Txhaj Pwm Kho

Pwm Kho & Hloov kho

Peb kho tag nrho cov pwm ua los ntawm peb lossis lwm tus neeg tsim khoom hauv 5 hnub.

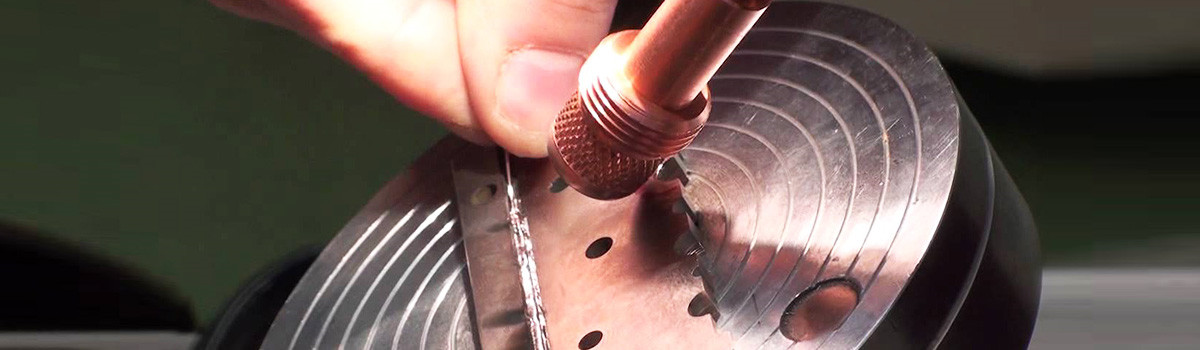

Cov cuab yeej cuab tam

Rau kev tsim thiab kev pab cuam ntawm pwm DJmolding siv dua li cov cav tov xws li lathes, round thiab ca sib tsoo tshuab, xyaum thiab milling tshuab nrog rau cov kws tshaj lij machining chaw.

Kev kho pwm ua haujlwm li cas

Peb muab kev pabcuam pwm los ntawm txhua lub chaw tsim khoom. Koj puas muaj cov pwm tawg? Peb tshuaj xyuas qhov kev puas tsuaj, tsim cov kev daws teeb meem uas yuav cuam tshuam tsawg kawg rau lub neej ntawm pwm, thiab tau mus ua haujlwm. Kev xav tau tsawg dua yuav ua tiav hauv 5 hnub. Txawm li cas los xij, peb tuaj yeem kho cov pwm sai dua, piv txwv li nyob rau lub asthiv yuav tsum cov pwm puas ua rau cov khoom poob qis. Tiv tauj peb, peb yuav nrhiav kev daws teeb meem.

Pwm kev ntxhib los mos nto kho los ntawm peb pab neeg no ntawm DJmoldng yuav paub tseeb tias koj qhov kev sib tw zoo tshaj plaws.

Peb cov kws ua haujlwm paub txog thiab cov kws tshaj lij yuav kho cov qauv puas. Txhua qhov kev kho pwm txawv seb nws yuav yog:

* Weld los ntawm kev kho cov kev puas tsuaj loj lossis kev hloov pauv engineering.

* Kev kho xeb thiab gloss

* Cov ntaub ntawv scuff los ntawm qhov tsawg kawg nkaus

* Cov ntawv refurbishes

* Sib faib kab burrs lossis dings

Yog xav tau vuam, ua raws li cov lus qhia hauv qab no rau kev kho kom zoo:

Weld nrog tib cov khoom uas pwm tau tsim los ntawm; xws li P-20, S-7, H-13 lossis stainless hlau. Yog tias tsis siv cov khoom siv tib yam, lub vuam yuav etch ntawm tus nqi sib txawv tawm hauv cov ntaub ntawv pov thawj nyob ib ncig ntawm lub vuam thaum kho qhov kev ntxhib los mos.

Pwm yuav tsum tau rhuab kom zoo ua ntej welding. Yog tias tsis ua kom sov zoo, nws tuaj yeem ua rau lub vuam txias sai heev. Yog tias qhov no tshwm sim, txawm tias thaum siv cov khoom siv tib yam, nws yuav ua rau cov vuam sib txawv ntawm qhov sib txawv uas yuav tsum tau muaj kev ntxhov siab rau cov hlau tsis tu ncua kom tau txais kev kho qhov zoo tshaj plaws.

Nrog rau kev nce qib ntawm kev lag luam laser texturing peb tau tsim cov txheej txheem kho laser ntawm DJmoldng uas tuaj yeem siv rau txhua yam pwm txawm tias nws yog laser textured lossis chemically etched los kho qhov chaw puas. Los ntawm cov txheej txheem no peb tuaj yeem laser kho thaj chaw thiab muab sib xyaw rau hauv qhov kev ntxhib los mos uas twb muaj lawm tshem tawm cov teeb meem tsis pom kev rov kho koj lub cuab yeej mus rau qhov zoo li-tshiab.

Hloov Moulds

Peb npaj cov ntaub ntawv peb tus kheej, CAD / CAM, thiab qhia txog txoj kev kho zoo tshaj plaws.

Pwm Kho

Peb siv peb tus kheej chemistry los ntxuav qhov txhaws thiab ua tsaug rau lub tonnage ntawm peb crane peb tuaj yeem pab pwm txog 20 tons.

Kev puas tsuaj pwm kho

Peb ntsuas cov duab puas thiab kho qhov qub qub.

Cov ntaub ntawv 2D/3D ploj lawm

Puas yog cov ntaub ntawv rau koj cov pwm ploj? Peb pab tau. Peb muaj peev xwm ntsuas thiab ua qee qhov chaw los kho cov pwm.

Qhov siab tshaj plaws

Peb ua tiav koj cov xaj hauv cov txheej txheem txheej txheem nrog qhov siab tshaj plaws. Peb lub peev xwm nce ntxiv nrog txhua qhov kev txiav txim ua tus muab kev pabcuam hauv qhov tshwj xeeb no. Peb siv niaj hnub, ib nrab tsis siv neeg vuam technologies xws li ntshav welding, E-welding thiab laser-welding. Tsis siv neeg CNC tshuab ua haujlwm nrog kev txhawb nqa lub computer thiab nrog qhov siab tshaj plaws.

Lwm yam kev pabcuam

Ntxiv rau kev tsim, kho thiab kho cov pwm txhaj tshuaj thiab ua cov tshuab semi-automatic rau kev lag luam tsheb, tshuaj thiab kev lag luam, peb kuj muaj lwm cov kev pabcuam cuam tshuam.

Designing

Peb tsim thiab tsim daim ntawv rau koj hauv 3D software program.

qauv

Peb npaj ib lub hom phiaj cuab yeej hauv 3D software kom koj tuaj yeem sim nws hauv kev xyaum ua ntej koj khiav cov koob.

Laser Vuam

Peb ua tib zoo kho koj cov pwm tawg. Tsis muaj kev ntxhov siab sab hauv ntawm cov hlau thaum vuam.

Precision Engineering thiab Machining

Peb ua haujlwm nrog qhov tseeb ntawm 0.01 hli. Peb cov kws paub txog kev ua haujlwm nrog NC tshuab, dab dej thiab cov tshuab txiav hlau.

Kev tsim khoom thiab tsim kev tswj thiab ntsuas Jigs

Kev tshuaj xyuas thiab ntsuas jigs ua kom yooj yim los xyuas koj cov molding tiav. Peb saib xyuas kev tsim thiab tsim khoom.

Customized Copper los yog Graphite Electrodes

Peb tsim cov tooj liab thiab graphite electrodes tsim nyog rau EDM (cavity sinking) machining.

Convincing zoo

Txawm hais tias kho, hloov pauv profile lossis kev tsim khoom tshiab - peb yuav txhawb koj nrog cov kev daws teeb meem tshiab rau koj tus kheej xav tau. Peb muab koj cov kev txiav txim siab tsim thiab xav tau kev daws teeb meem nrog cov txiaj ntsig zoo thiab kav ntev uas yuav ua rau koj siv txhua hnub hauv koj cov khoom.

Txhua qhov kev txiav txim yog qhov tshwj xeeb

Peb cov neeg xav tau cov khoom zoo, kev tshaj lij thiab kev ntseeg siab. Peb tsim kev sib koom tes ntev.