Liquid Silicone Rubber (LSR) Txhaj Molding

Liquid Silicone Rubber (LSR) Txhaj Moulding yog dab tsi?

Txhaj tshuaj molding ntawm Liquid Silicone Roj Hmab (LSR) yog txheej txheem siv los tsim pliable, ruaj qhov chaw nyob rau hauv siab ntim. Thaum lub sij hawm tus txheej txheem, ob peb yam yuav tsum tau: ib tug injector, ib tug metering unit, ib tug mov nruas, ib tug tov khoom, lub nozzle, thiab ib tug pwm clamp, thiab lwm yam.

Txhaj tshuaj molding ntawm Liquid Silicone Rubber (LSR) yog ib qho cuab yeej siv los tsim cov khoom sib txawv rau kev kho mob thiab hluav taws xob siv, thiab lwm yam. Ntxiv nrog rau cov khoom tsim los ntawm cov khoom siv, cov txheej txheem ntawm cov txheej txheem tseem ceeb heev. LSR txhaj tshuaj molding yog ib txheej txheem multistep uas tau nthuav tawm.

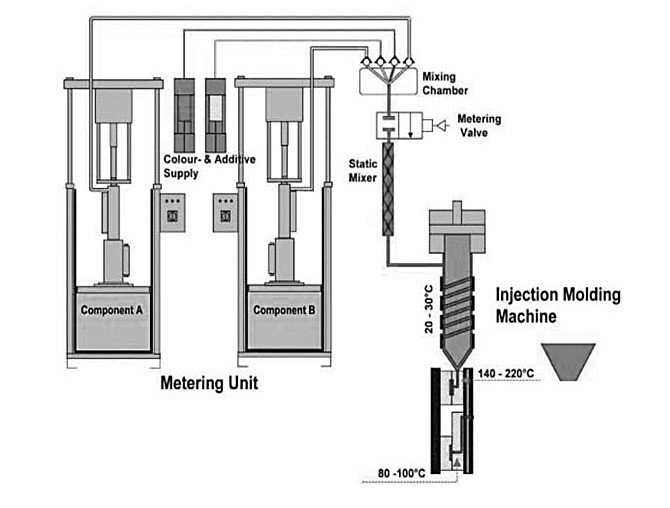

Thawj kauj ruam yog kev npaj ntawm qhov sib tov. LSR feem ntau muaj ob yam khoom, xim, thiab cov khoom siv ntxiv (piv txwv li fillers), nyob ntawm seb cov khoom xav tau ntawm cov khoom kawg. Hauv cov kauj ruam no, cov khoom xyaw ntawm cov khoom sib tov yog homogenized thiab tuaj yeem ua ke nrog qhov ntsuas kub kom ruaj khov rau kev tswj hwm zoo ntawm silicone kub (ambient kub lossis silicone preheating).

Tam sim no, daim ntawv thov ntau yam ntawm cov khoom siv roj hmab silicone tau dav thiab dav, thiab LSR txhaj tshuaj molding yog lub luag haujlwm tseem ceeb hauv kev lag luam no.

Liquid Silicone Rubber Moulding Ua Haujlwm Li Cas?

LSR molding txawv me ntsis los ntawm thermoplastic txhaj tshuaj molding vim nws yooj. Zoo li cov cuab yeej txhuas txheej txheem, LSR molding cov cuab yeej yog tsim los siv CNC machining los tsim cov cuab yeej kub kub tsim los tiv thaiv LSR molding txheej txheem. Tom qab milling, lub cuab tam yog polished los ntawm txhais tes rau cov neeg siv khoom specifications, uas tso cai rau XNUMX tus qauv nto tiav kev xaiv.

Los ntawm qhov ntawd, cov cuab yeej ua tiav tau thauj mus rau hauv qhov siab tshaj LSR-kev txhaj tshuaj molding xovxwm uas yog qhov tseeb npaj rau kev tswj xyuas qhov kev txhaj tshuaj loj los tsim cov LSR qhov zoo tshaj plaws. Ntawm Mould-Making, LSR qhov chaw raug tshem tawm ntawm cov pwm, vim tias cov pins txhaj tshuaj tuaj yeem cuam tshuam qhov zoo. LSR cov ntaub ntawv suav nrog cov qauv silicones thiab cov qib tshwj xeeb kom haum rau ntau yam kev siv thiab kev lag luam xws li kev kho mob, tsheb, thiab teeb pom kev zoo. Txij li thaum LSR yog cov thermosetting polymer, nws lub xeev molded yog ruaj khov - ib zaug nws tau teem, nws tsis tuaj yeem yaj dua li cov thermoplastic. Thaum qhov kev khiav tiav lawm, qhov chaw (lossis thawj tus qauv khiav) raug ntim thiab xa tawm sai tom qab ntawd.

Ntawm no cia peb tshawb xyuas nws, ua ntej, peb yuav tsum tham txog cov khoom siv silicone roj hmab, cov ntsiab lus tseem ceeb uas koj yuav tsum paub raws li hauv qab no:

Cov kua roj hmab silicone (LSR) yog cov rwb thaiv tsev zoo heev, haum rau cov khoom siv hluav taws xob zoo lossis cov khoom siv hluav taws xob siab.

Liquid silicone roj hmab (LSR) cov ntaub ntawv tsim nyog siv rau hauv qhov kub thiab txias ib puag ncig. Cov khoom rwb thaiv tsev, cov khoom siv kho tshuab, thiab lub cev ntawm cov ntaub ntawv tseem tsis hloov pauv ntawm 200 ℃ lossis qis li -40 ℃.

Nws yog resistant rau gasification thiab aging, yog li nws yog haum rau sab nraum zoov daim ntaub ntawv.

Liquid silicone roj hmab (LSR) yog roj resistant, tuaj yeem siv rau hauv kev lag luam roj av. Muaj ob lub qauv: ntsug ob chav swb kua silicone txhaj tshuaj molding tshuab, ntsug ib leeg swb kua silicone txhaj tshuab, siv los tsim txhua yam kev xav tau, siab precision silicone roj hmab khoom; Lub tog raj kheej lub kaum sab xis txhaj tshuaj tshuab, yog tsim cov khoom siv hluav taws xob sib txuas, Post insulators thiab cov qauv ntawm cov neeg ntes.

Qhov zoo ntawm LSR Txhaj Moulding (LIM).

Muaj ntau qhov zoo rau LSR Txhaj Moulding (LIM). Nws yog piv nrog silicone compression molding.

Cov khoom siv silicone roj hmab (LSR) muaj kev nyab xeeb dua, silicone gel muaj qib zaub mov lossis qib kho mob. Lub LSR txhaj tshuaj molding (LIM) muaj qhov ua tau zoo dua, tuaj yeem ua tau zoo heev cov khoom siv silicone roj hmab. Tsis tas li ntawd, nws muaj ib txoj kab nyias nyias thiab lub teeb me me.

Qhov zoo ntawm LSR molded qhov chaw

Tsim tsis txwv - Pab kom tsim tau ib feem geometry thiab kev daws teeb meem tsis tuaj yeem ua tau

Zoo ib yam - Muab qhov zoo sib xws hauv cov khoom dimension, precision thiab tag nrho zoo

Ntshiab - Silicone yog ib qho ntawm cov khoom siv tshuaj ntsuam xyuas ntau tshaj plaws nrog keeb kwm ntev ntawm kev siv nyab xeeb

Tseem ceeb - Flashless, tsis siv cov cuab yeej tsim cov ntsiab lus rau qhov hnyav ntawm 0.002 grams mus rau ntau pua grams

Txhim khu kev ntseeg - Siv cov thev naus laus zis tshiab hauv tshuab, cuab yeej thiab automation

Zoo - Zero-defect qib zoo los ntawm kev tswj cov txheej txheem

yuav luag - Ua kom muaj qhov ntim ntau tshaj plaws vim lub sijhawm luv luv, los ntawm ntau txhiab mus rau lab

Ntxuav - Siv cov txheej txheem kev ua haujlwm hauv lub xeev thiab kev tsim khoom hauv chav 7 thiab 8 chav huv

Nqi-zoo - Muab tus nqi qis tshaj ntawm Cov Tswv Cuab (TCO)

LSR Txhaj Molding

Innovative technology ntsib cov neeg siv khoom xav tau:

Liquid Silicone Rubber (LSR) tuaj yeem ua tiav hauv cov txheej txheem ua kua ua kua (LIM). Cov khoom siv ua kua yog sib xyaw los ntawm ob qhov sib cais hauv qhov sib piv ntawm 1: 1 thiab txhaj ntawm lub tshuab txias-khiav mus rau hauv pwm kub. Kev kho yuav siv sij hawm qhov chaw nyob rau hauv vib nas this, muab qhov kom zoo dua ntawm ceev cycling thiab zus tau tej cov ntau.

Vim qhov yooj yim ntawm kev tsim thiab cuab yeej, LSR txhaj tshuaj molding yog qhov zoo tagnrho rau kev tsim cov geometries nyuaj thiab tuaj yeem sib sau ua ke ntau yam haujlwm ua haujlwm rau hauv ib feem. Nws tseem muaj cov txiaj ntsig tseem ceeb ntawm cov khoom lag luam kev ntseeg siab thiab tag nrho cov nqi ntawm cov tswv cuab.

LSR Liquid Silicone Rubber Txhaj Molding Txheej Txheem

DJmolding kua silicone roj hmab txhaj tshuaj molding tshuab zoo nkaus li zoo li cov thermoplastic txhaj molding tshuab. Ob hom xovxwm siv tib lub tshuab yooj yim, chav tsev clamp, thiab chav txhaj tshuaj.

LSR txhaj tshuaj molding tshuab clamp tsev yog zoo tib yam rau cov kua silicone roj hmab thiab cov tshuab thermoplastic. Cov tshuab txhaj tshuaj silicone feem ntau muaj hydraulic ram thiab tej zaum yuav muaj hydraulic toggle. Qee cov xovxwm yog tsim nrog lub ram hluav taws xob nrog toggle. Tsis zoo li cov kev kub siab siv los pwm cov khoom siv thermoplastic, kua silicone txhaj tshuaj yog nyob rau hauv thaj tsam ntawm 800 PSI. Lub hom phiaj ntawm lub clamp yog kom muaj lub zog nthuav dav ntawm cov khoom siv silicone, los ntawm kev ua kom cov pwm kaw raws li cov khoom siv silicone.

Lub tshuab txhaj tshuaj rau cov kua silicone khiav txias nrog cov dej txias thiab lub taub hau los tiv thaiv cov kua silicone los ntawm kev kho. Thermoplastic txhaj units khiav txoj kev rov qab, lawv xav tau lub thoob thiab lub nozzle kom sov rau 300F lossis ntau dua kom cov khoom txav mus. Cov kua dej txhaj tshuaj molding kuj tseem khiav qis dua (hauv qab 1,000 PSI), thaum lawv cov thermoplastic counterparts khiav ntawm kaum tawm txhiab PSI.

Cov kua silicone feem ntau yog muab rau hauv 5 nkas loos pail lossis 55 nkas loos nruas. Muaj ib feem A thiab Tshooj B. Cov xim tuaj yeem ua rau hauv daim ntawv ntawm kev sib cais thiab feem ntau yog 1-3% los ntawm qhov hnyav ntawm cov khoom sib xyaw silicone. Lub silicone dousing unit twj tso kua mis ib feem A silicone thiab ib feem B silicone ntawm nyias hoses mus rau qhov zoo li qub tov khoom. Tsis tas li ntawd, xim yog pumped mus rau qhov sib tov zoo li qub ntawm lwm lub hose. Tom qab ntawd cov khoom sib xyaw ua ke tau muab tso rau hauv lub caj pas ntawm kev txhaj tshuaj molding chim los ntawm kev kaw lub valve.

DJmolding yog cov kws tshaj lij ua kua silicone roj hmab (LSR) txhaj tshuaj molding thiab kua silicone roj hmab qhov chaw tsim khoom los ntawm Tuam Tshoj.

Liquid Silicone Rubber Injection Rhiav

LSR Txhaj Prodcuts QC

LSR cov khoom

LSR cov khoom

Peb cov txheej txheem ua kua silicone roj hmab molding ua cov qauv kev cai thiab siv cov khoom siv kawg hauv 15 hnub lossis tsawg dua. Peb siv cov pwm txhuas uas muaj cov cuab yeej siv tau zoo thiab ua kom nrawm nrawm, thiab npaj ntau qib thiab durometers ntawm LSR cov ntaub ntawv.

Muab qhov zoo tshaj plaws sib xws hauv qhov ntev, precision, tag nrho zoo.

Peb holistic mus kom ze rau Liquid Silicone Roj Hmab molding cia siab rau kev koom tes nrog cov neeg siv khoom los tsim cov kev daws teeb meem tshiab raws li qhov tshwj xeeb tshwj xeeb thiab cov kev xav tau.

Liquid Silicone Rubber (LSR) Txhaj Moulding yog txheej txheem tsim khoom uas muaj cov kua roj hmab silicone rau hauv pwm los tsim ntau yam khoom. LSR yog cov khoom siv ntau yam uas tau nrov zuj zus vim nws cov khoom tshwj xeeb, suav nrog biocompatibility, thermal stability, thiab tshuaj tsis haum. Hauv tsab xov xwm no, peb yuav tham txog cov txiaj ntsig ntawm LSR txhaj tshuaj molding thiab tshawb txog ntau yam kev siv ntawm cov tshuab no.

LSR Txhaj Moulding Ua Haujlwm Li Cas?

LSR (Liquid Silicone Rubber) txhaj tshuaj molding yog cov txheej txheem tsim khoom uas tsim cov khoom zoo, precision silicone roj hmab qhov chaw. Nws yog qhov zoo rau kev tsim cov duab thiab cov qauv tsim nrog kev nthuav dav zoo thiab sib xws. Cov txheej txheem cuam tshuam nrog kev txhaj tshuaj silicone roj hmab rau hauv lub pwm kab noj hniav, tso cai rau nws kho thiab khov rau hauv cov duab uas xav tau. Nov yog cov ntsiab lus luv luv ntawm LSR txhaj tshuaj molding ua haujlwm li cas:

Kev Npaj Pwm: Cov txheej txheem pib nrog kev npaj pwm. Cov pwm feem ntau muaj ob sab, ib qho kev txhaj tshuaj, thiab sab clamping, uas haum ua ke los tsim cov kab noj hniav rau cov silicone. Tom qab kho, pwm yog ntxuav thiab coated nrog ib tug tso tawm tus neeg saib xyuas kom yooj yim rau tshem tawm ib feem.

Silicone Preparation: Cov kua roj hmab silicone yog ob qho khoom siv uas muaj lub hauv paus silicone thiab cov tshuaj tua kab mob. Cov khoom no yog sib xyaw ua ke hauv qhov sib piv meej. Qhov sib tov yog degassed kom tshem tawm cov huab cua npuas uas tuaj yeem cuam tshuam qhov zoo ntawm qhov kawg.

Kev Txhaj Tshuaj: Cov kua roj hmab sib xyaw thiab degassed silicone tau pauv mus rau chav txhaj tshuaj. Lub tshuab txhaj tshuaj heats cov khoom mus rau qhov kub thiab txias kom txo nws cov viscosity thiab ua kom yooj yim ntws. Cov khoom yog txhaj rau hauv pwm kab noj hniav los ntawm lub nozzle los yog sprue.

Kho: Thaum cov kua roj hmab silicone txhaj rau hauv pwm kab noj hniav, nws pib kho. Cov txheej txheem kho yog feem ntau pib los ntawm tshav kub, txawm tias qee cov pwm tuaj yeem siv lwm txoj hauv kev, xws li UV teeb. Thaum tshav kub kub ua rau cov silicone cross-links thiab solidify, tsim cov pwm kab noj hniav. Lub sijhawm kho nws txawv nyob ntawm qhov tsim thiab cov khoom siv silicone.

Txias thiab tshem tawm ib feem: Tom qab cov txheej txheem kho, cov pwm yog txias kom tso cai rau cov silicone kom tiav. Lub sijhawm txias tuaj yeem sib txawv tab sis feem ntau luv dua lub sijhawm kho. Thaum txias, cov pwm qhib, thiab qhov ua tiav raug tshem tawm. Txoj haujlwm yuav xav tau cov kauj ruam tom qab ua tiav ntxiv, xws li txiav cov khoom siv ntau dhau los yog tshuaj xyuas qhov tsis xws luag.

LSR txhaj tshuaj molding muaj ntau qhov zoo, suav nrog kev tsim cov geometries intricate thiab complex, ib feem zoo sib xws, siab precision, thiab tsis kam mus rau huab cua kub, tshuaj, thiab kev laus. Nws yog feem ntau siv nyob rau hauv ntau yam kev kho mob, tsheb, electronics, thiab cov neeg siv khoom industries.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias qhov no yog qhov yooj yim piav qhia ntawm LSR kev txhaj tshuaj molding txheej txheem, thiab kev ua haujlwm tiag tiag yuav txawv nyob ntawm cov khoom siv tshwj xeeb, cov khoom siv, thiab cov khoom yuav tsum tau ua.

Qhov zoo ntawm LSR Txhaj Molding

LSR (kua silicone roj hmab) txhaj tshuaj molding yog ntau yam txheej txheem tsim khoom uas muaj ntau yam zoo dua li cov txheej txheem molding. LSR txhaj tshuaj molding yuav tsum tau txhaj cov kua silicone rau hauv pwm thiab kho nws mus rau hauv ib qho khoom siv los tsim cov khoom tiav. Nov yog qee qhov zoo ntawm LSR txhaj tshuaj molding:

Precision thiab sib npaug

LSR kev txhaj tshuaj molding muaj qhov tshwj xeeb precision thiab sib xws hauv kev tsim cov khoom sib txuam nrog cov ntsiab lus zoo. Cov kua silicone yog txhaj rau hauv pwm nyob rau hauv kev kub siab, sau txawm tias qhov me me crevices thiab cov ces kaum los tsim cov khoom nyuaj. Tsis tas li ntawd, LSR molding tso cai rau kom muaj qhov sib xws thiab rov ua dua, txo qhov muaj feem cuam tshuam thiab tsis sib xws hauv cov khoom kawg.

Cov khoom zoo

LSR txhaj tshuaj molding tuaj yeem tsim cov khoom zoo, ruaj khov tiv taus hnav thiab tsim kua muag, tshav kub, thiab UV hluav taws xob. LSR cov ntaub ntawv muaj cov khoom zoo ntawm lub cev, nrog rau cov elasticity siab, tsis tshua muaj compression teeb, thiab tsis kam mus rau huab cua kub. Qhov no ua rau LSR txhaj tshuaj molding yog ib qho kev xaiv zoo tshaj plaws rau kev tsim cov khoom uas yuav tsum tau muaj kev ua haujlwm siab thiab ua haujlwm ntev, xws li cov khoom siv kho mob, cov khoom siv tsheb, thiab cov khoom siv.

Tus nqi-Ua tau zoo

LSR txhaj tshuaj molding tuaj yeem yog tus nqi tsim khoom siv rau kev tsim khoom loj. Cov txheej txheem siab precision thiab sib xws pab txo cov khoom pov tseg thiab cov khoom seem, thaum lub sijhawm ua haujlwm tsawg thiab lub sijhawm ua haujlwm tau zoo txo cov nqi tsim khoom. Tsis tas li ntawd, LSR cov ntaub ntawv muaj lub neej ntev, txo qhov xav tau kev hloov pauv ntau zaus lossis kho qhov chaw.

versatility

LSR txhaj tshuaj molding tuaj yeem tsim ntau yam nrog ntau qhov sib txawv, cov duab, thiab geometries. Cov kua silicone tuaj yeem raug molded rau hauv intricate thiab complex duab nrog refined cov ntsiab lus, ua rau nws zoo tagnrho rau ua qhov chaw uas yuav tsum tau high precision thiab raug. Tsis tas li ntawd, LSR txhaj tshuaj molding tuaj yeem muaj cov yam ntxwv ntawm qhov sib txawv ntawm hardness thiab softness, tso cai rau cov khoom tsim tshwj xeeb thiab ua haujlwm yooj yim.

Txo Lub Sijhawm Cycle

LSR txhaj tshuaj molding muaj lub sijhawm ceev ceev, tso cai rau kev tsim cov khoom loj hauv lub sijhawm luv luv. Cov kua silicone yog txhaj rau hauv pwm thiab kho rau hauv daim ntawv khov kho hauv vib nas this, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom ntim ntau lawm.

Tsawg Tsawg Tiam No

LSR txhaj molding tsim cov khoom pov tseg tsawg heev, raws li cov kua silicone yog txhaj ncaj qha rau hauv pwm thiab kho kom tsim tau cov duab uas xav tau. Qhov no sib piv nrog lwm cov txheej txheem tsim khoom, xws li machining lossis casting, uas tsim cov khoom seem tseem ceeb. Tsis tas li ntawd, LSR cov ntaub ntawv tuaj yeem siv tau thiab rov siv dua, txo qhov kev xav tau ntawm cov ntaub ntawv tshiab thiab txo cov khoom pov tseg.

Txhim Kho Txoj Kev Nyab Xeeb

LSR cov ntaub ntawv feem ntau tsis muaj cov tshuaj phem xws li phthalates, BPA, thiab PVC, ua rau lawv muaj kev nyab xeeb rau cov neeg ua haujlwm thiab cov neeg siv khoom. Tsis tas li ntawd, cov txheej txheem kub tsis tshua muaj siv hauv LSR txhaj tshuaj molding tsis tas yuav muaj cov kuab tshuaj lom lossis lwm yam tshuaj lom neeg, txo qhov kev pheej hmoo ntawm cov khoom phom sij.

Txo lub sij hawm mus ua lag luam

LSR txhaj tshuaj molding tuaj yeem txo lub sijhawm los ua lag luam rau cov khoom tshiab, vim nws tso cai rau kev tsim qauv sai thiab ua haujlwm sai. Cov txheej txheem siab precision thiab sib xws pab xyuas kom meej tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb, txo qhov xav tau rau ntau qhov kev sib tw ntawm prototyping thiab kuaj.

Automation

LSR txhaj tshuaj molding tuaj yeem ua tau zoo heev, txo qhov xav tau ntawm kev siv tes ua haujlwm thiab txo qis kev siv zog. Tsis tas li ntawd, automation tuaj yeem txhim kho kev ua tau zoo, txo cov nqi zog, thiab txhim kho qhov sib xws thiab zoo ntawm cov khoom kawg.

Disadvantages ntawm LSR Txhaj Molding

Thaum LSR (kua silicone roj hmab) txhaj tshuaj molding muaj ntau qhov zoo, kuj tseem muaj qee qhov tsis zoo los txiav txim siab seb puas yuav siv cov txheej txheem tsim khoom no. Nov yog qee qhov tsis zoo ntawm LSR txhaj tshuaj molding:

Kev nqis peev siab pib

Ib qho ntawm qhov tsis zoo ntawm LSR kev txhaj tshuaj molding yog qhov kev nqis peev loj tshaj plaws uas yuav tsum tau teeb tsa cov cuab yeej thiab pwm. LSR txhaj tshuaj molding tshuab thiab cuab yeej yuav kim, tshwj xeeb tshaj yog rau cov pwm kev cai lossis kev tsim me me. Qhov no tuaj yeem ua rau LSR txhaj tshuaj molding tsis tshua muaj nqi rau cov tuam txhab nrog cov peev nyiaj me me lossis cov khoom lag luam nrog kev thov tsawg.

Kev xaiv cov khoom siv tsawg

Thaum LSR cov ntaub ntawv muaj cov khoom zoo ntawm lub cev, lawv tsuas yog txwv rau kev xaiv cov khoom. Tsis zoo li cov thermoplastics ib txwm muaj, qee cov khoom siv silicone-raws li muaj nyob rau hauv LSR txhaj tshuaj molding. Nrhiav cov ntaub ntawv tsim nyog rau cov ntawv thov tshwj xeeb lossis cov khoom lag luam tuaj yeem ua rau nws nyuaj.

Lub Sijhawm Kho Mob Ntev

LSR txhaj tshuaj molding yuav tsum tau kho lub sij hawm ntev dua li cov txheej txheem txhaj tshuaj molding. Cov kua silicone xav tau lub sijhawm los kho thiab ua kom khov, uas tuaj yeem ua rau lub sijhawm tsim khoom ntev dua thiab txo qis kev ua haujlwm. Tsis tas li ntawd, lub sijhawm kho mob ntev dua tuaj yeem ua rau tsim qee qhov chaw nrog kev sib tw lossis cov duab geometry nyuaj nyuaj.

Yuav tsum muaj kev txawj tshwj xeeb

LSR txhaj tshuaj molding yuav tsum muaj kev paub tshwj xeeb thiab kev txawj ntse, suav nrog kev nkag siab tob txog cov khoom thiab tus cwj pwm ntawm cov kua silicone. Qhov no tuaj yeem ua rau nws nyuaj rau cov tuam txhab nrhiav cov neeg ua haujlwm tsim nyog los ua haujlwm thiab tswj cov khoom siv, tshwj xeeb tshaj yog nyob rau thaj chaw uas LSR txhaj tshuaj molding tsis tshua muaj.

Kev Sib Tw Moulding

LSR kev txhaj tshuaj molding tuaj yeem nthuav qhia ob peb qhov kev sib tw uas yuav tsum tau hais los xyuas kom meej tias cov khoom tsim tau zoo. Piv txwv li, kua silicone tuaj yeem ua rau flash lossis burrs, cuam tshuam rau qhov kawg ntawm cov khoom zoo. Tsis tas li ntawd, cov pwm tso tawm tuaj yeem yuav tsum tau tshem tawm cov khoom ntawm cov pwm, uas tuaj yeem cuam tshuam rau qhov kawg ntawm cov khoom tiav thiab cov khoom siv kho tshuab.

Limited Surface Finishes

LSR kev txhaj tshuaj molding yog txwv tsis pub hais txog qhov ua tiav, vim tias cov kua silicone tsis sib haum nrog qee cov txheej txheem los yog tiav. Qhov no tuaj yeem ua kom tau raws li qhov xav tau zoo nkauj lossis ua haujlwm zoo rau cov khoom tshwj xeeb lossis cov ntawv thov nyuaj.

Kev xaiv xim txwv

LSR txhaj tshuaj molding kuj tseem txwv rau cov xim xaiv, raws li cov khoom siv silicone feem ntau yog translucent lossis opaque. Thaum qee cov xim ntxiv muaj, lawv tuaj yeem nyuaj rau kev sib koom ua ke rau hauv cov khoom yam tsis muaj kev cuam tshuam rau lub cev los yog sib xws ntawm cov khoom kawg.

Muaj peev xwm ua kom muaj qhov paug paug

LSR txhaj tshuaj molding tuaj yeem ua rau muaj kev pheej hmoo ntawm kev kis kab mob yog tias cov khoom siv lossis pwm tsis raug tswj xyuas kom zoo lossis ntxuav. Kev sib kis tuaj yeem cuam tshuam rau cov khoom kawg ntawm lub cev, ua rau muaj qhov tsis xws luag lossis tsis ua haujlwm dhau sijhawm.

Precision thiab raug nyob rau hauv LSR Txhaj Moulding

Precision thiab raug yog qhov tseem ceeb ntawm LSR (Liquid Silicone Rubber) txhaj tshuaj molding, uas tsim cov khoom zoo silicone roj hmab nrog nruj tolerances thiab cov specifications. Nov yog qee yam tseem ceeb uas ua rau muaj qhov tseeb thiab qhov tseeb hauv LSR txhaj tshuaj molding:

- Pwm Tsim thiab Kev Tsim Kho: Cov pwm yog ib qho tseem ceeb ntawm LSR txhaj tshuaj molding txheej txheem, raws li nws txiav txim siab qhov kawg cov duab thiab qhov ntev ntawm ib feem. Cov pwm yuav tsum tau tsim thiab tsim kom muaj tseeb los xyuas kom meej qhov kawg ua tau raws li qhov xav tau tshwj xeeb. Cov pwm yuav tsum tau ua los ntawm cov ntaub ntawv zoo thiab tsim kom muaj kev tiv thaiv nruj kom txo tau qhov yuam kev thiab xyuas kom raug.

- Injection Unit Control: Lub tshuab txhaj tshuaj tswj qhov ntws ntawm cov kua silicone roj hmab rau hauv pwm. Kev tswj xyuas meej ntawm chav txhaj tshuaj yog qhov tseem ceeb kom ua tiav qhov tseeb thiab zoo ib yam. Lub tshuab txhaj tshuaj yuav tsum tau ntsuas thiab tswj xyuas kom ntseeg tau tias cov khoom raug txhaj rau hauv pwm kab noj hniav nrog qhov tseeb ceev, siab, thiab ntim.

- Kev Tswj Kub Kub: Kev tswj qhov kub thiab txias yog qhov tseem ceeb hauv LSR kev txhaj tshuaj molding txheej txheem, vim nws cuam tshuam rau viscosity ntawm cov khoom thiab lub sijhawm kho. Qhov kub thiab txias yuav tsum tau ua tib zoo tswj kom ntseeg tau tias cov khoom ntws mus rau hauv cov pwm thiab cov txheej txheem kho tau tshwm sim ntawm tus nqi raug.

- Cov Khoom Siv Zoo: Qhov zoo ntawm cov khoom siv LSR yog qhov tseem ceeb rau kev ua tiav qhov tseeb thiab qhov tseeb ntawm qhov kawg. Yuav kom kho kom zoo thiab sib xws, cov khoom siv yuav tsum tsis muaj impurities thiab sib xyaw kom raug qhov sib piv.

- Post-Processing: Cov kauj ruam tom qab ua tiav xws li kev txiav thiab tshuaj xyuas yog qhov tseem ceeb rau kev ua tiav qhov tseeb thiab qhov tseeb hauv LSR txhaj tshuaj molding. Ib feem yuav tsum tau muab txiav rau qhov tseeb qhov ntev thiab tshuaj xyuas qhov tsis xws luag lossis tsis zoo.

LSR txhaj tshuaj molding muaj qhov zoo tshaj plaws thiab qhov tseeb, tso cai rau kev tsim cov khoom nrog nruj tolerances thiab cov lus qhia meej. Nws tuaj yeem tsim cov khoom uas muaj qhov zoo sib xws thiab qhov sib txawv me me los ntawm daim mus rau qhov nthuav dav. Qhov no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas qhov tseeb thiab qhov tseeb yog qhov tseem ceeb, xws li hauv cov khoom siv kho mob, cov khoom siv tsheb, thiab cov khoom siv hluav taws xob.

Lub Sijhawm Ntau Lawm

Liquid silicone roj hmab (LSR) kev txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov uas tsim cov khoom zoo silicone nrog cov khoom zoo xws li tshuaj lom neeg, kub tsis kam, thiab biocompatibility. Txawm li cas los xij, lub sijhawm tsim khoom rau LSR txhaj tshuaj molding tuaj yeem ua haujlwm qeeb, uas tuaj yeem ncua kev tsim khoom thiab nce nqi. Nov yog qee txoj hauv kev los txhim kho lub sijhawm tsim khoom ntawm LSR txhaj tshuaj molding:

- Siv lub tshuab txhaj tshuaj molding zoo: Xaiv lub tshuab tsim nyog yog qhov tseem ceeb rau kev ua kom ntau lawm. Nrhiav ib lub cuab yeej uas tuaj yeem txhaj LSR sai yam tsis muaj kev txi zoo. Xav txog kev siv lub tshuab txhaj tshuaj siab ceev, txo lub sijhawm voj voog thiab txhim kho kev tsim khoom.

- Txhim kho pwm tsim: Cov pwm tsim kuj yog ib qho tseem ceeb cuam tshuam rau lub sij hawm tsim ntawm LSR txhaj molding. Txhim kho pwm tsim kom ntseeg tau tias LSR raug txhaj tshuaj zoo thiab sib npaug. Xav txog kev siv pwm nrog lub rooj vag loj dua los txhim kho qhov ntws ntawm LSR thiab txo lub sijhawm voj voog.

- Siv lub tshuab kub khiav: Lub tshuab kub khiav tuaj yeem txhim kho qhov ua tau zoo ntawm LSR txhaj tshuaj molding los ntawm kev ua kom LSR ntawm qhov kub zoo tshaj plaws thoob plaws hauv cov txheej txheem txhaj tshuaj. Qhov no tuaj yeem txo lub sijhawm voj voog thiab txhim kho qhov zoo ntawm cov khoom kawg.

- Preheat LSR: Preheating LSR ua ntej txhaj tshuaj kuj tuaj yeem pab txo lub sijhawm ntau lawm. Preheating LSR tuaj yeem txhim kho nws cov dej ntws thiab txo lub sijhawm txhaj tshuaj, ua rau lub sijhawm voj voog nrawm dua thiab txhim kho kev ua haujlwm.

- Txo lub sijhawm kho: Lub sijhawm kho ntawm LSR tuaj yeem raug txo los ntawm kev ua kom kub kub los yog siv cov tshuaj tua kab mob sai. Txawm li cas los xij, nws yog ib qho tseem ceeb kom tswj tau qhov zoo ntawm cov khoom kawg thaum txo lub sijhawm kho.

Kev tsim khoom raug nqi

Liquid silicone roj hmab (LSR) txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau kev tsim cov khoom zoo silicone. Txawm li cas los xij, tus nqi ntawm LSR txhaj tshuaj molding tuaj yeem cuam tshuam cov tuam txhab, feem ntau thaum tsim cov khoom loj. Nov yog qee txoj hauv kev los ua LSR txhaj tshuaj molding ntau tus nqi:

- Ua kom zoo rau kev tsim cov khoom lag luam: Cov khoom tsim qauv tuaj yeem cuam tshuam tus nqi ntawm LSR txhaj tshuaj molding. Los ntawm optimizing tus tsim, manufacturers yuav txo tau cov nqi ntawm cov khoom siv, uas yuav txo tau tag nrho cov nqi ntawm ntau lawm. Tsis tas li ntawd, kev ua kom yooj yim ntawm cov txheej txheem tuaj yeem txo qhov nyuaj ntawm pwm, txo cov cuab yeej siv.

- Siv cov txheej txheem automated: Siv cov txheej txheem automated tuaj yeem txhim kho qhov ua tau zoo ntawm LSR txhaj tshuaj molding thiab txo cov nqi zog. Cov txheej txheem tsis siv neeg xws li kev tuav cov neeg hlau thiab cov khoom siv tsis siv neeg pub mis tuaj yeem txo lub sijhawm voj voog thiab txhim kho tag nrho cov khoom tsim tau.

- Siv cov pwm zoo: Cov pwm zoo tuaj yeem txhim kho kev ua haujlwm ntawm LSR txhaj tshuaj molding thiab txo cov khoom pov tseg. Siv cov pwm ruaj khov thiab siab precision tuaj yeem txo qhov kev xav tau ntawm kev kho ntau zaus lossis hloov, txuag nyiaj hauv lub sijhawm ntev.

- Optimize cov txheej txheem ntau lawm: Optimizing cov txheej txheem ntau lawm yuav txo tau pov tseg thiab txhim kho efficiency, txo nqi. Qhov no tuaj yeem suav nrog kev ua kom zoo dua qhov kev txhaj tshuaj moldings tsis, xws li kev txhaj tshuaj nrawm, qhov kub thiab txias, kom txo cov khoom pov tseg thiab txo lub sijhawm voj voog.

- Txo cov khoom pov tseg: Txo cov khoom pov tseg tuaj yeem txo tus nqi ntawm LSR txhaj tshuaj molding. Qhov no tuaj yeem ua tiav los ntawm kev siv lub ntsuas ntsuas qhov tseeb los tswj cov khoom siv, kom ntseeg tau tias cov pwm tsim tau tsim thiab ua kom zoo kom txo qis cov khoom siv ntau, thiab rov ua dua cov khoom siv ntxiv rau yav tom ntej.

High-Quality Surface Finishes

Liquid silicone roj hmab (LSR) txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau kev tsim cov khoom zoo silicone nrog cov khoom zoo xws li kub tsis kam, tshuaj tiv thaiv, thiab biocompatibility. Ntxiv nrog rau cov khoom no, ua kom tiav qhov zoo ntawm qhov chaw tiav yog qhov tseem ceeb rau ntau daim ntawv thov. Nov yog qee txoj hauv kev kom ua tiav qhov zoo ntawm qhov chaw tiav hauv LSR txhaj tshuaj molding:

- Siv cov pwm zoo: Cov pwm zoo yog qhov tseem ceeb rau kev ua tiav cov khoom zoo. Cov pwm yuav tsum tau ua los ntawm cov ntaub ntawv zoo thiab muaj ib tug du nto. Tsis tas li ntawd, cov pwm yuav tsum tau tsim kom muaj qhov cua kom zoo kom tsis txhob muaj cua npuas los ntawm kev sib sau, uas tuaj yeem cuam tshuam tsis zoo rau saum npoo.

- Siv cov khoom siv LSR zoo: Siv cov khoom zoo LSR tuaj yeem txhim kho qhov chaw tiav. Cov ntaub ntawv zoo LSR yog tsim kom muaj cov viscosity tsawg, uas tuaj yeem txhim kho cov khoom ntws thiab txo cov tsos ntawm cov cim ntws thiab lwm yam tsis zoo.

- Optimize qhov kev txhaj tshuaj molding tsis: Optimizing qhov tsis xws li kub, txhaj tshuaj ceev, thiab siab kuj tuaj yeem txhim kho qhov chaw tiav. Kev txhaj tshuaj nrawm yuav tsum tau ua kom zoo kom tsis txhob muaj cov khoom tsim los yog streaking. Qhov kub thiab siab yuav tsum tau ua tib zoo tswj kom tsis txhob muaj cov khoom degradation los yog warping.

- Siv cov txheej txheem tom qab molding: Cov txheej txheem tom qab molding xws li trimming, polishing, thiab txheej kuj tuaj yeem txhim kho qhov tiav ntawm LSR cov khoom. Trim tuaj yeem tshem tawm cov flash lossis cov khoom siv ntau dhau ntawm qhov. Polishing tuaj yeem du tawm txhua qhov tsis zoo ntawm qhov chaw. Cov txheej txheej tuaj yeem muab cov txheej txheem tiv thaiv ntxiv thiab txhim kho tus cwj pwm zoo.

- Ua kom tsis tu ncua ntawm lub tshuab txhaj tshuaj molding: Kev saib xyuas tsis tu ncua yog qhov tseem ceeb los xyuas kom meej cov khoom zoo sib xws thiab zoo. Cov cuab yeej yuav tsum tau ntxuav tsis tu ncua kom tsis txhob muaj kab mob, thiab cov pwm yuav tsum tau kuaj xyuas seb puas muaj cov tsos mob ntawm kev hnav lossis kev puas tsuaj.

LSR Txhaj Moulding rau kev siv kho mob

LSR txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj silicone roj hmab (LSR) rau hauv pwm los tsim cov khoom kawg. Cov txheej txheem no tau siv dav hauv kev lag luam kho mob vim muaj cov khoom tshwj xeeb ntawm LSR, uas ua rau nws yog cov khoom siv zoo tshaj plaws rau kev siv kho mob.

LSR yog cov khoom siv biocompatible thiab hypoallergenic uas tsis muaj tshuaj lom neeg, ua rau nws muaj kev nyab xeeb rau cov khoom siv kho mob thiab cog qoob loo. Nws kuj tseem tiv taus cov kab mob loj hlob thiab yooj yim kom tsis muaj menyuam, uas yog qhov tseem ceeb hauv kev kho mob qhov chaw huv thiab kev tswj kab mob yog qhov tseem ceeb.

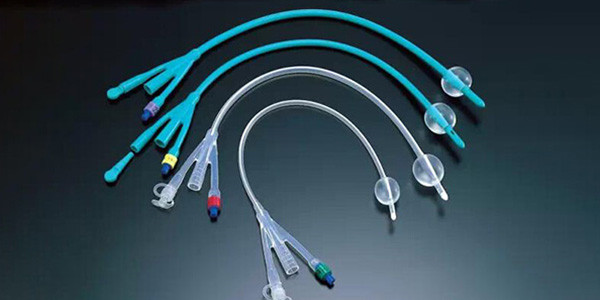

LSR txhaj tshuaj molding yog cov txheej txheem meej thiab muaj txiaj ntsig uas tso cai rau kev tsim cov khoom siv kho mob nyuaj thiab nyuaj nrog kev ua siab ntev. Qhov no yog qhov tseem ceeb hauv kev siv kho mob uas qhov tseeb thiab qhov tseeb yog qhov tseem ceeb, xws li hauv kev tsim cov khoom siv cog qoob loo xws li catheters, cov khoom siv pacemaker, thiab cov pob qij txha.

Ntxiv nrog rau nws cov biocompatibility thiab precision, LSR muaj cov cuab yeej zoo heev uas ua rau nws cov khoom siv rau kev siv kho mob. LSR tiv taus hnav thiab tsim kua muag, tiv taus qhov kub thiab txias, thiab muaj cov khoom siv hluav taws xob zoo heev. Cov khoom no ua rau LSR yog cov khoom siv nrov rau ntau yam kev siv kho mob, suav nrog:

- Catheters thiab tubing: LSR feem ntau yog siv los tsim cov catheters thiab tubing vim nws biocompatibility, yooj, thiab kink tsis kam.

- Cov khoom siv cog qoob loo: LSR feem ntau yog siv los tsim cov khoom siv cog qoob loo xws li cov pob qij txha, cov khoom siv pacemaker, thiab cov cuab yeej phais vim nws cov kav ntev thiab biocompatibility.

- Kev kho mob cov ntsaws ruaj ruaj thiab gaskets: LSR feem ntau siv los tsim lawv vim nws tsis kam mus rau qhov kub thiab txias thiab muaj peev xwm tswj tau nws cov khoom nyob rau lub sijhawm.

LSR txhaj tshuaj molding yog cov txheej txheem ntau yam thiab muaj txiaj ntsig rau kev tsim khoom siv kho mob thiab cov khoom siv. Nws cov khoom tshwj xeeb ua rau nws yog cov khoom siv zoo tshaj plaws rau ntau yam kev siv kho mob, thiab nws qhov tseeb thiab qhov tseeb kom ntseeg tau tias cov khoom ua tau raws li cov qauv zoo tshaj plaws thiab kev nyab xeeb.

Kev siv LSR hauv Automotive Industry

Liquid Silicone Rubber (LSR) tau siv ntau dua hauv kev lag luam tsheb rau ntau yam kev siv vim muaj cov khoom tshwj xeeb uas ua rau nws yog cov khoom siv zoo tshaj plaws rau cov khoom siv tsheb. LSR yog ib qho hluavtaws elastomer tsim los ntawm kev txhaj tshuaj molding, tso cai rau siab precision thiab raug nyob rau hauv manufacturing complex thiab intricate automotive qhov chaw.

LSR muaj cov khoom siv kho tshuab zoo heev, ua rau nws tsim nyog rau cov khoom siv tsheb uas xav tau kev ua haujlwm ntev, kev kub siab ua haujlwm, thiab lub neej ua haujlwm ntev. LSR tiv taus kev puas tsuaj, hnav, thiab tsim kua muag, uas ua rau nws zoo tagnrho rau cov khoom siv tsheb uas muaj kev sib txhuam tas li, xws li cov ntsaws ruaj ruaj, gaskets, thiab O-rings.

Ib qho txiaj ntsig tseem ceeb ntawm LSR hauv kev lag luam tsheb yog nws lub peev xwm tiv taus qhov kub thiab txias. LSR tuaj yeem ua haujlwm tau zoo nyob rau hauv qhov chaw kub thiab tsis kub, ua rau nws yog ib qho khoom siv zoo tshaj plaws rau cov khoom siv tsheb uas raug kub hnyiab, xws li cov khoom siv cav, cov pa tawm, thiab cov turbocharger hoses.

Lwm qhov txiaj ntsig tseem ceeb ntawm LSR hauv kev lag luam tsheb yog nws lub peev xwm los muab lub foob zoo heev tiv thaiv cov kua thiab roj. LSR yog cov khoom siv tiv thaiv zoo heev uas muab cov kev ruaj ntseg foob, txawm tias nyob rau hauv siab, ua rau nws zoo tagnrho rau kev siv hauv tsheb gaskets thiab seals.

LSR kuj muaj cov khoom siv hluav taws xob zoo heev, uas ua rau nws zoo tagnrho rau kev siv hauv cov khoom siv hluav taws xob hauv kev lag luam tsheb, xws li cov khoom sib txuas, sensors, thiab cov tshuab hluav taws xob. LSR tuaj yeem tiv taus hluav taws xob siab thiab muaj kev pheej hmoo tsawg ntawm hluav taws xob arcing lossis luv luv Circuit Court, ua rau nws yog ib qho khoom siv txhim khu kev qha rau kev siv hluav taws xob.

Zuag qhia tag nrho, LSR muaj ntau yam zoo uas ua rau nws yog ib qho khoom siv zoo tshaj plaws rau cov khoom siv tsheb, nrog rau kev ua haujlwm ntev, kev kub siab, kev sib khi zoo heev, thiab hluav taws xob rwb thaiv tsev. Kev siv LSR hauv kev lag luam tsheb yuav tsum loj hlob nyob rau xyoo tom ntej raws li cov tuam txhab nrhiav kev txhim kho kev ntseeg siab, kev nyab xeeb, thiab kev ua tau zoo ntawm lawv cov khoom thaum txo cov nqi thiab txhim kho kev tsim khoom.

Electronics Industry Applications of LSR

Liquid Silicone Rubber (LSR) yog cov khoom siv dav siv hauv kev lag luam hluav taws xob vim nws cov thermal stability zoo heev, tshuaj tiv thaiv, thiab hluav taws xob rwb thaiv tsev. Nws yog siv rau hauv ntau daim ntawv thov xws li encapsulation, sealing, thiab potting ntawm cov khoom siv hluav taws xob.

Ib qho ntawm cov kev siv tseem ceeb ntawm LSR hauv kev lag luam hluav taws xob yog nyob rau hauv lub encapsulation ntawm cov khoom siv hluav taws xob, xws li kev sib koom ua ke (ICs), sensors, thiab connectors. Encapsulation tiv thaiv cov khoom no los ntawm ya raws, plua plav, thiab lwm yam khoom paug, uas tuaj yeem ua rau corrosion thiab degrade kev ua haujlwm. LSR yog cov khoom siv zoo tshaj plaws rau kev ntim khoom vim nws cov viscosity tsawg, lub zog tsim kua muag, thiab zoo heev adhesion rau ntau yam substrates. Nws kuj muaj cov khoom zoo dielectric, uas yog qhov tseem ceeb hauv kev siv hluav taws xob.

LSR tseem kaw cov khoom siv hluav taws xob los tiv thaiv kev ya raws thiab lwm yam kab mob. Cov khoom siv tuaj yeem molded rau hauv cov duab kev cai thiab qhov ntau thiab tsawg kom haum rau ntau yam khoom siv hluav taws xob. LSR cov ntsaws ruaj ruaj feem ntau siv nyob rau hauv ib puag ncig hnyav, xws li kev siv tubrog nkoj thiab tsheb, qhov chaw lawv yuav tsum tiv taus qhov kub thiab txias thiab raug tshuaj lom neeg.

Potting yog lwm daim ntawv thov tseem ceeb ntawm LSR hauv kev lag luam hluav taws xob. Potting yuav tsum sau cov kab noj hniav nyob ib ncig ntawm cov khoom siv ua kua los tiv thaiv nws ntawm ib puag ncig xws li kev poob siab, kev vibration, thiab ya raws. LSR yog cov khoom siv zoo tshaj plaws rau potting vim nws cov viscosity tsawg, uas tso cai rau nws ntws yooj yim nyob ib ncig ntawm cov duab nyuaj, thiab nws cov thermal stability siab, uas ua kom cov khoom tiv thaiv tseem tiv thaiv qhov kub thiab txias.

LSR kuj tseem siv los tsim cov keypads thiab cov nyees khawm, cov khoom siv hauv cov khoom siv hluav taws xob xws li cov chaw taws teeb tswj, lub tshuab xam zauv, thiab cov keyboards. Cov khoom siv customizable heev tuaj yeem ua rau ntau yam duab thiab ntau thiab tsawg nrog cov textures sib txawv thiab qib hardness.

Aerospace Industry Applications ntawm LSR

Liquid Silicone Roj Hmab (LSR) yog cov khoom siv dav siv hauv kev lag luam aerospace vim nws cov khoom tshwj xeeb, xws li thermal stability, tshuaj tiv thaiv, thiab cov khoom zoo heev. Nws yog siv nyob rau hauv ntau yam kev siv aerospace xws li kev sib khi, kev sib txuas, thiab cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob, O-rings, thiab lwm yam ntsiab lus tseem ceeb.

Ib qho ntawm cov kev siv tseem ceeb ntawm LSR hauv kev lag luam aerospace yog kev sib khi thiab sib txuas cov khoom siv dav hlau. Cov khoom siv tau yooj yim molded rau hauv cov duab thiab ntau thiab tsawg, ua rau nws zoo tagnrho rau kev ntim thiab txuas cov roj tso tsheb hlau luam, cov khoom siv cav, thiab cov tshuab hluav taws xob. LSR muab cov nplaum zoo rau ntau lub substrates thiab tuaj yeem tiv taus ib puag ncig hnyav, xws li huab cua kub thiab tshuaj lom neeg raug.

LSR kuj tseem siv rau hauv potting ntawm cov khoom siv hluav taws xob hauv kev siv aerospace. Cov khoom siv tsis muaj viscosity tso cai rau nws ntws yooj yim nyob ib ncig ntawm cov duab, muab kev tiv thaiv zoo heev rau cov khoom siv hluav taws xob tiv thaiv kev co, kev poob siab, thiab ib puag ncig xws li av noo thiab kub hloov.

Lwm daim ntawv thov tseem ceeb ntawm LSR hauv kev lag luam aerospace yog tsim gaskets, O-rings, thiab lwm yam khoom sib khi. LSR tuaj yeem hloov kho kom tau raws li cov kev xav tau tshwj xeeb, xws li kub thiab siab ua haujlwm, thiab feem ntau siv rau hauv cov ntawv thov kev ua haujlwm siab uas cov khoom siv roj hmab tsoos yuav tsis haum.

Ntxiv nrog rau kev sib khi thiab kev sib txuas, LSR kuj tseem siv los tsim cov khoom siv dav hlau teeb pom kev zoo, xws li lo ntsiab muag thiab diffusers. Cov khoom siv kho qhov muag ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov no, muab lub teeb kis tau zoo, thaum nws cov khoom siv kho qhov muag kom ruaj khov thiab ua haujlwm rau ib puag ncig xws li UV hluav taws xob thiab kub hloov pauv.

Khoom noj khoom haus qib LSR Txhaj Moulding

Food-Grade Liquid Silicone Rubber (LSR) yog cov khoom siv tshwj xeeb uas siv rau hauv cov khoom siv tshuaj molding uas tuaj yeem cuam tshuam nrog cov khoom noj, xws li cov khoom siv hauv chav ua noj, cov khoom me me, thiab ntim khoom noj. Nws yog cov khoom siv purity siab uas ua tau raws li cov qauv kev cai nruj rau kev nyab xeeb khoom noj.

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm Food-Grade LSR yog nws qhov kev tiv thaiv rau qhov kub thiab txias, uas ua rau nws zoo tagnrho rau siv hauv chav ua noj xws li spatulas, diav, thiab ci pwm. Nws tuaj yeem tiv taus qhov kub txog li 450 ° F (232 ° C), ua kom muaj kev nyab xeeb rau kev ua noj thiab ci daim ntawv thov.

Food-Grade LSR kuj yog siv los tsim cov khoom me me, xws li pacifiers thiab lub raj mis mis. Cov khoom no yuav tsum ua raws li cov qauv kev nyab xeeb nruj kom ntseeg tau tias lawv muaj kev nyab xeeb rau menyuam mos. LSR yog cov khoom siv zoo tshaj plaws rau cov ntawv thov no vim nws cov biocompatibility zoo heev, softness, thiab durability.

Lwm daim ntawv thov tseem ceeb ntawm Food-Grade LSR yog nyob rau hauv ntim khoom noj. Cov khoom siv tuaj yeem ua rau ntau yam duab thiab qhov ntau thiab tsawg, ua rau nws zoo tagnrho rau kev tsim cov thawv ntim khoom noj, cov tais dej khov, thiab lwm yam khoom. LSR tiv taus cov tshuaj thiab muaj cov khoom sib khi zoo, ua kom cov ntsiab lus ntawm lub pob nyob twj ywm tshiab thiab tsis muaj kab mob.

Food-Grade LSR kuj tseem siv los tsim cov khoom kho mob xws li cov ntaub ntawv kho hniav thiab cov khoom siv prosthetic. Cov khoom siv biocompatibility, durability, thiab muaj peev xwm rov ua dua cov ntsiab lus zoo ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov no.

Zuag qhia tag nrho, Food-Grade LSR yog cov khoom siv tshwj xeeb zoo tshaj plaws rau kev tsim cov khoom lag luam uas tuaj yeem cuam tshuam nrog cov khoom noj, xws li cov tais diav hauv chav ua noj, cov khoom me me, thiab ntim khoom noj. Nws tsis kam mus rau qhov kub thiab txias, biocompatibility, thiab zoo heev sealing zog ua rau nws yog ib tug zoo tagnrho cov ntaub ntawv rau cov kev siv. Cov khoom siv kuj tseem siv los tsim cov khoom kho mob vim nws biocompatibility thiab muaj peev xwm rov ua cov ntsiab lus zoo.

LSR Txhaj Moulding rau cov khoom me nyuam

LSR (Liquid Silicone Rubber) txhaj tshuaj molding yog txheej txheem tsim khoom siv los tsim ntau yam khoom ua los ntawm silicone roj hmab. Ib qho ntawm cov ntawv thov nrov tshaj plaws ntawm LSR txhaj tshuaj molding yog tsim cov khoom me me, thiab qhov no yog vim muaj ntau yam txiaj ntsig uas LSR muab rau cov khoom me me, suav nrog kev nyab xeeb, kav ntev, thiab yooj yim ntawm kev tu.

LSR txhaj tshuaj molding yuav tsum tau txhaj cov kua silicone roj hmab rau hauv pwm, uas tom qab ntawd kho thiab ua kom khov. Cov txheej txheem no tso cai rau kev tsim cov duab sib txawv thiab cov qauv tsim thiab siv cov xim sib txawv thiab textures. Qhov tshwm sim yog cov khoom tiav uas yog mos, hloov tau, thiab tiv taus cua sov thiab tshuaj lom neeg.

Ib qho txiaj ntsig tseem ceeb ntawm LSR txhaj tshuaj molding rau cov khoom me me yog kev nyab xeeb. Silicone roj hmab yog non-toxic, hypoallergenic, thiab tsis muaj tshuaj lom neeg xws li BPA, phthalates, thiab PVC. Qhov no ua rau nws yog qhov kev xaiv nrov rau cov khoom lag luam uas tau ntsib nrog cov menyuam mos, xws li pacifiers, teething rings, thiab lub raj mis mis. LSR txhaj tshuaj molding tseem tso cai rau kev tsim cov khoom tsis muaj cov npoo ntse lossis cov seams uas tuaj yeem ua rau tus menyuam mos cov tawv nqaij.

Durability yog lwm qhov txiaj ntsig ntawm LSR txhaj tshuaj molding. Silicone roj hmab yog resistant rau hnav thiab tsim kua muag, ua rau nws zoo tagnrho rau cov khoom siv nquag los yog raug rau cov tuav ntxhib, xws li pacifiers los yog teething rings. Qhov muag muag thiab hloov pauv ntawm cov khoom siv kuj ua rau nws tsis tshua tawg lossis tawg thaum poob, txo qhov kev pheej hmoo ntawm kev raug mob rau tus menyuam.

LSR txhaj tshuaj molding kuj muaj kev tu yooj yim, uas yog qhov tseem ceeb rau cov khoom me me uas yuav tsum tau ua kom huv si ntau zaus. Silicone roj hmab tsis yog ntxeem tau thiab tuaj yeem ntxuav tau yooj yim nrog xab npum thiab dej los yog muab tso rau hauv lub tshuab ntxhua khaub ncaws kom huv si.

LSR Txhaj Moulding rau Cov Khoom Ua Si

LSR (Liquid Silicone Rubber) txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau ntau yam khoom, suav nrog cov khoom ua si. LSR txhaj tshuaj molding muaj ntau yam txiaj ntsig rau kev tsim cov khoom ua kis las, suav nrog kev yoog raws, ua haujlwm ntev, thiab ua haujlwm rau huab cua kub thiab ib puag ncig.

Ib qho txiaj ntsig tseem ceeb ntawm LSR txhaj tshuaj molding rau cov khoom ua si yog qhov yooj. Silicone roj hmab yog cov khoom siv mos, pliable uas tuaj yeem ua rau ntau yam duab thiab tsim. Qhov no tso cai rau kev tsim cov khoom ua kis las uas nyiam siv thiab ua raws li lub cev, xws li cov iav tiv thaiv lossis tuav cov khoom siv.

Durability yog lwm qhov txiaj ntsig ntawm LSR txhaj tshuaj molding rau cov khoom ua si. Silicone roj hmab yog resistant rau hnav thiab tsim kua muag, ua rau nws zoo tagnrho rau cov khoom siv nquag los yog raug rau cov tuav ntxhib, xws li pob, paddles, los yog rackets. Cov khoom siv kuj tuaj yeem tiv taus qhov kub thiab txias ib puag ncig, xws li raug tshav ntuj lossis dej, tsis muaj degrading lossis deteriorating.

LSR txhaj tshuaj molding kuj tso cai rau tsim cov khoom tiv thaiv kev cuam tshuam thiab puas. Cov khoom siv lub zog tsim kua muag thiab elongation ntawm kev tawg ua rau nws zoo tagnrho rau kev tsim cov iav tiv thaiv xws li cov kaus mom hlau, lub qhov ncauj qhov ntswg, thiab lub ntsej muag lub ntsej muag. Tsis tas li ntawd, LSR kev txhaj tshuaj molding tso cai rau kev tsim cov khoom siv tsis zoo los yog tuav rau cov khoom siv, xws li cov tes tuav lossis racquet grips.

Lwm qhov txiaj ntsig ntawm LSR txhaj tshuaj molding rau cov khoom ua si yog tsim cov khoom uas yooj yim los ntxuav thiab tswj. Silicone roj hmab tsis yog ntxeem tau thiab tuaj yeem yooj yim so nrog cov ntaub ntub dej lossis ntxhua nrog xab npum thiab dej. Qhov no ua rau nws yog ib qho khoom siv zoo tshaj plaws rau cov khoom siv nquag, xws li cov khoom siv gym lossis yoga lev.

LSR Txhaj Moulding rau Cov Khoom Siv Hauv Tsev

LSR txhaj tshuaj molding yog txheej txheem tsim khoom uas siv Liquid Silicone Rubber (LSR) los tsim cov pwm pwm. Cov txheej txheem no yog qhov zoo tagnrho rau kev tsim cov khoom siv hauv tsev zoo xws li cov khoom siv hauv chav ua noj, cov khoom me me, thiab cov khoom siv hauv chav dej. LSR txhaj tshuaj molding muaj ntau yam txiaj ntsig, suav nrog kev ua haujlwm siab, sib xws, thiab ua haujlwm ntev, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv hauv tsev uas yuav tsum tau ua kom nruj thiab ua haujlwm zoo.

Cov txheej txheem LSR txhaj tshuaj molding yuav tsum tau txhaj cov khoom siv silicone rau hauv pwm. Tom qab ntawd cov pwm yog rhuab, thiab cov khoom siv silicone yog kho thiab ua kom khov rau hauv cov duab uas xav tau. Cov txheej txheem yog automated heev, tso cai rau cov khoom zoo ib yam nrog nruj tolerances thiab zoo heev nto finishes. Cov txheej txheem no tseem tso cai rau kev tsim cov geometry nyuaj uas yuav nyuaj lossis tsis tuaj yeem ua tiav nrog lwm cov txheej txheem molding.

Cov khoom siv hauv tsev feem ntau tsim los siv LSR txhaj tshuaj molding suav nrog cov khoom siv hauv chav ua noj xws li spatulas thiab diav ua noj, cov khoom me me xws li pacifiers thiab lub raj mis, thiab cov khoom siv hauv chav dej xws li da dej thiab txhuam hniav. Cov khoom no yuav tsum tau txhaj tshuaj molding kom tau raws li cov qauv kev nyab xeeb thiab kev ua tau zoo, thiab LSR txhaj tshuaj molding muaj qhov tseeb thiab sib xws uas xav tau los tsim cov khoom zoo hauv tsev uas ua tau raws li cov qauv no.

Ib qho txiaj ntsig tseem ceeb ntawm LSR txhaj tshuaj molding rau cov khoom siv hauv tsev yog nws cov kav ntev. LSR cov ntaub ntawv tiv taus kub kub, UV hluav taws xob, thiab tshuaj lom neeg, ua rau lawv zoo tagnrho rau cov khoom siv ntev ntev. Tsis tas li ntawd, LSR cov ntaub ntawv yog hypoallergenic, ua rau lawv muaj kev nyab xeeb rau kev siv cov khoom me me thiab lwm yam khoom siv hauv tsev uas tuaj yeem tiv nrog daim tawv nqaij.

Lwm qhov txiaj ntsig ntawm LSR txhaj tshuaj molding yog nws lub peev xwm los tsim cov khoom nrog zoo heev nto tiav. Cov txheej txheem tso cai rau tsim cov yam ntxwv nrog tus du, glossy tiav resistant rau khawb thiab scuffs. Qhov no ua rau LSR txhaj tshuaj molding yog ib qho kev xaiv zoo tshaj plaws rau kev tsim cov khoom siv hauv tsev uas xav tau qhov zoo nkauj zoo nkauj, xws li cov khoom siv hauv chav ua noj thiab cov khoom siv hauv chav dej.

Kev sib piv nrog lwm hom roj hmab Moulding

LSR (Liquid Silicone Rubber) txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau kev tsim ntau yam khoom siv roj hmab, thiab nws muaj ntau yam zoo dua lwm hom roj hmab molding txheej txheem. Nov yog qee qhov kev sib piv ntawm LSR txhaj tshuaj molding thiab ntau hom roj hmab molding:

- Compression Molding: Compression molding yog txheej txheem txheej txheem los ua qhov loj lossis qhov chaw nrog cov duab nyuaj. Hauv compression molding, ib qho kev ntsuas ua ntej ntawm cov roj hmab tau muab tso rau hauv cov pwm kub, thiab siv zog kom txog thaum cov roj hmab kho tau. Piv rau LSR txhaj tshuaj molding, compression molding yog cov txheej txheem qeeb dua thiab tuaj yeem ua rau muaj qhov sib txawv ntawm qhov loj me vim qhov tsis sib xws ntawm kev faib tawm. LSR kev txhaj tshuaj molding, ntawm qhov tod tes, tso cai rau kev tswj hwm ntawm qhov ntev thiab tuaj yeem tsim cov duab nyuaj nrog nruj kam rau ua.

- Hloov Moulding: Hloov molding zoo ib yam li compression molding tab sis siv lub plunger hloov cov roj hmab los ntawm lub lauj kaub rau hauv pwm. Hloov molding tuaj yeem tsim cov khoom nrog qhov raug siab thiab tsim nyog rau kev ua qhov nruab nrab. Txawm li cas los xij, nws tuaj yeem ua qeeb qeeb thiab kim dua li LSR txhaj tshuaj molding.

- Txhaj Moulding: Txhaj tshuaj molding yog txheej txheem uas yuav tsum tau txhaj cov roj hmab molten rau hauv pwm ntawm lub siab. Kev txhaj tshuaj molding tuaj yeem tsim cov khoom sai thiab raug, tab sis nws yuav tsis haum rau kev ua cov khoom nrog cov qauv tsim lossis cov ntsiab lus. Piv nrog rau kev txhaj tshuaj molding, LSR txhaj molding tso cai rau kev tsim cov khoom nrog cov ntsiab lus meej thiab cov qauv tsim thiab cov qauv zoo sib xws.

- Extrusion: Extrusion yog txheej txheem siv los tsim cov khoom nrog cov ntu txuas txuas txuas ntxiv, xws li hoses, seals, thiab gaskets. Extrusion yog cov txheej txheem ceev thiab raug nqi, tab sis nws yuav tsis tsim nyog rau kev tsim cov duab los yog cov khoom nrog nruj tolerances. LSR txhaj tshuaj molding, ntawm qhov tod tes, tuaj yeem muaj qhov sib txawv nrog cov duab thiab nruj, ua rau nws zoo tagnrho rau kev tsim khoom xws li cov khoom siv kho mob, cov khoom siv tsheb, thiab cov khoom siv.

Kev txiav txim siab tsim qauv rau LSR Txhaj Moulding

Ntau qhov tseem ceeb yuav tsum tau txiav txim siab thaum tsim qhov chaw rau LSR txhaj tshuaj molding kom ntseeg tau tias kev tsim khoom tiav. Cov kev txiav txim siab no suav nrog kev xaiv cov khoom, pwm tsim, ib feem geometry, thiab kev ua haujlwm tom qab molding.

Kev xaiv cov khoom yog qhov tseem ceeb thaum tsim cov khoom rau LSR txhaj tshuaj molding. Cov ntaub ntawv silicone roj hmab ua kua tuaj hauv ntau yam durometers, viscosities, thiab xim, thiab xaiv cov khoom tsim nyog yog qhov tseem ceeb rau kev ua tiav cov khoom xav tau ntawm cov khoom kawg. Kev xaiv cov khoom siv yuav tsum xav txog cov kev xav tau ntawm daim ntawv thov, xws li kub tsis kam, tshuaj tiv thaiv, thiab kav ntev.

Pwm tsim yog lwm qhov tseem ceeb rau LSR txhaj tshuaj molding. Cov pwm tsim yuav tsum tau ua kom zoo dua los ua qhov xav tau ntawm qhov geometry thiab xav txog cov khoom ntws, txias, thiab ejection. Cov pwm yuav tsum tau tsim nrog lub rooj vag thiab qhov cua kom zoo thiab muaj cov kab noj hniav txaus kom ua tiav qhov kev tsim khoom siab.

Ib feem geometry tseem yog qhov tseem ceeb thaum tsim qhov chaw rau LSR txhaj tshuaj molding. Ib feem geometry yuav tsum tau ua kom zoo kom ua tiav cov khoom kawg qhov xav tau cov khoom siv kho tshuab thiab kev zoo nkauj. Qhov no tuaj yeem koom nrog kev siv cov kaum sab xis los pab txhawb kev tshem tawm ntawm cov pwm, siv cov tav los ua kom nruj, thiab tso cov rooj vag thiab qhov cua kom zoo dua cov khoom ntws.

Kev ua haujlwm tom qab molding yuav tsum tau txiav txim siab thaum tsim qhov chaw rau LSR txhaj tshuaj molding. Kev ua haujlwm tom qab molding tuaj yeem suav nrog kev txiav, tshem tawm, thiab kev ua haujlwm thib ob. Cov haujlwm no yuav tsum tau ua kom zoo kom txo qis cov khoom pov tseg thiab txo cov nqi zog.

Lwm qhov kev txiav txim siab tsim qauv rau LSR txhaj tshuaj molding tuaj yeem suav nrog kev siv cov undercuts, qhov chaw ntawm ejector pins, thiab kev siv cov kab sib cais. Cov yam tseem ceeb no yuav tsum tau txiav txim siab thaum lub sij hawm tsim qauv los xyuas kom meej tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb thiab tuaj yeem tsim tau zoo.

Environmental and Sustainability Benefits of LSR Txhaj Molding

LSR txhaj tshuaj molding muaj ntau yam kev pab cuam ib puag ncig thiab kev ruaj ntseg tshaj li cov txheej txheem tsim khoom ib txwm muaj, ua rau nws yog qhov kev xaiv zoo rau cov tuam txhab nrhiav kom txo lawv cov hneev taw ecological.

Ib qho ntawm cov txiaj ntsig zoo ib puag ncig ntawm LSR txhaj tshuaj molding yog nws cov khoom pov tseg tsawg. Cov txheej txheem tsim cov khoom pov tseg tsawg heev, raws li cov kua roj hmab silicone yog txhaj ncaj qha rau hauv pwm thiab kho kom tsim tau cov duab uas xav tau. Qhov no sib piv nrog lwm cov txheej txheem tsim khoom, xws li machining lossis casting, uas tsim cov khoom seem tseem ceeb.

LSR txhaj tshuaj molding kuj tseem muaj peev xwm txo qis kev siv hluav taws xob thiab cov pa hluav taws xob hauv tsev cog khoom. Cov txheej txheem tuaj yeem ua tau zoo heev, txo qhov xav tau ntawm kev siv tes ua haujlwm thiab txo qis kev siv zog. LSR kev txhaj tshuaj molding yog cov txheej txheem kub qis uas yuav tsum muaj lub zog tsawg dua li lwm cov txheej txheem molding, xws li txhaj tshuaj molding lossis tshuab molding. Qhov no tuaj yeem ua rau muaj kev txuag hluav taws xob tseem ceeb thiab txo cov pa hluav taws xob hauv tsev cog khoom.

Lwm qhov txiaj ntsig zoo ntawm LSR txhaj tshuaj molding yog lub peev xwm los siv cov khoom siv rov ua dua tshiab. LSR cov ntaub ntawv tuaj yeem siv tau thiab rov siv dua, txo qhov xav tau ntawm cov ntaub ntawv tshiab thiab txo cov khoom pov tseg. Tsis tas li ntawd, lub neej ntev ntawm LSR cov khoom lag luam txhais tau tias lawv tuaj yeem rov qab siv dua lossis rov ua dua tshiab, txo cov khoom pov tseg thiab txuas ntxiv cov khoom lag luam.

LSR txhaj tshuaj molding tuaj yeem txo kev siv cov tshuaj phem hauv kev tsim khoom. Cov ntaub ntawv LSR feem ntau tsis muaj tshuaj lom xws li phthalates, BPA, thiab PVC, ua rau lawv muaj kev nyab xeeb dua rau cov neeg ua haujlwm thiab cov neeg siv khoom. Tsis tas li ntawd, cov txheej txheem kub qis siv hauv LSR txhaj tshuaj molding tsis xav tau cov kuab tshuaj lom lossis lwm yam tshuaj lom neeg.

Yav tom ntej ntawm LSR Txhaj Molding

Lub neej yav tom ntej ntawm LSR txhaj tshuaj molding yog ci, nrog rau cov txheej txheem muab ntau yam zoo dua li kev tsim khoom ib txwm muaj. LSR kev txhaj tshuaj molding yuav dhau los ua kom muaj txiaj ntsig zoo, muaj txiaj ntsig zoo, thiab tus phooj ywg ib puag ncig raws li thev naus laus zis nce qib.

Ib qho chaw zoo tshaj plaws rau yav tom ntej ntawm LSR txhaj tshuaj molding yog kev siv cov txheej txheem tsim khoom ntxiv. Additive manufacturing, tseem hu ua 3D luam ntawv, tso cai rau tsim cov geometries complex thiab customized qhov chaw uas yuav nyuaj los yog tsis yooj yim sua los tsim siv cov tsoos manufacturing txoj kev. Raws li cov thev naus laus zis txhim kho, LSR kev txhaj tshuaj molding yuav dhau los ua kev sib xyaw nrog kev tsim khoom ntxiv, tso cai rau cov khoom lag luam siab dua thiab tsim tshiab.

Lwm thaj chaw ntawm kev txhim kho yav tom ntej rau LSR txhaj tshuaj molding yog siv cov khoom siv siab heev. Raws li cov ntaub ntawv tshiab tau tsim, LSR txhaj tshuaj molding tuaj yeem ua kom zoo dua ntawm lawv cov khoom tshwj xeeb, xws li kev txhim kho durability, kub tsis kam, lossis biocompatibility. Qhov no yuav tso cai rau cov khoom tshwj xeeb tshaj plaws, xws li cov khoom siv kho mob lossis cov khoom siv ua haujlwm siab.

Kev koom ua ke txuas ntxiv ntawm automation thiab robotics rau hauv LSR kev txhaj tshuaj molding txheej txheem kuj tseem yuav yog qhov tseem ceeb rau yav tom ntej. Automation tuaj yeem txhim kho kev ua haujlwm zoo, txo cov nqi zog, thiab txhim kho qhov sib xws thiab zoo ntawm cov khoom kawg. Raws li kev txhim kho thev naus laus zis, LSR txhaj tshuaj molding yuav dhau los ua kev siv tshuab ntau dua, nrog rau cov neeg hlau thiab kev txawj ntse txawj ntse ua lub luag haujlwm tseem ceeb hauv kev tsim khoom.

Thaum kawg, kev ruaj khov thiab kev lav phib xaub ntawm ib puag ncig yuav zoo li yuav yog tus tsav tsheb tseem ceeb nyob rau yav tom ntej ntawm LSR txhaj tshuaj molding. Raws li cov neeg siv khoom thiab cov lag luam nce siab rau txo cov pov tseg thiab txo qis lawv cov kev cuam tshuam ecological, LSR txhaj tshuaj molding yuav dhau los ua qhov kev xaiv zoo tshaj plaws rau kev tsim cov khoom zoo nrog ib puag ncig qis. Kev txhim kho cov ntaub ntawv muaj txiaj ntsig zoo dua qub, rov ua dua tshiab thiab rov ua dua cov ntaub ntawv, thiab siv cov khoom siv hluav taws xob txuas ntxiv tuaj yeem ua lub luag haujlwm tseem ceeb dua yav tom ntej ntawm LSR txhaj tshuaj molding.

xaus:

Hauv kev xaus, LSR txhaj tshuaj molding yog ib qho kev txhim khu kev qha thiab ua haujlwm tau zoo nrog ntau cov txiaj ntsig rau ntau yam kev lag luam. LSR yog cov khoom siv ntau yam nrog cov yam ntxwv ua tau zoo, ua rau nws zoo tagnrho rau ntau daim ntawv thov. Nrog txuas ntxiv kev nce qib hauv LSR thev naus laus zis thiab kev xav tau ntau ntxiv rau kev tsim khoom lag luam, lub neej yav tom ntej ntawm LSR txhaj tshuaj molding yog ci.