Case hauv Australia:

Vim li cas Australian Tuam Txhab Outsource Txhaj Moulding Rau DJmolding

Kev lag luam yog txhua yam hais txog kev txiav cov nqi. Muaj ib txwm tshawb nrhiav txoj hauv kev txuag nyiaj thiab nce cov txiaj ntsig hauv txhua lub lag luam, tsis hais nws qhov loj npaum li cas. Txoj hauv kev zoo tshaj plaws ntawm kev ua qhov no niaj hnub no yog outsourcing.

Ntau zuj zus, tuam txhab uas muag tau outsourcing lawv manufacturing rau Suav factories vim lawv ceev ceev, efficiency, thiab tsawg tus nqi. Cov khoom uas lawv xav tau ntawm tus nqi lawv tuaj yeem them tau txawm tias tau tawm mus rau Tuam Tshoj los ntawm cov tuam txhab Australian.

Qee cov tuam txhab lag luam los ntawm Australia, rau tib yam, lawv tau outsourced lawv cov yas txhaj tshuaj rau DJmolding.

Txhaj Moulding Nqi ntawm DJmolding

Piv nrog rau lwm lub teb chaws, Tuam Tshoj tau qis dua cov nqi zog thiab cov khoom siv raw, uas yog ib qho ntawm cov laj thawj cov tuam txhab outsource txhaj molding rau lawv. DJmolding profitability yuav nce los ntawm kev txo nqi ntau lawm.

Cov tuam txhab tshwj xeeb hauv kev tsim khoom ntim siab thiab nrhiav kev txuag nqi tshwj xeeb yog qhov yuav tau txais txiaj ntsig los ntawm qhov no. Tuam Tshoj cov pej xeem coob kuj txhais tau tias muaj cov neeg ua haujlwm tau yooj yim uas tuaj yeem ua tau raws li qhov xav tau ntawm koj lub tuam txhab. DJmolding tuaj yeem pab txo cov nqi kawm thiab nce kev tsim khoom.

Zoo Los ntawm DJmolding injection mov

DJmolding tau nqis peev hauv cov cuab yeej tsim khoom siab heev thiab tau cob qhia lawv cov neeg ua haujlwm hauv cov txheej txheem tsim khoom tshiab, uas tuaj yeem pab txhim kho lawv cov khoom zoo. DJmolding kuj tau nqis peev ntau rau hauv kev tshawb fawb thiab kev tsim kho, uas txhais tau hais tias DJmolding tau nkag mus rau cov thev naus laus zis uas tuaj yeem pab lawv tsim cov khoom tshiab. Qhov no yog qhov tseeb tshwj xeeb tshaj yog rau cov tuam txhab uas tshwj xeeb hauv kev tsim cov thev naus laus zis xws li aerospace, electronics thiab automotive Cheebtsam.

Lub Sijhawm Lead:

Outsourcing rau DJmolding feem ntau tuaj yeem ua rau lub sijhawm luv luv piv rau Australian kev tsim khoom hauv tsev, ua tsaug rau cov kev tsim kho kom zoo thiab qhov tseeb tias Tuam Tshoj nyob ze rau ntau lub khw loj hauv Asia.

Kev ceev ntawm DJmolding cov txheej txheem tsim khoom kuj tseem ceeb, peb tuaj yeem tig ib ncig ntawm cov khoom hauv ob peb lub lis piam. Qhov no tuaj yeem pab tau tshwj xeeb rau cov lag luam tab tom nrhiav kev tshaj tawm cov khoom tshiab lossis qhia cov kab raws caij nyoog, ua kom cov khoom txaus txaus ua ntej hnub tso tawm.

Kev paub ntawm DJmolding Txhaj Molding Kev Lag Luam:

DJmolding boasts ntau tus kws tshaj lij hauv kev tsim khoom, nthuav qhia cov kev pabcuam dav dav suav nrog kev tsim, kev tsim qauv, pwm tsim, txhaj tshuaj molding, thiab kev sib dhos.Our tes-on kev paub tshwj xeeb yog qhov tseem ceeb rau cov tuam txhab tshiab nrhiav lub Hoobkas uas tuaj yeem muab kev coj ua. Tsis tas li ntawd, ntau tus neeg muag khoom hauv Suav teb tau tsim kev sib txuas nrog cov chaw muab kev pabcuam hauv zos, ua rau lawv txuas cov neeg siv khoom nrog cov chaw tsim khoom tshwj xeeb rau cov kev pabcuam xws li ntim thiab xa khoom.

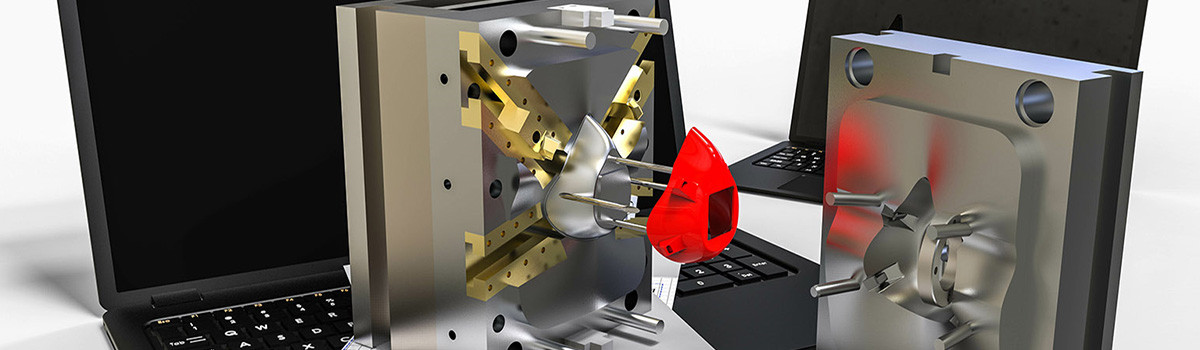

Nov yog cov lus qhia ua ntu zus ntawm DJmolding kev txhaj tshuaj molding txheej txheem:

1. Tsim cov pwm: Qhov no suav nrog kev tsim cov qauv 3D (tsim softwares: solidworks, ug, pro-e…) ntawm cov khoom thiab pwm, suav nrog cov khoom xws li cov khoom (PP, PE, ABS, PA ...), phab ntsa thickness, rooj vag loj, thiab lub sijhawm txias.

2.Fabricate pwm: Cov pwm feem ntau yog ua los ntawm steel los yog txhuas thiab yuav tsum tau fabricated kom meej specifications. Daim ntawv teev cov yas pwm steels nrog hardness:

* P20 Hlau - 28-32 HRc

* 420 Hlau - 48-52 HRc

* H13 Hlau - 48-52 HRc

* S7 Steel - 45-49 HRc

* NAK55 Hlau - 50-55 HRc

* NAK80 Hlau - 38-43 HRc

* DC53 Hlau - 50-58 HRc

* A2 Hlau - 60-64 HRc

* D2 Hlau - 60-64 HRc

Lus Cim: HRc yog hais txog Rockwell hardness scale, uas ntsuas qhov hardness ntawm cov khoom.

3.Nruab pwm: Cov pwm yog ntsia rau ntawm lub tshuab txhaj tshuaj molding thiab clamped ntawm 2 daim hlau ntawm lub tshuab.

4.Load cov khoom yas: Cov khoom siv yas ntim rau hauv lub plhaw ntawm lub tshuab txhaj tshuaj molding ntawm lub ntiajteb txawj nqus thiab qee qhov hopper yuav sim cov khoom yas thaum txhaj tshuaj molding.

5. Melt cov yas: Cov khoom siv yas yog yaj los ntawm tshav kub thiab siab nyob rau hauv lub thoob ntawm lub tshuab txhaj tshuaj molding.

6. Txhaj cov yas rau hauv pwm: Lub melted yas khiav mus rau hauv pwm ntawm nozzle thiab sprue nyob rau hauv siab siab, thiab mus thru khiav, rooj vag ces sau cov pwm kab noj hniav.

7.Cool thiab solidify: Cov pwm yog txias kom cia cov yas kom khov rau hauv pwm kab noj hniav ib ntus, thiab feem ntau, lub sij hawm txias yuav yog 2/3 ntawm tag nrho lub sij hawm.

8. Qhib lub pwm: Cov pwm qhib thiab cov khoom molded raug tshem tawm ntawm pwm, ces pwm kaw thiab lub voj voog tom ntej pib.

Cov cuab yeej thiab cov ntaub ntawv tsim nyog: Kev txhaj tshuaj molding tshuab, pwm, khoom siv yas, tshuab ziab khaub ncaws, ntsuas kub (rau qhov xav tau siab thiab txias heev rau kev txhaj tshuaj molding)

Cov pwm tuaj yeem raug kev txom nyem los ntawm ntau yam teeb meem nrog rau cov khoom siv ntau dhau ntawm cov npoo (Flash), uas tuaj yeem ua rau cov qauv tsis muaj zog. Warping los yog distortion tuaj yeem tshwm sim thaum lub molded qhov tsis ua kom nws cov duab los yog loj vim qhov tsis sib xws. Cov pob dub ntawm qhov molded yog qhov tshwm sim ntawm cov khoom siv tsis zoo los yog kev sib kis. Qhov saum npoo tsis zoo, tus cwj pwm los ntawm kev ntxhib los mos los yog roughness, tej zaum yuav tshwm sim los ntawm kev tsim pwm tsis zoo lossis xaiv cov khoom siv. Sink marks, indentations nyob rau hauv molded ib feem, tuaj yeem tshwm sim los ntawm kev sau cov pwm tsis zoo lossis tsis txaus siab thaum molding. Tsis tas li ntawd, qhov molded feem yuav nyuaj rau eject, ua rau cov khoom poob qis thiab nce nqi, los yog nws yuav ua puas thaum ejection.

Qhov tseem ceeb ntawm kev ntsuas kev nyab xeeb tsis tuaj yeem hais ntau dhau hauv cov txheej txheem txhaj tshuaj molding. Txhawm rau tiv thaiv kev raug mob, cov neeg ua haujlwm yuav tsum siv cov cuab yeej tiv thaiv xws li hnab looj tes thiab tsom iav kev nyab xeeb vim tias cov yas yaj tuaj yeem ncav cuag qhov kub thiab txias, qee zaum mus txog 300 degrees, thiab muaj peev xwm tawg tau. Nws yog ib qho tseem ceeb rau cov neeg ua haujlwm kom tau txais kev cob qhia kom raug ntawm cov txheej txheem kev ua haujlwm nyab xeeb.

Takeaway

Nws yog ib qho tseem ceeb uas yuav tsum ua tib zoo xav txog txhua yam cuam tshuam nrog kev xa tawm mus rau Tuam Tshoj, suav nrog kev thauj mus los, nqi thauj khoom, thiab muaj feem cuam tshuam rau koj cov saw hlau.

Ua haujlwm nrog tus neeg muaj npe nrov thiab muaj kev paub txog kev sib koom tes, DJmoldnig tuaj yeem pab koj lub tuam txhab kom ua tiav kev ua haujlwm zoo thiab ua tiav.