Case hauv Canada

Yuav ua li cas DJmolding Low Volume Manufacturing tuaj yeem pab Canadian Cov Lag Luam Me

Cov tswv lag luam me los ntawm Canada, qhov kawg uas lawv xav ua yog siv lawv lub sijhawm thiab nyiaj txiag ntawm kev tsim khoom. Lawv tsis tuaj yeem them taus thiab lawv tsis muaj sijhawm.

DJmolding muaj ib txoj hauv kev los txo lawv cov nqi tsim khoom yam tsis muaj kev cuam tshuam zoo lossis nce lawv cov haujlwm ua haujlwm?

Nws yog hu ua "tsawg ntim manufacturing." Thiab nws yog raws nraim li nws suab zoo li: ib txoj hauv kev tsim cov khoom ntim qis ntawm cov khoom zoo ntawm tus nqi pheej yig.

Kev tsim khoom ntim tsawg siv ntau cov ntsiab lus zoo ib yam li kev tsim khoom hauv lub sijhawm, tab sis nrog cov kev hloov kho tshwj xeeb uas ua rau nws zoo tagnrho rau cov lag luam me nrog cov peev nyiaj tsawg thiab cov peev txheej.

Qhov tseeb, raws li DJmolding txoj kev tshawb fawb, kev tsim khoom ntim tsawg tuaj yeem txo cov nqi txog li 50%.

Tshem tawm Tooling Txo

Qhov sib txawv tseem ceeb tshaj plaws ntawm cov ntim siab thiab cov khoom ntim qis los ntawm cov nqi siv cuab yeej. Kev ntim ntau lawm yuav tsum tau pwm kim thiab tuag rau txhua qhov, uas tuaj yeem kim heev.

Piv txwv li, yog tias koj xav tau 100 qhov chaw nrog 10 qhov sib txawv ntawm ib qho pwm, ces koj yuav xav tau 10 pwm lossis tuag. Tus nqi cuab yeej ib leeg tuaj yeem yog ntau txhiab daus las ib feem.

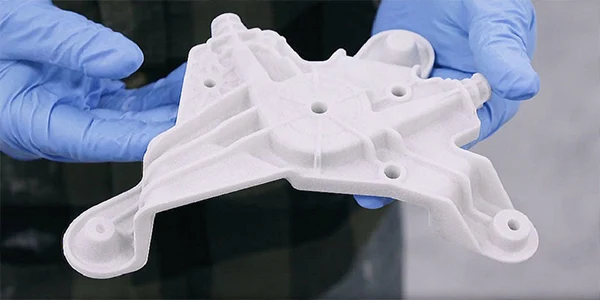

Hauv qhov sib piv, cov khoom ntim qis siv cov cuab yeej yooj yim xws li xuas nrig ntaus thiab tuag uas yog tsim los ntawm cov ntaub ntawv yooj yim xws li qib qis steel lossis aluminium. Qhov no tshem tawm ntau tus nqi ntawm cov cuab yeej cuam tshuam nrog cov txheej txheem tsim khoom loj.

Txawm li cas los xij, qhov no kuj txhais tau tias tsis muaj chaw rau qhov yuam kev thaum nws los tsim cov cuab yeej yooj yim no vim tias lawv yuav tsum muaj tseeb txhua lub sijhawm kom lawv ua haujlwm zoo nrog koj cov khoom tsim. Cov cuab yeej yooj yim no kuj tsis tuaj yeem rov siv dua thiab yuav tsum tau hloov tom qab txhua qhov kev tsim khoom.

Qhov no txhais tau hais tias cov cuab yeej siv tau ntau dua li lwm cov txheej txheem tsim khoom, tab sis nws kuj txo tus nqi tag nrho ntawm koj cov khoom los ntawm kev txo qhov xav tau cov cuab yeej kim dua li pwm lossis tuag.

High-Mix, Tsawg Volume Manufacturing

High-mix, low-volume manufacturing yog txheej txheem ntawm kev tsim ntau yam khoom nrog me me variations hauv kev tsim. Nws yog qhov zoo tagnrho rau cov tswv lag luam me uas xav tsim kom muaj ntau yam ntawm cov khoom sib txawv tab sis tsis muaj peev txheej los nqis peev hauv cov tshuab tsim khoom loj lossis cov khoom lag luam loj.

Cov lag luam me muaj kev sib tw tshwj xeeb thaum nws los tsim lawv cov khoom. Lawv tsis muaj peev txheej lossis peev txheej uas cov tuam txhab loj ua, yog li lawv feem ntau yuav tsum tau los nrog cov tswv yim daws teeb meem rau lawv cov kev xav tau tsim khoom.

Lub chaw tsim khoom siv high-mix low volume (HMLV) yog tsim tshwj xeeb rau cov lag luam me uas xav tau los tsim ntau yam kev hloov pauv ntawm ib qho khoom me me ntawm tus nqi pheej yig.

Cov chaw no feem ntau hu ua cov khw ua haujlwm vim tias lawv ua haujlwm los ntawm ntau tus neeg siv khoom sib txawv ib zaug thiab ua txhua txoj haujlwm sib cais yam tsis muaj kev sib tshooj. Qhov no yog ib qho kev xaiv zoo rau cov tuam txhab uas xav tsim cov khoom me me ntawm ntau yam khoom sib txawv, tab sis nws tsis yog qhov kev xaiv zoo tshaj yog tias koj xav tsom mus rau ib qho khoom lag luam thiab ntsuas nws sai.

Ntau lub lag luam me tsim cov khoom hauv qhov ntim tsawg, tab sis nrog kev sib xyaw ua ke. Qhov no txhais tau tias lawv yuav tsum tau tsim ntau yam sib txawv. Piv txwv li, yog tias koj muaj lub khw kho tsheb, koj yuav tsum tau tsim ntau pua hom sib txawv ntawm lub cav mounts, txhua tus nrog nws tus kheej qhov ntev.

Tsuas-In-Time Manufacturing

Kev tsim khoom tsuas yog nyob rau lub sijhawm yog qhov tseem ceeb ntawm cov khoom lag luam lean. Nws yog ib lub tswv yim uas tso cai rau cov tuam txhab lag luam txo cov nqi los ntawm kev txo cov khoom muag thiab cov khoom pov tseg. Lub sij hawm "tsuas yog-hauv-lub sijhawm" yog thawj zaug siv los ntawm Taiichi Ohno, leej txiv ntawm Toyota Motor Corporation cov txheej txheem tsim khoom hu ua Lean Manufacturing.

Just-in-time manufacturing tsom rua kev tshem tawm cov pov tseg hauv cov txheej txheem tsim khoom. Cov khib nyiab tuaj yeem suav nrog txhua yam los ntawm ntau lub sijhawm siv tos rau cov khoom lossis cov tshuab tuaj txog, kom dhau cov khoom tiav uas yuav tsis muag sai li sai tau.

Kev tsim khoom lag luam tsuas yog lub hom phiaj txhawm rau tshem tawm cov teeb meem no los ntawm kev xa cov khoom raws nraim thaum xav tau es tsis txhob khaws cov khoom muag ntau ntawm tes txhua lub sijhawm.

Cov txiaj ntsig ntawm kev tsim khoom hauv lub sijhawm muaj xws li:

* Txo cov khoom pov tseg los ntawm kev tshem tawm overproduction;

* Txhim kho kev ua tau zoo los ntawm kev tshem tawm qeeb vim tos rau cov khoom lossis cov khoom siv;

* Txo cov nqi khoom muag los ntawm kev txo cov khoom khaws cia ntawm tes.

Kev tsim khoom Complex

Kev tsim cov khoom lag luam xws li cov cuab yeej kho mob, cov cuab yeej siv dav hlau thiab lwm yam khoom siv high-tech yog qhov nyuaj. Cov khoom no feem ntau yuav tsum tau siv tshuab kim, kev tsim kho siab heev thiab ntau ntawm kev siv tes ua haujlwm.

Cov neeg tsim khoom yuav tsum ua tib zoo tswj cov khoom ntws los ntawm lawv qhov chaw, txhua txoj hauv kev los ntawm cov khoom siv raw hauv lub tsev rau khoom kom tiav cov khoom ntawm lub pallet khi rau cov chaw xa khoom lossis cov neeg siv khoom.

Qhov nyuaj ntawm cov txheej txheem tsim khoom no tuaj yeem ua rau nws nyuaj rau cov tuam txhab me kom ua raws li qhov xav tau, tshwj xeeb tshaj yog tias lawv tsis muaj cov neeg ua haujlwm txaus lossis qhov chaw rau kev mob siab rau kev tsim khoom.

Ntau lub tuam txhab xaiv los tawm cov khoom lag luam qis vim tias nws ua rau lawv tsom mus rau lawv cov lag luam tseem ceeb thaum tseem tsim cov khoom lag luam zoo raws sijhawm thiab nyob rau hauv pob nyiaj siv.

Cov txheej txheem cuam tshuam nrog outsourcing qhov chaw ntawm koj cov txheej txheem ntau lawm mus rau lwm lub tuam txhab uas tshwj xeeb hauv cov kev pabcuam ntim qis, xws li kev tsim cov khoom lag luam lossis kev kho cov khoom kom tau raws li cov lus qhia tshwj xeeb.

Qhov no tuaj yeem pab daws qee qhov kev ntxhov siab cuam tshuam nrog kev ua haujlwm ntawm kev tsim khoom tau zoo thaum tseem tswj xyuas cov qauv zoo thiab cov sijhawm sijhawm.

Hloov chaw tsim khoom los ze zog rau cov neeg siv khoom

Raws li kev lag luam thoob ntiaj teb tau dhau los ua digitized thiab kev pabcuam raws li kev pabcuam, lub ntiaj teb tau txuas ntxiv. Qhov no txhais tau hais tias cov khoom tuaj yeem tsim nyob rau hauv ib qho chaw, xa mus rau lwm qhov thiab sib sau ua ke. Qhov kawg tshwm sim yog tias kev tsim khoom tsis tas yuav tshwm sim hauv ntau qhov ntau thiab ntawm qhov chaw nruab nrab.

DJmolding qhov kev tsim khoom ntim qis muaj ntau yam txiaj ntsig rau cov lag luam uas xav kom muaj kev sib tw hauv kev lag luam thoob ntiaj teb niaj hnub no.

Koj tuaj yeem nyob ze koj cov neeg siv khoom. Yog tias koj yog cov chaw tsim khoom lag luam muag khoom ncaj qha rau cov neeg siv khoom, ces koj paub tias nws tseem ceeb npaum li cas kom nyob ze rau koj cov neeg siv khoom. Koj xav kom lawv tuaj yeem ncav cuag koj tau yooj yim nrog cov lus nug lossis kev txhawj xeeb uas lawv muaj txog koj cov khoom lossis kev pabcuam.

DJmolding cov khoom ntim qis tso cai rau koj los tsim cov khoom lag luam ze rau qhov chaw koj cov neeg siv khoom nyob yog li koj tuaj yeem ua haujlwm zoo dua rau lawv thaum muaj kev cuam tshuam cov neeg siv khoom txuas ntxiv nrog rau thaum pib muag khoom thaum lawv yuav los ntawm koj thawj zaug.