Injection Mold Manufacturing

Filastik abu ne da aka saba amfani da shi don samfuran masana'antu iri-iri. Kayan wasan yara, kayan aikin mota, na'urorin likitanci, kayan aiki, da ƙari duk an yi su daga filastik. Yawancin abubuwan filastik ko da muke ci karo da su a rayuwarmu ta yau da kullun ana samar da su ta hanyar sarrafa guduro narke cikin ƙayyadadden ƙira tare da tsarin masana'anta da ake kira gyare-gyaren alluran filastik. Wannan ingantaccen tsari yana iya yin sassa cikin girma da siffofi da yawa kuma yana iya maimaita sashi ɗaya sau da yawa ta amfani da ƙira iri ɗaya. A zuciyar wannan tsari shine mold, wanda kuma aka sani da kayan aiki. Tsarin ƙirar ƙirar ƙira mai inganci yana da mahimmanci don samar da sassa masu inganci yayin kiyaye ingantaccen aiki mai tsada. Ingancin sashi zai haura kuma farashin aikin gabaɗaya zai ragu lokacin da ake saka hannun jari a masana'antar ƙira mai inganci.

Matakan Gyaran Allura

Yin gyare-gyaren allura yana ɗaya daga cikin hanyoyin masana'antu na yau da kullun da ake amfani da su don samar da kayan filastik. Tsari ne mai girma wanda zai iya haifar da sashi iri ɗaya sau dubbai. Tsarin yana farawa da Fayil ɗin Taimakon Kwamfuta (CAD) mai ɗauke da kwafin dijital na ɓangaren. Ana amfani da fayil ɗin CAD azaman saitin umarni don taimakawa cikin tsarin ƙirar ƙira. Mold, ko kayan aiki, yawanci ana yin su ne daga ƙarfe guda biyu. An yanke rami a cikin siffar sashi a kowane gefen mold. Yawanci ana yin wannan ƙirar ne daga aluminum, karfe, ko gami.

Bayan samar da mold, mataki na gaba shine zabar kayan filastik da ya dace. Zaɓin kayan aiki zai dogara ne akan yadda za a yi amfani da ɓangaren ƙarshe. Kayan filastik suna da halaye iri-iri don yin la'akari. Wannan ya haɗa da duk bayyanar da ji, da juriya ga sinadarai, zafi, da ƙazanta. Yi magana da masana a DJmolding don ƙarin koyo game da samuwan kayan filastik don gyare-gyaren allura.

Kayan da aka zaɓa yana farawa azaman pellet ɗin filastik wanda aka ciyar da shi cikin hopper akan injin gyare-gyaren allura. Pellets suna kan hanyarsu ta wani ɗaki mai zafi inda ake narke su, a matse su, sannan a yi musu allura a cikin kogon. Da zarar sashin ya huce, rabi biyu na gyaggyarawa suna buɗe don fitar da sashin. Injin yana sake saitawa don sake fara aiwatarwa.

Wane Abu ne ake amfani dashi don Yin Molds?

Ana yin samar da ƙura da ƙarfe, aluminum, ko gami. DJmolding yana amfani da ƙarfe mai inganci don masana'anta. Samar da ƙirar ƙarfe ya ɗan fi tsada fiye da amfani da aluminium ko gami. Mafi girman farashi yawanci ana daidaita shi ta tsawon rayuwa mai tsayi don ƙirar ƙarfe. Aluminum molds, yayin da mai rahusa don samarwa, ba ya dawwama muddin karfe kuma dole ne a maye gurbinsu akai-akai. Ƙarfe gyare-gyare yawanci zai šauki fiye da dubu ɗari. Aluminum molds zai buƙaci sauyawa akai-akai. Samar da ƙera ƙarfe na iya haifar da ƙira mai sarƙaƙƙiya waɗanda ba za a iya cimma su da aluminum ba. Hakanan ana iya gyara gyare-gyaren ƙarfe ko gyara tare da walda. Ana buƙatar gyare-gyaren aluminium daga karce idan ƙirar ta lalace ko don ɗaukar canje-canje. Ana iya amfani da gyare-gyaren ƙarfe masu inganci dubbai, dubban ɗaruruwan, wani lokacin har zuwa zagayawa miliyan guda.

Abubuwan Allurar Mold

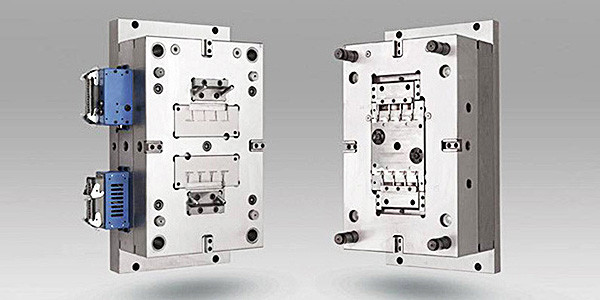

Yawancin nau'ikan allura sun ƙunshi sassa biyu - gefen A da gefen B, ko rami da ainihin. Bangaren rami yawanci shine mafi kyawun gefe yayin da sauran rabin, ainihin, za su sami wasu lahani na gani daga fitilun ejector waɗanda ke tura ɓangaren ƙãre daga cikin mold. Tsarin allura kuma zai haɗa da faranti na goyan baya, akwatin ejector, sandar ejector, fil ɗin ejector, faranti na ejector, bushing sprue, da zoben ganowa.

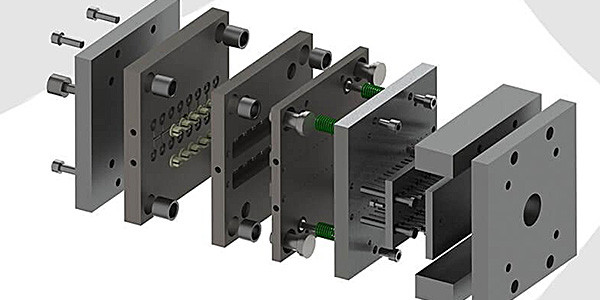

Yin gyare-gyaren allura shine tsarin masana'antu tare da yawancin motsi. A ƙasa akwai jerin sharuɗɗan da ke bayyana yawancin ɓangarorin da ake buƙata don samarwa da gyare-gyaren allura. Kayan aiki ya ƙunshi faranti na ƙarfe da yawa a cikin firam. Ana sanya firam ɗin ƙira a cikin injin gyare-gyaren allura kuma ana riƙe shi tare da matsi. Yanke wani nau'in allura da ake kallo daga gefe zai yi kama da sanwici mai nau'i daban-daban. Duba ƙamus ɗinmu na Injection Molding don cikakken jerin sharuɗɗan.

Tsararren Tsararru ko Tushe: Jerin faranti na ƙarfe waɗanda ke riƙe abubuwan ƙirar tare, gami da cavities, cores, tsarin mai gudu, tsarin sanyaya, da tsarin fitarwa.

A Plate: Daya rabin karfe m. Wannan farantin ba ya ƙunshi sassa masu motsi. Zai iya ƙunsar ko dai rami ko tushe.

B Plate: Sauran rabin karfen. Farantin yana ƙunshe da sassa masu motsi ko sarari don ƙyale sassa masu motsi suyi hulɗa tare da ɓangaren da aka gama - yawanci fil ɗin fitarwa.

Taimako Plates: Faranti na ƙarfe a cikin firam ɗin ƙira wanda ke ba da kwanciyar hankali yayin aiwatar da gyare-gyare.

Akwatin fitarwa: Ya ƙunshi tsarin fitarwa da ake amfani da shi don tura ɓangaren da ya ƙare daga cikin ƙirar.

Filayen fitarwa: Farantin karfe wanda ya ƙunshi sandar fitarwa. Farantin ejector yana motsawa don fitar da ƙãre samfurin bayan gyare-gyare.

Wutar lantarki: Bangaren farantin ejector. An haɗa fil ɗin fitarwa zuwa sandar ejector.

Fil masu fitarwa: Ƙarfe fil waɗanda ke tuntuɓar ɓangaren da aka gama kuma suna tura shi daga cikin ƙirar. Ana iya ganin alamomin fitilun fitilu akan wasu abubuwan da aka yi musu allura, yawanci tambarin zagaye da ake samu a bayan ɓangaren.

Bushewa: Wurin haɗawa tsakanin ƙura da injin gyare-gyaren allura inda narkakken guduro zai shiga cikin rami.

Sprue: Tabo akan firam ɗin ƙera inda guduro narkakkar ke shiga cikin kogon mold.

Zoben Mai Gano: Zoben ƙarfe wanda ke tabbatar da bututun ƙarfe na injin gyare-gyaren allura da kyau tare da bushing sprue.

Kogo ko Mutuwar Kogo: Ƙwararren ra'ayi a cikin mold, yawanci yana samar da farfajiyar waje na ɓangaren da aka ƙera. Ana sanya nau'i-nau'i azaman rami ɗaya ko rami mai yawa dangane da adadin irin waɗannan baƙin ciki.

core: Matsakaicin ra'ayi a cikin mold, yawanci yana ƙirƙirar saman ciki na ɓangaren da aka ƙera. Wannan wani yanki ne da aka taso na mold. Ita ce kishiyar rami. Narkakken guduro koyaushe ana tura shi cikin rami, yana cika sarari. Narkar da guduro zai yi kusa da tsakiyar da aka tashe.

Tsarin Gudu ko Gudu: Tashoshi a cikin nau'in ƙarfe wanda ke ba da damar narkakkar guduro don gudana daga sprue-zuwa-rago ko rami-zuwa rami.

Kofa: Ƙarshen mai gudu inda guduro narke ya shiga cikin kogon mold. Akwai ƙirar ƙofa daban-daban don aikace-aikacen daban-daban. Nau'o'in ƙofa da aka fi amfani da su sun haɗa da fil, magana, fan, baki, faifai, fan, rami, ayaba ko cashew, da chisel. Ƙofar ƙira da sanyawa suna da mahimmancin la'akari kafin fara aikin masana'anta.

Tsarin sanyaya: Jerin tashoshi a cikin harsashi na waje na mold. Waɗannan tashoshi suna zagaya ruwa don taimakawa aikin sanyaya. Sassan da ba su dace ba suna iya nuna lahani iri-iri na saman ko tsarin. Tsarin sanyaya yawanci shine ya zama mafi yawan sake zagayowar gyare-gyaren allura. Rage lokutan sanyaya na iya inganta ingantaccen ƙirar ƙira da ƙananan farashi. Fathom yana ba da Cooling Conformal don aikace-aikacen gyare-gyaren allura da yawa waɗanda za su ƙara ƙarfin mold har zuwa 60%

DJmolding mold Manufacturing don Daban-daban Tsarukan gyare-gyare

Ana iya daidaita tsarin yin gyare-gyaren filastik don ɗaukar buƙatu daban-daban da hadaddun. Yayin da ya dace don kera manyan juzu'i na sassa na filastik mai sauƙi, ana iya amfani da shi don ƙirƙirar sassa masu ban mamaki tare da hadaddun geometries ko majalisai.

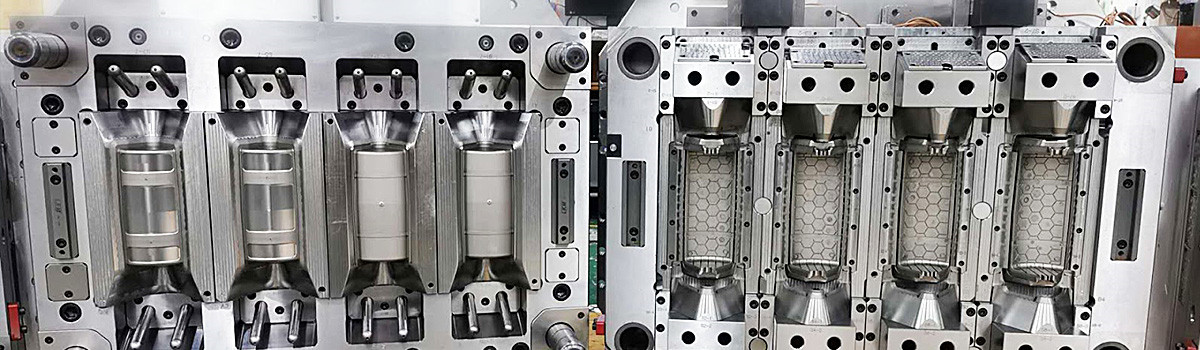

Multi-Cavity ko Family Mold – Wannan gyaggyarawa yana da ramummuka da yawa a cikin firam guda ɗaya wanda ke samar da da yawa iri ɗaya ko sassa masu alaƙa tare da kowane sake zagayowar allura. Wannan hanya ce mai kyau don ƙara juzu'in gudu da rage farashin kowane yanki.

Almubazzaranci - Ana amfani da wannan hanyar yin allura don ƙirƙirar sassan da aka yi da nau'ikan filastik iri biyu. Kyakkyawan misali na wannan zai zama jiki mai ɗaukar hoto ko mai kula da wasan tare da harsashi mai wuyar gaske tare da riko mai laushi, rubberized. An sake shigar da wani ɓangarorin da aka ƙera a baya a cikin wani ƙera na musamman. An rufe ƙirar kuma an ƙara Layer na biyu na filastik daban-daban a kan ɓangaren asali. Wannan tsari ne mai kyau lokacin da ake so nau'i-nau'i daban-daban guda biyu.

Saka Molding - Tsarin gyare-gyaren allura wanda ke ba da izinin haɗa ƙarfe, yumbu, ko kayan filastik zuwa ɓangaren ƙarshe. Ana sanya sassan ƙarfe ko yumbura a cikin ƙura sannan a narkar da robobi a cikin ƙirar don ƙirƙirar wani yanki marar lahani da aka yi da abubuwa daban-daban guda biyu. Saka gyare-gyare yana da kyau don aikace-aikacen mota saboda sabuwar hanya ce don rage nauyi da rage kaya mai tsada kamar karfe. Maimakon yin gaba ɗaya daga karfe, haɗin haɗin kawai yana buƙatar zama ƙarfe yayin da sauran kayan za a yi su daga filastik.

Haɗin-Injecting Molding - polymers daban-daban guda biyu ana yin su a jere ko a lokaci guda a cikin wani rami. Ana iya amfani da wannan tsari don ƙirƙirar sassa tare da fata irin nau'in filastik tare da ainihin wani.

Sirin-Bangaren Molding – Wani nau'i na gyare-gyaren allura wanda ke mai da hankali kan gajeriyar lokutan zagayowar da mafi girman yawan aiki don samar da sassan filastik na bakin ciki, haske da arha.

Allurar roba – Ana allurar roba a cikin wani tsari ta amfani da tsari mai kama da gyare-gyaren allurar filastik. Sassan roba suna buƙatar ƙarin matsa lamba don yin nasarar yin gyare-gyaren allura.

Allurar yumbu – Tsarin gyare-gyaren allura ta amfani da kayan yumbu. yumbu abu ne mai wuya ta halitta, sinadari marar aiki wanda ake amfani dashi a masana'antu iri-iri. Allurar yumbu na buƙatar ƙarin matakai da yawa; gami da tarwatsawa ko warkar da sabbin sassa da aka ƙera don tabbatar da dorewar halayen.

Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara - Sassan filastik waɗanda aka samar a ƙananan matsi. Wannan yana da amfani musamman ga ayyukan da ke buƙatar ɓoye sassa masu laushi, kamar na'urorin lantarki.

Tuntuɓi DJmolding don ƙarin bayani kan gyare-gyaren allurar filastik. Ƙwararrun ƙwararrunmu za su iya taimaka muku da aikin gyare-gyaren allurar filastik ku.