Automotive Yas Cheebtsam Txhaj Molding

Automotive Yas Cheebtsam niaj hnub no

High automotive kev ua tau zoo xav tau qhov chaw uas tuav nws tag nrho. Cov yas ua los ntawm lub cav mus rau lub chassis; thoob plaws sab hauv mus rau sab nrauv. Niaj hnub no automotive plastics ua rau kwv yees li 50% ntawm qhov ntim ntawm lub tsheb tshiab tab sis tsawg dua 10% ntawm nws qhov hnyav.

Kev Nyab Xeeb

Kev nyab xeeb kev nce qib hauv cov ntaub ntawv niaj hnub no cawm tau ntau tus neeg txoj sia. Airbags, windshields, sunroofs ntxiv rau lub zog absorbing innovation txo cov tsheb tuag. Yas pem hauv ntej-kawg modules, modular rooj thiab lub zog-absorbing bumpers pab cawm neeg txoj sia txhua xyoo.

Cov khoom siv yas sib xyaw tuaj yeem pab cov tsheb sib sib zog nqus thaum khaws cov yam ntxwv kev nyab xeeb. Thaum lub tsheb sib tsoo, engineers xav kom cov qauv tsoo hauv txoj kev kwv yees. Automotive cov ntaub ntawv yuav tsum nqus, tsis hloov, "kev cuam tshuam lub zog" rau tib neeg. Kev lag luam hu qhov no "tswj crushed."

Fiber-reinforced polymer composites nqus plaub zaug lub zog ntawm cov hlau. B-pillar yog tus ncej txhawb nqa uas txuas lub tsheb lub ru tsev rau nws lub cev. Nws yog nyob rau tom qab ntawm lub qhov rooj pem hauv ntej thiab muab lub hauv paus loj ntawm kev tiv thaiv kev nkag mus rau thaum muaj kev sib tsoo.

Lub National Highway Traffic Safety Administration tsis ntev los no tau pab nyiaj rau kev kawm ntawm B-pillars. Txoj kev tshawb no tau saib tshwj xeeb ntawm kev sib xyaw ua ke ntawm carbon fiber ntau thermoplastic B-pillar tsim. Lub hom phiaj yog los txiav txim siab tus qauv tsim qhov hnyav txuag thiab kev nyab xeeb ntawm lub tsheb sib tsoo piv rau lub hauv paus hlau. B-pillar pom 60 feem pua qhov hnyav txuag, thiab txaus siab rau kev cuam tshuam rau kev sib tsoo. Cov cuab yeej suav ua qauv ua piv txwv qhov cuam tshuam thiab cuam tshuam cov lus teb B-tus ncej.

Cov yas tseem pab cawm tib neeg txoj sia thaum muaj kev cuam tshuam rau cov neeg taug kev thiab. Polycarbonate-blend bumpers pab tiv thaiv cov neeg caij tsheb hauv kev sib tsoo. Plastics kuj tseem ua kom muaj kev xa mus sai dua rau kev tiv thaiv neeg taug kev ntau dua hauv Ford tsheb. Ib qho yooj yim taug kev-tiv thaiv kev sib tsoo ncaj qha-mounted sensor bracket txhaj tshuaj molded hauv yas. Saib ntxiv hauv peb "Crumple Zone Blog" thiab peb ncig saib ntawm BMW i3 Carbon Fiber Chassis Safety Cheebtsam.

Windshields, Windows & Sunroofs

North American windshields tuaj raws li ntau txheej chav tsev. Daim duab ib txheej ntawm cov yas ntawm ob daim iav nyias nyias. Kev sib xyaw ua ke tuaj yeem yog nyias, sib dua thiab muaj zog dua li tempered iav ib leeg. Cov kua muag-resistant txheej yas pab tiv thaiv cov neeg nyob ejection. Qhov tseeb, NHTSA kwv yees cov txheej txheem no pab tiv thaiv ntau dua 300 tus neeg tuag hauv ib xyoos.

Cov khoom siv yas sib sib zog nqus rau cov ru tsev txo qhov nruab nrab ntawm lub ntiajteb txawj nqus kom tsis txhob muaj kev cuam tshuam thaum lub sij hawm sib sib zog nqus cornering kev sib tsoo maneuvers. Clear non-distorting polycarbonate tam sim no tuaj yeem tiv taus UV thiab txo qhov hnyav. Tag nrho lub ru tsev sib dhos tuaj yeem ua tau raws li polymer.

DJmolding's Automotive Yas Cheebtsam Txhaj Molding

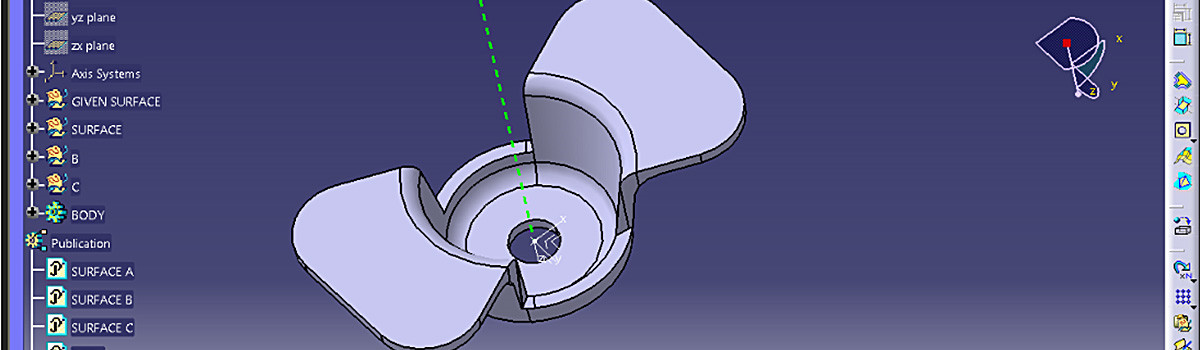

Djmolding yog automotive yas txhaj tshuaj molding tuam txhab uas muag nrog ISO / TS 16949: 2009, peb muab kev cai yas txhaj tshuaj molder, designer thiab chaw tsim tshuaj paus ntawm precision txhaj pwm siv engineering qib resins, iav, tungsten, carbon thiab hlau ntim cov ntaub ntawv rau automotive, aerospace, hluav taws xob, marine, kev kho mob thiab kev siv xov tooj.

Nees nkaum feem pua ntawm cov khoom siv rau kev tsim cov tsheb muaj xws li cov yas ntawm cov yam ntxwv sib txawv. Ntawm DJmolding peb muab tag nrho cov khoom yas rau cov tuam txhab tsheb, rau sab hauv thiab sab nraud ntawm tsheb, nrog rau cov khoom siv tsheb. Peb ua haujlwm nrog cov thev naus laus zis tshiab tshaj plaws rau kev txhaj tshuaj ntawm cov khoom yas thiab nrog cov khoom siv engineering rau kev tsim cov khoom lag luam uas siv cov khoom siv hlau, uas muaj kev tiv thaiv ntau dua, hnyav dua thiab yooj yim dua los siv dua.

DJmolding ua cov yas txhaj tshuaj molding chaw tsim tshuaj paus thiab tsum, tshwj xeeb hauv thermoplastic txhaj tshuaj molding tshuab. Peb cov txuj ci tseem ceeb muaj xws li roj txhaj tshuaj molding tshuab, siab gloss thiab e-moulding. Peb txhaj tshuaj molded sab nrauv thiab sab hauv lub tsheb Cheebtsam rau kev lag luam tsheb yog feem ntau tsim tawm ntawm cov ntaub ntawv hauv qab no: - polystyrene (PS), - polypropylene (PP), - ABS, - PC, - PC / ABS, - PC / PMMA.

Sab hauv txhaj tshuaj molded tsheb Cheebtsam

Rau lub dynamic tsheb kev lag luam peb yog ib tug txhim khu kev qha tus khub nyob rau hauv zus tau tej cov ntau yam ntawm txhaj molded sab hauv Cheebtsam. Hauv peb cov ISO IATF cov chaw tsim khoom tau lees paub peb ua cov haujlwm sab hauv rau cov tuam txhab ua lag luam. Peb muaj kev paub txog OEM, Tier 1 automotive tsum thiab chaw tsim khoom ntawm tsheb sab hauv thiab sab nrauv trim. Peb cov khoom lag luam ntawm cov khoom siv sab hauv kev txhaj tshuaj molding muaj xws li cov khoom siv yas xws li: cov khoom siv dashboard (xws li: hnab looj tes, qhov rooj thiab qhov rai ncej), steering kem trims, qhov rooj kov, cua vents, center consoles, ru tsev modules, thiab lwm yam.

Sab nrauv txhaj tshuaj molded tsheb Cheebtsam

Txhaj tshuaj molding yog cov txheej txheem zoo tshaj plaws los tsim cov khoom siv sab nrauv sab nrauv. Peb pab pawg ntawm cov kws tshaj lij kev txhaj tshuaj molding ua haujlwm zoo nrog cov tsheb OEMs thiab Tier 1 cov neeg siv khoom los ntsuas thiab txheeb xyuas txhua yam kev xav tau thiab yog li ua kom zoo tshaj plaws ntawm cov khoom siv tsheb sab nrauv uas tsis zoo. Peb yog cov yas txhaj tshuaj molding chaw tsim tshuaj paus ntawm automotive sab nrauv qhov chaw xws li: mudguards (fenders), log arches, grilles, sensor tuav, pem teb rails, trunk trims pem hauv ntej thiab nram qab coverings, bumpers thiab sab nrauv tsheb qhov rooj trim, qhov rooj panels. Peb cov yas txhaj tshuaj rau lub tsheb muaj nyob rau hauv ntau hom tsheb qauv thoob ntiaj teb.

Peb lub hom phiaj yog muab cov txiaj ntsig zoo tshaj plaws rau peb cov neeg siv khoom. Dhau li ntawm kev tsim cov khoom yas, DJmolding muaj kev txhaj tshuaj molding tsim thiab tsim cov kev pabcuam. Peb pab peb cov neeg muas zaub tau txais cov khoom yas hauv ib daim ntawv uas npaj xa tuaj rau lub khw. Peb npog tag nrho cov txheej txheem los ntawm lub tswv yim, los ntawm kev txhaj tshuaj molding, xa cov khoom tiav rau automotive yas Cheebtsam kev lag luam.

Raws li koj tuaj yeem pom, DJmolding tsis tso nws cov neeg siv khoom ntawm lawv tus kheej. Hauv txhua kauj ruam, peb nyob ntawd los pab peb cov neeg siv khoom los ntawm kev muab kev qhia dav dav. Peb tuaj yeem yooj yim tig qhov zoo li yog txheej txheem nyuaj thaum xub thawj rau hauv kev koom tes ua tiav uas tau txais txiaj ntsig zoo.

Kev lag luam automotive tau pom qhov kev nce qib zoo tshaj plaws hauv lub xyoo, hais txog cov khoom siv hnyav thiab siv tau zoo. Yas Cheebtsam yog qhov tseem ceeb hauv kev tsim tsheb niaj hnub no, muab kev ua haujlwm ruaj khov, tsim kev yooj yim, thiab kev ua haujlwm zoo. Ntawm cov txheej txheem tsim ntau yam rau cov khoom siv hauv tsheb, kev txhaj tshuaj molding yog dav siv. Cov ntawv tshaj tawm blog no yuav tshawb nrhiav cov khoom siv tsheb yas txhaj tshuaj molding, nws cov txiaj ntsig, kev siv, thiab cov qauv tshiab. Cia peb tshawb nrhiav lub ntiaj teb txaus nyiam ntawm molding automotive yas Cheebtsam!

Nkag siab Txhaj Moulding hauv Automotive Kev Lag Luam

Kev lag luam automotive siv kev txhaj tshuaj molding los tsim ntau yam khoom, xws li dashboards, bumpers, instrument panels, thiab lwm yam.

Nov yog qee qhov tseem ceeb los xav txog thaum nkag siab txog kev txhaj tshuaj molding hauv kev lag luam tsheb:

Cov khoom siv hauv kev txhaj tshuaj molding

Kev txhaj tshuaj molding siv ntau yam ntawm cov khoom siv thermoplastic thiab cov thermosetting, suav nrog:

- Polypropylene (PP)

- Polyethylene (PE)

- Polyvinyl tshuaj dawb (PVC)

- Acrylonitrile-butadiene-styrene (ABS)

- Cov tshuaj polycarbonate (PC)

- Polyamide (PA)

- Polyurethane (PU)

Txhua yam khoom muaj cov yam ntxwv tshwj xeeb thiab cov yam ntxwv, xws li yoog raws, lub zog, durability, thiab tsis kam mus rau tshav kub thiab tshuaj. Qhov kev xaiv ntawm cov khoom yog nyob ntawm qhov yuav tsum tau ua ntawm ib feem lossis cov khoom tsim.

Qhov zoo ntawm kev txhaj tshuaj molding hauv kev lag luam automotive

- Kev ua haujlwm siab ntau lawm: Kev txhaj tshuaj molding tuaj yeem tsim cov ntim loj ntawm cov khoom sai thiab ua tau zoo, txo cov sijhawm tsim khoom thiab cov nqi.

- Precision thiab sib xws: Kev txhaj tshuaj molding ua qhov tseeb thiab zoo ib yam nrog qhov sib txawv me me ntawm cov khoom.

- Tsim kev yooj yim: Txhaj molding tso cai rau cov geometries complex thiab intricate cov ntsiab lus kom muab tso rau hauv qhov chaw, ua rau cov neeg tsim qauv tsim cov khoom uas ua tau raws li cov kev xav tau tshwj xeeb thiab zoo nkauj.

- Tus nqi zoo: Kev txhaj tshuaj molding tuaj yeem tsim cov khoom ntawm tus nqi qis dua lwm txoj kev tsim khoom, xws li machining lossis casting.

Kev sib tw ntawm kev txhaj tshuaj molding hauv kev lag luam automotive

- Cov nqi cuab yeej: Kev txhaj tshuaj molding yuav tsum tau tsim pwm, uas tuaj yeem kim tsim thiab tsim khoom.

- Kev xaiv cov khoom siv: Xaiv cov khoom tsim nyog rau ib feem lossis cov khoom yuav nyuaj, vim cov khoom sib txawv muaj cov khoom sib txawv thiab yuav xav tau kev ua haujlwm ntxiv.

- Kev tu thiab kho: Cov cuab yeej txhaj tshuaj molding yuav tsum tau saib xyuas thiab kho tsis tu ncua kom ntseeg tau tias kev ua haujlwm zoo thiab tiv thaiv kev poob qis.

- Kev cuam tshuam ib puag ncig: Kev pov tseg ntawm cov yas pov tseg uas tsim los ntawm kev txhaj tshuaj molding tuaj yeem muaj qhov tsis zoo rau ib puag ncig.

Cov txiaj ntsig ntawm Automotive Yas Cheebtsam Txhaj Molding

Automotive yas Cheebtsam txhaj tshuaj molding yog txheej txheem uas muaj kev tsim ntawm complex qhov chaw los ntawm kev siv cov pwm thiab yas pellets. Txoj kev no tau siv dav hauv kev lag luam tsheb vim nws cov txiaj ntsig ntau. No blog ncej yuav tham txog qhov zoo ntawm kev txhaj tshuaj molding automotive yas Cheebtsam.

Nqi-zoo: Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm cov khoom siv yas yas txhaj tshuaj molding yog tias nws yog ib qho txiaj ntsig zoo ntawm kev tsim cov khoom. Qhov no yog vim hais tias cov txheej txheem tuaj yeem tsim cov ntu hauv cov khoom loj sai thiab ua tau zoo. Qhov no txo cov nqi tsim khoom, ua rau nws yog qhov kev daws teeb meem zoo tshaj plaws rau kev lag luam automotive, qhov twg tus nqi ib txwm muaj kev txhawj xeeb.

Lub teeb yuag: Lwm qhov tseem ceeb ntawm cov yas txhaj tshuaj molding hauv kev lag luam tsheb yog cov khoom siv yas yog lub teeb yuag. Qhov no yog qhov tseem ceeb vim tias nws txhim kho cov roj efficiency ntawm lub tsheb, uas yog ib qho tseem ceeb rau cov tuam txhab tsheb hauv kev ua kom tau raws li ib puag ncig cov cai thiab cov neeg siv khoom xav tau.

Lub zog thiab Durability: Cov khoom siv yas ua los ntawm kev txhaj tshuaj molding muaj lub zog zoo thiab ua haujlwm ntev. Qhov no yog vim tias cov txheej txheem tso cai rau kev tsim cov khoom nrog cov phab ntsa tuab zoo ib yam thiab tsawg kawg warping. Yog li ntawd, cov khoom siv yas tsim los ntawm kev txhaj tshuaj molding tuaj yeem tiv taus qhov nruj ntawm lub tsheb ib puag ncig, xws li qhov kub thiab txias.

customization: Txhaj tshuaj molding tso cai rau kev tsim cov khoom hauv ntau qhov ntau thiab tsawg. Qhov no ua rau nws yog ib qho kev daws teeb meem zoo tshaj plaws rau kev lag luam automotive, qhov twg customization yog qhov tseem ceeb. Los ntawm kev txhaj tshuaj molding, cov tuam txhab tsheb tuaj yeem yooj yim tsim cov khoom uas ua tau raws li cov kev xav tau tshwj xeeb, xws li qhov loj me, cov duab, thiab xim.

Txo cov pov tseg: Yas txhaj tshuaj molding tsim cov khoom pov tseg tsawg dua li cov txheej txheem tsim khoom. Cov txheej txheem muaj txiaj ntsig zoo thiab tuaj yeem tsim cov khoom nrog cov khoom seem tsawg. Yog li ntawd, kev lag luam tsheb tuaj yeem txo nws cov pa roj carbon hneev taw los ntawm kev siv tshuaj molding los tsim cov khoom yas.

Kev tsim tawm sai dua: Kev txhaj tshuaj molding yog ib txoj hauv kev sai thiab ua tau zoo ntawm kev tsim cov khoom yas. Cov txheej txheem tuaj yeem tsim cov khoom hauv vib nas this, ua rau nws yog ib qho kev daws teeb meem zoo tshaj plaws rau kev lag luam automotive, qhov chaw tsim khoom ceev ceev yog qhov tseem ceeb.

Txhim kho zoo: Cov khoom siv yas ua los ntawm kev txhaj tshuaj molding muaj qhov zoo ib yam. Qhov no yog vim tias cov txheej txheem tso cai rau kev tswj xyuas meej ntawm cov pwm pwm, xws li kub, siab, thiab lub sijhawm txias. Yog li ntawd, cov khoom yas tsim los ntawm kev txhaj tshuaj molding muaj qhov zoo ntawm qhov tseeb thiab qhov chaw tiav.

Tshawb nrhiav cov yas siv feem ntau hauv kev txhaj tshuaj molding

Kev txhaj tshuaj molding yuav tsum tau yaj cov yas pellets thiab txhaj rau hauv lub pwm kab noj hniav kom tsim tau ib qho duab tshwj xeeb. Lub versatility ntawm cov txheej txheem no tso cai rau cov tuam txhab tsim cov khoom siv nrog cov neeg siab thiab sib xws. Ntau yam ntaub ntawv yas yog siv rau hauv kev txhaj tshuaj molding kom ua tiav cov khoom xav tau. Cov ntawv tshaj tawm blog no yuav tshawb txog cov khoom siv uas feem ntau siv hauv kev txhaj tshuaj molding thiab lawv cov khoom.

- Acrylonitrile Butadiene Styrene (ABS): ABS yog cov thermoplastic polymer dav siv hauv kev txhaj tshuaj molding vim nws qhov cuam tshuam loj heev, tawv, thiab kub tsis kam. Nws yog feem ntau siv hauv cov khoom siv tsheb, cov khoom ua si, thiab cov khoom siv hluav taws xob.

- Polycarbonate (PC): PC yog cov khoom siv yas, pob tshab uas yog siv rau hauv kev txhaj tshuaj moldings rau cov khoom uas yuav tsum tau muaj kev cuam tshuam thiab kev pom tseeb, xws li tsom iav kev nyab xeeb, cov khoom siv hluav taws xob, thiab cov khoom siv tsheb.

- Polypropylene (PP): PP yog ntau yam khoom siv yas siv hauv kev txhaj tshuaj molding rau cov khoom uas xav tau kev hloov pauv, lub zog, thiab tshuaj tiv thaiv. Nws yog feem ntau siv hauv ntim khoom, khoom siv tsheb, thiab cov khoom siv.

- Polyethylene (PE): PE yog cov khoom siv yas siv hauv kev txhaj tshuaj molding rau cov khoom uas xav tau kev hloov pauv thiab ua haujlwm ntev. Nws yog feem ntau siv hauv ntim khoom, khoom siv hauv tsev, thiab cov khoom ua si.

- Polyoxymethylene (POM): POM yog cov khoom siv yas thiab tawv tawv siv hauv kev txhaj tshuaj molding rau cov khoom uas xav tau qhov ruaj khov thiab hnav tsis kam. Nws yog feem ntau siv nyob rau hauv lub zog, bearings, thiab lwm yam mechanical qhov chaw.

- Polystyrene (PS): PS yog lub teeb yuag thiab nruj cov khoom siv yas siv rau hauv kev txhaj tshuaj molding rau cov khoom uas xav tau qhov zoo ntawm qhov ruaj khov thiab rwb thaiv tsev. Nws yog feem ntau siv hauv ntim khoom noj, cov khoom siv pov tseg, thiab cov ntaub ntawv CD.

- Polyethylene Terephthalate (PET): PET yog cov khoom siv yas uas muaj zog thiab sib zog siv hauv kev txhaj tshuaj molding rau cov khoom uas xav tau kom meej meej, nruj, thiab tshuaj tiv thaiv. Nws yog feem ntau siv rau hauv lub raj mis haus, ntim khoom noj, thiab khoom siv kho mob.

- Nylon (PA): Nylon yog cov khoom siv yas uas muaj zog thiab ruaj khov siv rau hauv kev txhaj tshuaj molding rau cov khoom uas xav tau lub zog siab, tiv taus cua sov, thiab tshuaj lom neeg. Nws yog feem ntau siv nyob rau hauv automotive qhov chaw, electronics Cheebtsam, thiab industrial machinery.

Tsim kev txiav txim siab rau Automotive Yas Cheebtsam

Cov ntawv tshaj tawm blog no yuav tham txog qee qhov kev txiav txim siab tsim qauv tseem ceeb rau cov khoom siv hauv tsheb.

Kev xaiv cov khoom siv:

- Cov khoom siv yas tuaj yeem tsim los ntawm ntau yam ntaub ntawv, suav nrog polypropylene, polycarbonate, ABS, thiab lwm yam.

- Txhua yam khoom muaj cov khoom tshwj xeeb, xws li lub zog, nruj, thermal stability, thiab tsis kam mus rau cov tshuaj thiab UV hluav taws xob.

- Nws yog ib qho tseem ceeb heev uas yuav tau xaiv cov khoom uas ua tau raws li cov kev cai tshwj xeeb ntawm qhov kev npaj siv thiab cov qauv kev cai.

Txoj kev tsim khoom:

- Cov khoom yas tuaj yeem tsim tau siv ntau txoj hauv kev, suav nrog kev txhaj tshuaj molding, tshuab moulding, thermoforming, thiab rotational molding.

- Txhua txoj kev muaj qhov zoo thiab qhov tsis zoo ntawm tus nqi, ntau lawm ceev, complexity, thiab ib feem zoo.

- Txoj kev tsim khoom yuav tsum tau xaiv raws li qhov xav tau tshwj xeeb ntawm ib feem, xws li nws qhov loj me, cov duab, thiab ntim, nrog rau qhov xav tau qib ntawm precision thiab sib xws.

Ib feem ua haujlwm:

- Kev ua haujlwm ntawm cov khoom siv yas yuav tsum tau ua tib zoo xav txog thaum tsim nws.

- Tej yam yuav tsum tau tsim los tiv thaiv txhua yam kev nyuaj siab, kub hloov pauv, tshuaj lom neeg raug, thiab lwm yam ib puag ncig.

- Kev txiav txim siab yuav tsum tau muab rau qhov haum, daim ntawv, thiab kev ua haujlwm thiab txhua yam kev xav kom zoo nkauj.

Tsim rau kev sib dhos:

- Yas Cheebtsam yuav tsum tau tsim nrog yooj yim ntawm kev sib dhos hauv siab.

- Cov khoom siv uas nyuaj los yog siv sij hawm los sib sau ua ke tuaj yeem ua rau cov nqi tsim khoom thiab ua rau muaj teeb meem zoo.

- Cov khoom yuav tsum tau tsim kom haum ua ke yooj yim thiab ruaj ntseg, nrog tsawg kawg xav tau rau cov khoom siv ntxiv lossis cov fasteners.

Tsim rau manufacturability:

- Kev tsim cov khoom siv yas yuav tsum xav txog cov txheej txheem tsim khoom thiab cov kev txwv lossis kev txwv.

- Cov qauv tsim xws li cov kaum sab xis, phab ntsa tuab, thiab cov kab sib cais tuaj yeem cuam tshuam cov khoom zoo thiab tus nqi.

- Kev koom tes nrog cov chaw tsim khoom tuaj yeem pab xyuas kom tus qauv tsim tau zoo rau kev tsim khoom.

Testing thiab validation:

- Thaum tsim cov khoom siv yas ua tiav, nws yuav tsum tau sim thiab siv tau los xyuas kom meej tias nws ua tau raws li qhov tsim nyog kev ua tau zoo thiab kev nyab xeeb.

- Kev ntsuam xyuas tuaj yeem suav nrog txhua yam, tshuaj lom neeg, thiab kev ntsuas cua sov thiab kuaj kom haum thiab ua haujlwm.

- Kev lees paub yuav tsum tau ua thoob plaws hauv txoj kev txhim kho, los ntawm kev tsim thawj zaug mus rau qhov khoom kawg.

Lub luag haujlwm ntawm Prototyping hauv Txhaj Molding

Prototyping plays lub luag haujlwm tseem ceeb hauv ntiaj teb kev txhaj tshuaj molding. Nws yog ib kauj ruam tseem ceeb hauv kev tsim khoom, tso cai rau cov neeg tsim qauv thiab cov kws tsim qauv ua kom zoo dua lawv cov qauv tsim, sim ua haujlwm, thiab txheeb xyuas cov teeb meem muaj peev xwm ua ntej mus tom ntej nrog kev tsim tawm tag nrho. Ntawm no, peb yuav tshawb txog qhov tseem ceeb ntawm prototyping hauv kev txhaj tshuaj molding thiab nws cov txiaj ntsig ntau heev.

Tsim validation:

Prototyping ua rau cov neeg tsim qauv siv lawv cov khoom tsim thiab ntsuas lawv qhov ua tau zoo hauv lub ntiaj teb tiag. Los ntawm kev tsim cov qauv ntawm lub cev, cov neeg tsim qauv tuaj yeem ntsuas cov yam ntxwv xws li ib feem geometry, haum, thiab sib dhos. Nws pab txheeb xyuas qhov teeb meem tsim, ua kom cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb thiab ua tau raws li qhov xav tau.

Kev txhim kho rov qab:

Prototyping tso cai rau kev txhim kho rov ua dua thoob plaws hauv lub voj voog tsim khoom. Los ntawm kev tsim ntau yam qauv thiab sim lawv, cov neeg tsim qauv tuaj yeem sau cov lus qhia muaj txiaj ntsig thiab ua qhov tsim nyog hloov kho. Cov txheej txheem rov ua dua no pab kho qhov tsim, ua kom zoo dua qub, thiab txhim kho cov khoom kawg ntawm kev ua haujlwm tag nrho.

Nqi thiab sij hawm txuag:

Kev txheeb xyuas qhov teeb meem tsim los yog teeb meem kev ua haujlwm thaum lub sij hawm prototyping yog qhov ua tau zoo thiab txuag sij hawm ntau dua li nrhiav tau lawv thaum lub sij hawm tsim khoom loj. Kev tsim cov kev hloov pauv thaum ntxov yuav txo qhov tsim nyog rau kev rov ua dua tshiab thiab txo qhov kev pheej hmoo ntawm kev tsim khoom qeeb. Prototyping tso cai rau kev daws teeb meem thiab kev ua kom zoo ua ntej cog lus rau cov cuab yeej kim thiab cov txheej txheem tsim khoom.

Kev xaiv khoom siv:

Prototyping pab txhawb kev xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding. Los ntawm kev ntsuam xyuas cov ntaub ntawv sib txawv, cov kws tsim khoom tuaj yeem soj ntsuam lawv cov khoom, suav nrog lub zog, hloov tau yooj yim, thiab ua haujlwm kub, thiab xaiv cov khoom tsim nyog tshaj plaws rau daim ntawv thov uas xav tau. Los ntawm kev ua qhov no, peb lav tias qhov tshwm sim ua tau raws li cov qauv tsim nyog rau kev ua haujlwm thiab kav ntev.

Kev Tshawb Fawb Txog Kev Tsim Khoom:

Prototypes ua ib txoj hauv kev los txheeb xyuas qhov ua tau thiab ua tau zoo ntawm cov txheej txheem tsim khoom xaiv. Los ntawm kev tsim cov qauv siv tib cov ntaub ntawv thiab cov kev npaj rau kev tsim khoom loj, engineers tuaj yeem txheeb xyuas qhov teeb meem lossis kev txwv thaum ntxov. Cov txheej txheem pov thawj no pab txhawb kev tsim khoom, txo qhov tsis xws luag, thiab ua kom zoo ib yam hauv cov khoom kawg.

Kev sib txuas lus thiab cov neeg muaj feem cuam tshuam:

Prototypes yog cov sawv cev ntawm cov tswv yim tsim khoom, ua kom muaj kev sib txuas lus zoo thiab muaj kev koom tes nrog cov neeg koom tes. Txawm hais tias nws tab tom nthuav tawm lub tswv yim tsim rau cov neeg siv khoom lossis sib sau cov lus tawm tswv yim los ntawm cov neeg siv kawg, cov qauv ua kom yooj yim rau txhua tus neeg koom nrog pom cov khoom, muab tswv yim, thiab txiav txim siab paub. Kev txhim kho kev sib koom tes ua rau muaj kev nkag siab tsis zoo thiab kev txaus siab ntau dua.

Cov kauj ruam tseem ceeb hauv kev txhaj tshuaj molding txheej txheem

Cov ntawv blog no yuav tham txog cov kauj ruam tseem ceeb hauv kev txhaj tshuaj molding txheej txheem.

Kauj Ruam 1: Xaiv cov khoom siv

Thawj kauj ruam hauv kev txhaj tshuaj molding yog xaiv cov khoom siv.

Cov ntaub ntawv yas sib txawv muaj cov yam ntxwv tshwj xeeb, xws li lub zog, yoog raws, thiab tshuaj tiv thaiv.

Kev xaiv ntawm cov khoom siv yuav nyob ntawm seb qhov kev xav tau tshwj xeeb ntawm qhov thiab nws qhov kev npaj siv.

Kauj Ruam 2: Kev npaj pellet

Cov yas pellets yog npaj los ntawm kev ziab thiab sib tov rau qhov yuav tsum tau ua.

Cov kauj ruam no yog qhov tseem ceeb los xyuas kom meej tias cov yas tsis muaj dej noo thiab cov kab mob uas tuaj yeem cuam tshuam qhov zoo ntawm cov khoom kawg.

Kauj Ruam 3: Melting cov yas

Cov yas pellets ces yaj hauv lub tshuab txhaj tshuaj molding.

Qhov kub thiab siab ntawm cov txheej txheem melting yuav nyob ntawm seb hom khoom siv yas siv.

Kauj Ruam 4: Txhaj

Tom qab ntawd cov yas melted yog txhaj rau hauv pwm.

Cov pwm feem ntau yog tsim los ntawm cov hlau thiab yog tsim los tsim cov duab uas xav tau ntawm cov khoom kawg.

Kauj Ruam 5: Cua txias thiab solidification

Tom qab cov yas txhaj rau hauv pwm, nws txias thiab solidifies rau hauv cov duab uas xav tau.

Lub sijhawm txias yuav nyob ntawm qhov tuab thiab qhov nyuaj ntawm ntu.

Kauj Ruam 6: Tshem tawm

Thaum cov yas tau txias thiab ua kom khov, cov pwm qhib, thiab ib feem yog ejected.

Qee zaum, ejector pins yog siv los pab tshem tawm ib feem ntawm cov pwm.

Kauj Ruam 7: Trimming thiab tiav

Tom qab ib feem raug tshem tawm ntawm cov pwm, nws yuav xav tau ntxiv trimming thiab xov kom tshem tawm cov khoom ntau dhau thiab du cov npoo.

Kauj Ruam 8: Kev tswj kom zoo

Kev tswj kom zoo yog ib kauj ruam tseem ceeb hauv kev txhaj tshuaj molding txheej txheem.

Cov khoom kawg raug tshuaj xyuas qhov tsis xws luag, xws li warping, cracking, los yog inconsistencies nyob rau hauv cov xim los yog kev ntxhib los mos.

Cov txheej txheem los txhim kho lub zog thiab ua haujlwm ntev ntawm cov khoom siv yas

Txawm li cas los xij, lawv feem ntau ntsib teeb meem nrog lub zog thiab kav ntev, tshwj xeeb tshaj yog thaum raug kev nyuaj siab lossis hnyav ib puag ncig. Hauv tsab ntawv blog no, peb yuav tham txog qee cov tswv yim los txhim kho lub zog thiab ua haujlwm ntawm cov khoom yas.

Txhim kho nrog additives

- Cov khoom siv ntxiv tuaj yeem txhim kho lub zog thiab ua haujlwm ntev ntawm cov khoom yas los ntawm kev txhawb nqa lawv nrog fibers, fillers, lossis nanoparticles.

- Cov additives muaj xws li iav fibers, carbon fibers, silica, talc, thiab av nplaum.

Kev sib xyaw nrog lwm cov ntaub ntawv

- Kev sib xyaw cov yas nrog lwm cov ntaub ntawv, xws li roj hmab lossis elastomers, tuaj yeem txhim kho lawv lub zog thiab kav ntev.

- Piv txwv li, ntxiv cov roj hmab me me rau polypropylene tuaj yeem txhim kho nws qhov kev cuam tshuam.

Tshav kub kho

- Kev kho cua sov tuaj yeem ua rau muaj zog thiab ua haujlwm ntev ntawm qee yam ntawm cov khoom yas.

- Qhov no suav nrog kev nthuav tawm cov yas mus rau qhov kub thiab txias los hloov nws cov khoom siv tshuaj thiab lub cev.

Tshawb nrhiav

- Annealing yog txheej txheem kev kho cua sov uas muaj cua sov cov yas mus rau qhov kub thiab txias thiab maj mam txias.

- Cov txheej txheem no tuaj yeem txo cov kev ntxhov siab sab hauv hauv cov yas, txhim kho nws lub zog thiab kav ntev.

Txhaj molding txheej txheem optimization

- Optimizing cov txheej txheem txhaj tshuaj molding tuaj yeem txhim kho lub zog thiab kav ntev ntawm cov khoom yas.

- Qhov no suav nrog kev tswj qhov kub, qhov siab, thiab qhov txias txias thaum lub sij hawm molding.

Kev kho qhov chaw

- Cov txheej txheem kho deg, xws li corona, plasma, lossis kev kho nplaim hluav taws, tuaj yeem txhim kho qhov adhesion ntawm yas thiab lwm yam ntaub ntawv.

- Qhov no tuaj yeem txhim kho lub zog thiab ua haujlwm ntev ntawm cov khoom siv yas hauv cov ntawv thov uas kev sib txuas yog qhov tseem ceeb.

Kev Siv Lub Tshuab Hloov

- Cov txheej txheem tuaj yeem txhim kho lub zog thiab ua haujlwm ntev ntawm cov khoom yas los ntawm kev muab cov txheej txheem tiv thaiv ntxiv.

- Piv txwv li, txheej txheej corrosion-resistant tuaj yeem tiv thaiv cov khoom yas los ntawm kev puas tsuaj hauv ib puag ncig hnyav.

Kev Tswj Xyuas Zoo hauv Automotive Txhaj Molding

Automotive txhaj tshuaj molding yog txheej txheem tseem ceeb rau kev tsim cov khoom siv tsheb zoo. Cov txheej txheem suav nrog kev siv cov tshuab tshwj xeeb thiab cov pwm los tsim cov khoom uas ua tau raws li cov qauv nruj thiab kev ua haujlwm zoo. Kev tswj xyuas kev ua tau zoo yog tsim nyog los xyuas kom meej tias cov khoom siv tsheb ua los ntawm cov txheej txheem ua tau raws li cov qauv no. Nov yog qee qhov tseem ceeb ntawm kev tswj xyuas qhov zoo uas tau siv hauv kev txhaj tshuaj automotive:

Kev tshuaj xyuas cov khoom: Thawj kauj ruam hauv kev tswj kom zoo yog kev tshuaj xyuas cov khoom siv. Cov ntaub ntawv nyoos raug tshuaj xyuas kom ntseeg tau tias lawv ua tau raws li qhov xav tau tshwj xeeb. Qhov no suav nrog xyuas cov khoom muaj pes tsawg leeg, purity, thiab sib xws.

Moulding Txheej Txheem Saib Xyuas: Cov txheej txheem molding raug saib xyuas tsis tu ncua kom ntseeg tau tias cov khoom raug tsim nyob rau hauv cov kev xav tau tshwj xeeb. Qhov no suav nrog kev saib xyuas cov khoom siv 'qhov kub thiab txias, siab, thiab ntws tus nqi.

Kev tshuaj xyuas ntu: Cov khoom raug tshuaj xyuas tom qab tsim khoom kom ua tau raws li cov qauv xav tau. Qhov no suav nrog kev tshuaj xyuas qhov tsis xws luag xws li warping, sink marks, thiab flashing.

Statistical Process Control (SPC): SPC yog cov cuab yeej txheeb xyuas uas saib xyuas thiab tswj cov txheej txheem tsim khoom. Nws suav nrog kev siv cov txheej txheem txheeb cais los txheeb xyuas cov ntaub ntawv thiab txheeb xyuas cov xwm txheej lossis cov qauv uas qhia txog cov teeb meem muaj feem cuam tshuam nrog cov txheej txheem.

Quality Assurance (QA): QA suav nrog kev siv cov txheej txheem thiab cov txheej txheem los xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv tsim nyog. Qhov no suav nrog kev tshuaj xyuas thiab ntsuas cov khoom tiav kom ntseeg tau tias nws ua tau raws li qhov xav tau tshwj xeeb.

Traceability: Traceability yog lub peev xwm los taug qab cov khoom rov qab mus rau nws qhov chaw. Hauv automotive txhaj tshuaj molding, traceability yog ib qho tseem ceeb los xyuas kom meej tias txhua yam tsis xws luag lossis teeb meem zoo tuaj yeem taug qab mus rau lawv qhov chaw thiab kho.

Nruam Txhim Kho: Kev txhim kho tas mus li yog ib txoj hauv kev txuas mus ntxiv uas suav nrog kev txheeb xyuas thaj chaw rau kev txhim kho thiab siv cov kev hloov pauv los txhim kho cov khoom zoo. Qhov no suav nrog kev txheeb xyuas cov ntaub ntawv, txheeb xyuas cov xwm txheej, thiab siv cov kev hloov pauv ntawm cov txheej txheem los txhim kho cov khoom zoo thiab sib xws.

Kev Ntsuam Xyuas Tus Nqi: Txhaj Moulding vs. Kev Tsim Nyog Cov Qauv

Hauv kev lag luam tsim khoom, kev txheeb xyuas tus nqi yog qhov tseem ceeb ntawm kev txiav txim siab. Cov neeg tsim khoom yuav tsum ntsuas tus nqi ntawm kev tsim lawv cov khoom siv sib txawv los txiav txim siab tus nqi zoo tshaj plaws. Kev txhaj tshuaj molding thiab kev tsim khoom ib txwm siv yog ob qho tib si siv, thiab cov neeg tsim khoom yuav tsum txiav txim siab seb yam twg yog qhov zoo tshaj plaws rau lawv cov khoom. Ntawm no yog ib tug nqi tsom xam ntawm kev txhaj tshuaj molding vs. ib txwm raug txoj kev.

Txhaj Tshuaj Molding:

Txhaj tshuaj molding yog ib txoj kev tsim khoom uas koom nrog kev txhaj tshuaj molten yas rau hauv pwm los tsim cov khoom. Nov yog qee qhov zoo thiab qhov tsis zoo ntawm kev txhaj tshuaj molding:

Zoo:

- High ntau lawm ntim:Kev txhaj tshuaj molding yog qhov zoo tagnrho rau kev tsim cov phau ntawv siab ntawm cov khoom zoo ib yam.

- Cov nqi zog qis dua:Kev txhaj tshuaj molding yuav tsum tau ua haujlwm tsawg dua piv rau cov qauv tsim khoom.

- Zoo sib xws: Txhaj tshuaj molding ua rau cov khoom sib xws uas zoo ib yam rau ib leeg.

- Cov khoom siv qis qis: Kev txhaj tshuaj molding muaj cov khoom pov tseg tsawg dua li cov txheej txheem tsim khoom.

tsis zoo:

- Tus nqi siab dua:Tus nqi ntawm kev teeb tsa kev txhaj tshuaj molding yog siab dua piv rau cov qauv tsim khoom.

- Tsawg yooj yooj yim: Kev txhaj tshuaj molding yog qhov hloov pauv tsawg dua li cov qauv tsim khoom, ua rau nws tsis tshua zoo rau kev tsim cov khoom siv.

Txoj kev tsim khoom qub:

Cov txheej txheem tsim khoom ib txwm hais txog cov txheej txheem tsim khoom siv tau siv rau ntau xyoo. Cov txheej txheem no suav nrog milling, drilling, thiab tig. Nov yog qee qhov zoo thiab qhov tsis zoo ntawm cov txheej txheem tsim khoom ib txwm:

Zoo:

- Tsawg, tus nqi them ua ntej:Cov txheej txheem tsim khoom ib txwm xav tau cov nqi qis tshaj plaws, ua rau lawv zoo tagnrho rau kev tsim cov khoom qis.

- Flexibility:Cov txheej txheem tsim khoom qub yog hloov pauv ntau dua li kev txhaj tshuaj molding, ua rau lawv zoo tagnrho rau kev tsim cov khoom siv.

- Cov nqi cuab yeej qis dua:Cov txheej txheem tsim khoom ib txwm xav tau cov cuab yeej siv qis dua li kev txhaj tshuaj molding.

tsis zoo:

- Cov nqi zog ntau dua:Cov txheej txheem tsim khoom ib txwm xav tau kev ua haujlwm ntau dua li kev txhaj tshuaj molding, ua rau cov nqi zog ntau dua.

- Cov khoom pov tseg ntau dua:Kev tsim cov txheej txheem tsim khoom pov tseg ntau dua li kev txhaj tshuaj molding.

- Qhov tsis sib xws:Cov txheej txheem tsim khoom ib txwm tsim cov nyiaj uas yuav muaj kev hloov pauv me ntsis ntawm ib leeg.

Sustainability thiab Environmental Impact ntawm Txhaj Molding

Sustainability thiab ib puag ncig cuam tshuam yog qhov tseem ceeb uas cov lag luam thiab cov tuam txhab lag luam yuav tsum xav txog hauv lawv cov txheej txheem tsim khoom. Txhaj tshuaj molding, ib txoj kev tsim khoom nrov, muaj kev cuam tshuam zoo thiab tsis zoo rau ib puag ncig. Nyob rau hauv no blog ncej, peb yuav tham txog kev sustainability thiab ecological cuam tshuam ntawm kev txhaj tshuaj molding.

Muaj caij nyoog:

Sustainability hais txog kev ua kom tau raws li qhov xav tau ntawm tam sim no yam tsis muaj kev cuam tshuam lub peev xwm ntawm cov tiam tom ntej kom tau raws li lawv cov kev xav tau. Kev txhaj tshuaj molding muaj ntau yam txiaj ntsig zoo:

- Khoom siv efficiency:Txhaj tshuaj molding tsim cov khoom nrog cov khoom siv tsawg tsawg, txo cov khoom tsim nyog los ua cov khoom.

- Zog efficiency:Kev txhaj tshuaj molding yuav tsum muaj zog tsawg dua los tsim cov khoom dua li lwm txoj kev tsim khoom, xws li machining thiab casting.

- Ntev ntev: Cov khoom tsim los ntawm kev txhaj tshuaj molding yog qhov ruaj khov thiab siv tau ntev, txo qhov xav tau kev hloov pauv ntau zaus.

Environmental Impact:

Txhaj tshuaj molding kuj muaj kev cuam tshuam ib puag ncig uas yuav tsum tau xav txog. Nov yog qee qhov txiaj ntsig zoo thiab tsis zoo ntawm kev txhaj tshuaj molding:

Kev cuam tshuam ib puag ncig zoo:

- Rov qab siv dua: Ntau cov ntaub ntawv txhaj tshuaj molding, xws li yas, tuaj yeem rov ua dua, txo cov khib nyiab xa mus rau qhov chaw pov tseg.

- Qis carbon hneev taw:Kev txhaj tshuaj molding ua rau cov pa hluav taws xob tsawg tsawg dua li lwm txoj kev tsim khoom xws li machining thiab casting.

Tsis zoo Environmental Impact:

- Kev siv cov peev txheej tsis txuas ntxiv dua tshiab:Kev txhaj tshuaj molding siv cov khoom siv roj av xws li cov yas tau los ntawm cov khoom siv tsis siv dua tshiab.

- Kev tsim khoom pov tseg:Txawm hais tias kev txhaj tshuaj molding tsim cov khoom pov tseg tsawg dua li lwm txoj kev tsim khoom, nws tseem tsim cov khoom pov tseg, xws li cov khoom seem thiab ntim cov khib nyiab.

Sustainable Practices nyob rau hauv Txhaj Molding:

Txhawm rau txo qis qhov tsis zoo ib puag ncig ntawm kev txhaj tshuaj molding, cov tuam ntxhab tuaj yeem siv cov kev coj ua zoo xws li:

- Kev siv cov khoom siv rov ua dua tshiab:Cov neeg tsim khoom tuaj yeem siv cov khoom siv rov ua dua tshiab hauv lawv cov txheej txheem txhaj tshuaj molding, txo cov khib nyiab xa mus rau qhov chaw pov tseg.

- Kev siv lub zog tauj dua tshiab:Cov neeg tsim khoom tuaj yeem siv cov khoom siv hluav taws xob tauj dua tshiab xws li hnub ci lossis cua zog los txhawb lawv cov tshuab txhaj tshuaj molding, txo cov pa roj carbon monoxide.

- Kev txo pov tseg:Cov neeg tsim khoom tuaj yeem siv cov kev coj ua txo qis xws li siv cov ntim rov qab siv tau thiab txo cov khoom seem uas tsim tawm.

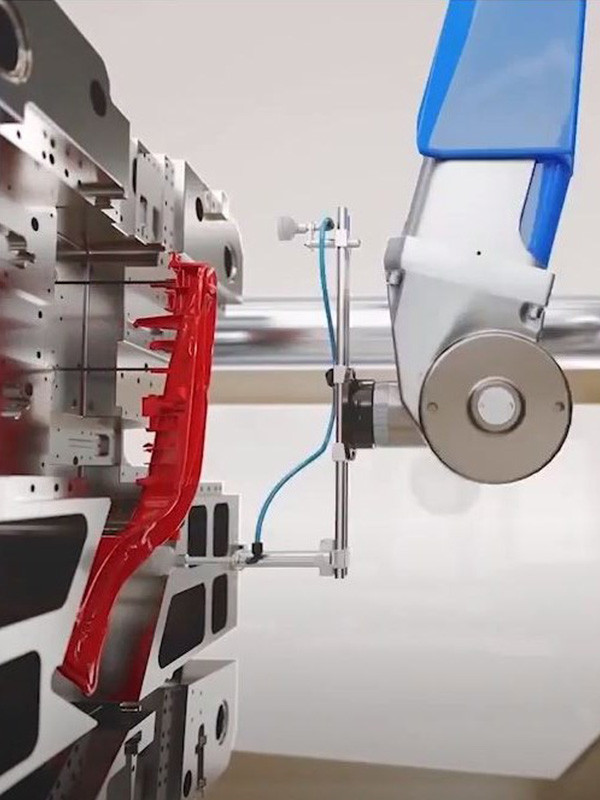

Automating Txhaj Moulding txheej txheem rau kev ua tau zoo

Hauv kev lag luam tsim khoom, kev ua tau zoo yog qhov tseem ceeb rau kev nyob sib tw thiab muaj txiaj ntsig. Txhaj tshuaj molding yog ib txoj kev tsim khoom nrov uas suav nrog kev tsim cov khoom los ntawm kev txhaj tshuaj molten rau hauv pwm. Automating txhaj tshuaj molding txheej txheem tuaj yeem txhim kho kev ua tau zoo thiab tsim khoom. Hauv no blog ncej, peb yuav tham txog cov txiaj ntsig ntawm kev txhaj tshuaj molding txheej txheem rau kev ua haujlwm zoo.

Cov txiaj ntsig ntawm Automating Txhaj Molding Txheej Txheem:

Nov yog qee qhov txiaj ntsig ntawm automating txhaj tshuaj molding txheej txheem:

- Nce ceev:Automation tuaj yeem ua kom nrawm nrawm ntawm cov txheej txheem txhaj tshuaj molding. Cov tshuab tsis siv neeg tuaj yeem tsim cov khoom ntawm tus nqi nrawm dua li cov tshuab phau ntawv.

- Zoo sib xws:Automated txhaj tshuaj molding tshuab tsim cov khoom sib xws nrog qhov sib txawv me me, ua kom zoo thiab kev ntseeg tau.

- Txhim kho qhov tseeb:Automated tshuab muaj siab precision thiab raug, ua qhov chaw nrog nruj tolerances thiab complex geometries.

- Txo cov nqi zog:Automating txhaj tshuaj molding txheej txheem tuaj yeem txo qhov xav tau ntawm kev siv tes ua haujlwm, txo cov nqi zog.

- Txhim kho kev nyab xeeb:Cov tshuab tsis siv neeg tuaj yeem ua haujlwm txaus ntshai rau tib neeg, txhim kho kev nyab xeeb hauv kev tsim khoom.

- Txo cov khoom pov tseg:Cov tshuab tsis siv neeg tuaj yeem tsim cov khoom nrog cov khoom siv tsawg tsawg, txo cov nqi khoom thiab kev cuam tshuam ib puag ncig.

Automating Txhaj Molding Txheej Txheem:

Nov yog qee txoj hauv kev los automate kev txhaj tshuaj molding txheej txheem:

- Robotic automation:Cov neeg hlau tuaj yeem ua haujlwm xws li thauj khoom thiab tshem tawm qhov chaw, tshuaj xyuas qhov chaw, thiab ntim cov khoom tiav. Robotic automation tuaj yeem ua kom nrawm thiab raug ntawm cov txheej txheem txhaj tshuaj molding.

- Automated khoom tuav:Cov khoom siv tsis siv neeg tuav cov tshuab tuaj yeem thauj cov ntaub ntawv mus rau lub tshuab txhaj tshuaj molding, txo qhov kev xav tau ntawm kev siv tes ua haujlwm.

- Automated zoo tswj:Cov txheej txheem tswj kev ua haujlwm tau zoo tuaj yeem tshawb xyuas qhov chaw rau qhov tsis xws luag thiab kev sib txawv, ua kom zoo ib yam thiab txo qhov xav tau ntawm phau ntawv tshuaj xyuas.

- Kev saib xyuas lub sijhawm tiag tiag: Cov kab ke no tuaj yeem taug qab lub tshuab ua haujlwm thiab txheeb xyuas cov teeb meem ntawm lub sijhawm, txo qis sijhawm thiab txhim kho kev ua haujlwm.

Cov kev sib tw ntawm Automating Txhaj Molding Txheej Txheem:

Txawm hais tias automating kev txhaj tshuaj molding txheej txheem muaj ntau cov txiaj ntsig, nws kuj nthuav tawm qee qhov kev cov nyom:

- Tus nqi siab dua:Automating txhaj tshuaj molding txheej txheem tuaj yeem kim vim cov khoom siv thiab kev siv.

- Nce complexity:Automated systems yog complex tshaj li phau ntawv systems, yuav tsum tau tshwj xeeb kev cob qhia thiab txij nkawm.

- Txo qhov yooj yim:Automated systems tsis hloov pauv ntau dua li kev siv phau ntawv, ua rau nws nyuaj rau kev hloov pauv ntawm cov kev xav tau ntau lawm.

Kev sib tw thiab kev txwv ntawm Automotive Yas Cheebtsam Txhaj Molding

Txawm li cas los xij, qee qhov kev sib tw thiab kev txwv yuav tsum tau txiav txim siab thaum siv cov tshuaj molding rau cov khoom siv hauv tsheb. Hauv tsab ntawv blog no, peb yuav tham txog qee qhov kev cov nyom thiab kev txwv ntawm cov khoom siv tsheb yas txhaj tshuaj molding.

Kev sib tw ntawm Automotive Yas Cheebtsam Txhaj Molding:

Nov yog qee qhov kev sib tw ntawm automotive yas khoom txhaj tshuaj molding:

- Kev xaiv cov khoom siv:Xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding automotive yas khoom yuav nyuaj. Cov khoom siv yuav tsum muaj zog, ruaj, thiab tiv taus huab cua kub thiab hnyav ib puag ncig.

- Tooling nqi:Tus nqi ntawm cov cuab yeej rau kev txhaj tshuaj molding tuaj yeem kim, tshwj xeeb tshaj yog rau qhov nyuaj nrog cov qauv tsim.

- Tshooj tsim:Kev tsim qhov chaw rau kev txhaj tshuaj molding tuaj yeem nyuaj, vim tias tus qauv tsim yuav tsum xav txog yam xws li moldability, shrinkage, thiab warping.

- Kev tswj kom zoo:Kev ua kom zoo ib yam thiab kev ua tau zoo ntawm kev txhaj tshuaj molded automotive yas Cheebtsam tuaj yeem nyuaj vim cov khoom siv, txheej txheem, thiab cov cuab yeej hloov pauv.

Kev txwv ntawm Automotive Yas Cheebtsam Txhaj Molding:

Nov yog qee qhov kev txwv ntawm automotive yas khoom txhaj tshuaj molding:

- Kev txwv qhov loj:Kev txhaj tshuaj molding muaj qhov txwv loj, thiab nws yuav tsis tuaj yeem tsim cov khoom siv yas loj loj uas siv cov tshuaj molding.

- Ntau lawm ntim:Kev txhaj tshuaj molding yog qhov zoo tshaj plaws rau cov khoom ntim ntau thiab tej zaum yuav tsis raug nqi rau cov khoom ntim qis.

- complexity:Kev txhaj tshuaj molding yog tsis tsim nyog rau cov khoom uas muaj cov geometry nyuaj lossis cov qauv tsim uas xav tau ntau yam khoom lossis sib dhos.

- Kev cuam tshuam ib puag ncig:Kev txhaj tshuaj molding ua cov khoom pov tseg thiab siv cov khoom siv tsis siv dua tshiab, uas tuaj yeem ua mob rau ib puag ncig.

Overcoming Challenges thiab Limitations:

Nov yog qee txoj hauv kev los kov yeej cov kev cov nyom thiab cov kev txwv ntawm automotive yas khoom txhaj tshuaj molding:

- Kev xaiv cov khoom siv:Xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding yuav tsum tau ua tib zoo xav txog qhov yuav tsum tau ua thiab kev ua tau zoo. Cov neeg tsim khoom tuaj yeem ua haujlwm nrog cov neeg muag khoom los xaiv cov ntaub ntawv uas ua tau raws li cov kev xav tau tshwj xeeb ntawm ntu.

- Tooling nqi:Kev nqis peev hauv cov cuab yeej ua tau zoo tuaj yeem txo cov nqi nyob rau lub sijhawm ntev los ntawm kev txo qis qis thiab nce cov khoom tsim tau.

- Tshooj tsim:Kev ua kom zoo ib feem tsim rau kev txhaj tshuaj molding yuav tsum muaj kev sib koom tes ntawm cov tsim qauv, engineers, thiab cov kws tshaj lij tsim khoom kom ntseeg tau tias qhov chaw tuaj yeem ua tau zoo thiab ua tau zoo siv kev txhaj tshuaj molding.

- Kev tswj kom zoo:Ua raws li kev tswj hwm kev tswj hwm zoo tuaj yeem txhim kho qhov sib xws thiab txo qhov sib txawv ntawm qhov zoo.

Innovations nyob rau hauv Txhaj Molding Technology

Txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv los tsim cov khoom yas nyuaj. Nws koom nrog kev txhaj tshuaj molten yas rau hauv pwm nyob rau hauv kev kub siab thiab txias nws los tsim cov duab uas xav tau. Nrog rau qhov kev thov loj zuj zus rau qhov tseeb thiab kev ua tau zoo hauv kev lag luam tsim khoom, kev tsim kho tshiab hauv kev txhaj tshuaj molding tshuab tau ua lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li cov kev cai no. Hauv tsab ntawv blog no, peb yuav tshawb txog qee qhov kev txhim kho tshiab hauv kev txhaj tshuaj molding tshuab.

- Micro txhaj molding: Qhov kev siv tshuab no ua rau kev tsim cov khoom me me, nrog rau kev ua siab ntev li tsawg li ob peb microns. Micro-injection molding yog tshwj xeeb tshaj yog pab tau nyob rau hauv kev kho mob thiab electronics industries, qhov twg qhov kev thov rau me me, complex qhov chaw yog nce.

- Multi-component molding: Cov txheej txheem no suav nrog kev txhaj tshuaj sib txawv rau hauv tib lub pwm, tso cai rau kev tsim cov khoom nrog ntau xim lossis cov khoom siv. Cov tshuab no feem ntau siv hauv kev lag luam tsheb thiab cov khoom siv.

- Hauv-pwm kho kom zoo nkauj:Lub tshuab no suav nrog kev ntxiv cov duab, textures, thiab cov qauv rau molded qhov chaw thaum txhaj tshuaj molding. Kev kho kom zoo nkauj hauv pwm yog ib txoj hauv kev zoo kom ua tiav cov khoom zoo yam tsis muaj kev ua haujlwm ntxiv.

- Kev txhaj tshuaj molding: Lub tshuab no txhaj ob cov ntaub ntawv ib txhij, tsim ib feem nrog daim tawv nqaij thiab cov khoom tseem ceeb. Kev txhaj tshuaj molding yog qhov tseem ceeb rau kev tsim cov khoom nrog lub ntsej muag muag lossis cov khoom siv kho kom zoo.

- Gas-pab txhaj tshuaj molding:Cov tshuab no suav nrog kev txhaj tshuaj, feem ntau nitrogen, rau hauv pwm thaum txhaj tshuaj molding. Cov roj tsim cov channel hauv ib feem, txo cov khoom siv thiab txhim kho cov khoom lag luam.

- Kev kub ceev txhaj tshuaj molding:Cov cuab yeej no ua rau kev txhaj tshuaj sai dua thiab lub sijhawm voj voog, ua kom cov khoom siv tau zoo thiab txo cov nqi. High-speed txhaj molding yog tshwj xeeb tshaj yog pab tau nyob rau hauv zus tau tej cov nyias-walled qhov chaw.

- Intelligent molding: Cov tshuab no siv cov sensors thiab cov ntaub ntawv txheeb xyuas kom zoo rau kev txhaj tshuaj molding txheej txheem. Intelligent molding tuaj yeem txhim kho cov khoom zoo thiab txo cov khoom pov tseg los ntawm kev saib xyuas yam xws li kub, siab, thiab cov khoom ntws.

Daim ntawv thov tsom teeb: Sab hauv cov khoom siv yas

Hauv kev lag luam tsheb, kev tsim sab hauv thiab kev ua haujlwm yog qhov tseem ceeb rau kev xa cov kev tsav tsheb zoo dua. Cov khoom siv yas sab hauv ua lub luag haujlwm tseem ceeb hauv kev ua tiav lub hom phiaj no, muab kev nplij siab, style, thiab kav ntev. Cov ntawv tshaj tawm blog no yuav tshawb txog qee qhov feem ntau siv cov khoom yas hauv tsheb sab hauv.

- Dashboard: Lub dashboard yog ib qho tseem ceeb sab hauv uas muaj xws li ntsuas, cua vents, infotainment systems, thiab lwm yam tseem ceeb tswj. Cov khoom siv yas feem ntau yog siv los tsim cov dashboards vim lawv cov kav ntev, tsim kom yooj yim, thiab yooj yim ntawm kev ua.

- Qhov rooj panels:Qhov rooj panels yog qhov tseem ceeb rau kev tsim sab hauv, muab kev tiv thaiv thiab kev nplij siab. Cov khoom siv yas feem ntau yog siv los tsim cov vaj huam sib luag qhov rooj vim lawv muaj peev xwm tiv taus qhov cuam tshuam, txo suab nrov, thiab lub teeb yuag.

- Rooj zaum:Cov rooj zaum hauv tsheb xav tau cov khoom siv ua haujlwm siab uas muab kev nplij siab thiab kev txhawb nqa. Cov khoom siv yas yog siv los tsim lub rooj zaum nraub qaum, armrests, thiab lwm qhov chaw ntawm lub rooj zaum. Cov khoom no muab lub zog thiab yoog raws thiab tuaj yeem ua tau yooj yim zoo li tus kom haum rau cov qauv sib txawv.

- Center console:Lub hauv paus console yog lub hub rau kev tswj hwm tseem ceeb xws li kev tswj hwm huab cua, lub tshuab suab, thiab kev cia khoom. Cov khoom siv yas feem ntau yog siv los tsim cov chaw nruab nrab vim lawv muaj peev xwm tiv taus cua sov, av noo, thiab lwm yam ib puag ncig.

- Trim panels: Trim panels yog siv los npog thaj chaw sab hauv ntawm lub tsheb, xws li cov ncej, headliners, thiab lub rooj zaum nraub qaum. Yas Cheebtsam yog siv los tsim cov vaj huam sib luag no vim lawv qhov tsim tau yooj yim, xim ntau yam, thiab kev ua haujlwm yooj yim.

Daim ntawv thov tsom teeb: Sab nrauv cov khoom siv yas

Cov khoom yas sab nrauv tau dhau los ua ntau dua hauv kev lag luam tsheb. Nrog rau qhov kev thov rau cov khoom siv hnyav, txhim kho roj efficiency, thiab kev tsim tshiab, cov khoom siv yas tau dhau los ua qhov kev xaiv nrov rau kev tsim ntau yam sab nrauv ntawm lub tsheb. Hauv tsab ntawv blog no, peb yuav tshawb xyuas qee qhov feem ntau siv sab nrauv yas hauv kev lag luam tsheb.

- Bumpers: Bumpers yog ib qho tseem ceeb rau sab nrauv uas tiv thaiv lub tsheb thaum muaj kev sib tsoo. Plastic Cheebtsam feem ntau yog siv los tsim cov bumpers vim hais tias lawv yog ib lub teeb yuag, cuam tshuam-resistant, thiab nqi-zoo.

- Grilles: Lub grille yog ib qho tseem ceeb sab nrauv ntawm lub tsheb, thiab nws plays lub luag haujlwm tseem ceeb hauv nws cov qauv tsim thiab aerodynamics. Yas Cheebtsam feem ntau yog siv los tsim cov hniav nyiaj hniav kub vim lawv qhov tsim tau yooj yim thiab muaj peev xwm los ua pwm rau hauv cov duab nyuaj.

- Sab nrauv trims:Sab nrauv trims muaj xws li moldings, fender flares, thiab lwm yam zoo nkauj Cheebtsam uas txhim khu cov tsos ntawm lub tsheb. Cov khoom siv yas feem ntau yog siv los tsim cov khoom siv no vim lawv tuaj yeem ua xim thiab textured, muab ntau yam kev xaiv tsim.

- Tsom iav: Daim iav yog ib qho tseem ceeb ntawm txhua lub tsheb, muab kev pom thiab kev nyab xeeb. Cov khoom siv yas feem ntau yog siv los tsim cov iav vaj tse vim lawv lub teeb yuag, kev cuam tshuam tsis zoo, thiab tsim kom yooj yim.

- Spoilers: Spoilers yog qhov nrov ntxiv rau ntau lub tsheb, txhim kho aerodynamics thiab txhim kho tag nrho cov tsos. Cov khoom siv yas feem ntau yog siv los tsim cov spoilers vim lawv lub teeb yuag thiab tsim kom yooj yim.

Yav tom ntej ntawm Automotive Yas Cheebtsam Txhaj Molding

Automotive yas Cheebtsam txhaj tshuaj molding tau dhau los ua qhov tseem ceeb hauv kev lag luam tsheb. Raws li thev naus laus zis txuas ntxiv mus, lub neej yav tom ntej ntawm cov txheej txheem no zoo li muaj kev vam meej. Nov yog qee qhov sib txawv thiab kev kwv yees rau yav tom ntej ntawm automotive yas khoom txhaj tshuaj molding:

- Kev siv cov khoom siv hnyav dua: Cov khoom siv hnyav xws li carbon fiber thiab thermoplastics tau dhau los ua neeg nyiam hauv kev lag luam tsheb. Qhov no yog vim lawv cov txiaj ntsig ntawm cov roj efficiency, kev ua tau zoo, thiab txo qis emissions. Yog li ntawd, automotive yas Cheebtsam txhaj tshuaj molding yuav ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom hnyav no.

- Integration ntawm Additive Manufacturing:Kev tsim khoom ntxiv, tseem hu ua 3D luam ntawv, tau dhau los ua ntau dua hauv kev lag luam tsheb. Cov cuab yeej no tso cai rau kev tsim cov geometry nyuaj thiab cov duab uas yuav nyuaj lossis tsis tuaj yeem tsim los siv cov tshuaj txhaj tshuaj molding. Nyob rau hauv lub neej yav tom ntej, automotive yas Cheebtsam txhaj molding tej zaum yuav integrate additive manufacturing rau ntau lawm los tsim intricate ntau designs.

- Nce Automation: Raws li kev siv thev naus laus zis, peb tuaj yeem cia siab tias yuav pom ntau dua automation hauv cov txheej txheem txhaj tshuaj molding. Qhov no yuav ua rau kom muaj kev ua tau zoo thiab txo lub sij hawm tsim khoom. Tsis tas li ntawd, automation tuaj yeem txo qhov tshwm sim ntawm tib neeg kev ua yuam kev, ua rau cov khoom lag luam zoo dua.

- Ntau Sustainable Materials: Sustainability tau dhau los ua qhov teeb meem tseem ceeb hauv kev lag luam tsheb. Automotive yas Cheebtsam txhaj tshuaj molding yuav tsum tau hloov mus rau qhov sib txawv no los ntawm kev siv cov ntaub ntawv ruaj khov dua. Piv txwv li, bio-based plastics thiab cov khoom siv rov ua dua tuaj yeem siv rau hauv kev txhaj tshuaj molding los txo cov khib nyiab thiab carbon emissions.

- Nce Customization:Cov neeg siv khoom tau dhau los ua qhov xav tau ntawm kev hloov kho thiab tus kheej. Nyob rau hauv lub neej yav tom ntej, automotive yas Cheebtsam txhaj tshuaj molding tej zaum yuav siv technologies uas tso cai rau ntau customization ntawm cov khoom. Qhov no tuaj yeem suav nrog lub peev xwm los tsim tus kheej tsim, xim, thiab kev ntxhib los mos ntawm cov khoom yas.

- Kev koom ua ke ntawm Smart Technologies: Cov cuab yeej ntse xws li sensors thiab Internet ntawm Yam (IoT) cov cuab yeej tau dhau los ua ntau dua hauv kev lag luam tsheb. Nyob rau hauv lub neej yav tom ntej, automotive yas Cheebtsam txhaj tshuaj molding tej zaum yuav muab cov technologies rau hauv ntau lawm. Qhov no tuaj yeem tso cai rau tsim cov khoom sib txuas lus nrog lwm qhov ntawm lub tsheb thiab tus neeg tsav tsheb.

Case Study: Ua tau zoo ntawm Kev Txhaj Tshuaj Molding hauv Automotive Kev Lag Luam

Txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv uas tau dhau los ua neeg nyiam hauv kev lag luam tsheb. Hauv no blog ncej, peb yuav tham txog cov ntaub ntawv kawm txog kev ua tiav ntawm kev txhaj tshuaj molding hauv kev lag luam tsheb.

Case: Automotive Teeb pom kev zoo

Ib cheeb tsam uas txhaj tshuaj molding tau ua tiav tshwj xeeb hauv kev lag luam tsheb yog kev tsim cov khoom siv hluav taws xob tsheb. Hauv qhov kev tshawb fawb no, peb yuav tsom mus rau kev siv cov tshuaj molding los tsim lub teeb pom kev zoo rau cov qauv nrov.

Cov Kev Sib Ceg:

Lub taillight lens yuav tsum tau ua raws li cov cai hauv qab no:

- Resistance rau UV teeb thiab huab cua

- Zoo optical clarity

- durability

- Kev tsim kho zoo nkauj

- Lub sijhawm ua haujlwm tau zoo

tshuaj:

Tom qab soj ntsuam cov kev xav tau thiab cov kev sib tw, lub tsheb teeb pom kev lag luam tau xaiv kev txhaj tshuaj molding raws li qhov kev daws teeb meem zoo tshaj plaws rau kev tsim lub lens taillight. Cov chaw tsim khoom tau koom tes nrog lub tuam txhab paub txog kev txhaj tshuaj molding uas muaj cov ntaub ntawv teev tseg ntawm kev tsim cov khoom siv tsheb zoo.

Cov txheej txheem txhaj tshuaj molding koom nrog cov kauj ruam hauv qab no:

- Kev xaiv cov khoom siv:Cov khoom siv polycarbonate UV-resistant tau raug xaiv rau lub teeb lub teeb.

- Pwm tsim:Lub tuam txhab txhaj tshuaj molding tau tsim cov pwm kev cai los tsim lub taillight lens kom tau raws li qhov yuav tsum tau ua.

- Txhaj tshuaj molding:Tom qab ntawd cov pwm tau siv rau hauv cov txheej txheem txhaj tshuaj molding los tsim lub taillight lens.

- Kev tswj kom zoo:Lub taillight lens tau ua raws li kev tswj xyuas nruj kom ntseeg tau tias nws ua tau raws li cov qauv xav tau.

tau:

Kev siv ntawm kev txhaj tshuaj molding rau kev tsim cov taillight lens ua pov thawj ua tiav. Lub tsheb teeb pom kev lag luam tsim lub teeb pom kev zoo zoo uas ua tau raws li txhua qhov yuav tsum tau ua.

Cov txiaj ntsig ntawm kev siv tshuaj molding rau daim ntawv thov no suav nrog:

- Qhov zoo ib yam:Txhaj tshuaj molding ua kom zoo ib yam ntawm lub taillight lens, uas ua tau raws li cov qauv xav tau.

- Kev tsim khoom muaj txiaj ntsig: Txoj kev txhaj tshuaj molding tau tso cai rau kev tsim cov taillight lens, uas ua rau txo cov sij hawm tsim khoom thiab cov nqi.

- Aesthetically pleasing design:Txhaj tshuaj molding tso cai rau tsim kom muaj kev zoo nkauj zoo nkauj tsim rau lub teeb lub teeb.

- Sij hawm: Lub taillight lens tsim los ntawm kev txhaj tshuaj molding yog ruaj thiab tiv taus UV teeb thiab huab cua.

Feem ntau Misconceptions txog Txhaj Molding

Txhaj tshuaj molding yog ib txoj kev tsim khoom siv dav siv uas koom nrog kev txhaj tshuaj ntawm cov khoom molten rau hauv pwm los tsim cov duab uas xav tau. Txawm li cas los xij, ntau qhov kev xav tsis zoo txog kev txhaj tshuaj molding tuaj yeem ua rau muaj kev nkag siab tsis zoo txog cov txheej txheem. Tsab ntawv blog no yuav tham txog qee qhov kev xav tsis zoo txog kev txhaj tshuaj molding.

Misconception 1: Kev txhaj tshuaj molding tsuas yog tsim nyog rau kev tsim cov khoom loj.

Ntau tus ntseeg tias kev txhaj tshuaj molding tsuas yog tsim nyog rau kev tsim cov khoom loj. Thaum txhaj tshuaj molding tuaj yeem tsim cov khoom lag luam ntau, nws kuj tuaj yeem siv rau kev ua haujlwm me me. Kev txhaj tshuaj molding tuaj yeem ua tau zoo thiab raug nqi rau kev tsim cov khoom me me rau nruab nrab.

Misconception 2: Kev txhaj tshuaj molding yog txheej txheem qeeb.

Lwm qhov kev xav tsis zoo txog kev txhaj tshuaj molding yog tias nws yog txheej txheem qeeb. Thaum nws muaj tseeb tias kev txhaj tshuaj molding yuav tsum muaj qee lub sijhawm teeb tsa, thaum cov txheej txheem nce thiab khiav, nws tuaj yeem tsim cov khoom lag luam ntau sai thiab ua tau zoo. Tsis tas li ntawd, kev nce qib hauv thev naus laus zis tau tso cai rau kev txhaj tshuaj molding tshuab sai dua thiab cov txheej txheem.

Misconception 3: Kev txhaj tshuaj molding tsuas yog tsim los tsim cov duab yooj yim.

Kev txhaj tshuaj molding feem ntau cuam tshuam nrog kev tsim cov duab yooj yim, tab sis qhov no tsis yog qhov tseeb. Kev nce qib hauv pwm tsim thiab xaiv cov khoom siv tau tso cai rau kev tsim cov duab ntau dua thiab tsim los ntawm kev txhaj tshuaj molding. Tsis tas li ntawd, kev sib koom ua ke ntawm 3D luam ntawv thiab lwm yam thev naus laus zis tau nthuav dav txoj hauv kev rau kev txhaj tshuaj molding ntxiv.

Misconception 4: Txhaj tshuaj molding tsis yog ib puag ncig tus phooj ywg.

Kev txhaj tshuaj molding feem ntau raug thuam vim tsis yog ib puag ncig zoo. Thaum nws muaj tseeb tias kev txhaj tshuaj molding tsim qee cov khoom pov tseg, kev nce qib hauv kev xaiv cov khoom siv thiab cov thev naus laus zis rov ua dua tau tso cai rau kev tsim cov khoom lag luam zoo ib puag ncig los ntawm kev txhaj tshuaj molding. Tsis tas li ntawd, kev txhaj tshuaj molding tso cai rau kev tsim cov khoom hnyav thiab ruaj khov uas tuaj yeem pab txo qis cov pa roj carbon hneev taw ntawm cov khoom.

Misconception 5: Txhaj tshuaj molding yog kim.

Ntau tus neeg ntseeg tias kev txhaj tshuaj molding yog txheej txheem tsim khoom kim. Thaum nws muaj tseeb tias muaj qee tus nqi them ua ntej cuam tshuam nrog kev txhaj tshuaj molding, xws li tus nqi tsim thiab tsim pwm, tus nqi ntawm ib chav tsev txo qis raws li qhov ntim ntau lawm. Tsis tas li ntawd, kev nce qib hauv thev naus laus zis tau ua rau kev txhaj tshuaj molding ntau dua thiab siv tau zoo dua li yav dhau los.

Kev daws teeb meem tshwm sim hauv Kev Txhaj Tshuaj Molding

Txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv uas tsim cov khoom yas zoo rau ntau yam lag luam. Txawm li cas los xij, zoo li txhua txoj kev tsim khoom, kev txhaj tshuaj molding tuaj yeem ntsib cov teeb meem tshwm sim uas tuaj yeem cuam tshuam tsis zoo rau cov khoom kawg. Hauv tsab ntawv blog no, peb yuav tham txog qee yam teeb meem hauv kev txhaj tshuaj molding thiab yuav daws teeb meem li cas.

Qhov teeb meem 1: Hlawv Marks

Hlawv cov cim tuaj yeem tshwm sim ntawm qhov chaw txhaj tshuaj molded vim overheating cov khoom, ua rau resin degradation thiab discoloration. Qhov teeb meem no tuaj yeem tshwm sim los ntawm ntau yam, suav nrog:

- Kub yaj kub

- Lub sijhawm nyob ntev

- Lub sijhawm txias tsis txaus

- Kev txhaj tshuaj nrawm

Txhawm rau daws qhov teeb meem kub hnyiab, cov neeg tsim khoom yuav tsum xav txog cov hauv qab no:

- Txo qhov kub thiab txias

- Txo lub sij hawm nyob

- Ua kom lub sijhawm txias

- Txo kev txhaj tshuaj ceev

Qhov teeb meem 2: Warping

Warping yog ib qho teeb meem tshwm sim hauv kev txhaj tshuaj molding uas tuaj yeem tshwm sim vim qhov tsis sib xws ntawm cov khoom. Qhov no tuaj yeem ua rau cov khoom kawg yog warped lossis distorted, uas tuaj yeem cuam tshuam tsis zoo rau nws txoj haujlwm. Qhov teeb meem no tuaj yeem tshwm sim los ntawm ntau yam, suav nrog:

- Kev txias txias tsis sib xws

- Tsis txaus ntim siab

- Kev tsim pwm tsis tsim nyog

Txhawm rau daws teeb meem warping, manufacturers yuav tsum xav txog cov hauv qab no:

- Xyuas kom txawm tias txias thoob plaws hauv pwm

- Nce packing siab

- Hloov kho pwm tsim los txhim kho ib feem geometry

Qhov teeb meem 3: Sink Marks

Cov cim dab dej yog kev nyuaj siab uas tuaj yeem tshwm sim ntawm qhov chaw txhaj tshuaj molded vim qhov tsis sib xws ntawm qhov txias lossis ntim khoom. Qhov teeb meem no tuaj yeem tshwm sim los ntawm ntau yam, suav nrog:

- Kev txhaj tshuaj nrawm

- Tsis txaus ntim siab

- Kub yaj kub

- Lub sijhawm nyob ntev

Yuav kom daws tau qhov teeb meem dab dej, manufacturers yuav tsum xav txog cov hauv qab no:

- Txo kev txhaj tshuaj ceev

- Nce packing siab

- Txo qhov kub thiab txias

- Txo lub sij hawm nyob

Qhov teeb meem 4: Flashing

Flashing yog ib qho teeb meem tshwm sim hauv kev txhaj tshuaj molding uas tshwm sim thaum cov khoom siv ntau dhau yog nyem tawm ntawm pwm. Qhov no tuaj yeem ua rau cov khoom siv ntau dhau ntawm cov npoo ntawm cov khoom kawg, uas tuaj yeem cuam tshuam tsis zoo rau nws txoj kev zoo nkauj thiab kev ua haujlwm. Qhov teeb meem no tuaj yeem tshwm sim los ntawm ntau yam, suav nrog:

- Cov khoom siv pwm ua kom tawg

- Tsis txaus clamping quab yuam

- Lub sijhawm txias tsis txaus

Txhawm rau daws teeb meem flashing, manufacturers yuav tsum xav txog cov hauv qab no:

- Hloov cov khoom siv pwm uas tsis muaj pwm

- Nce clamping quab yuam

- Ua kom lub sijhawm txias

Cov kws tshaj lij kev nkag siab: Kev xam phaj nrog cov kws tshaj lij kev lag luam hauv Automotive Txhaj Molding

Kev txhaj tshuaj molding yog txheej txheem tseem ceeb hauv kev lag luam tsheb, tsim cov khoom yas zoo hauv ntau yam tsheb. Peb tau hais rau cov kws tshaj lij hauv kev lag luam uas tau qhia lawv cov kev xav thiab kev nkag siab txog kev txhaj tshuaj automotive kom tau txais kev pom zoo rau kev lag luam thiab nws lub xeev tam sim no.

Kws tshaj lij 1: John Doe, CEO ntawm Lub Tuam Txhab Txhaj Tshuaj Molding

- Doe tau qhia tias kev siv bioplastics hauv kev lag luam tsheb tau dhau los ua neeg nyiam. Cov yas no yog cov phooj ywg ib puag ncig thiab tuaj yeem txo lub tsheb cov pa roj carbon hneev taw, ua rau lawv muaj kev xaiv zoo rau cov neeg tsim tsheb.

- Nws kuj tau sau tseg tias kev nce qib hauv 3D luam ntawv tau tso cai rau kev tsim pwm ntau dua, ua rau cov khoom zoo dua zaum kawg.

- Hais txog cov teeb meem, nws tau hais txog qhov tsis txaus ntawm cov neeg ua haujlwm txawj ua haujlwm yog qhov teeb meem tseem ceeb hauv kev lag luam, ua rau cov nqi zog ntau dua.

Kws tshaj lij 2: Jane Smith, Tus Tsim Qauv Tsim Qauv ntawm Lub Tuam Txhab Automotive

- Smith tau qhia tias muaj kev loj hlob hauv kev lag luam rau cov khoom siv sib xws, xws li cov khoom sib xyaw thiab cov yas, txhawm rau txhim kho roj efficiency thiab txo cov pa phem.

- Nws kuj tau sau tseg tias kev siv cov software simulation hauv cov txheej txheem tsim tau dhau los ua neeg nyiam, tso cai rau kev txhim kho cov khoom lag luam zoo dua thiab raug nqi.

- Hais txog kev sib tw, nws hais txog qhov nyuaj ntawm cov khoom siv tsheb thiab xav tau cov txheej txheem tsim khoom ntau dua.

Kws tshaj lij 3: Bob Johnson, Tus Thawj Saib Xyuas Kev Tswj Xyuas Zoo ntawm Lub Tuam Txhab Txhaj Tshuaj Molding

- Johnson tau qhia tias kev tswj hwm zoo yog qhov tseem ceeb hauv kev lag luam tsheb. Txawm tias me me tsis xws luag tuaj yeem cuam tshuam kev nyab xeeb thiab kev ua haujlwm.

- Nws tau sau tseg tias kev txhim kho thev naus laus zis, xws li kev tshuaj xyuas cov tshuab tsis siv neeg, tau tso cai rau cov txheej txheem tswj tau zoo dua thiab raug.

- Hais txog cov teeb meem, nws hais txog qhov kev thov nce ntxiv rau lub sijhawm tsim khoom sai dua thaum tswj hwm cov qauv zoo.

Kws tshaj lij 4: Sarah Lee, Tus Neeg Muag Khoom Muag ntawm Lub Tuam Txhab Txhaj Tshuaj Molding

- Lee qhia tias cov neeg siv khoom xav tau hloov pauv tas li, nrog rau kev tsom mus rau kev ruaj khov thiab kev ua tau zoo.

- Nws tau sau tseg tias kev sib txuas lus thiab kev sib koom tes ntawm cov neeg tsim khoom thiab cov neeg siv khoom yog qhov tseem ceeb los xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv tsim nyog thiab kev cia siab. Hais txog kev sib tw, nws tau hais txog kev sib tw hauv kev lag luam thiab kev xav tau rau cov tuam txhab txhaj tshuaj molding kom sib txawv lawv tus kheej los ntawm kev tsim kho tshiab thiab zoo.

xaus

Raws li kev lag luam tsheb txuas ntxiv mus ntxiv, kev txhaj tshuaj molding tseem yog txheej txheem tsim khoom tseem ceeb rau kev tsim cov khoom yas zoo. Txawm hais tias sab hauv lossis sab nrauv, kev txhaj tshuaj molding muaj kev ywj pheej tsim kev ywj pheej, tus nqi siv tau, thiab cov txiaj ntsig kev ruaj ntseg. Cov neeg tsim khoom tuaj yeem qhib qhov muaj peev xwm tshiab rau kev tsim cov tsheb tshiab thiab txhim khu kev qha los ntawm kev nkag siab txog qhov tsis sib xws ntawm cov khoom siv hauv tsheb yas txhaj tshuaj molding. Nyob twj ywm rau qhov blog no rau kev nkag siab ntxiv rau hauv lub ntiaj teb ntawm kev txhaj tshuaj molding thiab nws qhov cuam tshuam rau kev lag luam tsheb.