Tsawg Volume Txhaj Moulding - Tsawg Volume Manufacturing Service

Yuav Ua Li Cas Leverage Low-Volume Txhaj Molding (Low Volume Manufacturing Service)

Siv cov khoom siv raws li qhov xav tau los txo cov nqi tsim khoom thiab txo cov kev xav tau volatility

Txawm hais tias koj tab tom tsim cov cuab yeej kho mob cawm siav lossis lub dav hlau ya dav hlau, nqis peev $ 100,000 lossis ntau dua - feem ntau ntau ntxiv - hauv cov khoom siv hlau loj yog qhov kev pheej hmoo nyiaj txiag uas tuaj nrog kev txav mus rau kev tsim khoom loj. Compounding qhov kev pheej hmoo yog lub hlis ntawm lub sijhawm tsis ua haujlwm thaum koj tos koj lub cuab yeej steel kom npaj tau thaum koj tuaj yeem ua iterating ib feem tsim lossis txawm tias tsim cov khoom uas tsim cov nyiaj tau los. Muaj txoj hauv kev zoo dua: kev tsim khoom raws li kev thov.

Dab tsi yog On-Demand Manufacturing (tsawg ntim txhaj tshuaj molding)?

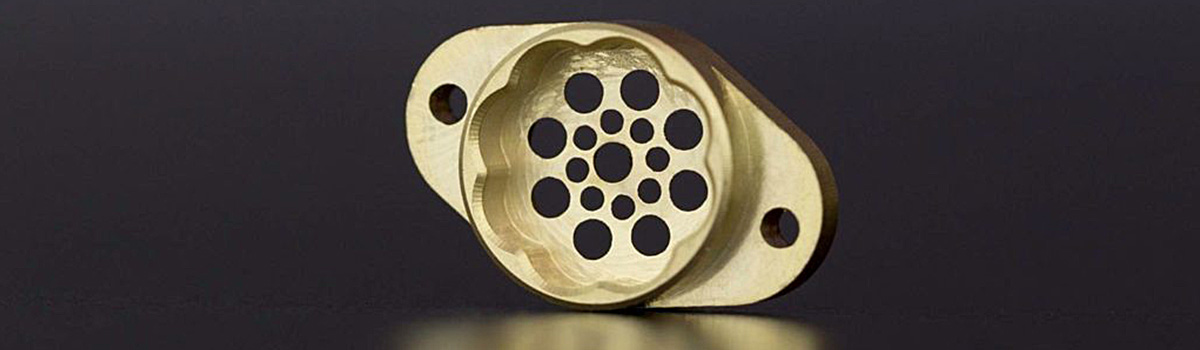

Ntawm DJmolding, peb qhov kev xav tau, cov khoom ntim qis nrog kev txhaj tshuaj molding-uas siv cov cuab yeej siv txhuas-yog txoj hauv kev nrawm, nqi-zoo los tsim ntau pua txhiab qhov kawg-siv molded qhov chaw.

Siv cov txheej txheem no ua thawj txoj kev tsim khoom rau koj cov khoom. On-demand manufacturing kuj yog ib txoj hauv kev zoo tshaj plaws los ntawm kev tsim qauv mus rau cov khoom ntim qis rau cov khoom molded. DJmolding yog qhov ua tau zoo tshaj plaws ntawm kev tsim khoom. Kev khiav qis qis kuj tseem tuaj yeem pab koj txheeb xyuas qhov tsim qauv thiab tswj cov khoom lag luam nyiaj siv ua haujlwm nrog kev tsim cov khoom tsuas yog thaum xav tau dictates. Tsis tas li ntawd, txawm hais tias koj yuav tsum tau hloov mus rau qhov loj ntawm cov khoom yas, koj tseem tuaj yeem siv peb cov cuab yeej siv hluav taws xob zoo li tus choj ua ntej cog lus rau cov nqi peev nrog cov cuab yeej steel. Thaum kawg, qhov kev xav tau ntawm qhov kev xav tau no kuj tseem ua rau koj cov khoom siv tau zoo, ua rau nws zoo dua rau kev tswj hwm qhov kev xav tau volatility.

Hu tawm Cov Nta Tseem Ceeb-rau-Quality

Thaum koj siv peb qhov kev xav tau kev tsim khoom, koj yuav tuaj yeem qhia hauv koj qhov tsim qhov ntev uas yog qhov tseem ceeb tshaj plaws rau qhov kev ua haujlwm. Los ntawm kev hu tawm cov Critical-to-Quality (CTQ) cov yam ntxwv hauv koj tus qauv 3D CAD, koj tuaj yeem paub tseeb tias cov khoom xaj tau zoo ib yam nrog tus qauv. Tsis tas li ntawd, qhov ntawd txhais tau hais tias lwm zaus koj xaj cov khoom, peb tuaj yeem ua raws li cov kauj ruam meej los tsim cov khoom sib xws, rov ua dua tshiab uas ua raws li koj qhov CTQ specifications.

Kev tshuaj xyuas yog qhov tseem ceeb ntawm cov txheej txheem CTQ no. Yog li ntawd, peb pab neeg ua haujlwm engineering yuav tshuaj xyuas koj tus qauv thiab xa email rau koj Daim Ntawv Qhia Txog Kev Ua Haujlwm (ISOW), uas tso cai rau koj paub yog tias muaj cov yam ntxwv uas koj tau ncig muaj teeb meem nrog kev ua siab ntev thiab pwm. Thaum peb xa cov ISOW, peb tsim thiab tshuaj xyuas koj daim ntawv xaj.

Thaum peb tau ua tiav cov txheej txheem molding, uas ua kom peb muaj cov txheej txheem zoo ib yam thiab rov ua dua los tsim cov khoom zoo, peb yuav tshuaj xyuas thawj peb qhov kev txhaj tshuaj los ntawm lub cuab yeej, siv lub tshuab automated Coordinate-measuring Machine (CMM), thiab muab peb -part First Article Inspection (FAI) report, and a Process Capability Report.

Tau txais cov saw hlau hloov tau yooj yim los ntawm DJmolding qhov ntim qis txhaj tshuaj molding kev pabcuam

Niaj hnub no, raws li peb txhua tus tau txuas ntxiv mus rau kev sib kis thoob ntiaj teb, kev txiav txim siab ntawm cov saw hlau yog qhov tseem ceeb. Ib txoj hauv kev tsim khoom raws li qhov xav tau tuaj yeem pab koj tsim cov saw hlau ntau dua los ntawm:

* Kev yuav khoom raws li qhov xav tau yam tsis muaj qhov tsawg kawg nkaus Order Quantity (MOQ)

* Txo cov nqi khoom muag thiab cov nqi khoom lag luam nrog cov khoom siv raws li qhov xav tau

* Tswj kev nce hauv qhov kev thov volatility yam tsis tau rov qab txiav txim

* Txo kev pheej hmoo ntawm kev xa khoom hauv tsev thiab thoob ntiaj teb qeeb

* Txo qis qis qis thiab txo qhov kev pheej hmoo ntawm cov khoom lag luam tawm thaum cov cuab yeej loj raug kho

DJmolding's Low-Volume Production

Qhov no yog ib qho kev pabcuam tshwj xeeb uas muab tag nrho cov khoom tsim tau zoo tab sis hauv cov ntim feem ntau txwv rau 10,000 daim lossis tsawg dua, nyob ntawm tus txheej txheem siv. Peb cov molding uas tsis tshua muaj, tseem hu ua luv luv, raug saib xyuas thiab tswj kom koj tuaj yeem paub tseeb ntawm txhua yam ntawm pwm tsim thiab tsim. Hom kev tsim khoom no zoo tagnrho rau cov lag luam me thiab nruab nrab lossis me me-batch manufacturing.

Tsawg ntim kev tsim khoom yog qhov chaw tshiab ncaj ncees hauv kev tsim khoom lag luam uas yog txhua yam hais txog outsourcing qhov chaw, khoom, thiab cov khoom siv rau cov neeg thib peb.

Qhov no tso cai rau koj lub tuam txhab tsom mus rau kev tsim khoom ntau dua thaum cov lag luam me ua haujlwm tsim thiab tsim cov khoom lag luam. Qhov kev loj hlob no yuav nthuav dav hauv txhua qhov kev lag luam vim tias cov lag luam me saib kom loj hlob lawv txoj kev lag luam los ntawm kev tawm mus rau lwm lub tuam txhab thiab khaws cov nqi qis.

DJmolding's Small Volume Txhaj Moulding

Ntau tus neeg hnov lo lus "Tuam Tshoj" thiab "muab" hauv tib kab lus thiab lawv xav tias qhov phem tshaj. Lawv xav txog cov khoom pheej yig, cov khoom tsis zoo uas tau tsim los ntawm kev siv cov kev tsim khoom tsis zoo uas ua rau cov neeg ua haujlwm muaj kev pheej hmoo.

Tab sis qhov ntawd, tsis yog txhua lub sijhawm.

DJmolding los ntawm Tuam Tshoj muaj keeb kwm ntev ntawm kev tsim cov khoom zoo rau kev xa tawm. Qhov tseeb, qee qhov khoom tsim tau zoo tshaj plaws hauv ntiaj teb los ntawm Tuam Tshoj! Thiab thaum nws los txog rau cov yas txhaj tshuaj molding, Tuam Tshoj yog ib lub teb chaws sophisticated tshaj plaws nyob rau hauv lub ntiaj teb no.

Kev txhaj tshuaj molding yog ib txoj hauv kev nrov los tsim cov khoom yas thiab cov khoom siv. DJmolding yog lub chaw tsim khoom zoo kom tau txais cov khoom ntim qis qis vim tias tus nqi ntawm kev ua haujlwm tsawg dua hauv Tebchaws Meskas lossis Europe. DJmolding muaj qhov tsawg kawg nkaus txiav txim kom muaj nuj nqis (MOQs) tsuas yog 1,000 daim thiab coj lub sij hawm luv luv li 3-4 lub lis piam. Qhov no tuaj yeem pab tau zoo heev rau cov tuam txhab me me uas xav pib nrog lawv tus kheej cov khoom lag luam tab sis tsis xav nqis peev nyiaj ntau hauv cov cuab yeej thiab cov nqi tsim khoom ua ntej.

Yog li yuav ua li cas koj thiaj paub yog tias koj tab tom cuam tshuam nrog tus neeg muag khoom txhim khu kev qha? Koj yuav tsum tau saib cov ntsiab lus

Yam tsawg kawg nkaus Order Quantity (MOQ) - Tus neeg muag khoom muaj npe yuav tsis nug koj txog qhov kev txiav txim loj ua ntej lawv tseem muaj sijhawm ntsib koj lossis pom koj cov khoom. Hloov chaw, peb yuav xav kom paub tseeb tias koj mob siab rau koj qhov project ua ntej yuav siv sijhawm ntau dhau los lossis nyiaj txiag rau nws.

Lub Sijhawm Lead - Cov neeg muag khoom zoo tshaj plaws yuav muaj lub sijhawm ua haujlwm ceev kom lawv tuaj yeem xa koj cov khoom sai li sai tau (thiab tseem ua tau raws li cov qauv zoo).

Kev txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau cov khoom siv yas, tab sis yuav ua li cas yog tias koj xav tau qee qhov me me rau koj qhov project? Qhov ntawd yog qhov uas tsis tshua muaj ntim txhaj tshuaj molding tuaj rau hauv. Nws yog ib txoj hauv kev zoo los tsim cov khoom me me ntawm cov yas yam tsis tau tawg lub txhab nyiaj. Hauv tsab ntawv tshaj tawm no, peb yuav nkag mus rau hauv cov txiaj ntsig thiab kev siv ntawm cov ntim ntim qis, nws txawv li cas ntawm kev txhaj tshuaj molding siab, thiab nws yuav pab tau koj li cas.

Nkag siab Tsawg Volume Txhaj Molding

Tsawg ntim txhaj tshuaj molding yog txheej txheem tsim khoom uas tso cai rau kev tsim cov khoom yas me me. Nws yog ib qho kev daws teeb meem zoo thiab raug nqi rau cov tuam txhab uas xav tau kev tsim khoom me me lossis muaj peev nyiaj tsawg.

- Cov txheej txheem ntawm cov ntim tsawg txhaj tshuaj molding pib nrog tsim pwm. Feem ntau, cov tuam txhab tsim cov pwm los ntawm cov hlau los yog txhuas thiab tsim nws kom ua tiav cov duab ntawm cov yas uas xav tau. Thaum lub sij hawm txhaj tshuaj molding txheej txheem, manufacturers tuav ua ke ob halves ntawm pwm: kab noj hniav thiab cov tub ntxhais.

- Ua ntej txhaj tshuaj molding tshwm sim, cov khoom yas yog rhuab thiab melted nyob rau hauv ib tug cais chamber. Cov neeg tsim khoom txhaj cov yas rau hauv pwm nyob rau hauv siab siab thaum nws ncav cuag qhov xav tau kub. Cov yas ntim cov kab noj hniav thiab siv rau ntawm cov pwm.

- Tom qab cov yas tau txias thiab solidified, manufacturers qhib lub pwm thiab eject qhov tiav. Lub sij hawm lub voj voog rau cov ntim ntim qis yog luv luv, tso cai rau kev tsim khoom sai dua li lwm cov txheej txheem tsim khoom.

- Tsawg ntim txhaj tshuaj molding muaj ntau yam zoo. Firstly, nws yuav pab tau rau zus tau tej cov complex thiab intricate qhov chaw nrog high precision thiab repeatability. Kev lag luam uas xav tau cov khoom siv nyuaj, xws li tsheb, hluav taws xob, thiab cov khoom siv kho mob, yuav muaj txiaj ntsig zoo los xaiv qhov kev xaiv no.

- Tsis tas li ntawd, qhov ntim tsawg txhaj tshuaj molding muab cov nqi txuag piv rau cov txheej txheem ntau lawm. Txij li thaum thawj zaug kev nqis peev hauv cov cuab yeej qis dua, nws yooj yim dua rau cov lag luam me lossis kev pib ua lag luam. Nws kuj tseem ua rau lub sijhawm ua lag luam sai dua, vim tias lub sijhawm ua cov cuab yeej siv luv dua.

- Lwm qhov txiaj ntsig ntawm kev txhaj tshuaj molding tsawg yog nws qhov yooj. Nws tso cai rau tsim kev hloov kho thiab rov ua dua yam tsis muaj nqi ntxiv. Tias yog vim li cas qhov kev hloov pauv tsim tau xav tau thaum lub sijhawm pib ua rau muaj txiaj ntsig zoo rau kev tsim khoom thiab kev tsim qauv.

- Txawm hais tias nws cov txiaj ntsig zoo, qhov ntim qis txhaj tshuaj molding muaj qee qhov kev txwv. Raws li lub npe qhia, nws tsis haum rau cov khoom ntim siab. Tus nqi ib feem tuaj yeem siab dua li cov txheej txheem ntau lawm vim yog tus nqi siab dua ntawm cov cuab yeej thiab teeb tsa. Yog li ntawd, nws yog tsim nyog rau me me mus rau nruab nrab ntau lawm khiav.

- Kev xaiv cov khoom kuj yog ib qho kev txiav txim siab nyob rau hauv cov ntim tsawg txhaj molding. Kev xaiv cov khoom siv tsawg yog muaj piv rau cov txheej txheem ntau lawm. Txawm li cas los xij, ntau cov ntaub ntawv thermoplastic, suav nrog ABS, polycarbonate, nylon, thiab polypropylene, tseem tuaj yeem siv tau.

- Ua haujlwm nrog kev paub txog thiab paub txog kev txhaj tshuaj molding chaw tsim khoom yog qhov tseem ceeb rau kev tsim cov ntim tsawg. Lawv tuaj yeem coj kev xaiv cov khoom, pwm tsim, thiab kev ua kom zoo tshaj plaws los xyuas kom meej cov txiaj ntsig zoo tshaj plaws.

Qhov zoo ntawm Tsawg Volume Txhaj Molding

Tsawg ntim txhaj tshuaj molding muaj ntau qhov zoo rau cov tuam txhab uas xav tau kev tsim khoom me me rau nruab nrab. Qee qhov txiaj ntsig tseem ceeb ntawm cov txheej txheem tsim khoom no suav nrog:

Tus nqi tsim khoom

- Kev nqis peev qis dua hauv kev siv cuab yeej piv rau cov txheej txheem tsim khoom lag luam ib txwm muaj. Nkag mus rau cov lag luam me lossis kev pib ua lag luam.

- Faster lub sij hawm-rau-kev ua lag luam vim lub sij hawm luv luv rau cov cuab yeej, txo tag nrho cov nqi tsim khoom.

Complex thiab meej qhov chaw

- Cov txheej txheem enables zus tau tej cov complex thiab intricate qhov chaw nrog high precision thiab repeatability. Zoo tagnrho rau kev lag luam xws li tsheb, khoom siv hluav taws xob, thiab cov khoom siv kho mob uas xav tau cov khoom siv sib txawv.

- Cov txheej txheem tso cai rau nruj tolerances thiab kev koom ua ke ntawm cov ntsiab lus zoo hauv kev tsim.

Tsim yooj

- Cov txheej txheem tso cai rau yooj yim tsim kev hloov kho thiab rov ua dua yam tsis muaj nqi ntxiv.

- Tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau kev tsim khoom thiab kev tsim qauv, qhov kev tsim kho thiab kho kom zoo nkauj yog tus qauv thaum lub sijhawm pib.

Khoom siv versatility

- Cov txheej txheem muaj ntau yam khoom siv thermoplastic, xws li ABS, polycarbonate, nylon, thiab polypropylene.

- Ua tau raws li cov cai tshwj xeeb thiab cov khoom xav tau ntawm cov khoom kawg.

Kev tsim khoom sai dua

- Cov txheej txheem boasts kuj luv luv lub sij hawm voj voog, enabling sai ntau lawm tshaj lwm yam manufacturing txheej txheem.

- Pab tau raws li lub sijhawm teem sijhawm los yog ua raws li kev xav tau ntawm kev lag luam sai.

- Txhim kho cov khoom tsim tau thiab muab sijhawm hloov pauv sai dua.

Txo cov pov tseg thiab kev cuam tshuam ib puag ncig

- Cov txheej txheem txo qis cov khoom pov tseg los ntawm kev siv cov yas tsim nyog xwb.

- Cov txheej txheem txo kev siv hluav taws xob thiab emissions piv rau cov txheej txheem ntau lawm.

- Environmentally-friendly manufacturing xaiv.

Zoo thiab sib xws

- Cov txheej txheem ua kom cov khoom zoo nrog qhov ntev thiab cov khoom zoo sib xws.

- Cov txheej txheem muab kev tswj hwm zoo tshaj qhov kub, siab, thiab txias hloov pauv.

- Kev ntseeg siab hauv kev lag luam uas cov khoom lag luam ua tau zoo thiab kev ntseeg tau yog qhov tseem ceeb.

Customization thiab personalization

- Cov txheej txheem muab lub sijhawm rau customization thiab personalization ntawm cov khoom.

- Kev tsim cov khoom tshwj xeeb raws li cov neeg siv khoom tshwj xeeb.

- Cov txheej txheem txhim kho cov khoom sib txawv thiab cov neeg siv khoom txaus siab.

Risk mitigation thiab kev sim ua lag luam

- Cov txheej txheem yog qhov kev xaiv qis dua rau kev tsim khoom tshiab lossis kev sim ua lag luam.

- Cov txheej txheem tsim cov khoom txwv rau kev sim, kev lees paub, thiab kev lag luam tawm tswv yim.

- Txo qhov kev pheej hmoo ntawm kev nqis peev hauv ntau qhov chaw uas yuav xav tau kev hloov kho lossis tsis ua raws li kev xav tau ntawm kev lag luam.

Tsawg Volume vs. High Volume Txhaj Molding

Koj tuaj yeem hloov kho kev txhaj tshuaj molding, ntau yam txheej txheem tsim khoom, kom haum rau ntau yam kev xav tau. Ob qho kev hloov pauv ntawm kev txhaj tshuaj molding yog qhov ntim tsawg thiab ntim siab. Cia peb sib piv ob txoj hauv kev no thiab tshawb nrhiav lawv qhov sib txawv:

Tsawg Volume Txhaj Molding

- Nws yog haum rau cov tuam txhab uas muag me me mus rau nruab nrab cov kev xav tau ntau lawm.

- Muab cov nqi tsim khoom, ua rau nws nkag mus rau cov lag luam me lossis kev pib ua lag luam.

- Cov txheej txheem yuav tsum tau nqis peev thawj zaug hauv kev siv cuab yeej piv rau cov khoom ntim siab.

- Tso cai rau lub sijhawm ua lag luam sai dua vim lub sij hawm luv luv rau cov cuab yeej, txo cov nqi tsim khoom tag nrho.

- Cov txheej txheem enables zus tau tej cov complex thiab intricate qhov chaw nrog high precision thiab repeatability.

- Muab kev tsim qauv yooj yim, tso cai rau kev hloov kho kev tsim qauv yooj yim thiab rov ua dua yam tsis muaj nqi ntxiv.

- Txhawb cov khoom siv ntau yam, muab ntau yam khoom siv thermoplastic kom tau raws li cov kev xav tau tshwj xeeb.

- Muab cov voj voog ntau lawm sai dua piv rau lwm cov txheej txheem tsim khoom, ua rau muaj txiaj ntsig ntau ntxiv thiab lub sijhawm luv luv.

- Txo cov khoom pov tseg los ntawm kev siv tsuas yog cov khoom tsim nyog ntawm cov yas, txo kev cuam tshuam ib puag ncig.

- Ua kom ntseeg tau cov khoom zoo nrog qhov ntev thiab cov khoom sib xws yog qhov tseem ceeb hauv kev lag luam uas cov khoom lag luam kev ua tau zoo thiab kev ntseeg siab yog qhov tseem ceeb.

- Muaj kev xaiv customization thiab personalization, tso cai rau kev tsim cov khoom tshwj xeeb raws li cov neeg siv khoom tshwj xeeb.

- Txo cov kev pheej hmoo thaum lub sij hawm tsim khoom tshiab thiab kev soj ntsuam kev lag luam, tso cai rau cov tuam txhab tsim cov khoom siv tsawg tsawg rau kev siv tau thiab cov lus tawm tswv yim ua ntej cog lus rau kev tsim khoom tag nrho.

High Volume Txhaj Molding

- Haum rau cov tuam txhab uas xav tau kev tsim khoom loj.

- Lub ntim ntau lawm muaj feem ntau pib peev hauv cov cuab yeej thiab pwm.

- Yuav tsum tau siv sij hawm ntev dua rau kev siv cuab yeej, uas yuav ncua sij hawm mus rau kev lag luam.

- Nws muab cov txiaj ntsig zoo vim kev lag luam ntawm cov nplai, vim tias qhov ntim ntau dua kis tus nqi ruaj khov dua cov chav loj.

- Cov txheej txheem ua kom muaj txiaj ntsig zoo ntawm cov khoom loj hauv lub sijhawm luv.

- Zoo tagnrho rau kev lag luam nrog cov khoom lag luam siab thiab tsim kev lag luam muaj nyob.

- Nws tuaj yeem muab ntau qhov kev xaiv ntawm cov khoom siv nqaim dua piv rau cov ntim qis qis.

- Yuav tsum tau ua tib zoo npaj thiab kev kwv yees kom ua kom zoo tshaj plaws ntawm kev tsim khoom thiab txo cov khoom pov tseg.

- Cov txheej txheem txhawb kev tswj kom zoo ib yam thiab ua raws li cov lus qhia tshwj xeeb thoob plaws hauv cov txheej txheem ntau lawm.

- Muab cov qauv tsim kom yooj yim, vim tias kev hloov pauv tsim yuav ua rau muaj nqi ntxiv.

Daim ntawv thov ntawm Tsawg Volume Txhaj Molding

Tsawg ntim txhaj tshuaj molding yog txheej txheem tsim khoom ntau yam uas pom cov ntawv thov thoob plaws ntau yam kev lag luam. Nws lub peev xwm los muab cov nqi tsim nyog, tsim kev yooj yim, thiab kev xaiv kev hloov kho ua rau nws haum rau ntau daim ntawv thov. Cia peb tshawb txog qee yam kev siv ntawm cov ntim qis txhaj tshuaj molding:

Automotive kev lag luam

- Kev tsim khoom ntawm cov khoom sib txawv thiab meej rau kev siv tsheb sab hauv, sab nrauv, thiab hauv qab-lub-hood siv.

- Kev tsim cov kev cai dashboard panels, trim pieces, knobs, thiab keyboards.

- Prototyping thiab tsim cov khoom tshwj xeeb hauv tsheb nrog cov khoom siv tshwj xeeb.

- Tsim cov cua vents, ducts, thiab connectors rau tsheb HVAC systems.

Electronics thiab Hluav Taws Xob Kev Lag Luam

- Kev tsim cov khoom sib txawv rau cov neeg siv khoom siv hluav taws xob xws li smartphones, ntsiav tshuaj, thiab laptops.

- Kev tsim cov connectors, vaj tse, thiab enclosures rau cov khoom siv hluav taws xob.

- Customization ntawm keypads, nyees khawm, thiab keyboards nrog ntau yam textures thiab xim.

- Kev tsim cov khoom siv hluav taws xob sib txuas thiab cov qhov (socket) rau cov cuab yeej siv khoom lag luam.

- Prototyping thiab zus tau tej cov microelectromechanical systems (MEMS) li.

Kev Kho Mob thiab Kev Kho Mob Kev Lag Luam

- Kev tsim cov khoom siv kho mob xws li cov phom syringe, IV connectors, thiab cov cuab yeej phais.

- Kev tsim cov khoom siv kho mob rau cov khoom siv kho mob thiab cov cuab yeej kuaj mob.

- Prototyping thiab zus tau tej cov biocompatible qhov chaw rau kev kho mob implants thiab prosthetics.

- Kev tsim cov tshuaj xa khoom thiab cov khoom ntim khoom.

- Kev tsim cov khoom siv kho hniav xws li cov tais kev cai, orthodontic aligners, thiab cov lus qhia kev phais.

Cov Neeg Siv Khoom

- Customization ntawm cov khoom siv xws li cov khoom ua si, cov khoom siv hauv tsev, thiab cov khoom tu tus kheej.

- Kev tsim cov khoom ntim tshwj xeeb nrog cov khoom lag luam.

- Kev tsim cov khoom me me ua haujlwm rau cov khoom lag luam tsawg lossis cov lag luam niche.

- Kev tsim cov khoom zoo nkauj thiab cov khoom siv zoo nkauj rau cov khoom dai hauv tsev.

- Tsim cov khoom lag luam customized txhawb nqa thiab muab khoom plig.

Muaj Khoom Siv

- Prototyping thiab tsim cov khoom tshwj xeeb rau kev lag luam machinery thiab khoom siv.

- Kev tsim cov cuab yeej cuab tam, jigs, thiab fixtures.

- Customization ntawm cov khoom siv khoom lag luam kom tau raws li cov kev xav tau tshwj xeeb.

- Kev tsim cov khoom siv ruaj khov thiab ua haujlwm siab rau kev siv hnyav.

- Tsim cov npog tiv thaiv, tiv thaiv, thiab mounts rau tshuab.

Cov kev ua si thiab ua si

- Kev tsim khoom ntawm cov khoom siv xws li tes tuav, tuav, thiab cov iav tiv thaiv.

- Kev tsim cov khoom siv rau cov tsheb kauj vab, kayaks, thiab lwm yam khoom ua si.

- Tsim cov khoom tshwj xeeb rau cov khoom siv dag zog.

- Prototyping thiab tsim cov khoom siv rau cov khoom ua si sab nraum zoov.

Kev lag luam uas tau txais txiaj ntsig los ntawm Tsawg Volume Txhaj Molding

Tsawg ntim txhaj tshuaj molding muaj qhov zoo rau ntau qhov kev lag luam, suav nrog cov khoom siv kho mob, aerospace, tsheb, hluav taws xob, khoom siv, khoom siv hauv tsev, kev tsim qauv, cov khoom tshwj xeeb, thiab cov khoom hloov pauv. Cov txheej txheem tsim khoom ntau yam no ua rau muaj txiaj ntsig zoo ntawm cov khoom me me, ua kom muaj kev tsim kho tshiab, kev tsim kho tshiab, thiab kev tsim khoom zoo.

- Cov cuab yeej kho mob:Tsawg ntim txhaj tshuaj molding yog qhov zoo tagnrho rau kev tsim cov khoom siv kho mob thiab cov khoom siv nrog cov lus qhia meej. Nws tso cai rau tus nqi tsim nyog ntawm cov khoom me me, ua rau cov tuam txhab kho mob kom tau raws li cov neeg mob sib txawv.

- Aerospace:Kev lag luam aerospace yuav tsum muaj qhov nyuaj nrog kev ua haujlwm siab thiab cov qauv nruj. Tsawg ntim txhaj tshuaj molding ua rau tsim cov khoom hnyav, cov khoom siv ruaj khov, txo qhov hnyav thiab txhim kho roj efficiency hauv aircraft.

- Automotive:Tsawg ntim txhaj tshuaj molding yog qhov tseem ceeb rau kev tsim qauv thiab tsim cov khoom siv tsheb tshwj xeeb. Nws tso cai rau cov tuam txhab lag luam kom nrawm nrawm thiab kho cov qauv tsim, kom ntseeg tau tias qhov kev ua tau zoo thiab kev ua haujlwm zoo ua ntej kev tsim tawm tag nrho.

- Electronics:Kev lag luam hluav taws xob tau txais txiaj ntsig los ntawm cov ntim qis qis rau kev tsim cov khoom sib txawv, xws li cov khoom sib txuas thiab cov casings. Cov txheej txheem no ua rau muaj txiaj ntsig zoo ntawm cov khoom me me, ua raws li qhov ceev ceev ntawm cov khoom siv hluav taws xob.

- Cov khoom siv: Tsawg ntim txhaj tshuaj molding yog qhov zoo rau kev tsim cov khoom lag luam customized nrog cov qauv tsim thiab nta. Nws ua kom sai sai ntawm cov khoom me me, ua kom yooj yim rau kev kuaj kev lag luam thiab kev kho kom haum raws li cov neeg siv khoom nyiam.

- Khoom siv: Tsawg ntim txhaj tshuaj molding tsim cov khoom siv hauv kev lag luam, xws li iav, li qub, thiab vaj tse. Cov txheej txheem no tso cai rau tus nqi tsim khoom ntawm cov khoom me me, ua tau raws li cov kev cai tshwj xeeb ntawm cov ntawv thov kev lag luam.

- Prototyping thiab Product Development: Cov tuam txhab lag luam dav siv cov ntim qis qis hauv cov txheej txheem prototyping thiab cov khoom tsim kho. Nws muab tus nqi tsim nyog los tsim cov qauv tsim ua haujlwm, ua kom muaj kev pov thawj tsim, kuaj, thiab kho kom zoo ua ntej ntau lawm.

- Cov khoom tshwj xeeb: Ntau lub niche industries yuav tsum tau tshwj xeeb qhov chaw tsis tsim nyob rau hauv loj. Tsawg ntim txhaj tshuaj molding muaj cov kev daws teeb meem rau kev tsim cov khoom tshwj xeeb no tau zoo, ua raws li kev xav tau ntawm kev lag luam tshwj xeeb.

- Hloov Chaw:Tsawg ntim txhaj tshuaj molding yog qhov zoo rau kev tsim khoom hloov pauv rau ntau yam kev lag luam. Nws tso cai rau kev xav tau ntawm cov khoom me me, ua kom muaj kev ruaj khov ntawm cov khoom tseem ceeb yam tsis xav tau cov khoom muag loj.

Hom Cov Khoom Siv Hauv Cov Khoom Siv Hluav Taws Xob Tsawg

Tsawg ntim txhaj tshuaj molding siv ntau yam ntaub ntawv kom haum rau ntau hom kev tsim khoom.

- Thermoplastics: Thermoplastics yog cov khoom siv ntau tshaj plaws hauv kev txhaj tshuaj molding tsawg. Lawv tuaj yeem yaj, txias, thiab rov ua dua ntau zaus yam tsis tau hloov pauv lawv cov khoom. Piv txwv ntawm cov thermoplastics muaj xws li polyethylene (PE), polypropylene (PP), polystyrene (PS), thiab polycarbonate (PC).

- Elastomers:Elastomers, tseem hu ua cov ntaub ntawv zoo li roj hmab, tsim cov khoom siv tau yooj yim hauv cov ntim ntim qis. Lawv muab cov elasticity zoo, resilience, thiab cuam tshuam tsis kam. Cov qauv elastomers suav nrog silicone, polyurethane (PU), thiab thermoplastic elastomers (TPE).

- Engineering Plastics:Engineering plastics yog cov khoom siv ua haujlwm siab uas nthuav tawm cov khoom tshwj xeeb, thermal, thiab tshuaj lom neeg. Kev lag luam dav siv rau lawv qhov chaw muaj zog thiab ruaj khov. Qee cov khoom siv hluav taws xob ntau hauv cov yas txhaj tshuaj tsawg yog acrylonitrile butadiene styrene (ABS), nylon (PA), polyethylene terephthalate (PET), thiab polyoxymethylene (POM).

- Biodegradable thiab Sustainable Materials: Nrog rau kev loj hlob ntawm qhov tseem ceeb ntawm kev ruaj khov, qhov ntim qis qis kuj tseem siv cov khoom siv biodegradable thiab ruaj khov. Cov ntaub ntawv no tuaj yeem muab tau los ntawm cov peev txheej txuas ntxiv mus thiab muab cov txiaj ntsig ib puag ncig. Piv txwv xws li polylactic acid (PLA), bio-based polyethylene (PE), thiab bio-based polypropylene (PP).

- Hlau thiab Ceramic Hmoov: Ntxiv nrog rau cov khoom siv yas, qhov ntim qis qis tuaj yeem siv cov hlau thiab cov hmoov ceramic los tsim cov hlau lossis cov khoom siv ceramic. Cov txheej txheem, hu ua hlau txhaj tshuaj molding (MIM) lossis ceramic txhaj tshuaj molding (CIM), suav nrog cov hmoov sib xyaw nrog cov ntawv khi thiab txhaj rau hauv pwm. Tom qab ntawd, cov khoom tau txais kev debinding thiab sintering kom ua tiav lawv cov khoom kawg.

- Cov khoom siv sib xyaw:Cov khoom sib xyaw ua ke sib xyaw cov khoom sib txawv kom ua tiav cov khoom xav tau. Cov ntaub ntawv sib xyaw tuaj yeem txhim kho lub zog, nruj, lossis kub tsis kam nyob rau hauv qhov ntim qis txhaj tshuaj molding. Piv txwv li muaj xws li carbon fiber-reinforced polymers (CFRP), iav fiber-reinforced polymers (GFRP), thiab mineral-filled polymers.

- Liquid Silicone Rubber (LSR): LSR yog cov khoom siv tshwj xeeb rau kev tsim cov khoom hloov tau yooj yim, kub-resistant, thiab biocompatible qhov chaw. Nws yog qhov tshwj xeeb tshaj yog rau cov ntawv thov uas xav tau cov khoom sib khi zoo, xws li hauv kev kho mob thiab kev lag luam tsheb.

Tsawg Volume Txhaj Molding Ua Haujlwm li cas

Tsawg ntim txhaj tshuaj molding yog cov txheej txheem tsim khoom uas tau txais txiaj ntsig ntau yam kev lag luam thiab tso cai rau tsim cov khoom me me ntawm cov khoom siv. Nws koom nrog kev tsim thiab tsim cov pwm thiab kev npaj cov khoom uas yog tom qab ntawd yaj thiab txhaj rau hauv pwm kab noj hniav nyob rau hauv siab.

- Pwm Tsim:Cov txheej txheem pib nrog kev tsim thiab tsim cov pwm sib haum rau qhov xav tau qhov geometry. Cov pwm muaj ob sab, cov kab noj hniav thiab cov tub ntxhais, uas tsim cov duab ntawm qhov kawg thaum coj los ua ke.

- Kev npaj khoom siv: Cov khoom xaiv, feem ntau nyob rau hauv daim ntawv ntawm pellets, yog loaded rau hauv lub hopper thiab pub rau hauv lub tshuab txhaj tshuaj molding. Tom qab ntawd, lub plhaub yog rhuab thiab yaj mus rau lub xeev molten.

- Kev Txhaj Tshuaj:Cov khoom molten yog txhaj rau hauv pwm kab noj hniav nyob rau hauv siab siv ib tug reciprocating ntsia hlau los yog ib tug plunger. Lub siab no ua kom cov khoom ntim tag nrho cov ntsiab lus sib txawv ntawm cov pwm thiab tswj nws cov duab thaum lub sij hawm solidification.

- Cooling thiab Solidification:Tom qab sau cov pwm kab noj hniav, cov khoom molten raug tso cai kom txias thiab khov rau hauv pwm. Cov cua txias sib xyaw ua ke rau hauv pwm dissipate tshav kub thiab ua kom cov txheej txheem solidification.

- Pwm Qhib thiab Ejection:Cov pwm qhib thaum cov khoom muaj txaus solidified, cais ob halves. Ejector pins los yog daim hlau thawb ib feem tawm ntawm lub pwm kab noj hniav, mus rau hauv ib qho chaw sau, los yog mus rau ib txoj siv conveyor.

- Kev xaus:Qhov ejected ib feem tuaj yeem ua cov txheej txheem sib txawv kom ua tiav qhov kev xav tau saum npoo tiav thiab qhov tseeb qhov tseeb. Cov haujlwm no yuav suav nrog kev txiav cov khoom siv ntau dhau, tshem tawm flash lossis burrs, thiab ua haujlwm theem nrab xws li machining lossis pleev xim.

- Rov ua txheej txheem:Cov pwm kaw, thiab lub voj voog rov ua dua los tsim cov ntu tom ntej. Tsawg ntim txhaj tshuaj molding tso cai rau ntau yam iterations thiab hloov kho pwm thiab txheej txheem, ua kom yooj yim rau kev tsim khoom thiab tsim kev txhim kho.

- Kev Tswjhwm Zoo:Kev tswj xyuas kev ua tau zoo yog siv thoob plaws hauv cov txheej txheem los xyuas kom meej cov khoom tsim tau raws li qhov yuav tsum tau ua. Cov dej num no yuav suav nrog kev tshuaj xyuas tsis tu ncua, ntsuas qhov ntsuas, thiab ntsuas kev ua haujlwm.

- Scalability:Tsawg ntim txhaj tshuaj molding feem ntau tsom rau kev tsim cov khoom me me, tab sis nws tseem tuaj yeem ua lub pob zeb rau kev tsim khoom loj dua.Cov tuam txhab tuaj yeem ua kom zoo dua cov txheej txheem rau ntau dua yog tias xav tau nce los ntawm kev siv cov tshuab loj lossis ntau lub pwm.

Hom Tsawg Volume Txhaj Moulding Tshuab

Ntau lub tshuab txhaj tshuaj molding tshuab muaj ntau yam thiab tsim los ua kom haum rau kev tsim khoom sib txawv. Cov yam ntxwv xws li cov khoom siv, qhov nyuaj ntawm kev tsim ib feem, thiab qhov xav tau precision thiab efficiency txiav txim siab qhov kev xaiv ntawm lub tshuab. Kev xaiv lub tshuab kom raug yog qhov tseem ceeb rau kev ua tiav cov txiaj ntsig xav tau thiab ua kom muaj txiaj ntsig zoo hauv kev tsim khoom.

- Hydraulic Machinery:Hydraulic tsawg ntim txhaj tshuaj molding tshuab siv hydraulic twj los tsim lub siab xav tau rau txhaj cov khoom rau hauv pwm kab noj hniav. Lawv tuaj yeem tsim cov khoom siv nrog kev ua haujlwm siab thiab rov ua dua thiab tuav ntau yam ntaub ntawv.

- Cov tshuab hluav taws xob:Lub tshuab hluav taws xob tsawg ntim txhaj tshuaj molding tshuab siv lub tshuab hluav taws xob tsis siv cov twj hydraulic los tsav cov txheej txheem txhaj tshuaj. Lawv muab kev siv zog ntau dua, txo kev txij nkawm, thiab ua haujlwm ntsiag to dua li cov tshuab hydraulic.

- Hybrid Machinery:Hybrid low volume txhaj molding tshuab muab cov txiaj ntsig ntawm ob qho tib si hydraulic thiab hluav taws xob. Lawv ua ke hydraulic thiab hluav taws xob tsav, txhim kho precision, zog efficiency, thiab txo suab nrov.

- Vertical Machinery:Vertical low volume txhaj molding tshuab siv lub ntiajteb txawj nqus los pub cov khoom rau hauv pwm kab noj hniav, thiab cov pwm yog mounted vertically. Lawv yog qhov zoo tagnrho rau kev tsim cov khoom nrog cov geometry nyuaj thiab tuaj yeem txuag chaw hauv pem teb hauv cov chaw tsim khoom.

- Micro-Molding Tshuab:Micro-molding uas tsis tshua muaj ntim txhaj tshuaj molding tshuab yog tsim tshwj xeeb rau kev tsim cov khoom nrog qhov me me thiab siab precision. Lawv siv cov cuab yeej tshwj xeeb kom ua tiav cov txiaj ntsig xav tau, suav nrog cov tshuab txhaj tshuaj thiab micro-pwm kab noj hniav.

- Multi-Shot Machines:Multi-shot low volume txhaj tshuaj molding tshuab siv ntau qhov kev txhaj tshuaj los tsim cov khoom nrog ntau yam khoom lossis xim. Qhov kev muaj peev xwm no tso cai rau tsim qhov nyuaj nrog sib txawv textures thiab tiav.

- Cleanroom Machinery:Cov neeg tsim qauv tsim cov tshuab ntxhua khaub ncaws uas tsis tshua muaj ntim rau hauv cov chaw tsis muaj menyuam, xws li chaw kho mob lossis chaw tsim tshuaj. Cov neeg tsim khoom tsim lawv los ntawm cov ntaub ntawv uas yooj yim los ntxuav, ntxuav, thiab sib xyaw ua ke kom txo tau cov kab mob sib kis.

Yam Tseem Ceeb Uas Muaj Feem Tsawg Volume Txhaj Molding

Ntau yam cuam tshuam rau qhov tshwm sim thiab kev ua tau zoo ntawm cov ntim qis txhaj tshuaj molding. Xav txog cov xwm txheej no thiab ua kom zoo rau txhua qhov ntawm cov txheej txheem yuav pab ua kom muaj kev vam meej tsawg ntim txhaj tshuaj molding ntau lawm.

- Kev txiav txim siab tsim:Cov qauv tsim ua lub luag haujlwm tseem ceeb hauv kev txhaj tshuaj molding tsawg. Tej yam xws li phab ntsa thickness, lub kaum sab xis, thiab undercuts 'muaj cuam tshuam rau ib feem ntawm moldability thiab tag nrho cov zoo. Cov qauv tsim zoo nrog cov duab geometry zoo tuaj yeem pab ua tiav cov txiaj ntsig zoo dua.

- Kev xaiv khoom siv:Kev xaiv cov khoom siv rau kev txhaj tshuaj molding tsawg yog qhov tseem ceeb. Cov ntaub ntawv sib txawv muaj cov khoom sib txawv, xws li cov yam ntxwv ntawm cov dej ntws, cov nqi shrinkage, thiab kub rhiab heev. Cov khoom tsim nyog uas ua tau raws li qhov yuav tsum tau ua thiab xav tau kev zoo nkauj yog qhov tseem ceeb rau kev ua tiav molding.

- Pwm Tsim thiab Kev Tsim Kho:Kev tsim thiab kev tsim cov pwm ncaj qha cuam tshuam rau qhov zoo thiab qhov ua tau ntawm qhov ntim qis txhaj tshuaj molding. Txhawm rau kom ua tiav qhov ntim, txias, thiab ejection, ib qho yuav tsum ua tib zoo xav txog cov khoom siv pwm, cov cua txias, qhov cua, thiab qhov rooj kaw lus.

- Txheej txheem Parameter:Rau kev txhaj tshuaj molding tsawg, ib qho yuav tsum ua kom zoo dua ntau yam txheej txheem, suav nrog kev txhaj tshuaj nrawm, kub, siab, thiab lub sijhawm txias. Nrhiav qhov sib npaug ntawm cov kev ntsuas no yog qhov tseem ceeb rau kev ua tiav qhov zoo tshaj plaws, txo qhov tsis xws luag, thiab ua kom muaj kev tsim khoom zoo ib yam.

- Kev Tswjhwm Zoo:Ua raws li kev tswj xyuas zoo thoob plaws hauv cov txheej txheem txhaj tshuaj molding tsawg yog qhov tseem ceeb. Kev tshuaj xyuas tsis tu ncua, kev kuaj xyuas qhov ntev, thiab kev sim ua haujlwm pab txheeb xyuas thiab daws cov teeb meem lossis qhov tsis xws luag thaum ntxov, kom ntseeg tau tias cov khoom tsim tau raws li qhov xav tau tshwj xeeb.

- Tooling thiab Equipment Maintenance:Kev saib xyuas tsis tu ncua thiab kev tu lub tshuab txhaj tshuaj molding thiab cov pwm tsim nyog rau kev tsim khoom zoo ib yam. Kev tu kom zoo, lubrication, thiab tshuaj xyuas cov cuab yeej thiab cov pwm tuaj yeem pab tiv thaiv kev tawg, txo qis sijhawm, thiab ua kom cov cuab yeej siv tau ntev.

- Ntau lawm ntim:Txawm hais tias cov tuam ntxhab tsim cov ntim ntim qis rau cov khoom me me, cov ntim ntau lawm tseem tuaj yeem cuam tshuam rau yam xws li tus nqi ib feem, lub sijhawm ua haujlwm, thiab cov cuab yeej xaiv. Nkag siab txog qhov xav tau ntau lawm yog qhov tseem ceeb rau kev txhim kho cov txheej txheem thiab xaiv cov tswv yim tsim khoom tsim nyog.

- Kev txiav txim siab nqi: Tus nqi ntawm kev txhaj tshuaj molding tsawg suav nrog ntau yam, suav nrog cov nqi khoom siv, cov nqi tsim pwm, kev teeb tsa lub tshuab thiab cov nqi khiav lag luam, thiab cov nuj nqis tom qab ua tiav. Kev ntsuas tus nqi-ua tau zoo nrog qhov xav tau zoo thiab kev ua haujlwm ntawm cov khoom yog qhov tseem ceeb rau kev ua tiav cov ntim qis.

Kev txiav txim siab tsim qauv rau Kev Txhaj Tshuaj Molding Tsawg

Kev tsim cov khoom siv rau cov ntim qis qis yuav tsum tau ua tib zoo xav txog ntau yam. Cov no suav nrog:

Phab Ntsa Thickness

- Kev tswj kom zoo ib yam thiab tsim nyog phab ntsa yog qhov tseem ceeb

- Cov phab ntsa tuab tuaj yeem ua rau lub sijhawm txias dua thiab muaj peev xwm warping.

- Cov phab ntsa nyias tuaj yeem ua rau lub zog tsis zoo.

- Kev tsim qauv nrog cov phab ntsa tuab tuab ua kom cov khoom ntws zoo thiab pom qhov zoo.

Draft Angles

- Kev sib xyaw cov kaum sab xis hauv qhov tsim yog qhov tseem ceeb rau qhov yooj yim ejection

- Cov kaum sab xis tso cai rau kev tshem tawm ntawm qhov tsis muaj kev puas tsuaj.

- Lub kaum sab xis tsim nyog pab tiv thaiv kev ua kom zoo thiab ua kom muaj txiaj ntsig zoo.

Undercuts thiab Side Actions

- Kev txo qis qis qis thiab ua haujlwm sab yog pom zoo

- Undercuts ua rau ejection nyuaj thiab tej zaum yuav xav tau complex pwm tsim los yog lwm yam hauj lwm.

- Simplifying ib feem geometry thiab tsis txhob intricate nta txhim kho moldability thiab txo cov nqi.

Qhov Chaw Qhov Chaw

- Kev tso chaw zoo ntawm lub rooj vag yog qhov tseem ceeb rau kev pom cov khoom ntws thiab txo qhov tsis xws luag

- Qhov chaw ntawm lub rooj vag cuam tshuam rau qhov zoo li, lub zog, thiab kev ua tsov rog.

- Muab cov rooj vag ntawm qhov chaw tsim nyog txhim kho qhov zoo thiab zoo nkauj.

Parting Line thiab Parting Surface

- Kev txhais cov kab uas tsim nyog thiab qhov chaw yog qhov tsim nyog rau kev tsim pwm thiab kev sib dhos

- Ib txoj kab uas huv thiab zoo-txhais tau muab faib ua kom yooj yim rau kev tsim pwm thiab txo qhov kev pheej hmoo ntawm qhov tsis xws luag.

Ribs thiab Bosses

- Kev sib xyaw cov tav thiab cov thawj coj txhim kho cov qauv kev ncaj ncees thiab kev ua haujlwm

- Ribs muab lub zog thiab nruj rau nyias ntu.

- Cov thawj coj ua haujlwm raws li cov ntsiab lus txuas lossis ntxig rau cov haujlwm thib ob.

Surface Finish thiab Texture

- Xav txog qhov xav tau qhov chaw tiav thiab kev ntxhib los mos yog qhov tseem ceeb

- Pwm kho los yog kab noj hniav zoo nkauj tuaj yeem ua tiav qhov chaw du lossis textured.

- Kev xaiv kom raug thiab kev sib txuas lus ntawm cov txheej txheem saum npoo av ua rau muaj kev xav zoo nkauj thiab kev ua haujlwm.

Tolerance thiab Dimensional Accuracy

- Kev qhia kom tsim nyog kam rau ua thiab qhov tseeb qhov tseeb yog qhov tseem ceeb

- Kev nkag siab txog qhov muaj peev xwm ntawm qhov ntim qis qis yog qhov tseem ceeb.

Los ntawm kev xav txog cov qauv tsim, cov tuam ntxhab tuaj yeem ua kom zoo dua qhov ntim qis txhaj tshuaj molding, uas ua rau cov khoom zoo, cov khoom tsim tau zoo, thiab cov nqi tsim nyog.

Kev Tswjhwm Zoo nyob rau hauv Tsawg Volume Txhaj Molding

Kev tswj kev ua tau zoo yog qhov tseem ceeb hauv kev txhaj tshuaj tsawg tsawg kom ntseeg tau tias cov khoom siv tau zoo uas ua tau raws li qhov yuav tsum tau ua. Nov yog qee yam tseem ceeb los txiav txim siab rau kev tswj xyuas kom zoo hauv cov ntim qis txhaj tshuaj molding:

- Kev Tshawb Fawb thiab Kev Xeem:Kev tshuaj xyuas tsis tu ncua thiab kev sim thoob plaws hauv kev tsim khoom pab txheeb xyuas qhov tsis xws lossis teeb meem thaum ntxov. Txhawm rau kom cov khoom ua tau raws li cov lus qhia tshwj xeeb, ib tus yuav tsum ua qhov ntsuas qhov ntsuas, ntsuas qhov pom, thiab ntsuas kev ua haujlwm.

- Cov ntaub ntawv pov thawj: Ua kom ntseeg tau qhov zoo thiab sib xws ntawm cov khoom siv hauv cov ntim ntim qis yog qhov tseem ceeb heev. Kev txheeb xyuas cov ntaub ntawv suav nrog kev tshuaj xyuas cov khoom siv, xws li yaj ntws, viscosity, thiab xim, kom paub meej tias lawv phim cov kev xav tau tshwj xeeb.

- Pwm Maintenance:Kev saib xyuas kom zoo thiab kev tu cov pwm yog qhov tseem ceeb rau kev tsim khoom zoo ib yam thiab zoo. Kev tu tsis tu ncua, lubrication, thiab tshuaj xyuas cov pwm tuaj yeem pab tiv thaiv qhov tsis xws luag, txo qis sijhawm, thiab txuas ntxiv lub neej ntawm cov pwm.

- Txheej Txheem Saib Xyuas:Kev soj ntsuam tas li ntawm cov txheej txheem txhaj tshuaj molding tsis yog qhov tseem ceeb rau kev tswj kom zoo. Nws yog ib qho tsim nyog los saib xyuas qhov sib txawv xws li qhov kub thiab txias, siab, thiab lub sijhawm voj voog kom ntseeg tau tias lawv nyob hauv qhov chaw teev tseg thiab txheeb xyuas qhov sib txawv lossis qhov txawv txav.

- Statistical Process Control (SPC):Kev siv cov txheej txheem SPC pab saib xyuas thiab tswj qhov sib txawv ntawm cov txheej txheem tsim khoom. Nws suav nrog kev sau thiab tshuaj xyuas cov ntaub ntawv los ntawm cov txheej txheem tsim khoom txhawm rau txheeb xyuas cov xwm txheej, cov qauv, thiab cov peev txheej ntawm kev hloov pauv, tso cai rau kev hloov kho thiab kev txhim kho.

- Kev Kho thiab Tiv Thaiv Kev Ua Haujlwm:Kev ua raws li kev kho thiab kev tiv thaiv yog qhov tseem ceeb rau kev daws teeb meem zoo lossis tsis ua raws. Thaum txheeb xyuas qhov tsis xws luag lossis kev sib txawv, pab neeg tam sim ntawd sim kho lawv thiab tiv thaiv lawv qhov rov tshwm sim, ua kom muaj kev txhim kho txuas ntxiv hauv cov txheej txheem tsim khoom.

- Cov ntaub ntawv thiab Traceability:Kev tuav cov ntaub ntawv kom raug thiab traceability ntawm cov txheej txheem ntau lawm yog qhov tseem ceeb rau kev tswj kom zoo. Txhawm rau pab txhawb kev tawm mus thiab kev ntsuas kev ua kom zoo, tshuaj xyuas cov txheej txheem, thiab cov ntaub ntawv tshuaj xyuas, thiab cov ntaub ntawv cov ntaub ntawv ntawm txhua qhov tsim tawm, yog qhov tseem ceeb.

- Supplier Quality Management:Ua kom ntseeg tau qhov zoo ntawm cov khoom thiab cov khoom siv los ntawm cov neeg muab khoom yog qhov tseem ceeb. Tsim kom muaj cov txheej txheem tswj xyuas cov khoom lag luam zoo, suav nrog kev tsim nyog, kev ntsuam xyuas, thiab kev saib xyuas tsis tu ncua, pab xyuas kom muaj kev siv cov khoom siv zoo hauv kev tsim khoom.

Los ntawm kev siv cov kev tswj xyuas zoo, cov tuam txhab tsim khoom tuaj yeem tsim cov khoom zoo, zoo ib yam, thiab txhim khu kev qha los ntawm kev txhaj tshuaj molding tsawg.

Tooling rau Tsawg Volume Txhaj Molding

Cov cuab yeej siv rau kev txhaj tshuaj molding tsawg yuav tsum tau ua tib zoo xav txog kev xaiv cov khoom pwm, tsim, tsim, kho, kho, ntxig, ntsuas, thiab khaws cia.

Pwm Khoom Xaiv

Xaiv cov khoom siv pwm tsim nyog yog qhov tseem ceeb rau kev txhaj tshuaj tsawg tsawg. Xav txog tej yam xws li durability, kub tsis kam, thiab compatibility thaum xaiv cov khoom. Cov khoom siv pwm muaj xws li steel alloys, aluminium alloys, thiab cov ntaub ntawv sib xyaw.

Pwm Tsim

Tsim cov pwm rau kev txhaj tshuaj pwm tsawg yuav tsum tau ua tib zoo xav txog yam xws li ib feem geometry, qhov rooj kaw lus, cua txias, thiab ejection mechanism.

- Qhov zoo tshaj plaws geometry pab txhawb kom tsim nyog filling, txias, thiab ejection ntawm ib feem.

- Lub rooj vag tsim tau zoo ua kom cov khoom siv tau zoo thiab txo qhov tsis xws luag.

- Tsim kom raug cov cua txias raws pab tswj lub voj voog lub sij hawm thiab xyuas kom zoo ib feem zoo.

- Ib tug zoo ejection mechanism tso cai rau kom yooj yim tshem tawm ib feem ntawm lub pwm.

Kev tsim pwm

Ua cov pwm tsim nrog precision thiab ua tib zoo saib kom meej.

- Cov kws tshaj lij cov cuab yeej siv machining, CNC milling, thiab EDM (Electrical Discharge Machining) cov txheej txheem los tsim cov pwm pwm.

- Ua tib zoo sib dhos thiab sib dhos ntawm cov pwm pwm yog qhov tseem ceeb rau kev ua haujlwm zoo thiab ua haujlwm zoo.

Pwm Kho thiab kho

Kev saib xyuas tsis tu ncua thiab kho raws sijhawm ntawm cov pwm yog qhov tseem ceeb kom ntseeg tau tias lawv lub neej ntev thiab kev ua haujlwm zoo ib yam.

- Cov neeg ua haujlwm yuav tsum ua haujlwm tu, lubrication, thiab tshuaj xyuas kom tsis txhob muaj teeb meem thiab txhim kho kev tsim khoom.

- Kev kho tam sim ntawm kev puas tsuaj lossis hnav hauv cov pwm pwm pab kom tsis txhob muaj qhov tsis xws luag thiab kev cuam tshuam ntau lawm.

Pwm Inserts thiab Interchangeable Cheebtsam

Kev siv cov pwm ntxig thiab cov khoom sib hloov tau tso cai rau kev hloov pauv tau yooj yim thiab siv tau zoo hauv cov ntim ntim qis.

- Cov neeg khiav dej num tuaj yeem hloov kho lossis hloov cov ntaub ntawv los hloov kho cov qauv kev hloov pauv lossis lwm yam kev xav tau - kev hloov pauv ntawm ntu.

- Cov khoom sib pauv hloov tau ua rau cov pwm hloov pauv sai, txo qis sijhawm thiab nce kev ua haujlwm ntau lawm.

Mould Testing thiab Validation

Kev soj ntsuam zoo thiab kev siv tau ntawm cov pwm yog qhov tseem ceeb ua ntej pib tsim khoom.

- Peb ua cov kev sim pwm los txhim kho cov txheej txheem tsis zoo, xyuas kom muaj qhov zoo, thiab txheeb xyuas qhov tsim nyog hloov kho.

- Peb tuaj yeem ua pwm kev tsom xam thiab tshuab computer simulation los kwv yees thiab txhim kho cov txheej txheem molding.

Pwm Cia thiab Preservation

Kev khaws cia thiab khaws cia kom zoo yog qhov tseem ceeb los tswj kom zoo thiab ua haujlwm zoo thaum cov pwm tsis siv.

- Pwm yuav tsum tau muab khaws cia rau hauv qhov chaw tswj hwm kom tsis txhob muaj kev puas tsuaj los ntawm qhov kub thiab txias, av noo, thiab cov kab mob.

- Txawm tias nyob rau lub sijhawm tsis siv, cov neeg ua haujlwm yuav tsum tau kuaj xyuas thiab tu.

Cov tswv yim tsim nyog rau tus nqi qis rau kev txhaj tshuaj molding

Kev siv cov tswv yim zoo rau kev txhaj tshuaj molding tsawg yuav tsum muaj kev sib koom ua ke uas suav nrog pwm tsim, xaiv cov khoom siv, kev ua kom zoo dua qub, automation, thiab kev koom tes nrog cov neeg siv khoom. Los ntawm kev siv cov tswv yim no, cov tuam txhab tuaj yeem ua tiav cov txiaj ntsig zoo thaum txo cov nqi thiab ua kom muaj txiaj ntsig zoo tshaj plaws hauv lawv cov khoom lag luam qis.

- Kev tsim pwm zoo:Kev tsim cov pwm zoo rau kev txhaj tshuaj tsawg tsawg tuaj yeem txo cov nqi. Simplifying lub pwm tsim thiab txo tus naj npawb ntawm cov kab noj hniav tuaj yeem txo cov nqi cuab yeej thiab txo lub sijhawm ntau lawm.

- Kev xaiv cov khoom siv:Xaiv cov khoom tsim nyog yog qhov tseem ceeb rau tus nqi qis-ntim txhaj tshuaj molding. Kev xaiv cov resins uas tsis tshua kim los yog tshawb nrhiav lwm cov ntaub ntawv uas ua tau raws li qhov xav tau tshwj xeeb tuaj yeem ua rau kom txuag tau nyiaj ntau yam tsis muaj kev cuam tshuam zoo.

- Automation thiab robotics:Kev siv automation thiab robotics hauv kev txhaj tshuaj molding tuaj yeem txhim kho kev ua haujlwm thiab txo cov nqi zog. Cov tshuab tsis siv neeg tuaj yeem ua haujlwm rov ua haujlwm dua, txo qhov ua yuam kev, thiab nce cov khoom tsim tawm, ua rau lawv zoo tagnrho rau cov khoom ntim qis.

- Txheej txheem optimization:Fine-tuning cov txheej txheem txhaj tshuaj molding tuaj yeem ua rau txo nqi. Kev txheeb xyuas thiab ua kom zoo dua qhov tsis zoo xws li qhov kub, qhov siab, thiab lub sijhawm voj voog tuaj yeem txo cov khoom pov tseg, txhim kho qhov zoo, thiab ua kom cov khoom tsim tau.

- On-demand manufacturing:Embracing on-demand manufacturing tso cai rau ntau yooj thiab nqi-zoo nyob rau hauv tsawg ntim txhaj molding. Los ntawm kev tsim cov khoom tsuas yog thaum xav tau, cov tuam txhab tuaj yeem zam dhau cov nqi khoom muag thiab txo qis kev pheej hmoo ntawm kev ploj mus.

- Lwm cov cuab yeej siv:Tshawb nrhiav lwm txoj kev xaiv, xws li 3D-luam pwm los yog cov cuab yeej mos, tuaj yeem raug nqi rau cov khoom ntim tsawg. Cov kev xaiv no feem ntau muaj cov nqi qis dua thiab cov sij hawm luv luv dua li cov pwm steel.

- Kev sib koom tes ntawm cov neeg muab khoom:Kev sib koom tes nrog kev ntseeg siab thiab paub txog kev txhaj tshuaj molding lwm tus tuaj yeem pab txhim kho cov nqi. Cov neeg muag khoom nrog cov kws tshaj lij hauv cov khoom ntim qis tuaj yeem muab cov kev pom zoo, qhia txog kev txuag nqi, thiab muab cov nqi sib tw ntawm cov khoom siv thiab cov cuab yeej.

- Post-processing optimization:Streamlining tom qab ua haujlwm, xws li trimming, sib dhos, thiab ua tiav, tuaj yeem txo cov nqi. Kev nqis peev hauv cov cuab yeej siv tau zoo tom qab ua tiav thiab cov txheej txheem tuaj yeem txo cov kev xav tau ntawm kev ua haujlwm thiab txo qis cov nqi ua haujlwm thib ob.

Cov txiaj ntsig ntawm Kev Siv 3D Printing rau Tsawg Volume Txhaj Molding

Kev siv 3D luam ntawv rau qhov ntim qis txhaj tshuaj molding muaj ntau yam zoo. Nws enables prototyping sai, tso cai rau kom ceev iterations thiab txo tus tsim yuam kev. 3D luam ntawv txo qis kev tsim khoom pov tseg thiab pab txo cov kev pheej hmoo los ntawm kev tso cai rau kev sim thiab kev siv tau ua ntej cog lus rau kev tsim tawm tag nrho.

- Rapid prototyping: 3D luam ntawv muaj qhov zoo ntawm kev tsim qauv sai, tso cai rau cov neeg tsim qauv rov ua dua thiab kho lawv cov khoom tsim sai. Txoj hauv kev no ua rau cov tuam txhab tuaj yeem nqa cov khoom lag luam sai dua thiab zam kev tsim khoom kim heev.

- Cost-effective tooling:3D luam ntawv tuaj yeem yog lwm txoj hauv kev siv nyiaj tsawg rau kev txhaj tshuaj molding tshuab. Los ntawm kev siv 3D-luam pwm los yog cov ntawv ntxig, cov tuam txhab tuaj yeem txuag tau ntawm cov nqi ua ntej ntawm cov pwm pwm, tshwj xeeb tshaj yog rau cov khoom me me.

- Tsim yooj yooj yim: 3D luam ntawv tso cai rau intricate thiab complex designs uas tej zaum yuav tsis ua tau nrog ib txwm machining txoj kev. Qhov kev hloov pauv no ua rau kev tsim khoom ntawm cov khoom siv tshwj xeeb thiab tshwj xeeb, catering rau cov neeg siv khoom tshwj xeeb.

- Txo cov sij hawm txhuas: Los ntawm kev siv 3D luam ntawv, cov tuam txhab lag luam tuaj yeem txo cov sij hawm ua hmoov txhuas piv rau cov qauv tsim khoom. Tsis muaj cov cuab yeej thiab lub peev xwm los tsim cov khoom raws li qhov xav tau ua kom cov txheej txheem ntau lawm, ua kom cov neeg siv khoom xa khoom sai.

- Khoom siv ntau yam:3D luam ntawv muaj ntau yam ntaub ntawv, nrog rau cov thermoplastics, resins, thiab composites. Cov khoom siv versatility no tso cai rau tsim qhov chaw nrog cov khoom sib txawv, ua raws li cov kev xav tau tshwj xeeb thiab kev zoo nkauj.

- Kev txo pov tseg:3D luam ntawv yog cov txheej txheem tsim khoom ntxiv, txhais tau tias nws tsuas yog siv cov khoom tsim nyog los tsim ib feem, ua rau cov khoom pov tseg tsawg heev. Txo cov nqi ntawm cov khoom siv kuj tseem pab txhawb kev txhawb nqa kev ruaj ntseg.

- Risk mitigation: Siv 3D luam ntawv rau kev txhaj tshuaj tsawg tsawg tso cai rau cov tuam txhab txo qis kev pheej hmoo cuam tshuam nrog kev nqis peev hauv cov cuab yeej kim rau cov qauv tsim tsis muaj pov thawj lossis kev xav tau ntawm kev lag luam tsis meej. Nws yuav ua kom muaj kev sim ua lag luam nrog cov khoom me me ua ntej cog lus rau kev tsim tawm tag nrho.

- Choj rau kev tsim khoom:3D luam ntawv tuaj yeem ua tus choj rau kev tsim khoom, tso cai rau cov tuam txhab kom siv tau sai sai rau lawv cov qauv tsim thiab sim ua haujlwm ntawm cov khoom ua ntej nqis peev hauv cov cuab yeej siv tshuaj kim heev. Kev txheeb xyuas qhov tsis zoo ntawm cov qauv tsim thaum ntxov tuaj yeem txuag cov nqi hauv lub sijhawm ntev.

Sustainability ntawm Tsawg Volume Txhaj Molding

Tsawg ntim txhaj tshuaj molding tuaj yeem yog qhov kev xaiv tsim khoom ruaj khov thaum mus txog nrog kev coj ua ib puag ncig.

- Khoom siv efficiency:Tsawg ntim txhaj tshuaj molding txhawb cov khoom siv tau zoo los ntawm kev tsim cov khoom tsim nyog, txo qis kev tsim khoom pov tseg. Txoj hauv kev no yuav pab txo qis kev cuam tshuam ib puag ncig cuam tshuam nrog kev siv cov khoom siv ntau dhau.

- Kev txuag hluav taws xob:Piv nrog rau cov txheej txheem ntim ntau lawm, cov ntim ntim qis qis siv lub zog tsawg dua vim qhov kev ua haujlwm luv luv thiab txo lub sijhawm ua haujlwm ntawm lub tshuab. Los ntawm kev ua li no, peb tuaj yeem txuag hluav taws xob thiab txo cov pa hluav taws xob hauv tsev cog khoom.

- Kev txo pov tseg:Tsawg ntim txhaj tshuaj molding tso cai rau cov khoom siv ntau lawm, txo qhov xav tau ntawm cov khoom muag ntau thiab txo cov khoom pov tseg. Cov tuam txhab lag luam tuaj yeem txo cov khoom pov tseg thiab cov nqi pov tseg los ntawm kev txhim kho kev npaj tsim khoom thiab kev kwv yees xav tau.

- Txoj hauv kev rov ua dua tshiab:Tsawg ntim txhaj tshuaj molding feem ntau siv cov khoom siv rov ua dua tshiab xws li cov thermoplastics. Peb tuaj yeem rov siv cov ntaub ntawv thiab txo qis kev cia siab ntawm cov peev txheej nkauj xwb los ntawm kev koom ua ke cov kev coj ua rov ua dua tshiab rau hauv cov txheej txheem tsim khoom. Kev koom ua ke cov kev coj ua rov ua dua tshiab rau hauv cov txheej txheem tsim khoom tso cai rau rov siv cov ntaub ntawv thiab txo kev cia siab rau cov peev txheej ntshiab.

- Sustainable khoom xaiv:Cov tuam txhab lag luam tuaj yeem ua ntej siv cov khoom siv ruaj khov thiab eco-phooj ywg hauv cov ntim ntim qis. Bio-based plastics, cov khoom siv rov ua dua tshiab, thiab cov khoom siv biodegradable muaj cov kev xaiv siv tau uas txo cov kev cuam tshuam ib puag ncig thiab txhawb kev lag luam ncig.

- Localized ntau lawm:Kev txhaj tshuaj tsawg tsawg tso cai rau kev tsim khoom hauv zos, txo kev thauj mus los thiab cuam tshuam cov pa roj carbon emissions. Los ntawm kev ua kom ze rau qhov kawg kev ua lag luam, tuam txhab lag luam tuaj yeem txo qis ib puag ncig hneev taw ntawm lawv cov saw hlau.

- Tsim rau sustainability:Tsawg ntim txhaj tshuaj molding tso cai rau ib qho los koom nrog cov qauv tsim qauv. Kev tsim cov khoom siv nrog cov qauv hnyav, kev ua kom zoo dua qub, thiab kev siv cov khoom siv tau zoo tuaj yeem txhim kho kev ruaj khov ntawm cov txheej txheem tsim khoom.

- Kev ntsuas lub neej:Kev ntsuas lub neej ntawm cov txheej txheem txhaj tshuaj molding tsawg pab txheeb xyuas qhov chaw rau kev txhim kho thiab kev ua kom zoo dua qub. Kev txheeb xyuas qhov cuam tshuam ntawm ib puag ncig ntawm txhua theem, los ntawm kev rho tawm cov khoom siv raw mus rau qhov kawg ntawm lub neej pov tseg, ua rau cov tuam txhab txiav txim siab paub thiab siv cov kev coj ua kom ruaj khov.

Cov kev cai thiab cov qauv rau kev txhaj tshuaj tsawg tsawg

Ua raws li cov cai thiab cov qauv hauv cov ntim ntim qis yog qhov tseem ceeb los xyuas kom meej cov khoom muaj kev nyab xeeb, lub luag haujlwm ib puag ncig, kev nyab xeeb ntawm chaw ua haujlwm, thiab ua raws li kev cai lij choj thiab kev lag luam. Cov tuam txhab yuav tsum nyob twj ywm paub txog cov kev cai thiab cov qauv siv tau thiab muab tso rau hauv lawv cov txheej txheem tsim khoom.

- Cov qauv kev nyab xeeb khoom:Tsawg ntim txhaj tshuaj molding yuav tsum ua raws li cov qauv kev nyab xeeb ntawm cov khoom lag luam kom ntseeg tau tias cov khoom tsim tau raws li qhov yuav tsum tau ua thiab kev nyab xeeb. Cov qauv no yuav txawv nyob ntawm kev lag luam, xws li tsheb, kev kho mob, lossis cov khoom siv.

- Cov cai ntawm cov khoom siv:Ua raws li cov cai tshwj xeeb thiab cov qauv hauv kev xaiv thiab siv cov khoom siv rau kev txhaj tshuaj tsawg tsawg yog tsim nyog los xyuas kom meej cov txheej txheem tsim khoom. Cov kev cai no tswj hwm cov khoom muaj pes tsawg leeg, qib toxicity, thiab kev cuam tshuam ib puag ncig. Kev ua raws li kev cai lij choj xws li REACH (Kev Sau Npe, Kev Ntsuam Xyuas, Kev Tso Cai, thiab Kev Txwv Cov Tshuaj) yog qhov tseem ceeb rau kev siv cov khoom siv nyab xeeb thiab ruaj khov.

- Environmental kev cai:Tsawg ntim txhaj tshuaj molding kev ua haujlwm yuav tsum ua raws li kev cai ib puag ncig kom txo lawv cov kev cuam tshuam ecological. Cov kev cai no hais txog cov teeb meem xws li huab cua emissions, kev tswj dej khib nyiab, pov tseg pov tseg, thiab kev siv hluav taws xob. Ua raws li cov kev txwv xws li ISO 14001 (Environmental Management Systems) qhia tau hais tias kev cog lus rau ib puag ncig lub luag haujlwm.

- Cov qauv kev noj qab haus huv thiab kev nyab xeeb:Ua kom muaj kev nyab xeeb ib puag ncig ua haujlwm yog qhov tseem ceeb hauv cov khoom ntim qis qis. Ua raws li cov qauv kev noj qab haus huv thiab kev nyab xeeb, xws li OSHA (Occupational Safety and Health Administration) cov kev cai, pab tiv thaiv cov neeg ua haujlwm los ntawm kev phom sij cuam tshuam nrog cov tshuab, khoom siv, thiab cov txheej txheem.

- Quality Management Systems:Kev ua raws li kev tswj hwm kev tswj hwm zoo, xws li ISO 9001, yog qhov tseem ceeb rau kev ua haujlwm qis qis. Cov kab ke no muab lub hauv paus rau kev xa khoom tsis tu ncua uas ua tau raws li cov neeg siv khoom xav tau thiab ua raws li cov cai thiab cov qauv siv tau.

- Traceability thiab labeling yuav tsum:Kev ntsuas traceability tej zaum yuav tsim nyog rau qhov ntim qis txhaj tshuaj molding los taug qab cov khoom siv thiab cov khoom siv hauv kev tsim khoom. Cov kev cai sau npe, xws li kev txheeb xyuas cov khoom, cov lej batch, thiab cov lus ceeb toom txog kev nyab xeeb, xyuas kom meej kev sib txuas lus thiab ua raws li cov kev cai cuam tshuam.

- Kev txiav txim siab txog khoom ntiag tug:Kev tiv thaiv cov cuab yeej cuab tam yog qhov tseem ceeb hauv kev txhaj tshuaj molding tsawg, feem ntau yog thaum tsim khoom rau cov khoom lag luam. Cov tuam txhab lag luam yuav tsum hwm cov cai patent thiab xyuas kom lawv cov txheej txheem tsim khoom tsis ua txhaum cai ntawm kev txawj ntse.

- Cov cai tswj kev lag luam thoob ntiaj teb:Yog tias koom nrog kev lag luam thoob ntiaj teb, kev lag luam ntim qis qis yuav tsum ua raws li kev cai lag luam thiab cov qauv tshwj xeeb rau cov teb chaws koom nrog. Ua raws li cov cai tswj kev lis kev cai thiab kev txwv ntshuam/export tej zaum yuav tsim nyog los xyuas kom meej ua raws li cov kev pom zoo thoob ntiaj teb kev lag luam.

Xaiv Txoj Cai Tsawg Volume Txhaj Molding Kev Pabcuam

Ib tus khub txhim khu kev qha thiab muaj peev xwm yuav pab txhawb rau kev ua tiav ntawm koj qhov kev tsim khoom qis qis.

- Kev paub thiab kev paub:Nrhiav ib tus neeg muab kev pabcuam tshwjxeeb hauv kev txhaj tshuaj molding tsawg, nrog kev paub thiab kev paub txog kev tuav haujlwm ntawm cov nplai zoo sib xws thiab qhov nyuaj. Ib tus kws kho mob nrog cov ntaub ntawv pov thawj tuaj yeem muab cov kev pom zoo, cov txheej txheem ua tau zoo, thiab cov txiaj ntsig zoo.

- Customization muaj peev xwm: Ntsuam xyuas tus kws kho mob lub peev xwm los muab cov kev daws teeb meem uas haum rau koj qhov project xav tau. Saib rau lawv qhov yooj yim hauv kev ua kom haum raws li kev tsim qauv, kev xaiv cov khoom siv, thiab cov ntim ntau lawm kom paub meej tias qhov kev ua kom haum.

- Kev ruaj ntseg:Xyuas kom tseeb tias tus neeg muab kev pabcuam muaj cov txheej txheem kev ruaj ntseg zoo. Txhawm rau kom ntseeg tau tias muaj kev ntseeg siab thiab sib xws ntawm cov khoom, peb ua raws li cov qauv kev lag luam thiab cov ntawv pov thawj (xws li ISO 9001) thiab ua tib zoo tshuaj xyuas thiab kuaj.

- Muaj peev xwm thiab scalability:Ntsuam xyuas tus neeg muab kev pab cuam lub peev xwm thiab scalability kom tau raws li koj cov kev xav tau ntawm cov khoom ntim qis. Lawv yuav tsum muaj peev xwm ua tau raws li koj qhov kev xav tau ntau lawm, txawm tias me me lossis nruab nrab, thiab ntsuas yog tias xav tau.

- Technology thiab khoom siv:Ntsuam xyuas tus kws kho mob lub peev xwm thev naus laus zis thiab cov cuab yeej siv thev naus laus zis uas lawv ua haujlwm. Advanced txhaj tshuaj molding tshuab thiab thev naus laus zis txhim kho cov txheej txheem kev ua tau zoo, ib feem sib xws, thiab cov voj voog ntau lawm.

- Kev paub txog khoom siv:Xav txog tus neeg muab kev pabcuam kev tshaj lij hauv kev ua haujlwm nrog ntau yam khoom tsim nyog rau kev txhaj tshuaj molding tsawg. Lawv yuav tsum paub cov resins sib txawv thiab lawv cov khoom thiab muaj peev xwm qhia cov khoom siv uas ua tau raws li koj qhov kev xav tau.

- Cov kev pabcuam muaj nqis ntxiv:Ntsuas cov kev pabcuam ntxiv uas muab los ntawm tus neeg muab kev pabcuam, xws li tom qab ua tiav, sib dhos, thiab ua tiav. Cov kev pabcuam muaj nqis ntxiv tuaj yeem txhim kho koj cov txheej txheem tsim khoom, txo cov logistics complexities, thiab muab cov kev daws teeb meem zoo txij thaum pib mus rau qhov kawg.

- Kev tswj cov khoom siv:Txheeb xyuas tus kws kho mob cov peev txheej tswj cov khoom siv, suav nrog cov khoom siv thiab cov khoom siv. Cov saw hlau tswj tau zoo ua kom muaj cov khoom siv raws sij hawm, txo qis kev tsim khoom, thiab ua kom zoo dua cov nqi.

- Cov neeg siv khoom txhawb nqa thiab kev sib txuas lus:Xav txog qhov chaw muab kev pabcuam cov neeg siv khoom txhawb nqa thiab kev sib txuas lus. Kev sib txuas lus meej thiab teb tau zoo, hloov kho qhov project tsis tu ncua, thiab kev sib koom tes yog qhov tseem ceeb rau kev sib koom tes ua tiav.

- Nqi-effectiveness:Txawm hais tias tus nqi yuav tsum tsis yog ib qho kev txiav txim siab, kev ntsuam xyuas tus kws kho mob tus nqi qauv thiab tag nrho cov nqi-zoo yog qhov tseem ceeb. Sib piv cov nqe lus, ntsuas tus nqi rau cov nyiaj, thiab xyuas kom meej meej txog cov nqi ntxiv lossis nqi them.

Common Challenges nyob rau hauv Tsawg Volume Txhaj Molding

Kev daws cov teeb meem no hauv kev txhaj tshuaj tsawg tsawg yuav tsum muaj kev nkag siab zoo txog qhov yuav tsum tau ua ntawm qhov project, kev sib raug zoo nrog cov neeg muag khoom thiab cov neeg koom tes, thiab kev txhim kho txuas ntxiv ntawm cov txheej txheem.

- Tooling nqi:Tsawg ntim txhaj tshuaj molding feem ntau cuam tshuam nrog kev tsim khoom me me, ua rau cov cuab yeej ua ntej tus nqi yog qhov nyuaj heev. Kev tsim thiab tsim pwm tuaj yeem ua kom muaj txiaj ntsig ntau dua ib feem ntau dua li cov khoom ntim siab, yuav tsum tau ua tib zoo saib xyuas tus nqi thiab kev ua kom zoo.

- Tsim complexity:Cov khoom ntim qis qis yuav suav nrog cov qauv tsim thiab sib txawv. Qhov kev sib tw yog nyob rau hauv kom ntseeg tau tias txoj kev muaj peev xwm ua tau rau kev txhaj tshuaj molding thiab cov pwm tuaj yeem tsim cov duab raws li qhov xav tau. Kev tsim kho thiab rov ua dua tshiab yuav tsim nyog kom ua tiav cov txiaj ntsig zoo.

- Kev xaiv cov khoom siv:Xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding tsawg tuaj yeem nyuaj. Peb yuav tsum xav txog tus nqi, functionality, durability, thiab muaj. Nrhiav qhov sib npaug ntawm cov khoom siv thiab cov kev xav tau ntawm qhov project yog qhov tseem ceeb kom ua tiav qhov kev xav tau zoo thiab kev ua haujlwm.

- Qhov zoo sib xws:Kev tswj xyuas qhov zoo ib yam thoob plaws hauv kev tsim cov ntim qis tuaj yeem nyuaj. Kev hloov pauv hauv cov txheej txheem tsis, pwm hnav, thiab cov yam ntxwv ntawm cov khoom tuaj yeem cuam tshuam qhov loj me, qhov chaw tiav, thiab cov khoom siv kho tshuab. Kev tswj xyuas nruj nruj thiab kev soj ntsuam tas li yog tsim nyog los txo cov kev hloov pauv.

- Lub sijhawm ua haujlwm:Tsawg ntim txhaj tshuaj molding feem ntau yuav tsum siv sij hawm luv luv dua li cov khoom ntim ntau. Kev npaj ua tau zoo thiab kev sib koom tes yog qhov tseem ceeb rau kev txhim kho cov sijhawm tsim khoom, txo lub sijhawm poob qis, thiab ua kom cov khoom xa tuaj raws sijhawm. Kev sib txuas lus zoo nrog cov neeg muag khoom thiab cov neeg koom tes yog qhov tseem ceeb kom ua tau raws li lub sijhawm nruj.

- Scalability txwv:Tsawg ntim txhaj tshuaj molding txheej txheem yuav muaj kev txwv thaum nws los txog rau scalability. Kev hloov pauv ntawm qhov ntim qis mus rau qhov ntim ntau dua tuaj yeem xav tau cov cuab yeej, cov cuab yeej siv, thiab cov txheej txheem hloov kho. Kev cia siab tias muaj kev sib tw scalability thiab kev npaj rau yav tom ntej kev xav tau yog qhov tseem ceeb.

- Nqi rau ib feem:Tus nqi ib feem ntawm qhov tsawg ntim txhaj tshuaj molding nyhav siab dua piv rau cov khoom ntim siab vim peb nthuav tawm cov nqi ntawm cov cuab yeej tshaj cov khoom me. Kev ntsuas tus nqi ntsuas thaum tswj cov qauv zoo thiab ua tau raws li qhov yuav tsum tau ua yog qhov tseem ceeb.

- Risk ntawm obsolescence:Tsawg ntim ntau lawm feem ntau ua raws li kev lag luam niche lossis cov khoom sib txawv tshwj xeeb. Qhov kev pheej hmoo ntawm cov khoom ua tsis tiav lossis xav tau hloov pauv tuaj yeem ua rau muaj teeb meem. Ua tib zoo tshuaj xyuas kev lag luam, kev xav tau kev kwv yees, thiab cov tswv yim tswj cov khoom lag luam yog qhov tsim nyog los txo qis qhov kev pheej hmoo ntawm kev ploj mus.

Yav tom ntej ntawm Tsawg Volume Txhaj Molding

Lub neej yav tom ntej ntawm kev txhaj tshuaj molding tsawg yog qhov ci ntsa iab, nrog cov hauv kev tshiab los ntawm kev nce qib hauv automation, kev tsim khoom ntxiv, cov khoom siv ruaj khov thiab cov txheej txheem, kev hloov kho, thiab digitalization. Cov neeg tsim khoom lag luam uas lees txais cov qauv no thiab nqis peev hauv cov thev naus laus zis tshiab thiab cov txheej txheem yuav ua haujlwm tau zoo kom ua tiav hauv kev lag luam sai sai.

- Automation thiab Kev Lag Luam 4.0:Tsawg ntim txhaj tshuaj molding yog npaj kom tau txais txiaj ntsig los ntawm automation thiab Kev Lag Luam 4.0 technologies xws li robotics, artificial txawj ntse, thiab IoT. Automation tuaj yeem pab txo cov sij hawm txhuas, txhim kho qhov zoo sib xws, thiab nce kev tsim khoom thaum txo nqi zog.

- Additive Manufacturing thiab Hybrid Txheej Txheem: Txhawm rau txhim kho lub peev xwm ntawm cov khoom ntim qis, kev tsim khoom ntxiv thiab cov txheej txheem hybrid, xws li kev sib txuas 3D luam ntawv thiab txhaj tshuaj molding, tuaj yeem ua haujlwm. Cov thev naus laus zis no tuaj yeem ua kom muaj kev tsim qauv sai dua, tsim kev ywj pheej ntau dua, thiab txhim kho qhov zoo.

- Sustainable Materials thiab txheej txheem:Sustainability yog ib qho kev tsom mus rau kev tsim khoom. Lub neej yav tom ntej ntawm kev txhaj tshuaj molding tsawg yog nyob rau hauv kev siv cov khoom siv thiab cov txheej txheem. Biodegradable thiab cov ntaub ntawv txuas ntxiv tuaj yeem txo qhov cuam tshuam ib puag ncig, thaum cov txheej txheem kev ua haujlwm hauv eco tuaj yeem txo cov khib nyiab thiab siv hluav taws xob tsawg.

- Customization thiab Personalization:Cov neeg siv khoom thov rau customization thiab personalization drives innovation nyob rau hauv tsawg ntim txhaj molding. Advanced software thiab automation technologies tuaj yeem ua kom muaj kev hloov pauv loj ntawm cov khoom nrog cov nqi siv tsawg, qhib cov hauv kev tshiab hauv kev lag luam niche.

- Digitalization thiab kev sib txuas:Digitalization thiab kev sib txuas yog lub neej yav tom ntej ntawm kev txhaj tshuaj molding tsawg. Cov neeg tsim khoom tuaj yeem txhim kho kev tsim khoom, txhim kho kom zoo, thiab txhim kho cov saw hlau pob tshab los ntawm kev siv cov ntaub ntawv txheeb xyuas thiab cov huab-raws li platforms. Cov thev naus laus zis no tseem tuaj yeem pab saib xyuas tej thaj chaw deb thiab kev saib xyuas kev kwv yees.

xaus

Tsawg ntim txhaj tshuaj molding muaj qhov zoo tseem ceeb rau kev ua haujlwm me me. 3D luam ntawv thev naus laus zis ua rau kev tsim qauv sai sai, siv cov cuab yeej siv tau zoo, thiab tsim kom yooj yim. Nws tso cai rau cov lag luam los txo cov sij hawm txhuas, xaiv los ntawm ntau yam khoom siv, txo cov khib nyiab, thiab txo cov kev pheej hmoo. Los ntawm kev lees txais cov txiaj ntsig no, cov lag luam me tuaj yeem txhim kho lawv cov txheej txheem tsim khoom, ua tau raws li cov neeg siv khoom xav tau, thiab tswj kom muaj kev sib tw hauv kev lag luam. Tsawg ntim txhaj tshuaj molding muab cov kev daws teeb meem zoo, tus nqi tsim nyog uas txhawb nqa cov khoom me me kom muaj kev vam meej nyob rau niaj hnub no dynamic manufacturing toj roob hauv pes.