Case hauv Is Nrias teb

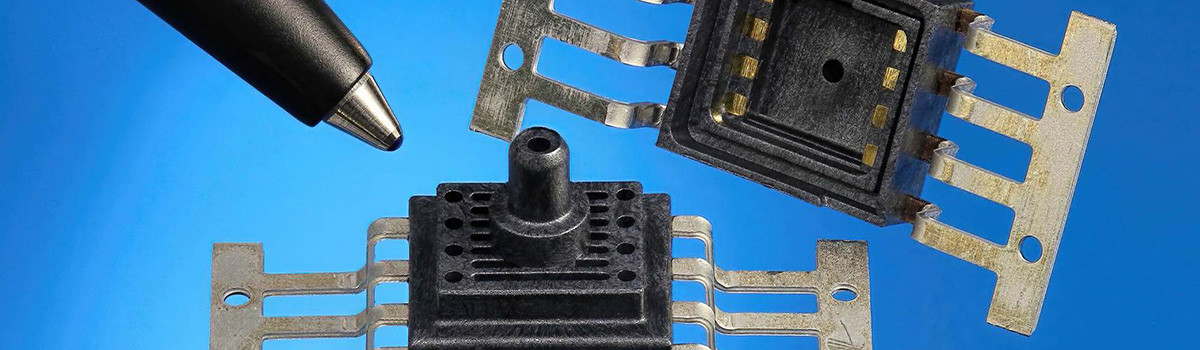

DJmolidng's Insert Pwm nyob rau hauv Txhaj Molding Service rau Indian tuam txhab

Ntxig pwm feem ntau yog ib hom pwm uas ua rau cov txiv ntoo, cov khoom siv hlau lossis cov yas tawv tawv hauv cov kab noj hniav rau kev txhaj tshuaj molding.

DJmolding muab cov insert mlod txhaj tshuaj molding kev pab cuam rau Is Nrias teb ua lag luam, thiab peb tsim ntau ntau insert molding cov yas qhov chaw rau txawv industries, especaly rau cov khoom siv hauv tsev ' manufacturers. Qee cov khoom siv hauv tsev Indian 'ua lag luam yuav cov ntxig molding cov khoom yas rau lub sijhawm ntev ntawm DJmolding. Peb muaj kev koom tes zoo heev nrog cov tuam txhab Is Nrias teb.

Ntxig txiv ntseej txhaj tshuaj molding: cov khoom siv txiv ntoo tuaj yeem yog cov hlau tsis muaj steel, tooj liab, tooj liab thiab hlau, feem ntau siv tooj liab txiv ntoo. tooj liab yog ib qho yooj yim rau knurl, uas pab ceev thiab yas splice zoo dua. Kev kam rau siab ntawm cov txiv ntoo sab hauv bores yuav tsum tswj tsis pub dhau 0.02mm, txwv tsis pub yooj yim ua rau flash yog tias kam rau siab tshaj 0.02mm. Hauv pwm haum, yuav tsum tau sib sau cov txiv ntoo rau hauv cov pins rau kev sim. Yog tias nws nruj nruj ntawm cov txiv ntseej thiab cov pins, nws yuav nyuaj rau ejector qhov thiab ua rau eject qhab nia lossis teeb meem sticking. Yog hais tias nws yog xoob haum, nws yuav ua rau flash.

Insert hlau qhov chaw txhaj tshuaj molding:

Cov khoom siv hlau tuaj yeem yog stainless hlau, txhuas, tooj liab, hlau ... thiab lwm yam. Lub siab ntev ntawm cov khoom hlau yuav tsum tau tswj tsis pub dhau 0.02mm, txwv tsis pub nws yog ib qho nyuaj rau kev kaw cov khoom thiab yooj yim kom muaj flash. Lub acreage ntawm cov hlau tsis tuaj yeem tsim loj heev.

Yog hais tias qhov filling acreage rau hlau qhov loj heev, nws yuav nyuaj heev kom ua tiav kev txhaj tshuaj tag nrho raws li qhov kub thiab txias sib txawv ntawm cov hlau. Txoj hauj lwm ntawm cov hlau feem ntau yog tsim los rau hauv kab noj hniav vim kab noj hniav tsis txav mus los, uas yuav pab kom tsis txhob muaj qhov tshwm sim ntawm cov hlau los ntawm kev txav mus los (hauv qhov xwm txheej hnyav, yuav ua rau pwm puas). Hauv tshwj xeeb, txoj haujlwm ntawm cov khoom hlau tsuas tuaj yeem tsim hauv cov tub ntxhais lossis sab saum npoo ntawm cov khoom.

Insert tawv yas txhaj molding:

Feem ntau xaiv cov yas tawv nrog cov ntsiab lus melting siab, xws li PEEK, PA66 + 30GF, PP + 30GF, PA12 + 30GF, PPS .... thiab lwm yam. Kev kam rau cov yas tawv no yuav tsum yog qhov tseeb. Cov teeb meem xws li shrinkage, dent, thiab deformation tsis tuaj yeem muaj nyob rau hauv qhov chaw sib khi. Nyob rau hauv pwm haum, cov yas tawv yuav tsum muab tso rau hauv pwm rau kev kuaj, thiab sab laug 0.05-0.1 hli ua ntej nias nyob ib ncig ntawm lub sealing cheeb tsam kom ua tau zoo sealing.

Cov yas tawv tawv yuav tsum tsis txhob tsim cov av loj heev, uas yuav ua rau qhov kub thiab txias sib txawv thiab ua rau nws nyuaj rau sau cov khoom hauv kev txhaj tshuaj. Feem ntau ua rau cov yas tawv tawv nyob rau sab ntawm kab noj hniav, vim tias cov kab noj hniav tsis txav, kom tsis txhob muaj teeb meem los yog ua rau pwm pwm txav mus los. Hauv tshwj xeeb, txoj haujlwm ntawm cov khoom hlau tsuas yog tsim los ntawm cov tub ntxhais lossis sab saum toj ntawm cov khoom.

Tsim cov ntsiab lus tseem ceeb

1.Design shrinkage rau cov khoom nrog txiv ntseej inserts, thaum tsis xav tau tsim shrinkage rau cov khoom uas muaj hlau qhov chaw thiab tawv yas inserts. Rau cov cheeb tsam uas xav tau kev zam nruj, hloov cov khoom lag luam 'loj kam rau nruab nrab.

2.Us feem ntau txais yuav pwm puag nrog tus qauv pin-point rooj vag hauv pwm tsim, thiab hauv kev txhaj tshuaj thib ob, muab tso rau hauv kab noj hniav kom ntau li ntau tau. Ntawm qhov xwm txheej ntawm kev ua cov ntxig rau hauv kab noj hniav, xav txog yuav ua li cas ua ib feem ntawm cov tub ntxhais tom qab txhaj tshuaj molding, nyob rau hauv txoj kev no, ib feem tuaj yeem raug tshem tawm. Feem ntau ntxiv elastic blocks nyob rau hauv kab noj hniav thiab elastic kua nplaum ua ib feem nyob rau hauv cov tub ntxhais. Qhov kev ncua deb ntawm elastic blocks thiab cov kua nplaum tsis tuaj yeem loj dhau, txwv tsis pub lub elastic quab yuam yuav ua rau cov yas tawv lossis hlau deformation. Qhov kev ncua deb feem ntau yog tsim nyob rau hauv 2 hli, thiab tsim nyog kom muaj nuj nqis ntawm elastic blocks thiab elastic kua nplaum thaum cov hlau los yog tawv yas inserts muaj kuj loj acreage.

3.Thickness ntawm cov khoom yog qhov zoo tshaj plaws nyob rau hauv 1.3-1.8mm (nyob ib ncig ntawm 1.5mm yog qhov zoo tshaj plaws), yog tias tsis yog, yuav tsum tau xyuas los ntawm cov khoom kos duab thiab qhia cov neeg siv khoom hloov nws. Yog hais tias cov khoom thickness yog thinner dua 1.3 hli, nws yog ib qho nyuaj rau cov khoom filling, thaum cov khoom thickness yog thicker tshaj 1.8 hli, shrinkage yog ib qho yooj yim tshwm sim nyob rau hauv ntau lawm.

4.Gating tseem ceeb heev hauv pwm. Qhov sib npaug ntawm cov khoom ntim rau lub rooj vag taw tes yuav tsum tau txiav txim siab tag nrho.Thaum cov khoom siv khiav mus rau thaj chaw uas cov hlau lossis cov yas tawv tawv raug kho, qhov ceev ntawm cov khoom ntim thiab lub siab yuav qis dua vim tias cov khoom ntxig thiab kub sib txawv.

5.Rau pwm ejector system, qhov sib npaug ntawm ejecting yuav tsum tau txiav txim siab los yog deformation yuav tshwm sim tom qab ejecting. Rau qhov tsis tuaj yeem raug tshem tawm hauv qhov sib npaug, yuav tsum xav txog kev sib tsoo los txhim kho qhov teeb meem sib npaug hauv kev tsim qauv.

6.Kom kom paub tseeb tias qhov tsim nyog ntawm qhov zoo li tom qab raug tshem tawm hauv kev txhaj tshuaj molding, cov khoom siv ejector yuav tsum yog cov yas tawv tawv ntxig nrog ABS lossis PMMA. Yog tias cov pwm dhau lawm muaj swb sealing, tsim cov slides hauv kab noj hniav kom ntau li ntau tau, vim cov swb hauv kab noj hniav yooj yim rau pwm haum.

7.Kom kom paub tseeb tias lub zog ntawm sealing SA (cov nyiaj seam), rau cov khoom tsim los ntawm ob zaug txhaj tshuaj molding, qhov dav ntawm sealing SA yuav tsum yog tsawg kawg yog 0.8 hli. Rau cov khoom siv txhaj tshuaj thib ob yog cov yas tawv, qhov dav ntawm sealing SA yuav tsum yog tsawg kawg yog 1.0mm, txwv tsis pub, xav kom cov neeg siv khoom hloov kho cov khoom.

8.In pwm tsim, peb yuav tsum coj cov tshuab txhaj tshuaj molding rau hauv kev txiav txim siab rau kev tsim khoom kom pom tias hom tshuab twg nws siv, ntsug lossis kab rov tav. Nws tau pom zoo tias tsis txhob tsim cov kab noj hniav ntau dhau, tshwj xeeb tshaj yog rau cov pwm nrog cov neeg khiav dej txias vim tias cov kab noj hniav ntau dhau ua rau cov kab noj hniav ntev dua, cov khoom siv khib nyiab thiab tseem muaj teeb meem rau kev txhaj tshuaj zoo. Yuav kom phim lub tshuab txhaj tshuaj molding tshuab, peb yuav tsum xav txog seb nws puas yog compact thiab tsim nyog rau cov khoom npaj.Cov khoom yuav tsum tau kho kom paub tseeb tias cov khoom nyob rau hauv tib lub sij hawm thaum lawv muab tso rau hauv pwm. Lwm txoj hauv kev yog qhov tsim cov tshuaj tiv thaiv kom ceeb toom yog tias qhov chaw tsis nyob hauv qhov chaw ua ntej pwm kaw, uas yuav pab tiv thaiv pwm kaw. Nyob rau hauv txoj kev no, qhov chaw yog nyob rau hauv tib qhov teeb meem nyob rau hauv pwm, uas nce tus nqi tsim nyog thiab ntau lawm efficiency nyob rau hauv txhaj tshuaj molding.

9.A steel kev txhawb nqa yuav tsum tau tsim raws li qhov chaw txhaj tshuaj pwm bears siab heev hauv kev txhaj tshuaj (yuav tsum yog 5-10 hli loj dua li ntawm cov duab thiab loj). Yuav tsum tsis txhob tso qhov sib txawv ntawm qhov chaw nyob ib ncig ntawm Over- molding cheeb tsam, txwv tsis pub lub feem yuav tsis zoo tom qab txhaj tshuaj thib ob. Rau qhov chaw uas tsis muaj SA (kev tso cai seam) yuav xav tau kev saib xyuas ntau ntxiv rau qhov no.

10.Air mus txawv tebchaws yog yooj yim Cua mus txawv tebchaws tshwm sim yooj yim nyob rau hauv txhaj tshuaj molding, yog li yuav tsum tau tag nrho xav txog venting nyob rau hauv pwm tsim. Nyob rau hauv tag nrho cov qhov muag tsis pom cov ces kaum thiab txoj hauj lwm rau cov kab dej nyob deb, yuav tsum tsim qhov venting qhov ntawm cov yas nyuaj vim nws nyuaj dua los sau cov khoom hauv qhov muag tsis pom.

11. Kom paub meej tias cov khoom siv txhaj tshuaj thiab qhov tsim nyog thrust tau ua tiav, ib txoj hauv kev yog tsim cov undercuts ntawm cov ces kaum ntawm ib feem los txhim kho cov nplaum nplaum thiab tom qab ntawd ua kom cov khoom ua kom nruj dua.

12.Hauv cheeb tsam sealing thiab parting kab cheeb tsam, peb yuav tsum tsis txhob demould los ntawm kab noj hniav thiab cov tub ntxhais, vim hais tias clamping kab nyob rau hauv pwm thiab demoulding cua ntsawj ntshab yuav ua rau flash nyob rau hauv pwm haum. Sim demould los ntawm LISS-OFF.

Lub rooj vag taw tes hom ntxig pwm

Lub rooj vag taw tes rau ntxig pwm tuaj yeem tsim los ncaj qha kub sprue valve rooj vag, kub sprue tus pin rooj vag, tus pin-point rooj vag, sub rooj vag, ntug rooj vag ... thiab lwm yam.

Kub sprue valve rooj vag: zoo liquidity, txoj hauj lwm xaiv saj zawg zog, me me rooj vag taw tes. Haum rau kev tsim khoom loj thiab rau cov khoom siv nrog cov phab ntsa tuab. tuaj yeem pab txuag cov khoom siv, tsis muaj cov khoom pov tseg rau lub rooj vag, lub sij hawm luv luv, thiab zoo. Qhov tsuas yog qhov tsis xws luag yog qhov chaw me me.

Hot sprue pin rooj vag: zoo liquidity, txoj hauj lwm xaiv saj zawg zog, me me rooj vag point. Haum rau kev tsim khoom loj thiab rau cov khoom siv nrog cov phab ntsa tuab. tuaj yeem pab txuag cov khoom siv, tsis muaj cov khoom pov tseg rau lub rooj vag, lub sij hawm luv luv, thiab zoo. Tab sis muaj qhov tsis xws luag, xws li cov khoom siv 0.1mm sab laug nyob ib ncig ntawm lub rooj vag taw tes, thiab yooj yim rau burr. Yuav tsum tau ua grooves los npog cov khoom sab laug nyob ib ncig ntawm lub rooj vag taw tes.

Pin-point rooj vag: txoj hauj lwm xaiv saj zawg zog, tsis muaj zog liquidity, ntev khiav deb, me me rooj vag point. Haum rau me me batch ntau lawm. Ntau cov khoom pov tseg nyob ib ncig ntawm lub rooj vag taw tes. Xav tau cov cuab yeej cuab yeej cuab tam kom clamp qhov rooj taw tes hauv kev tsim khoom. Lub sijhawm ua haujlwm ntev. Qhov tsis xws luag yog 0.1-0.2mm cov khoom seem nyob ib ncig ntawm lub rooj vag taw tes, xav tau ua grooves los npog cov khoom sab laug nyob ib ncig ntawm lub rooj vag taw tes.

Sub gate: tuaj yeem tsim los ntawm tav hauv kab noj hniav, core, sab phab ntsa, thiab ejector pins. Muaj peev xwm xaiv rooj vag taw tes flexibly, pouring rooj vag cais los ntawm ib feem txiav, me ntsis gating kab. Qhov tsis xws luag: yooj yim rub cov khoom tawm ib ncig ntawm lub rooj vag taw tes, yooj yim ua kom qhuav cov cim hauv qhov rooj, xav tau cov khoom siv los ntawm tes, ntau cov xovxwm poob ntawm lub rooj vag taw tes ntawm kab noj hniav.

Ntug rooj vag: molten yas ntws los ntawm lub rooj vag, muab lateral tusyees, txo kev ntxhov siab; txo qhov muaj peev xwm ntawm huab cua nkag mus rau hauv kab noj hniav, tsis txhob ua rau streaks thiab npuas. Qhov tsis xws luag: pouring rooj vag tsis tuaj yeem cais tawm ntawm ib feem tuaj yeem, sab laug sprue cov cim ntawm ib feem ntawm cov npoo, xav tau cov cuab yeej los ua cov txheej txheem pouring rooj vag tiaj tus. Ntug rooj vag tuaj yeem pab faib cov kev txhaj tshuaj thiab lub zog tuav, thiab kuj yog qhov zoo rau kev tuav thiab pub mis, nyob rau hauv txoj kev no, nws yog qhov zoo dua rau kev txhim kho cua kab, ntws cov cim ... thiab lwm yam.

Ua thiab haum rau ntxig pwm

1.Ua ntej ua, ua hauj lwm tawm lub tshuab ua pwm. Xaiv cov tshuab ua haujlwm siab, lub tshuab ua haujlwm siab, pub mis qeeb NC hlau txiav tshuab, iav EDM (fais fab machining) tshuab thiab lwm yam.

2.Design 0.05-0.1mm sab laug nyob rau hauv qhov chaw ntawm pre-pressing.

3.Nco ntsoov qhov yuav tsum tau ua hauv pwm pwm, tshuaj xyuas kev kam rau siab tom qab tau txais cov pwm pwm thiab tsis siv nws yog tias qhov kam rau ua tsis tsim nyog.

4. Muab cov txiv ntseej, cov khoom hlau thiab cov yas tawv hauv pwm rau pwm haum. Yog tias pom muaj teeb meem hauv pwm haum, tshawb xyuas los ntawm cov txiv ntoo, cov khoom hlau, cov yas tawv thiab cov pwm kom pom tias qhov twg yog qhov tsis raug. Txheej txheem ib feem raws li kev kos duab kom deb li deb tau, uas yuav pab taug qab cov ntaub ntawv yav tom ntej.

5.Tsis tuaj yeem siv grinder rau pwm haum. Tig rau cov cav tov kom kho qhov twg pwm haum tsis zoo.

6.Ua kev sim ua ntej mus sib hais, tsis txhob plam kev sib sau ua ke thiab kev sib dhos yuam kev. Kev sib dhos yuam kev yuav ua rau kev puas tsuaj ntawm pwm puag.

Kev kuaj pwm rau ntxig pwm

1.Hauv kev kuaj pwm, ib tus yuav tsum paub meej txog cov kab ke ntawm kev qhib, kaw thiab ejecting pwm. Nkag siab txog cov yam ntxwv thiab cov yam ntxwv ntawm cov khoom hlau thiab cov khoom yas tawv.

2.Ua kom paub meej txog cov qauv kom muaj nuj nqis uas cov neeg siv khoom xav tau, npaj cov txiv ntseej txaus, cov khoom siv hlau thiab cov yas tawv, vim nws xav tau ntau cov qauv hauv kev kuaj pwm.

3.Nco ntsoov seb puas tuaj yeem kuaj pwm yam tsis muaj qhov ntxig ntawm cov txiv ntoo, cov khoom hlau lossis cov yas tawv. Yog hais tias ntxig cov txiv ntseej, cov khoom hlau thiab cov yas tawv tsis sib sau ua ke hauv pwm, ib feem yuav muaj qhov tsis xws luag xws li ua rau pwm lossis txhaj tshuaj luv luv.

4.Ntau zaus, yuav tsum tau kho cov phaj dej ntawm cov pwm, tab sis qee zaum nws tsis tuaj yeem kho cov kab dej hauv qee qhov ntxig pwm raws li lawv cov qauv, lossis tseem phem dua, pwm yog hnyav hnyav thiab xav tau kev hloov kho, lossis pwm puas lawm hauv cov pwm. qhib.

5. Cov teeb meem tuaj yeem tshwm sim hauv kev kuaj pwm, xws li kev txhaj tshuaj luv luv, kev mus ncig hauv huab cua, flashes, lossis ua raws li cov pwm. Yog tias muaj teeb meem tuaj yeem txheeb xyuas ntawm lub tshuab txhaj tshuaj molding, nws yog qhov zoo dua los daws nws.

DJmolding muaj ntau tshaj 10+ xyoo ntxig molding kev, yog tias koj muaj lus nug, thov hu rau peb.