5 Cov Plastic Resins Siv Hauv Kev Txhaj Tshuaj Molding

1 am text block. Nyem edit khawm kom hloov no cov ntawv nyeem. Lorem ipsum dolor zaum amet, consectetur xyuas elit. Tej zaum elit elit, luctus NEC ullamcorper mattis, dapibus iPad pulvinar.

Nrog ntau pua cov khoom lag luam thiab engineering resins muaj nyob rau hauv kev ua lag luam niaj hnub no, cov txheej txheem xaiv cov khoom siv rau cov yas txhaj tshuaj molding cov hauj lwm feem ntau zoo li daunting thaum xub thawj.

Ntawm DJmolding, peb nkag siab txog cov txiaj ntsig tshwj xeeb thiab cov khoom ntawm ntau hom yas thiab ua haujlwm nrog cov neeg siv khoom kom pom qhov zoo tshaj plaws haum rau lawv qhov project.

Plastic Resins yog dab tsi?

Peb nyob hauv lub ntiaj teb ib puag ncig los ntawm cov yas resins. Vim lawv ob peb yam khoom uas tsim nyog, yas resins tuaj yeem pom nyob rau hauv txhua yam los ntawm lub raj mis thiab ntim rau tsheb thiab cov khoom siv kho mob thiab ntau ntxiv. Yas resins suav nrog tsev neeg loj ntawm cov ntaub ntawv uas txhua tus muaj lawv tus kheej cov khoom uas ua rau lawv zoo tagnrho rau kev siv sib txawv. Thaum xaiv cov resin txoj cai rau koj qhov project, nws yog ib qho tseem ceeb kom nkag siab tias txhua yam yuav tsum muaj.

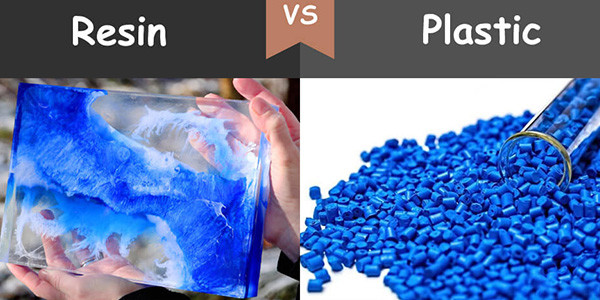

Qhov txawv ntawm Resin thiab yas yog dab tsi?

Resin thiab yas yog ob qho tib si tseem ceeb, tab sis muaj qee qhov sib txawv tseem ceeb, suav nrog:

* Keeb kwm: Thaum cov resins tshwm sim nyob rau hauv cov nroj tsuag, cov yas yog hluavtaws thiab feem ntau yog muab los ntawm petrochemicals.

* Txhais: Yas yog ib hom hluavtaws cob, hos resins yog amorphous compounds uas tuaj yeem yog semi-khoom los yog khoom.

* Stability thiab impurities: Plastics ruaj khov dua li resin thiab tsis muaj impurities. Nrog resins, impurities tsis tuaj yeem zam.

* Hardness: Yas yog ntom thiab tawv, thaum resin feem ntau yog ib qho kua nplaum thiab khov.

* Kev cuam tshuam ib puag ncig: Txij li cov resin yog ntuj, nws muaj ntau yam kev phooj ywg zoo rau cov yas. Yas degrades maj mam thiab feem ntau muaj tshuaj lom additives uas yuav ua rau ib puag ncig muaj kuab paug.

Kev siv ntau yam rau yas Resin Txhaj Molding

Yas txhaj tshuaj molding yog sib xws nrog ntau yam khoom siv cob. Thaum txiav txim siab txoj cai resin rau koj cov kev xav tau, nws yog ib qho tseem ceeb kom nkag siab txog cov kev xav tau ntawm koj daim ntawv thov tshwj xeeb. Cov ntawv thov sib txawv rau kev txhaj tshuaj molding resins muaj xws li:

ABS

Txhaj-pwm ABS yog siv rau ntau yam kev siv, nrog rau cov phab ntsa yas rau cov hluav taws xob hluav taws xob, kev tiv thaiv lub taub hau, cov keyboards, cov khoom siv hluav taws xob, thiab cov khoom siv tsheb xws li tsheb lub cev, lub log npog, thiab dashboards. Nws kuj tseem siv tau rau ntau yam kev lag luam fittings, khoom siv kis las, thiab cov khoom siv.

Celson (Acetal)

Vim nws cov coefficient tsis tshua muaj kev sib txhuam, kev txhaj tshuaj molded Celson yog qhov zoo tagnrho rau cov log tsheb, conveyor siv, zog, thiab bearings. Cov khoom siv no kuj tuaj yeem pom nyob rau hauv ntau yam kev ua haujlwm siab engineering, lub kaw lus kaw, riam phom, tsom iav qhov muag, thiab fasteners.

Polypropylene

Txhaj-molding polypropylene yog siv nyob rau hauv ntau yam kev lag luam, kev lag luam, thiab cov neeg siv khoom siv. Piv txwv li, nws tuaj yeem pom hauv lub cev lub zog, cov khoom siv, cov khoom ntim, cov khoom ua si, cov thawv ntim khoom, thiab cov khoom ua si menyuam yaus.

HIPS

Vim tias HIPS nta lub zog muaj zog dua, nws tuaj yeem pom hauv cov khoom siv, cov khoom siv luam ntawv, kos npe, thiab cov khoom siv. Lwm yam kev siv xws li cov menyuam yaus cov khoom ua si thiab cov khoom siv hluav taws xob.

LDPE

Vim nws yooj yim thiab tsis kam mus ya raws thiab tshuaj, txhaj tshuaj molded LDPE feem ntau yog siv rau daim ntaub ntawv nrog rau cov khoom siv kho mob, hlau thiab cable insulators, toolboxes, thiab cov me nyuam cov khoom ua si.

Yam tseem ceeb uas yuav tsum tau xav txog thaum xaiv cov khoom txhaj tshuaj molding

Kev cai yas qhov chaw los ntawm DJmolding kom paub meej tias koj xaiv cov resin txoj cai rau koj qhov project, nco ntsoov cov hauv qab no sib txawv:

* Kev cuam tshuam lub zog - Qee daim ntawv thov yuav tsum muaj lub zog ntau dua li lwm tus, yog li cov resin Izod cuam tshuam lub zog yuav tsum tau txiav txim siab txij thaum pib.

* Lub zog tensile - Qhov kawg tensile lub zog, los yog qhov kawg lub zog, ntsuas cov resin tsis kam mus rau tension thiab nws muaj peev xwm tiv taus ib tug muab load yam tsis muaj rub tawm.

* Flexural modulus ntawm elasticity - Qhov no yog hais txog qib uas cov khoom tuaj yeem khoov yam tsis muaj kev puas tsuaj thiab tseem rov qab mus rau nws daim ntawv qub.

* Kub deflection - Qhov no yog qhov tseem ceeb tshwj xeeb rau cov ntawv thov uas xav tau kev ua haujlwm insulating lossis kev ua siab ntev rau ntau qhov kub thiab txias.

* Kev nqus dej - Qhov no yog raws li qhov feem pua ntawm cov kua uas coj los ntawm cov khoom siv tom qab 24 teev ntawm kev tso dej.

Kev cai khoom xaiv nrog DJmolding

Djmolding yog yas txhaj tshuaj molding chaw tsim tshuaj paus, tsim yas qhov chaw nrog acrylic (PMMA), acrylonitrile butadiene styrene (ABS), nylon (polyamide, PA), polycarbonate (PC), polyethylene (PE), polyoxymethylene (POM), polypropylene (PP), polystyrene (PS) thiab lwm yam

Xaiv cov khoom tsim nyog los ntawm qhov pib yuav tsis tsuas yog txuag koj lub sijhawm, thiab nyiaj txiag tab sis tseem yuav ua kom pom kev ua tau zoo thiab kev tsim khoom. Tshawb xyuas koj cov kev xaiv ua tib zoo, thiab sab laj nrog tus kws paub txog kev txhaj tshuaj molder los pab txiav txim siab qhov kev xaiv zoo tshaj plaws.