Ka'idojin Gyaran Allurar Filastik

Bincika tsarin gyaran allura da yadda yake aiki.

Filastik gyare-gyaren gyare-gyaren sananniyar fasaha ce ta masana'anta inda ake juyar da pellet ɗin thermoplastic zuwa manyan juzu'i na hadaddun sassa. Tsarin gyare-gyaren allura ya dace da nau'ikan kayan filastik kuma muhimmin al'amari ne na rayuwar yau da kullun-lambobin waya, gidajen lantarki, kayan wasan yara, har ma da sassan mota ba za su yiwu ba tare da shi ba. Wannan labarin zai rushe tushen gyare-gyaren allura, kwatanta yadda aikin allura ke aiki, da kwatanta yadda ya bambanta da bugun 3D.

Menene Tushen Gyaran Allurar Filastik?

Tushen tsarin yin gyare-gyaren filastik ya haɗa da ƙirƙirar ƙirar samfuri, yin kayan aikin kayan aiki don dacewa da ƙirar samfuri, narkar da pellet ɗin resin filastik, da yin amfani da matsa lamba don allurar narke cikin ƙirar.

Dubi ɓarna kowane mataki a ƙasa:

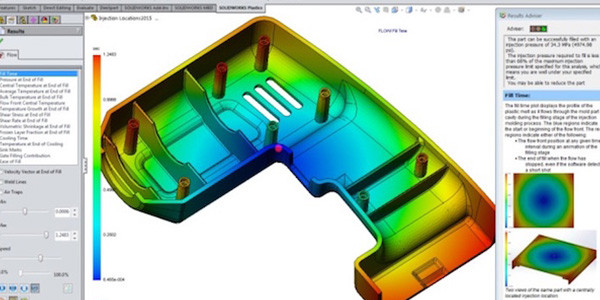

1. Ƙirƙirar Ƙirƙirar Samfur

Masu zanen kaya (injiniyoyi, kasuwancin ƙera ƙira, da sauransu) ƙirƙirar wani sashi (a cikin nau'in fayil ɗin CAD ko wani tsari mai canzawa), bin ƙa'idodin ƙira na musamman ga tsarin gyare-gyaren allura. Masu ƙira su yi ƙoƙarin haɗa abubuwa masu zuwa a cikin ƙirarsu don taimakawa haɓaka nasarar ƙirar ƙirar filastik:

* Shugabanni don abubuwan sakawa / masu ɗaure

*Kaurin bango na dindindin ko kusa-kusa

* Sauƙi mai laushi tsakanin kaurin bango mai canzawa

* Ramin rami a cikin sassa masu kauri

* Zagaye gefuna

* Zayyana kusurwoyi akan bangon tsaye

* Haƙarƙari don tallafi

* Gwagwarmaya daidai gwargwado, haɗin gwiwa mai dacewa, da sauran abubuwan haɗin haɗin da ba masu sauri ba

* Hannun hanji

Bugu da ƙari, ya kamata masu zanen kaya su rage abubuwan da ke gaba don rage lahani a cikin ƙirar su:

*Kaurin bango mara Uniform ko musamman sirara/kaurin bango

* Ganuwar tsaye ba tare da daftarin kusurwoyi ba

* Canje-canje na geometric kwatsam (kusurwoyi, ramuka, da sauransu)

*Rashin ƙira mai kyau

* Ƙarƙashin ƙasa / wuce gona da iri

2. Yin Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Kayan Ƙasa

ƙwararrun ƙwararrun mashinan masana'anta da masu yin kayan aiki, ta yin amfani da ƙirar samfuri, suna ƙirƙira ƙirar kayan aiki don injin gyare-gyaren allura. Kayan aikin kayan aiki (wanda kuma aka sani da kawai kayan aiki) shine zuciya da ruhin injin gyare-gyaren allura. An tsara su a hankali don ƙunsar mummunan rami don ƙirar samfurin da ƙarin fasali kamar su sprues, masu gudu, ƙofofi, filaye, tsarin fitarwa, tashoshi mai sanyaya, da abubuwan motsi. Ana yin gyare-gyaren kayan aiki daga takamaiman nau'ikan ƙarfe da aluminum waɗanda za su iya jure dubun dubbai (kuma wasu lokuta dubban ɗaruruwan) na zagayowar dumama da sanyaya, kamar 6063 aluminum, P20 karfe, H13 karfe, da bakin karfe 420. Tsarin ƙirƙira ƙirar yana ɗaukar sama da makonni 20 don kammalawa, gami da ƙirƙira da yarda, yin wannan matakin ya zama mafi fa'ida mafi tsayi na gyare-gyaren allura. Har ila yau, shine mafi tsada na gyaran gyare-gyaren allura, kuma da zarar an ƙera kayan aiki, ba za a iya canza shi sosai ba tare da ƙarin farashi ba.

3. Narkar da Ƙwayoyin Gudun Filastik

Bayan masu aiki sun sami ƙãre samfurin, an saka shi a cikin injin yin gyare-gyaren allura, kuma ƙirar ta rufe, ta fara zagayowar gyare-gyaren allura.

Ana ciyar da granules na filastik a cikin hopper da cikin ganga. An dawo da kullin mai maimaitawa, yana barin kayan su zamewa cikin sarari tsakanin dunƙule da ganga. Sa'an nan dunƙule ya zube gaba, tilasta kayan cikin ganga da kuma kusa da hita makada inda ya narke a cikin narkakkar robobi. Ana kiyaye zafin jiki mai narkewa kamar yadda ƙayyadaddun kayan aiki suke don kada lalacewa ta faru a cikin ganga ko a cikin ƙirar kanta.

4. Amfani da Matsi don Allurar Narkewar Pellets A cikin Mold

Matsakaicin juzu'i yana tilasta wannan robobin da ya narke ta cikin bututun ƙarfe, wanda ke zaune a cikin baƙin ciki a cikin ƙirar da aka fi sani da ƙwanƙwasa sprue bushing. Matsin farantin mai motsi ya dace da ƙirar da bututun ƙarfe tare sosai, yana tabbatar da cewa babu filastik da zai iya tserewa. Wannan narkarwar robobin yana matse shi ta hanyar wannan tsari, yana haifar da shi ya shiga duk sassan ramin ƙirƙira kuma yana fitar da iska mai fitar da iska ta cikin iska.

Abubuwan Injuna Molding Machine

Abubuwan da ke cikin injin gyare-gyaren allura sun haɗa da hopper, ganga, dunƙule mai jujjuyawa, hita(s), farantin mai motsi, bututun ƙarfe, mold, da rami mai ƙura.

Ƙarin bayani kan kowane ɓangaren gyare-gyaren allura a cikin jerin da ke ƙasa:

*Hopper: bude inda ake ciyar da granules filastik a cikin injin.

* Ganga: Gidan waje na injin gyare-gyaren allura, wanda ya ƙunshi dunƙule mai juyawa da granules na filastik. An nannade ganga a cikin madaurin dumama da yawa kuma an dunkule shi da bututun ƙarfe mai zafi.

* Matsakaicin screw: Bangaren corkscrew wanda ke aikawa da matse kayan filastik yayin da yake narkewa ta cikin ganga.

*Masu zafi: Wanda kuma aka sani da makada masu dumama, waɗannan abubuwan suna samar da makamashi mai zafi ga ƙwanƙolin filastik, suna juya su daga wani tsari mai ƙarfi zuwa ruwa. tsari.

* Platen Motsi: Bangaren motsi da aka haɗa da ƙirar ƙira wanda ke aiwatar da matsa lamba don kiyaye nau'ikan nau'ikan guda biyu suna tsayawa iska sannan kuma yana sakin ginshiƙan ƙirar lokacin bayyana ɓangaren da ya gama.

* Nozzle: bangaren mai zafi wanda ke ba da madaidaicin madaidaicin madaidaicin filastik narkakkarwa a cikin rami mai ƙura, kiyaye zafin jiki da matsa lamba a matsayin karko kamar yadda zai yiwu.

*Mildi: bangaren ko aka gyara da ke dauke da kogon mold da ƙarin fasalulluka masu goyan baya kamar ejector fil, tashoshi masu gudu, tashoshi masu sanyaya, vents, da sauransu. core (a kan farantin motsi).

*Cikin Tsari: Wurin mara kyau wanda, idan an cika shi da robobi narkakkar, zai siffata shi zuwa sashin karshe da ake so tare da goyon baya, ƙofofi, masu gudu, sprues, da sauransu.

Ta yaya allura Molding ke Aiki?

Da zarar robobin ya cika gyare-gyaren da suka haɗa da sprues, masu gudu, ƙofofinsa, da dai sauransu, ana ajiye ƙirar a yanayin zafin da aka saita don ba da damar daidaita kayan abu cikin siffar sashi. Ana kiyaye matsin lamba yayin sanyaya don duka biyun dakatar da komawa cikin ganga da rage tasirin raguwa. A wannan lokacin, ana ƙara ƙarin granules na filastik zuwa hopper don tsammanin sake zagayowar (ko harbi). Lokacin da aka sanyaya, farantin yana buɗewa kuma yana ba da izinin fitar da ɓangaren da aka gama, kuma za a sake ja da dunƙule a baya, yana barin abu ya shiga cikin ganga kuma ya sake farawa.

Zagayowar gyare-gyaren allura yana aiki ta wannan ci gaba da tsari-rufe gyare-gyare, ciyarwa / dumama granules filastik, matsa su cikin ƙirar, sanyaya su cikin wani yanki mai ƙarfi, fitar da sashin, da sake rufe mold ɗin. Wannan tsarin yana ba da damar samar da sassa na filastik cikin sauri, kuma sama da ɓangarorin filastik 10,000 za a iya yin su a cikin ranar aiki dangane da ƙira, girma, da kayan aiki.

Djmolly