Kuumba jekeseni wa pulasitiki Zofunika Kwambiri

Ntchito iliyonse yopambana yopangira jakisoni iyenera kuganizira zinthu zingapo nthawi imodzi.

Kusankha Kwachuma

Zipangizo zimagwira ntchito yayikulu pakuumba jekeseni. Wothandizira jekeseni waluso amatha kukuthandizani kusankha thermoplastic yomwe ikugwirizana ndi bajeti yanu komanso zomwe mukufuna kuchita. Chifukwa oumba amapeza kuchotsera pamakalasi ambiri a thermoplastic omwe amagula, amatha kukupatsirani ndalamazo.

Kulekerera Kusiyanasiyana

Chida chilichonse chopangidwa kudzera mu jekeseni chiyenera kukhala ndi zololera kuti zigwirizane ndi zomwe akufuna. Zida zina zimatha kukhala zovuta kuumba kapena kugwirizira zololera zofunika, komanso kapangidwe ka zida zimathanso kukhudza kulolerana kwa gawo lomaliza. Nthawi zonse kambiranani ndi choumba jekeseni wanu za kuvomereza kulolerana kwazinthu zinazake.

Kutentha kwa Barel ndi Nozzle

Oumba amayenera kusunga kutentha kwa mbiya ndi mphuno mu jekeseni chifukwa amakhudza mphamvu ya utomoni kuyenda mu nkhungu yonse. Kutentha kwa migolo ndi mphuno kuyenera kukhazikitsidwa ndendende pakati pa kuwola kwa thermo ndi kutentha kosungunuka. Kupanda kutero, kungayambitse kusefukira, kung'anima, kuyenda pang'onopang'ono, kapena magawo osadzazidwa.

Mitengo ya Thermoplastic Flow

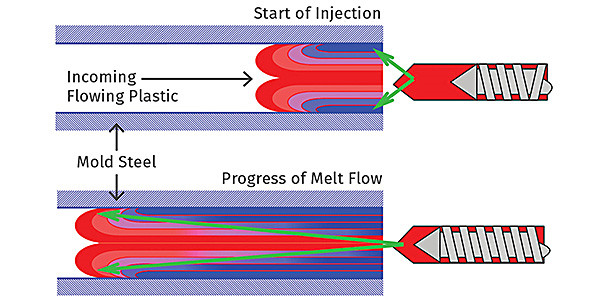

Ma molders ayenera kukhala othamanga kwambiri kuti awonetsetse kuti pulasitiki yotenthedwa imabayidwa mwachangu momwe angathere mumtsempha wa nkhungu mpaka itadzaza 95% mpaka 99%. Kukhala ndi liwiro loyenda bwino kumatsimikizira kuti pulasitiki imasunga mulingo woyenera wa viscosity kuti ulowe mumtsempha.

Zina zomwe ziyenera kuganiziridwa popanga jekeseni iliyonse ndi:

*Malo a gate

*Zizindikiro zakuya

*Makona otseka

* Kujambula

* Kuwongolera ndi kuwongolera kolowera

*Magawo otetezeka achitsulo

Njira Zisanu ndi Zimodzi Zofunika Pakuumba jekeseni

Njira yopangira jakisoni imaphatikizapo masitepe asanu ndi limodzi, ndipo nkhani zimatha kubwera pazigawo zilizonse ngati sizikuchitidwa moyenera.

1.Kuthina

Pochita izi, magawo awiri a nkhungu amatetezedwa mwamphamvu pogwiritsa ntchito clamping unit, yomwe imagwiritsa ntchito mphamvu ya hydraulic kuti ikhale ndi mphamvu zokwanira kuti itseke nkhungu. Popanda kukakamiza kokwanira, njirayi imatha kupangitsa kuti pakhale magawo osagwirizana ndi khoma, zolemera zosagwirizana, ndi kukula kosiyanasiyana. Kukakamiza kopitilira muyeso kungayambitse kuwombera mwachidule, kuyaka, ndi kusintha kwa gloss.

2.Kubaya

Ma molders amabaya jekeseni wosungunuka wa thermoplastic mu nkhungu ndi ramming chipangizo kapena wononga pansi pa kupsyinjika kwakukulu. Kenako, gawolo liyenera kuloledwa kuziziritsa pamlingo wofanana. Ngati sichoncho, gawo lomaliza likhoza kukhala ndi mizere yoyenda kapena zosafunikira zomwe zimakhudza kukongola kwake.

3.Dwelling Pressure

Thermoplastic material ikalowetsedwa mu nkhungu, zoumba zimakakamiza kwambiri kudzaza mabowowo mokwanira. Nthawi zambiri amasunga zinthu zosungunula za thermoplastic mpaka chipata cha nkhungu chizizizira. Nthawi yokhalamo iyenera kugwiritsa ntchito mphamvu yoyenera - yotsika kwambiri ndipo imatha kusiya zipsera pazomaliza. Kupanikizika kwambiri kungayambitse ma burrs, kukula kwake, kapena vuto lotulutsa gawolo mu nkhungu.

4. Wozizilitsa

Pambuyo pokhazikika, nkhungu imadzazidwa, koma imakhala yotentha kwambiri kuti isachotsedwe mu nkhungu. Choncho, oumba amapatula nthawi yochuluka kuti nkhungu itenge kutentha kwa pulasitiki. Zoumba ziyenera kusunga kuziziritsa kokwanira, kofananako kwa zida za thermoplastic kapena zitha kusokoneza chomaliza.

5.Kutsegula kwa nkhungu

Ma mbale osunthika a makina ojambulira nkhungu amatseguka. Zikhungu zina zimakhala ndi kuwongolera kwa mpweya kapena kukoka kwapakati, ndipo makina opangira amawongolera kuchuluka kwa mphamvu zomwe zimagwiritsidwa ntchito potsegula nkhungu ndikuteteza gawolo.

6.Kuchotsa Gawo

Chomaliza chimatulutsidwa mu nkhungu ya jakisoni ndi kugunda kwa ejection system, ndodo, kapena robotics. Zopaka zotulutsa za nano pamtunda wa nkhungu zimathandizira kupewa misozi kapena misozi pakutulutsa.

Zomwe Zimapangidwira Zowonongeka Zomwe Zimayambitsidwa ndi Mavuto a Njira

Pali zolakwika zingapo zomaumba zomwe zimagwirizanitsidwa ndi jekeseni, monga:

Warping: Warping ndi kupunduka komwe kumachitika pamene gawolo likukumana ndi kuchepa kosagwirizana. Amawoneka ngati mawonekedwe opindika kapena opindika osakonzekera.

Jetting: Ngati jekeseni wa thermoplastic wabayidwa pang'onopang'ono ndikuyamba kukhazikika pabowo lisanadzaze, zitha kuyambitsa kugwedezeka kwa chinthu chomaliza. Kuthamanga kumawoneka ngati mtsinje wa wavy jet pamwamba pa gawolo.

Sink zizindikiro: Awa ndi madontho a pamwamba omwe amapezeka ndi kuzizira kosiyana kapena pamene zoumba sizilola nthawi yokwanira kuti gawolo lizizire, zomwe zimapangitsa kuti zipangizozo zichepetse mkati.

Mizere yowotcherera: Izi ndi mizere yopyapyala yomwe nthawi zambiri imapanga mozungulira magawo okhala ndi mabowo. Pamene pulasitiki yosungunuka imayenda mozungulira dzenje, maulendo awiriwa amakumana, koma ngati kutentha sikuli bwino, madziwo sangagwirizane bwino. Zotsatira zake ndi mzere wowotcherera, womwe umachepetsa kukhazikika ndi mphamvu ya gawo lomaliza.

Chotsani zizindikiro: Ngati gawolo litulutsidwa msanga kwambiri kapena ndi mphamvu yochulukirapo, ndodo za ejector zimatha kusiya zizindikiro pazomaliza.

Vacuum voids: Vacuum voids zimachitika pamene matumba a mpweya atsekeredwa pansi pa gawolo. Zimayambitsidwa ndi kulimba kosagwirizana pakati pa zigawo zamkati ndi zakunja za gawolo.

Jekeseni Woumba Ntchito Zochokera ku DJmolding

The DJmolding, voliyumu yayikulu, katswiri wopanga jekeseni, ali ndi zaka 13 zopanga jekeseni. Chiyambireni DJmolding, takhala tikudzipereka kuti tipatse makasitomala athu magawo opangidwa ndi jakisoni apamwamba kwambiri omwe alipo. Masiku ano, chiwopsezo chathu ndi chochepera 1 gawo pa miliyoni.