Case nyob rau hauv Kauslim

Yas Txhaj Xeem 'Pab Phab Ntsa Thickness Tus Qauv Tsim rau Kauslim Auto Tuam Txhab

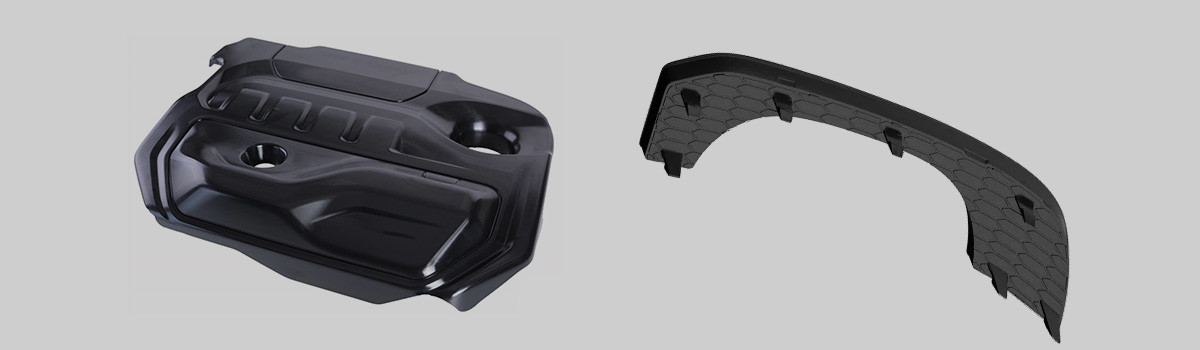

Cov khoom yas yog ntshuam heev rau lub tsheb, thiab nws cov qauv muaj zog yuav cuam tshuam rau lub neej thiab tsav kev nyab xeeb, yog li Korean Auto manufacturers yuav cov khoom yas nruj heev. Kev lag luam Auto yuav siv ntau yam yas hauv lub tsheb, Kaus Lim Kauslim cov tuam txhab txhaj tshuaj hauv zos tsis tuaj yeem muab cov khoom loj, thiab cov tuam txhab Auto no yuav yuav cov khoom yas txawv teb chaws, ib yam li DJmolding los ntawm Tuam Tshoj.

Cov khoom yas tseem ceeb heev rau lub tsheb, yog li yuav ua li cas los tsim cov yas txhaj tshuaj 'phab ntsa thickness structural rau Korean Auto tuam txhab uas muag? Tam sim no, DJmolding yuav qhia koj txog kev tsim cov yas txhaj tshuaj 'thickness structural.

Txhais ntawm phab ntsa thickness

Phab ntsa thickness yog cov yam ntxwv ntawm cov khoom yas. Yog hais tias sab nrauv ntawm cov khoom yas yog hu ua phab ntsa sab nrauv, sab hauv sab hauv yog hu ua phab ntsa sab hauv, ces muaj cov thickness ntawm cov phab ntsa sab nrauv thiab sab hauv. Tus nqi hu ua phab ntsa thickness. Tus nqi nkag thaum lub plhaub tau muab rho tawm ntawm software thaum lub sij hawm tsim qauv kuj tuaj yeem hais tias yog phab ntsa tuab.

Kev ua haujlwm ntawm phab ntsa thickness

Rau sab nrauv phab ntsa ntawm cov khoom

Cov phab ntsa sab nrauv ntawm qhov chaw yog zoo li daim tawv nqaij ntawm qhov chaw. Sab hauv phab ntsa yog cov txheej txheem skeletons ntawm qhov chaw. Cov tsos mob sib txawv tuaj yeem ua tiav los ntawm kev kho deg ntawm cov phab ntsa sab nrauv ntawm qhov chaw. Sab hauv phab ntsa tsuas yog txuas cov qauv (ribs, ntsia hlau tuav, buckle thiab lwm yam) ua ke thiab ua kom muaj zog rau cov khoom. Nyob rau lub sijhawm no, lwm cov qauv tuaj yeem ua tiav thaum lub sijhawm ua cov txheej txheem molding. Tsis muaj cov cai tshwj xeeb rau cov phab ntsa sab hauv thiab sab nrauv (txias, sib dhos). Nquag, nws yog tsim los ua ib qho tag nrho kom cov khoom tuaj yeem muaj lub zog txaus los tiv thaiv cov khoom sab hauv los ntawm kev puas tsuaj lossis cuam tshuam los ntawm ib puag ncig.

Rau cov khoom siv sab hauv

Raws li cov kabmob lossis kev sib txuas, tsis muaj kev txwv nruj rau cov phab ntsa sab hauv thiab sab nrauv, uas tuaj yeem tsim tau lwm cov qauv (ribs, ntsia hlau tuav, buckles thiab lwm yam) ntawm phab ntsa sab nrauv raws li qhov tseeb. Txawm li cas los xij, rau lub hom phiaj ntawm kev tsim khoom yooj yim (feem ntau yog hais txog thaum cov pwm pem hauv ntej thiab nram qab sib cais, txhawm rau khaws cov khoom yas hauv cov pwm tom qab, lub ntsej muag ntawm pwm, uas cov phab ntsa sab nrauv yuav tsum tau tsim kom yooj yim li sai tau. . Yog tias tsis yog, kho lub kaum sab xis ntawm cov pwm pem hauv ntej thiab nram qab, txawm tias muaj qhov thimble nyob rau hauv pem hauv ntej pwm los yog ib qho me me undercut nyob rau hauv cov pwm nram qab), thiab feem ntau tsim lwm cov qauv ntawm sab hauv phab ntsa.

Txawm hais tias nws yog lub plhaub qhov chaw lossis qhov chaw sab hauv, phab ntsa tuab yog qhov tseem ceeb raws li qhov tau txais qhov chaw ntawm lub ejector tus pin ntawm cov pwm, ua rau cov khoom yuav raug tshem tawm zoo.

Tsim cov qauv ntawm phab ntsa thickness:

Hauv kev tsim cov khoom yas, phab ntsa thickness yog qhov tseem ceeb, uas yog qhov tseem ceeb raws li lub hauv paus ntawm lub tsev. Lwm cov qauv yuav tsum tau tsim los ntawm nws. Lub sijhawm no, nws tseem cuam tshuam rau cov khoom siv kho tshuab, formability, tsos, nqi ntawm cov khoom yas. Yog li ntawd, phab ntsa thickness yuav tsum tau raws li cov saum toj no yam los tsim.

Nws tau hais tias phab ntsa thickness yuav tsum yog tus nqi tshwj xeeb. Yog tias muaj tus nqi, nws hais txog cov phab ntsa tuab. Yog tias muaj ntau qhov tseem ceeb, nws hais txog qhov tsis sib xws ntawm phab ntsa-thickness. Qhov sib txawv ntawm txawm los yog tsis sib xws yuav raug qhia tom qab. Tam sim no, peb yuav tham txog lub hauv paus ntsiab lus ntawm phab ntsa thickness tsim yuav tsum tau ua raws li.

1. Raws li lub hauv paus ntsiab lus ntawm txhua yam khoom:

Nws tau hais tias tsis hais nws yog lub plhaub lossis cov khoom sab hauv, ob qho tib si xav tau qee theem ntawm lub zog. Sib nrug los ntawm lwm yam, qhov kev tawm tsam tawm tsam yog xav tau thaum xav txog kev tsim cov khoom. Nws yog yooj yim deformed yog hais tias ib feem yog nyias. Feem ntau hais lus, cov phab ntsa tuab dua, qhov siab dua qhov muaj zog (phab ntsa thickness nce rau 10%, lub zog yuav nce li ntawm 33%). Yog hais tias phab ntsa thickness ntau tshaj ib tug ntau yam, ntxiv mus rau phab ntsa thickness yuav txo lub zog ntawm qhov chaw vim lub shrinkage thiab porosity. Qhov nce ntawm phab ntsa thickness yuav txo qis lub zog ntawm qhov chaw thiab nce qhov hnyav, ncua kev txhaj tshuaj molding lub voj voog, tus nqi, thiab lwm yam pom tseeb, ua kom lub zog ntawm qhov chaw los ntawm tsuas yog nce phab ntsa thickness tsis yog qhov kev pab cuam zoo. Nws yog qhov zoo tshaj plaws los siv cov yam ntxwv geometric kom muaj zog, xws li tav, nkhaus, corrugated nto, stiffeners, thiab lwm yam.

Nws tsis tau txiav txim siab tias vim qhov kev txwv ntawm qhov chaw thiab lwm yam, lub zog ntawm qee qhov feem ntau pom tau los ntawm phab ntsa thickness. Yog li, nws raug nquahu kom txiav txim siab cov phab ntsa tsim nyog los ntawm kev ua raws li cov neeg kho tshuab simulation yog tias lub zog yog qhov tseem ceeb. Tseeb, tus nqi rau phab ntsa thickness kuj yuav tsum tau ua raws li cov hauv qab no formalities.

2. Raws li lub hauv paus ntsiab lus ntawm formability:

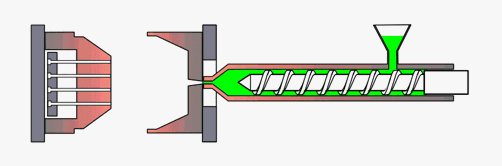

Qhov tseeb phab ntsa thickness yog lub thickness ntawm pwm kab noj hniav ntawm pem hauv ntej thiab nram qab pwm. Thaum cov molten resin sau tawm cov pwm kab noj hniav thiab txias, cov phab ntsa thickness tau txais.

1) Lub molten resin ntws li cas thaum lub sij hawm txhaj tshuaj thiab filling txheej txheem?

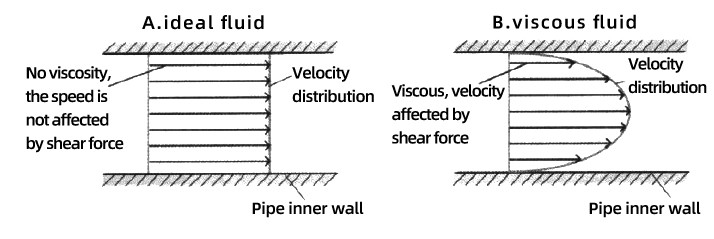

Cov dej ntws ntawm cov yas hauv cov kab noj hniav tuaj yeem suav tias yog laminar flow. Raws li txoj kev xav ntawm lub tshuab ua kua, cov kua laminar tuaj yeem suav tau tias yog cov txheej txheem ntawm cov kua ib sab ntawm ib leeg swb nyob rau hauv qhov kev txiav txim ntawm shearing quab yuam.

Thaum lub sij hawm txhaj tshuaj molding txheej txheem, cov molten resin tiv tauj nrog phab ntsa ntawm cov neeg khiav dej num (phab ntsa ntawm pwm kab noj hniav), ua rau cov kwj txheej ua raws li phab ntsa ntawm cov neeg khiav dej num (los yog phab ntsa ntawm pwm kab noj hniav) ua ntej. Qhov ceev yog xoom, thiab muaj kev sib txhuam tsis kam ua nrog nws cov kua txheej uas nyob ib sab. Dhau li no, qhov ceev ntawm nruab nrab-kwj txheej yog siab tshaj. Daim ntawv ntws uas lub laminar tshaj tawm txo qis nyob ze ntawm phab ntsa khiav (lossis pwm kab noj hniav) ntawm ob sab.

Cov txheej txheem nruab nrab yog txheej txheej dej, thiab txheej txheej ntawm daim tawv nqaij yog txheej txheej solidified. Raws li lub sijhawm txias dhau mus, txheej ntawm kev foom phem yuav nce ntxiv. Tus ntoo khaub lig seem ntawm cov kua txheej yuav me me maj mam. Qhov hnyav dua qhov txhaws, qhov loj dua qhov kev txhaj tshuaj. Tseeb, nws yog qhov nyuaj dua los thawb lub yaj mus rau hauv pwm kab noj hniav kom ua tiav qhov kev txhaj tshuaj.

Yog li ntawd, qhov loj ntawm phab ntsa tuab muaj qhov cuam tshuam zoo rau kev ntws thiab txhaws ntawm qhov chaw txhaj tshuaj molded thaum lub sijhawm txhaj tshuaj molding txheej txheem, thiab nws cov nqi yuav tsis tuaj yeem tsawg dhau.

2) Lub viscosity ntawm cov yas yaj kuj muaj qhov cuam tshuam zoo rau cov dej ntws

Thaum cov yaj yog nyob rau hauv qhov kev txiav txim sab nraud, thiab muaj kev sib txheeb ntawm cov txheej txheem, yuav muaj kev sib txhuam sab hauv tsim los cuam tshuam cov txheeb ze txav ntawm cov dej txheej. Lub zog sib txhuam sab hauv uas ua los ntawm cov kua yog hu ua viscosity. Kev ntsuas lub zog viscosity nrog dynamic viscosity (los yog viscosity coefficient). Tus lej ntawm qhov sib piv ntawm shear stress rau shear rate ntawm yaj.

Lub viscosity ntawm melts qhia txog cov yam ntxwv ntawm qhov yooj yim uas cov yas yaj ntws. Nws yog ib qho kev ntsuas ntawm melt flow resistance. Qhov siab dua qhov viscosity, qhov loj dua qhov dej tsis kam, qhov nyuaj dua qhov ntws. Cov yam tseem ceeb ntawm yaj viscosity cuam tshuam tsis tsuas yog cuam tshuam nrog cov qauv molecular, tab sis kuj muaj feem xyuam rau qhov kub, siab, shear npaum li cas, additives, thiab lwm yam. thiab lwm yam thaum lub sij hawm txhaj tshuaj molding txheej txheem yuav hloov pauv cov fluidity ntawm yas nyob rau hauv cov txheej txheem txhaj molding.

Thaum, hauv daim ntawv thov tiag tiag, yaj Index qhia txog qhov fluidity ntawm cov ntaub ntawv yas hauv kev ua haujlwm. Qhov siab dua tus nqi, qhov zoo dua qhov fluidity ntawm cov khoom. Ntawm qhov tsis sib xws, qhov fluidity ntawm cov khoom yuav phem dua.

Yog li ntawd, yas nrog zoo fluidity yog yooj yim dua los sau cov pwm kab noj hniav, tshwj xeeb tshaj yog rau kev txhaj tshuaj molding qhov chaw nrog complex qauv.

Lub fluidity ntawm cov khoom siv feem ntau tuaj yeem muab faib ua peb pawg raws li cov qauv tsim pwm:

①Good fluidity: PA, PE, PS, PP, CA, poly(4) methyl pentylene;

② Nruab nrab fluidity: polystyrene series resins (xws li ABS, AS), PMMA, POM, PPO;

③ Cov dej tsis zoo: PC, tawv PVC, PPO, PSF, PASF, fluoroplastics.

Raws li peb tuaj yeem pom los ntawm daim duab saum toj no, cov khoom siv nrog cov dej tsis zoo, qhov yuav tsum tau ua rau qhov tsawg kawg nkaus phab ntsa thickness yuav siab dua. Qhov no tau raug qhia hauv laminar flow theory.

Qhov pom zoo tus nqi ntawm phab ntsa thickness saum toj no tsuas yog tus naj npawb conservative. Hauv daim ntawv thov tiag tiag, qhov ntau thiab tsawg ntawm cov khoom suav nrog me me, nruab nrab thiab loj, daim duab saum toj no tsis qhia txog qhov siv ntau yam.

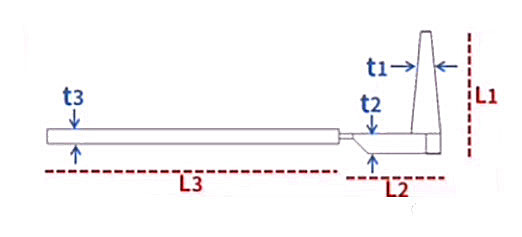

3) Peb tuaj yeem suav los ntawm qhov sib piv qhov ntev

Qhov ntev ntawm cov yas yog hais txog qhov sib piv ntawm qhov ntev (L) rau phab ntsa thickness (T) ntawm cov yas yaj ntws. Qhov ntawd txhais tau hais tias rau cov phab ntsa tuab, qhov siab dua qhov ntev ntawm qhov sib piv, qhov deb ntawm cov yas yaj ntws. Los yog thaum qhov ntev ntawm cov yas yaj ntws yog qhov tseeb, qhov loj dua qhov ntev ntawm qhov sib piv, qhov me me ntawm phab ntsa tuab tuaj yeem ua tau. Yog li, qhov sib piv ntev ntawm cov yas ncaj qha cuam tshuam rau tus naj npawb ntawm kev pub mis thiab kev faib khoom ntawm cov khoom yas. Tsis tas li ntawd, nws cuam tshuam rau phab ntsa thickness ntawm yas.

Yuav kom muaj tseeb dua, cov nqi tshwj xeeb ntawm cov phab ntsa tuab tuaj yeem tau los ntawm kev suav ntawm qhov sib piv qhov ntev. Tseeb, tus nqi no muaj feem xyuam rau cov khoom kub, pwm kub, polishing degree, thiab lwm yam. nws tsuas yog kwv yees ntau tus nqi, cov xwm txheej txawv txawv, nws nyuaj rau qhov tseeb, tab sis nws tuaj yeem siv los ua tus nqi siv.

Kev suav ntawm flow length ratio:

L / T (tag nrho) = L1 / T1 (lub ntsiab channel) + L2 / T2 (split channel) + L3 / T3 (khoom) Qhov ntsuas qhov ntev ntawm qhov sib piv yuav tsum tsawg dua tus nqi muab rau hauv lub rooj vaj huam sib luag, txwv tsis pub muaj ua tus phenomenon ntawm pluag filling.

Piv txwv li

Lub plhaub roj hmab, cov khoom siv PC, phab ntsa thickness yog 2, qhov kev ncua deb yog 200, khiav yog 100, txoj kab uas hla ntawm cov neeg khiav yog 5.

Calculation: L/T(total)=100/5+200/2=120

Tus nqi siv rau qhov ntev ntawm qhov sib piv ntawm PC yog 90, uas yog pom tseeb siab dua tus nqi xa mus. Kev txhaj tshuaj nrawm thiab siab yuav tsum tau nce ntxiv vim tias nws nyuaj rau txhaj, lossis txawm tias yuav tsum tau muaj cov tshuab txhaj tshuaj molding tshwj xeeb. Yog tias siv ob lub ntsiab lus pub mis lossis hloov cov ntsiab lus pub mis, qhov kev ncua deb ntawm cov khoom tuaj yeem raug txo mus rau 100, uas yog L / T (tag nrho) = 100/5 + 100 / 2 = 70. Qhov ntev piv tam sim no yog tsawg dua li tus nqi siv thiab yooj yim rau kev txhaj tshuaj molding. L / T (tag nrho) = 100 / 5 + 200 / 3 = 87 thaum lub phab ntsa thickness hloov mus rau hauv 3, uas tso cai rau lub cev txhaj tshuaj molding.

3. Raws li lub hauv paus ntsiab lus pom:

Qhov kev ua tau zoo ntawm phab ntsa thickness cuam tshuam rau cov tsos ntawm qhov chaw yog raws li hauv qab no:

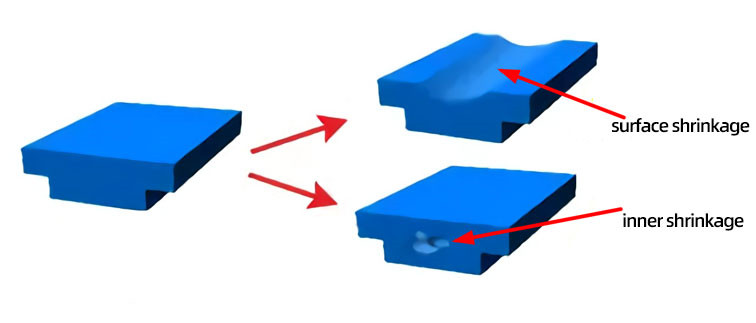

1) Cov phab ntsa tuab tsis sib xws: nto shrinkage (nrog rau cov tsos mob xws li shrinkage, pits, tuab thiab nyias prints), warping deformation, thiab lwm yam.

2) Ntau phab ntsa thickness: tsis xws li deg shrinkage thiab sab hauv shrinkage qhov.

3) Phab ntsa thickness me me dhau lawm: qhov tsis xws luag xws li tsis muaj kua nplaum, thimble luam ntawv, warpage thiab deformation.

shrinkage los yog porosity

shrinkage lossis porosity feem ntau tshwm sim ntawm cov phab ntsa tuab tuab. Lub mechanism: raws li cov ntaub ntawv solidification txoj cai, lub internal porosity thiab deg shrinkage thaum txhaj tshuaj molding txheej txheem yog vim lub tas mus li contraction thaum lub sij hawm txias txheej txheem. Thaum lub shrinkage yog concentrated ntawm qhov chaw khov tom qab, tab sis tsis tuaj yeem tsim tau tam sim ntawd, shrinkage thiab porosity yuav tshwm sim hauv sab hauv.

Cov qauv tsim ntawm phab ntsa thickness saum toj no yog qhia los ntawm plaub yam, uas yog txhua yam khoom, formability, tsos, nqi. Yog tias siv ib kab lus los piav qhia txog kev tsim cov phab ntsa thickness, uas yog tus nqi ntawm phab ntsa thickness ntawm cov tshuaj molded qhov chaw yuav tsum me me npaum li sai tau thiab sib xws li qhov ua tau raws li qhov ua tau raws li qhov ua tau zoo ntawm cov khoom siv thiab kev ua haujlwm. Yog tsis yog, nws yuav tsum tau uniformly hloov.

DJmolding muaj cov khoom yas 'tsim thiab tsim cov kev pabcuam rau lub ntiaj teb markte, yog tias koj xav pib koj qhov project, thov hu rau peb tam sim no.