Luso Lamapangidwe Ang'onoang'ono Apulasitiki Apulasitiki: Kuwongolera Kupanga Molondola

Luso Lamapangidwe Ang'onoang'ono Apulasitiki Apulasitiki: Kuwongolera Kupanga Molondola

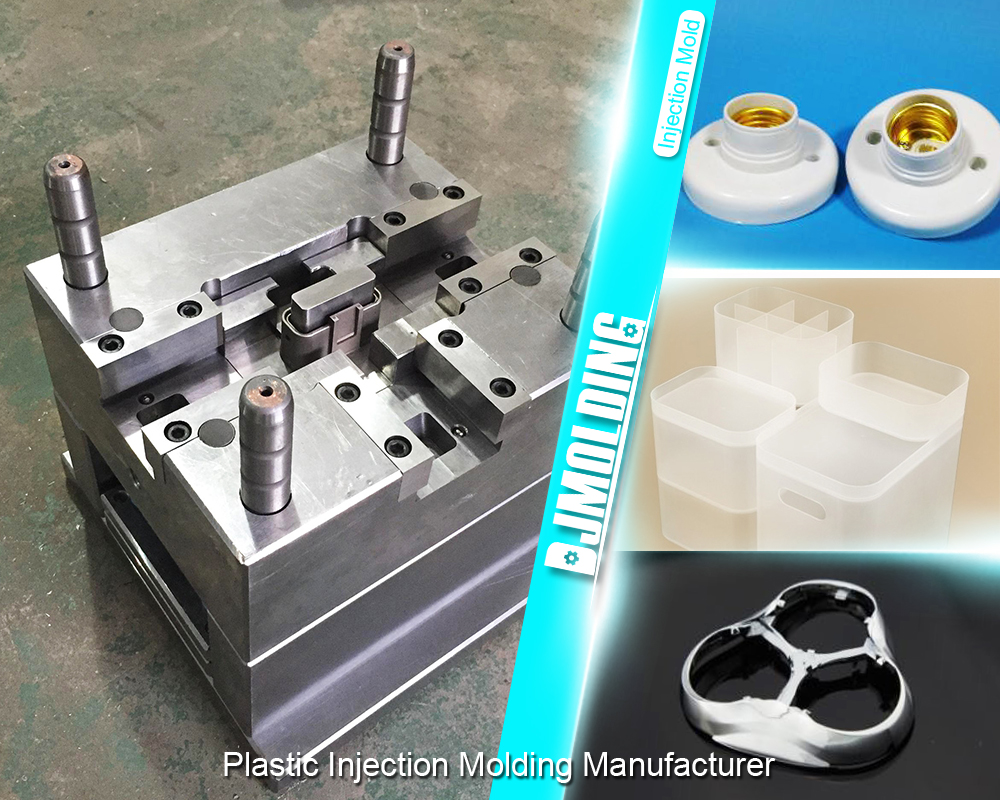

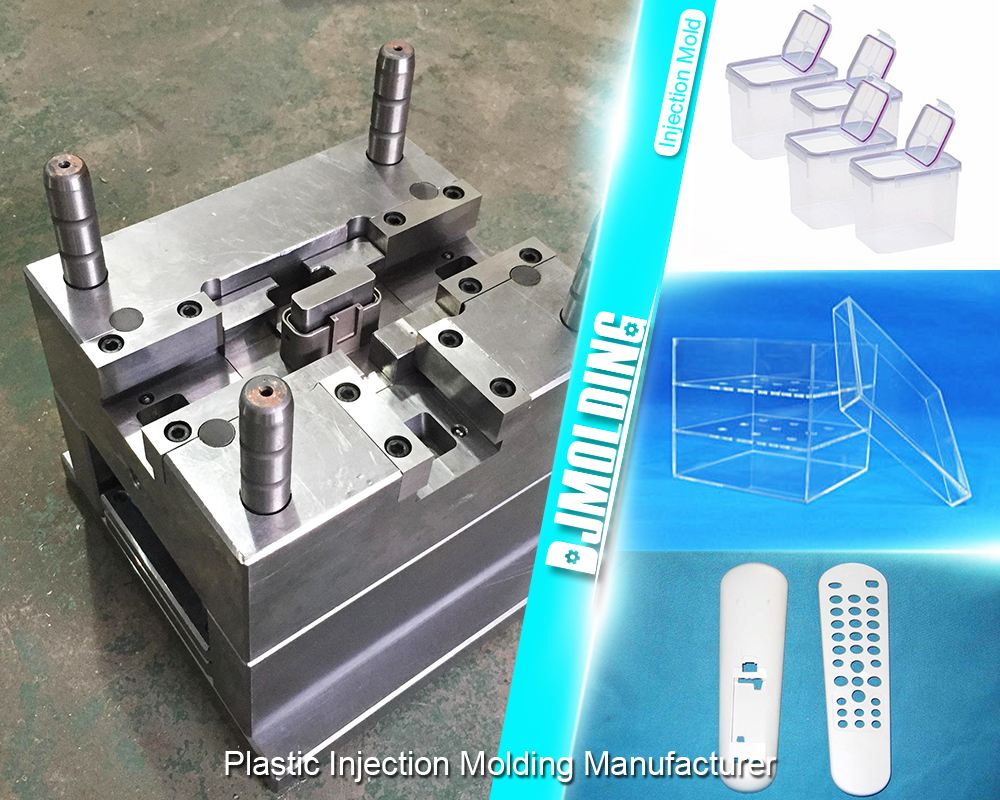

Kumangira jekeseni wa pulasitiki yatulukira ngati njira yosinthira masewera m'mawonekedwe amasiku ano opanga zinthu mwachangu. Kumangirira mwatsatanetsatane komanso kuchita bwino kumathandizira kupanga zinthu zambiri zapulasitiki zovuta. Nkhaniyi ikufotokoza zovuta za kuumba jekeseni wa pulasitiki, ndikuwunikira kufunikira kwake, ubwino wake, ndi ntchito zake m'mafakitale osiyanasiyana.

Kumvetsetsa Small Batch Plastic Injection Molding

Tanthauzo ndi Njira Mwachidule

Kumangira jekeseni wa pulasitiki ndi njira yopangira yomwe imaphatikizapo kubaya pulasitiki yosungunuka mu nkhungu kuti apange mawonekedwe ovuta komanso olondola. Gawoli likufotokoza njira zoyambira, kuyambira pakusankha zinthu mpaka kugwiritsa ntchito zida zazikulu monga nkhungu, mayunitsi a jakisoni, ndi makina otsekera.

Mitundu ya Pulasitiki Yogwiritsidwa Ntchito

Kupambana kwa jekeseni wa pulasitiki kumadalira kugwiritsa ntchito mitundu yosiyanasiyana ya mapulasitiki opangidwa ndi ntchito zinazake. Apa, tikuwunika mapulasitiki omwe amagwiritsidwa ntchito kwambiri, kuphatikiza ma thermoplastics ndi ma polima a thermosetting. Pomvetsetsa mawonekedwe awo apadera ndi katundu, opanga amatha kukhathamiritsa njira yowumba kuti ikhale ndi zotsatira zabwino.

Ubwino Waikulu Wopangira Majekeseni Apulasitiki

Kumangira jakisoni wa pulasitiki kumapereka zabwino zambiri kuposa njira zina zopangira. Chigawochi chikuwunikira momwe mtengo wake umagwirira ntchito, kusinthasintha kwa kapangidwe kake, kupanga bwino kwambiri, komanso kuwongolera kokhazikika. Zitsanzo zenizeni komanso nkhani zopambana zikuwonetsanso kusintha kwa jekeseni wa pulasitiki pamafakitale osiyanasiyana.

Njira Yopangira jekeseni wa Plastiki

Kukonzekera kwa Nkhungu ndi Kukonzekera

Kupanga nkhungu ndi mbali yofunika kwambiri pulasitiki yopangira jekeseni. Timakambirana za kufunikira kopanga zisankho kuti zigwire ntchito bwino, kulimba, komanso kupanga bwino. Kuonjezera apo, timakhudza zinthu zosiyanasiyana nkhungu ndi katundu wawo kuonetsetsa kusankha njira yabwino kwambiri ntchito iliyonse.

Gawo la jakisoni

Gawo la jekeseni limaphatikizapo kusungunula zinthu zapulasitiki, kuzikakamiza, ndi kuzibaya mu nkhungu. Apa, timapereka tsatanetsatane wa gawoli, kutsindika kufunika kwa kulondola ndi kuwongolera. Opanga amafufuza kutentha, kuthamanga, ndi nthawi yoziziritsa kuti akwaniritse mtundu wazinthu.

Kuziziritsa ndi Kulimbitsa

Gawo lozizirira limakhala ndi gawo lofunikira pakuumba jekeseni wa pulasitiki. Timafufuza njira zoziziritsira kuti zitsimikizire kulimba koyenera kwa pulasitiki, kukulitsa kukhulupirika kwadongosolo ndikuchepetsa zolakwika. Akatswiri amakambirana njira monga kuwongolera kutentha kwa nkhungu, kuzizira kofananira, ndi njira zozizirira mwachangu.

Kutulutsa ndi Kumaliza

Chikombolecho chimatulutsa mankhwala pambuyo polimba. Chigawochi chikufotokozera ndondomeko ya ejection ndikuwunikira ntchito zachiwiri monga kudula, kupukuta, ndi kumaliza pamwamba. Pothana ndi zomalizazi, opanga amatha kukulitsa kukongola, magwiridwe antchito, komanso kutsatsa kwazinthuzo.

Kugwiritsa Ntchito Plastic Injection Molding

- Zamgululi: Opanga ambiri amagwiritsa ntchito pulasitiki jakisoni akamaumba kuti ogula katundu. Opanga amagwiritsa ntchito njirayi popanga zida zakukhitchini, zida zapakhomo, zoseweretsa, ndi zamagetsi. Kusinthasintha kwa jekeseni wa pulasitiki kumapangitsa kuti pakhale mapangidwe odabwitsa, mitundu yowoneka bwino, ndi zinthu zolimba zomwe zimapititsa patsogolo moyo wathu watsiku ndi tsiku.

- Makampani Agalimoto: Makampani opanga magalimoto amadalira kwambiri jekeseni wa pulasitiki kuti apange zinthu zosiyanasiyana. Kuchokera pazitsulo zamkati ndi mapanelo a dashboard kupita ku mbali zakunja monga ma bumpers ndi ma grilles, jekeseni wa pulasitiki umapereka kusinthasintha kwa mapangidwe, kuchepetsa kulemera, komanso kukwera mtengo. Zimathandizira makampani amagalimoto kuti akwaniritse zokongoletsa, kuphatikiza magwiridwe antchito, komanso kuwongolera mafuta.

- Zachipatala ndi Zaumoyo: Kuumba jakisoni wa pulasitiki ndikofunikira kwambiri m'magawo azachipatala ndi azaumoyo. Opanga amachigwiritsa ntchito popanga zida zamankhwala, zida, ndi zogwiritsidwa ntchito zokhala ndi miyezo yapamwamba komanso kutsata malamulo. Opanga amapanga zinthu monga ma syringe, zolumikizira za IV, zida zopangira opaleshoni, ndi ma implants pogwiritsa ntchito zida zofananira ndi biocompatible kuonetsetsa chitetezo cha odwala komanso magwiridwe antchito ake.

- Makampani Opaka: Kumangira jekeseni wa pulasitiki ndikothandiza kwambiri pantchito yonyamula katundu. Imathandizira kupanga zotengera zapulasitiki, mabotolo, zipewa, ndi zotsekera zomwe zimagwiritsidwa ntchito m'magawo osiyanasiyana monga chakudya ndi zakumwa, chisamaliro chamunthu, ndi mankhwala. Kutha kupanga mawonekedwe osinthika, kukula kwake, ndi mawonekedwe ake kumapangitsa kuumba kwa jekeseni wa pulasitiki kukhala njira yabwino yopangira mayankho.

- Zamagetsi ndi Zamagetsi: Kumangira jekeseni wa pulasitiki kumapindulitsa kwambiri makampani opanga zamagetsi. Imathandizira kupanga ma casings, zolumikizira, zosinthira, ndi magawo ena ovuta omwe amafunikira pazida zamagetsi ndi makina amagetsi. Kumangira jekeseni wa pulasitiki kumatsimikizira kulondola, kukhazikika kwa mawonekedwe, komanso chitetezo kuzinthu zachilengedwe pazinthu zamagetsi.

- Zamlengalenga ndi Chitetezo: Kumangira jekeseni wa pulasitiki kumapeza ntchito m'magawo azamlengalenga ndi chitetezo. Opanga amagwiritsa ntchito jekeseni wa pulasitiki kuti apange zinthu zopepuka, zamphamvu kwambiri zomwe zimakwaniritsa zofunikira zolimba komanso chitetezo. Zitsanzo ndi zotengera mkati, mapanelo a zida, mabulaketi, ndi makina oyendetsa ndege.

- Zomangamanga ndi Zomangamanga: Kumangira jakisoni wa pulasitiki kumathandizira pantchito yomanga popanga zinthu monga mapaipi, zomangira, zotsekereza, ndi zida zofolera. Kukhalitsa, kukana kwa dzimbiri, komanso kukwera mtengo kwa zinthu zopangidwa ndi jakisoni wapulasitiki zimawapangitsa kukhala abwino pomanga.

- Masewera ndi Zosangalatsa: Kumangira jakisoni wa pulasitiki kumapanga zida zamasewera, zinthu zosangalatsa, ndi zida zakunja. Opanga ali ndi zinthu monga zipewa, zida zodzitetezera, zida za mpira, ndi zogwirira ntchito pogwiritsa ntchito njirayi. Kumangira jekeseni wa pulasitiki amalola kupanga zinthu zopepuka, zosagwira ntchito zomwe zimakulitsa magwiridwe antchito ndi chitetezo.

Zotsogola ndi Zochitika Zamtsogolo

Zamakono Zamakono

- Mwadzidzidzi: Makina ochita kupanga asintha mawonekedwe a jekeseni wa pulasitiki, kuwongolera njira zopangira ndikuwongolera bwino. Makina odzipangira okha amatha kugwira ntchito, kusintha nkhungu, ndi kuwongolera khalidwe, kuchepetsa zolakwika za anthu ndikuwonjezera zokolola.

- Kusindikiza kwa 3D: Kuphatikiza ukadaulo wosindikiza wa 3D wokhala ndi jekeseni wa pulasitiki watsegula mwayi watsopano wopangira ma prototyping mwachangu komanso makonda. Zoumba zosindikizidwa za 3D ndi zoyikapo zitha kugwiritsidwa ntchito limodzi ndi nkhungu zachikhalidwe, kulola kubwereza mwachangu komanso kupanga tinthu tating'ono kotsika mtengo.

- Artificial Intelligence (AI): AI imagwira ntchito yofunika kwambiri pakuumba jakisoni wapulasitiki. Pulogalamu ya AI yoyendetsedwa ndi AI imatha kusanthula zomwe zikuchitika munthawi yeniyeni, kukhathamiritsa magawo monga kutentha, kupanikizika, ndi nthawi yoziziritsa kuti gawo likhale labwino. Njira zokonzera zolosera zam'tsogolo za AI zingathandizenso kupewa kutsika kosayembekezereka ndikuchepetsa mtengo wokonza.

- Multi-Material Molding: Kutha kugwiritsa ntchito zida zingapo munjira imodzi yopangira jakisoni ikuyamba kukopa. Opanga amatha kugwiritsa ntchito jekeseni wa pulasitiki kuti apange magawo ovuta okhala ndi zinthu zosiyanasiyana, monga kuphatikiza mapulasitiki olimba komanso osinthika. Njira yopangira iyi imalola kuwongolera bwino pakuwumba, kupangitsa kukwaniritsa magawo osiyanasiyana amitundu ndi ma geometries zotheka. Kumangirira kwazinthu zambiri kumakulitsa kuthekera kwa mapangidwe ndikuwonjezera magwiridwe antchito azinthu.

- Kumangirira kwa Micro-Injection: Miniaturization ndi njira yomwe ikukula m'mafakitale, ndipo kuumba kwa jekeseni yaying'ono kumakwaniritsa izi. Njirayi imapanga tizigawo tating'ono tating'ono tating'ono tambiri, zovuta, zotsegula mwayi m'magawo monga zamagetsi, zida zamankhwala, ndi ma microfluidics.

- Zida Zokhazikika: Popeza kukhazikika kumakhala kofunikira kwambiri, makampani akuwunika zida zina zopangira jakisoni wapulasitiki. Mapulasitiki opangidwa ndi biodegradable ndi bio-based opangidwa kuchokera kuzinthu zongowonjezedwanso akutchuka. Kuphatikiza apo, kugwiritsa ntchito mapulasitiki obwezerezedwanso kumachepetsa zinyalala komanso kumathandizira chuma chozungulira.

- Kupanga Mwanzeru: Kuphatikiza ukadaulo wa Internet of Things (IoT) pakuumba jakisoni wapulasitiki kumalola kuwunika mwanzeru ndikuwongolera njira zopangira. Zomverera ndi kulumikizana zimathandizira kusonkhanitsa deta nthawi yeniyeni, kusanthula, ndi kuyang'anira kutali. Kugwiritsa ntchito njira zodzipangira okha pakuumba jakisoni wapulasitiki kumawonjezera kuwongolera, kumachepetsa nthawi yopumira, ndikuwongolera magwiridwe antchito. Njirazi zingaphatikizepo kugwiritsa ntchito zinthu zodziwikiratu, kuchotsa magawo a robotic, ndi makina owunikira pamizere.

- Zowona Zowona ndi Zowonjezereka: Popanga jakisoni wa pulasitiki, opanga ndi mainjiniya amagwiritsa ntchito matekinoloje enieni ndi augmented kuti atsimikizire mapangidwe ndi kukhathamiritsa njira. Opanga amatha kuzindikira zomwe zingachitike, kukhathamiritsa mapangidwe, ndikuchepetsa nthawi ndi msika popanga ma prototypes enieni ndikutengera momwe amawumba.

Kupita patsogolo kumeneku ndi zomwe zikuchitika m'tsogolomu pakuumba jekeseni wa pulasitiki zikupanga mawonekedwe amakampani, kupangitsa kupanga mwachangu, kogwira mtima, komanso kosunga chilengedwe. Mwa kukumbatira ma automation, kugwiritsa ntchito makina osindikizira a 3D ndi AI, kuyang'ana zida zatsopano, ndikutengera njira zopangira mwanzeru, opanga amatha kukhala opikisana ndikukwaniritsa zomwe msika ukufunikira. Kufufuza kosalekeza kwatsopano kumatsimikizira kuti kuumba jekeseni wa pulasitiki kumakhalabe patsogolo pakupanga zamakono.

Kutsiliza

Kuumba jekeseni wa pulasitiki ndi mwala wapangodya wamakono opanga zinthu, zomwe zimathandiza kupanga bwino zigawo za pulasitiki zovuta. Kumangira jekeseni wa pulasitiki kwasintha zinthu posintha njira zoyambira, kupereka zabwino zambiri, ndikupeza ntchito m'mafakitale angapo. Opanga amatha kukwaniritsa zofuna za ogula zomwe zikuchulukirachulukira potengera kulondola, kusinthasintha kwa mapangidwe, komanso kutsika mtengo. Makampani opanga ma jakisoni apulasitiki akuyembekezeka kukhala ndi tsogolo lodzaza ndi zatsopano komanso udindo wa chilengedwe monga kupita patsogolo kwaukadaulo ndi zoyesayesa zokhazikika zikupitilirabe. Tikukupemphani owerenga kuti afufuze mopitilira ndikupeza mwayi wopanda malire womwe jekeseni wa pulasitiki umapereka.

Kuti mudziwe zambiri ang'onoang'ono mtanda pulasitiki jekeseni akamaumba,mutha kuyendera ku Djmolding pa https://www.djmolding.com/injection-mould-manufacturing/ chifukwa Dziwani zambiri.