Sib tshooj

Overmolding yog txheej txheem tsim khoom uas lub substrate lossis lub hauv paus tivthaiv yog ua ke nrog ib lossis ntau cov ntaub ntawv los tsim cov khoom kawg nrog kev ua haujlwm zoo dua qub, durability, thiab zoo nkauj. Cov txheej txheem no tau txais koob meej nyob rau xyoo tas los no vim nws muaj peev xwm txhim kho qhov zoo thiab kev ua tau zoo ntawm cov khoom thaum txo cov nqi thiab ua kom yooj yim rau cov txheej txheem sib dhos. Overmolding pom cov ntawv thov hauv ntau qhov kev lag luam, xws li tsheb, hluav taws xob, khoom siv kho mob, thiab cov khoom siv. Yuav kom nkag siab txog cov txheej txheem no, tsab xov xwm no yuav qhia txog ntau yam ntawm overmolding, nrog rau nws cov tswv yim, cov ntaub ntawv, thiab kev siv.

Txhais thiab Cov Ntsiab Cai ntawm Overmolding

Overmolding yog molding ib yam khoom dua lwm tus, feem ntau yog siv cov thermoplastic elastomers (TPE) los yog thermoset roj hmab. Cov txheej txheem no tsim ib qho kev tivthaiv nrog ob lossis ntau cov ntaub ntawv, txhua tus muaj cov khoom tshwj xeeb uas ua haujlwm rau lub hom phiaj tshwj xeeb.

Cov ntsiab cai ntawm Overmolding

Muaj peb lub hauv paus ntsiab lus ntawm overmolding uas manufacturers yuav tsum xav txog:

- Khoom Siv Tau Zoo:Cov ntaub ntawv siv los ua overmolding yuav tsum tau sib xws, thiab cov ntaub ntawv yuav tsum muaj peev xwm sib txuas los tsim kom muaj kev sib koom ua ke thiab muaj zog. Lub adhesion ntawm cov ntaub ntawv yog ib qho tseem ceeb los xyuas kom meej tias lub caij muaj cov yam ntxwv xav tau.

- Tsim rau Overmolding:Ua ntej overmolding, ib tug yuav tsum ua tib zoo xav txog cov txheej txheem ntawm cov khoom. Tus tsim yuav tsum tau yooj yim molding cov khoom thib ob tshaj thawj tus yam tsis muaj kev cuam tshuam. Kev tsim ntawm txoj kab sib cais, qhov twg ob cov ntaub ntawv sib ntsib, yuav tsum ua tib zoo xyuas kom tsis muaj qhov khoob lossis qhov khoob ntawm ob cov ntaub ntawv.

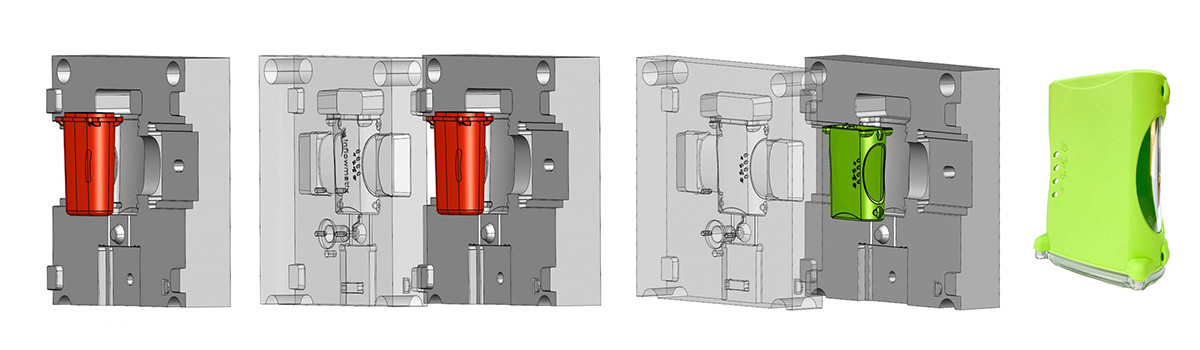

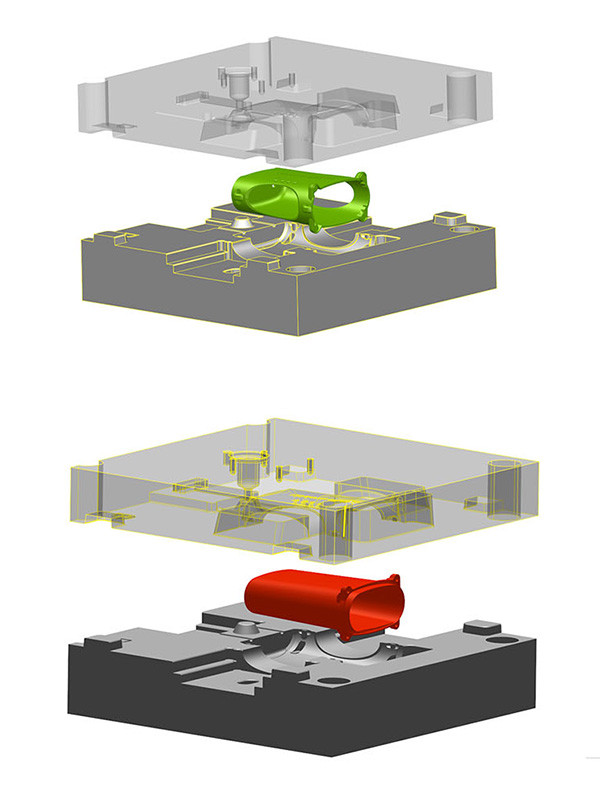

- Cov txheej txheem tsim:Overmolding yuav tsum muaj cov txheej txheem tsim tshwj xeeb uas suav nrog molding ib qho khoom siv dua lwm tus. Txoj kev siv ob los yog ntau tshaj pwm, qhov twg thawj pwm tsim thawj cov khoom, thiab pwm thib ob tsim cov khoom thib ob tshaj thawj. Tom qab ntawd, peb koom nrog ob lub pwm ua ke los tsim ib qho khoom siv.

Cov txiaj ntsig ntawm Overmolding

Overmolding muaj ntau yam txiaj ntsig uas ua rau nws muaj kev xaiv nrov rau ntau lub tuam txhab, suav nrog:

- Enhanced Durability:Overmolding tuaj yeem txhim kho qhov ruaj khov ntawm cov khoom siv los ntawm kev ntxiv cov txheej txheem tiv thaiv uas tuaj yeem tiv taus hnav thiab tsim kua muag.

- Txhim kho Aesthetics: Overmolding tuaj yeem txhim kho qhov zoo nkauj ntawm cov khoom siv los ntawm kev ntxiv xim lossis kev ntxhib los mos rau saum npoo.

- Enhanced Functionality:Overmolding tuaj yeem txhim kho kev ua haujlwm ntawm cov khoom siv los ntawm kev ntxiv cov yam ntxwv xws li tuav, khawm, lossis cov keyboards.

Kev siv ntawm Overmolding

Cov neeg tsim khoom feem ntau siv overmolding los tsim cov khoom siv hluav taws xob xws li xov tooj ntawm tes, cov chaw taws teeb tswj, thiab khoos phis tawj peripherals. Nws tseem muaj cov khoom siv kho mob, cov khoom siv tsheb, thiab cov khoom siv.

Txhaj Molding vs. Overmolding: Qhov txawv yog dab tsi?

Kev txhaj tshuaj molding thiab overmolding feem ntau yog siv cov txheej txheem tsim khoom hauv cov khoom yas. Thaum ob txoj kev koom nrog molding yas, lawv muaj qhov sib txawv. Tsab ntawv blog no yuav tham txog qhov sib txawv ntawm kev txhaj tshuaj molding thiab overmolding.

Txhaj Tshuaj Molding

Kev txhaj tshuaj molding yog txheej txheem tsim khoom uas muaj cov yas pellets yaj thiab txhaj cov yas molten rau hauv pwm kab noj hniav. Cov yas yog ces txias thiab ejected los ntawm pwm, uas ua rau ib tug khoom yas ib feem. Cov neeg tsim khoom siv kev txhaj tshuaj molding raws li cov txheej txheem meej thiab muaj txiaj ntsig los tsim cov khoom ntim siab. Qee qhov tseem ceeb ntawm kev txhaj tshuaj molding muaj xws li:

Ua ib feem ntawm cov khoom siv

- Ib qho tshuaj txhaj rau hauv cov pwm kab noj hniav hauv ib kauj ruam.

- Cov txheej txheem pom daim ntawv thov hauv kev tsim cov khoom ntim ntau.

- Tus nqi ib feem txo qis raws li qhov ntim ntawm ntau lawm nce.

Sib tshooj

Overmolding yog txheej txheem tsim khoom uas suav nrog molding ib qho khoom dua lwm yam khoom. Cov txheej txheem feem ntau ntxiv cov khoom muag muag, zoo li roj hmab dhau ntawm cov yas nruj kom txhim kho nws cov kav ntev thiab zoo nkauj. Qee qhov tseem ceeb ntawm overmolding muaj xws li:

Ua ib tug ob-khoom siv

- Ua ntej, peb pwm thawj cov khoom, thiab tom qab ntawd cov khoom siv thib ob dhau thawj.

- Cov txheej txheem txhim kho lub durability thiab zoo nkauj ntawm lub caij.

- Tus nqi ib feem yog siab dua li kev txhaj tshuaj molding vim yog cov txheej txheem ntxiv ntawm molding thib ob tshaj thawj zaug.

- Qhov txawv ntawm Txhaj Molding thiab Overmolding

Qhov sib txawv tseem ceeb ntawm kev txhaj tshuaj molding thiab overmolding yog:

- Cov khoom siv:Txhaj tshuaj molding ua ib feem ntawm cov khoom, thaum overmolding ua ob-khoom siv.

- txheej txheem:Txhaj tshuaj molding txhaj cov yas molten rau hauv pwm kab noj hniav nyob rau hauv ib kauj ruam, thaum overmolding yuav molding thawj cov khoom ua ntej thiab ces molding cov khoom thib ob tshaj thawj cov khoom.

- lub hom phiaj: Cov neeg tsim khoom siv kev txhaj tshuaj molding los tsim cov khoom ntim ntau ntawm cov yas, thaum lawv siv overmolding los txhim kho cov kav ntev thiab zoo nkauj ntawm ib daim yas.

- Tus nqi: Kev txhaj tshuaj molding feem ntau tsis tshua kim ib feem ntau dua li overmolding, vim yog cov txheej txheem ntxiv ntawm molding cov khoom thib ob tshaj thawj zaug.

Daim ntawv thov ntawm Txhaj Molding thiab Overmolding

Cov neeg tsim khoom feem ntau siv kev txhaj tshuaj molding los tsim cov khoom siv, cov khoom siv tsheb, thiab cov khoom siv kho mob. Lawv kuj feem ntau ntiav overmolding los txhim kho cov kav ntev thiab zoo nkauj hauv cov khoom siv hluav taws xob xws li xov tooj ntawm tes thiab cov chaw taws teeb tswj.

Ob-Shot Overmolding: Ib Txoj Kev Nrov Nrov

Ob-shot overmolding, tseem hu ua ob-shot molding lossis multi-shot molding, yog cov txheej txheem nrov siv los ua cov khoom yas. Cov txheej txheem no suav nrog molding ob cov ntaub ntawv rau ib leeg los tsim cov khoom tiav. Cov ntawv tshaj tawm blog no yuav tham txog cov hauv paus ntawm ob-shot overmolding thiab nws cov txiaj ntsig.

Cov txiaj ntsig ntawm Ob-Shot Overmolding

Ob-shot overmolding muaj ntau yam txiaj ntsig ntawm cov txheej txheem overmolding ib txwm muaj, suav nrog:

- Ua kom zoo nkauj zoo nkauj: Ob-shot overmolding tso cai rau cov creation complex qhov chaw nrog ntau xim los yog textures. Kev siv ntau yam ntaub ntawv tuaj yeem ua rau cov khoom kawg uas yog qhov pom kev zoo nkauj dua li ib qho uas ua los ntawm ib qho khoom siv.

- Txhim kho kev ua haujlwm: Ob-shot overmolding tuaj yeem txhim kho kev ua haujlwm ntawm cov khoom. Piv txwv li, qhov muag muag tuav ntawm lub hauv paus yas nruj tuaj yeem txhim kho cov khoom lag luam ergonomics thiab cov neeg siv kev paub.

- Tus nqi txo:Ob-shot overmolding tuaj yeem pab txo cov nqi los ntawm kev tshem tawm qhov kev xav tau ntawm kev ua haujlwm thib ob xws li pleev xim lossis txheej txheej. Kev ua raws li qhov no tuaj yeem ua rau kev tsim khoom sai dua thiab txo cov nuj nqis.

- Nce Durability: Ob-steev overmolding kuj tuaj yeem txhim kho qhov ruaj khov ntawm cov khoom. Los ntawm kev siv lub hauv paus yas nruj nrog qhov muag muag, piv txwv li, cov khoom yuav tsis tshua muaj kev tawg lossis tawg thaum poob.

Kev siv ntawm Ob-Shot Overmolding

Ntau yam kev lag luam feem ntau siv ob-shot overmolding, suav nrog:

- Automotive: Ob-steev overmolding ua rau tsheb qhov chaw, xws li dashboard Cheebtsam thiab sab hauv trim pieces.

- Cov khoom siv:Ob-shot overmolding ua rau cov txhuam hniav, rab chais, thiab cov khoom siv hluav taws xob.

- Cov cuab yeej kho mob:Ob-steev overmolding tsim cov cuab yeej kho mob xws li cov cuab yeej phais thiab cov khoom xa tshuaj.

Ntxig Moulding: Muab ob yam sib txawv

Ntxig molding yog txheej txheem tsim khoom uas koom nrog molding cov khoom siv yas nyob ib ncig ntawm lub hauv ntej uas twb muaj lawm los yog substrate. Lub insert feem ntau yog ua los ntawm cov hlau los yog yas thiab tuaj yeem yog threaded insert, ib tug hlau, los yog ib tug luam Circuit Court board. Cov ntawv blog no yuav tham txog cov hauv paus ntawm kev ntxig molding thiab nws cov txiaj ntsig.

Insert Moulding ua haujlwm li cas?

Ntxig molding yog txheej txheem ob-kauj ruam uas muaj cov hauv qab no:

- Peb muab qhov ntxig rau hauv pwm.

- Yas yog txhaj nyob ib ncig ntawm lub insert, tsim ib tug molded yas tivthaiv uas yog nrees txuas mus rau lub insert.

- Lub ntxig ntxiv lub zog thiab ruaj khov rau qhov ua tiav, ua rau nws haum rau ntau yam kev siv.

Cov txiaj ntsig ntawm Insert Molding

Ntxig molding muaj ntau yam txiaj ntsig ntawm cov txheej txheem molding ib txwm, suav nrog:

- Txhim kho lub zog: Ntxig molding tsim cov khoom lag luam ruaj khov thiab ruaj khov, vim tias qhov ntxig ntxig txuas nrog rau cov khoom siv yas. Txhim kho lub durability thiab lifespan ntawm cov khoom yog ua tau nrog qhov no.

- Txo lub sij hawm los ua ke: Ntxig molding pab txo lub sij hawm sib dhos thiab cov nqi zog los ntawm kev sib txuas ntau yam khoom rau hauv ib qho molded ib feem.

- Txhim khu kev tsim Flexibility:Ntxig molding ua rau kev tsim cov khoom nyuaj nrog ntau yam ntaub ntawv, textures, thiab xim, uas ua rau qhov zoo dua qhov kawg tshwm sim.

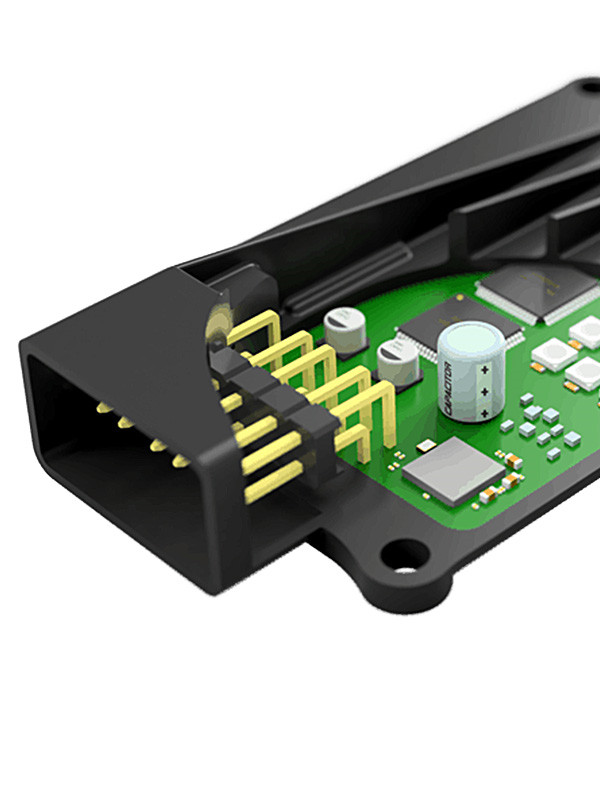

- Enhanced Functionality: Los ntawm kev siv cov ntxig molding, cov tuam txhab tsim khoom tuaj yeem txhim kho kev ua haujlwm ntawm cov khoom lag luam los ntawm kev sib txuas cov yam ntxwv xws li threaded inserts lossis hluav taws xob tiv tauj.

Daim ntawv thov ntawm Insert Molding

Insert molding feem ntau yog siv rau ntau yam kev lag luam, suav nrog:

- Automotive: Ntxig molding tsim cov khoom siv tsheb xws li cov khoom sib txuas, sensors, thiab cov keyboards.

- Electronics: Ntxig molding ua cov khoom siv hluav taws xob xws li cov khoom sib txuas, vaj tsev, thiab cov keyboards.

- Cov cuab yeej kho mob:Ntxig molding ua catheters, connectors, thiab sensors.

Mos Overmolding: Txhim kho tuav thiab xis nyob

Mos overmolding yog txheej txheem siv hauv kev tsim khoom los ntxiv cov khoom muag muag, hloov pauv mus rau cov khoom siv tsis zoo. Cov txheej txheem tso cai rau ntxiv ib txheej ntawm kev nplij siab thiab tuav rau ib yam khoom, yog li txhim kho nws cov functionality thiab zoo nkauj. Cov ntawv blog no yuav tham txog cov hauv paus ntawm cov mos mos overmolding thiab nws cov txiaj ntsig.

Yuav Ua Li Cas Soft Overmolding Ua Haujlwm?

Mos overmolding yog ob kauj ruam txheej txheem uas muaj cov hauv qab no:

- Peb mould cov khoom siv tsis zoo.

- Ib qho khoom muag, hloov tau yooj yim yog txhaj ib ncig ntawm cov khoom siv molded, tsim kom muaj qhov zoo nkauj thiab tactile nto.

- Feem ntau, cov tuam txhab tsim cov khoom muag muag los ntawm cov thermoplastic elastomers (TPE) lossis silicone. Cov khoom tsim tau muaj qhov du, xis nyob uas muab kev tuav zoo dua thiab txhim kho kev tuav.

Cov txiaj ntsig ntawm Soft Overmolding

Mos overmolding muaj ntau yam txiaj ntsig ntawm cov txheej txheem molding ib txwm, suav nrog:

- Txhim kho kev nplij siab: Mos overmolding muab qhov chaw xis nyob uas txhim kho cov neeg siv kev paub. Cov khoom muag muag ua raws li tus neeg siv tes, txo cov ntsiab lus siab thiab txhim kho tuav.

- Enhanced Grip: Cov khoom siv mos siv hauv cov mos mos overmolding muab kev tuav zoo dua, txo qhov kev pheej hmoo ntawm kev poob lossis poob ntawm cov khoom. Kev txhim kho kev ntsuas kev nyab xeeb tuaj yeem txo qhov kev pheej hmoo ntawm cov khoom puas tsuaj.

- Aesthetically Pleasing: Mos overmolding tuaj yeem txhim kho qhov zoo ntawm cov khoom, ua kom zoo nkauj dua. Cov khoom muag muag tuaj yeem hloov kho kom haum rau cov xim thiab kev ntxhib los mos ntawm cov khoom, tsim kom muaj kev sib haum xeeb.

- Sij hawm: Mos overmolding tsim cov khoom siv ruaj khov uas tuaj yeem tiv taus kev siv thiab hnav. Cov khoom muag muag muab kev tiv thaiv ntxiv tiv thaiv kev cuam tshuam thiab khawb, txo qhov kev pheej hmoo ntawm kev puas tsuaj rau cov khoom.

Kev siv ntawm Soft Overmolding

Ntau yam kev lag luam feem ntau siv cov mos overmolding, suav nrog:

- Consumer Electronics: Mos overmolding tsim cov khoom siv hluav taws xob xws li cov chaw taws teeb tswj, lub mloog pob ntseg, thiab cov tswj kev ua si.

- Cov khoom siv ncaws pob: Cov neeg tsim khoom siv mos overmolding los tsim cov khoom ntaus pob ncaws pob xws li tuav rau golf clubs, tennis rackets, thiab tsheb kauj vab.

- Cov cuab yeej kho mob: Mos overmolding tsim cov cuab yeej kho mob xws li cov cuab yeej phais thiab cov khoom siv hnov lus.

Hard Overmolding: Ntxiv kev tiv thaiv thiab kav ntev

Hard overmolding ntxiv txheej yas nruj dua cov khoom uas twb muaj lawm, xws li roj hmab lossis silicone, los tsim kom muaj kev ruaj khov thiab tiv thaiv nto. Qhov tshwm sim yog cov khoom lag luam uas tuaj yeem tiv taus ib puag ncig hnyav, tiv thaiv kev puas tsuaj, thiab siv zog rov ua dua.

Nov yog qee qhov txiaj ntsig ntawm kev siv zog overmolding hauv cov khoom tsim:

- Ntxiv durability: Hard overmolding muab ib txheej ntxiv ntawm kev tiv thaiv uas yuav ua rau kom lub neej ntawm cov khoom. Tiv thaiv cov khoom siv los ntawm kev hnav thiab tsim kua muag ua rau muaj kev cuam tshuam tsawg dua los yog ua tsis tiav.

- Txhim kho tuav:Los ntawm kev ntxiv cov txheej yas tsis yooj yim rau cov khoom muag, xws li roj hmab lossis silicone, cov tuam ntxhab tuaj yeem tsim kev tuav zoo rau cov neeg siv. Nws yog ib qho tseem ceeb uas yuav tau xav txog qhov no, tshwj xeeb tshaj yog rau cov khoom siv nyob rau hauv ntub dej los yog nplua nyob ib puag ncig.

- Resistance rau ib puag ncig yam:Hard overmolding tuaj yeem tiv thaiv cov khoom los ntawm kev raug tshav ntuj, tshuaj lom neeg, thiab lwm yam ib puag ncig uas tuaj yeem ua rau muaj kev puas tsuaj rau lub sijhawm. Qhov kev txhim kho no txhim kho cov khoom muaj peev xwm hloov kho thiab tiv taus ntau yam ib puag ncig.

- Aesthetic thov: Hard overmolding kuj tuaj yeem txhim kho qhov zoo ntawm cov khoom. Los ntawm kev ntxiv cov txheej yas tsis yooj yim, cov neeg tsim khoom tuaj yeem tsim qhov zoo nkauj, polished uas tsis yooj yim sua nrog ib qho khoom siv.

- customization: Los ntawm kev ua haujlwm nyuaj overmolding, tuam txhab lag luam tuaj yeem kho lawv cov khoom los ntawm kev ntxiv cov logos, xim, thiab lwm yam khoom tsim rau saum npoo. Lub tswv yim kev lag luam no pab txhawb kev pom hauv kev lag luam.

Cov neeg tsim khoom siv zog overmolding nyob rau hauv ntau yam khoom, xws li cov khoom siv rau cov neeg siv khoom siv hluav taws xob. Nov yog qee qhov piv txwv:

- Handheld devices: Ntau cov khoom siv tes tuav, xws li xov tooj ntawm tes thiab ntsiav tshuaj, siv cov khoom siv tawv tawv los tsim cov txheej tiv thaiv ib puag ncig ntawm lub cuab yeej. Cov yam ntxwv no pab tiv thaiv lub cuab yeej los ntawm kev puas tsuaj los ntawm kev poob thiab cuam tshuam.

- Cov cuab yeej muaj zog:Cov cuab yeej fais fab feem ntau ntsib qhov chaw hnyav, xws li plua plav thiab khib nyiab. Kev siv zog overmolding tuaj yeem tiv thaiv cov cuab yeej no los ntawm kev puas tsuaj thiab txuas ntxiv lawv txoj sia.

- Cov cuab yeej kho mob: Cov cuab yeej kho mob xav tau kev ua haujlwm siab thiab ua haujlwm rau ib puag ncig yam. Hard overmolding tuaj yeem tiv thaiv cov cuab yeej no thiab xyuas kom lawv ua haujlwm kom raug.

Thermoplastic Elastomers (TPEs): Cov Khoom Zoo Tshaj Plaws rau Overmolding

Thaum nws los txog rau overmolding, muaj ntau yam khoom xaiv los ntawm, tab sis tsis muaj leej twg nyiam dua Thermoplastic Elastomers (TPEs). TPEs yog cov khoom siv ntau yam uas muaj ntau yam txiaj ntsig thaum nws los txog rau overmolding. Nov yog qee qhov laj thawj vim li cas TPEs yog cov khoom siv zoo tshaj plaws rau kev overmolding:

- Ntau yam:Cov neeg tsim khoom tuaj yeem siv TPEs los ua ntau yam ntaub ntawv, suav nrog hlau, yas, thiab roj hmab. Cov neeg tsim khoom tuaj yeem siv lawv hauv ntau yam khoom tsim los ntawm cov khoom sib txawv, ua rau lawv xaiv tau yooj yim.

- Softness thiab yooj: TPEs muaj qhov muag muag thiab hloov tau yooj yim, ua rau lawv zoo tagnrho rau cov khoom overmolding uas xav tau kev tuav zoo. Lawv tuaj yeem tsim cov khoom uas yuav tsum tau khoov lossis flex yam tsis muaj kev tawg.

- Tiv thaiv cov tshuaj thiab UV hluav taws xob:TPEs tiv taus cov tshuaj lom neeg thiab UV hluav taws xob, ua rau lawv zoo tagnrho rau cov khoom raug mob hnyav.

- Durability: TPEs muaj kev ruaj khov thiab tiv taus hnav thiab tsim kua muag, ua rau lawv zoo tagnrho rau cov khoom siv nquag lossis raug siv hnyav.

- Nqi tsim nyog: TPEs yog tus nqi-zoo piv rau lwm yam ntaub ntawv siv rau overmolding, ua rau lawv muaj nqis xaiv rau manufacturers.

- Yooj yim rau txheej txheem:TPEs tuaj yeem ua tiav sai nrog kev txhaj tshuaj molding, ua rau lawv muaj kev xaiv nrov rau cov tuam txhab uas xav tau los tsim cov khoom lag luam ntau sai thiab ua tau zoo.

Qee qhov piv txwv ntawm cov khoom siv TPEs rau overmolding muaj xws li:

- Grips rau cov cuab yeej siv tes: Cov neeg tsim khoom feem ntau siv TPEs txhawm rau txhawm rau txhawm rau tuav cov cuab yeej tes, xws li cov pliers thiab cov ntsia hlau. TPEs 'mos thiab yoog raws kev ntxhib los mos ua rau lawv zoo tagnrho rau kev tsim kom muaj kev tuav zoo uas yuav tsis plam.

- Cov khoom siv ua kis las: Cov neeg tsim khoom feem ntau siv TPEs los ua cov khoom siv ua kis las, xws li golf club grips thiab tennis racket handles. TPEs 'mos thiab yoog raws kev ntxhib los mos ua rau lawv zoo tagnrho rau kev tsim kom muaj kev tuav zoo uas yuav tsis plam.

- Cov khoom siv hluav taws xob: TPEs feem ntau overmold electronic gadgets zoo li cov chaw taws teeb tswj thiab xov tooj ntawm tes. TPEs 'mos thiab yoog raws kev ntxhib los mos ua rau lawv zoo tagnrho rau kev tsim cov txheej txheem tiv thaiv ib puag ncig cov cuab yeej uas yuav tsis khawb lossis ua rau lub ntsej muag puas.

Silicone Overmolding: Zoo tagnrho rau cov khoom siv kho mob thiab cov khoom siv

Silicone overmolding yog txheej txheem uas cuam tshuam nrog kev txhaj tshuaj ntawm cov khoom siv silicone ua kua rau ntawm cov khoom siv substrate. Cov txheej txheem no tuaj yeem tsim ntau yam khoom siv rau ntau yam kev lag luam tab sis tshwj xeeb tshaj yog rau cov khoom siv kho mob thiab cov khoom siv. Cov ntawv blog no yuav tshawb txog qhov zoo ntawm silicone overmolding rau cov kev lag luam no.

Qhov zoo ntawm Silicone Overmolding rau Cov Khoom Siv Kho Mob

- Biocompatibility:Cov cuab yeej kho mob uas tuaj yeem sib cuag nrog tib neeg cov ntaub so ntswg xav tau cov ntaub ntawv zoo rau lub cev. Silicone yog cov khoom siv biocompatible uas tsis muaj tshuaj lom lossis tsis zoo rau cov ntaub so ntswg. Kev siv cov khoom no hauv cov cuab yeej kho mob yog qhov zoo heev.

- Kom tsis muaj menyuam: Cov cuab yeej kho mob yuav tsum tau ua kom tsis muaj menyuam ua ntej siv kom ntseeg tau tias lawv tsis muaj kab mob thiab lwm yam kab mob phem. Cov kws kho mob tuaj yeem siv ntau txoj hauv kev los kho silicone, suav nrog chav, hluav taws xob, thiab tshuaj tua kab mob. Cov khoom siv kho mob tuaj yeem tau txais txiaj ntsig los ntawm ntau yam ntawm cov khoom siv no.

- Flexibility: Silicone lub siab yooj tso cai rau molding rau hauv ntau yam duab thiab ntau thiab tsawg. Cov khoom muaj peev xwm ua tau raws li lub cev lub cev ua rau nws zoo meej rau cov khoom siv kho mob.

- Durability: Silicone yog cov khoom siv ruaj khov uas tuaj yeem tiv taus kev siv dua thiab raug rau cov tshuaj hnyav. Nws cov kav ntev thiab muaj peev xwm tiv taus rov siv dua thiab tu ua rau nws yog ib qho khoom siv rau kev kho mob.

Qhov zoo ntawm Silicone Overmolding rau cov khoom siv

- Kev Siab: Silicone yog cov khoom muag muag thiab hloov tau yooj yim uas nyiam hnav tawm tsam ntawm daim tawv nqaij. Cov khoom siv hauv kev sib cuag nrog lub cev, xws li lub mloog pob ntseg, watches, thiab qoj trackers, yog zoo meej rau cov ntaub ntawv zoo li no.

- Dej Kuj: Silicone yog cov khoom siv dej-resistant uas tuaj yeem tiv taus cov dej noo tsis muaj deteriorating lossis poob zoo. Cov neeg siv khoom siv hauv qhov chaw ntub dej, xws li cov tsom iav da dej thiab cov neeg hais lus tsis muaj dej, yog tsim los ntawm cov khoom siv no.

- Tsim Flexibility: Silicone tuaj yeem ua rau ntau yam duab thiab ntau thiab tsawg, tso cai rau cov neeg tsim khoom tsim cov khoom tshwj xeeb thiab tshiab. Cov cuab yeej no ua rau silicone zoo tagnrho rau cov neeg siv khoom xav tau cov duab thiab cov qauv tsim.

- Durability:Silicone yog cov khoom siv ruaj khov uas tuaj yeem tiv taus qhov raug UV hluav taws xob, qhov kub thiab txias, thiab cov tshuaj hnyav. Cov yam ntxwv no ua rau nws zoo tagnrho rau cov neeg siv khoom siv uas xav tau kev ua haujlwm ntev thiab tuaj yeem tiv taus ntau yam huab cua.

Polyurethane Overmolding: Ntau yam thiab Durable

Polyurethane overmolding yog cov txheej txheem tsim khoom uas nyuam qhuav tau txais koob meej vim nws muaj ntau yam thiab ua haujlwm ntev. Cov txheej txheem no suav nrog kev siv cov txheej txheem ntawm cov khoom siv polyurethane dhau ntawm lub substrate uas twb muaj lawm, tsim cov txheej txheem seamless, tiv thaiv txheej txheem uas txhim kho qhov qub ntawm lub zog, ua haujlwm ntev, thiab ua haujlwm.

Overmolding nrog polyurethane muaj ntau yam txiaj ntsig, ua rau nws yog qhov kev xaiv zoo nkauj rau cov tuam ntxhab thoob plaws ntau qhov kev lag luam. Nov yog qee qhov txiaj ntsig tseem ceeb:

versatility

Cov neeg tsim khoom tuaj yeem siv cov txheej txheem ntau yam ntawm polyurethane overmolding nrog ntau lub substrates, nrog rau cov yas, hlau, thiab cov khoom sib xyaw.

Qhov kev ua tau zoo no ua rau polyurethane overmolding ib qho kev daws teeb meem zoo tshaj plaws rau cov ntawv thov uas yuav tsum tau sib txuas cov ntaub ntawv sib txawv rau hauv ib feem.

durability

Polyurethane yog cov khoom siv ruaj khov uas tuaj yeem tiv taus ntau yam ib puag ncig, nrog rau qhov kub thiab txias, hnyav tshuaj, thiab hnyav hnyav. Cov ntawv thov uas xav tau kev ua haujlwm ruaj khov thiab kev tiv thaiv tuaj yeem tau txais txiaj ntsig los ntawm kev xaiv qhov no raws li lawv qhov kev xaiv zoo tshaj plaws.

customization

Cov neeg tsim khoom tuaj yeem ua tiav qib siab ntawm kev hloov kho nrog polyurethane overmolding, tso cai rau lawv los tsim cov duab nyuaj thiab tsim qauv. Qhov no feature ua rau nws zoo meej xaiv rau cov khoom xav tau ib tug tshwj xeeb tsos los yog tswv yim layout.

Tus nqi-Ua tau zoo

Polyurethane overmolding tuaj yeem yog qhov kev daws teeb meem zoo tshaj plaws piv rau lwm txoj kev tsim khoom, xws li kev txhaj tshuaj molding lossis machining. Nws tseem tuaj yeem txo cov naj npawb ntawm cov khoom yuav tsum tau ua rau daim ntawv thov, txo lub sijhawm sib dhos thiab cov nqi.

Txhim kho tuav thiab xis nyob

Polyurethane overmolding tuaj yeem txhim kho kev tuav thiab kev nplij siab ntawm cov khoom, xws li cov cuab yeej thiab cov tes tuav, los ntawm kev muab cov khoom tsis muaj plam uas yooj yim tuav thiab xis nyob.

Polyurethane overmolding tuaj yeem siv rau ntau yam kev siv, suav nrog:

- Automotive:rau sab hauv thiab sab nrauv, xws li qhov rooj tuav, dashboard Cheebtsam, thiab trim pieces.

- Electronics:rau kev tiv thaiv rhiab hluav taws xob Cheebtsam los ntawm ib puag ncig puas.

- Kho mob: los tsim cov khoom siv kho mob kom ruaj thiab tu cev, xws li cov tes tuav rau cov cuab yeej phais.

- Cov khoom siv: rau kev tsim cov khoom lag luam nrog cov qauv tsim tshwj xeeb thiab txhim kho kev ua haujlwm zoo, xws li cov khoom siv ncaws pob thiab cov khoom siv hauv tsev.

Overmolding rau Automotive Applications: Txhim khu kev zoo nkauj thiab kev ua haujlwm

Hauv kev lag luam automotive, overmolding tau dhau los ua nrov rau kev txhim kho kev zoo nkauj thiab kev ua haujlwm ntawm cov khoom siv tsheb. Cov txheej txheem tsim khoom no tsim ntau yam khoom siv tsheb, xws li tuav, tuav, thiab pob qhov rooj. Ntawm no, peb yuav tham txog yuav ua li cas overmolding yog siv nyob rau hauv automotive daim ntaub ntawv los txhim kho aesthetics thiab functionality.

Txhim kho Aesthetics

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm overmolding hauv kev lag luam tsheb yog nws lub peev xwm los txhim kho kev zoo nkauj. Overmolding tso cai rau cov neeg tsim qauv tsim cov duab nyuaj thiab cov qauv tsim uas yuav nyuaj rau kev ua tiav nrog cov txheej txheem tsim khoom. Nov yog qee txoj hauv kev overmolding txhim kho qhov zoo nkauj ntawm cov khoom siv tsheb:

- customization: Overmolding tso cai rau kev hloov kho, ua kom yooj yim los tsim qhov chaw nrog cov qauv tsim tshwj xeeb thiab cov xim sib xyaw ua ke uas phim lub tsheb sab hauv lossis sab nrauv.

- Kev ntxhib los mos: Overmolding tuaj yeem tsim ntau yam ntawm qhov chaw, los ntawm mos-kov mus rau siab tuav, txhim kho qhov kev xav tag nrho.

- Branding:Cov neeg tsim khoom tuaj yeem siv overmolding los koom nrog cov khoom lag luam, xws li logos lossis cov npe lag luam, rau hauv kev tsim.

- zoo: Overmolding tsim cov khoom ua tau zoo nrog kev ua tiav zoo ib yam, txhim kho tag nrho saib thiab xav.

Txhim khu kev ua haujlwm

Ntxiv nrog rau kev txhim kho kev zoo nkauj, overmolding tuaj yeem txhim kho cov khoom siv hauv tsheb 'kev ua haujlwm. Nov yog qee txoj hauv kev uas cov tuam txhab siv overmolding los txhim kho kev ua haujlwm:

- Nyem: Overmolding tuaj yeem tsim kom muaj qhov tsis zoo hauv qab uas txhim kho kev tuav, ua kom cov khoom siv yooj yim dua thiab muaj kev nyab xeeb dua rau cov neeg tsav tsheb thiab cov neeg caij tsheb.

- Durability: Overmolding tuaj yeem ua rau kom muaj zog ntawm qhov chaw los ntawm kev tiv thaiv lawv los ntawm kev hnav thiab tsim kua muag thiab raug rau ib puag ncig hnyav.

- Noise txo: Overmolding tuaj yeem txo cov suab nrov los ntawm kev tsim cov nyhuv dampening uas txo cov kev vibrations thiab absorbs suab.

- Kev tiv thaiv:Overmolding tuaj yeem tiv thaiv qhov chaw los ntawm kev puas tsuaj los ntawm kev cuam tshuam lossis kev puas tsuaj, uas pab txhawb lawv txoj sia.

Kev siv ntawm Overmolding hauv Automotive Kev Lag Luam

Cov neeg tsim khoom siv overmolding hauv ntau yam kev siv tsheb, suav nrog:

- Cov khoom siv sab hauv:Overmolding tsim cov pob qhov rooj, keyboards, thiab tes rau cov yam ntxwv sab hauv xws li dashboards, qhov rooj vaj huam sib luag, thiab armrests.

- Cov khoom siv sab nrauv: Overmolding tsim cov yam ntxwv sab nraud xws li cov hniav nyiaj hniav kub, lub taub hau puag ncig, thiab daim iav npog.

- Hauv qab hood: Overmolding tsim cov khoom xws li cav mounts, sensors, thiab brackets uas yuav tsum tau tiv taus kub thiab hnyav hnyav.

Overmolding rau Electronics: Txhim kho kev ua tau zoo thiab kev ntseeg tau

Hauv kev lag luam hluav taws xob, overmolding tau dhau los ua nrov rau nws lub peev xwm los txhim kho kev ua tau zoo thiab kev ntseeg siab ntawm cov khoom siv hluav taws xob. Ntawm no, peb yuav tham txog yuav ua li cas overmolding siv nyob rau hauv electronics los txhim kho kev ua tau zoo thiab kev ntseeg tau.

Txhim kho kev ua tau zoo

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm overmolding hauv kev lag luam hluav taws xob yog nws lub peev xwm los txhim kho kev ua haujlwm. Overmolding tuaj yeem txhim kho kev ua haujlwm ntawm cov khoom siv hluav taws xob hauv ntau txoj hauv kev:

- Kev tsis paub dej:Overmolding ua rau cov dej tsis zoo ntawm cov khoom siv hluav taws xob, ua rau nws yog qhov tseem ceeb rau cov ntawv thov uas ib feem tuaj yeem cuam tshuam nrog cov dej noo lossis lwm yam dej.

- Vibration Resistance: Overmolding tuaj yeem tsim ib qho kev thaiv uas pab cov khoom siv hluav taws xob tiv thaiv kev co, uas yog qhov tseem ceeb hauv cov ntawv thov uas qhov yuav raug poob siab lossis kev co.

- Thermal Management: Overmolding pab dissipate tshav kub kom deb ntawm cov khoom siv hluav taws xob, yog li txhim kho lawv cov kev ua tau zoo thiab ua rau lawv lub neej ntev.

- Hluav taws xob rwb thaiv tsev:Overmolding tuaj yeem tsim cov txheej txheej insulating uas tiv thaiv cov khoom siv hluav taws xob los ntawm kev cuam tshuam hluav taws xob, uas tuaj yeem pab txhim kho lawv cov kev ua tau zoo.

Txhim kho kev ntseeg siab

Ntxiv nrog rau kev txhim kho kev ua tau zoo, overmolding kuj tuaj yeem txhim kho kev ntseeg tau ntawm cov khoom siv hluav taws xob. Nov yog qee txoj hauv kev uas overmolding txhim kho kev ntseeg tau:

- Kev tiv thaiv los ntawm kev puas tsuaj: Overmolding tuaj yeem tiv thaiv cov khoom siv hluav taws xob los ntawm kev puas tsuaj rau lub cev, xws li kev cuam tshuam lossis kev puas tsuaj, uas tuaj yeem pab txuas ntxiv lawv txoj sia.

- Chemical Resistance:Overmolding tuaj yeem tiv thaiv cov khoom siv hluav taws xob los ntawm cov tshuaj uas tuaj yeem ua rau corrosion lossis lwm yam kev puas tsuaj, uas tuaj yeem pab txhim kho lawv txoj kev ntseeg tau.

- Txo kev pheej hmoo ntawm kev ua tsis tiav: Overmolding tuaj yeem pab txo qis kev pheej hmoo ntawm kev ua tsis tiav los ntawm kev tiv thaiv cov khoom siv hluav taws xob los ntawm ib puag ncig xws li ya raws, kev vibration, thiab kub heev.

Daim ntawv thov ntawm Overmolding hauv Electronics Kev Lag Luam

Ntau yam kev siv hluav taws xob siv siv overmolding, suav nrog:

- connectors:Overmolding tsim cov dej tsis sib haum thiab kev co-resistant connectors uas pom cov ntawv thov hauv ntau yam khoom siv hluav taws xob.

- Circuit Court cam:Overmolding tuaj yeem tiv thaiv Circuit Court boards los ntawm ya raws, kev co, thiab lwm yam ib puag ncig uas tuaj yeem ua rau kev puas tsuaj lossis tsis ua haujlwm.

- Sensors: Overmolding tuaj yeem tiv thaiv cov sensors los ntawm kev puas tsuaj los ntawm kev raug cov tshuaj hnyav lossis lwm yam ib puag ncig.

- Handheld Devices:Overmolding tsim cov ntaub ntawv ruaj khov thiab dej tsis zoo rau cov khoom siv tuav, xws li xov tooj ntawm tes, koob yees duab, thiab GPS khoom siv.

Overmolding rau Cov Khoom Siv Kho Mob: Ua kom muaj kev nyab xeeb thiab xis nyob

Overmolding tau dhau los ua neeg nyiam hauv kev lag luam kho mob txhawm rau txhim kho kev nyab xeeb thiab kev nplij siab ntawm cov cuab yeej kho mob. Ntawm no, peb yuav tham txog yuav ua li cas overmolding siv nyob rau hauv cov cuab yeej kho mob kom muaj kev nyab xeeb thiab kev nplij siab.

Ua kom muaj kev nyab xeeb

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm overmolding hauv kev lag luam kho mob yog nws lub peev xwm los xyuas kom muaj kev nyab xeeb. Overmolding tuaj yeem txhim kho kev ruaj ntseg ntawm cov cuab yeej kho mob hauv ntau txoj hauv kev:

- Biocompatibility: Overmolding enables tsim cov khoom siv kho mob biocompatible, ua kom lawv muaj kev nyab xeeb rau kev siv hauv tib neeg lub cev yam tsis ua rau muaj kev phiv tshuaj.

- Kom tsis muaj menyuam: Overmolding tuaj yeem tsim cov cuab yeej kho mob yooj yim kom tsis muaj menyuam, uas yog qhov tseem ceeb rau kev tiv thaiv kev kis kab mob hauv chaw kho mob.

- Ergonomics: Overmolding ua rau muaj kev tsim cov khoom siv kho mob ergonomically tsim, uas tuaj yeem pab txo qis kev pheej hmoo ntawm kev raug mob rov qab thiab lwm yam kab mob musculoskeletal ntawm cov neeg ua haujlwm kho mob.

- Durability: Overmolding tuaj yeem tsim cov cuab yeej kho mob uas muaj zog dua, uas tuaj yeem pab txo qis kev pheej hmoo ntawm kev ua tsis tiav lossis ua haujlwm tsis zoo thaum siv.

Saib Xyuas Kev Nyab Xeeb

Ntxiv nrog rau kev ua kom muaj kev nyab xeeb, overmolding kuj tuaj yeem txhim kho kev nplij siab ntawm cov khoom siv kho mob. Nov yog qee txoj hauv kev uas overmolding muab kev nplij siab:

- Kev ntxhib los mos: Overmolding tuaj yeem tsim cov cuab yeej kho mob nrog lub ntsej muag zoo nkauj uas muab kev tuav zoo dua thiab txhim kho kev nplij siab.

- Flexibility: Overmolding tuaj yeem tsim cov cuab yeej kho mob uas hloov tau yooj yim dua, uas tuaj yeem pab txhim kho kev nplij siab thiab txo qhov kev pheej hmoo ntawm kev raug mob lossis tsis xis nyob thaum siv.

- customization: Overmolding tso cai rau kev hloov kho ntawm cov duab thiab tsim cov khoom siv kho mob kom haum rau cov kev xav tau tshwj xeeb ntawm cov neeg mob zoo dua, txhim kho kev nplij siab thiab txo qhov kev pheej hmoo ntawm cov teeb meem.

Kev siv ntawm Overmolding hauv Kev Kho Mob Kev Lag Luam

Ntau yam kev siv kho mob siv overmolding, suav nrog:

- Kev phais phais: Overmolding tuaj yeem tsim cov cuab yeej phais nrog kev tuav zoo dua, zoo dua ergonomics, thiab txhim kho cov kav ntev.

- Implants:Overmolding tuaj yeem tsim cov kev cog qoob loo biocompatible uas yooj yim dua rau cov neeg mob thiab tsis tshua muaj teeb meem.

- Diagnostic Devices: Overmolding tuaj yeem tsim cov cuab yeej kuaj mob uas yooj yim rau kev tswj hwm, ruaj khov dua, thiab yooj yim dua rau cov neeg mob.

- Wearables: Overmolding ua rau kev tsim cov khoom siv kho mob hnav uas muaj kev nplij siab thiab yooj yim dua, ua rau lawv yooj yim dua rau cov neeg mob hnav thiab siv.

Overmolding rau Consumer Products: Ntxiv tus nqi thiab thov rov hais dua

Ntawm no, peb yuav tham txog yuav ua li cas overmolding yog siv nyob rau hauv cov khoom siv los ntxiv tus nqi thiab rov hais dua.

Txhim kho Aesthetics

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev overmolding hauv kev lag luam khoom siv yog nws lub peev xwm los txhim kho kev zoo nkauj. Overmolding tuaj yeem txhim kho qhov zoo thiab kev xav ntawm cov khoom siv hauv ntau txoj hauv kev:

- Tsim Flexibility:Overmolding tso cai rau tsim kom yooj yim dua, tsim cov khoom nrog cov duab tshwj xeeb thiab textures yooj yim dua.

- Xim Customization: Overmolding enables ntau xim nyob rau hauv ib yam khoom, tsim eye-catching designs uas sawv ntawm txee.

- Soft-Touch Feel:Overmolding tuaj yeem tsim cov khoom lag luam nrog lub ntsej muag muag muag, txhim kho tag nrho cov neeg siv kev paub dhau los thiab rov hais dua.

Ntxiv Functionality

Ntxiv nrog rau kev txhim kho kev zoo nkauj, overmolding tuaj yeem ntxiv kev ua haujlwm rau cov neeg siv khoom. Nov yog qee txoj hauv kev uas overmolding ntxiv tus nqi:

- Txhim kho tuav: Overmolding tso cai rau kev tsim cov khoom lag luam nrog kev tuav zoo dua, txhim kho qhov yooj yim ntawm kev siv thiab kev nplij siab thaum tuav lawv.

- Enhanced Durability:Overmolding tuaj yeem tsim cov khoom siv ruaj khov, txhim kho lawv lub neej thiab tag nrho tus nqi.

- Kev tsis paub dej: Overmolding ua rau kev tsim cov khoom siv dej tsis zoo, ua rau lawv muaj ntau yam thiab thov rau cov neeg siv khoom.

Kev siv ntawm Overmolding nyob rau hauv Consumer Product Industry

Ntau yam ntawm cov neeg siv khoom siv kev siv overmolding, suav nrog:

Electronics: Overmolding tuaj yeem tsim cov rooj plaub stylish thiab ruaj khov rau cov khoom siv hluav taws xob xws li xov tooj thiab ntsiav tshuaj.

Khoom siv ua kis las: Overmolding tuaj yeem tsim cov cuab yeej nrog txhim kho tuav thiab ua haujlwm ntev, xws li tsheb kauj vab tes thiab ntaus pob tesniv tuav.

Chav ua noj: Overmolding tuaj yeem tsim cov khoom siv hauv chav ua noj nrog lub ntsej muag muag thiab txhim kho tuav, xws li cov tais diav ua noj thiab tes rau lub lauj kaub thiab lauj kaub.

Cov Khoom Siv Kho Tus Kheej: Overmolding tuaj yeem tsim cov khoom tu tus kheej nrog rau qhov zoo nkauj thiab zoo nkauj, xws li txhuam hniav thiab rab chais.

Overmolding Design Considerations: From Prototyping to Production

Overmolding yuav tsum txhaj cov khoom thib ob dhau ntawm cov khoom tsim ua ntej, tsim kom muaj cov khoom sib koom ua ke. Overmolding tuaj yeem muab cov txiaj ntsig tseem ceeb, xws li txhim kho kev zoo nkauj, ntxiv kev ua haujlwm, thiab txhim kho cov kav ntev. Txawm li cas los xij, tsim thiab tsim cov khoom overmolded yuav tsum tau ua tib zoo xav kom ua tiav.

Nov yog qee qhov kev tsim qauv tseem ceeb rau cov khoom overmolded:

Khoom siv compatibility: Cov ntaub ntawv siv hauv overmolding yuav tsum tau sib xws kom muaj kev sib raug zoo. Qhov adhesion ntawm ob cov ntaub ntawv tseem ceeb heev rau kev ua haujlwm ntawm ib feem. Cov khoom uas muaj cov khoom zoo sib xws thiab qhov kub thiab txias yog qhov zoo tagnrho rau overmolding.

Tshooj tsim: Kev tsim cov khoom tsim ua ntej yuav tsum xav txog qhov loj, zoo li, thiab qhov chaw ntawm qhov chaw overmolded. Ib feem zoo tsim yuav muaj cov phab ntsa tuab tuab thiab tsis muaj qhov cuam tshuam los xyuas kom muaj kev hloov pauv ntawm cov ntaub ntawv.

Tooling tsim: Cov cuab yeej rau overmolding yog qhov nyuaj dua li kev txhaj tshuaj molding. Cov cuab yeej tsim yuav tsum tuav cov khoom ua ntej tsim nyob rau hauv qhov chaw thaum lub sij hawm overmolding txheej txheem, cia cov khoom thib ob ntws ncig thiab hla ib feem.

Tus tsim qauv yuav tsum tsim cov cuab yeej los txo qhov flashing thiab xyuas kom muaj kev sib raug zoo ntawm cov khoom siv.

Txheej txheem optimization: Cov txheej txheem overmolding muaj ntau theem, suav nrog molding cov khoom ua ntej tsim, txias, thiab tom qab ntawd txhaj cov khoom thib ob. Tus engineer yuav tsum ua kom zoo dua cov txheej txheem los xyuas kom meej qhov zoo tshaj plaws kev sib raug zoo ntawm ob cov ntaub ntawv thiab txo qhov tsis xws luag xws li warping los yog dab dej cim.

Thaum tsiv los ntawm prototyping mus rau ntau lawm, muaj cov kev xav tau ntxiv kom nco ntsoov:

Volume thiab tus nqi: Overmolding tuaj yeem kim dua li kev txhaj tshuaj molding ib txwm muaj vim qhov nyuaj ntawm cov txheej txheem thiab tus nqi ntawm cov cuab yeej. Raws li ntim nce, tus nqi ib feem tuaj yeem txo qis, ua rau overmolding ntau tus nqi-zoo rau kev ua haujlwm loj dua.

Kev tswj kom zoo: Overmolding yuav tsum tau nruj me ntsis ntsuas los xyuas kom meej ib feem zoo thiab tiv thaiv tsis xws luag. Pab neeg tswj kev ua tau zoo yuav tsum ua kev tshuaj xyuas thiab kev sim ntawm txhua theem ntawm cov txheej txheem tsim khoom kom ntseeg tau tias qhov ua tau raws li cov lus qhia tshwj xeeb.

Kev xaiv tus neeg muag khoom: Xaiv tus neeg muab khoom tsim nyog rau overmolding yog qhov tseem ceeb rau txoj haujlwm ua tiav. Nrhiav tus neeg muag khoom nrog kev paub dhau los hauv kev overmolding thiab cov ntaub ntawv teev tseg ntawm kev tsim cov khoom zoo. Tus neeg muag khoom yuav tsum muaj peev xwm muab kev pab tsim, kev ua kom zoo dua qub, thiab ntsuas kev tswj kom zoo.

Tus nqi-zoo tsim nrog Overmolding

Overmolding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj thib ob ntawm cov khoom ua ntej tsim los tsim ib qho khoom sib koom ua ke. Cov txheej txheem no tuaj yeem muab cov txiaj ntsig tseem ceeb, xws li txhim kho kev zoo nkauj, ntxiv kev ua haujlwm, thiab txhim kho kev ua haujlwm ntev. Overmolding kuj tuaj yeem yog qhov kev daws teeb meem zoo rau cov khoom tshwj xeeb.

Nov yog qee txoj hauv kev uas overmolding tuaj yeem pab txo cov nqi tsim khoom:

Txo lub sij hawm sib dhos: Overmolding tuaj yeem tshem tawm qhov xav tau ntawm cov khoom sib cais thiab cov txheej txheem siv sijhawm ntawm kev sib sau ua ke. Overmolding tuaj yeem txo lub sijhawm sib dhos thiab cov nqi zog los ntawm kev tsim cov khoom sib koom ua ke.

Txo cov khoom pov tseg: Kev txhaj tshuaj molding feem ntau tsim cov khoom pov tseg tseem ceeb vim yog cov sprues thiab cov neeg khiav dej num tsim nyog los sau cov pwm. Overmolding tuaj yeem txo cov khoom pov tseg los ntawm kev siv cov khoom ua ntej tsim ua lub hauv paus thiab txhaj cov khoom thib ob tsuas yog qhov xav tau.

Txhim kho qhov ua tau zoo: Overmolding tuaj yeem txhim kho qhov ua tau zoo thiab ua haujlwm ntev, txo qhov xav tau kev hloov pauv lossis kho dua. Kev txo qis qis thiab kev saib xyuas cov nqi tuaj yeem ua rau muaj txiaj ntsig zoo rau lub sijhawm ntev.

Txo cov nqi cuab yeej: Overmolding tuaj yeem kim dua li kev txhaj tshuaj molding ib txwm muaj vim qhov nyuaj ntawm cov txheej txheem thiab tus nqi ntawm cov cuab yeej. Txawm li cas los xij, qee zaum, overmolding tuaj yeem txo cov nqi siv los ntawm kev tshem tawm qhov xav tau ntawm cov pwm cais rau txhua qhov khoom. Overmolding tuaj yeem ua kom yooj yim rau kev tsim khoom, tshwj xeeb tshaj yog rau qhov me me thiab nyuaj.

Txo nqi tsheb thauj mus los: Overmolding txo cov nqi tsheb thauj mus los los ntawm kev tshem tawm qhov xav tau los thauj thiab sib sau cov khoom sib cais tom qab. Los ntawm kev ua raws li qhov no, yuav txo tau qhov kev pheej hmoo ntawm kev puas tsuaj thaum lub sij hawm thauj mus los, ua rau txo qis ntawm qhov tsis lees paub thiab pov tseg.

Thaum xav txog overmolding rau cov nqi tsim khoom, nws yog ib qho tseem ceeb kom nco ntsoov cov hauv qab no:

Kev xaiv cov khoom siv: Cov ntaub ntawv siv hauv overmolding yuav tsum tau sib xws kom muaj kev sib raug zoo. Cov khoom uas muaj cov khoom zoo sib xws thiab qhov kub thiab txias yog qhov zoo tagnrho rau overmolding. Kev xaiv cov khoom tsim nyog kuj tuaj yeem cuam tshuam rau kev txuag nyiaj mus sij hawm ntev los ntawm kev txhim kho ib feem ntawm kev ua haujlwm thiab txo cov nqi tu.

Txheej txheem optimization: Cov txheej txheem overmolding muaj ntau theem, suav nrog molding cov khoom ua ntej tsim, txias, thiab tom qab ntawd txhaj cov khoom thib ob. Cov txheej txheem optimization pab neeg yuav tsum optimize tus txheej txheem los xyuas kom meej qhov zoo tshaj plaws kev sib raug zoo ntawm ob cov ntaub ntawv thiab txo qhov tsis xws luag xws li warping los yog dab dej cim. Kev ua kom zoo ntawm cov txheej txheem kuj tuaj yeem ua rau lub sijhawm voj voog nrawm dua thiab ua kom zoo dua qub, txo cov nqi tsim khoom.

Kev xaiv tus neeg muag khoom: Xaiv tus neeg muab khoom tsim nyog rau overmolding yog qhov tseem ceeb rau txoj haujlwm ua tiav. Nrhiav tus neeg muag khoom nrog kev paub dhau los hauv kev overmolding thiab cov ntaub ntawv teev tseg ntawm kev tsim cov khoom zoo. Tus neeg muag khoom yuav tsum muaj peev xwm muab kev pab tsim, kev ua kom zoo dua qub, thiab ntsuas kev tswj kom zoo.

Environmental Sustainability thiab Overmolding

Overmolding yog cov txheej txheem tsim khoom nrov uas suav nrog molding ib qho khoom siv los tsim ib yam khoom. Cov txheej txheem no muaj ntau yam txiaj ntsig, suav nrog kev txhim kho zoo nkauj, ntxiv kev ua haujlwm, thiab ua kom muaj zog ntxiv. Tab sis dab tsi txog nws qhov cuam tshuam rau ib puag ncig? Puas yog overmolding ib puag ncig kev tsim khoom lag luam?

Nov yog qee txoj hauv kev uas overmolding tuaj yeem yog ib puag ncig kev tsim khoom lag luam:

Txo cov khoom pov tseg: Overmolding tuaj yeem txo cov khoom pov tseg los ntawm kev siv cov khoom ua ntej tsim ua lub hauv paus thiab txhaj cov khoom thib ob tsuas yog qhov xav tau. Siv cov khoom siv tsawg dua hauv kev tsim khoom txo cov khoom pov tseg tag nrho.

Txo kev siv hluav taws xob: Overmolding tuaj yeem ua kom muaj zog ntau dua li cov txheej txheem tsim khoom ib txwm siv vim tias molding ib yam khoom yuav tsum muaj zog tsawg dua li kev tsim cov khoom sib cais thiab sib sau ua ke tom qab.

Kev siv cov khoom siv rov ua dua tshiab: Ntau cov ntaub ntawv overmolding tuaj yeem siv dua, txo cov khib nyiab hauv qhov chaw pov tseg. Kev siv cov khoom siv rov ua dua tuaj yeem txo qhov kev xav tau ntawm cov ntaub ntawv nkauj xwb, txuag cov peev txheej ntuj thiab txo kev siv hluav taws xob.

Cov khoom lag luam ntev dua: Overmolding tuaj yeem txhim kho qhov ua tau zoo thiab ua haujlwm ntev, ua rau cov khoom siv ntev dua thiab yuav tsum tau hloov tsawg dua. Txo cov khoom pov tseg uas tsim los ntawm cov khoom lag luam lub neej tuaj yeem txo nws qhov kev cuam tshuam ib puag ncig.

Txo kev thauj mus los: Los ntawm kev tshem tawm qhov xav tau ntawm kev thauj mus los sib cais thiab tom qab sib dhos ntawm cov khoom, overmolding tuaj yeem txo cov nqi tsheb thauj mus los. Txo cov roj siv hauv lub tsheb tuaj yeem txo qhov cuam tshuam ib puag ncig thiab txo qis kev cuam tshuam emissions.

Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias overmolding tsis yog ib qho kev tsim khoom ib puag ncig. Nov yog qee qhov kev xav kom nco ntsoov:

Kev xaiv cov khoom siv: Cov ntaub ntawv siv hauv overmolding yuav tsum tau ua tib zoo xaiv kom ntseeg tau tias lawv yog ib puag ncig zoo. Piv txwv li, qee cov ntaub ntawv yuav nyuaj rau kev rov ua dua lossis yuav xav tau kev siv hluav taws xob tseem ceeb los tsim.

Txheej txheem optimization: Overmolding yuav tsum tau optimized kom txo tau lub zog noj thiab pov tseg. Ib txoj hauv kev los txo cov khoom pov tseg tsawg kawg yog los ntawm kev txhim kho cov tshuab lossis kho cov txheej txheem molding kom ua tau zoo dua.

Kev txiav txim siab kawg ntawm lub neej: Thaum xav txog qhov kawg ntawm cov khoom lag luam lub neej, cov tib neeg lossis cov koom haum yuav tsum xav txog seb lawv yuav muab pov tseg li cas. Cov khoom overmolded tej zaum yuav nyuaj dua rau kev rov ua dua lossis yuav xav tau ntau lub zog los pov tseg dua li cov khoom siv ib txwm muaj.

Overmolding thiab Kev Lag Luam 4.0: Innovations thiab Opportunities

Overmolding yog txheej txheem kev tsim khoom uas suav nrog molding cov khoom mus rau lwm yam khoom lossis substrate. Kev lag luam tsheb, kev kho mob, thiab hluav taws xob siv dav siv. Nrog rau qhov tshwm sim ntawm Kev Lag Luam 4.0, overmolding tau dhau los ua qhov tshiab thiab muaj txiaj ntsig. Ntawm no, peb yuav tshawb nrhiav cov kev tsim kho tshiab thiab cov hauv kev ntawm overmolding hauv Kev Lag Luam 4.0 era.

Kev tsim kho tshiab hauv Overmolding

Kev koom ua ke Kev Lag Luam 4.0 technologies xws li automation, artificial txawj ntse, thiab Is Taws Nem ntawm Yam (IoT), tau hloov pauv cov txheej txheem overmolding. Nov yog qee qhov kev tsim kho tshiab uas tau tshwm sim:

- Ntse Moulds: Cov pwm no tau nruab nrog cov sensors thiab tuaj yeem sib txuas lus nrog cov tshuab los kho cov txheej txheem molding. Lawv kuj tuaj yeem kuaj xyuas qhov tsis xws luag thiab ceeb toom rau cov neeg ua haujlwm kom ua haujlwm kho.

- Robotics:Kev siv cov neeg hlau hauv overmolding tau nce kev ua tau zoo thiab txo nqi zog. Cov neeg hlau tuaj yeem ua haujlwm rov ua haujlwm xws li thauj khoom thiab tshem tawm cov ntaub ntawv, txo cov kev pheej hmoo ntawm tib neeg.

- 3D Luam Ntawv:3D luam ntawv tau tsim cov pwm nyuaj uas yav tas los tsis tuaj yeem tsim. Kev tsim kom yooj yim dua tau ua rau txo cov sij hawm txhuas.

- Predictive Maintenance:Kev saib xyuas kwv yees yog cov txheej txheem uas siv cov ntaub ntawv txheeb xyuas los kwv yees thaum lub tshuab yuav xav tau kev saib xyuas. Cov txheej txheem no tuaj yeem pab tiv thaiv kev poob qis thiab txo tus nqi kho.

Cov sijhawm hauv Overmolding

Overmolding muaj ntau lub sijhawm hauv Kev Lag Luam 4.0, suav nrog:

- Lub teeb yuag:Overmolding tuaj yeem tsim qhov sib sib zog nqus los ntawm molding ib txheej nyias ntawm cov khoom mus rau lub teeb substrate. Txo qhov hnyav ntawm cov khoom kawg txhim kho roj efficiency thiab txo emissions.

- customization: Overmolding tso cai rau kev hloov kho ntawm qhov chaw los ntawm kev siv cov khoom sib txawv thiab xim. Hauv kev lag luam kho mob thiab cov neeg siv khoom siv hluav taws xob, zoo li tseem ceeb heev, thiab nws tseem ceeb heev uas yuav tau xav txog qhov no.

- Muaj caij nyoog:Overmolding tuaj yeem pab txo cov khoom pov tseg los ntawm kev siv cov khoom siv rov ua dua li cov substrates. Los ntawm kev txo cov kev cuam tshuam ib puag ncig ntawm kev tsim khoom, tuam txhab lag luam tsis tuaj yeem txhim kho lawv cov npe lag luam thiab pab txhawb rau yav tom ntej.

- Kev txuag nqi: Automation, robotics, thiab kev saib xyuas kev kwv yees tuaj yeem txo cov nqi zog thiab ua kom muaj txiaj ntsig, ua rau cov chaw tsim khoom txuag nyiaj.

Overmolding Challenges thiab Solutions

Txawm li cas los xij, overmolding ua rau qee qhov teeb meem uas cov tuam txhab lag luam yuav tsum kov yeej los tsim cov khoom zoo tshaj plaws. Hauv tsab xov xwm no, peb tshawb txog qee qhov kev nyuaj dhau los thiab kev daws teeb meem.

Txoj kev sib tw

- Adhesion: Overmolding yuav tsum tau hais tias ob cov ntaub ntawv siv adhering rau ib leeg, thiab tsis zoo adhesion ua rau delamination, cracking, los yog detachment ntawm cov khoom overmolded.

- Warping:Thaum lub sij hawm overmolding txheej txheem, lub substrate tuaj yeem deform vim lub siab kub thiab siab thov. Warping adversely cuam tshuam tag nrho qhov zoo ntawm ib feem.

- Khoom siv compatibility:Cov ntaub ntawv siv hauv overmolding yuav tsum tau sib xws los xyuas kom meej adhesion zoo thiab tiv thaiv warping. Cov ntaub ntawv tsis sib haum tuaj yeem ua rau muaj kev sib txuas tsis zoo thiab cov khoom tsis ua haujlwm.

- Kev faib kab: Lub parting kab yog qhov twg ob cov ntaub ntawv sib ntsib. Kev tsim kab tsis zoo tuaj yeem ua rau cov ntsiab lus tsis muaj zog hauv cov khoom tiav thiab txo cov kav ntev.

- Khoom ntws: Cov txheej txheem overmolding xav tau cov khoom thib ob kom ntws ncig ntawm lub substrate, sau txhua qhov crevice. Cov khoom siv tsis zoo tuaj yeem ua rau tsis tiav kev pab them nqi, voids, lossis cov ntsiab lus tsis muaj zog.

Solutions

- Kev npaj deg: Kev npaj lub substrate nto yog qhov tseem ceeb heev kom ua tiav adhesion zoo. Qhov saum npoo yuav tsum huv, qhuav, thiab tsis muaj kab mob xws li roj thiab khib nyiab. Ua ntej kho lub substrate nrog adhesion txhawb nqa tuaj yeem txhim kho kev sib raug zoo.

- Kev tsim cov cuab yeej tsim nyog: Tus tsim yuav tsum xav txog cov ntaub ntawv siv thiab cov geometry ib feem kom tiv thaiv warping thiab xyuas kom meej cov ntaub ntawv zoo. Siv cov cuab yeej tshwj xeeb, xws li ntxig molding, tuaj yeem txhim kho qhov ua haujlwm ntev thiab lub zog.

- Kev xaiv cov khoom siv: Cov ntaub ntawv siv hauv overmolding yuav tsum tau sib haum nrog kev ua tiav kev sib raug zoo thiab tiv thaiv warping. Siv cov ntaub ntawv nrog cov thermal expansion coefficients zoo sib xws tuaj yeem txo qhov kev ntxhov siab thaum lub sij hawm molding.

- Parting kab tsim: Thaum tsim cov khoom lag luam, nws yog ib qho tseem ceeb uas yuav tau xav txog txoj kab sib cais kom ntseeg tau tias nws lub zog ua tib zoo. Siv cov kab sib npaug sib npaug yog pom zoo kom tiv thaiv kev ntxhov siab.

- Txhaj molding txheej txheem optimization: Kev ua kom zoo ntawm cov txheej txheem tuaj yeem txhim kho cov khoom ntws thiab tiv thaiv cov voids lossis cov ntsiab lus tsis muaj zog. Kev tswj qhov kub, siab, thiab kev txhaj tshuaj nrawm yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig zoo.

Cov Lus Qhia Yav Tom Ntej ntawm Overmolding: Kev Tawm Tsam Tawm Tsam thiab Kev Lag Luam

Overmolding, ib txheej txheem uas muaj molding ib yam khoom mus rau lwm tus, yog ib tug nrov txoj kev nyob rau hauv manufacturing kev lag luam rau ntau xyoo lawm. Txawm li cas los xij, nrog kev nce qib hauv kev siv thev naus laus zis thiab kev tsom mus rau kev ruaj khov, overmolding tam sim no muaj kev nce qib hauv kev muaj koob npe. Ntawm no, peb yuav tham txog yav tom ntej cov lus qhia ntawm overmolding, nrog rau cov tiam tshiab thiab technologies.

Trends nyob rau hauv Overmolding:

Muaj caij nyoog: Sustainability yog qhov tseem ceeb tshaj plaws rau ntau lub tuam txhab, thiab overmolding tuaj yeem pab txo cov khib nyiab thiab txhim kho kev ua haujlwm hauv kev tsim khoom. Kev siv cov khoom siv rov ua dua tshiab thiab biodegradable polymers hauv overmolding tau dhau los ua ntau dua, txo kev cuam tshuam ib puag ncig.

Miniaturization: Raws li thev naus laus zis hloov zuj zus, qhov kev thov rau cov khoom me me, sib dua, thiab cov khoom sib txawv ntau ntxiv. Overmolding tso cai rau kev tsim cov me me, ntau qhov chaw uas muaj zog thiab ua haujlwm zoo, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov qauv miniaturization.

customization: Cov neeg siv khoom xav tau ntau tus kheej cov khoom, thiab overmolding muab lub peev xwm los kho cov khoom nrog cov xim sib txawv, textures, thiab cov ntaub ntawv. Raws li kev hloov kho tau yooj yim dua thiab pheej yig, peb cia siab tias qhov sib txawv no yuav loj tuaj.

Technology hauv Overmolding:

Hauv Pwm Kho Kom Zoo Nkauj (IMD): Hauv Pwm Kho Kom Zoo Nkauj yog ib qho cuab yeej uas tsim kom muaj qhov chaw dai kom zoo nkauj thaum overmolding. Cov cuab yeej no ua rau kev tsim cov khoom lag luam nrog cov qauv tsim thiab cov qauv zoo sib xws, ua rau nws zoo tagnrho rau kev hloov kho.

Ntxig Moulding: Ntxig molding yuav overmolding ib feem los yog cov khoom uas twb muaj lawm. Cov tshuab no zoo meej rau miniaturization vim nws tsim me me, ntau yam nta.

Multi-Shot Overmolding: Multi-shot overmolding yuav siv ntau yam ntaub ntawv los tsim ib feem lossis cov khoom. Lub tshuab no tso cai rau cov khoom tsim nrog cov textures sib txawv, xim, thiab cov ntaub ntawv, ua rau nws zoo tagnrho rau cov kev hloov kho.

Kev txhaj tshuaj molding: Kev txhaj tshuaj molding koom nrog kev txhaj tshuaj ob lossis ntau dua rau hauv ib qho pwm. Cov cuab yeej no tso cai rau kev tsim cov khoom lag luam nrog kev sib xyaw ua ke ntawm cov khoom, xws li lub zog thiab yoog raws.

Cov txiaj ntsig ntawm Overmolding:

Txo cov pov tseg: Overmolding tshem tawm qhov xav tau ntawm cov khoom sib cais thiab cov khoom, ua rau kom muaj txiaj ntsig zoo thiab kev tsim khoom lag luam.

Txhim kho Durability: Overmolding muab kev ua kom ntev thiab lub zog rau cov khoom, ua rau lawv tiv taus hnav thiab tsim kua muag.

Tus nqi-Siv tau: Overmolding tuaj yeem yog ib qho txiaj ntsig zoo rau lwm txoj hauv kev tsim khoom, feem ntau yog thaum tsim cov khoom me me, ntau qhov sib txawv.

Overmolding Services thiab muab kev pab: Xaiv tus khub zoo

Txawm li cas los xij, nrhiav txoj cai overmolding tus neeg muab kev pab cuam tuaj yeem nyuaj, tshwj xeeb yog muab ntau yam kev pabcuam thiab cov kev pabcuam muaj. Ntawm no, peb yuav tham txog cov ntsiab lus tseem ceeb uas yuav tsum tau xav txog thaum xaiv tus muab kev pabcuam overmolding.

Factors yuav xav txog:

kev: Nrhiav ib tus neeg muab kev pabcuam nrog cov ntaub ntawv pov thawj hauv kev overmolding. Tshawb xyuas tus kws kho mob cov ntaub ntawv pov thawj kom pom tias lawv muaj kev paub ua haujlwm ntawm cov haujlwm zoo ib yam li koj li.

Peev Xwm: Xyuas kom meej tias tus kws kho mob tuaj yeem ua tau raws li koj cov kev xav tau tshwj xeeb, suav nrog kev xaiv cov khoom siv, kev xaiv kho kom haum, thiab ntim ntau lawm.

zoo: Kev ua tau zoo yog qhov tseem ceeb hauv kev overmolding, vim tias txawm tias me me tsis xws luag tuaj yeem ua rau cov khoom tsis ua haujlwm. Nrhiav ib tus kws kho mob uas muaj kev tswj xyuas zoo uas muaj ntawv pov thawj los ntawm cov koom haum tswj hwm.

Tus nqi: Kev overmolding tuaj yeem kim, yog li xaiv tus nqi sib tw uas tsis muaj kev cuam tshuam zoo yog qhov tseem ceeb.

Kev Sib Txuas Lus: Nrhiav ib tus kws kho mob uas muaj nuj nqis rau kev sib txuas lus meej thiab pob tshab. Tus kws kho mob yuav tsum teb rau koj cov lus nug thiab qhia koj paub thoob plaws hauv cov txheej txheem tsim khoom.

Lead Lub sij hawm: Xav txog tus kws kho mob lub sijhawm ua haujlwm, vim tias kev ncua sij hawm tuaj yeem cuam tshuam koj lub sijhawm tsim khoom. Xyuas kom tus kws kho mob tuaj yeem ua tau raws li koj cov sijhawm teem tseg.

Qhov chaw: Xaiv ib tus neeg muab kev pabcuam thaj chaw ze rau koj lub lag luam tuaj yeem txo cov nqi tsheb thauj mus los thiab sijhawm ua haujlwm.

Customer Service: Xaiv ib tus neeg muab kev pabcuam uas muaj nuj nqis rau cov neeg siv khoom thiab yuav ua haujlwm nrog koj los daws txhua yam teeb meem.

Cov muab kev pabcuam:

Txhaj Moulding tuam txhab uas muag: Ntau lub tuam txhab txhaj tshuaj molding muab cov kev pabcuam overmolding raws li kev muab ntxiv. Cov tuam txhab no muaj qhov zoo ntawm cov kev paub hauv kev txhaj tshuaj molding thiab tuaj yeem muab ntau yam kev pabcuam, suav nrog kev xaiv cov khoom siv thiab kev xaiv xaiv.

Cov tuam txhab cog lus tsim khoom: Cov tuam txhab tsim khoom cog lus muab kev pabcuam tsim khoom rau ntau yam kev lag luam. Cov tuam txhab no feem ntau muaj kev paub dhau los hauv kev overmolding thiab tuaj yeem muab cov kev daws teeb meem zoo rau cov khoom ntim loj.

Cov kws kho mob tshwj xeeb: Cov kws kho mob tshwj xeeb tsom rau qhov tshwj xeeb ntawm kev overmolding, xws li cov cuab yeej lossis cov khoom xaiv. Cov chaw muab kev pabcuam no tuaj yeem muab cov kws tshaj lij tshwj xeeb uas yuav muaj txiaj ntsig rau cov haujlwm nyuaj lossis tshwj xeeb.

xaus

Overmolding yog txheej txheem ntau yam thiab siv tau uas tuaj yeem txhim kho cov khoom ua haujlwm, ua haujlwm ntev, thiab zoo nkauj thoob plaws kev lag luam sib txawv. Nrog rau ntau yam khoom siv, cov txheej txheem, thiab kev siv, overmolding muaj ntau txoj hauv kev rau cov tuam txhab tsim cov khoom lag luam zoo uas ua tau raws li cov kev xav tau thiab kev nyiam ntawm cov neeg siv khoom. Cov neeg tsim khoom tuaj yeem txiav txim siab paub thiab nyob twj ywm hauv kev lag luam niaj hnub no los ntawm kev xav txog kev tsim, tus nqi, kev ruaj khov, thiab kev tsim kho tshiab ntawm overmolding. Txawm hais tias koj yog tus tsim khoom tsim, engineer, lossis tus tswv lag luam, kev nkag siab lub tswv yim ntawm overmolding tuaj yeem pab koj coj koj cov khoom mus rau qib tom ntej.