Sabbin Abubuwan Ci gaba A cikin Gyaran Allurar Filastik

Filastik allura gyare-gyare a matsayin masana'antu dabara ya kusa shekaru da yawa. Koyaya, sabbin hanyoyin gyare-gyaren allura suna ciyar da wannan hanyar gaba, suna kawo sabbin fa'idodin da ba a taɓa gani ba ga kamfanonin da suka zaɓi hakan.

Nemo abin da sabbin hanyoyin gyaran allura suke na shekaru masu zuwa da kuma yadda kamfanin ku zai amfana daga amfani da su.

Ta yaya ƙirar allurar filastik ta samo asali?

Duk da yake robobi sun kasance tun daga shekarun 1850, ba sai a shekarun 1870 ba ne aka ƙirƙira nau'ikan robobi masu sassauƙa. A sakamakon haka, an haɓaka hanyoyin gyaran allura. Tun daga nan, ci gaba da dama sun ingiza yiwuwar yin gyare-gyaren filastik a gaba:

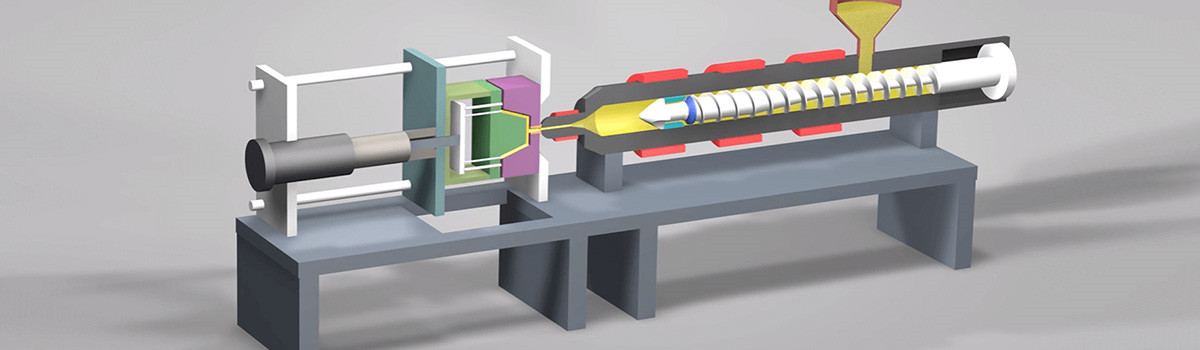

Ƙirƙirar injunan gyare-gyaren allura yana nufin cewa saurin allura yana da sauƙin sarrafawa ta yadda samfurin ƙarshe kuma ya gabatar da inganci mafi girma. Wannan tsari kuma ya ba da damar yin amfani da gaurayawan kayan, buɗe kofa don yin amfani da robobi masu launi da sake sarrafa su.

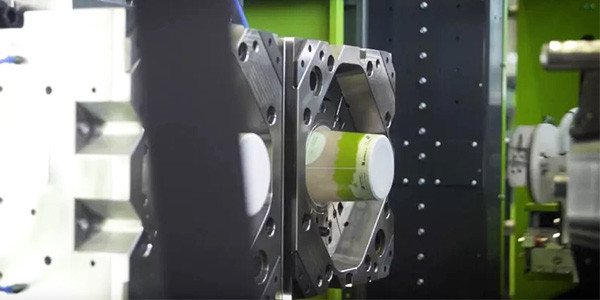

Na'urorin dunƙule masu taimakon iskar gas kuma sun ba da damar ƙirƙirar ƙarin hadaddun, mafi sassauƙa da ƙarfi. Wannan hanyar kuma tana nufin farashin tattalin arziki ya ragu, saboda lokacin samarwa, sharar gida, da nauyin samfurin duk an rage su.

Ƙarin gyare-gyare masu rikitarwa sun wanzu yanzu godiya ga masana'antun da ke taimaka wa kwamfuta, masu zanen kaya yanzu za su iya samar da siffofi masu rikitarwa (za su iya samun sassan da yawa ko kuma sun zama cikakkun bayanai da kuma daidai).

Gyaran allura mai taimakon gas

A cikin wannan nau'i na gyare-gyaren allura, nau'in filastik narke na yau da kullun yana taimakawa ta hanyar allurar iskar gas mai matsa lamba a cikin ƙirar - ana amfani da nitrogen don wannan tsari. Gas ɗin yana haifar da kumfa wanda ke tura filastik zuwa ƙarshen ƙirar; don haka, yayin da kumfa ta fadada, an cika sassa daban-daban. Akwai nau'ikan gyare-gyare da yawa da aka yi amfani da su a cikin masana'antar robobi waɗanda aka bambanta da matsayin da aka yi amfani da iskar gas lokacin jefa polymer.

Musamman ma, ana iya allurar iskar gas ta hanyar bututun ƙarfe a cikin injin, ko kai tsaye zuwa cikin rami na ƙera a ƙarƙashin matsi ko ƙara. Wasu daga cikin waɗannan hanyoyin ana kiyaye su ta hanyar haƙƙin mallaka; don haka ya kamata a kulla yarjejeniyar ba da izini da kyau don amfani da su.

Kumfa Injection Molding

Wannan dabarar tana ba da ingantacciyar hanya, mai araha don cimma babban juriya da tsayin daka a cikin sassa na tsari. Baya ga wannan fa'idar, sassan kumfa na tsari suna da keɓancewar yanayin zafi mafi girma, mafi girman juriya na sinadarai, da ingantattun halayen lantarki da ƙararrawa. Wannan ɓangarorin sun haɗa da tushen kumfa tsakanin yadudduka biyu; Ana samun wannan ainihin ta hanyar narkar da iskar gas a cikin resin kuma ba shi damar faɗaɗa lokacin shigar da maganin gas-plastic a cikin rami na mold. A ina za mu iya samun sassan da aka kera ta hanyar gyaran kumfa? Ana amfani da wannan tsari a cikin sassan abin hawa azaman madadin rage nauyin sashi.

Sirin-bangon allura Molding

Babban fasaha na fasaha a cikin wannan yanayin yana da alaƙa da sakamakon ƙarshe: wani sashe da ganuwar bakin ciki sosai.

Babban wahalar wannan tsari shine yanke shawarar abin da faɗin bango ya kamata a ɗauka a matsayin "bangon bakin ciki". A matsayinka na gaba ɗaya, lokacin da aka kera sassan sassan masu faɗin ƙasa da rabin millimita (1/50th na inch), ana ɗaukar su da bangon bakin ciki.

Amfanin da ke tattare da rage girman bangon yana da matukar godiya kuma ana nema a zamanin yau.

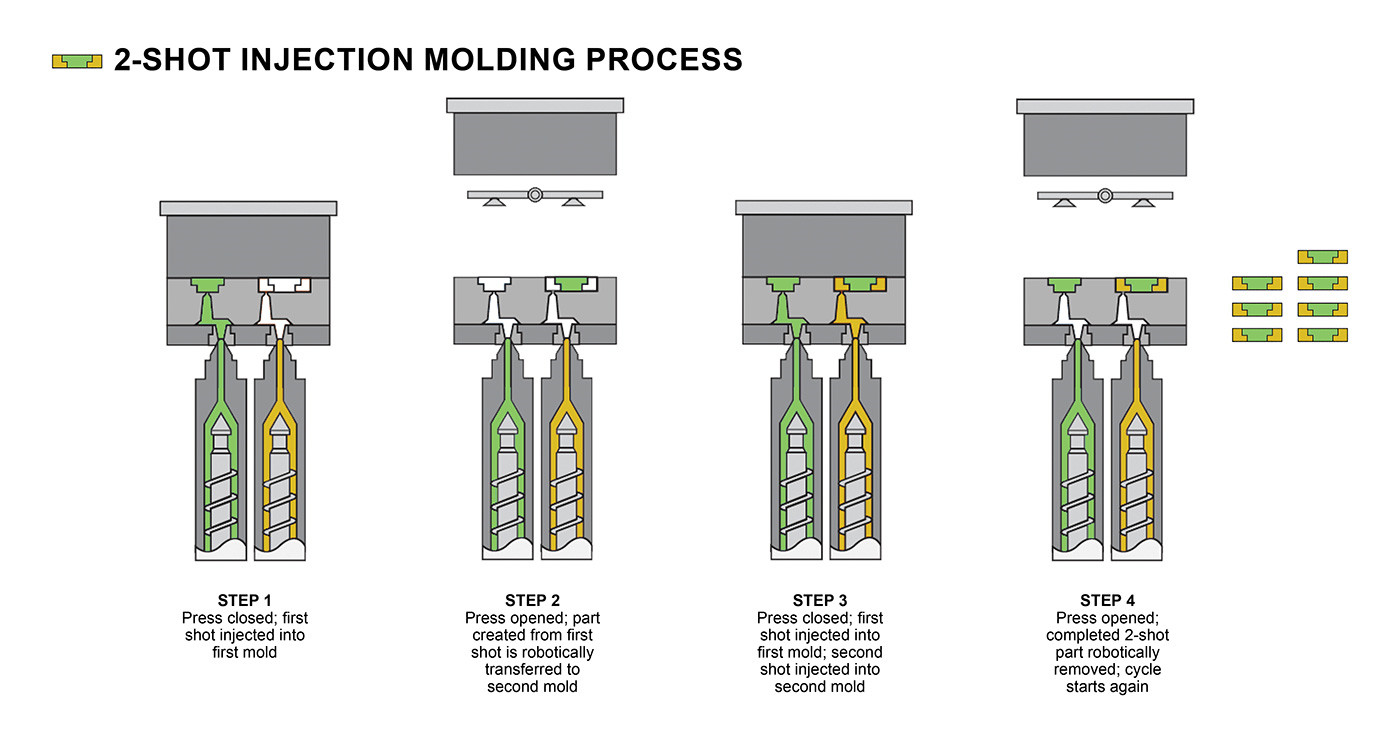

Multi Bangaren Injection Molding

Har ila yau, an san shi da overmoulding ko overinjection , tun da wannan aikin ya ƙunshi yin amfani da polymer mai wuya ko mai laushi a kan wani abu mai tushe (substrate), wanda shine gabaɗaya ɓangaren filastik ko ƙarfe.

Gabaɗaya, ana iya bayyana wannan fasaha azaman allurar fiye da ɗaya sashi ko abu a cikin nau'in ƙira ɗaya kuma a matsayin wani ɓangare na tsari guda ɗaya, yana ba da damar haɗa abubuwa biyu, uku ko fiye da launuka daban-daban, laushi da siffofi.

Menene fa'idar yin gyare-gyaren kayan allura da yawa?

gyare-gyaren allura da yawa yana ba da damar kera hadaddun sassa waɗanda ƙila za a iya samu ta nau'ikan robobi daban-daban. Babban fa'idar wannan aikin allurar filastik shine ana iya samun sassan da ke da babban injin inji, zafi da juriya na sinadarai.

Filastik allura gyare-gyare trends na gaba shekara

Dorewar gyare-gyaren alluran filastik

Masana'antar gyaran gyare-gyaren filastik tana saurin daidaitawa zuwa sabbin dabi'u da ka'idoji masu dorewa, musamman a lokacin da ake ƙara sa ido da daidaita masana'antar filastik. Don haka, sabbin hanyoyin gyaran allura suna nuni zuwa:

Amfani da kayan filastik 100% da za a sake yin amfani da su waɗanda kuma ba su da aminci da tsaka tsaki na muhalli.

Neman hanyoyin da za a rage sawun carbon yayin masana'antu. Wannan na iya haɗawa da amfani da sabbin hanyoyin samar da makamashi da yin aiki don rage asarar makamashi yayin ayyukan masana'antu

A lokaci guda, dole ne kamfanoni su ba da garantin cewa jujjuyawar samfuri masu dorewa baya yin sulhu akan ingancin samfur, gami da kayan inji da na zahiri na samfuran.

Ƙara yawan buƙatun kayan nauyi

Kayayyakin masu nauyi galibi suna fassara zuwa ƙarancin tattalin arziƙi (kamar waɗanda ke da hannu wajen jigilar kaya), da ƙarancin kuɗin kuzari (misali, a cikin sassan mota). Kayan marasa nauyi a cikin na'urorin likitanci kuma na iya inganta sakamakon marasa lafiya.

Filastik allura gyare-gyaren al'ada mafita

Binciken ƙarin zaɓuɓɓuka masu inganci a cikin gyare-gyaren alluran filastik ya kuma haifar da fifikon mafita na al'ada, yayin da kamfanoni da yawa ke fahimtar ROI ɗin su yana ƙaruwa lokacin da sassan fasahar su ke yin al'ada don dacewa da takamaiman bukatun su.

Filastik allura gyare-gyare aiki da kai da sababbin fasaha

Zaɓuɓɓukan software na sarrafa kansa daban-daban, gami da gabatarwar AI, Koyon Injin, da kuma nazarce-nazarce, suna ƙara yuwuwar gyare-gyaren allurar filastik gaba.

Waɗannan fasahohin suna ba da damar rage ƙarancin lokaci da rashin aiki a cikin kayan aiki, haɓaka shirye-shiryen kiyaye tsinkaya, da kuma saurin samar da hawan keke. A lokaci guda kuma, sabbin software na baiwa kamfanoni damar kwaikwayi kewayon gyare-gyaren allura yayin aikin ƙira, gwada batutuwan kamar tsarin cika ba bisa ka'ida ba. Wannan yana fassara zuwa gyara al'amurra kafin ci gaba zuwa tsarin samarwa, don haka adana lokaci da kuɗi.