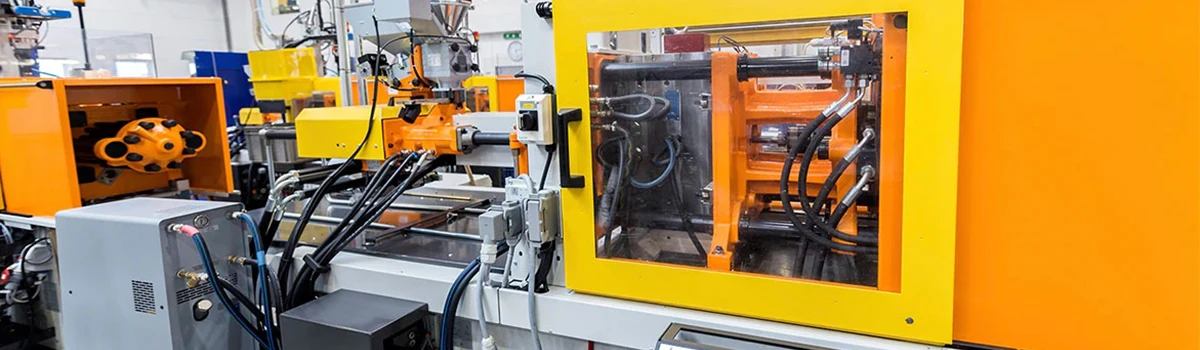

Menene gyare-gyaren allurar filastik

Yin gyare-gyaren allurar thermoplastic hanya ce don kera sassa masu girma da kayan filastik. Saboda amincinsa da sassaucin ra'ayi a cikin zaɓuɓɓukan ƙira, ana amfani da gyare-gyaren allura a masana'antu da yawa, gami da: marufi, mabukaci & lantarki, motoci, likita, da ƙari mai yawa.

Yin gyare-gyaren allura yana ɗaya daga cikin hanyoyin masana'antu da aka fi amfani da su a duniya. Thermoplastics su ne polymers waɗanda ke yin laushi kuma suna gudana lokacin da zafi, kuma suna ƙarfafa yayin da suke sanyi.

Aikace-aikace

Yin gyare-gyaren allura shine mafi yawan hanyoyin zamani na kera sassan filastik; yana da kyau don samar da babban kundin abu ɗaya. Ana amfani da gyare-gyaren allura don ƙirƙirar abubuwa da yawa, ciki har da spools na waya, marufi, kwalaben kwalba, sassa na mota da kayan aiki, kayan wasan kwaikwayo na wasan kwaikwayo, combs na aljihu, kayan kiɗa, kujeru da ƙananan tebur, kwantena na ajiya, sassa na inji, da sauran kayan filastik da yawa.

Tsarin ƙira

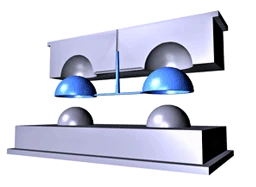

Bayan da aka ƙera samfuri a cikin Software kamar fakitin CAD, ana ƙirƙira gyare-gyare daga ƙarfe, yawanci ƙarfe ko aluminium, kuma ana yin daidaitaccen mashin don samar da fasalin ɓangaren da ake so. Samfurin ya ƙunshi sassa biyu na farko, allura mold (A plate) da ejector mold (B farantin). Resin robobi yana shiga cikin ƙirar ta hanyar sprue, ko kofa, kuma yana gudana zuwa cikin rami ta hanyar tashoshi, ko masu gudu, waɗanda aka kera su cikin fuskokin farantin A da B.

Tsarin gyaran allura

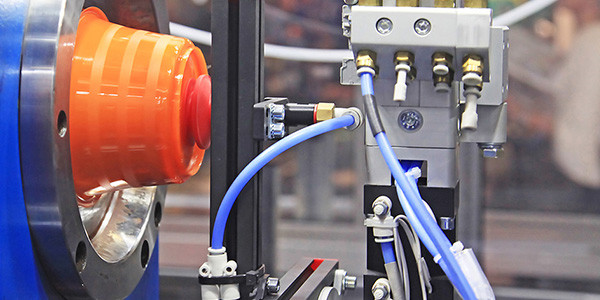

Lokacin da ake gyare-gyaren thermoplastics, galibi ana ciyar da albarkatun ƙasa ta cikin hopper a cikin ganga mai zafi tare da dunƙule mai juyawa. Screw ɗin yana isar da albarkatun ƙasa gaba, ta hanyar bawul ɗin dubawa, inda yake tarawa a gaban dunƙule cikin ƙarar da aka sani da harbi.

Harbin shine adadin guduro da ake buƙata don cika sprue, mai gudu da kogon ƙwanƙwasa. Lokacin da isassun kayan ya taru, kayan ana tilastawa a babban matsi da sauri cikin ɓangaren kafa rami.

Ta yaya allura Molding ke Aiki?

Da zarar robobin ya cika gyare-gyaren da suka haɗa da sprues, masu gudu, ƙofofinsa, da dai sauransu, ana ajiye ƙirar a yanayin zafin da aka saita don ba da damar daidaita kayan abu cikin siffar sashi. Ana kiyaye matsin lamba yayin sanyaya don duka biyun dakatar da komawa cikin ganga da rage tasirin raguwa. A wannan lokacin, ana ƙara ƙarin granules na filastik zuwa hopper don tsammanin sake zagayowar (ko harbi). Lokacin da aka sanyaya, farantin yana buɗewa kuma yana ba da izinin fitar da ɓangaren da aka gama, kuma za a sake ja da dunƙule a baya, yana barin abu ya shiga cikin ganga kuma ya sake farawa.

Zagayowar gyare-gyaren allura yana aiki ta wannan ci gaba da tsari-rufe gyare-gyare, ciyarwa / dumama granules filastik, matsa su cikin ƙirar, sanyaya su cikin wani yanki mai ƙarfi, fitar da sashin, da sake rufe mold ɗin. Wannan tsarin yana ba da damar samar da sassa na filastik cikin sauri, kuma sama da ɓangarorin filastik 10,000 za a iya yin su a cikin ranar aiki dangane da ƙira, girma, da kayan aiki.

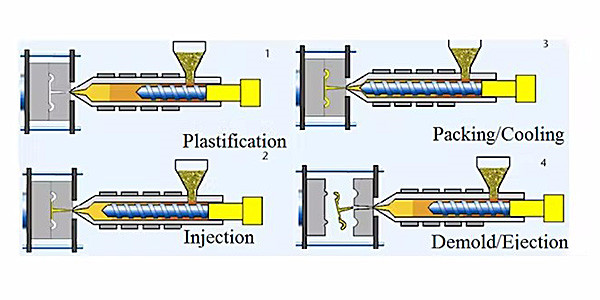

Zagayen gyare-gyaren allura

Zagayowar gyaran allura gajere ce, yawanci tsakanin daƙiƙa 2 da tsayin mintuna 2. Akwai matakai da yawa:

1.Camping

Kafin shigar da kayan a cikin gyaggyarawa, rabi biyu na ƙirar suna rufe, amintacce, ta hanyar matsawa. Naúrar matsawa mai ƙarfi da ruwa mai ƙarfi tana tura raƙuman ƙirar tare kuma tana yin isasshen ƙarfi don kiyaye ƙirar a rufe yayin da ake allurar kayan.

2.Alurar rigakafi

Tare da mold rufe, da polymer harbi ne allura a cikin mold rami.

3. sanyaya

Lokacin da rami ya cika, ana amfani da matsi mai riƙewa wanda zai ba da damar ƙarin polymer don shiga cikin rami don ramawa don raguwar filastik yayin da yake sanyi. A halin yanzu, dunƙule ya juya yana ciyar da harbi na gaba zuwa dunƙule na gaba. Wannan yana haifar da dunƙulewa don ja da baya yayin da aka shirya harbi na gaba.

4.Fitowa

Lokacin da ɓangaren ya yi sanyi sosai, ƙirar ta buɗe, za a fitar da ɓangaren, kuma sake zagayowar zata fara.

Abũbuwan amfãni

1.Fast samar; 2.Design sassauci; 3. Daidaito; 4. Low aiki halin kaka; 5.Rashin sharar gida