Kev cai yas txhaj Molding

Kev txhaj tshuaj molding yog qhov zoo tagnrho rau cov khoom yas uas qhov kev vam meej vam khom rau kev ua tiav cov yam ntxwv tshwj xeeb lossis zoo nkauj. DJmolding yas txhaj tshuaj molding yog tsav los ntawm lub hom phiaj tseem ceeb ntawm kev pab cov neeg muas zaub tsim cov yas zoo tshaj plaws. Tsis muaj neeg txawv txawv rau qhov nyuaj, tsim kev sib tw yeej ua rau peb lub siab xav tsim kho tshiab rau koj. Kev koom nrog peb thaum ntxov ua rau peb ntxiv tus nqi hauv cov txheej txheem tsim.

Cov txiaj ntsig ntawm Kev Txhaj Tshuaj Molding

Cov ncauj lus kom ntxaws ntxaws

Xav txog cov ntsiab lus zoo nkauj lossis ua haujlwm zoo los txhim kho koj lub hom: imprinted ntawv, cosmetic los yog textured nto, nyob rau hauv-pwm decorating, snap fits, saj zawg zog hinges, varied hardness.

High Performance

Qhov kev ua tau zoo ntawm cov yas txhaj tshuaj molding yog qhov tsis sib xws. Peb tsim cov nqi tsis tsim nyog tawm ntawm koj qhov chaw thiab cov cuab yeej. Peb cov engineers ntev-ntev tsim thiab cov tswv molders yeej ua tau zoo ntawm qhov no.

Kev Ua Tau Zoo Dua

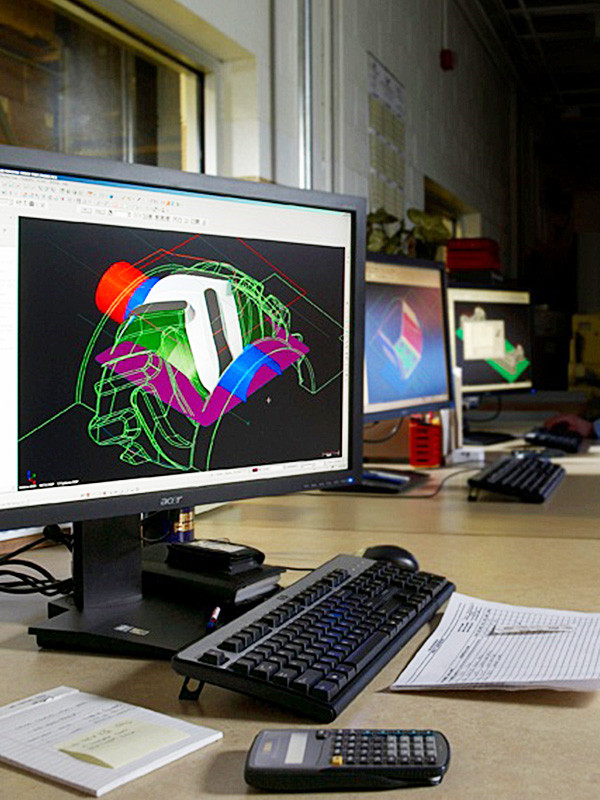

Peb ua hauj lwm nyuaj kom nkag siab txog txoj haujlwm uas koj xav tau thiab ua tau raws li koj lub hom phiaj tseem ceeb los ntawm kev siv cov ntaub ntawv tshawb fawb, cov qauv tsim, cov cuab yeej tshuaj ntsuam xyuas, thiab cov txheej txheem tswj.

Khoom siv ntau yam

Xaiv los ntawm ntau tshaj 200 cov ntaub ntawv, khoom siv thiab engineering resins. Peb yuav pab koj sib npaug kev ua tau zoo thiab tus nqi thiab txheeb xyuas lwm cov khoom sib npaug los txo cov nqi.

Txhaj Moulding txheej txheem

Yas txhaj tshuaj molding yog ib qho ntawm cov txheej txheem qub tshaj plaws ntawm kev tsim cov yas thiab cov kauj ruam tseem ceeb hauv kev tsim cov khoom lag luam. Nws kuj yog ib qho kev daws teeb meem zoo rau cov tuam txhab nrhiav kom hloov cov hlau hnyav rau cov yas. Piav hauv nws daim ntawv yooj yim tshaj plaws, cov txheej txheem siv cov polymers lossis yas resins uas thaum tshav kub kub, yaj thiab txhaj rau hauv siab siab rau hauv pwm kev cai, yuav tsim cov khoom yas los siv rau hauv kev tsim khoom.

Thaum cov txheej txheem ntawd zoo li yooj yim, nws tuaj yeem ua tau yooj yim thiab yuav tsum muaj kev paub ntau los ntawm kev txhaj tshuaj molder tus khub uas tuaj yeem ua raws li koj qhov kev xav tau tshwj xeeb hauv kev lag luam, kev qhia tshwj xeeb, kev siv kawg thiab sijhawm / nyiaj txiag txwv. Qhov chaw zoo tshaj plaws los pib yog los ntawm kev tau txais kev paub yooj yim ntawm cov txheej txheem yas molding thiab tsim cov kev coj ua zoo tshaj plaws.

Kev Moulding

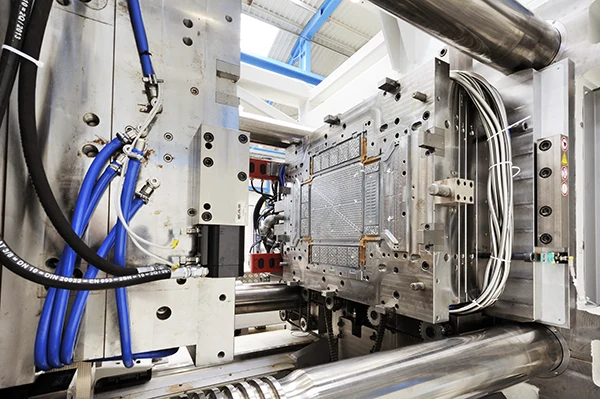

Kev tshawb fawb molding mus kom ze tau txais txiaj ntsig ntawm kev tsim cov khoom tseem ceeb uas xav tau kev ua haujlwm tshwj xeeb thiab siab precision. Peb cov tshuab molding siab heev ua kom rov ua tau zoo thiab sib xws. Qhov ntawd txhais tau tias cov khoom peb ua rau koj hnub no, yog cov khoom peb ua rau koj tag kis.

Kev txhaj tshuaj molding pib thaum lub sij hawm tsim cov cuab yeej. Cov yam ntxwv xws li lub siab, qhov kub thiab txias, lub sij hawm ntim cov kab noj hniav yog optimized kom cov pwm tsim minimizes lub sij hawm rau variation. Mould flow analysis qhia txog qhov kawg ntawm ntu los sau, yuav ua li cas cov khoom yuav taw qhia nrog pwm, thiab nthuav tawm qhov muaj peev xwm warp thiab kev ntxhov siab. Nws yog ib kauj ruam proactive uas muab engineering kev kwv yees tsom xam thiab ntsuas thiab tso cai rau kev yooj yim txiav txim siab ntawm kev ua tiav lossis tsis ua tiav ntawm ib feem lossis qhov project.

Cov txheej txheem tsim khoom muaj zog ntxiv siv txoj hauv kev tshawb fawb los ntawm kev saib xyuas thiab kev tswj hwm cov txheej txheem uas txo cov khoom seem thiab sijhawm ua haujlwm. Yog tias muaj kev hloov pauv lossis ua haujlwm tsis zoo tshwm sim, nws raug txheeb xyuas sai thiab cais tawm ua ntej qhov tsis sib xws.

Sib tshooj

Ob (lossis ntau dua) cov ntaub ntawv tuaj yeem ua ke rau hauv ib feem nrog overmolding. Cov txheej txheem no feem ntau yog siv rau qhov sib txawv tactile nto, xws li thaj tsam softer. Overmolding tuaj yeem yog cov yas hla cov yas substrate lossis roj hmab hla cov yas substrate, feem ntau ua tiav los ntawm ob txoj kev txhaj tshuaj molding. Resin formulation thiab xim tuaj yeem sib txawv. Cov txiaj ntsig zoo nkauj ntawm overmolding yog qhov yooj yim rau kev pom, tab sis lawv kuj tshem tawm cov haujlwm thib ob. Overmolding yog qhov zoo tshaj plaws rau cov cuab yeej siv tes tuav, cov khoom tuav tes, cov neeg hlau uas xav tau cov roj hmab, lossis tsuas yog txhawm rau txhim kho cov tsos ntawm ib feem nrog cov xim sib txawv.

Ntxig Moulding

Ntxig molding zoo ib yam li overmolding tab sis sib txuas ib yam khoom uas muab tso rau hauv lub pwm kab noj hniav. Ntxig molding bonds yas rau inserts, feem ntau yog hlau los yog yas. Threaded inserts muaj ntau. Qhov no tshem tawm kev ua haujlwm thaum siv los ua lwm txoj hauv kev fasteners, adhesives, lossis kub-staking. Inserts kuj ntxiv dag zog rau ib feem. Inserts yog loaded manually los yog nrog robotic automation.

Part Decorating thiab Labeling

Nyob rau hauv-pwm kho kom zoo nkauj (IMD) thiab nyob rau hauv-pwm labeling (IML) yog siv los tsim ib tug zoo nkauj tsos nrog cov duab los yog cov ntawv lo. Ua kom yooj yim los ntawm cov neeg hlau thiab electrostatic los yog lub tshuab nqus tsev, cov ntaub ntawv luam tawm tau muab ntxiv rau hauv pwm kab noj hniav ua ntej txhaj tshuaj molten yas resin. Cov txheej txheem no tsim ib daim ntawv cog lus ruaj khov ntawm daim ntawv lo thiab qhov ua tiav, feem ntau tshem tawm qhov xav tau rau kev ua haujlwm tom qab ua tiav. Ntau hom kev ntxhib los mos, xim, thiab xim txheej txheej xaiv tawm qhov rooj qhib rau kev muaj tswv yim zoo. Peb xav kom koj tham nrog koj tus thawj tswj hwm qhov project txog cov kev xaiv los txhim kho koj lub hom phiaj.

Kev cai Yas Txhaj Moulding Service Tuam Tshoj

DJmolding Ua haujlwm txij li xyoo 2010 | AFAQ ISO / TS 16949, UL thiab ISO daim ntawv pov thawj, feem ntau muab rau ntau lub tuam txhab 3D Printing Hauv Ntiaj Teb Tam sim no.

Ntawm Djmolding peb tshwj xeeb hauv kev tsim cov yas txhaj tshuaj pwm zoo thiab cov cuab yeej pwm. Peb tsuas yog muab peb cov yas txhaj tshuaj rau ntau lub tuam txhab 3D luam ntawv hauv ntiaj teb. Peb muaj 55 lub tshuab rau cov neeg hlau thiab cov yas txhaj tshuaj tsis siv neeg.Peb muab tag nrho cov kev pabcuam machining thiab ua tiav los ua cov cuab yeej los ntawm ntau yam ntaub ntawv, thiab tuaj yeem tsim tau 100 txog 200k + cov khoom tiav hauv tag nrho cov yas loj. Dab tsi tiag tiag ua rau peb sib nrug yog peb cov ntaub ntawv pov thawj qib siab, tshuaj xyuas thiab kev sim kom ntseeg tau tias koj cov khoom ua tau raws li koj qhov kev cia siab tshaj plaws. Hu rau peb cov kws tshaj lij thoob ntiaj teb kev txhaj tshuaj molding rau kev tsocai pub dawb hnub no.

DJmolding Yas Txhaj Moulding txheej txheem

Thaum koj cov cuab yeej txhaj tshuaj molding tau npaj tiav, cov txheej txheem molding muaj cov kauj ruam hauv qab no:

Kauj Ruam 1. Cov khoom siv yas tuaj rau hauv cov pellets nyoos. Cov no tau qhuav kom zoo noo noo cov ntsiab lus, thiab tom qab ntawd yog tias tsim nyog lawv tuaj yeem muab sib xyaw nrog cov xim lossis cov xim zoo nkauj.

Kauj Ruam 2. Cov pellets qhuav yog nchuav rau hauv lub hopper ntawm lub tshuab molding. Ib tug reciprocating ntsia hlau nyob rau hauv lub chim ntawm lub tshuab yuav thauj cov pellets mus rau lub pwm.

Kauj Ruam 3. Nyob rau hauv lub thoob, cov pellets yog tov thiab rhuab kom txog thaum tag nrho molten, tsim cov kua resin.

Kauj Ruam 4. Cov pwm rhuab kaw tau thiab cov resin, nyob rau hauv lub siab zoo, yog txhaj los ntawm lub rooj vag thiab mus rau hauv lub pwm kab noj hniav.

Kauj Ruam 5. Cov pwm yog txias kom khov rau sab hauv.

Kauj Ruam 6. Cov pwm qhib thiab qhov raug tshem tawm kom pib lub voj voog tshiab.

Yas Txhaj Molding Tolerances

Tag nrho cov khoom siv yas yuav nthuav dav thiab cog lus nyob rau hauv lub zog ntawm cov cua sov thiab noo noo. Peb phau ntawv qhia kev kam rau siab yuav muab cov ntaub ntawv dav dav ntxiv ntawm cov yam ntxwv ntawm cov hom resin feem ntau rau cov yam ntxwv zoo ib yam.

Peb yuav ua haujlwm ze nrog koj txhawm rau txhim kho koj cov qauv tsim rau kev tsim khoom. Peb yuav qhia txhua qhov chaw uas tsim tsis zoo yuav ua rau muaj kev ntxhov siab thermal, shrinkage, warping, thiab lwm yam

Tshwj tsis yog tias tau teev tseg, peb ua raws li DIN 16742 tus qauv kam rau ua rau cov yas txhaj tshuaj molding. Nyeem txog cov qauv kev pom zoo uas peb siv rau kev txhaj tshuaj molded qhov chaw.

Yas Txhaj Moulding Khoom

Djmolding ua cov cuab yeej txhaj tshuaj molding thiab tuag los ntawm Aluminium 7075, P20 thiab NAK80 semi-hardened steels thiab H13 tag nrho-hardened steel. Tsis tas li ntawd, peb muab cov qauv SPI tiav, EDM texturing thiab ntau yam ntawm etched textures.

Txhua yam ntawm cov khoom siv no yuav muaj qhov zoo sib xws rau qee yam kev siv. * Cov kev xav tau suav nrog:

* Tus nqi ntawm cov khoom siv raw

* Durability thiab tiv thaiv corrosion los yog puas

*Machinability

* Muaj peev xwm coj lub ntsej muag polishing siab

* Lub sijhawm xav tau rau kev kho cua sov

* Cia siab tias lub cuab tam lub neej

Hu rau peb cov kws tshaj lij kom paub ntau ntxiv txog qhov twg yog qhov zoo rau koj.

Yas Txhaj Qhov Chaw

Muaj ntau txhiab tus thermoforming thiab thermosetting yas xaiv los ntawm koj qhov project. Tsis tas li ntawd, cov yam ntxwv ntawm cov neeg kho tshuab thiab tshuaj kuj tuaj yeem txhim kho nrog cov khoom siv ntxiv xws li iav fibers, UV stabilizers thiab lubricants. Peb cov ntaub ntawv cov ntaub ntawv yuav muab cov ncauj lus kom ntxaws ntxiv rau koj txog cov qauv qauv thiab kev kam rau siab rau txhua tus.

Koj qhov kev xaiv ntawm cov resins tuaj yeem nyob ntawm ib lossis ntau qhov kev txiav txim siab hauv qab no:

* UV, tshuaj lom neeg, puas thiab cuam tshuam tsis kam

* Tus nqi ntawm cov khoom siv raw

* Mechanical zog

* Nyhav thiab ntom

* Yooj yim

* Pob tshab

* Kev rov ua dua tshiab

Hu rau ib qho ntawm peb cov kws tshaj lij kom paub ntau ntxiv txog cov khoom siv.

DJmolding khw muag khoom:

Ua cov yas txhaj tshuaj pwm thiab cov chaw tsim khoom sai prototyping

Djmolding yog ib qho ntawm cov paub zoo yas txhaj tshuaj molding tuam txhab nyob rau hauv Suav teb. Peb lub khw txhaj tshuaj molding yog nruab nrog 50 txheej ntawm kev txhaj tshuaj molding tshuab, xws li 30 tons txog 800 tons, Lawv feem ntau yog los ntawm Taiwan thiab Nyiv, peb lub khw txhaj tshuaj khiav 24 teev ib hnub, 7 hnub hauv ib lub lis piam, thiab muab ntau lawm. kev pabcuam.

Peb tau ntsib nrog ntau yam khoom yas rau ntau yam kev lag luam, suav nrog: tsheb, kho mob, teeb pom kev zoo, khoom siv ua kis las, khoom siv hauv tsev, thiab kev ua liaj ua teb. Djmolding tau dhau AFAQ ISO/TS 16949, UL thiab ISO 9001 Certifications txij thaum 2010, Peb kuj muaj 15 IPQC cov neeg lossi saib peb cov ntau lawm thiab xyuas ib feem zoo, Qhov no xyuas kom meej peb cov khoom tswj lub siab tshaj plaws zoo. Hauv 9 xyoo dhau los, Djmolding tau tsim lub koob npe nrov ntawm kev tsim cov cuab yeej zoo thiab ib feem ntawm tus nqi tsim nyog.Peb muaj kev sib raug zoo ua lag luam nrog appx. 50 cov neeg siv khoom, feem ntau yog los ntawm Asmeskas thiab Europe.

Kev cai yas txhaj Molding

Kev cai yas txhaj tshuaj molding yog ib txoj kev tshiab thiab muaj txiaj ntsig ntawm kev tsim cov khoom yas zoo. Cov txheej txheem tsim khoom no siv cov pwm los tsim cov ntaub ntawv yas rau hauv cov duab thiab qhov ntau thiab tsawg, ua rau nws zoo tagnrho rau ntau yam kev lag luam. Cov ntawv blog no yuav nkag mus tob rau hauv kev cai yas txhaj tshuaj molding thiab tshawb txog nws cov txiaj ntsig, kev siv, thiab kev coj ua zoo tshaj.

Nkag siab txog kev cai txhaj tshuaj molding txheej txheem

Kev cai txhaj tshuaj molding yog txheej txheem tsim khoom siv los tsim cov khoom yas hauv cov ntim loj. Nws koom nrog melting yas pellets los yog granules thiab txhaj rau hauv pwm nyob rau hauv lub siab, qhov chaw uas lawv txias thiab solidify los ua ib tug xav tau. Nov yog li cas cov txheej txheem txhaj tshuaj molding ua haujlwm:

- Clamping: Ob lub puab tsaig ntawm cov pwm, hu ua "cov cuab yeej," yog clamped ua ke nrog lub zog txaus los tiv thaiv kev txhaj tshuaj.

- Txhaj Tshuaj: Cov yas pellets yog yaj nyob rau hauv ib lub thoob rhuab thiab txhaj rau hauv pwm los ntawm ib tug khiav system nyob rau hauv siab. Cov yas ntim cov pwm kab noj hniav thiab siv cov pwm pwm.

- Txias: Cov yas tuaj yeem txias thiab khov rau hauv pwm kom tswj tau cov duab uas xav tau.

- Ejection: Cov pwm qhib thaum cov yas tau txias thiab qhov ua tiav yog ejected.

- Rov ua dua: Cov txheej txheem yog rov ua dua los tsim ntau qhov chaw zoo ib yam.

Kev txhaj tshuaj molding ua cov khoom yas, los ntawm cov khoom me me mus rau cov khoom loj xws li cov khoom siv tsheb thiab cov khoom siv hauv tsev. Cov txheej txheem no muaj txiaj ntsig zoo thiab tuaj yeem tsim cov khoom nrog cov geometries nyuaj thiab nruj tolerances, thiab nws kuj yog qhov tseeb, nrog cov khib nyiab tsawg thiab cov khoom seem tsawg.

Cov txheej txheem yuav tsum muaj cov cuab yeej tshwj xeeb, suav nrog pwm, txhaj tshuaj molding tshuab, thiab kev tswj xyuas kom ntseeg tau tias qhov tseeb thiab zoo ib yam. Cov pwm feem ntau yog ua los ntawm cov hlau thiab tuaj yeem tsim los tsim ntau qhov chaw siv ntau kab noj hniav molding.

Kev txhaj tshuaj molding tuaj yeem siv nrog ntau yam ntaub ntawv, suav nrog cov thermoplastics, thermosets, thiab elastomers. Txhua yam khoom muaj cov khoom tshwj xeeb thiab tuaj yeem ua raws li cov ntawv thov tshwj xeeb.

Zuag qhia tag nrho, kev txhaj tshuaj molding yog ib qho kev siv ntau yam thiab muaj txiaj ntsig kev tsim khoom siv dav hauv ntau lub lag luam.

Qhov zoo ntawm kev cai yas txhaj tshuaj molding

Kev cai yas txhaj tshuaj molding yog cov txheej txheem tsim khoom siv los tsim cov khoom siv yas hauv cov ntim loj. Nov yog qee qhov zoo ntawm cov txheej txheem no:

High efficiency thiab productivity: Kev cai yas txhaj tshuaj molding yog cov txheej txheem ua tau zoo uas tuaj yeem tsim cov ntim loj ntawm cov khoom zoo tib yam sai thiab tsis tu ncua. Qhov no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov khoom yas loj.

Ntau yam: Cov txheej txheem tuaj yeem siv nrog ntau yam khoom siv yas, nrog rau cov thermoplastics, thermosets, thiab elastomers. Qhov no tso cai rau ntau yam ntawm cov qauv tsim thiab kev siv.

Consistency thiab precision: Txhaj tshuaj molding muab cov txiaj ntsig zoo ib yam thiab meej, nrog rau kev ua siab ntev thiab qhov sib txawv me me ntawm qhov chaw. Qhov no ua kom ntseeg tau tias txhua daim yog zoo ib yam rau lwm qhov, uas yog qhov tseem ceeb rau ntau daim ntawv thov.

Tus nqi zoo: Kev cai yas txhaj tshuaj molding tuaj yeem raug nqi zoo rau cov khoom ntim ntau lawm. Tus nqi pib cov cuab yeej tuaj yeem siab, tab sis tus nqi ib feem txo qis thaum lub ntim nce.

complexity: Kev txhaj tshuaj molding tuaj yeem tsim cov khoom nrog cov duab nyuaj thiab cov duab geometry, nrog rau cov phab ntsa nyias thiab cov yam ntxwv zoo sib xws. Qhov no tso cai rau tsim kom yooj yim dua thiab ua rau cov khoom tsim tawm uas yuav nyuaj lossis tsis yooj yim los tsim siv lwm txoj hauv kev.

Yam tsawg kawg nkaus: Kev txhaj tshuaj molding tsim cov khoom pov tseg tsawg dua piv rau lwm cov txheej txheem tsim khoom, vim tias cov yas ntau dhau tuaj yeem rov ua dua thiab rov siv dua.

Qhov ntev tiav: Kev txhaj tshuaj molding tuaj yeem tsim qhov chaw nrog qhov zoo ntawm qhov chaw tiav yam tsis muaj kev ua haujlwm tom qab lossis ua tiav. Qhov no ua rau nws muaj txiaj ntsig zoo rau kev tsim cov khoom nrog lub ntsej muag du thiab polished.

Automation: Kev txhaj tshuaj molding tuaj yeem ua tau yooj yim automated, nrog cov neeg hlau thauj khoom thiab tshem tawm qhov chaw ntawm cov pwm thiab tshuaj xyuas thiab txheeb xyuas cov yam ntxwv. Qhov no txo qhov kev xav tau ntawm kev siv tes ua haujlwm thiab ua kom muaj txiaj ntsig zoo.

Kev cai yas txhaj tshuaj molding yog ib qho kev tsim ntau yam thiab muaj txiaj ntsig zoo uas muab ntau yam zoo dua lwm txoj hauv kev. Nws muaj peev xwm ua tau sai thiab raug tsim kom muaj ntau qhov zoo ib yam ua rau nws zoo tagnrho rau ntau lub lag luam, suav nrog tsheb, aerospace, kho mob, thiab cov khoom siv.

Kev siv ntawm kev txhaj tshuaj molding

Txhaj tshuaj molding yog ib txoj kev siv dav siv los tsim ntau yam khoom siv yas. Nov yog qee qhov kev siv feem ntau ntawm kev txhaj tshuaj molding:

- Automotive kev lag luam: Txhaj tshuaj molding ua ntau yam khoom siv tsheb, nrog rau sab hauv thiab sab nrauv trim, dashboard Cheebtsam, qhov rooj tuav, thiab cav qhov chaw. Nws yog qhov zoo dua vim tias nws tuaj yeem muaj cov yam ntxwv nrog lub zog siab thiab qhov tseeb qhov tseeb.

- Cov khoom siv: Kev txhaj tshuaj molding tsim ntau yam khoom siv, nrog rau cov khoom ua si, khoom siv hauv tsev, thiab cov khoom siv hluav taws xob. Nws tso cai rau tsim cov duab nyuaj thiab geometries thiab cov khoom zoo tshaj plaws.

- Cov khoom siv kho mob: Kev txhaj tshuaj molding yog siv los tsim ntau yam khoom siv kho mob, suav nrog cov koob txhaj tshuaj, cov khoom siv IV, thiab cov cuab yeej kuaj mob. Nws muaj kev ua haujlwm siab, kev tsim khoom huv si, thiab muaj peev xwm tsim cov khoom nrog cov geometry nyuaj, uas yog qhov tseem ceeb hauv kev kho mob kev lag luam.

- Kev lag luam ntim khoom: Kev txhaj tshuaj molding tsim cov khoom ntim, nrog rau lub raj mis, hub, thiab hau. Nws tso cai rau tsim lub teeb yuag thiab ruaj khov ntim thiab customizing xim, textures, thiab duab.

- Aerospace kev lag luam: Txhaj tshuaj molding yog siv los tsim ntau yam khoom ntawm aerospace qhov chaw, nrog rau cov khoom siv thiab cov khoom siv sab hauv. Nws tso cai rau tsim cov khoom siv ua haujlwm siab uas tuaj yeem tiv taus qhov kub thiab txias.

- Kev tsim kho kev lag luam: Txhaj tshuaj molding tsim ntau yam khoom siv, suav nrog PVC kav, gutter systems, thiab cov ntaub ntawv vov tsev. Nws muaj kev ua haujlwm siab, tiv taus huab cua thiab tshuaj lom neeg, thiab muaj peev xwm tsim cov khoom hauv cov ntim loj.

- Kev lag luam Electronics: Txhaj tshuaj molding tsim ntau yam khoom siv hluav taws xob, suav nrog tsev nyob, cov khoom sib txuas, thiab cov keyboards. Nws muaj cov precision siab, uniformity, thiab muaj peev xwm los tsim qhov chaw nrog complex geometry, uas yog ib qho tseem ceeb nyob rau hauv lub electronics kev lag luam.

Zuag qhia tag nrho, kev txhaj tshuaj molding yog ntau yam txheej txheem tsim khoom uas tuaj yeem tsim ntau yam yas rau ntau qhov kev lag luam. Nws lub peev xwm los tsim cov khoom nrog cov geometry nyuaj, siab precision, thiab zoo ib yam ua rau nws yog qhov kev xaiv nrov rau ntau lub tuam txhab.

Hom khoom siv hauv kev txhaj tshuaj molding

Txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten rau hauv cov pwm kab noj hniav kom tsim tau ib qho duab tshwj xeeb. Cov ntaub ntawv sib txawv tuaj yeem siv rau hauv kev txhaj tshuaj molding, nyob ntawm qhov xav tau ntawm cov khoom kawg. Nov yog qee yam ntawm cov khoom siv feem ntau siv hauv kev txhaj tshuaj molding:

- Thermoplastics: Cov no yog cov khoom siv feem ntau siv hauv kev txhaj tshuaj molding. Lawv yog ib hom yas uas ua mos thiab moldable thaum rhuab thiab hardens thaum txias. Thermoplastics tuaj yeem molded thiab remolded ntau zaus yam tsis poob lawv cov khoom. Cov thermoplastics feem ntau siv hauv kev txhaj tshuaj molding muaj xws li polypropylene, polyethylene, polystyrene, thiab nylon.

- Thermosets: Cov no yog cov yas uas tuaj yeem molded ib zaug xwb. Lawv raug rhuab thiab tsim rau hauv cov duab tshwj xeeb, thiab thaum lawv harden, lawv tsis tuaj yeem rov ua dua. Thermosets yog siv rau cov ntawv thov uas yuav tsum muaj lub zog siab thiab ua haujlwm ntev. Cov thermosets feem ntau siv hauv kev txhaj tshuaj molding muaj xws li epoxy, melamine, thiab phenolic resins.

- Elastomers: Cov ntaub ntawv no muaj cov khoom elastic thiab tuaj yeem ncab thiab rov qab mus rau lawv qhov qub. Elastomers yog siv rau cov ntawv thov uas yuav tsum tau hloov tau yooj yim thiab kev poob siab. Cov txheej txheem elastomers siv hauv kev txhaj tshuaj molding muaj xws li roj hmab, silicone, thiab polyurethane.

- Cov ntaub ntawv biodegradable: Cov no tuaj yeem tawg hauv ib puag ncig yam tsis muaj kev puas tsuaj. Lawv yog siv rau cov ntawv thov uas ib puag ncig sustainability yog ib qho kev txhawj xeeb. Cov khoom siv biodegradable siv hauv kev txhaj tshuaj molding muaj xws li polylactic acid (PLA) thiab polyhydroxyalkanoates (PHAs).

- Composites yog cov khoom tsim los ntawm kev sib txuas ob lossis ntau cov ntaub ntawv sib txawv los tsim cov khoom tshiab nrog cov khoom tshwj xeeb. Composites yog siv rau cov ntawv thov uas yuav tsum tau muaj zog thiab nruj. Cov txheej txheem sib xyaw siv hauv kev txhaj tshuaj molding suav nrog iav fiber ntau cov yas (GRP) thiab carbon fiber-reinforced plastics (CFRP).

- Cov yas uas muaj hlau yog cov yas ntim nrog cov khoom siv hlau los tsim cov khoom siv hluav taws xob thiab thermal conductivity thiab lwm yam khoom tshwj xeeb. Cov yas ntim hlau yog siv rau cov ntawv thov uas tsim nyog siv hluav taws xob lossis thermal conductivity. Cov hlau uas muaj cov yas uas siv hauv kev txhaj tshuaj molding muaj xws li tooj liab-filled plastics thiab nickel-filled plastics.

Zuag qhia tag nrho, kev xaiv ntawm cov khoom siv txhaj tshuaj yog nyob ntawm qhov kawg ntawm cov khoom tshwj xeeb, suav nrog lub zog, yoog raws, conductivity, thiab durability. Cov neeg tsim khoom feem ntau xaiv cov khoom siv raws li tus nqi, muaj, yooj yim ntawm kev ua, thiab cov khoom tsim nyog rau cov khoom kawg.

Yam yuav tsum tau xav txog thaum xaiv cov khoom siv txhaj tshuaj molding

Xaiv cov khoom tsim nyog yog qhov tseem ceeb thaum nws los txog rau kev txhaj tshuaj molding, vim nws tuaj yeem cuam tshuam rau cov khoom thiab kev ua tau zoo ntawm cov khoom kawg. Nov yog qee yam uas yuav tsum xav txog thaum xaiv cov khoom siv txhaj tshuaj molding:

- Mechanical zog: Ib qho tseem ceeb tshaj plaws uas yuav tsum tau xav txog thaum xaiv cov khoom yog nws cov khoom siv kho tshuab. Qhov no suav nrog nws lub zog, tawv, tawv, thiab tsis kam hnav thiab tsim kua muag. Cov khoom siv kho tshuab xav tau rau cov khoom kawg yuav nyob ntawm daim ntawv thov thiab cov kev ntxhov siab uas cov khoom yuav raug nthuav tawm.

- Cov khoom siv thermal: Cov khoom siv thermal ntawm cov khoom siv kuj tseem ceeb, tshwj xeeb tshaj yog yog tias cov khoom kawg yuav raug rau qhov kub thiab txias los yog thermal cycling. Qhov no suav nrog cov khoom siv melting point, thermal conductivity, thiab coefficient ntawm thermal expansion.

- Chemical resistance: Yog tias cov khoom kawg raug rau cov tshuaj, xaiv cov khoom uas tuaj yeem tiv taus cov tshuaj degradation yog qhov tseem ceeb. Cov khoom siv yuav tsum tiv taus cov kua qaub, cov hauv paus, cov kuab tshuaj, thiab lwm yam tshuaj yam tsis tau tawg lossis poob nws cov khoom.

- Environmental factor: Environmental factor, xws li av noo thiab UV raug, kuj tuaj yeem cuam tshuam cov khoom thiab kev ua haujlwm ntawm cov khoom. Nws yog ib qho tseem ceeb los xav txog qhov kawg ntawm cov khoom ib puag ncig thiab xaiv cov khoom uas tuaj yeem tiv taus lawv.

- Tus nqi: Tus nqi ntawm cov khoom siv kuj yog ib qho tseem ceeb rau kev txiav txim siab, tshwj xeeb tshaj yog rau cov khoom ntim ntau lawm. Tus nqi ntawm cov khoom siv yuav tsum tau hnyav rau nws cov kev ua tau zoo thiab cov khoom kom ntseeg tau tias nws yog qhov kev xaiv zoo rau cov khoom kawg.

- Cov kev xav tau ntawm kev ua haujlwm: Cov txheej txheem ua tiav rau cov khoom siv kuj tuaj yeem cuam tshuam cov txheej txheem xaiv. Qee cov ntaub ntawv yuav xav tau cov cuab yeej ua haujlwm tshwj xeeb lossis cov txheej txheem, thiab qee qhov yuav nyuaj rau kev ua haujlwm. Cov txheej txheem ua tiav yuav tsum raug txiav txim siab kom ntseeg tau tias cov khoom tuaj yeem siv tau zoo hauv cov txheej txheem txhaj tshuaj molding.

- Kev ua raws cai: Thaum kawg, nws yog ib qho tseem ceeb los txiav txim siab txog cov kev cai tswj hwm uas cov khoom kawg yuav tsum tau ua. Qee qhov kev lag luam, xws li kev lag luam kho mob thiab zaub mov, muaj cov cai tshwj xeeb rau cov khoom siv hauv lawv cov khoom. Xaiv cov khoom uas ua tau raws li cov kev cai tswj hwm no yog qhov tseem ceeb los xyuas kom meej tias cov khoom kawg muaj kev nyab xeeb thiab ua raws.

Zuag qhia tag nrho, xaiv cov khoom tsim nyog rau kev txhaj tshuaj molding yuav tsum tau ua tib zoo xav txog ntau yam, suav nrog cov khoom siv hluav taws xob thiab thermal, tshuaj lom neeg tsis kam, ib puag ncig yam, nqi, kev ua raws cai, thiab kev tswj hwm. Cov neeg tsim khoom yuav tsum ntsuas cov xwm txheej no rau ib leeg los xaiv cov khoom siv uas haum rau cov khoom kawg.

Qhov tseem ceeb ntawm kev tsim pwm hauv kev txhaj tshuaj molding

Pwm tsim yog ib qho tseem ceeb ntawm txoj kev txhaj tshuaj molding. Kev tsim cov pwm tuaj yeem cuam tshuam qhov zoo ntawm cov khoom kawg, nrog rau kev ua tau zoo thiab tus nqi-zoo ntawm cov txheej txheem tsim khoom. Nov yog qee qhov laj thawj vim li cas pwm tsim yog qhov tseem ceeb hauv kev txhaj tshuaj molding:

- Cov khoom lag luam zoo: Cov pwm tsim tuaj yeem cuam tshuam rau qhov kawg ntawm cov khoom zoo. Yog tias cov pwm tsis tsim kom zoo, nws tuaj yeem ua rau muaj qhov tsis xws luag xws li warping, sink marks, thiab flash. Cov kev tsis zoo no tuaj yeem ua rau cov khoom kawg siv tsis tau, txo kev ua haujlwm, thiab nce cov nqi seem thiab cov nqi tsim khoom.

- Manufacturing efficiency: Kev tsim cov pwm tuaj yeem cuam tshuam rau kev ua haujlwm ntawm cov txheej txheem tsim khoom. Yog tias cov pwm tsis tsim los rau qhov zoo tshaj plaws khiav thiab txias, nws tuaj yeem ua rau lub sij hawm voj voog ntev dua, kev siv hluav taws xob ntau ntxiv, thiab txo cov khoom siv. Kev tsim pwm zoo tuaj yeem txhim kho kev ua haujlwm thiab txo cov nqi tsim khoom.

- Nqi-zoo: Pwm tsim kuj tuaj yeem cuam tshuam tus nqi-zoo ntawm cov txheej txheem txhaj tshuaj molding. Lub pwm tsim tau zoo tuaj yeem txo cov khoom pov tseg, txhim kho qhov zoo, thiab ua kom muaj zog, txo cov nqi tsim khoom. Tsis tas li ntawd, cov pwm tsim los rau cov khoom ntim siab tuaj yeem txo tus nqi ib feem thiab ua kom cov nyiaj rov qab los ntawm kev nqis peev.

- Customization: Pwm tsim kuj ua lub luag haujlwm tseem ceeb hauv kev hloov kho ntawm cov khoom kawg. Los ntawm kev tsim cov pwm rau cov duab tshwj xeeb thiab cov yam ntxwv, cov tuam ntxhab tuaj yeem tsim cov khoom lag luam raws li lawv cov neeg siv khoom xav tau. Qhov no tso cai rau kev hloov pauv ntau dua thiab kev sib txawv hauv kev ua lag luam, ua rau muaj kev txaus siab rau cov neeg siv khoom thiab kev ntseeg siab.

- Kev xaiv cov khoom siv: Cov pwm tsim tuaj yeem cuam tshuam rau kev xaiv cov khoom siv hauv kev txhaj tshuaj molding. Txoj kev molding tuaj yeem cuam tshuam cov khoom ntws thiab txias, uas tuaj yeem cuam tshuam cov khoom siv hluav taws xob thiab thermal ntawm cov khoom kawg. Los ntawm kev xaiv cov pwm tsim, cov tuam ntxhab tuaj yeem txhim kho cov khoom xaiv thiab xyuas kom meej tias cov khoom kawg ua tau raws li qhov xav tau kev ua haujlwm.

Zuag qhia tag nrho, kev tsim pwm yog qhov tseem ceeb hauv kev txhaj tshuaj molding txheej txheem. Lub pwm tsim tau zoo tuaj yeem txhim kho cov khoom zoo, kev tsim khoom, kev ua haujlwm zoo, kev tsim kho, thiab kev xaiv cov khoom siv. Cov neeg tsim khoom yuav tsum nqis peev sijhawm thiab cov peev txheej los tsim cov pwm zoo rau lawv cov kev xav tau tshwj xeeb kom ua tiav cov txiaj ntsig zoo tshaj plaws hauv cov txheej txheem txhaj tshuaj molding.

Ntau hom pwm siv hauv kev txhaj tshuaj molding

Txhaj tshuaj molding yog txheej txheem tsim khoom ntau yam uas tuaj yeem tsim ntau yam khoom yas. Ib qho tseem ceeb ntawm kev txiav txim siab qhov zoo thiab kev ua haujlwm ntawm kev txhaj tshuaj molding yog hom pwm siv. Nov yog qee qhov sib txawv ntawm cov pwm siv hauv kev txhaj tshuaj molding:

- Ob-phaj pwm: Ob-phaj pwm yog cov pwm feem ntau siv hauv kev txhaj tshuaj molding. Lawv muaj ob daim hlau uas sib cais los ntawm cov kab noj hniav pwm. Cov khoom siv yas yog txhaj rau hauv kab noj hniav, sib txuas ob daim hlau los ua cov khoom kawg.

- Peb-phaj pwm: Peb-phaj pwm zoo ib yam li ob-phaj pwm tab sis muaj ib lub phaj ntxiv cais cov kab khiav ntawm qhov pwm. Qhov no tso cai rau kom yooj yim ejection ntawm ib feem thiab tuaj yeem txo lub sijhawm voj voog.

- Kub khiav pwm: Kub khiav pwm yog siv rau cov khoom ntim ntau lawm, raws li lawv tuaj yeem txo lub sijhawm voj voog thiab cov khoom pov tseg. Cov pwm muaj cov cua kub khiav uas xa cov yas molten ncaj qha mus rau cov pwm kab noj hniav, tshem tawm qhov xav tau rau kev khiav txias.

- Cov pwm txias khiav pwm: Cov pwm txias khiav pwm yog hom pwm pwm yooj yim tshaj plaws thiab muaj cov pwm, cov pwm khiav, thiab pwm kab noj hniav. Cov yas molten yog txhaj rau hauv lub sprue, uas pub cov yas rau hauv cov neeg khiav dej num thiab tom qab ntawd mus rau hauv pwm kab noj hniav.

- Tsev neeg pwm: Tsev neeg pwm tsim ntau yam hauv ib lub voj voog. Cov pwm muaj ntau cov kab noj hniav, txhua qhov muaj qhov sib txawv. Tsev neeg pwm feem ntau yog siv rau cov khoom me me, cov khoom ntim siab.

- Stack pwm: Cov pwm pwm tsim ntau txheej yas hauv ib lub voj voog. Cov pwm muaj ntau txheej kab noj hniav, uas tau muab tso rau saum ib leeg. Cov yas yog txhaj rau hauv lub qhov, thiab cov khaubncaws sab nraud povtseg tau muab coj los ua ib qho, ntau txheej khoom.

- Ntxig pwm: Ntxig pwm yog siv los ntxig cov hlau lossis yas rau hauv qhov molded thaum lub sijhawm molding. Lub ntxig yog muab tso rau hauv lub pwm kab noj hniav ua ntej cov yas txhaj tshuaj, thiab cov yas ces nyob ib ncig ntawm lub insert.

Zuag qhia tag nrho, hom pwm siv hauv kev txhaj tshuaj molding yog nyob ntawm cov kev cai tshwj xeeb ntawm cov khoom tsim. Los ntawm kev xaiv hom pwm kom raug, cov tuam txhab tsim khoom tuaj yeem ua kom zoo rau cov txheej txheem txhaj tshuaj molding kev ua tau zoo, zoo, thiab kev ua haujlwm zoo.

Cov kev coj ua zoo tshaj plaws rau kev txhaj tshuaj molding

Kev txhaj tshuaj molding yog txheej txheem tsim khoom uas yuav tsum tau ua tib zoo npaj thiab ua tiav kom ua tiav cov txiaj ntsig xav tau. Nov yog qee qhov kev coj ua zoo tshaj plaws rau kev txhaj tshuaj molding uas tuaj yeem pab ua kom pom kev zoo, ua haujlwm tau zoo, thiab tus nqi zoo:

- Tsim rau manufacturability: Cov khoom tsim yuav tsum ua kom zoo rau kev txhaj tshuaj molding. Qhov no suav nrog txo cov naj npawb ntawm cov khoom, kom ntseeg tau tias cov phab ntsa tuab tuab, thiab tsis txhob muaj kev cuam tshuam thiab lwm yam uas cuam tshuam rau molding.

- Kev xaiv cov khoom siv: Cov khoom siv hauv kev txhaj tshuaj molding yuav tsum raug xaiv raws li cov khoom xav tau. Cov yam ntxwv xws li cov khoom siv hluav taws xob, cov khoom siv thermal, thiab kev tiv thaiv ib puag ncig yuav tsum raug txiav txim siab.

- Pwm tsim: Cov pwm tsim yuav tsum ua kom zoo rau cov khoom tshwj xeeb. Qhov no suav nrog kev ua kom cov cua txias kom zoo, qhov cua, thiab qhov rooj, nrog rau xaiv hom pwm tsim nyog.

- Kev txhaj tshuaj tsis haum: Cov kev txhaj tshuaj, xws li kev txhaj tshuaj, qhov kub thiab txias, yuav tsum tau ua tib zoo tswj thiab saib xyuas kom zoo thiab sib xws.

- Kev Kho: Kev txhaj tshuaj molding tshuab tsis tu ncua thiab kev saib xyuas pwm yog qhov tseem ceeb rau kev ua haujlwm zoo thiab tiv thaiv kev poob qis.

- Kev Tswjhwm Zoo: Kev tswj kom zoo yuav tsum tau ua tiav thoob plaws hauv cov txheej txheem txhaj tshuaj molding, los ntawm kev tshuaj xyuas cov khoom nkag mus rau qhov kawg ntawm kev tshuaj xyuas cov khoom. Qhov no suav nrog kev saib xyuas cov teeb meem xws li warpage, dab dej cim, thiab flash.

- Txheej txheem optimization: Kev txhim kho cov txheej txheem txuas ntxiv yuav tsum yog qhov tseem ceeb ntawm kev txhaj tshuaj molding kev ua haujlwm. Qhov no suav nrog kev saib xyuas cov txheej txheem kev ntsuas kev ua tau zoo xws li lub sijhawm voj voog, tus nqi seem, thiab kev siv tshuab thiab kev hloov kho raws li qhov tsim nyog los ua kom zoo dua qub thiab zoo.

Zuag qhia tag nrho, kev txhaj tshuaj molding yuav tsum tau ua tib zoo saib xyuas kom meej thiab tsom mus rau kev txhim kho txuas ntxiv. Los ntawm kev ua raws li cov kev coj ua zoo tshaj plaws rau kev txhaj tshuaj molding, cov tuam txhab tsim khoom tuaj yeem ua kom pom kev zoo, ua haujlwm zoo, thiab tus nqi-zoo thiab tsim cov khoom zoo yas uas ua tau raws li lawv cov neeg siv khoom xav tau.

Kev tswj xyuas zoo rau kev txhaj tshuaj molding

Kev tswj kom zoo yog qhov tseem ceeb rau kev txhaj tshuaj molding, vim nws ua kom cov khoom kawg ua tau raws li qhov yuav tsum tau ua thiab cov qauv. Nov yog qee qhov kev tswj xyuas zoo rau kev txhaj tshuaj molding:

- Kev tshuaj xyuas cov khoom xa tuaj: Cov txheej txheem tswj kom zoo yuav tsum pib nrog kev tshuaj xyuas cov khoom siv raw siv rau kev txhaj tshuaj molding. Qhov no suav nrog kev txheeb xyuas qhov tseeb tias cov khoom siv yog hom, qib, thiab xim thiab ua tau raws li qhov yuav tsum tau muaj cov khoom siv hluav taws xob thiab thermal specifications.

- Kev tshuaj xyuas hauv cov txheej txheem: Thaum lub sijhawm txhaj tshuaj molding, cov neeg ua haujlwm tswj xyuas zoo yuav tsum tsis tu ncua xyuas cov khoom kom ntseeg tau tias nws raug molded raug. Qhov no suav nrog kev saib xyuas qhov tsis xws luag xws li cov cim dab dej, warping, thiab flash thiab xyuas kom meej tias cov khoom ua tau raws li qhov yuav tsum tau muaj qhov ntev ntev.

- Kev tshuaj xyuas cov khoom kawg: Thaum cov txheej txheem txhaj tshuaj molding tiav, cov khoom kawg yuav tsum raug tshuaj xyuas kom ntseeg tau tias nws ua tau raws li qhov xav tau tshwj xeeb thiab cov qauv. Qhov no suav nrog kev txheeb xyuas tias cov khoom lag luam tsis muaj qhov tsis xws luag, xws li tawg, npuas, thiab voids thiab ua tau raws li qhov yuav tsum tau ua kom ntev ntev.

- Statistical process control: Statistical process control (SPC) yog ib txoj hauv kev los saib xyuas thiab tswj cov txheej txheem los xyuas kom meej tias nws ua tau zoo ib yam. SPC suav nrog kev sau cov ntaub ntawv ntawm cov txheej txheem tseem ceeb, xws li kev txhaj tshuaj siab thiab qhov kub thiab txias, thiab siv cov ntaub ntawv txheeb xyuas los txheeb xyuas cov xwm txheej thiab cov qauv uas qhia txog kev hloov pauv ntawm cov txheej txheem.

- Kev txhim kho tas mus li: Kev tswj kom zoo yuav tsum yog tus txheej txheem ntawm kev txhim kho tas li. Qhov no suav nrog kev txheeb xyuas cov ntaub ntawv ntawm cov txheej txheem kev ua tau zoo, txheeb xyuas thaj chaw rau kev txhim kho, thiab hloov cov txheej txheem los ua kom zoo thiab ua haujlwm zoo.

- Cov ntaub ntawv thiab traceability: Cov neeg ua haujlwm tswj tau zoo yuav tsum khaws cov ntaub ntawv ntxaws ntxaws ntawm cov txheej txheem txhaj tshuaj molding, suav nrog cov txheej txheem tsis, tshuaj ntsuam xyuas, thiab kev kho kom raug. Cov ntaub ntawv no muab traceability thiab pab xyuas kom meej tias txhua yam teeb meem zoo tuaj yeem txheeb xyuas thiab kho sai.

Zuag qhia tag nrho, kev tswj kom zoo yog qhov tseem ceeb ntawm kev txhaj tshuaj molding thiab yuav tsum tau muab tso rau hauv txhua qhov ntawm cov txheej txheem tsim khoom. Los ntawm kev siv cov kev tswj xyuas zoo, cov tuam txhab tsim khoom tuaj yeem tsim cov khoom yas zoo uas ua tau raws li lawv cov neeg siv khoom xav tau.

Feem ntau tsis xws luag hauv kev txhaj tshuaj molding thiab yuav tiv thaiv lawv li cas

Kev txhaj tshuaj molding yog txheej txheem nyuaj uas tuaj yeem ua rau muaj qhov tsis xws luag yog tias ua tsis raug. Nov yog qee qhov tsis xws luag hauv kev txhaj tshuaj molding thiab yuav ua li cas tiv thaiv lawv:

- Sink marks yog kev nyuaj siab los yog dents ntawm cov khoom nto. Lawv tshwm sim los ntawm qhov tsis sib xws ntawm qhov txias txias lossis tsis txaus ntim siab. Xyuas kom cov pwm tsim muaj xws li cov phab ntsa tuab thiab cov qauv tsim kom txaus los tiv thaiv cov cim dab dej. Kho qhov ntim siab thiab lub sijhawm txias tuaj yeem pab tiv thaiv cov cim dab dej.

- Warpage: Warpage yog qhov cuam tshuam ntawm cov khoom tom qab nws tau raug tshem tawm ntawm pwm. Nws yog tshwm sim los ntawm qhov tsis sib xws ntawm qhov txias txias lossis kev ntxhov siab hauv cov khoom. Txhawm rau tiv thaiv warpage, xyuas kom cov pwm tsim muaj xws li cov phab ntsa tuab thiab lub sijhawm txias txaus. Tsis txhob hnov qab cov ces kaum ntse los yog tam sim ntawd hloov ntawm cov khoom geometry, uas tuaj yeem tsim cov ntsiab lus kev ntxhov siab.

- Flash: Flash yog cov yas ntau dhau uas txuas mus dhau ntawm cov khoom ciam teb, feem ntau tshwm sim nyob ib ncig ntawm cov npoo ntawm pwm. Nws yog tshwm sim los ntawm kev txhaj tshuaj ntau dhau, lub zog clamping tsis txaus, lossis pwm hnav. Txhawm rau tiv thaiv flash, kho qhov kev txhaj tshuaj siab thiab clamping quab yuam thiab tsis tu ncua xyuas cov pwm rau cov cim ntawm hnav.

- Kev txhaj tshuaj luv luv: Kev txhaj tshuaj luv luv tshwm sim thaum cov pwm yog ib nrab ntim nrog cov yas. Qhov no tuaj yeem tshwm sim los ntawm kev txhaj tshuaj tsis txaus lossis qhov kub thiab txias lossis qhov thaiv los yog txwv cov dej ntws. Txhawm rau tiv thaiv kev txhaj tshuaj luv luv, kho qhov kev txhaj tshuaj thiab qhov kub thiab txias, thiab xyuas kom meej tias cov channel ntws tau meej thiab tsis muaj kev cuam tshuam.

- Hlawv cov cim: Hlawv cov cim yog cov xim tsaus nti ntawm cov khoom nto uas tshwm sim los ntawm overheating lossis kev sib txhuam ntau dhau ntawm cov pwm. Txhawm rau tiv thaiv qhov kub hnyiab, xyuas kom cov pwm tau txias txaus thiab lubricated, thiab kho qhov kev txhaj tshuaj nrawm thiab siab raws li qhov tsim nyog.

- Voids thiab npuas: Voids thiab npuas yog cov khoom lag luam uas tsis muaj cov khoom lossis cov hnab ntim cua. Lawv tshwm sim los ntawm cov huab cua los yog roj hauv cov pwm los yog cov khoom siv tsis txaus. Txhawm rau tiv thaiv cov voids thiab npuas, xyuas kom meej tias cov pwm yog vented kom raug thiab qhov kev txhaj tshuaj ceev thiab siab txaus los xyuas kom meej cov khoom zoo sib xws.

Cov lus qhia txog kev kho cov khoom siv txhaj tshuaj molding

Cov cuab yeej txhaj tshuaj molding yog qhov peev txheej tseem ceeb rau cov tuam txhab tsim khoom, thiab kev saib xyuas kom zoo yog qhov tseem ceeb los xyuas kom meej qhov ua tau zoo thiab ua haujlwm ntev. Nov yog qee cov lus qhia txog kev kho mob rau cov khoom siv txhaj tshuaj molding:

- Ua kev soj ntsuam tsis tu ncua: Tshawb xyuas cov cuab yeej tsis tu ncua txhawm rau txheeb xyuas qhov hnav thiab tsim kua muag, kev puas tsuaj, lossis lwm yam teeb meem. Tshawb xyuas cov hydraulic hoses, cov ntsaws ruaj ruaj, thiab lwm yam tseem ceeb kom ntseeg tau tias lawv nyob rau hauv qhov zoo.

- Ntxuav thiab lubricate cov cuab yeej: Ntxuav thiab lubricate cov cuab yeej tsis tu ncua los tiv thaiv corrosion thiab hnav. Siv cov khoom tu thiab lubrication tau pom zoo, thiab ua raws li cov chaw tsim khoom cov lus qhia.

- Saib xyuas thiab tswj cov roj hydraulic: Saib xyuas nws tsis tu ncua kom paub tseeb tias nws huv thiab ntawm qhov tseeb viscosity. Hloov cov roj raws li xav tau, thiab siv hom roj pom zoo.

- Khaws cov cua sov ua kom sov: xyuas lawv tsis tu ncua kom ntseeg tau tias lawv nyob hauv qhov zoo thiab cua sov kom raug. Hloov cov kab hluav taws xob puas los yog hnav tam sim ntawd.

- Saib xyuas thiab tswj cov cua txias: Nws yog ib qho tseem ceeb rau kev txhaj tshuaj molding, vim nws tiv thaiv overheating thiab warpage. Saib xyuas lub tshuab ua kom txias tsis tu ncua kom nws ua haujlwm kom raug, thiab ntxuav cov cua txias raws li xav tau.

- Cov neeg tsav tsheb ciav hlau: Qhia cov neeg tsav tsheb ntawm kev ua haujlwm ntawm cov cuab yeej siv thiab kev saib xyuas kom tsis txhob muaj kev puas tsuaj thiab ua kom pom kev ua haujlwm zoo.

- Teem caij saib xyuas tsis tu ncua: Tsim lub sijhawm saib xyuas thiab ua raws li nws. Teem sijhawm ua haujlwm tu txhua hnub, xws li lubrication thiab roj hloov, thiab sau tag nrho cov haujlwm tu.

- Khaws cov khoom seem ntawm tes: Muab cov khoom seem, xws li hydraulic hoses, cov ntsaws ruaj ruaj, thiab cov cua sov. Qhov no yuav hloov cov khoom puas los yog hnav sai sai thiab txo qis sijhawm.

Kev kho kom zoo ntawm cov cuab yeej txhaj tshuaj molding yog qhov tseem ceeb los xyuas kom meej tias nws ua haujlwm zoo, tsim cov khoom zoo, thiab muaj lub neej ntev. Los ntawm kev ua raws li cov lus qhia txog kev saib xyuas no, cov tuam txhab tsim khoom tuaj yeem khaws lawv cov khoom nyob rau hauv qhov zoo tshaj plaws thiab txo qis sijhawm thiab kho cov nqi.

Yuav ua li cas xaiv qhov tsim nyog txhaj tshuaj molding chaw tsim tshuaj paus

Xaiv qhov tsim nyog txhaj tshuaj molding chaw tsim tshuaj paus yog qhov kev txiav txim siab tseem ceeb uas tuaj yeem cuam tshuam qhov zoo thiab tus nqi ntawm koj cov khoom. Nov yog qee yam uas yuav tsum xav txog thaum xaiv cov chaw tsim tshuaj molding:

- Kev paub thiab kev txawj ntse: Nrhiav ib lub chaw tsim khoom uas muaj kev paub dhau los thiab kev txawj ntse hauv kev txhaj tshuaj molding. Nug txog lawv cov txheej txheem tsim khoom, ntsuas kev tswj xyuas zoo, thiab cov ntawv pov thawj.

- Technology thiab khoom siv: Nrhiav ib lub chaw tsim khoom uas siv cov cuab yeej siv niaj hnub thiab khoom siv. Qhov no tuaj yeem pab ua kom zoo ib yam, lub sij hawm luv luv, thiab kev siv nyiaj zoo.

- Cov khoom siv thiab muaj peev xwm: Xav txog cov khoom siv uas cov chaw tsim khoom tuaj yeem ua haujlwm nrog thiab lawv lub peev xwm. Nrhiav ib lub chaw tsim khoom uas tuaj yeem tswj tau ntau yam khoom siv, suav nrog cov ntaub ntawv tshwj xeeb, thiab tuaj yeem tsim ntau yam khoom loj thiab cov duab.

- Kev Tswjhwm Zoo: Nrhiav ib lub chaw tsim khoom uas tsom ntsoov rau kev tswj kom zoo. Nug txog lawv cov kev tswj xyuas zoo, xws li cov txheej txheem tshuaj xyuas thiab kuaj, thiab cov ntawv pov thawj uas lawv muaj.

- Kev Pabcuam Cov Neeg Siv Khoom: Nrhiav cov chaw tsim khoom uas muab kev pabcuam zoo rau cov neeg siv khoom. Xav txog kev teb, kev sib txuas lus, thiab kev txaus siab ua haujlwm nrog koj kom ua tau raws li koj cov kev xav tau tshwj xeeb.

- Tus nqi thiab lub sijhawm ua haujlwm: Xav txog cov chaw tsim khoom tus nqi thiab lub sijhawm ua haujlwm rau koj qhov project. Nrhiav ib lub chaw tsim khoom uas muab cov nqi sib tw thiab cov sij hawm ua kom muaj tseeb uas ua tau raws li koj qhov yuav tsum tau ua.

- Cov ntaub ntawv pov thawj thiab tshuaj xyuas: Nug rau cov ntaub ntawv siv thiab tshawb xyuas online ntawm cov chaw tsim khoom. Qhov no tuaj yeem pab koj tau txais kev nkag siab zoo ntawm lawv lub koob npe nrov thiab kev paub ntawm lwm tus neeg siv khoom.

Koj tuaj yeem xaiv qhov chaw tsim tshuaj molding tsim nyog rau koj qhov project los ntawm kev txiav txim siab txog cov xwm txheej no thiab ua kev tshawb fawb zoo. Lub chaw tsim khoom muaj npe nrov nrog cov kev paub zoo, muaj peev xwm, thiab kev cog lus rau qhov zoo tuaj yeem pab xyuas kom koj cov khoom tsim tau zoo, raug nqi, thiab raws li koj cov lus qhia meej.

Kev txiav txim siab nqi hauv kev cai yas txhaj tshuaj molding

Kev cai yas txhaj tshuaj molding yog cov txheej txheem tsim khoom muaj ntau yam uas tuaj yeem tsim cov khoom sib txuam, zoo ntawm qhov ntsuas. Txawm li cas los xij, kev txiav txim siab nqi yog qhov tseem ceeb hauv kev siv cov txheej txheem tsim khoom no. Nov yog qee qhov kev txiav txim siab tus nqi tseem ceeb hauv kev cai yas txhaj tshuaj molding:

- Cov nqi khoom siv: Hom thiab ntau ntawm cov khoom siv hauv kev txhaj tshuaj molding yuav cuam tshuam tus nqi. Qee cov ntaub ntawv, xws li kev ua haujlwm siab engineering plastics, yog kim dua lwm tus. Tus nqi ntawm cov ntaub ntawv tseem tuaj yeem cuam tshuam los ntawm kev cuam tshuam ntawm cov khoom lag luam, kev xav tau ntawm kev lag luam, thiab tus nqi hloov pauv.

- Cov nqi cuab yeej: Tus nqi ntawm cov cuab yeej, lossis cov pwm siv los tsim cov khoom, yog ib qho tseem ceeb hauv kev cai yas txhaj tshuaj molding. Ib feem ntawm qhov nyuaj, tus naj npawb ntawm cov kab noj hniav hauv pwm, thiab cov khoom siv los tsim pwm yuav cuam tshuam tag nrho cov cuab yeej siv. Cov cuab yeej tuaj yeem kim ua ntej tab sis tuaj yeem pab txo cov nqi tsev nyob rau lub sijhawm los ntawm kev ua kom muaj txiaj ntsig ntau lawm.

- Kev ntim ntau lawm: Lub ntim ntawm cov khoom tsim tawm yuav cuam tshuam tus nqi txhaj tshuaj molding. Cov khoom ntim siab tuaj yeem pab txo cov nqi tsev, thaum cov khoom ntim qis yuav muaj cov nqi tsev ntau dua vim qhov xav tau ntau dua cov cuab yeej thiab lub sijhawm teeb tsa.

- Cov nqi ua haujlwm: Cov nqi ua haujlwm yog ib qho tseem ceeb hauv kev txhaj tshuaj molding, tshwj xeeb tshaj yog rau ntau qhov chaw uas yuav tsum tau ua haujlwm ntau dua. Cov theem kev txawj ntawm cov neeg ua haujlwm thiab qhov nyuaj ntawm ntu yuav cuam tshuam rau tus nqi xa khoom.

- Tus nqi tswj kev ua tau zoo: Kev tswj xyuas qhov zoo yog qhov tseem ceeb los xyuas kom meej qhov kev ncaj ncees. Tus nqi ntawm kev tswj kom zoo tuaj yeem suav nrog cov cuab yeej tshuaj xyuas, kev sim, thiab kev ua haujlwm.

- Cov nqi thauj khoom: Kev xa khoom mus rau cov neeg siv khoom lossis lwm qhov chaw tuaj yeem yog tus nqi tseem ceeb, tshwj xeeb tshaj yog rau cov ntsiab lus loj lossis hnyav.

Cov neeg tsim khoom tuaj yeem tsim cov khoom zoo ntawm tus nqi qis los ntawm kev txiav txim siab txog cov nqi no thiab ua kom zoo rau cov txheej txheem txhaj tshuaj molding. Qhov no tuaj yeem ua tiav los ntawm kev txo cov khoom pov tseg, txhim kho kev tsim khoom, thiab txo qis kev teeb tsa thiab hloov sijhawm. Ua haujlwm nrog kev paub txog thiab paub txog kev txhaj tshuaj molding chaw tsim khoom kuj tuaj yeem pab txhim kho cov txheej txheem thiab txo cov nqi.

Trends thiab innovation nyob rau hauv kev txhaj tshuaj molding tshuab

Txhaj tshuaj molding tshuab tau nyob ib puag ncig rau ntau xyoo, tab sis tseem muaj ntau qhov kev tsim kho tshiab thiab cov qauv tsim tsim cov txheej txheem tsim khoom yav tom ntej. Nov yog qee qhov kev nyiam tshaj plaws thiab kev tsim kho tshiab hauv kev txhaj tshuaj molding tshuab:

- 3D printing thiab additive manufacturing: 3D printing thiab additive manufacturing yog ua nrov nyob rau hauv kev txhaj tshuaj molding kev lag luam. Cov cuab yeej no tso cai rau kev tsim cov duab nyuaj thiab cov duab geometry uas nyuaj los yog tsis tuaj yeem ua tiav nrog kev txhaj tshuaj molding.

- Multi-material txhaj tshuaj molding: Ntau cov khoom siv tshuaj molding tso cai rau kev tsim cov khoom nrog ntau cov ntaub ntawv lossis xim hauv ib zaug. Cov txheej txheem no tuaj yeem txo cov sijhawm tsim khoom thiab cov nqi thiab tsim cov haujlwm nrog cov khoom tshwj xeeb thiab qhov tshwm sim.

- Automation thiab Kev Lag Luam 4.0: Automation thiab Industry 4.0 technologies, xws li IoT sensors thiab robotics, tau muab tso rau hauv kev txhaj tshuaj molding tshuab thiab cov txheej txheem. Qhov no tuaj yeem txhim kho kev tsim khoom, txo cov nqi zog, thiab txhim kho kev tswj kom zoo.

- Sustainable cov ntaub ntawv thiab cov txheej txheem: Raws li cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig, cov ntaub ntawv ruaj khov thiab cov txheej txheem tau dhau los ua qhov tseem ceeb hauv kev txhaj tshuaj molding kev lag luam. Qhov no suav nrog kev siv cov khoom siv biodegradable lossis rov ua dua tshiab thiab cov txheej txheem uas txo cov khib nyiab thiab siv hluav taws xob tsawg.

- Kev tsim khoom ntse thiab kev saib xyuas kev kwv yees: Kev tsim cov thev naus laus zis, xws li kev kawm tshuab thiab kev saib xyuas kev kwv yees, tau siv los ua kom zoo dua cov txheej txheem txhaj tshuaj molding thiab txo qis sijhawm. Qhov no tuaj yeem txhim kho kev ua haujlwm tag nrho thiab txo cov nqi kho.

- Cov ntaub ntawv ua tau zoo: Cov ntaub ntawv ua tau zoo tshiab tau tsim los rau kev txhaj tshuaj molding, nrog rau cov khoom siv nrog kev txhim kho lub zog, durability, thiab kub tsis kam. Cov ntaub ntawv no tuaj yeem siv rau ntau yam kev siv, los ntawm cov khoom siv tsheb mus rau cov khoom siv kho mob.

Los ntawm kev ua raws li cov qauv no thiab kev tsim kho tshiab, cov tuam txhab txhaj tshuaj molding tuaj yeem nyob twj ywm kev sib tw thiab txuas ntxiv muab cov khoom zoo rau lawv cov neeg siv khoom. Raws li cov thev naus laus zis tshiab thiab cov ntaub ntawv tsim tawm, kev txhaj tshuaj molding kev lag luam yuav txuas ntxiv txhim kho thiab hloov kho kom tau raws li cov kev hloov pauv ntawm cov neeg siv khoom thiab kev lag luam.

Sustainability hauv kev txhaj tshuaj molding: txo cov khib nyiab thiab siv zog

Sustainability tau dhau los ua qhov tseem ceeb hauv kev txhaj tshuaj molding kev lag luam raws li cov tuam txhab nrhiav kom txo lawv cov kev cuam tshuam ib puag ncig thiab ua tau raws li qhov kev thov loj hlob rau cov khoom lag luam hauv eco. Nov yog qee txoj hauv kev uas cov tuam txhab txhaj tshuaj molding tuaj yeem txo cov khib nyiab thiab siv zog:

- Siv cov khoom siv ruaj khov: Kev xaiv cov khoom siv yog qhov tseem ceeb hauv kev ruaj ntseg. Txhaj tshuaj molding tuam ntxhab tuaj yeem siv cov khoom siv biodegradable lossis rov siv dua los txo cov kev cuam tshuam ib puag ncig. Biodegradable plastics, piv txwv li, tuaj yeem rhuav tshem ib txwm dhau sijhawm thiab txo cov khoom pov tseg hauv qhov chaw pov tseg. Cov khoom siv rov ua dua tshiab, xws li cov khoom siv rov qab siv dua tshiab, tuaj yeem pab txo cov khoom pov tseg thiab siv zog.

- Txo cov khoom pov tseg: Txhaj tshuaj molding tuam txhab tuaj yeem txo cov khoom pov tseg los ntawm kev ua kom zoo ntawm cov qauv tsim thiab pwm. Qhov no suav nrog txo cov khoom siv ntau dhau, txo cov kab noj hniav hauv pwm, thiab txo qhov hnyav tag nrho ntawm ib feem. Los ntawm kev txo cov khoom pov tseg, cov tuam txhab lag luam tuaj yeem txuag cov nqi khoom siv thiab txo lawv cov kev cuam tshuam ib puag ncig.

- Optimize ntau lawm efficiency: Txhaj molding manufacturers tuaj yeem txhim kho lawv cov txheej txheem ntau lawm kom txo tau lub zog noj. Qhov no suav nrog kev siv cov tshuab txhaj tshuaj molding ua haujlwm siab, ua kom zoo rau cov txheej txheem molding, thiab txo qis sijhawm. Los ntawm kev txo qis kev siv hluav taws xob, cov tuam txhab lag luam tuaj yeem txuag cov nqi hluav taws xob thiab txo lawv cov pa roj carbon monoxide.

- Siv cov kev coj ua kom ruaj khov: Cov tuam txhab txhaj tshuaj molding tseem tuaj yeem siv cov kev coj ua kom ruaj khov hauv lawv cov haujlwm, xws li kev rov ua dua tshiab thiab txo cov pov tseg, siv cov khoom siv hluav taws xob txuas ntxiv mus, thiab txhawb kev ruaj khov ntawm lawv cov neeg ua haujlwm thiab cov neeg muag khoom. Los ntawm kev txhawb nqa cov kev coj ua kom ruaj khov thoob plaws hauv cov khoom siv, cov tuam txhab tsim khoom tuaj yeem pab tsim kom muaj kev lag luam ruaj khov dua tag nrho.

- Siv cov ntim khoom ruaj khov: Thaum kawg, cov tuam txhab txhaj tshuaj molding tuaj yeem siv cov khoom ntim ruaj khov thiab tsim qauv los txo cov khib nyiab thiab ib puag ncig. Qhov no suav nrog kev siv biodegradable lossis recyclable ntim cov ntaub ntawv, txo cov ntim pov tseg, thiab tsim cov ntim rov qab siv tau lossis rov ua dua.

Los ntawm kev ua raws li cov kev coj ua niaj hnub no, cov tuam txhab txhaj tshuaj molding tuaj yeem txo lawv cov kev cuam tshuam ib puag ncig thiab tsim kom muaj kev lag luam ruaj khov dua. Raws li kev ruaj ntseg tau dhau los ua qhov tseem ceeb rau cov neeg siv khoom thiab cov lag luam, cov tuam txhab txhaj tshuaj molding ua ntej qhov kev ruaj ntseg yuav tsum tau ua kom tau raws li qhov xav tau ntawm cov khoom lag luam hauv eco.

Yuav ua li cas kev cai yas txhaj molding piv rau lwm cov txheej txheem tsim

Kev cai yas txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau kev tsim cov khoom yas zoo hauv ntau qhov ntau. Txawm li cas los xij, ob peb lwm cov txheej txheem tsim khoom tuaj yeem siv los ua cov khoom yas, txhua qhov zoo thiab qhov tsis zoo. Nov yog kev sib piv ntawm kev cai yas txhaj tshuaj molding nrog rau lwm cov txheej txheem tsim khoom:

- 3D Printing: 3D luam ntawv yog ib lub tshuab loj hlob sai uas tso cai rau kev tsim cov duab nyuaj thiab geometries. Thaum 3D luam ntawv tuaj yeem siv rau kev tsim khoom me me, kev txhaj tshuaj molding feem ntau tsis tshua muaj nqi thiab ua haujlwm zoo dua li kev txhaj tshuaj molding rau kev tsim cov khoom loj.

- Tshuab Moulding: Tshuab moulding yog txheej txheem tsim khoom uas tsim cov khoom yas hollow, xws li lub raj mis thiab ntim. Thaum tshuab moulding yog tsim los tsim cov ntim siab ntawm cov yam ntxwv, kev txhaj tshuaj molding feem ntau tsis tshua meej dua li kev txhaj tshuaj molding thiab tej zaum yuav tsis zoo tagnrho rau kev tsim ntau cov duab thiab cov duab geometry.

- CNC Machining: CNC machining yog cov txheej txheem tsim tawm uas suav nrog kev txiav thiab tsim cov khoom los ntawm cov khoom thaiv. Thaum CNC machining tsim nyog rau kev tsim cov khoom ua haujlwm siab hauv cov khoom me me, nws feem ntau tsis raug nqi lossis siv tau zoo li kev txhaj tshuaj molding.

- Rotational Moulding: Rotational molding yog txheej txheem tsim khoom uas muaj kev hloov pwm nyob ib ncig ntawm ob lub kaum sab xis thaum cua sov. Thaum kev sib hloov moulding tuaj yeem tsim cov khoom loj nrog cov geometry nyuaj, kev txhaj tshuaj molding feem ntau tsis tshua meej dua li kev txhaj tshuaj molding thiab tej zaum yuav tsis haum rau kev ua cov khoom me.

- Thermoforming: Thermoforming yog txheej txheem tsim khoom uas muaj cua sov ntawm cov ntawv yas thiab tom qab ntawd shaping nws hla lub pwm. Thaum thermoforming tuaj yeem tsim cov khoom loj nrog cov geometry yooj yim, kev txhaj tshuaj molding feem ntau tsis tshua meej dua li kev txhaj tshuaj molding thiab tej zaum yuav tsis tsim nyog rau kev tsim ntau cov duab thiab cov duab geometry.

Kev cai yas txhaj tshuaj molding yog ib qho kev siv ntau yam thiab raug nqi tsim nyog rau kev tsim cov khoom yas zoo hauv ntau qhov ntau. Thaum lwm cov txheej txheem tsim khoom yuav zoo dua rau cov ntawv thov tshwj xeeb lossis cov ntim ntau lawm, kev txhaj tshuaj molding feem ntau yog qhov kev xaiv zoo tshaj plaws rau ntau lub tuam txhab vim nws qhov ceev, precision, thiab nqi-zoo. Thaum kawg, kev xaiv ntawm cov txheej txheem tsim khoom yuav nyob ntawm ntau yam, suav nrog cov qauv tsim, ntim ntau lawm, thiab pob nyiaj siv.

Pros thiab cons ntawm outsourcing txhaj molding

Outsourcing txhaj tshuaj molding yog ib qho kev coj ua rau cov tuam txhab nrhiav los tsim cov khoom yas yam tsis tau nqis peev hauv lawv tus kheej cov cuab yeej txhaj tshuaj molding lossis kev txawj ntse. Thaum outsourcing tuaj yeem muab ntau yam txiaj ntsig, nws kuj muaj qee qhov tsis zoo. Nov yog qee qhov zoo thiab qhov tsis zoo ntawm outsourcing txhaj tshuaj molding:

pros:

- Kev Txuag Nqi: Outsourcing txhaj tshuaj molding feem ntau siv nyiaj ntau dua li kev teeb tsa hauv tsev tsim khoom. Qhov no yog qhov tseeb tshwj xeeb tshaj yog rau cov tuam txhab me me rau nruab nrab uas xav tau nyiaj ntau dua los yog ntim kom pom tseeb kev nqis peev hauv cov cuab yeej kim thiab cov neeg ua haujlwm.

- Cov kws tshaj lij: Cov tuam txhab txhaj tshuaj molding tshwj xeeb hauv kev tsim khoom thiab muaj kev txawj ntse los xyuas kom meej tias cov khoom raug tsim los rau cov qauv zoo. Los ntawm outsourcing txhaj tshuaj molding, tuam txhab uas muag tuaj yeem tau txais txiaj ntsig los ntawm kev paub txog cov kws tshaj lij.

- Peev Xwm: Cov tuam txhab txhaj tshuaj molding tuaj yeem tsim ntau qhov chaw sai thiab ua tau zoo. Qhov no tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau cov tuam txhab uas yuav tsum tsis tu ncua ua cov ntim loj ntawm cov yam ntxwv.

- Flexibility: Outsourcing txhaj tshuaj molding tso cai rau cov tuam txhab hloov pauv hauv lawv cov sijhawm tsim khoom. Cov tuam txhab tuaj yeem kho lawv cov ntim ntau lawm lossis hloov mus rau qhov sib txawv yam tsis muaj kev txhawj xeeb txog cov nqi peev ntawm kev hloov khoom siv thiab pwm.

cons:

- Kev sib txuas lus: Outsourcing txhaj tshuaj molding tuaj yeem tsim kev sib tw ntawm cov neeg siv khoom thiab lub tuam txhab. Kev nkag siab yuam kev lossis qeeb hauv kev sib txuas lus tuaj yeem ua rau yuam kev lossis qeeb hauv kev tsim khoom.

- Kev Tswjhwm Zoo: Outsourcing txhaj tshuaj molding txhais tau tias tso siab rau lub tuam txhab sab nraud los tsim cov khoom raws li cov qauv tsim nyog. Kev tswj xyuas zoo tuaj yeem nyuaj thaum ua haujlwm nrog lub tuam txhab sab nraud, thiab ib txwm muaj kev pheej hmoo ntawm kev txais cov yam ntxwv uas yuav tsum ua kom tau raws li qhov xav tau tshwj xeeb.

- Kev vam meej: Outsourcing txhaj tshuaj molding txhais tau tias nyob ntawm lub tuam txhab tsim khoom sab nraud. Qhov no tuaj yeem tsim kev pheej hmoo txog tus neeg muag khoom qhov kev ntseeg siab, ruaj khov, thiab lub sijhawm xa khoom.

- Kev Txawj Ntse: Outsourcing txhaj tshuaj molding tuaj yeem tsim kev pheej hmoo rau kev tiv thaiv cov khoom ntiag tug. Cov tuam txhab lag luam yuav tsum xyuas kom meej tias lawv cov qauv tsim thiab thev naus laus zis raug tiv thaiv los ntawm kev ntsuas tsim nyog.

Yav tom ntej kev cia siab rau kev cai yas txhaj tshuaj molding

Kev cai yas txhaj tshuaj molding yog ib qho kev txhim khu kev qha thiab ntau yam kev tsim khoom rau ntau xyoo lawm. Nyob rau hauv xyoo tas los no, kev nce qib hauv kev siv tshuab thiab cov khoom siv tau txuas ntxiv txhim kho lub peev xwm thiab muaj peev xwm ntawm kev txhaj tshuaj molding. Nov yog qee qhov kev cia siab yav tom ntej rau kev cai yas txhaj tshuaj molding:

- Kev Txais Kev Lag Luam 4.0 thev naus laus zis: Kev sib koom ua ke ntawm Kev Lag Luam 4.0 thev naus laus zis, xws li kev txawj ntse txawj ntse, kev kawm tshuab, thiab Is Taws Nem ntawm Yam (IoT), yuav tsum nce automation, txhim kho kev tswj kom zoo, thiab txhim kho cov txheej txheem ntau lawm hauv kev txhaj tshuaj molding.

- Kev siv cov khoom siv biodegradable ntxiv: Kev txhawj xeeb ib puag ncig tsav kev siv cov khoom siv biodegradable hauv kev txhaj tshuaj molding. Biodegradable cov ntaub ntawv muab kev hloov pauv mus rau cov khoom siv yas thiab tuaj yeem pab txo cov khoom pov tseg thiab kev cuam tshuam ib puag ncig.

- Kev thov loj hlob rau kev tsim khoom siv kho mob: Kev xav tau ntawm cov cuab yeej kho mob tau nce ntxiv vim cov neeg laus thiab kev nce qib hauv kev kho mob thev naus laus zis. Kev txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov rau cov khoom siv kho mob vim nws qhov tseeb, ceev, thiab tus nqi-zoo.

- Kev nthuav dav ntawm 3D luam ntawv muaj peev xwm: Txoj kev loj hlob ntawm 3D tshuab luam ntawv tau ua rau kev tsim cov khoom sib txawv thiab sib txawv uas yav tas los tsis tuaj yeem tsim siv kev txhaj tshuaj molding. Txawm li cas los xij, 3D luam ntawv tseem tseem qeeb thiab kim piv rau kev txhaj tshuaj molding, thiab ob lub thev naus laus zis yuav zoo li txuas ntxiv rau ib leeg es tsis hloov ib leeg.

- Kev txhaj tshuaj molding ntau ntxiv: Cov khoom siv ntau yam kev txhaj tshuaj molding yuav tsum siv ob lossis ntau qhov sib txawv ntawm cov txheej txheem txhaj tshuaj molding. Cov thev naus laus zis no muaj ntau yam txiaj ntsig, suav nrog kev ua haujlwm zoo dua qub, txo qhov hnyav, thiab txuag nqi.

- Kev nce qib hauv cov cuab yeej siv tshuab: Kev tsim cov khoom siv tshiab thiab cov qauv tsim yuav tsum ua kom nrawm, ua haujlwm tau zoo, thiab qhov tseeb ntawm kev txhaj tshuaj molding. Piv txwv li, conformal cooling channels hauv cov cuab yeej tuaj yeem txhim kho lub voj voog lub sij hawm thiab txo kev siv zog.

xaus:

Kev cai yas txhaj tshuaj molding yog cov txheej txheem tsim khoom muaj zog uas ua rau kev tsim cov khoom zoo yas nrog kev ua tau zoo thiab kev ua haujlwm zoo. Los ntawm kev nkag siab txog cov txheej txheem txhaj tshuaj molding, xaiv cov khoom tsim nyog thiab pwm tsim, thiab ua raws li cov kev coj ua zoo tshaj plaws rau kev tswj xyuas cov cuab yeej zoo, cov lag luam tuaj yeem ua kom zoo dua lawv cov kev txhaj tshuaj molding thiab ua tiav zoo kawg nkaus. Raws li cov qauv tshiab thiab kev tsim kho tshiab tshwm sim hauv kev lag luam, nyob twj ywm tshiab thiab tshawb nrhiav cov hauv kev tshiab los txhim kho kev ruaj ntseg, kev ua tau zoo, thiab cov txiaj ntsig ntawm kev cai yas txhaj tshuaj molding yog qhov tseem ceeb.