Txhaj Mould Design

Yuav ua li cas ua ib lub pwm yas

Hauv kev tsim khoom niaj hnub no, plastics tau siv los tsim ntau yam khoom. Txhua daim ntawv thov yuav tsum muaj cov txheej txheem tsim tshwj xeeb, uas tuaj yeem tsim cov khoom raws li lawv cov specifications. Yog tias koj tab tom ua cov khoom yas, thawj qhov koj yuav tsum tau txiav txim siab yog hom molding uas zoo tshaj plaws rau koj daim ntawv thov tshwj xeeb. Ntawm DJmolding, peb tsom rau kev cai yas molding.

DJmolding Pwm Tsim Kev Pabcuam

DJmolding tsim pwm txij li xyoo 2010, uas peb ua tau raws li cov neeg siv khoom tshwj xeeb. DJmolding muab cov kev pabcuam saum toj kawg nkaus engineering los ntawm kev sib txuas cov qauv tsim qauv nrog cov txheej txheem niaj hnub niaj hnub no rau kev tsim thiab tsim cov yas txhaj tshuaj molded qhov chaw.

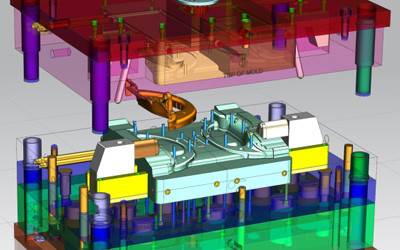

Peb muaj cov kws tsim qauv tsim nyog nrog kev paub zoo heev hauv kev tsim software & pwm tsim. Lawv ua hauj lwm los ntawm kev sib koom tes nrog cov cuab yeej chav & molding khw. Yog li peb txaus siab rau kev tsim cov yas txhaj tshuaj pwm rau cov khoom me me rau nruab nrab qhov chaw uas siv rau hauv kev kho mob, hluav taws xob, hluav taws xob, tsheb, aviation, connector, cov khoom siv, textile thiab industrial fields.

DJmolding engineers muab kev pab tsim yas thiab dhau los ua qhov tseem ceeb ntawm koj pab pawg tsim khoom. DJmolding pab tsim koj cov khoom nrog cov cuab yeej tsim, xaiv cov khoom siv, thiab cov khoom siv hauv siab los pab tswj tus nqi thiab tiv thaiv teeb meem ua ntej lawv tshwm sim.

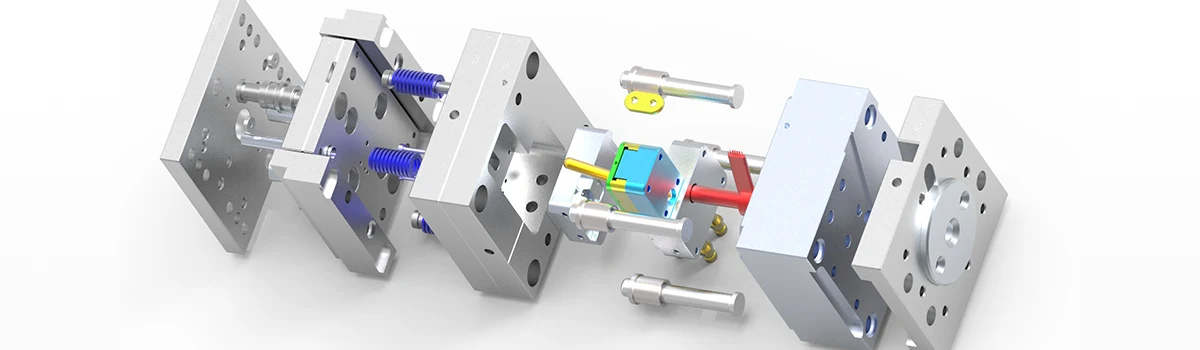

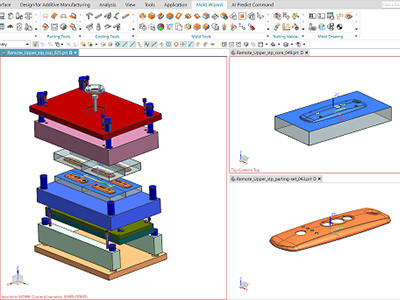

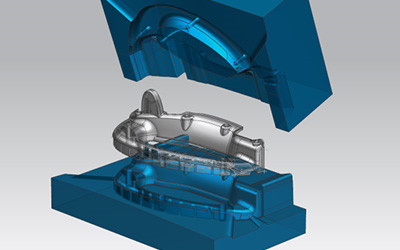

Tsim cov pwm zoo sib koom ua ke rau cov qauv tsim

DJmolding streamlines tag nrho cov txheej txheem tsim pwm nrog rau kev tsim ib feem, tsim cov cuab yeej thiab cov lus tsa suab validation. Koj tuaj yeem ua kom cov lus teb sai rau kev tsim cov kev hloov pauv thiab cov pwm zoo.

Ceev nrooj tsim cov pwm uas nyuaj tshaj plaws uas siv cov kev ua haujlwm siab heev, kev taw qhia ib kauj ruam thiab kev koom ua ke nrog cov qauv ib feem kom paub meej cov lus teb sai rau kev tsim cov kev hloov pauv thiab cov pwm zoo.

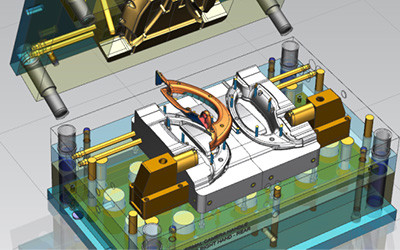

DJmolding engineers txhim kho tag nrho cov txheej txheem pwm tsim kom luv luv txhuas lub sij hawm thiab tswj cov nqi los ntawm kev siv cov lus qhia ib kauj ruam rau pwm tsim, cov cuab yeej sib dhos, cov cuab yeej tsim, thiab cov cuab yeej siv tau. Excel ntawm qhov nyuaj tshaj plaws pwm tsim nrog cov txheej txheem automation thaum ua raws li kev coj ua zoo tshaj plaws hauv kev lag luam.

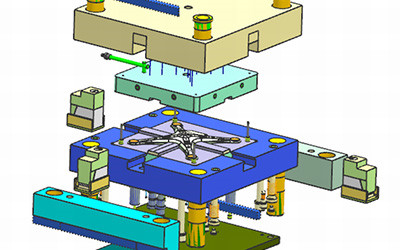

Rov Siv Lub Tuam Txhab Cov Qauv

Txo cov cuab yeej tsim kho lub sijhawm los ntawm kev rov siv lub tuam txhab cov qauv, suav nrog:

* Rov qab siv cov qauv tsim ua ntej, cov khoom siv, cov cuab yeej thiab cov txheej txheem thiab hloov cov qauv ua pov thawj rau cov pwm tshiab.

* Ua kom nrawm thiab ua kom zoo dua cov txheej txheem pwm tsim los ntawm kev tsim cov txheej txheem thiab cov khoom siv.

* Automate tiam ntawm cov npe, kos duab, cov ntaub ntawv cov qauv, thiab NC toolpaths,

* Tsim cov khoom siv rov siv tau thiab txuag lawv hauv cov tsev qiv ntawv kev cai.

* Txhim kho koj tus kheej rov siv tau pwm puag txheej txheej.

DJmolding Pwm Tsim Kev Pabcuam nrawm tsim cov pwm uas nyuaj tshaj plaws uas siv cov kev ua haujlwm siab heev, kev taw qhia ib qib zuj zus thiab kev koom tes nrog cov qauv ua qauv kom ntseeg tau cov lus teb sai rau kev hloov pauv thiab pwm zoo.

Txhaj pwm tsim yog ib qho tseem ceeb tshaj plaws ntawm kev ua tiav pwm ua qhov project, peb tam sim no muaj 10 tus tsim pwm zoo Suav nrog ntau tshaj 10 xyoo tsim kev paub. Rau txhua qhov ntawm pwm qhov project, peb yuav hu rau lub rooj sib tham sab hauv ncaws tawm los txiav txim siab qhov layout, khiav tsim, rooj vag txoj kev, ejection method, txias layout, thiab lwm yam. Cov no yuav cia peb ib txwm tsim koj pwm nrog tag nrho peb cov kev txawj ntse. cov peev txheej tsis yog los ntawm ib tus kws tsim pwm nkaus xwb. Peb muab qhov kev pom tshwj xeeb hauv kev txhaj tshuaj yas pwm thiab cov khoom tsim. Muaj ntau xyoo ntawm kev txhaj tshuaj pwm tsim ua rau peb koom nrog "moldability" yam rau hauv peb cov khoom tsim thiab kev ntsuam xyuas.

Engineers thiab designers koom tes nrog peb cov neeg muas zaub los coj lub tswv yim rau kev muaj tiag siv cov txheej txheem niaj hnub tshaj plaws nyob rau hauv peb lub computer tsim center.Our pwm tsim / engineering technologies muaj xws li:

*Pro/Engineer/UG (3D)

* AutoCad (2D)

* Moldflow tsom xam (Plastic flow / deform simulation)

* MasterCam (CNC Programming)

Peb muab DFM cov ntaub ntawv qhia thiab muab cov neeg siv khoom saib tag nrho ntawm kev tsim khoom thiab tsim ib feem, nrog rau peb cov kev paub dhau los thiab kev tshaj lij, peb muaj peev xwm kwv yees qhov muaj peev xwm txaus ntshai thiab tuaj nrog cov kev daws teeb meem zoo.

Tiv tauj peb, Djmolding yuav muab cov kev pabcuam pwm tsim zoo tshaj plaws rau koj.