri chifukwa cha kukhazikitsa, kugwiritsa ntchito zida, komanso kuwononga zinthu.

- Nthawi Yozungulira: Nthawi yozungulira, yomwe imaphatikizapo magawo oziziritsa ndi otulutsa, imakhudza mphamvu yopangira komanso mtengo wonse. Kutenga nthawi yayitali kumabweretsa kuchepa kwa zotulutsa komanso mitengo yokwera. Kuwongolera kapangidwe ka nkhungu, makina oziziritsa, ndi magawo azinthu kumatha kuchepetsa nthawi yozungulira ndikuwongolera bwino.

- Zofunika Zapamwamba:Zofunikira zapamwamba kwambiri kapena ziphaso zinazake zitha kukhudza mtengo wopangira jakisoni. Kukumana ndi kulolerana kwenikweni, zofunika kumaliza pamwamba, kapena kuyezetsa kwina kungafunike zinthu zina, njira, kapena kuwunika, zomwe zikuwonjezera mtengo wonse.

- Zochita Zachiwiri:Ngati mbali zowumbidwa zimafuna kukonzanso pambuyo pokonza monga kusonkhanitsa, kupenta, kapena masitepe ena omaliza, izi zitha kuwonjezera pa mtengo wonse wopangira jakisoni.

- Wopereka ndi Malo:Kusankhidwa kwa jekeseni wopangira jekeseni ndi malo awo kungakhudze ndalama. Ndalama zogwirira ntchito, zolipiridwa, zoyendetsera, ndi zoyendera zimasiyana malinga ndi komwe wogulitsa ali, zomwe zimakhudza mtengo wonse wopanga.

Kuwongolera Kwabwino mu Kumangirira Jakisoni

Kukhazikitsa njira zowongolera zamphamvu panthawi yonse yopangira jakisoni kumathandiza kuzindikira ndi kuthana ndi zolakwika zomwe zingachitike, zopatuka, kapena zosagwirizana, kuwonetsetsa kuti pakupanga magawo apamwamba kwambiri omwe amakwaniritsa zomwe makasitomala amafuna.

- Kuyang'anira Njira: Kuwunika kosalekeza kwa magawo ofunikira, monga kutentha kwa sungunuka, kuthamanga kwa jakisoni, nthawi yozizira, ndi nthawi yozungulira, kumatsimikizira kusasinthika komanso kubwereza pang'ono kupanga. Kuwunika kwanthawi yeniyeni ndi makina odzipangira okha amatha kuzindikira kusiyanasiyana kapena kupatuka pazigawo zokhazikitsidwa, kulola kusintha kwanthawi yake ndikusunga bata.

- Kuyang'ana ndi Kuyeza:Kuwunika pafupipafupi komanso kuyeza kwa magawo owumbidwa ndikofunikira kuti muwonetsetse kulondola kwa mawonekedwe, mtundu wagawo, komanso kutsatira zomwe zafotokozedwa. Ntchito zathu zimakhala ndi njira zingapo zowongolera zabwino, monga kuyeza kukula, kusanthula mawonekedwe apamwamba, kuyang'anira zowonera, ndi kuyesa magwiridwe antchito. Njira zosiyanasiyana zowunikira, monga makina oyezera ma coordinate (CMM) ndi makina owunikira ndi owonera, amagwiritsidwa ntchito kuti awunike molondola.

- Statistical Process Control (SPC): SPC imaphatikizapo kusonkhanitsa ndi kusanthula deta kuti iwunikire ndikuwongolera mtundu wa jekeseni. Njira zowerengera, monga ma chart owongolera ndi kusanthula kuthekera kwa njira, zimathandizira kuzindikira zomwe zikuchitika, kuzindikira kusiyanasiyana kwa njira, ndikuwonetsetsa kuti njirayo ikukhalabe m'malire owongolera. SPC imathandizira kuzindikira mwachangu zovuta komanso kuwongolera kukhathamiritsa kwazinthu.

- Kuyesa Zinthu: Kuyesa zopangira, monga thermoplastics, zowonjezera, ndi zopaka utoto, zimatsimikizira mtundu wawo komanso kukwanira pakuwumba jekeseni. Kuyesa kwazinthu kungaphatikizepo kusanthula kwa melt flow index (MFI), makina amakina, mawonekedwe amafuta, ndi kapangidwe kazinthu. Kutsimikizira mtundu wazinthu kumathandiza kupewa zolakwika ndi zosagwirizana m'zigawo zoumbidwa.

- Kusamalira Zida ndi Kuyang'anira:Kusamalira moyenera ndikuwunika nthawi zonse kwa nkhungu za jakisoni ndikofunikira kuti muwonetsetse kuti jekeseniyo ili yabwino. Kuyeretsa nthawi zonse, kuthira mafuta, ndikuwunika zigawo za nkhungu kumathandizira kupewa kuwonongeka, kuwonongeka, kapena kuwonongeka komwe kungakhudze mtundu wina. Kukonza nthawi yake kapena kusintha zinthu zomwe zatha kapena zowonongeka ndizofunikira kuti zisungidwe bwino.

- Documentation and Traceability:Kusunga zolemba zonse ndi zolemba zowunikira ndikofunikira pakuwongolera kwamtundu wa jakisoni. Ndikofunikira kulemba magawo, zotsatira zowunikira, zidziwitso zakuthupi, ndi kusintha kulikonse komwe kumachitika panthawi yopanga. Zolemba zolondola zimathandizira kutsatiridwa kwa magawo, kuwongolera zomwe zimayambitsa, ndikuwonetsetsa kuti zikuyenda bwino.

- Maphunziro ndi Kukulitsa Luso: Kupereka maphunziro okwanira ndi mapulogalamu opititsa patsogolo luso kwa ogwira ntchito, amisiri, ndi ogwira ntchito yoyang'anira khalidwe kumawonjezera kumvetsetsa kwawo kwa njira zopangira jekeseni, zofunikira za khalidwe, ndi njira zoyendera. Ogwira ntchito ophunzitsidwa bwino amatha kuzindikira zolakwika, kuthetsa mavuto, ndikugwiritsa ntchito njira zowongolera moyenera, ndikuwonetsetsa kupanga kwapamwamba.

Zolakwika Zowumba Jakisoni Wamba ndi Momwe Mungapewere

Kuwunika pafupipafupi, kuyang'anira, ndi kusanthula njira zopangira jekeseni ndikukonza moyenera ndikusintha zida ndi nkhungu zitha kuthandizira kuzindikira ndi kuthana ndi zolakwika zomwe wambazi.

- Sink Marks:Sink marks ndi zopindika kapena zopindika pamwamba pa gawo lowumbidwa chifukwa cha kuzizira kosiyana kapena kuchepa. Mmodzi ayenera kuganizira malo oyenera a chipata ndi kamangidwe kake, kamangidwe kabwino ka kuzizira kozizira, ndi kagawidwe kofanana ndi makulidwe a khoma kuti apewe ma sink marks. Kuonjezera mphamvu ya jekeseni kapena kusintha nthawi yozizirira kungathandizenso kuchepetsa zizindikiro za kumira.

- Nkhondo:Warpage imatanthawuza kupindika kapena kupindika kwa gawo lopangidwa pambuyo pa kutulutsa chifukwa cha kuzizira kosiyana kapena kupsinjika kotsalira. Kusunga makulidwe a khoma lofanana, kugwiritsa ntchito njira zozizirira bwino, komanso kuonetsetsa kuti nkhunguyo yadzaza ndi kulongedza moyenera ndikofunikira kuti tipewe kuphulika. Kupititsa patsogolo kutentha kwa nkhungu, kugwiritsa ntchito ngodya zoyenera, ndikuwongolera kutentha kwa zinthu ndi liwiro la jekeseni kungathandize kuchepetsa tsamba la nkhondo.

- Kukula:Kung'anima kumachitika pamene zinthu zowonjezera zimalowa mumzere wolekanitsa nkhungu, zomwe zimapangitsa kuti zikhale zowonda, zosafunikira kapena zina zowonjezera pamapeto. Munthu angathe kuteteza kung'anima mwa kuonetsetsa kuti nkhungu imapangidwa moyenerera, kuphatikizapo kugwiritsa ntchito mphamvu yokhotakhota yokwanira, kulunjika bwino, ndi kugwiritsa ntchito njira zoyenera zopumira mpweya. Kukonzekera magawo azinthu monga kuthamanga kwa jekeseni, kutentha, ndi nthawi yozungulira kumachepetsa kung'anima.

- Kuwombera Kwachidule:Kuwombera mwachangu kumachitika pamene jekeseniyo sidzaza nkhungu, zomwe zimapangitsa kuti pakhale gawo losakwanira. Kusankhidwa koyenera kwa zinthu, kuonetsetsa kutentha kokwanira kusungunuka ndi kukhuthala, komanso kusunga jekeseni yoyenera ndi nthawi ndizofunikira kuti mupewe zithunzi zazifupi. Kuphatikiza apo, kutsimikizira kapangidwe ka nkhungu kothamanga kokwanira komanso kukula kwa zipata komanso mpweya wabwino kungathandize kupewa kuwombera mwachangu.

- Weld Lines:Mizere yowotcherera imachitika pamene mbali ziwiri kapena zingapo zosungunula zimakumana ndikulimba, zomwe zimapangitsa mzere wowoneka kapena chizindikiro pagawolo. Kapangidwe kabwino kachipata ndi othamanga, kutentha koyenera kusungunuka, kuthamanga kwa jakisoni, ndikusintha kayendedwe kazinthu ndi gawo la geometry kumatha kuchepetsa mizere yowotcherera. Kusanthula koyenda kwa nkhungu ndi kukhathamiritsa kwa kuyika zipata kungathandizenso kupewa kapena kuchepetsa mizere yowotcherera.

- Zizindikiro Zowotcha:Kuwotcha zizindikiro ndi discolorations kapena wakuda mawanga pamwamba pa kuumbidwa mbali chifukwa cha kutentha kwambiri kapena kutenthedwa kwa zinthu. Kupewa kutentha kwambiri kusungunuka, kugwiritsa ntchito njira zozizirira zoyenera, komanso kuwongolera nthawi yozungulira kungathandize kupewa zizindikiro zoyaka. Kutulutsa mpweya kokwanira, kamangidwe koyenera ka zipata, ndi kuwongolera kutentha kwa nkhungu zimathandizanso kuchepetsa zizindikiro zopsa.

Ntchito za Post-Molding: Kumaliza ndi Kusonkhana

Pambuyo jekeseni akamaumba, ambiri kuumbidwa mbali zingafune zina kumaliza ndi msonkhano ntchito kukwaniritsa ankafuna chomaliza. Izi zitha kukhala:

- Kuchepetsa:Chotsani chilichonse chowonjezera kapena kung'anima kuzungulira gawo lopangidwa pogwiritsa ntchito zida zodulira.

- Pamwamba Chithandizo:Kupititsa patsogolo mawonekedwe kapena magwiridwe antchito a gawolo pogwiritsa ntchito njira zosiyanasiyana monga kujambula, zokutira, kapena kulemba.

- Msonkhano:Kulowa magawo angapo opangidwa kapena kuwonjezera zinthu monga zomangira, zoyikapo, kapena zilembo kuti mumalize chomaliza.

- Kuyesedwa:Kutsimikizira kwa gawo limodzi ndi magwiridwe antchito kudzera m'njira zosiyanasiyana zoyesera monga kusanthula mawonekedwe, kuyesa katundu wazinthu, kapena kuyesa magwiridwe antchito.

- Kupaka ndi Kutumiza:Kuyika koyenera ndikulemba zolemba zomwe zamalizidwa kuti zitumizidwe kwa makasitomala kapena ogwiritsa ntchito.

Kusankhidwa kwa ntchito zowumba pambuyo poumba zimatengera kagwiritsidwe ntchito kake komanso mawonekedwe omwe amafunidwa. Mgwirizano wapakati pakati pa akatswiri opangira jekeseni, akatswiri omaliza ndi osonkhanitsa, ndipo kasitomala ndikofunikira kuti akwaniritse zomwe akufuna komanso magwiridwe antchito. Kukonzekera koyenera ndi kuphatikizira ntchito zomwe zimapangidwira pambuyo popanga kupanga zingathandize kuonetsetsa kuti kupanga bwino komanso kutumiza kwanthawi yake kwa zinthu zabwino kwambiri.

Jekeseni akamaumba vs. Njira Zina za Pulasitiki Kupanga

Njira iliyonse yopangira pulasitiki imakhala ndi zabwino komanso zoperewera, zomwe zimawapangitsa kukhala oyenera ntchito zosiyanasiyana.

- Jekeseni akamaumba: Kuumba jekeseni ndi njira yosinthika kwambiri komanso yogwiritsidwa ntchito kwambiri popanga zida zapulasitiki. Imapereka maubwino monga kupanga bwino kwambiri, kubwereza kolondola, komanso kuthekera kopanga ma geometri ovuta. Kujambula kwa jekeseni ndikoyenera kuthamangitsidwa kwapamwamba kwambiri ndipo kumalola kugwiritsa ntchito zipangizo zosiyanasiyana za thermoplastic. Imakhala yolondola kwambiri komanso yomaliza pamwamba, ndikupangitsa kuti ikhale yabwino m'mafakitale osiyanasiyana monga magalimoto, katundu wogula, ndi zida zamankhwala.

- Kuwomba: Blow molding ndi njira yomwe imagwiritsidwa ntchito makamaka popanga zida zapulasitiki zopanda kanthu, monga mabotolo, zotengera, ndi zida zamagalimoto. Kumaphatikizapo kusungunula pulasitiki ndikuupaka mu nkhungu, kupanga mawonekedwe ofunikira. Kuwomba kowomba ndikoyenera kupanga ma voliyumu ambiri ndipo kumatha kupanga magawo akulu, opepuka okhala ndi makulidwe a khoma lofanana. Komabe, ndizochepa potengera zovuta ndi kusankha kwazinthu poyerekeza ndi jekeseni.

- Thermoforming:Thermoforming ndi njira yomwe imagwiritsidwa ntchito popanga zida zapulasitiki powotcha pepala la thermoplastic ndikulipanga pogwiritsa ntchito nkhungu kapena vacuum. Imapeza kugwiritsidwa ntchito kofala pamapaketi, zinthu zotayidwa, ndi zinthu zazikulu monga ma tray ndi zovundikira. Thermoforming imapereka kupanga kotsika mtengo kwa magawo akulu ndipo imalola kuwonetsa mwachangu. Komabe, ili ndi malire okhudzana ndi zovuta zina, kusankha zinthu, komanso kulondola kwazithunzi poyerekeza ndi jekeseni.

- Kuthamanga:Extrusion ndi njira yopitilira kupanga mbiri zamapulasitiki, mapepala, machubu, ndi mafilimu. Zimaphatikizapo kusungunula utomoni wa pulasitiki ndikuukakamiza kupyolera mukufa kuti apange mawonekedwe omwe akufuna. Extrusion ndi yoyenera kupanga utali wautali, wosalekeza wa mankhwala apulasitiki okhala ndi gawo lofanana. Ngakhale extrusion imapereka mitengo yokwera kwambiri komanso yotsika mtengo, imakhala yocheperako malinga ndi magawo ovuta a geometries ndi kuwongolera kolondola kofananira ndi jekeseni.

- Compression Molding:Kumangirira kumaphatikizapo kuyika zinthu zoyezeratu za thermosetting pabowo lotentha la nkhungu ndikulipondereza kwambiri mpaka litachira. Imagwiritsidwa ntchito kwambiri popanga zida zolimba kwambiri komanso zokhazikika, monga zida zamagalimoto ndi kutsekereza magetsi. Kumangirira kophatikizika kumapereka kusasinthika kwa gawo, kupanga bwino kwambiri, komanso kuthekera kogwiritsa ntchito zida zosiyanasiyana. Komabe, ndizochepa potengera zovuta komanso nthawi yozungulira poyerekeza ndi jekeseni.

Kugwiritsa Ntchito Thermoplastic Injection Molding

Mafakitale osiyanasiyana amagwiritsa ntchito kwambiri jekeseni wa thermoplastic chifukwa cha kusinthasintha kwake, kuchita bwino, komanso kutsika mtengo. Zina mwazomwe zimagwiritsidwa ntchito popanga jakisoni wa thermoplastic ndi:

- Makampani Agalimoto: Makampani opanga magalimoto amagwiritsa ntchito kwambiri jekeseni wa thermoplastic kupanga zinthu zosiyanasiyana, kuphatikiza mkati ndi kunja, ma dashboards, mapanelo a zitseko, mabampu, ndi zolumikizira zamagetsi. Njirayi imalola kubwereza ndendende, ma geometri ovuta, ndi zida zopepuka, kuwongolera mphamvu yamafuta komanso kusinthasintha kwa mapangidwe.

- Katundu Wogula:Kumangira jekeseni kumapeza ntchito zambiri popanga zinthu zogula zinthu monga zida zapakhomo, zida zamagetsi, zotengera, ndi zoseweretsa. Njirayi imathandizira kupanga zinthu zambiri zokhazikika, zapamwamba kwambiri zokhala ndi miyeso yofananira komanso kutha kwa pamwamba. Komanso amalola makonda options ndi mofulumira mankhwala iterations.

- Zida Zachipatala:Kumangira jekeseni kumagwira ntchito yofunika kwambiri m'makampani azachipatala popanga zida zosiyanasiyana, kuphatikiza ma syringe, zida zopangira opaleshoni, zoyikapo, ndi njira zoperekera mankhwala. Njirayi imawonetsetsa kuti magawo osabala, olondola, komanso ogwirizana ndi biocompatible omwe amakwaniritsa zofunikira pazachipatala.

- Makampani a Zamagetsi ndi Zamagetsi:Makampani opanga zamagetsi amagwiritsa ntchito jekeseni kuti apange zolumikizira zamagetsi, zotsekera, zosinthira, ndi zinthu zina. Njirayi imapereka kulondola kwapamwamba kwambiri, kutsirizika kwapamwamba kwambiri, komanso kuthekera kophatikizira zinthu monga kuyikapo kuumba ndi kufota, kulola kupanga bwino kwamagulu amagetsi ovuta.

- Makampani Opaka:Mafakitale osiyanasiyana, kuphatikiza zakudya ndi zakumwa, mankhwala, ndi chisamaliro chamunthu, nthawi zambiri amagwiritsa ntchito jekeseni popanga zotengera zapulasitiki, zipewa, zotsekera, ndi mabotolo. Njirayi imathandizira kuti pakhale njira zopakira zopepuka, zolimba, komanso zowoneka bwino zokhala ndi mizere yopangira bwino.

- Makampani apamlengalenga:Gawo lazamlengalenga limagwiritsa ntchito jekeseni popanga zinthu zopepuka komanso zogwira ntchito kwambiri monga ma ducts a mpweya, mabulaketi, mapanelo amkati, ndi zida zamapangidwe. Njirayi imalola kugwiritsa ntchito zida zapamwamba komanso magawo odabwitsa a geometri, zomwe zimathandizira kuchepetsa kulemera komanso kuwongolera mafuta.

Environmental Impact of Thermoplastic Injection Molding

Kumangira jakisoni wa Thermoplastic ndi njira yotchuka yopangira chifukwa cha zabwino zake zambiri, koma ndikofunikiranso kuganizira momwe zimakhudzira chilengedwe. Nazi mfundo zina zofunika kuziganizira:

- Mwachangu:Kuumba jekeseni wa thermoplastic kumathandizira kuti zinthu ziziyenda bwino pochepetsa zinyalala. Njirayi imagwiritsa ntchito kuwongolera moyenera kuchuluka kwa zinthu zomwe zimalowetsedwa mu nkhungu, kuchepetsa kufunikira kwa zinthu zochulukirapo. Opanga angagwiritsenso ntchito njira zogayanso ndi zobwezeretsanso kuti agwiritsenso ntchito zidutswa zotsalira kapena zokanidwa, kuchepetsa kuwononga zinthu.

- Mphamvu Zamagetsi:Opanga amapanga makina omangira jakisoni kuti akhale opatsa mphamvu, okhala ndi mitundu yamakono yophatikizira umisiri wapamwamba kwambiri monga ma servo motors ndi ma drive othamanga. Zinthuzi zimawonjezera mphamvu yogwiritsira ntchito mphamvu pochepetsa kugwiritsa ntchito mphamvu pakumawumba, zomwe zimapangitsa kuti magetsi azikhala ochepa komanso kuti chilengedwe chichepe.

- Kuwongolera Zinyalala:Pomwe akuchepetsa kuwononga zinthu, opanga akuyenera kugwiritsa ntchito njira zoyendetsera zinyalala kuti agwiritse ntchito zotsalira, sprues, kapena othamanga. Opanga atha kukhazikitsa mapulogalamu obwezeretsanso kuti atolere ndikugwiritsanso ntchito zinyalala za pulasitiki zomwe zidapangidwa pomanga jekeseni, potero kuchepetsa zinyalala zomwe zimatumizidwa kudzala.

- Kuchepetsa Kutulutsa: Kumangira jakisoni wa thermoplastic nthawi zambiri kumatulutsa mpweya wocheperako kuposa njira zina zopangira. Opanga amatha kuchepetsa kutulutsa mpweya pogwiritsa ntchito zinthu zokomera chilengedwe, kugwiritsa ntchito zida zowongola mphamvu, komanso kugwiritsa ntchito zida zapamwamba zotulutsa ndi kusefera kuti agwire mpweya uliwonse womwe watulutsidwa.

- Zosankha Zosatha:Kusankhidwa kwa zida za thermoplastic kumatha kukhudza kwambiri kukhazikika kwa chilengedwe pakuumba jekeseni. Kusankha mapulasitiki opangidwa ndi biodegradable kapena bio-based, komanso zinthu zobwezerezedwanso kapena zobwezerezedwanso, zitha kuthandiza kuchepetsa momwe chilengedwe chimakhalira.

Zolinga Zozungulira Moyo: Kuganizira za moyo wonse wa chinthu chowumbidwa ndikofunikira pakuwunika momwe chilengedwe chimakhudzira. Pamagawo opangira ndi kusankha zinthu, opanga aganizire zinthu monga kulimba kwa gawolo, kubwezanso, komanso kuthekera kotayidwa kapena kugwiritsidwanso ntchito kumapeto kwa moyo.

Tsogolo la Thermoplastic Injection Molding

Tsogolo la jekeseni wa thermoplastic likuwoneka ngati labwino, ndikupita patsogolo kwaukadaulo komanso kufunikira kwa magawo apamwamba kwambiri, olondola m'mafakitale osiyanasiyana. Zina mwazinthu zazikulu zomwe zikuyembekezeka m'zaka zikubwerazi ndi izi:

- Kuchulukitsa kugwiritsa ntchito ma automation ndi ma robotics kuti apititse patsogolo magwiridwe antchito ndikuchepetsa mtengo.

- Khama limayang'ana pakupanga zida zatsopano ndi njira zowonjezera magwiridwe antchito ndikupangitsa ntchito zatsopano.

- Ndikukula kutengera njira zokhazikika, monga kugwiritsa ntchito zida zobwezerezedwanso komanso kukhathamiritsa kugwiritsa ntchito mphamvu, kuti muchepetse kuwononga chilengedwe pakuumba jekeseni.

- Kuphatikiza kwakukulu kwaukadaulo wa digito, monga kusindikiza kwa 3D ndi pulogalamu yofananira, kupititsa patsogolo mapangidwe ndi kupanga.

Msika wapadziko lonse lapansi wopangira ma jakisoni ukukula, makamaka m'maiko omwe akutukuka kumene, motsogozedwa ndi kuchuluka kwazinthu zamapulasitiki m'mafakitale osiyanasiyana.

Kusankha Wothandizira Jakisoni Woyenera

Kusankha bwenzi loyenera kuumba jekeseni ndikofunikira kuti polojekiti yanu ikhale yabwino. Tengani nthawi yowunikira zosankha zingapo, kuyendera malo, ndikukambirana mozama kuti mutsimikizire mgwirizano wogwirizana komanso wokhalitsa.

- Katswiri ndi Zochitika:Yang'anani bwenzi lopanga jekeseni yemwe ali ndi chidziwitso chochuluka komanso chidziwitso pamakampani. Ayenera kukhala ndi mbiri yotsimikizika yopereka zinthu zapamwamba kwambiri ndi mayankho kwa makasitomala m'magawo osiyanasiyana. Ganizirani za kumvetsetsa kwawo kwa zinthu zosiyanasiyana, mapangidwe a nkhungu, ndi njira zopangira.

- Maluso Opanga: Unikani kuthekera kopanga kwa mnzake wowumba jekeseni. Onetsetsani kuti ali ndi malo okonzekera bwino okhala ndi makina amakono ndi matekinoloje kuti athe kuthana ndi zomwe polojekiti yanu ikufuna. Ganizirani za mphamvu zawo zopangira, kuthekera kosamalira magawo osiyanasiyana ndi zovuta, komanso kuthekera kokwaniritsa kuchuluka kwa zomwe mukufuna komanso nthawi.

- Chitsimikizo chadongosolo:Ubwino ndiwofunika kwambiri pakuumba jekeseni. Unikani machitidwe owongolera zabwino ndi ziphaso za omwe angakhale ogwirizana nawo. Yang'anani abwenzi omwe amatsatira miyezo yapamwamba kwambiri, omwe ali ndi njira zowunikira mwamphamvu, ndikuchita kuyezetsa kokwanira kuti muwonetsetse kuti mbali yake ili yabwino komanso yosasinthika.

- Thandizo la Design ndi Engineering:Wothandizira jekeseni wodalirika ayenera kupereka chithandizo cha mapangidwe ndi ukadaulo kuti muwongolere gawo lanu kuti lipangidwe. Ayenera kukhala ndi mainjiniya aluso omwe atha kupereka zofunikira pakusankha zinthu, kapangidwe ka nkhungu, ndi kukhathamiritsa kwazinthu kuti apititse patsogolo luso la gawo ndikuchita bwino.

- Kupikisana Mtengo:Ngakhale mtengo suyenera kukhala chinthu chokhacho chodziwira, ndikofunikira kuunika mitengo ndi kupikisana kwa mtengo wa mnzake woumba jekeseni. Funsani zatsatanetsatane ndikuganizira mtengo wa zida, mtengo wazinthu, ndalama zogwirira ntchito, ndi zina zilizonse zomwe amapereka.

- Kulumikizana ndi Mgwirizano:Kuyankhulana kogwira mtima ndi mgwirizano ndizofunikira kuti mgwirizano ukhale wopambana. Onetsetsani kuti womanga naye jekeseni ali ndi njira zabwino zoyankhulirana, amayankha mafunso anu, ndipo akhoza kukupatsani zosintha za polojekiti nthawi zonse. Njira yothandizirana idzakuthandizani kuonetsetsa kuti tikukwaniritsa zomwe mukufuna ndikuthana ndi zovuta zilizonse.

- Ndemanga za Makasitomala:Fufuzani maumboni amakasitomala kapena werengani ndemanga/umboni kuti mudziwe zambiri zomwe makasitomala ena amakumana nawo ndi mnzake womanga jekeseni. Kupeza izi kungathandize kudziwa kudalirika kwawo, kufulumira, komanso kukhutitsidwa kwamakasitomala.

Kutsiliza

Kumangira jakisoni wa Thermoplastic ndi njira yosunthika komanso yotsika mtengo yopangira zida zapulasitiki zambiri. Kutha kwake kupanga mawonekedwe ovuta mwatsatanetsatane komanso kusasinthika kwakhala chisankho chodziwika bwino m'mafakitale osiyanasiyana, kuphatikiza zamagalimoto, zamankhwala, zamagetsi, ndi zinthu zogula. Pomvetsetsa mbali zosiyanasiyana za jekeseni wa thermoplastic, kuphatikizapo ubwino wake, kuipa kwake, ndi kulingalira kwa mapangidwe, mukhoza kupanga zisankho zanzeru posankha bwenzi loyenera jekeseni pazofuna zanu zabizinesi.