Bokamoso ba Moshoelella oa Tlhahiso ea Plastiki ea Batch e Nyane ka Mould ea Ente e Nyenyane

Bokamoso ba Moshoelella oa Tlhahiso ea Plastiki ea Batch e Nyane ka Mould ea Ente e Nyenyane

Ho etsa lipolasetiki tse nyane e se e tumme haholo lilemong tsa morao tjena, kaha e thusa likhoebo ho etsa lihlahisoa tse ikhethileng tse ipapisitseng le litlhoko tsa bareki ba tsona. Leha ho le joalo, liphello tse kotsi tsa polasetiki tikolohong li ke ke tsa hlokomolohuoa, li susumetsa tlhokahalo ea mekhoa e tsitsitseng ea tlhahiso. Ha lefats'e le ntse le ela hloko haholoanyane phello ea litšila tsa polasetiki tikolohong, bokamoso ba tlhahiso ea polasetiki e nyane e holim'a ts'ebetso.

Kajeno, re tla hlahloba bokamoso ba moshoelella oa tlhahiso ea polasetiki ea lihlopha tse nyane, ho kenyeletsoa le lintlafatso tsa morao-rao tsa theknoloji le melemo ea ho sebelisa mekhoa e baballang tikoloho.

Ho Utloisisa Tlhahiso e Tsoelang Pele ea Batch e Nyane ea Plastiki

Ho etsa lihlahisoa tsa polasetiki tse nyane tse tsitsitseng ho bolela tlhahiso ea lihlahisoa tsa polasetiki ka bongata bo fokolang ho sebelisoa mekhoa e baballang tikoloho. Ts'ebetso ena e mabapi le ho hlahisa lihlahisoa tsa polasetiki ka bongata ha ho ntse ho fokotsa tšusumetso tikolohong. Tšebeliso ea mehloli ea matla a tsosolositsoeng e thusa ho fokotsa ho ntšoa ha khabone, athe ho sebelisa litšila ho etsa bonnete ba hore litšila li fokotsehile. Ho etsa li-batch tse nyane ho molemo kaha ho lumella ho ikamahanya le maemo, ho feto-fetoha ha maemo tlhahisong, 'me haholo-holo, tikoloho e bolokehileng bakeng sa basebetsi le bareki.

Ts'ebetso ea tlhahiso e hlahlojoa ka hloko ho netefatsa hore lihlahisoa li etsoa ho latela litekanyetso tse behiloeng, ntle le ho sekisetsa boleng. Ho etsa lipolasetiki tse nyane tse tsitsitseng ke mokhoa oa ho etsa likhoebo tse batlang ho ba le tšusumetso e ntle tikolohong ha li ntse li fihlela tlhoko ea bareki.

Bohlokoa ba Mekhoa ea Moshoelella ea Tlhahiso

Mekhoa e tsitsitseng ea tlhahiso e se e le ea bohlokoa haholo lilemong tsa morao tjena, kaha lik'hamphani li lemoha tlhokahalo ea ho fokotsa tšusumetso ea tsona tikolohong le sechabeng ka kakaretso. Melemo ea mekhoa e tsitsitseng ea tlhahiso e mengata, ho tloha ho fokolloa ke litšila le tšebeliso ea matla ho ea ho ntlafatso ea boitšoaro ba basebetsi le botšepehi ba bareki.

Ka ho sebelisa mekhoa e tsitsitseng ea tlhahiso, lik'hamphani li ka fokotsa khabone le ho baballa lisebelisoa tsa tlhaho. Sena se ka finyelloa ka mehato e kang mechine e baballang matla, mananeo a ho e sebelisa hape, le tšebeliso ea mehloli ea matla a ka nchafatsoang. Sena ha se thuse tikoloho feela, empa hape se ka lebisa ho bolokeng litšenyehelo bakeng sa k'hamphani ka nako e telele.

Ntle le melemo ea tikoloho, mekhoa e tsitsitseng ea tlhahiso e ka boela ea ntlafatsa boitšoaro ba basebetsi le botšepehi ba bareki. Ho na le monyetla oa hore basebetsi ba ikutloe ba le motlotlo ka mosebetsi oa bona mme ba susumetsoa ke k'hamphani e etelletsang pele botsitso. Bareki ba ntse ba batla lihlahisoa tse tsitsitseng mme ba na le monyetla oa ho lula ba tšepahala ho k'hamphani e bontšang boitlamo ba ho boloka botsitso.

Bokamoso ba Tlhahiso e Ts'oarellang ea Batch e Nyane ea Plastic

Bokamoso ba moshoelella tlhahiso ea polasetiki e nyane ea ts'episa. Ho na le mokhoa o ntseng o eketseha o lebisang ho mekhoa e tsitsitseng ea tlhahiso, 'me bareki ba ntse ba ela hloko haholoanyane tikoloho. Tšebeliso ea mehloli ea matla a ka nchafatsoang, ho sebelisoa hape ha lintho tse senyehileng, le phokotso ea mesi ea khabone e tla tsoela pele ho tsepamisa maikutlo nakong e tlang. Tlhokahalo ea lihlahisoa tse tšoarellang le eona e tla eketseha, e lebisang kholong ea tlhahiso ea polasetiki e nyane e tšoarellang.

Litlhahiso tsa Theknoloji e Tsoelang Pele ea Tlhahiso ea Plastic

Mekhoa e mecha ea theknoloji e tsitsitseng ea ho etsa polasetiki e ntse e tsoela pele. Ho ntse ho ntlafatsoa mahlale a macha ho fokotsa tšusumetso ea tikoloho ea tlhahiso ea polasetiki. Theknoloji ena e kenyelletsa tšebeliso ea lisebelisoa tse senyehang habonolo, khatiso ea 3D, le tšebeliso ea mehloli ea matla a ka nchafatsoang. Lisebelisoa tse senyehang ka tlhaho li ntse li tsebahala haholo ha li ntse li senyeha ka tlhaho 'me ha li kenye letsoho tšilafalong ea tikoloho. Khatiso ea 3D e lumella tlhahiso ea lihlahisoa tse ikhethileng, ho fokotsa litšila le ho eketsa bokhoni. Tšebeliso ea mehloli ea matla a tsosolositsoeng e kang matla a letsatsi le a moea e fokotsa ho ntšoa ha carbon le ho khothalletsa ho tšoarella.

Seabe sa Moruo oa Sedikadikwe ho Tlhahiso ea Plastiki ea Batch e Nyenyane

Moruo oa selikalikoe o bolela mokhoa oa ho fokotsa litšila le ho khothaletsa tšebeliso ea thepa hape. Ka tlhahiso ea polasetiki e nyane, mekhoa ea moruo e chitja e ka sebelisoa ho fokotsa litšila le ho khothaletsa botsitso. Sena se kenyelletsa tšebeliso ea thepa e nchafalitsoeng, ho fokotsa tšebeliso ea lisebelisoa tse ke keng tsa nchafatsoa, le ho khothaletsa tšebeliso ea lihlahisoa hape. Mekhoa ea moruo ea selikalikoe e boetse e khothalletsa tšebeliso ea thepa e sa sireletsehang tikolohong le ho fokotsa litšila.

Kameho ea Tlhahiso ea Moshoelella Tikolohong

Tlhahiso e tsitsitseng e na le phello e ntle tikolohong. E fokotsa tšebeliso ea lisebelisoa tse sa tsosolositsoeng, e khothalletsa tšebeliso ea mehloli ea matla a ka nchafatsoang, 'me e fokotsa ho ntšoa ha khabone. Ho etsa lintho ka mokhoa o tsitsitseng ho boetse ho khothalletsa tšebeliso ea thepa e baballang tikoloho le ho fokotsa litšila. Ha ho bapisoa le mekhoa ea khale ea tlhahiso, tlhahiso e tsitsitseng e na le phello e fokolang haholo ea tikoloho.

Melemo ea Moruo ea Tlhahiso e Ts'oarellang ea Batch e Nyane ea Plastic

Ho etsa lipolasetiki tse nyane tse tsitsitseng ho na le melemo ea moruo. E fokotsa litšenyehelo tsa tlhahiso ka ho khothaletsa tšebeliso ea mehloli ea matla a tsosolositsoeng, ho fokotsa litšila, le ho khothaletsa katleho. Lihlahisoa tse tsitsitseng le tsona li na le tlhokahalo e phahameng, e lebisang ho eketseha ha thekiso le chelete. Mekhoa e tsitsitseng ea tlhahiso e boetse e khothalletsa mekhoa e mecha le boiqapelo, e lebisang ho nts'etsopele ea lihlahisoa le litšebeletso tse ncha.

Mathata a Hona Joale ho Tlhahiso e Ts'oarellang ea Batch e Nyane ea Plastic

Ha lefats'e le ntse le tsoela pele ho sebetsana le tšusumetso ea tikoloho ea polasetiki, tlhahiso ea polasetiki e nyane e tobane le liphephetso tse 'maloa ho fihlella botsitso.

E 'ngoe ea mathata a maholo ke khaello ea meaho ea ho e sebelisa hape le ho sebelisa liphaphatha tse nyane tsa polasetiki. Bahlahisi ba bangata ba na le lisebelisoa tsa ho tsetela ho potlakisa le ho sebelisa mananeo hape, empa baetsi ba li-batch tse nyane hangata ba fumana ho le thata ho kenya tšebetsong mananeo a joalo ka lebaka la litšenyehelo tse phahameng tse amehang.

Phephetso e 'ngoe ke boteng bo fokolang ba lisebelisoa tse tšoarellang bakeng sa tlhahiso ea polasetiki e nyane. Baetsi ba bangata ba itšetlehile ka lipolasetiki tsa setso, tse entsoeng ka mehloli e sa tsosolosoeng 'me li na le tšusumetso e mpe tikolohong. Le hoja ho na le mekhoa e meng e tsitsitseng e fumanehang, hangata e theko e boima haholo ebile ho thata ho e fumana.

Ho feta moo, baetsi ba lihlopha tse nyane ba tobana le mathata a ho fokotsa litšila nakong ea tlhahiso. Ho fapana le bahlahisi ba bangata ba ka tsetelang mochining le lits'ebetsong tse tsoetseng pele, baetsi ba li-batch tse nyane hangata ba na le lisebelisoa tse fokolang tsa ho ntlafatsa ts'ebetso ea bona ea tlhahiso.

fihlela qeto e

Ho etsa lipolasetiki tse nyane tse tsitsitseng ho bohlokoa bakeng sa ho khothaletsa botsitso le ho fokotsa tšusumetso ea tikoloho ea tlhahiso ea polasetiki. Tšebelisano-'moho le mekhoa e mecha lia hlokahala bakeng sa kholo ea mekhoa e tsitsitseng ea tlhahiso. Baetsi le bareki ba tlameha ho etelletsa pele botsitso ho khothaletsa bokamoso bo tsitsitseng. Tšebeliso ea mehloli ea matla a ka nchafatsoang, ho sebelisoa hape ha litšila, le phokotso ea mesi ea khabone e tlameha ho tsepamisoa maikutlo nakong e tlang. Ho etsa lipolasetiki tse nyenyane tse tsitsitseng ho na le melemo ea moruo, ho khothalletsa mekhoa e mecha, le ho fokotsa tšusumetso ea tikoloho ea tlhahiso.

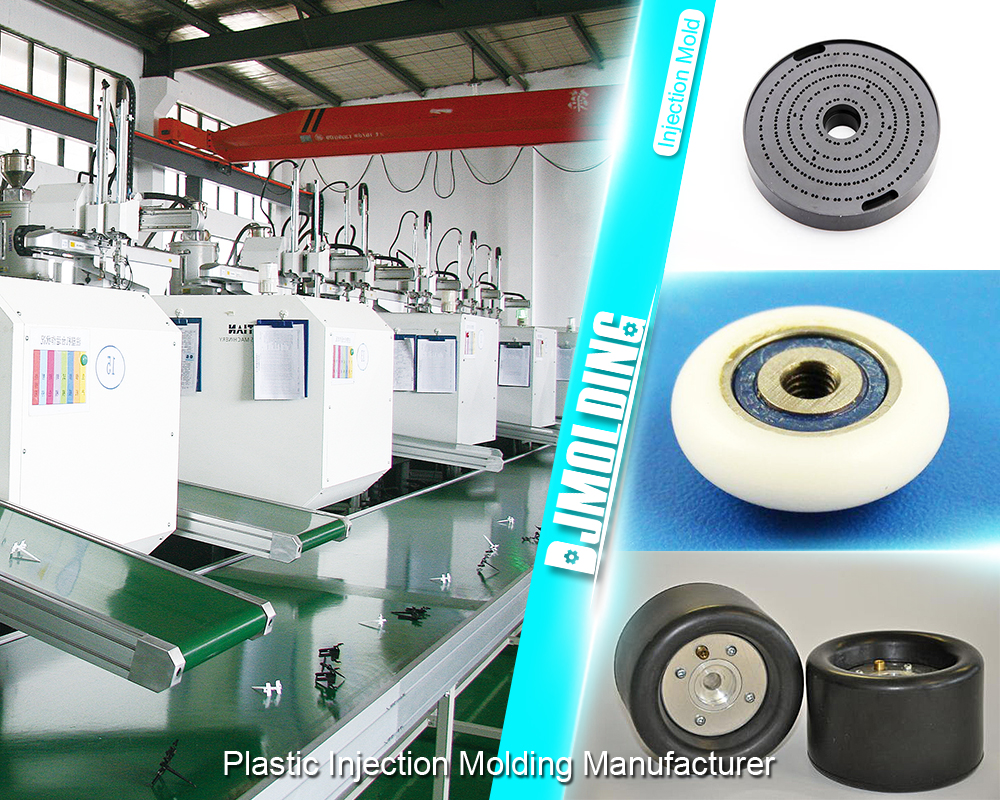

Bakeng sa ho eketsehileng ka bokamoso ba moshoelella nyenyane batch polasetiki tlhahiso le ho bopa ente e nyane, o ka etela Djmolding ho https://www.djmolding.com/low-volume-injection-molding/ etsoe Info more.