Shari'a a Koriya

Tsare Tsare Tsaren Kaurin bangon Ƙararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙaƙwalwa na Ƙaƙwal ) na Koriya ta Yi

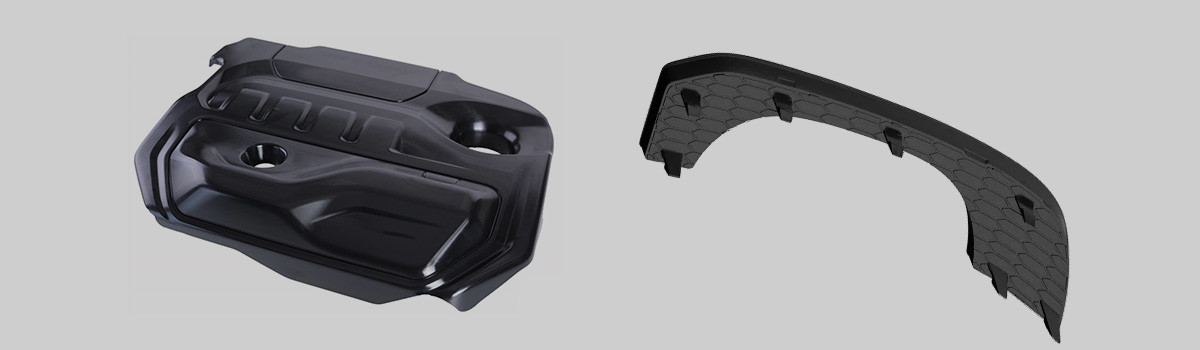

Sassan filastik suna shigo da kaya sosai don mota, kuma tsarinsa yana da ƙarfi zai yi tasiri akan rayuwa da tuki lafiya, don haka masana'antun Koriya ta Koriya suna siyan sassan filastik mai tsauri. Kamfanonin kera motoci za su yi amfani da kayan robobi da yawa a cikin mota, kamfanonin alluran na Koriya na cikin gida ba za su iya ba da kayayyaki masu yawa ba, kuma waɗannan masana'antun kera motoci za su sayi sassan filastik a ketare, kamar DJmolding daga China.

Sassan filastik suna da mahimmanci ga mota, don haka ta yaya za a tsara tsarin kaurin bangon sassan alluran filastik don kamfanonin motocin Koriya? Yanzu, DJmolding zai nuna muku ƙira na roba allura sassa' kauri tsarin.

Ma'anar kaurin bango

Kaurin bango shine ainihin fasalin fasalin sassa na filastik. Idan ana kiran gefen waje na sassan filastik bangon waje, ana kiran saman ciki bangon ciki, to akwai darajar kauri tsakanin bangon waje da na ciki. Ana kiran ƙimar kaurin bango. Ƙimar da aka shiga lokacin da aka fitar da harsashi a kan software a lokacin ƙirar tsari kuma ana iya cewa kaurin bango ne.

Aiki na kauri bango

Don bangon waje na samfurori

bangon waje na sassa yana kama da fata na waje. bangon ciki shine kwarangwal na sassa. Ana iya samun tasirin bayyanar daban-daban ta hanyar jiyya na bangon waje na sassa. Katangar ciki kawai tana haɗa tsarin (haƙarƙari, sandunan dunƙule, ƙugiya da sauransu) tare kuma yana ba da wani ƙarfi ga sassan. A halin yanzu, ana iya cika wasu sifofi yayin aikin gyare-gyaren kamuwa da cuta. Babu takamaiman buƙatu don bangon ciki da na waje (sanyi, taro). A al'ada, an yi shi gaba ɗaya don sassa su sami isasshen ƙarfi don kare sassan ciki daga lalacewa ko tsoma baki daga muhalli.

Don sassan ciki na samfurin

A matsayin ma'auni ko haɗin haɗin kai, babu ƙaƙƙarfan buƙatu don bangon ciki da na waje, wanda zai iya kafa wasu sifofi (haƙarƙari, sanduna, buckles da sauransu) a bangon waje bisa ga ainihin yanayin. Duk da haka, domin kare kanka da m masana'antu (yafi nufin lokacin da gaba da raya kyawon tsayuwa ne rabu, domin su ci gaba da filastik sassa a cikin raya mold, gaban fuskar mold, wanda m bango ya kamata a tsara a matsayin mai sauki kamar yadda zai yiwu. Idan ba haka ba, daidaitawa da zayyana kwana na gaba da raya kyawon tsayuwa, ko da suna da thimble a gaban mold ko wani kananan undercut a raya mold), da kuma gaba ɗaya tsara wasu Tsarin a kan ciki bango.

Komai sassan harsashi ne ko sassa na ciki, kaurin bango yana da mahimmanci kamar yadda ake samun saman fil ɗin ejector na ƙirar, yana ba da damar sassan da za a fitar da su lafiya.

Ka'idodin ƙira na kaurin bango:

A cikin zayyana sassan filastik, kaurin bango shine fifiko, wanda yake da mahimmanci a matsayin tushen ginin. Sauran gine-ginen suna buƙatar ginawa a kai. A halin yanzu, yana kuma tasiri kayan aikin injiniya, tsari, bayyanar, farashin sassa na filastik. Don haka, kaurin bango ya kamata ya dogara ne akan abubuwan da ke sama don tsarawa.

Ya ambaci cewa kauri na bango yana buƙatar zama takamaiman ƙima. Idan akwai darajar, yana nufin ko da kauri bango. Idan akwai dabi'u da yawa, yana nufin kaurin bango mara daidaituwa. Bambanci tsakanin ko da ko m za a gabatar bayan. Yanzu, zamuyi magana game da ka'idar ƙirar bangon bango ya kamata a bi.

1. Bisa ka'idar kayan aikin injiniya:

Ya ambaci cewa komai sassa harsashi ne ko sassan ciki, duka biyun suna buƙatar wani matakin ƙarfi. Baya ga wasu dalilai, ana buƙatar ƙarfin sakin juriya yayin la'akari da samuwar sassa. Yana da sauƙi a ɓata idan ɓangaren ya yi bakin ciki sosai. Gabaɗaya magana, ƙaurin bangon bangon, mafi girman ƙarfin sassan (kaurin bango yana ƙaruwa don 10%, ƙarfin zai ƙaru da kusan 33%). Idan kaurin bangon ya wuce wani yanki, ƙara har zuwa kauri na bango zai rage ƙarfin sassa saboda raguwa da porosity. Haɓaka kauri na bango zai rage ƙarfin sassa kuma yana ƙara nauyi, ƙara da'irar gyare-gyaren allura, farashi, da sauransu a fili, ƙara ƙarfin sassa ta hanyar ƙara kauri kawai ba shine mafi kyawun shirin ba. Zai fi kyau a yi amfani da siffofi na geometric don ƙara taurin kai, kamar haƙarƙari, masu lanƙwasa, tarkace, stiffeners, da dai sauransu.

Ba a yanke hukunci ba cewa saboda ƙarancin sararin samaniya da wasu dalilai, ƙarfin wasu sassa yana samuwa ne ta hanyar kaurin bango. Don haka, ana bada shawara don ƙayyade girman bangon da ya dace ta hanyar yin koyi da simintin inji idan ƙarfin yana da mahimmanci. Lallai, ƙimar kaurin bango kuma yakamata a bi ka'idodin ƙa'idodi masu zuwa.

2. Bisa ka'idar tsari:

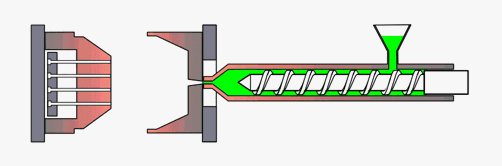

Ainihin kauri bango shine kauri na ƙurawar ƙura tsakanin gaba da baya. Lokacin da narkakkar guduro ya cika fitar da mold rami da sanyaya, da kauri da aka samu a bango.

1) Ta yaya narkakken guduro yake gudana yayin aikin allura da cikawa?

Ana iya ɗaukar kwararar filastik a cikin rami a matsayin kwararar laminar. Bisa ga ka'idar injiniyoyin ruwa, ana iya ɗaukar ruwan laminar azaman yadudduka na ruwa kusa da juna suna zamewa ƙarƙashin aikin ƙarfi.

A lokacin aikin gyaran allura, narkakken guduro yana hulɗa da bangon masu gudu (bangon rami), yana sanya yadudduka rafi manne da bangon masu gudu (ko bangon ƙura) da farko sanyaya. Gudun ba shi da sifili, kuma akwai juriyar juriya da aka samar tare da layin ruwa na kusa. Ci gaba kamar haka, gudun tsakiyar rafi shine mafi girma. Siffofin kwarara wanda saurin laminar ya ragu kusa da bangon mai gudu (ko bangon kogin mold) a ɓangarorin biyu.

Matsakaicin Layer shine Layer na ruwa, kuma fatar fatar jiki shine mai ƙarfi. Yayin da lokacin sanyi ya wuce, la'anar la'ana za ta karu. Wurin giciye na ruwan ruwa zai zama ƙarami a hankali. Mafi tsananin cika, ƙarfin allurar ya fi girma. Lalle ne, yana da wuya a tura narke a cikin rami don cika allurar.

Sabili da haka, girman kaurin bango yana da tasiri mai girma akan kwarara da kuma cika sassan alluran da aka ƙera yayin aikin gyaran allura, kuma ƙimarsa ba zai iya zama ƙanƙanta ba.

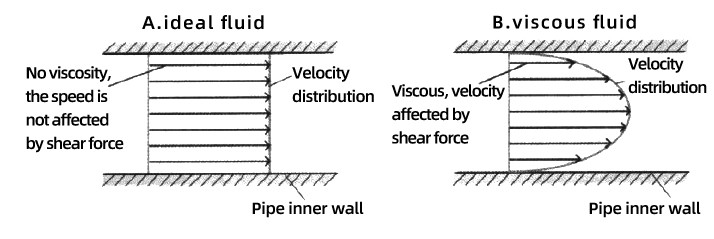

2) Danko na narke filastik kuma yana da tasiri mai yawa akan ruwa

Lokacin da narke yana ƙarƙashin aikin waje, kuma akwai motsi na dangi tsakanin yadudduka, za'a sami ƙarfin juzu'i na ciki wanda aka haifar don tsoma baki game da motsi tsakanin matakan ruwa. Ƙarfin juzu'i na ciki da ruwan ya haifar ana kiransa danko. Ƙimar ƙarfin danko tare da danko mai ƙarfi (ko madaidaicin danko). Adadin rabon damuwa mai ƙarfi zuwa ƙimar juzu'i na narkewa.

Danko na narkewa yana nuna halaye na sauƙi wanda narke filastik ke gudana. Ma'auni ne na juriya na narkewa. Mafi girman danko, mafi girman juriya na ruwa, mafi wahalar kwarara. Abubuwan da ke da tasiri na narkewar danko yana rinjayar ba kawai suna hade da tsarin kwayoyin halitta ba, amma kuma suna da alaka da yanayin zafi, matsa lamba, adadin shear, additives, da dai sauransu (bayan yanke shawarar nau'in kayan filastik, zafin jiki, matsa lamba, raguwa, ƙararrawa, da dai sauransu). da sauran dalilai yayin aikin gyaran allura na iya canza canjin ruwa na filastik a cikin tsarin allura.

Yayin, a cikin ainihin aikace-aikacen, Index narke yana nuna ruwa na kayan filastik a cikin sarrafawa. Mafi girman ƙimar, mafi kyawun ingancin kayan abu. Akasin haka, yawan ruwa na kayan zai zama mafi muni.

Sabili da haka, filastik tare da ruwa mai kyau ya fi sauƙi don cika rami na mold, musamman don sassan gyare-gyaren allura tare da sifofi masu rikitarwa.

Za a iya raba yawan ruwan robobi da aka saba amfani da su zuwa sassa uku bisa ga buƙatun ƙirar ƙira:

① Kyakkyawan ruwa mai kyau: PA, PE, PS, PP, CA, poly (4) methyl pentylene;

②Matsakaicin ruwa: polystyrene jerin resins (kamar ABS, AS), PMMA, POM, PPO;

③ Rashin ruwa mara kyau: PC, PVC mai wuya, PPO, PSF, PASF, fluoroplastics.

Kamar yadda za mu iya gani daga Fig. a sama, kayan da ke da mafi ƙarancin ruwa, abubuwan da ake buƙata don ƙananan bangon bango zai zama mafi girma. An gabatar da wannan a cikin ka'idar kwararar laminar.

Ƙimar da aka ba da shawarar kaurin bangon da ke sama lamba ce kawai. A cikin ainihin aikace-aikacen, girman girman sassan sun haɗa da ƙanana, matsakaici da babba, hoton da ke sama ba ya ƙayyade iyakar tunani.

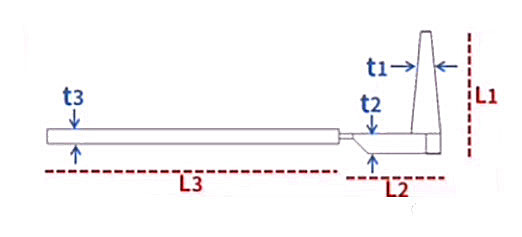

3) Za mu iya ƙididdigewa ta hanyar ma'auni na tsawon tsayi

Rabon tsayin kwararar filastik yana nufin rabon tsayin (L) zuwa kauri na bango (T) na kwararar filastik filastik. Wannan yana nufin ga kaurin bangon da aka ba da, mafi girman ƙimar tsayin kwarara, mafi nisa na narkewar filastik. Ko kuma lokacin da tsayin kwararar narkewar filastik ya tabbata, mafi girman girman girman rabo, ƙaramin kauri na bango zai iya zama. Don haka, ƙimar tsayin kwararar filastik kai tsaye yana shafar adadin ciyarwa da rarraba samfuran filastik. Har ila yau, yana rinjayar kaurin bangon filastik.

Don zama mafi daidai, za a iya samun takamaiman ƙimar ƙimar bangon bango ta hanyar ƙididdige ƙimar ƙimar tsayin kwarara. Lalle ne, wannan darajar tana da alaƙa da zafin jiki na kayan abu, zafin jiki na ƙima, digiri na gogewa, da dai sauransu kawai ƙimar iyaka ce kawai, yanayi daban-daban sun bambanta, yana da wuyar zama daidai, amma ana iya amfani dashi azaman ƙimar tunani.

Kididdigar tsawon rabo:

L / T (duka) = L1 / T1 (babban tashar) + L2 / T2 (tashar tashoshi) + L3 / T3 (samfurin) Matsakaicin tsayin da aka ƙididdige ya kamata ya zama ƙasa da ƙimar da aka bayar a cikin tebur na kayan jiki, in ba haka ba za'a iya zama Al'amarin rashin cikawa.

Misali

Harsashi na roba, kayan PC, kaurin bango shine 2, nisan cikawa shine 200, mai gudu shine 100, diamita na masu gudu shine 5.

Calculation: L/T(total)=100/5+200/2=120

Ƙimar ma'auni don ƙimar tsayin kwararar PC shine 90, wanda a bayyane yake ya fi ƙimar mai magana. Ana buƙatar ƙara saurin allura da matsa lamba saboda yana da wuyar allura, ko ma suna buƙatar takamaiman injunan gyare-gyaren allura. Idan ya ɗauki maki biyu na ciyarwa ko canza matsayin wuraren ciyarwa, za a iya rage nisan cikar samfuran zuwa 100, wanda shine L/T (duka) = 100/5+100/2=70. Matsakaicin tsayi a yanzu bai kai ƙimar tunani ba kuma yana da sauƙi don gyare-gyaren allura. L/T(total)=100/5+200/3=87 lokacin da aka canza kaurin bango zuwa 3, wanda ke ba da damar gyare-gyaren allura na yau da kullun.

3. Bisa ka'idar bayyanar:

Takamaiman aikin kauri na bango yana shafar bayyanar sassa shine kamar haka:

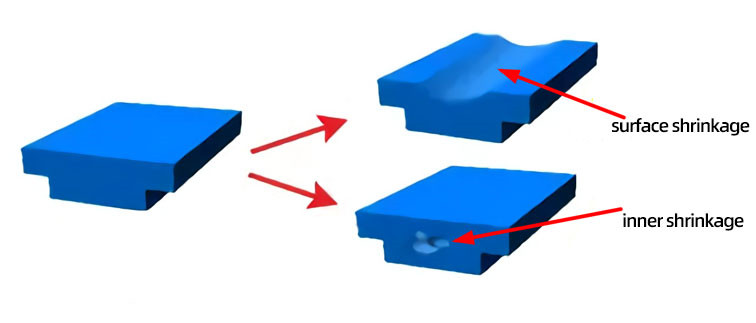

1) Kaurin bango mara daidaituwa: raguwar saman (ciki har da lahani irin su shrinkage, rami, kauri da kwafi), nakasar warping, da sauransu.

2) Kaurin bango da ya wuce kima: lahani kamar shrinkage saman da ramukan raguwa na ciki.

3) Kaurin bango ya yi ƙanƙanta: lahani kamar rashin mannewa, bugu na thimble, warge da nakasawa.

shrinkage ko porosity

raguwa ko porosity yawanci yana faruwa a wuraren kaurin bango mai kauri. Hanyar: bisa ga ka'idar ƙarfafa kayan aiki, porosity na ciki da raguwa a lokacin aikin gyaran allura shine saboda ƙaddamar da kullun yayin aikin sanyaya. Lokacin da shrinkage ya mayar da hankali a cikin daskararre matsayi a baya, amma ba za a iya samu nan da nan, shrinkage da porosity sun fi faruwa a ciki.

Ka'idodin ƙira na kauri na bangon da ke sama an gabatar da su daga bangarori huɗu, waɗanda ke da kaddarorin injiniya, tsari, bayyanar, farashi. Idan aka yi amfani da jumla ɗaya don kwatanta ƙirar bangon kauri, wannan shine ƙimar kauri na bangon sassan da aka ƙera ya kamata ya zama ƙanƙanta gwargwadon yuwuwa kuma daidai gwargwado kamar yadda zai yiwu a ƙarƙashin yanayin gamsar da kayan injin da aikin sarrafawa. In ba haka ba, ya kamata a canza shi daidai.

DJmolding yana ba da ƙirar sassa na filastik da sabis na kera don markte na duniya, idan kuna son fara aikin ku, da fatan za a tuntuɓe mu a yanzu.