Harka a Jamus:

Aikace-aikacen Yin gyare-gyaren allura a cikin Ƙirƙirar Kayan Kayan Mota

A Jamus, gyare-gyaren allura na ɗaya daga cikin hanyoyin samar da robobi da aka fi amfani da su. Wannan ya yi daidai saboda yana ba da mafita mai dacewa don samar da ɗimbin ɗimbin ɓangarorin injunan allura daga ɗimbin polymers. A cikin masana'antar kera motoci, inda daidaito, aminci, da inganci ke da matuƙar mahimmanci, ƙirar allurar filastik na mota muhimmin tsari ne na masana'anta.

Akwai sanannun masana'antun kera motoci da yawa daga Jamus, suna ba da haɗin kai tare da DJmolding, siyan kayan aikin filastik mota daga sabis na gyare-gyaren allura na DJmolding, gami da fenders, grilles, bumpers, fatunan kofa, dogo na ƙasa, gidaje masu haske, da ƙari.

A DJmolding, muna ba da sabis na gyare-gyaren allura na ƙwararru, da isar da ɓangarorin motocin filastik da aka samar da jama'a ga abokan ciniki a cikin kera motoci da sauran masana'antu. Ayyukanmu sun haɗa da gyare-gyaren allura na thermoplastic, gyare-gyare fiye da kima, saka gyare-gyare, da yin gyare-gyare. A cikin akwati na ƙarshe, ƙwararrunmu suna aiki tare da abokan cinikin Jamus don samar da samfurori masu inganci don samfuri ko manyan ayyukan samarwa.

DJmolding kuma yana aiki tare da nau'ikan kayan allura na filastik, gami da ƙarfi, juriya mai zafi, da tsayayyen thermoplastics; m, mai sauri warkewar thermoplastics; da robobin roba masu zafi masu ɗorewa. Sabis ɗinmu na ƙwararrun ƙirar ƙirar filastik suna ba abokan cinikinmu damar samun ingantattun sassa na kera motoci waɗanda suka dace da bukatun aikace-aikacen su, musamman ga ƙasashe masu ƙarfi na masana'antar kera motoci, kamar Gemany, Amurka, Japan.

Aikace-aikacen Ƙirƙira don Ƙirƙirar allurar Mota

A bangaren kera motoci, gyare-gyaren allura na daya daga cikin manyan hanyoyin da masana'antun ke amfani da su wajen samar da sassan roba. Duk da haka, zai yi wuya a yi jerin abubuwan da aka yi amfani da su na filastik a cikin mota da aka samar ta hanyar yin amfani da allura, don haka za mu dubi wasu daga cikin manyan.

1. Abubuwan da ke ƙarƙashin-kaho

A cikin shekaru ashirin da suka gabata ko makamancin haka, yawancin abubuwan da ke ƙarƙashin kaho waɗanda masana'antun da aka yi daga ƙarfe a baya an canza su zuwa filastik. Don waɗannan aikace-aikacen, ƙwararrun polymers kamar ABS, Nylon, da PET na gama gari. Koyaya, masana'antun yanzu suna yin sassa kamar murfin kan silinda da kwanon mai ta amfani da gyare-gyaren allura. Wannan hanya tana ba da ƙananan ma'auni da farashi idan aka kwatanta da sassan karfe.

2. Abubuwan da ke waje

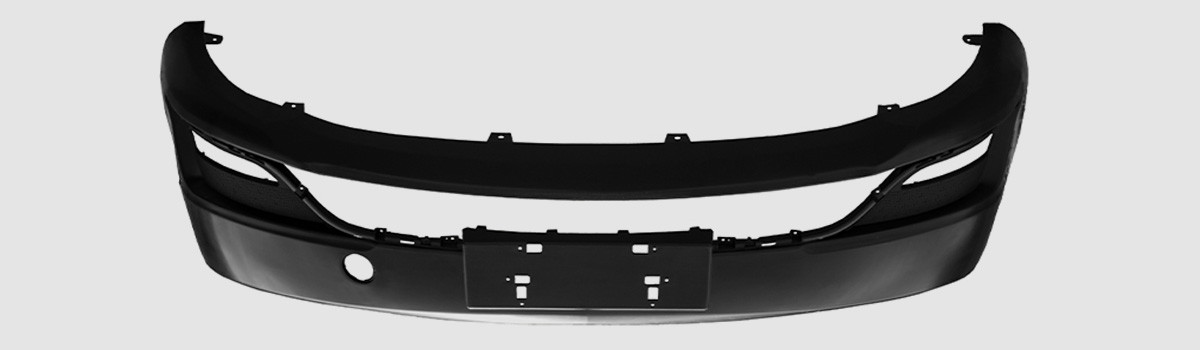

Yin gyare-gyaren allura wani tsari ne da aka kafa don yawancin abubuwan haɗin mota na waje, gami da fenders, grilles, bumpers, fatunan kofa, dogo na ƙasa, gidaje masu haske, da ƙari. Masu gadin fantsama misali ne mai kyau don nuna tsayin daka na sassan allura. Bugu da kari, abubuwan da ke kare mota daga tarkacen hanya da kuma rage tarwatsewa, galibi ana yin su ne daga roba ko wasu abubuwa masu ɗorewa da sassauƙa.

3. Abubuwan Cikin Gida

Masu masana'anta kuma suna samar da sassa na ciki da yawa na motoci ta amfani da gyare-gyaren alluran filastik mota. Sun haɗa da kayan aikin kayan aiki, saman ciki, dashboard faceplates, hanun kofa, ɗakunan safar hannu, hulunan iska, da ƙari. Bugu da kari, suna kuma amfani da gyare-gyaren allura don samar da abubuwan ado na filastik.

Madadin gyare-gyaren allura don Samfuran Motoci masu ƙarancin farashi

A yawancin lokuta, robobi da aka ƙera suna zama madadin ƙarfe. A da, masana'antun suna yin abubuwa kamar maɓalli, murfi na akwati, ƙirar bel ɗin kujera, da kwantenan jakar iska kawai daga ƙarfe. A zamanin yau, yin gyare-gyaren allura ita ce hanyar samarwa da aka fi so don waɗannan robobi.

A gefe guda, masana'antun na iya maye gurbin sassa na filastik da aka ƙera a wasu lokuta tare da ɓangarorin motar filastik da aka buga ta 3D. Wannan yana faruwa musamman a cikin samfuri, inda babu ƙarancin buƙatu don tsayin daka ko ƙarewar ƙasa mai santsi. Yawancin robobi masu gyare-gyare na iya aiki azaman filament na firinta na FDM 3D ko azaman foda na SLS 3D na nailan. Wasu ƙwararrun ƙwararrun firintocin 3D masu zafi kuma za su iya buga abubuwan ƙarfafawa don sassa masu ƙarfi.

Don samfura guda ɗaya, musamman waɗanda ba na injina ba, bugu na 3D na iya ba da madadin ƙira mai tsadar gaske. Saboda rashin farashin kayan aiki, farashin samarwa ba su da yawa.

A wasu lokuta, masana'antun na iya amfani da bugu na 3D don ɗimbin sassa na motoci masu amfani da ƙarshe. Suna iya amfani da bugu na SLM 3D don yin abubuwan sarrafa ruwa kamar bawuloli (ba yawanci ana yin allura ba). Koyaya, wani zaɓi yana amfani da bugu na SLS 3D don yin sassa kamar bumpers, datsa, da iska, waɗanda wasu lokuta ana yin allura.

Masu masana'anta na iya amfani da masana'anta ƙari don faɗuwar kewayon sassan mota na allura a nan gaba mara nisa. Wannan na iya kasancewa daga kofofi da sassan jiki (SLM) zuwa ƙarfin wutar lantarki da sassan tuƙi (EBM).

DJmolding yana da kyau sosai a gyare-gyaren filastik filastik don kayan haɗin mota, idan kuna son fara aikin samar da kayan aikin ku, da fatan za a tuntuɓe mu, za mu sami kyakkyawan haɗin gwiwa.