Tsev Neeg Txhaj Moulds

Tsev neeg txhaj tshuaj pwm yog cov txheej txheem tsim khoom nrov rau kev tsim ntau yam khoom yas. Lawv ua kom muaj kev tsim ib txhij ntawm ntau qhov chaw, ua rau kev txuag nqi thiab nce kev ua haujlwm zoo. Txawm li cas los xij, nws yog ib qho tseem ceeb kom nkag siab tias tsev neeg txhaj tshuaj molds ua haujlwm li cas, hom khoom uas lawv zoo tshaj plaws rau, thiab lawv qhov zoo thiab qhov tsis zoo ua ntej txiav txim siab seb cov txheej txheem tsim khoom no puas haum rau koj qhov project.

Family Txhaj Moulds yog dab tsi?

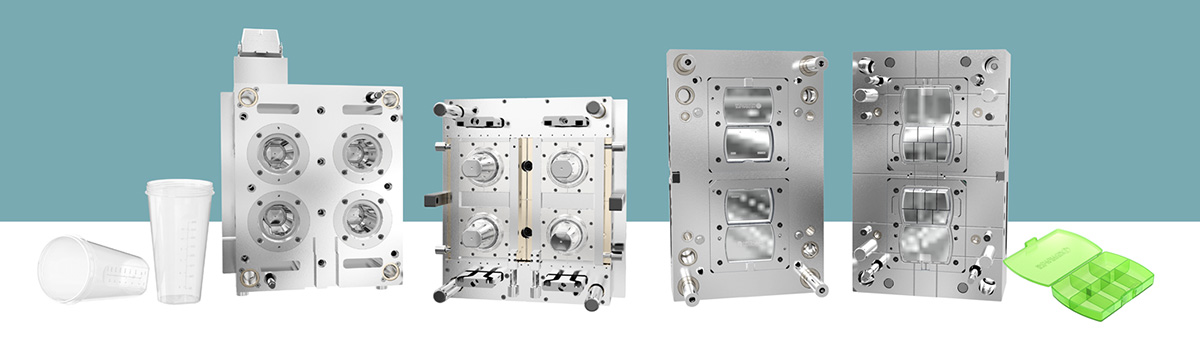

Tsev neeg txhaj tshuaj pwm yog cov pwm siv rau hauv cov txheej txheem txhaj tshuaj molding los tsim ntau qhov chaw lossis cov khoom siv ib txhij. Cov neeg tsim qauv tsim lawv kom haum rau ntau qhov kab noj hniav lossis kev xav hauv ib qho pwm, ua kom muaj ntau yam sib txawv hauv ib lub voj voog molding. Cov neeg tsim khoom feem ntau siv cov pwm hauv tsev neeg thaum muaj qhov xav tau los tsim cov txheej txheem sib xws uas siv ua ke lossis muaj cov yam ntxwv zoo sib xws. Txoj hauv kev no muab kev ua haujlwm zoo thiab kev txuag nyiaj los ntawm kev txo cov cuab yeej siv thiab teeb tsa lub sijhawm, ua kom muaj txiaj ntsig zoo tshaj plaws, thiab ua kom muaj txiaj ntsig zoo thoob plaws txhua qhov tsim.

Tsev Neeg Txhaj Moulds ua haujlwm li cas?

Tsev neeg txhaj tshuaj moulds yog cov cuab yeej nyuaj uas ua haujlwm los ntawm cov txheej txheem kom zoo los tsim ntau qhov chaw ib txhij. Nov yog qee cov ntsiab lus tseem ceeb kom nkag siab tias tsev neeg txhaj tshuaj pwm ua haujlwm li cas:

- Pwm tsim: Cov neeg tsim qauv ua tib zoo tsim tsev neeg pwm kom haum rau ntau qhov kab noj hniav lossis kev xav hauv ib lub cuab yeej. Cov neeg tsim qauv npaj cov txheej txheem pwm los txhim kho cov kab noj hniav 'kev npaj thiab qhov sib txawv, ua kom cov khoom tsim tau zoo thiab zoo ib yam.

- Kev xaiv cov khoom siv: Peb xaiv cov khoom siv thermoplastic uas tsim nyog raws li cov khoom xav tau thiab cov kev xav tau los tsim cov khoom. Cov yam ntxwv xws li lub zog, yoog raws, kub tsis kam, thiab cov tsos yog qhov tseem ceeb hauv kev xaiv cov khoom.

- Kev txhaj tshuaj molding txheej txheem pib los ntawm cua sov cov khoom siv thermoplastic xaiv rau nws cov ntsiab lus melting, tsim cov molten resin. Peb txhaj cov khoom molten rau hauv pwm kab noj hniav los ntawm ib qho kev khiav hauj lwm thiab cov rooj vag, faib cov khoom rau txhua lub qhov.

- Cooling thiab solidification:Thaum cov khoom molten nyob rau hauv cov kab noj hniav, nws txias thiab solidifies. Cov cua txias hauv pwm pab tswj qhov kub thiab txias thiab ua kom muaj zog. Kev ua kom txias kom zoo yog qhov tseem ceeb los xyuas kom meej qhov sib npaug ntawm qhov ntev, txo qis kev sib tw, thiab txhawb nqa lub sijhawm ua haujlwm zoo.

- Ejection ntawm qhov chaw:Tom qab cov khoom solidifies, peb qhib lub pwm thiab tshem tawm cov yam ntxwv ntawm cov pwm kab noj hniav. Peb tuaj yeem ua tiav ejection los ntawm ntau txoj hauv kev, suav nrog cov tshuab ejection tshuab, cua blasts, lossis hydraulic ejector pins. Peb yuav tsum tiv thaiv kev puas tsuaj rau cov khoom thaum lub sij hawm ejection txheej txheem.

- Kev tswj kom zoo: Thoob plaws hauv lub voj voog ntau lawm, peb siv cov kev ntsuas los xyuas kom meej tias cov khoom ua tau raws li qhov yuav tsum tau ua. Peb ua tib zoo saib xyuas yam tseem ceeb xws li kub, siab, thiab lub sijhawm voj voog. Peb kuj ua qhov kev tshuaj xyuas qhov muag thiab kev kuaj xyuas qhov ntev.

- Kev tu thiab kev daws teeb meem:Kev saib xyuas tsis tu ncua yog tsim nyog rau kev ua haujlwm zoo ntawm tsev neeg pwm. Qhov kev saib xyuas no suav nrog kev tu, lubrication, thiab xyuas lub sijhawm rau kev hnav lossis kev puas tsuaj. Yog tias muaj teeb meem tshwm sim thaum tsim khoom, peb tuaj yeem siv cov txheej txheem daws teeb meem los txheeb xyuas thiab daws cov teeb meem ntsig txog pwm.

Qhov zoo ntawm Tsev Neeg Txhaj Pwm

Tsev neeg txhaj tshuaj moulds muaj ntau yam zoo, ua rau lawv nyiam xaiv hauv kev tsim khoom. Nov yog qee cov ntsiab lus tseem ceeb uas qhia txog cov txiaj ntsig ntawm kev siv tsev neeg txhaj tshuaj pwm:

- Nce productivity: Tsev neeg pwm ua kom muaj kev tsim khoom ib txhij ntawm ntau qhov chaw, txo lub sijhawm voj voog thiab ua kom tag nrho cov khoom tsim tau. Nrog rau txhua lub voj voog molding ua ntau yam khoom, cov tuam ntxhab tuaj yeem ua tiav cov zis ntau dua thiab ua tau raws li qhov xav tau loj ntim tau zoo.

- Kev txuag nqi: Los ntawm kev tsim ntau yam hauv ib lub voj voog, tsev neeg txhaj tshuaj pwm pab txo cov nqi tsim khoom. Kev tshem tawm qhov xav tau ntawm cov pwm sib cais rau txhua yam ua rau cov cuab yeej siv tau, kev saib xyuas, thiab kev khaws cia. Tsis tas li ntawd, optimized ntau lawm efficiency thiab txo cov khoom pov tseg ua rau cov nqi txuag.

- Sijhawm Efficiency:Cov neeg tsim khoom tuaj yeem txo cov sij hawm txhuas ntau lawm nrog tsev neeg pwm. Lub peev xwm los tsim ntau qhov chaw hauv ib lub voj voog tshem tawm qhov xav tau ntawm cov cuab yeej sib txuas lossis cov pwm hloov pauv, txuag lub sijhawm muaj txiaj ntsig. Cov txheej txheem tsim khoom nrawm no ua rau lub sijhawm ua lag luam sai dua thiab teb sai dua rau cov neeg siv khoom xav tau.

- Consistency thiab zoo:Tsev neeg txhaj tshuaj moulds ua kom muaj qhov zoo sib xws thoob plaws txhua qhov kab noj hniav. Tib lub sijhawm tsim cov khoom hauv tib lub pwm kom zoo ib yam ntawm qhov ntev, qhov pom, thiab cov khoom siv. Cov txheej txheem tsim khoom no txo qis kev hloov pauv thiab ua kom txhua qhov chaw ua tau raws li qhov xav tau tshwj xeeb.

- Tsim yooj yooj yim: Tsev neeg pwm muab kev tsim qauv yooj yim, tso cai rau kev tsim cov khoom sib txawv nrog cov duab sib txawv, qhov loj me, lossis cov yam ntxwv hauv ib lub cuab yeej. Qhov no versatility ua rau lawv haum rau kev tsim khoom nrog complex geometries, customized qhov chaw, los yog variations nyob rau hauv tsim.

- Txo cov khoom pov tseg: Nrog tsev neeg pwm, cov ntaub ntawv pov tseg raug txo qis dua piv rau kev siv cov pwm cais rau txhua qhov. Kev ua kom zoo ntawm cov pwm tsim, rooj tog zaum, thiab cov qauv tsim ua haujlwm pab txo cov khoom seem thiab txhim kho kev siv cov khoom, pab txhawb kev tsim khoom lag luam zoo dua thiab muaj txiaj ntsig zoo.

- Streamlined sib dhos:Tsev neeg txhaj tshuaj pwm pab txhawb kev sib dhos ua ke. Raws li peb tsim cov khoom ib txhij, kev sib dhos ua haujlwm tau zoo dua, txo cov nqi zog thiab sijhawm sib dhos. Tsis tas li ntawd, cov khoom tsim los ntawm tsev neeg pwm feem ntau muaj qhov sib xws ntawm qhov chaw sib tw thiab qhov loj me, ua rau kev sib dhos yooj yim dua thiab ua kom haum zoo.

Qhov zoo ntawm tsev neeg txhaj tshuaj pwm, suav nrog kev tsim khoom lag luam, txuag nqi, txuag lub sijhawm, zoo ib yam, tsim kev yooj yim, txo cov khoom pov tseg, thiab cov txheej txheem sib dhos ua kom yooj yim, ua rau lawv muaj txiaj ntsig zoo rau kev tsim khoom lag luam, muab cov txiaj ntsig zoo dua thiab kev sib tw zoo hauv lub khw.

Disadvantages ntawm Tsev Neeg Txhaj Pwm

Thaum tsev neeg txhaj tshuaj pwm muaj ntau yam txiaj ntsig, kuj tseem muaj qee qhov tsis zoo. Nov yog qee cov ntsiab lus tseem ceeb uas qhia txog qhov tsis zoo ntawm kev siv tsev neeg txhaj tshuaj pwm:

- Tus nqi pib:Tsev neeg pwm feem ntau xav tau kev nqis peev ntau dua li cov pwm ib leeg. Cov qauv tsim tsis yooj yim thiab qhov xav tau rau cov kab noj hniav kom meej ua rau cov cuab yeej siv tau zoo, ua rau nws yog ib qho tseem ceeb rau cov tuam txhab tsim khoom. Tus nqi pib no tuaj yeem cuam tshuam cov lag luam nrog cov peev nyiaj tsawg lossis cov khoom lag luam tsawg.

- Cov kev txwv tsim:Tsim ib tsev neeg pwm yuav tsum tau ua tib zoo xav txog qhov geometry, qhov loj me, thiab kev sib raug zoo hauv cov pwm. Tej yam nyuaj lossis qhov loj yuav tsis haum rau tsev neeg molding vim muaj kev txwv hauv kab noj hniav, qhov yuav tsum tau ua kom txias, los yog ejection mechanisms. Cov kev cai hauv kev tsim qauv yuav xav tau kev siv cov pwm customized rau qhov tshwj xeeb.

- Tooling thiab tu complexity:Cov pwm hauv tsev neeg tuaj yeem sib txawv ntau dua li cov pwm ib leeg. Lub xub ntiag ntawm ntau cov kab noj hniav, cov neeg khiav dej num, thiab cov rooj tog zaum yuav tsum tau ua tib zoo saib xyuas thiab kho qee zaus. Kev tu vaj tse tuaj yeem siv sijhawm ntev thiab yuav xav tau cov kws tshaj lij. Txhua yam teeb meem lossis kev kho hauv pwm tuaj yeem cuam tshuam rau kev tsim khoom ntawm ntau qhov chaw.

- Tsawg yooj yooj yim:Thaum tsev neeg pwm muab kev tsim qauv yooj yim hauv cov pwm, kev hloov lossis hloov kho rau cov khoom sib txawv tuaj yeem nyuaj. Hloov cov qauv tsim lossis kev qhia tshwj xeeb ntawm ib feem hauv tsev pwm tuaj yeem xav tau kev hloov kho rau tag nrho cov pwm, cuam tshuam rau kev tsim khoom ntawm txhua qhov chaw. Qhov tsis muaj qhov hloov pauv no tuaj yeem ua rau muaj kev txwv rau cov tuam txhab tsim khoom uas xav tau kev hloov pauv tsim lossis hloov kho.

- Risk ntawm kev cuam tshuam ntau lawm:Nyob rau hauv qhov kev tshwm sim ntawm molding tsis ua hauj lwm los yog puas, zus tau tej cov ntau yam yuav cuam tshuam. Kev txheeb xyuas qhov tsis xws luag hauv ib kab noj hniav tuaj yeem cuam tshuam rau tag nrho cov khoom tsim tawm hauv tsev neeg pwm. Qhov kev pheej hmoo ntawm kev cuam tshuam ntau lawm tuaj yeem cuam tshuam tag nrho cov sijhawm tsim khoom thiab cov sijhawm xa khoom.

- Volume xav tau:Cov kev xav tau ntim ua lub luag haujlwm tseem ceeb hauv kev txiav txim siab qhov tsim nyog ntawm tsev neeg pwm rau kev tsim khoom. Vim lawv cov nqi-zoo thiab kev ua haujlwm zoo, tsev neeg pwm yog qhov kev xaiv zoo tshaj plaws rau kev tsim cov khoom ntim siab, ua rau lawv xaiv zoo heev. Txawm li cas los xij, tsev neeg pwm yuav tsis muaj txiaj ntsig zoo rau kev tsim khoom qis lossis kev tsim qauv. Kev xaiv rau cov pwm ib leeg lossis lwm txoj hauv kev tsim khoom yuav ua tau zoo dua.

Kev nkag siab txog qhov tsis zoo ntawm tsev neeg txhaj tshuaj pwm yog qhov tseem ceeb hauv kev txiav txim siab paub txog lawv qhov kev siv. Thaum cov teeb meem no tshwm sim, kev npaj tsim nyog, kev saib xyuas, thiab kev txiav txim siab ntawm kev tsim khoom tshwj xeeb tuaj yeem txo lawv.

Hom Kev Txhaj Tshuaj Rau Tsev Neeg

Tsev neeg txhaj tshuaj pwm tuaj nyob rau hauv ntau hom, txhua tus tsim los ua kom haum raws li cov kev xav tau ntau lawm thiab cov kev xav tau. Nov yog qee yam tseem ceeb ntawm tsev neeg txhaj tshuaj pwm:

- Sab-los-sab tsev neeg pwm:Hom pwm no muaj ntau cov kab noj hniav uas tau teem ib sab ntawm ib sab, nrog rau txhua lub qhov ua ib qho sib txawv. Cov pwm tsim kom ntseeg tau tias txhua lub niche raug cais tawm, tso cai rau kev tswj hwm tus kheej thiab kev cuam tshuam tsawg kawg ntawm ib feem.

- Tandem tsev neeg pwm:Tandem tsev neeg pwm muaj ntau cov kab noj hniav txheej txheem nyob rau hauv ib tug kab sib lawv liag, txhua tus tsim ib tug sib txawv Cheebtsam. Cov pwm tsim ua rau kev tsim cov khoom txuas ntxiv lossis cov uas muaj ntau yam hauv kev teeb tsa.

- Stack tsev neeg pwm: Stack tsev neeg pwm muaj ntau cov kab noj hniav sib dhos rau ib leeg. Txhua pab pawg tsim cov khoom sib txawv, tso cai rau kev tsim ntau qhov sib txawv hauv ib lub voj voog. Cov txheej txheem tsim kuj tseem ua rau kev tsim cov khoom siab lossis ntsug nrog cov cuab yeej tsawg.

- Rotary tsev neeg pwm: Cov pwm no muaj ntau kab noj hniav teem rau ntawm lub rooj teb. Lub tshuab txhaj tshuaj molding tig cov pwm mus rau txhua qhov kab noj hniav thaum lub sijhawm tsim khoom, ua kom muaj ntau qhov chaw nrog ib qho khoom siv. Cov qauv tsim teb tso cai rau kev tsim cov khoom sib xyaw ua ke, xws li lub zog lossis lub log.

- Kub khiav tsev neeg pwm:Kub khiav tsev neeg pwm siv lub tshuab kub khiav los faib cov yas yaj rau txhua qhov kab noj hniav. Qhov kev tsim no tshem tawm qhov xav tau ntawm cov neeg khiav dej num lossis cov rooj vag, tso cai rau kev ua kom huv si thiab txo cov khoom pov tseg. Kub khiav tsev neeg pwm yog tsim rau high-volume ntau lawm.

Txhua hom kev txhaj tshuaj hauv tsev neeg muaj qhov tshwj xeeb zoo thiab cov kev txwv, thiab xaiv cov qauv tsim nyog tshaj plaws nyob ntawm qhov yuav tsum tau ua, ib feem geometry, thiab cov khoom siv. Xaiv txoj cai ntawm tsev neeg pwm tuaj yeem txhim kho kev tsim khoom thiab muaj txiaj ntsig zoo.

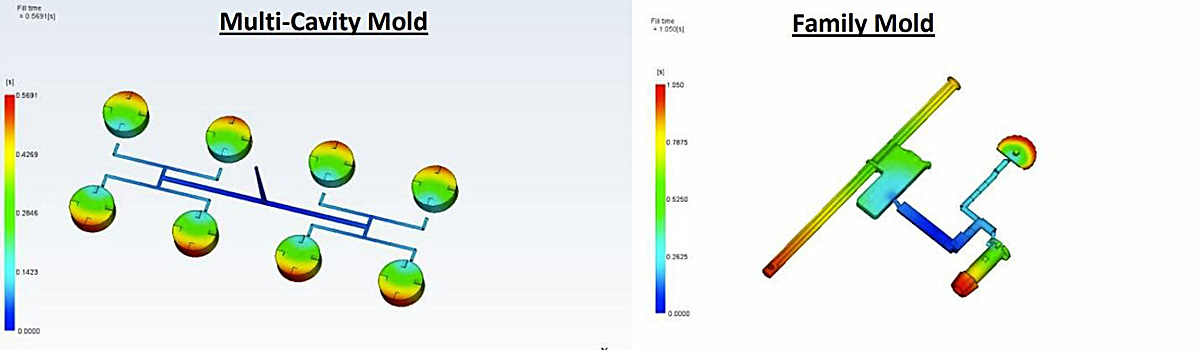

Tib kab noj hniav vs. Multi-Cavity Pwm

Hais txog kev txhaj tshuaj molding, manufacturers tuaj yeem xaiv ntawm ib leeg thiab ntau kab noj hniav pwm, muab qhov zoo sib xws thiab kev txiav txim siab. Nov yog qee cov ntsiab lus tseem ceeb piv rau ib leeg-cav pwm thiab ntau kab noj hniav pwm:

Ib Kab Kab Moulds:

- Simplicity: Ib kab noj hniav pwm muaj ib kab noj hniav, ua ib feem ntawm txhua lub voj voog molding. Lawv yog cov ncaj ncaj hauv kev tsim thiab kev tsim kho, ua rau lawv tsis yooj yim thiab yooj yim rau kev tsim khoom.

- Flexibility:Cov kab noj hniav ib leeg muaj kev hloov pauv ntau dua txog kev tsim qauv hloov lossis hloov kho. Yog tias ib feem tshwj xeeb xav tau kev hloov tsim, tsuas yog cov pwm rau qhov yuav tsum tau hloov kho, txo qhov cuam tshuam rau cov txheej txheem ntau lawm.

- Prototyping thiab low-volume ntau lawm:Cov kab noj hniav ib leeg yog qhov zoo rau kev tsim qauv lossis cov ntawv ntim qis. Lawv tso cai rau kev sim ua tau zoo ntawm cov qauv tsim tshiab lossis tsim cov khoom me me yam tsis muaj kev nqis peev loj.

- Tus nqi siab dua ib feem:Cov kab noj hniav ib leeg yog tus nqi qis dua rau cov khoom ntim siab vim lawv ua kom tsawg dua ib lub voj voog molding. Tus nqi ib feem yog feem ntau siab dua ntau cov kab noj hniav pwm vim yog cov cuab yeej siv ntau dua thiab lub sij hawm ntev dua.

Multi-Cavity Moulds:

- Nce productivity:Multi-cavity pwm muaj ntau kab noj hniav, ua ntau yam hauv txhua lub voj voog molding. Txoj kev no tuaj yeem ua kom muaj txiaj ntsig zoo thiab cov khoom tsim tawm thaum txo cov nqi tsim khoom thiab lub sijhawm voj voog.

- Tus nqi efficiency:Multi-cavity pwm muab cov nqi zoo rau cov khoom ntim siab. Lawv xav tau cov cuab yeej siv qis dua ib feem tsim, ua rau lawv raug nqi ntau dua hauv kev tsim khoom loj.

- Consistency thiab uniformity:Multi-cavity pwm ua kom muaj qhov zoo sib xws thoob plaws txhua qhov kab noj hniav, raws li lawv tau tsim ib txhij nyob rau hauv tib txoj kev ua haujlwm. Qhov no ua rau txhua qhov sib npaug ntawm qhov ntev, qhov pom, thiab cov khoom siv.

- Qhov chaw thiab khoom siv yuav tsum:Multi-cavity pwm xav tau cov tshuab txhaj tshuaj loj dua nrog lub zog clamping txaus kom haum rau cov cuab yeej loj dua. Lawv kuj xav tau qhov chaw txaus rau ntau cov kab noj hniav, cov neeg khiav dej num, thiab cov cua txias.

- Kev xav txog kev tsim:Kev tsim cov pwm kab noj hniav ntau yuav tsum tau ua tib zoo xav txog qhov sib nrug ntawm kab noj hniav, qhov rooj kaw lus, thiab qhov yuav tsum tau ua kom txias. Cov geometries nyuaj lossis qhov loj tuaj yeem ua rau muaj kev txwv lossis xav tau kev tsim qauv ntxiv.

Kub Khiav vs. Txias Runner Pwm

Kub thiab txias khiav pwm yog ob hom kev txhaj tshuaj pwm, txhua tus muaj qhov zoo thiab xav tau. Nov yog qee cov ntsiab lus tseem ceeb piv rau cov kub khiav pwm thiab cov pwm khiav txias:

Kub khiav Moulds:

- Kev siv cov khoom siv tau zoo: Kub khiav pwm siv lub tshuab cua sov thiab lub taub hau kom xa cov yas molten ncaj qha mus rau pwm kab noj hniav. Tshem tawm qhov xav tau ntawm cov neeg khiav dej num thiab cov rooj vag txo cov khoom pov tseg thiab ua kom zoo dua cov khoom siv.

- Txo lub sij hawm voj voog:Tshem tawm cov neeg khiav dej num hauv cov pwm kub khiav ua rau lub sij hawm luv luv dua li cov pwm khiav txias. Qhov no nce efficiency txhais mus rau ntau lawm ntau lawm thiab txhim kho tag nrho productivity.

- Ib feem zoo: Kub khiav pwm muab ntau qhov zoo ib yam, raws li cov yas molten tseem nyob ntawm qhov kub thiab txias thoob plaws hauv cov txheej txheem - qhov no ua rau cov khoom sib xws thiab txo qhov ntev, qhov pom, thiab cov khoom sib txawv.

- Flexibility thiab kev xaiv tsim:Kub khiav tshuab muab ntau dua tsim yooj, tso cai rau ntau geometries complex thiab ua qhov chaw nrog ntau lub rooj vag. Qhov kev ua tau zoo no tuaj yeem tau txais txiaj ntsig cov yam ntxwv xav tau kev sib npaug sib npaug lossis cov kev xav tau tshwj xeeb.

Cold Runner Pwm:

- Tus nqi pib qis dua:Cov pwm txias khiav yog feem ntau tsis tshua kim los tsim thiab teeb tsa dua cov pwm kub khiav. Lawv tsis xav tau cov khoom siv ntxiv thiab cov khoom cua sov uas cuam tshuam nrog cov txheej txheem kub khiav, ua rau cov nqi qis dua.

- Khoom siv compatibility:Cov pwm txias khiav yog tsim rau ntau yam khoom siv, nrog rau cov uas muaj cua sov-rhiab heev lossis ua rau degradation thaum raug cua sov ntev. Qhov kev ua tau zoo no ua rau cov pwm khiav txias txias nyiam rau cov ntaub ntawv tshwj xeeb thiab kev siv.

- Kev kho yooj yim:Cov pwm txias khiav yog feem ntau yooj yim los tswj thiab daws teeb meem dua li cov pwm kub khiav. Qhov tsis muaj cua sov tshuab thiab cov khoom siv ua kom yooj yim rau kev txij nkawm, txo qis sijhawm thiab kev cuam tshuam ntau lawm.

Txo cov cuab yeej complexity: Cov txheej txheem txhaj tshuaj molding tshuab tuaj yeem siv cov pwm txias khiav tsis tas yuav tsum tau tshwj xeeb kub khiav controllers. Cov neeg tsim khoom nrog cov khoom siv uas twb muaj lawm lossis leej twg xav tau kev teeb tsa ncaj nraim tuaj yeem tau txais txiaj ntsig.

Kev xaiv ntawm cov pwm kub thiab txias khiav yog nyob ntawm qhov ntim ntau lawm, cov khoom xav tau, qhov nyuaj, thiab kev xav txog nyiaj txiag. Cov neeg tsim khoom yuav tsum ua tib zoo ntsuas lawv cov kev xav tau thiab sab laj nrog cov kws tshaj lij pwm los txiav txim siab qhov kev xaiv tsim nyog tshaj plaws rau lawv cov txheej txheem txhaj tshuaj molding.

Ob-Plate vs. Peb-Plate Pwm

Ob-phaj thiab peb-phaj pwm yog ob hom kev txhaj tshuaj pwm siv hauv kev tsim khoom. Nov yog qee cov ntsiab lus tseem ceeb piv rau ob-phaj pwm thiab peb-phaj pwm:

Ob-Plate Moulds:

- Simplicity: Ob lub phaj pwm muaj ob lub phaj tseem ceeb uas sib cais kom tshem tawm cov pwm pwm. Qhov yooj yim ntawm tus qauv tsim ua rau lawv yooj yim rau kev tsim, teeb tsa, thiab tswj tau piv rau peb-phaj pwm.

- Tus nqi efficiency:Ob-phaj pwm yog feem ntau siv nyiaj ntau dua, yuav tsum muaj cov khoom siv tsawg dua thiab cov cuab yeej siv tsawg dua. Qhov txo qis ntawm daim hlau thiab kev tsim kho yooj yim dua ua rau txo qis cov cuab yeej siv.

- Limited qhov rooj xaiv xaiv:Ob-phaj pwm feem ntau muaj kev txwv kev xaiv rooj vag, nrog cov neeg khiav dej num thiab cov rooj vag tso rau ntawm ib sab ntawm cov pwm. Qhov kev txwv no tuaj yeem cuam tshuam rau kev tsim thiab kev hloov pauv yooj yim, tshwj xeeb tshaj yog rau ntau qhov nyuaj lossis qhov tseem ceeb.

Peb-Plate Moulds:

- Part ejection yooj: Peb-phaj pwm muab tau yooj yim dua nyob rau hauv ib feem ejection. Lub phaj ntxiv, lub phaj stripper, tso cai rau kev cais tawm ntawm cov neeg khiav dej num thiab qhov molded. Txoj kev no tso cai rau kev tsim cov khoom siv tsis yooj yim, cov khoom siv uas yuav tsum tau muaj ntau lub ntsiab lus nkag, thiab cov cheeb tsam nyuaj mus txog thaum tsim khoom.

- Txhim khu qhov zoo:Peb-phaj pwm muab kev txhim kho qhov zoo los ntawm kev sib cais cov neeg khiav dej num thiab cov rooj vag los ntawm qhov molded. Qhov kev sib cais no txo cov kev pheej hmoo ntawm cov qhab nia lossis cov khoom siv kho kom zoo nkauj ntawm cov khoom kawg, uas ua rau muaj qhov ua tiav zoo dua.

- Nce tsim complexity:Peb-phaj pwm tso cai rau ntau qhov kev tsim qauv thiab suav nrog cov yam ntxwv xws li kev ua haujlwm sab, nqa, lossis swb. Qhov kev tsim qauv no tuaj yeem muaj txiaj ntsig zoo thaum tsim cov khoom nrog cov duab zoo nkauj lossis xav tau cov yam ntxwv ntxiv tshaj qhov yooj yim core thiab kab noj hniav.

- Lub sijhawm voj voog ntev dua: Peb-phaj pwm feem ntau muaj lub voj voog ntev dua li ob-phaj pwm. Cov phaj ntxiv thiab qhov tsis yooj yim hauv pwm txav tau ua rau lub sijhawm voj voog nce ntxiv, cuam tshuam rau kev ua haujlwm ntawm tag nrho.

Kev xaiv ntawm ob-phaj thiab peb-phaj pwm nyob ntawm yam xws li ib feem complexity, gating yuav tsum tau, xav tau ib feem zoo, thiab cov nqi txiav txim siab. Cov neeg tsim khoom yuav tsum ntsuas lawv cov kev xav tau tshwj xeeb thiab sab laj nrog cov kws tshaj lij pwm los txiav txim siab qhov kev xaiv tsim nyog tshaj plaws rau lawv cov txheej txheem txhaj tshuaj molding.

Kev xaiv cov khoom siv rau Tsev Neeg Txhaj Pwm

Kev xaiv cov khoom siv rau tsev neeg txhaj tshuaj pwm yog qhov tseem ceeb uas tuaj yeem cuam tshuam rau kev tsim khoom thiab qhov kawg ntawm qhov zoo. Nov yog qee cov ntsiab lus tseem ceeb uas yuav tsum xav txog thaum xaiv cov khoom siv rau tsev neeg txhaj tshuaj pwm:

- Mould puag khoom:Cov khoom siv pwm yuav tsum muaj cov khoom siv zoo heev, qhov ruaj khov, thiab thermal conductivity. Cov kev xaiv feem ntau suav nrog cov hlau alloys, xws li P20 lossis H13, uas muab cov tawv tawv zoo, hnav tsis kam, thiab kav ntev rau lub neej ntev pwm.

- Cavities thiab cores:Cov khoom siv rau cov kab noj hniav thiab cov cores yuav tsum muaj siab hardness, hnav tsis kam, thiab kub tsis kam tiv thaiv molding thiab rov siv dua. Cov khoom siv rau cov kab noj hniav thiab cov cores muaj xws li cov cuab yeej hardened xws li S136 los yog 420 stainless hlau los yog high-speed steels zoo li M2.

- Qhov system khiav:Cov ntaub ntawv uas muaj thermal conductivity zoo thiab hnav tsis kam yog qhov zoo dua rau kev khiav haujlwm kom ntseeg tau tias cov dej ntws tau zoo thiab txo cov khoom degradation. Vim lawv cov thermal zoo heev, cov tuam txhab lag luam feem ntau siv tooj liab alloys lossis beryllium tooj liab rau kev sib tw khiav.

- Hot runner Cheebtsam:Thaum siv cov txheej txheem kub khiav, cov ntaub ntawv uas muaj cua sov ua haujlwm, zoo thermal stability, thiab cov khoom ntws zoo yog tsim nyog. Cov kev xaiv zoo tshaj plaws rau cov khoom sib tw kub muaj xws li stainless hlau zoo li 420 lossis 17-4 PH lossis cov khoom tshwj xeeb xws li Inconel lossis Hastelloy rau cov ntawv thov.

- Cua txias channel:Cov neeg tsim khoom feem ntau siv tooj liab alloys lossis beryllium tooj liab rau cov cua txias vim lawv cov thermal conductivity siab. Cov ntaub ntawv no pab ua kom muaj cua sov kom zoo thiab tswj cov pwm kub zoo ib yam.

- Ejector pins thiab slides:Ejector pins thiab slides xav tau cov ntaub ntawv nrog zoo hnav tsis kam, siab hardness, thiab txaus toughness. Cov kev xaiv muaj xws li H13 cov cuab yeej hlau, D2 cuab yeej hlau, lossis qib stainless hlau zoo li 420 lossis 440C.

Thaum xaiv cov khoom siv rau tsev neeg txhaj tshuaj pwm, nws yog ib qho tseem ceeb uas yuav tau xav txog cov khoom siv, pwm complexity, ntau lawm ntim, thiab nqi. Kev koom tes nrog cov neeg muab khoom, cov neeg tsim pwm, thiab cov kws tshaj lij tuaj yeem pab txiav txim siab cov ntaub ntawv tsim nyog tshaj plaws uas ua tau raws li cov kev xav tau tshwj xeeb thiab ua kom zoo dua qhov kev ua tau zoo thiab lub neej ntev ntawm pwm.

Tsim Kev Txiav Txim Rau Tsev Neeg Txhaj Pwm

Tsim tsev neeg txhaj tshuaj pwm yuav tsum tau ua tib zoo xav txog kev ua haujlwm zoo, kev ua haujlwm zoo, thiab ib feem zoo. Nov yog qee qhov kev tsim qauv tseem ceeb rau tsev neeg txhaj tshuaj pwm:

- Ib feem compatibility: Txheeb xyuas qhov sib txuam ntawm qhov sib txawv hauv tsev neeg pwm, txiav txim siab qhov loj me, geometry, thiab cov khoom siv. Xyuas kom cov txheej txheem tsim tau zoo tsim cov khoom ua ke yam tsis muaj kev cuam tshuam lossis teeb meem zoo.

- Kab noj hniav: Txiav txim siab qhov kev ua tau zoo tshaj plaws ntawm cov kab noj hniav hauv cov pwm kom ua kom zoo dua qhov chaw siv thiab ua haujlwm ntau lawm. Xav txog yam xws li kev taw qhia ib feem, qhov chaw ntawm qhov rooj, thiab qhov yuav tsum tau ua kom txias kom ua tiav qhov sib npaug thiab qhov zoo ib yam.

- Khiav thiab rooj vag system: Tsim kom muaj kev sib tw khiav zoo thiab qhov rooj kaw lus uas tso cai rau cov khoom siv tau zoo rau txhua qhov kab noj hniav thaum txo cov khib nyiab thiab kev poob siab. Xav txog hom rooj vag (piv txwv li, ntug rooj vag, lub rooj vag, lossis cov rooj sib tw kub) thiab kev tso chaw ntawm cov rooj vag kom ua tiav qhov kev pom zoo thiab tsis txhob muaj qhov tsis xws luag.

- Cua txias system:Ua ib qho kev ua kom txias kom tsim nyog kom ua kom txias zoo ib yam thiab ua kom muaj cua sov kom zoo. Optimize cua txias channel tsim, qhov chaw, thiab txoj kab uas hla kom ua tau raws li qhov kub thiab txias faib thiab txo lub sij hawm voj voog.

- Ejection mechanism: Tsim kom muaj lub zog ejection mechanism los pab txhawb kev tshem tawm ntawm cov pwm. Xav txog hom ejection (xws li, ejector pins, slides, los yog lifters) thiab lawv txoj hauj lwm los xyuas kom meej qhov tso tawm kom zoo yam tsis muaj kev puas tsuaj los yog deformation.

- Qhov cua:Kev ua kom zoo yog qhov tseem ceeb los tiv thaiv cov cuab yeej cua thiab ua kom tiav cov pwm puv. Xyuas kom muaj cov vents txaus kom tso cai rau huab cua kom khiav tawm thaum lub sij hawm txhaj tshuaj, txo qhov kev pheej hmoo ntawm qhov tsis xws luag xws li txhaj tshuaj luv luv lossis roj porosity.

- Pwm tu thiab siv tau:Tsim cov pwm kom yooj yim txij nkawm, kho, thiab tu. Xav txog kev nkag mus rau cov khoom tseem ceeb xws li swb, cores, thiab ejector pins los pab txhawb kev saib xyuas thiab txo qis sijhawm.

- Pwm lub zog thiab rigidity:Xyuas kom cov pwm tsim muaj lub suab zoo thiab muaj peev xwm tiv taus lub zog thiab kev kub ntxhov thaum lub sij hawm txhaj tshuaj molding txheej txheem. Xav txog yam xws li kev xaiv cov khoom siv pwm, ribbing, thiab kev txhawb nqa cov qauv kom tswj pwm kev ncaj ncees.

Los ntawm ua tib zoo hais txog cov kev xav tsim no, cov tuam ntxhab tuaj yeem ua kom zoo rau tsev neeg txhaj tshuaj pwm kev ua tau zoo, kev ua tau zoo, thiab kev ua haujlwm ntev, ua rau cov khoom zoo thiab cov txheej txheem ntau lawm. Kev koom tes nrog cov kws tsim pwm thiab cov kws tshaj lij tuaj yeem muab kev nkag siab zoo thiab kev txawj ntse kom ua tiav qhov kev tsim qauv zoo.

Daim ntawv thov ntawm Tsev Neeg Txhaj Pwm

Tsev neeg txhaj tshuaj pwm muaj ntau daim ntawv thov thoob plaws ntau yam kev lag luam, muab cov kev daws teeb meem zoo rau kev tsim ntau yam hauv ib lub voj voog molding. Nov yog qee qhov kev siv tseem ceeb ntawm tsev neeg txhaj tshuaj pwm:

- Tus neeg siv khoom:Cov neeg tsim khoom siv cov pwm hauv tsev neeg los tsim cov khoom siv xws li hluav taws xob, khoom siv, thiab khoom siv hauv tsev. Lawv ua rau tib lub sijhawm tsim cov khoom sib txawv lossis cov khoom sib txawv, txo cov sijhawm tsim khoom thiab cov nqi.

- Automotive kev lag luam:Tsev neeg txhaj tshuaj pwm pom kev siv dav hauv kev lag luam tsheb rau kev tsim khoom ntau yam xws li sab hauv trim, dashboard qhov chaw, qhov rooj vaj huam sib luag, thiab cov khoom siv cav. Kev tsim ntau qhov chaw hauv ib lub voj voog txhim kho kev tsim khoom thiab kev siv nyiaj hauv kev tsim tsheb.

- Cov cuab yeej kho mob: Tsev neeg pwm yog qhov tseem ceeb hauv kev tsim cov cuab yeej kho mob thiab khoom siv, suav nrog cov tshuaj txhaj tshuaj, cov tshuab xa tshuaj, cov cuab yeej phais, thiab cov cuab yeej kuaj mob. Kev ua tau zoo ntawm ntau qhov chaw ua kom lub sijhawm hloov pauv sai dua thiab txuag nqi hauv kev lag luam kho mob.

- Ntim:Kev lag luam ntim khoom siv tsev neeg txhaj tshuaj pwm los tsim cov khoom xws li lub kaus mom, kaw, ntim, thiab ntim ntim. Los ntawm kev tsim ntau qhov chaw ib txhij, tsev neeg pwm txhim kho kev tsim khoom thiab ua kom cov lus teb sai dua rau kev xav tau ntawm kev lag luam.

- Cov khoom siv hluav taws xob thiab hluav taws xob:Cov neeg tsim khoom feem ntau siv cov pwm hauv tsev neeg los tsim cov khoom siv hluav taws xob thiab hluav taws xob, xws li cov khoom sib txuas, cov keyboards, cov khoom vaj tse, thiab cov khoom siv hluav taws xob. Lawv ua kom muaj txiaj ntsig zoo ntawm ntau lub ntsiab lus nrog qhov zoo ib yam thiab txo lub sij hawm voj voog.

- Aerospace kev lag luam:Tsev neeg pwm pom cov ntawv thov hauv kev lag luam aerospace rau kev tsim khoom xws li cov khoom siv hauv tsev, cov khoom siv zaum, thiab cov pa cua. Kev tsim ntau qhov chaw hauv ib lub voj voog txhim kho kev tsim khoom thiab kev siv nyiaj zoo.

- Industrial khoom:Cov neeg tsim khoom siv cov pwm hauv tsev los tsim cov cuab yeej siv thiab cov cuab yeej siv tshuab, suav nrog cov iav, bearings, li qub, thiab cov khoom sib txuas. Los ntawm kev txhim kho cov txheej txheem tsim khoom thiab txo lub sijhawm tsim khoom, cov pwm hauv tsev neeg pab txhawb kev tsim khoom thiab kev txuag nqi.

Tsev neeg txhaj tshuaj pwm muaj qhov zoo ntawm kev ua tau zoo, txuag nqi, thiab kev tsim kho kom zoo rau ntau yam lag luam. Lawv versatility thiab muaj peev xwm los tsim ntau yam nyob rau hauv ib lub voj voog ua rau lawv yog ib qho tseem ceeb cov cuab yeej rau manufacturers nrhiav optimized txhaj molding txheej txheem.

Tus Neeg Siv Khoom Siv Kev Lag Luam

Kev lag luam khoom noj khoom haus suav nrog ntau yam khoom siv thiab siv los ntawm tib neeg rau tus kheej lossis tsev neeg lub hom phiaj. Nws yog kev lag luam sib txawv nrog ntau lub sectors thiab kev lag luam. Nov yog qee cov ntsiab lus tseem ceeb ntawm kev lag luam cov khoom siv:

- Ntau yam khoom:Kev lag luam khoom noj khoom haus muaj ntau yam khoom, nrog rau cov khoom noj thiab dej haus, cov khoom tu tus kheej, cov khoom siv hauv tsev, hluav taws xob, khaub ncaws, thiab lwm yam. Qhov kev lag luam no ua rau cov neeg siv khoom xav tau txhua hnub thiab nyiam, muab ntau yam kev xaiv.

- Kev ua lag luam xav tau:Cov neeg siv khoom xav tau thiab kev nyiam ua rau kev tsim cov khoom siv. Raws li cov neeg siv khoom nyiam thiab nyiam hloov zuj zus, kev lag luam yuav tsum hloov kho thiab tsim kho tshiab kom tau raws li cov kev xav tau hloov pauv. Cov kev xav tau ntawm cov neeg siv khoom, xws li kev ruaj ntseg, yooj yim, thiab cov khoom siv tus kheej, cuam tshuam rau kev lag luam kev coj ua.

- Kev ua lag luam thoob ntiaj teb:Kev lag luam khoom noj khoom haus ua haujlwm thoob ntiaj teb, nrog cov khoom tsim, xa tawm, thiab muag thoob ntiaj teb. Globalization tau nthuav dav hauv kev lag luam, tso cai rau cov tuam txhab kom ncav cuag cov neeg siv khoom dav dua thiab koom nrog kev lag luam hla ciam teb.

- Branding thiab marketing: Kev tsim cov khoom lag luam zoo thiab cov tswv yim kev lag luam yog qhov tseem ceeb hauv kev lag luam cov khoom lag luam kom sib txawv cov khoom lag luam, tsim cov khoom lag luam loyalty, thiab cuam tshuam rau cov neeg siv khoom kev txiav txim siab. Cov tuam txhab lag luam nqis peev ntau hauv kev tshaj tawm, kev tshaj tawm, kev tsim khoom ntim, thiab kev tsim khoom lag luam los tsim kev sib raug zoo nrog cov neeg siv khoom.

- Supply Chain thiab Distribution:Kev lag luam khoom noj khoom haus yog nyob ntawm kev tswj xyuas cov saw hlau kom zoo los xyuas kom cov tuam txhab tsim khoom, faib, thiab xa cov khoom rau cov neeg siv khoom sai. Nws suav nrog kev sib koom ua ke ntau theem, suav nrog kev tsim cov khoom siv raw, kev tsim khoom, kev xa khoom, kev xa khoom, thiab kev muag khoom.

- Consumer trends thiab innovation:Txhawm rau kom muaj kev sib tw, cov neeg siv khoom lag luam yuav tsum nyob twj ywm kom hloov pauv cov neeg siv khoom nyiam thiab nyiam. Innovation plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom tshiab, txhim kho cov khoom uas twb muaj lawm, thiab hais txog cov neeg siv khoom xav tau thiab kev xav tau.

- Kev sib tw thiab kev ua lag luam dynamics:Kev lag luam khoom noj khoom haus muaj kev sib tw, nrog ntau lub tuam txhab sib tw rau kev lag luam. Kev ua lag luam muaj zog, xws li tus nqi, kev ua tau zoo, kev tsim khoom lag luam, thiab kev paub txog cov neeg siv khoom, muaj kev cuam tshuam ntau rau cov neeg siv khoom xaiv thiab hom loyalty.

Kev lag luam khoom noj khoom haus yog dynamic thiab ceev-paced, tas li yoog raws li cov neeg siv khoom xav tau. Nws ua lub luag haujlwm tseem ceeb hauv kev lag luam thoob ntiaj teb, tsav kev ua haujlwm, kev tsim kho tshiab, thiab kev loj hlob ntawm kev lag luam.

Automotive kev lag luam

Kev lag luam automotive yog ib qho kev lag luam loj uas suav nrog kev tsim, kev tsim kho, tsim khoom, thiab muag tsheb thiab lwm yam khoom. Nov yog qee cov ntsiab lus tseem ceeb ntawm kev lag luam automotive:

- Kev tsim tsheb: Kev lag luam tsheb yog feem ntau koom nrog kev tsim tsheb, suav nrog tsheb, tsheb thauj khoom, SUVs, maus taus, thiab tsheb ua lag luam. Nws koom nrog ntau theem: tsim, engineering, prototyping, ntau lawm, sib dhos, thiab tswj kom zoo.

- Supply chain: Kev lag luam automotive cia siab rau cov khoom lag luam thoob ntiaj teb, nrog ntau tus neeg muag khoom muab cov khoom, tshuab, thiab cov khoom siv raw. Kev tswj cov saw hlau yog qhov tseem ceeb hauv kev ua kom lub sijhawm xa khoom ntawm cov khoom siv los txhawb kev tsim tsheb.

- Technological kev nce qib: Kev lag luam automotive yog nyob rau hauv pem hauv ntej ntawm kev nce qib, nrog rau cov hluav taws xob thiab kev tsav tsheb, kev sib txuas cov yam ntxwv, kev ruaj ntseg siab tshaj, thiab lwm yam roj technologies. Kev tsim kho tshiab hauv tsheb hluav taws xob, kev tsav tsheb tsis muaj zog, thiab kev sib txuas tau hloov pauv kev lag luam.

- Kev sib tw ua lag luam:Kev lag luam automotive muaj kev sib tw heev, nrog ntau tus kws tsim tsheb vying rau kev lag luam sib faib raws li tus nqi, kev ua tau zoo, kev ua tau zoo, kev ruaj ntseg nta, thiab lub npe nrov npe tsav kev sib tw. Automakers tsis tu ncua sib zog ua kom sib txawv lawv cov khoom thiab ua tau raws li cov neeg siv khoom xav tau.

- Kev ua lag luam thoob ntiaj teb: Kev lag luam automotive ua haujlwm thoob ntiaj teb, nrog cov chaw tsim khoom, kev muag khoom sib txuas, thiab cov khoom siv sib txuas thoob plaws lub tebchaws. Cov kev cai hauv cheeb tsam, kev nyiam ua lag luam, kev lag luam, thiab kev lag luam kev lag luam cuam tshuam nws.

- Environmental xav txog:Kev lag luam automotive ntsib kev nyuaj siab los daws cov kev txhawj xeeb ntawm ib puag ncig, suav nrog kev txo qis carbon emissions, txhim kho roj efficiency, thiab txhawb kev tsim khoom lag luam. Automakers nqis peev hauv kev tsim hluav taws xob thiab hybrid tsheb, cov khoom siv hnyav, thiab cov txheej txheem tsim khoom hauv eco.

- Cov kev pab cuam tom qab muag:Kev lag luam automotive suav nrog ntu tseem ceeb tom qab muag khoom, uas faib cov khoom hloov pauv, khoom siv, tu, kho cov kev pabcuam, thiab kho tsheb. Cov dej num tom qab ua haujlwm pab txhawb kev lag luam tag nrho cov nyiaj tau los thiab muab kev txhawb nqa tsis tu ncua rau cov tswv tsheb.

Kev Lag Luam Kho Mob

Kev lag luam kho mob suav nrog ntau yam hauv kev tsim, tsim khoom, faib, thiab xa cov cuab yeej kho mob, khoom siv, tshuaj, thiab kev pabcuam kho mob. Nov yog qee cov ntsiab lus tseem ceeb txog kev lag luam kho mob:

- Cov cuab yeej kho mob:Kev lag luam kev kho mob tau koom tes nrog ntau yam khoom siv kho mob, suav nrog cov cuab yeej kuaj mob, cov cuab yeej phais, kev cog lus, cov khoom siv prosthetics, cov duab kos duab, thiab cov cuab yeej saib xyuas. Cov cuab yeej no tseem ceeb heev hauv kev kuaj mob, kev kho mob, thiab kev saib xyuas neeg mob.

- Kws tshuaj:Kev lag luam kho mob suav nrog cov tuam txhab tshuaj koom nrog hauv kev tshawb fawb, kev tsim kho, thiab kev tsim tshuaj thiab tshuaj. Pharmaceuticals muaj ntau yam los ntawm cov tshuaj hauv khw muag khoom mus rau cov tshuaj kws kho mob rau kev kho kab mob, kev tiv thaiv, thiab kev tswj hwm.

- Kev pab kho mob:Kev lag luam kho mob suav nrog cov kws kho mob, xws li tsev kho mob, tsev kho mob, tsev laus, thiab cov chaw kho mob sab nraud. Cov koom haum no muab kev kho mob rau cov neeg mob, kuaj mob, kho, kho dua tshiab, thiab lwm yam kev kho mob.

- Kev tshawb kawm thiab kev loj hlob:Kev lag luam kho mob tau nqis peev ntau hauv kev tshawb fawb thiab kev tsim kho (R&D) txhawm rau txhim kho kev paub txog kev kho mob, tsim kho tshiab, txhim kho cov kev kho mob uas twb muaj lawm, thiab txhim kho cov txiaj ntsig ntawm tus neeg mob. R&D kev siv zog tsom mus rau kev tshawb nrhiav tshuaj, kev sim tshuaj, kev kho mob thev naus laus zis tshiab, thiab cov kab ke kev noj qab haus huv.

- Kev cai ua raws:Kev lag luam kho mob yog ua raws li kev tswj hwm nruj kom ntseeg tau tias cov neeg mob muaj kev nyab xeeb, kev ua tau zoo ntawm cov khoom, thiab kev coj ncaj ncees. Cov koom haum tswj hwm, xws li Food and Drug Administration (FDA) hauv Tebchaws Meskas, tswj cov qauv thiab cov lus qhia rau cov khoom siv kho mob, tshuaj, kev sim tshuaj, thiab kev kho mob.

- Technological kev nce qib: Kev lag luam kho mob tsis tu ncua txhawb kev siv thev naus laus zis txhawm rau txhim kho kev saib xyuas tus neeg mob, txhim kho kev kuaj mob kom raug, thiab pab txhawb cov txheej txheem kho mob. Kev tsim kho tshiab xws li telemedicine, electronic health records (EHR), robotics, AI-driven diagnostics, and precision medicine are transforming the industry.

- Cov teeb meem kev noj qab haus huv thoob ntiaj teb:Kev lag luam kho mob hais txog cov teeb meem kev noj qab haus huv thoob ntiaj teb, suav nrog cov kab mob sib kis, mob ntev, cov neeg laus, kev nkag mus rau kev kho mob hauv thaj chaw tsis muaj kev pab, thiab nce nqi kho mob. Cov neeg koom nrog kev lag luam ua haujlwm los tsim cov kev daws teeb meem thiab txhim kho kev noj qab haus huv thoob ntiaj teb.

Kev lag luam kho mob ua lub luag haujlwm tseem ceeb hauv kev khaws cia thiab txhim kho tib neeg kev noj qab haus huv. Nws muab cov kev tshawb fawb tshawb fawb, thev naus laus zis tshiab, kev tsim khoom, thiab kev pabcuam kev noj qab haus huv los txhim kho cov txiaj ntsig ntawm tus neeg mob, txhim kho kev cawm neeg txoj sia, thiab ua kom muaj kev noj qab haus huv tag nrho ntawm cov tib neeg thoob ntiaj teb.

Ntim Kev Lag Luam

Kev lag luam ntim khoom ua lub luag haujlwm tseem ceeb hauv kev tsim, tsim, thiab faib cov khoom ntim thiab cov kev daws teeb meem rau ntau yam khoom. Nov yog qee cov ntsiab lus tseem ceeb ntawm kev lag luam ntim khoom:

- Cov khoom tiv thaiv: Lub luag haujlwm tseem ceeb ntawm kev ntim khoom yog los tiv thaiv cov khoom thaum khaws cia, thauj, thiab tuav. Cov ntaub ntawv ntim khoom muab kev tiv thaiv lub cev tiv thaiv kev cuam tshuam, ya raws, qhov kub thiab txias hloov pauv, thiab lwm yam uas tuaj yeem ua rau cov khoom puas.

- Branding thiab marketing:Ntim yog ib qho cuab yeej muaj zog rau kev lag luam thiab kev lag luam. Tsim kom muaj ib lub hom phiaj tshwj xeeb, nyiam cov neeg siv khoom, thiab xa cov ntaub ntawv khoom lag luam yog qhov tseem ceeb. Ntim tsim cov ntsiab lus xws li xim, logos, duab, thiab cov ntawv sib txawv pab cov khoom sib txawv thiab cuam tshuam rau cov neeg siv khoom txiav txim siab.

- Sustainability thiab eco-friendliness: Kev lag luam ntim khoom nce zuj zus tsom mus rau cov kev coj ua ruaj khov thiab cov khoom siv hauv eco. Siv cov khoom siv rov ua dua tshiab, biodegradable, thiab rov ua dua tshiab ntim cov ntaub ntawv pab txo kev cuam tshuam ib puag ncig thiab txhawb nqa kev lag luam ncig.

- Supply chain efficiency:Cov kev daws teeb meem ntim tau zoo pab txhawb rau kev ua haujlwm ntawm cov saw hlau. Kev ntim khoom tsim tau zoo ua kom yooj yim tuav, khaws cia, thiab kev thauj mus los ntawm cov khoom lag luam, txhim kho cov txheej txheem logistics thiab txo nqi tsawg.

- Customization thiab innovation:Kev lag luam ntim khoom embraces customization thiab tshiab kev daws teeb meem kom tau raws li ntau haiv neeg cov kev xav tau thiab kev lag luam xav tau. Customized ntim designs, qhov ntau thiab tsawg, thiab cov ntaub ntawv tso cai tshwj xeeb thiab tailored ntim kev daws teeb meem uas ua raws li tej yam khoom yuav tsum tau.

- Kev lag luam sectors: Kev lag luam ntim khoom noj rau ntau yam, suav nrog zaub mov thiab dej haus, tshuaj, kev saib xyuas tus kheej, khoom siv hauv tsev, khoom siv hluav taws xob, thiab cov khoom lag luam. Txhua qhov kev lag luam muaj cov kev cai ntim tshwj xeeb, xws li cov khoom thaiv kev tiv thaiv, tamper-pov thawj cov yam ntxwv, lossis cov kev cai tshwj xeeb ntawm cov khoom.

- Technological kev nce qib:Kev lag luam ntim khoom sib xyaw ua ke cov txheej txheem thev naus laus zis los txhim kho cov txheej txheem ntim khoom thiab muaj peev xwm. Automation, robotics, digital printing, innovative packaging, thiab track-and-trace systems are revolutionizing the packing industry, improved efficiency, and enabling innovative functionalities.

Kev lag luam ntim khoom yog ib qho kev lag luam uas tsis tu ncua hloov mus rau kev hloov pauv ntawm cov neeg siv khoom nyiam, cov hom phiaj kev ruaj khov, thiab kev nce qib thev naus laus zis. Nws yog ib qho tseem ceeb ntawm kev sib txuas ntawm cov khoom thiab cov neeg siv khoom, ua kom cov khoom ncaj ncees, kev lees paub ntawm cov khoom lag luam, thiab kev txhim kho cov neeg siv khoom.

Aerospace Kev Lag Luam

Kev lag luam aerospace yog kev lag luam thev naus laus zis tsom mus rau kev tsim, tsim khoom, thiab ua haujlwm dav hlau, dav hlau, satellites, thiab lwm yam khoom. Nov yog qee cov ntsiab lus tseem ceeb txog kev lag luam aerospace:

- Kev lag luam aviation:Kev lag luam aerospace suav nrog kev lag luam aviation, suav nrog kev lag luam dav hlau tsim khoom, xws li dav hlau thiab helicopters. Cov tuam txhab loj, xws li Boeing thiab Airbus, ua lag luam hauv kev tsim thiab tsim cov dav hlau lag luam rau cov neeg caij tsheb thiab cov khoom thauj.

- Kev tiv thaiv thiab kev ua tub rog:Kev lag luam aerospace ze ze rau kev tiv thaiv thiab kev siv tub rog. Nws suav nrog kev tsim cov tub rog dav hlau, cov tsheb tsis muaj dav hlau (UAVs), thiab cov tshuab tiv thaiv. Cov thev naus laus zis no tseem ceeb heev rau kev ruaj ntseg hauv tebchaws, kev soj ntsuam, kev soj ntsuam, thiab kev ua haujlwm sib ntaus sib tua.

- Kev tshawb nrhiav chaw thiab satellites: Kev lag luam aerospace plays lub luag haujlwm tseem ceeb hauv kev tshawb nrhiav chaw thiab kev tsim kho satellite. Nws suav nrog kev tsim, tsim khoom, thiab xa tawm lub dav hlau, satellites, thiab chaw sojntsuam rau kev tshawb fawb, kev sib txuas lus, kev saib xyuas huab cua, thiab navigation systems.

- Technological kev nce qib: Kev lag luam aerospace yog nyob rau hauv pem hauv ntej ntawm kev ua haujlwm thev naus laus zis, tsav kev tsim kho tshiab hauv aerodynamics, cov ntaub ntawv, tshuab propulsion, avionics, thiab satellite technologies. Kev tshaj tawm muaj xws li cov ntaub ntawv sib xyaw, cov roj siv hluav taws xob zoo, cov tshuab ua haujlwm siab tshaj plaws, thiab satellite duab yees.

- Kev sib koom tes thoob ntiaj teb:Kev lag luam aerospace feem ntau xav tau kev koom tes thoob ntiaj teb vim qhov nyuaj ntawm cov haujlwm thiab kev xav tau thoob ntiaj teb. Kev sib koom tes ntawm tsoomfwv, tuam txhab dav hlau, chaw tshawb fawb, thiab cov chaw muag khoom yog ib txwm muaj rau cov peev txheej, kev txawj ntse, thiab nyiaj txiag rau cov haujlwm loj hauv aerospace.

- Kev nyab xeeb thiab kev cai:Kev nyab xeeb yog qhov tseem ceeb hauv kev lag luam aerospace. Cov kev cai nruj thiab cov txheej txheem ntawv pov thawj kom ntseeg tau tias lub dav hlau thiab lub dav hlau ua tau raws li cov qauv kev nyab xeeb nruj. Cov kev cai tswjfwm, xws li Tsoom Fwv Tebchaws Aviation Administration (FAA) thiab European Aviation Safety Agency (EASA), tswj hwm kev nyab xeeb thiab saib xyuas cov ntawv pov thawj huab cua.

- Kev tswj cov khoom siv: Kev lag luam aerospace vam khom rau cov saw hlau thoob ntiaj teb uas muaj cov khoom siv, cov khoom, cov khoom siv, thiab cov khoom siv tshwj xeeb. Kev tswj cov saw hlau zoo ua kom cov khoom xa tuaj raws sijhawm, kev tswj xyuas zoo, thiab ua raws li cov qauv kev lag luam.

Kev lag luam aerospace yog kev siv thev naus laus zis thiab kev tswj hwm kev lag luam uas ua rau muaj kev vam meej hauv kev tshawb fawb, kev tiv thaiv hauv tebchaws, thiab kev sib txuas thoob ntiaj teb. Nws yuav tsum muaj kev sib koom tes dav dav, kev tsim kho tshiab, thiab kev ua haujlwm zoo kom ua tau raws li qhov xav tau ntawm kev ua haujlwm dav hlau thiab dav hlau.

Kev Lag Luam Electronics

Kev lag luam hluav taws xob yog ib qho kev lag luam muaj zog uas suav nrog kev tsim, tsim khoom, thiab faib cov khoom siv hluav taws xob, khoom siv, thiab tshuab. Nov yog qee cov ntsiab lus tseem ceeb txog kev lag luam hluav taws xob:

- Consumer electronics:Kev lag luam hluav taws xob tsim tawm ntau yam khoom siv hluav taws xob, suav nrog smartphones, TVs, laptops, ntsiav tshuaj, koob yees duab, thiab khoom siv hauv tsev. Cov khoom no yog tsim los rau kev siv tus kheej thiab kev ua si thiab feem ntau suav nrog cov thev naus laus zis thiab nta.

- Kev lag luam semiconductor:Cov khoom siv hluav taws xob ntau dhau los ntawm cov khoom siv hluav taws xob los tsim cov hluav taws xob sib txuas (ICs), microchips, thiab cov khoom siv hluav taws xob. Semiconductors yog lub hauv paus tsim thaiv hauv cov khoom siv hluav taws xob, ua kom suav, nco cia, kev sib txuas lus, thiab tswj kev ua haujlwm.

- Kev tshawb kawm thiab kev loj hlob:Kev tshawb fawb thiab kev tsim kho (R&D) yog ib qho tseem ceeb ntawm kev lag luam hluav taws xob. Cov tuam txhab lag luam nqis peev hauv R & D los tsim kho tshiab thiab tsim cov thev naus laus zis tshiab, txhim kho cov khoom uas twb muaj lawm, thiab ua tau raws li cov neeg siv khoom xav tau. R & D kev siv zog tsom mus rau kev ua haujlwm me me, kev siv hluav taws xob, kev sib txuas, thiab kev txawj ntse (AI).

- Ntiaj teb no supply chain:Kev lag luam hluav taws xob ua haujlwm thoob ntiaj teb, nrog rau cov khoom siv sib txuas nrog cov khoom lag luam ntawm cov khoom siv raw, cov khoom siv hluav taws xob, cov cuab yeej tsim khoom, thiab kev faib khoom sib txuas. Kev sib koom tes thoob ntiaj teb yog qhov tseem ceeb rau cov khoom siv, tsim khoom, thiab sib sau cov khoom siv hluav taws xob.

- Cov txheej txheem tsim khoom: Kev tsim khoom siv hluav taws xob suav nrog ntau txoj hauv kev, suav nrog cov ntawv luam tawm Circuit Board (PCB) sib dhos, nto mount thev naus laus zis (SMT), nti ntim, thiab cov khoom kawg sib dhos. Cov txheej txheem no yuav tsum tau ua kom tiav engineering, kev tswj kom zoo, thiab ua raws li cov qauv kev lag luam.

- Kev sib tw ua lag luam: Kev lag luam hluav taws xob muaj kev sib tw heev, nrog ntau lub tuam txhab vying rau kev sib koom ua lag luam. Cov tuam txhab sib txawv ntawm lawv tus kheej los ntawm cov khoom nta, tsim kom zoo nkauj, tus nqi, lub koob npe nrov, thiab cov neeg siv khoom. Kev lag luam tau ntsib cov khoom lag luam sai sai thiab xav tau kev hloov pauv tshiab kom nyob twj ywm kev sib tw.

- Emerging technologies:Kev lag luam hluav taws xob tau tsav kev txhim kho thiab kev siv cov thev naus laus zis tshiab, suav nrog kev nce qib hauv AI, Is Taws Nem ntawm Yam (IoT), virtual reality (VR), augmented reality (AR), cov cuab yeej siv tau, thiab cov thev naus laus zis hauv tsev. Cov thev naus laus zis no tau tsim ntau yam haujlwm, suav nrog kev kho mob, tsheb, thiab kev lom zem.

Kev lag luam hluav taws xob yog qhov tseem ceeb hauv kev cuam tshuam ntau yam ntawm lub neej niaj hnub. Nws tsis tu ncua hloov zuj zus mus ua kom tau raws li qhov xav tau ntawm cov neeg siv khoom thiab kev lag luam, ua kom muaj kev sib txuas, kev tsim khoom, thiab kev nce qib thev naus laus zis. Kev lag luam muaj peev xwm los tsim kho tshiab, tsim cov khoom lag luam zoo, thiab ua tau raws li cov kev xav tau ntawm kev lag luam ua rau nws qhov tseem ceeb hauv kev lag luam thoob ntiaj teb.

Kev lag luam khoom siv ncaws pob

Kev lag luam khoom siv kev ua kis las yog ntau yam kev lag luam uas suav nrog kev tsim, tsim khoom, thiab kev faib khoom thiab cov khoom siv hauv ntau yam kev ua si thiab kev ua si. Nov yog qee cov ntsiab lus tseem ceeb txog kev lag luam khoom siv ncaws pob:

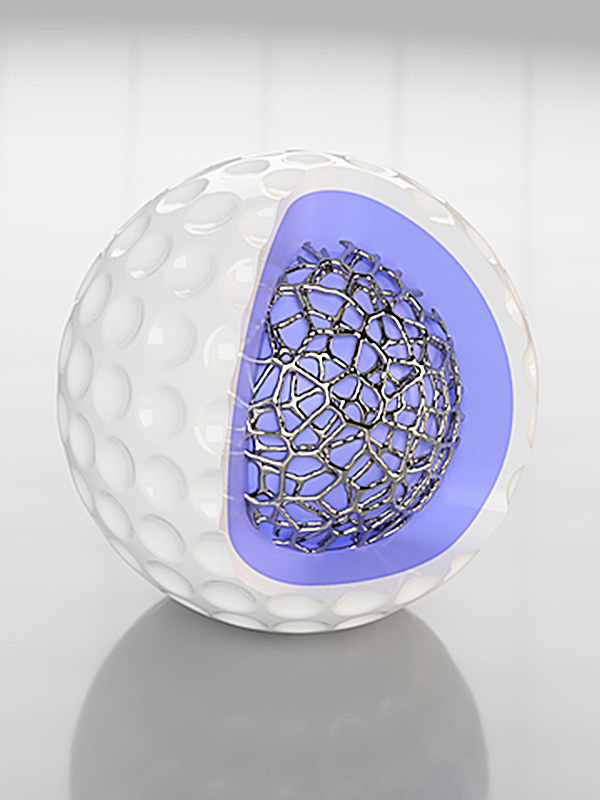

- Cov khoom siv ncaws pob:Kev lag luam khoom siv ua kis las tsim ntau yam khoom ua si, suav nrog cov khoom siv rau kev ua kis las (xws li ncaws pob, ntaus pob, thiab hockey), cov kis las tus kheej (xws li tennis, golf, thiab khiav), kev ua si hauv dej (xws li ua luam dej thiab caij nthwv dej) , kev ua si sab nraum zoov (xws li mus pw hav zoov thiab hiking), thiab qoj ib ce (xws li cov khoom siv gym thiab khoom siv).

- Kev ua tau zoo thiab kev nyab xeeb: Cov tuam txhab tsim khoom siv ua kis las tseem ceeb rau kev ua haujlwm thiab kev nyab xeeb hauv lawv cov qauv tsim. Cov kws tsim qauv tsim cov khoom siv los txhim kho cov neeg ncaws pob kev ua tau zoo, txhim kho lawv cov kev txawj ntse, thiab tiv thaiv lawv los ntawm kev raug mob. Peb siv cov khoom siv siab heev, cov txheej txheem ergonomic, thiab ua raws li cov qauv kev nyab xeeb kom muaj kev nyab xeeb.

- Innovation thiab technology:Kev lag luam khoom siv kev ua kis las tas li embraces innovation thiab technology los txhim kho cov khoom ua tau zoo thiab cov neeg siv kev paub. Kev tsim kho tshiab muaj xws li cov khoom siv hnyav, cov qauv tsim aerodynamic, cov tshuab cushioning siab heev, cov cuab yeej ntse ntse, thiab kev siv thev naus laus zis. Cov kev nce qib no txhim kho kev ua tau zoo, tiv thaiv kev raug mob, thiab cov ntaub ntawv kis las kis las.

- Customization thiab personalization: Kev lag luam khoom siv kis las paub txog qhov tseem ceeb ntawm kev hloov kho thiab tus kheej. Ntau lub tuam txhab muab cov kev xaiv kho kom haum, xws li xaiv cov xim, ntxiv cov logos, lossis cov khoom siv txiav kom haum rau tus neeg ncaws pob cov ntsiab lus. Muab kev paub txog tus kheej tuaj yeem txhawb cov neeg ncaws pob kom paub txog tus kheej.

- Kev txhawb nqa thiab kev pom zoo:Kev lag luam khoom siv kis las tso siab rau kev txhawb nqa thiab kev lees paub los ntawm cov kws ncaws pob thiab pab pawg kis las los tsim kev lees paub thiab kev ntseeg siab. Kev sib koom tes ntawm cov tuam txhab tsim khoom thiab cov neeg ncaws pob feem ntau koom nrog kev tsim khoom, kev sim, thiab kev sib koom ua lag luam.

- Muaj caij nyoog:Kev lag luam khoom siv kev ua kis las nce ntxiv rau kev ruaj ntseg thiab lub luag haujlwm ib puag ncig. Cov neeg tsim khoom siv cov khoom siv eco-phooj ywg, txo cov khoom pov tseg hauv cov txheej txheem tsim khoom, thiab txhawb nqa cov kev pabcuam rov ua dua tshiab. Sustainable kev coj ua kom txo qis kev lag luam ib puag ncig kev cuam tshuam thiab txhawb kev ruaj ntseg mus ntev.

- Kev ua lag luam thoob ntiaj teb:Kev lag luam khoom siv kis las ua haujlwm thoob ntiaj teb, nrog cov khoom tsim thiab xa tawm thoob ntiaj teb. Lub tuam txhab ua kom muaj kev lag luam sib txawv thiab kev nyiam ntawm kev coj noj coj ua, hloov cov khoom kom tau raws li cov cheeb tsam sib txawv 'thiab kev ua kis las' tshwj xeeb xav tau thiab nyiam.

Kev lag luam khoom siv kis las txhawb nqa cov neeg ncaws pob, txhawb nqa kev ua si ntawm lub cev, thiab txhim kho kev ua kis las. Kev tsim kho tshiab tsis tu ncua, ua raws li cov qauv kev nyab xeeb, thiab cov kev xaiv kho kom haum ua rau kev lag luam loj hlob thiab muaj peev xwm ua tau raws li cov kev xav tau ntawm cov neeg ncaws pob thiab cov neeg nyiam ua kis las.

Kev lag luam khoom ua si thiab kev ua si

Kev lag luam khoom ua si thiab kev ua si yog ib qho kev lag luam loj uas suav nrog kev tsim, tsim khoom, thiab faib cov khoom ua si thiab kev ua si rau menyuam yaus thiab cov neeg laus. Nov yog qee cov ntsiab lus tseem ceeb txog kev lag luam khoom ua si thiab kev ua si:

- Hom khoom ua si thiab kev ua si: Kev lag luam khoom ua si thiab kev ua si tsim ntau yam khoom, nrog rau cov khoom ua si ib txwm muaj xws li cov menyuam roj hmab, cov duab ua yeeb yam, thiab cov duab dhos ua si, nrog rau cov khoom ua si hauv hluav taws xob, board games, card games, thiab video games. Kev lag luam caters rau ntau yam kev nyiam, hnub nyoog, thiab qib kev txawj.

- Innovation thiab technology:Cov khoom ua si thiab kev ua si kev lag luam tsis tu ncua hloov zuj zus, nrog cov tuam txhab siv cov cuab yeej tshiab los tsim cov khoom tshiab thiab txhim kho cov neeg siv kev paub. Txhawm rau tsim kom muaj txiaj ntsig zoo thiab muaj txiaj ntsig, peb tuaj yeem suav nrog virtual, augmented kev muaj tiag, thiab kev sib tham sib tham.

- Kev nyab xeeb thiab zoo: Kev nyab xeeb thiab kev ua tau zoo yog qhov tseem ceeb rau kev lag luam khoom ua si thiab kev ua si. Cov neeg tsim khoom yuav tsum ua raws li cov cai thiab cov qauv kev nyab xeeb kom ntseeg tau tias lawv cov khoom tsis ua mob rau cov neeg siv khoom. Txhawm rau kom ntseeg tau tias peb cov khoom lag luam zoo, peb ua qhov kev sim ua kom zoo, siv cov kev tswj xyuas nruj, thiab tsis tu ncua saib xyuas lawv.

- Daim ntawv tso cai thiab branding: Ntau yam khoom ua si thiab kev ua si yog ua raws li cov cim nrov, cov yeeb yaj kiab, thiab TV qhia, ua rau muaj kev tso cai thiab kev sib koom tes ntawm cov tuam txhab thiab cov tuam txhab kev lom zem. Cov khoom muaj ntawv tso cai feem ntau nrov ntawm cov neeg siv khoom, vim lawv muab kev nkag siab ntawm kev paub thiab txuas rau cov cim nyiam.

- Kev ua lag luam thoob ntiaj teb:cov khoom ua si thiab kev ua si kev lag luam ua haujlwm thoob ntiaj teb, nrog cov tuam txhab tsim khoom thiab cov neeg muag khoom tsim thiab xa tawm cov khoom lag luam thoob ntiaj teb. Lub tuam txhab caters rau ntau haiv neeg kev lag luam thiab kab lis kev cai nyiam, hloov cov khoom kom tau raws li cov kev xav tau tshwj xeeb thiab nyiam ntawm cov cheeb tsam sib txawv thiab cov pej xeem.

- Kev cuam tshuam rau kev loj hlob:Cov khoom ua si thiab kev ua si muaj txiaj ntsig zoo rau menyuam yaus txoj kev loj hlob, txhawb kev muaj tswv yim, kev xav, kev txawj sib raug zoo, thiab kev txawj ntse. Ntau cov khoom ua si thiab game designers tsim cov khoom los txhawb kev kawm thiab kev loj hlob, feem ntau koom tes nrog cov kws paub txog kev loj hlob me nyuam kom ntseeg tau tias lawv ua tau raws li cov hom phiaj no.

Kev lag luam khoom ua si thiab kev ua si yog qhov tseem ceeb hauv kev muab kev lom zem thiab txhawb kev loj hlob ntawm cov menyuam yaus thiab cov neeg laus. Kev tsim kho tshiab tsis tu ncua, ua raws li cov qauv kev nyab xeeb, thiab kev tso cai thiab kev sib koom ua lag luam muaj txiaj ntsig ua rau kev lag luam loj hlob thiab nws lub peev xwm los ua kom tau raws li cov kev xav tau ntawm cov neeg siv khoom.

Xaiv Cov Chaw Tsim Khoom Zoo rau Tsev Neeg Txhaj Pwm

Xaiv cov chaw tsim khoom tsim nyog rau tsev neeg txhaj tshuaj pwm yog ib kauj ruam tseem ceeb hauv kev ua kom tiav koj qhov project. Nov yog qee cov ntsiab lus tseem ceeb uas yuav tsum xav txog thaum xaiv cov chaw tsim khoom:

- Kev paub thiab kev paub:Nrhiav ib lub chaw tsim khoom nrog kev paub dav thiab kev paub hauv tsev neeg txhaj tshuaj molding. Xav txog lawv cov ntaub ntawv teev tseg, xyoo ua haujlwm, thiab nkag siab txog koj lub hom phiaj kev lag luam lossis cov khoom lag luam.

- Technical peev xwm:Ntsuam xyuas cov chaw tsim khoom cov peev txheej, suav nrog cov khoom siv, tshuab, thiab cov txheej txheem tsim khoom. Xyuas kom lawv muaj cov cuab yeej tsim nyog thiab cov peev txheej los daws qhov nyuaj thiab qhov tshwj xeeb ntawm tsev neeg txhaj tshuaj pwm.

- Kev tswj kom zoo:Kev tswj kom zoo yog qhov tseem ceeb hauv kev txhaj tshuaj molding kom tswj tau qhov sib xws thiab qhov tseeb hauv kev tsim cov pwm. Xyuas yog tias cov chaw tsim khoom tau tsim cov kev tswj xyuas zoo thiab cov ntawv pov thawj, xws li ISO 9001, kom ntseeg tau tias lawv ua raws li cov qauv kev lag luam thiab xa cov pwm zoo.

- Customization thiab yooj:Tsev neeg txhaj tshuaj pwm feem ntau xav tau kev hloov kho kom haum rau ntau qhov chaw thiab tsim qauv. Xaiv cov chaw tsim khoom uas tuaj yeem ua raws li koj cov kev xav tau tshwj xeeb thiab muaj qhov hloov pauv hloov pauv lossis hloov kho thaum lub sijhawm tsim khoom.

- Kev sib txuas lus thiab kev sib koom tes:Kev sib txuas lus zoo thiab kev sib koom tes yog qhov tseem ceeb rau kev sib koom tes ua tiav. Ntsuam xyuas cov chaw tsim khoom, kev txaus siab rau kev sib txuas lus, thiab muaj peev xwm nkag siab txog koj cov kev xav tau. Ib lub chaw tsim khoom uas tuaj yeem muab cov kab lus meej thiab qhib kev sib txuas lus thoob plaws hauv qhov project yuav pab ua kom muaj kev tsim khoom zoo.

- Nqi thiab ncua sij hawm: Xav txog cov chaw tsim khoom tus nqi qauv thiab lub sijhawm ua haujlwm. Thaum tus nqi yog qhov tseem ceeb, ceev faj ntawm cov nqi meager uas tuaj yeem cuam tshuam qhov zoo. Nrhiav qhov sib npaug ntawm tus nqi sib tw thiab lub sijhawm ua haujlwm tsim nyog kom ua tau raws li koj qhov project hnub kawg.

- Cov ntaub ntawv thiab cov ntawv pov thawj:Thov cov ntaub ntawv pov thawj lossis cov lus pov thawj los ntawm lwm cov neeg siv khoom uas tau ua haujlwm nrog cov chaw tsim khoom. Koj tuaj yeem tau txais kev nkag siab zoo los ntawm kev txheeb xyuas lawv lub koob npe nrov, kev txaus siab ntawm cov neeg siv khoom, thiab muaj peev xwm ua raws li kev cog lus.

Los ntawm ua tib zoo soj ntsuam cov xwm txheej no thiab ua tib zoo tshawb fawb, koj tuaj yeem txiav txim siab paub thaum xaiv cov chaw tsim khoom tsim nyog rau koj tsev neeg txhaj tshuaj pwm. Ib lub tuam txhab txhim khu kev qha thiab muaj peev xwm yuav ua rau muaj kev vam meej ntawm koj qhov project thiab ua kom cov pwm tsim tau zoo uas ua tau raws li koj cov kev qhia tshwj xeeb.

xaus

Tsev neeg txhaj tshuaj pwm muaj ntau yam txiaj ntsig rau cov tuam txhab nrhiav kev tsim cov khoom yas kom zoo thiab raug nqi. Nkag siab txog ntau hom pwm, lawv qhov zoo thiab qhov tsis zoo, thiab kev xav txog kev tsim qauv yog qhov tseem ceeb rau kev ua kom zoo tshaj plaws ntawm cov txheej txheem tsim khoom no. Nrog rau cov chaw tsim khoom thiab tsim kom zoo, tsev neeg txhaj tshuaj pwm tuaj yeem ua tau zoo thiab muaj txiaj ntsig zoo rau ntau yam kev lag luam thiab kev siv.