Ntxig Txhaj Molding

Ntxig txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav hauv kev tsim cov khoom yas nyuaj nrog cov khoom sib xyaw. Cov txheej txheem no suav nrog kev ntxig hlau lossis yas rau hauv cov pwm kab noj hniav ua ntej txheej txheem txhaj tshuaj molding. Cov khoom molten ces ntws ncig lub ntsiab lus, tsim kom muaj kev sib raug zoo ntawm ob cov ntaub ntawv. Ntxig txhaj tshuaj molding muaj ntau qhov zoo, suav nrog kev txhim kho kev tsim qauv yooj yim, txo lub sijhawm sib dhos, thiab txhim kho qhov ua haujlwm zoo. Cov lus qhia dav dav no yuav tshawb txog cov txheej txheem sib txawv, cov txiaj ntsig, thiab kev siv ntawm kev txhaj tshuaj molding.

Dab tsi yog Insert Injection Molding?

Kev txhaj tshuaj molding yog txheej txheem tsim khoom siv los tsim ntau yam khoom thiab cov khoom. Ntxig txhaj tshuaj molding yog ib hom kev txhaj tshuaj molding uas tso cai rau kev ntxig cov khoom preformed, los yog ntxig rau hauv pwm ua ntej txheej txheem molding pib. Cov txheej txheem no tso cai rau kev tsim cov khoom uas xav tau cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav.

Ntxig kev txhaj tshuaj molding ua haujlwm los ntawm kev tso lub preformed ntxig rau hauv pwm kab noj hniav ua ntej txheej txheem molding pib. Lub insert tuaj yeem muaj ntau yam ntaub ntawv, suav nrog hlau, yas, thiab ceramics. Cov txheej txheem molding pib li niaj zaus, nrog cov yas molten txhaj rau hauv pwm kab noj hniav. Raws li cov yas txias thiab solidifies, nws fuses nrog cov ntxig, tsim ib qho, sib xyaw ua ke.

Muaj ntau qhov zoo rau kev siv cov tshuaj txhaj tshuaj molding. Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm cov txheej txheem no yog tias nws tso cai rau kev tsim cov khoom nrog cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav. Piv txwv li, kev txhaj tshuaj molding tuaj yeem siv tau yog tias muaj kev ua haujlwm yuav tsum muaj cov hlua ntxig lossis cov khoom siv hlau rau kev txhawb nqa. Cov txheej txheem no tseem tso cai rau kev tsim cov khoom siv nrog cov khoom sib xyaw ua ke, xws li ib feem yas nrog cov hlau ntxig.

Lwm qhov zoo ntawm kev txhaj tshuaj molding yog txuag lub sijhawm thiab nyiaj txiag. Es tsis txhob sib sau ua ke ntau yam, ntxig txhaj tshuaj molding tsim ib qho, sib xyaw ua ke. Los ntawm kev ua li ntawd, cov tuam txhab tuaj yeem txo lub sijhawm thiab cov nqi tsim nyog rau kev sib dhos.

Ntxig txhaj tshuaj molding kuj tseem pab tau rau kev tsim cov khoom siv. Vim hais tias cov ntxig tuaj yeem muab tso rau hauv pwm kab noj hniav ua ntej txheej txheem molding pib, nws muaj peev xwm tsim cov khoom nrog cov geometry nyuaj thiab cov yam ntxwv uas yuav nyuaj rau kev ua tiav los ntawm cov txheej txheem txhaj tshuaj molding.

Kev Txhaj Tshuaj Molding Ua Haujlwm Li Cas?

Nws yog ib hom kev txhaj tshuaj molding txheej txheem uas tso cai rau kev nkag ntawm cov khoom preformed, los yog ntxig rau hauv pwm ua ntej cov txheej txheem molding pib. Cov txheej txheem no tso cai rau kev tsim cov khoom nrog cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav thiab tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau kev tsim cov khoom nyuaj. Ntawm no peb yuav tham txog yuav ua li cas ntxig txhaj tshuaj molding ua haujlwm.

Cov txheej txheem txhaj tshuaj molding muaj cov kauj ruam hauv qab no:

- Ntxig qhov chaw:Thawj kauj ruam hauv kev txhaj tshuaj molding txheej txheem yog muab cov preformed ntxig rau hauv pwm kab noj hniav. Cov neeg tsim khoom tuaj yeem tsim cov ntxig no los ntawm ntau yam ntaub ntawv, xws li hlau, yas, lossis ceramics.

- Pwm Clamping:Cov pwm raug kaw thiab clamped kaw thaum lub ntxig rau hauv qhov chaw. Lub hom phiaj yog khaws cov ntxig rau hauv qhov chaw thaum lub sij hawm molding txheej txheem.

- Txhaj ntawm Molten Plastic:Kev txhaj tshuaj molding txheej txheem txhaj cov yas molten rau hauv pwm kab noj hniav. Cov neeg tsim khoom feem ntau ua kom sov cov yas rau qhov kub ntawm 200 thiab 300 degrees Celsius, txiav txim siab raws li cov yas siv tshwj xeeb.

- Cooling thiab Solidification: Raws li cov yas txias thiab solidifies, nws fuses nrog cov ntxig, tsim ib qho, sib xyaw ua ke. Lub sijhawm txias thiab khov kho yog nyob ntawm cov yas siv tshwj xeeb thiab qhov nyuaj ntawm kev tsim cov khoom.

- Pwm Qhib thiab Ejection: Thaum ib feem tau txias thiab solidified, tus neeg teb xov tooj qhib lub pwm thiab ejects cov khoom. Cov khoom tuaj yeem ua tiav thiab npaj rau kev siv.

Muaj ntau qhov zoo rau kev siv cov tshuaj txhaj tshuaj molding. Qee qhov txiaj ntsig no suav nrog:

- Lub peev xwm los tsim qhov chaw nrog cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav

- Cov ntsiab lus tuaj yeem ua tau raws li ib qho, sib xyaw ua ke, ua rau txo lub sijhawm sib dhos thiab cov nqi

- Muaj peev xwm tsim qhov nyuaj nrog cov duab geometry thiab cov yam ntxwv

- Muaj peev xwm siv ntau yam ntaub ntawv, suav nrog hlau, yas, thiab ceramics

- Kev txhaj tshuaj molding yog cov txheej txheem ua haujlwm tau zoo thiab rov ua dua tshiab uas tuaj yeem tsim ntau qhov chaw nrog qhov tseeb thiab raug.

Hom Inserts siv nyob rau hauv Txhaj Molding

Cov neeg tsim khoom siv tau ntau yam ntaub ntawv, suav nrog hlau, yas, thiab ceramics, los ua cov ntxig. Cov inserts no pab tsim cov khoom uas muaj cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav. Ntawm no peb yuav tham txog ntau hom kev ntxig uas siv hauv kev txhaj tshuaj molding.

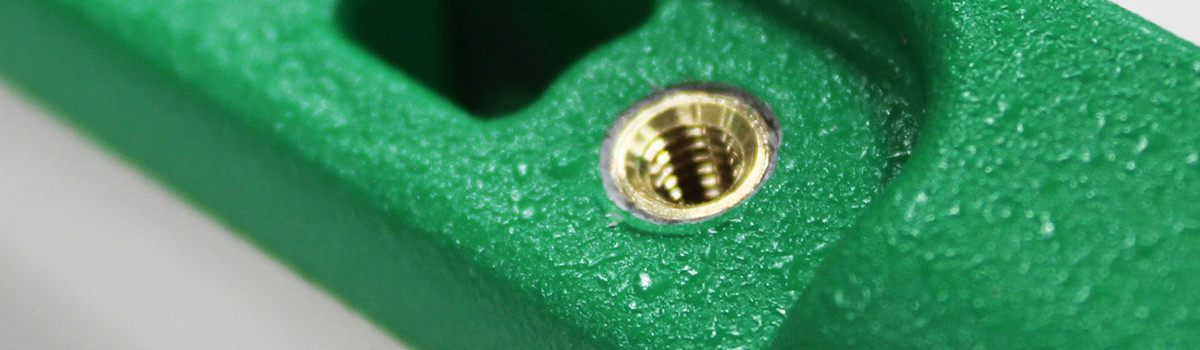

- Hlau Inserts:Hlau inserts feem ntau yog siv rau hauv kev txhaj tshuaj molding los muab lub zog ntxiv thiab ruaj khov rau cov khoom yas. Lawv feem ntau yog ua los ntawm tooj dag, hlau, lossis txhuas thiab tuaj yeem ua threaded lossis unthreaded, nyob ntawm daim ntawv thov. Cov neeg tsim khoom tuaj yeem siv cov khoom siv hlau los tsim cov khoom nrog cov geometry nyuaj thiab cov yam ntxwv uas yuav tsum tau muaj zog thiab ua haujlwm ntev.

- Plastic Inserts: Plastic inserts feem ntau yog siv rau hauv kev txhaj tshuaj molding los txhawb thiab txhawb nqa cov khoom yas. Lawv feem ntau yog tsim los ntawm nylon, ABS, lossis polycarbonate cov ntaub ntawv thiab tuaj yeem tsim cov khoom nrog cov yam ntxwv tshwj xeeb xws li kev sib txuas snap-haum lossis threaded qhov. Cov neeg tsim khoom muaj nqis rau cov yas ntxig rau lawv lub peev xwm los muab lub teeb yuag, kev daws teeb meem zoo thiab pwm yooj yim rau hauv ntau yam duab thiab ntau thiab tsawg.

- Ceramic Inserts: Ceramic inserts yog siv rau hauv kev txhaj tshuaj molding los tsim qhov chaw uas yuav tsum tau muaj zog thiab tsis kam hnav thiab tsim kua muag. Lawv feem ntau yog tsim los ntawm cov ntaub ntawv xws li zirconia lossis alumina thiab tuaj yeem siv los tsim cov khoom siv rau tsheb, aerospace, thiab kev kho mob kev lag luam. Ceramic inserts yog heev resistant rau kub kub, corrosion, thiab puas, ua rau lawv zoo tagnrho rau ib puag ncig hnyav.

- Composite Inserts: Cov neeg tsim khoom ua ke ob lossis ntau cov ntaub ntawv, xws li hlau thiab yas, thiab pwm lawv los tsim cov khoom sib xyaw, ua rau ib qho, sib xyaw ua ke. Cov neeg tsim khoom tuaj yeem siv cov khoom sib xyaw los tsim cov khoom uas muaj cov yam ntxwv tshwj xeeb uas cov txheej txheem txhaj tshuaj molding tsis tuaj yeem ua tiav. Tsis tas li ntawd, lawv tuaj yeem hloov kho cov ntawv ntxig no kom tau raws li qhov xav tau tshwj xeeb ntawm cov ntawv thov tshwj xeeb.

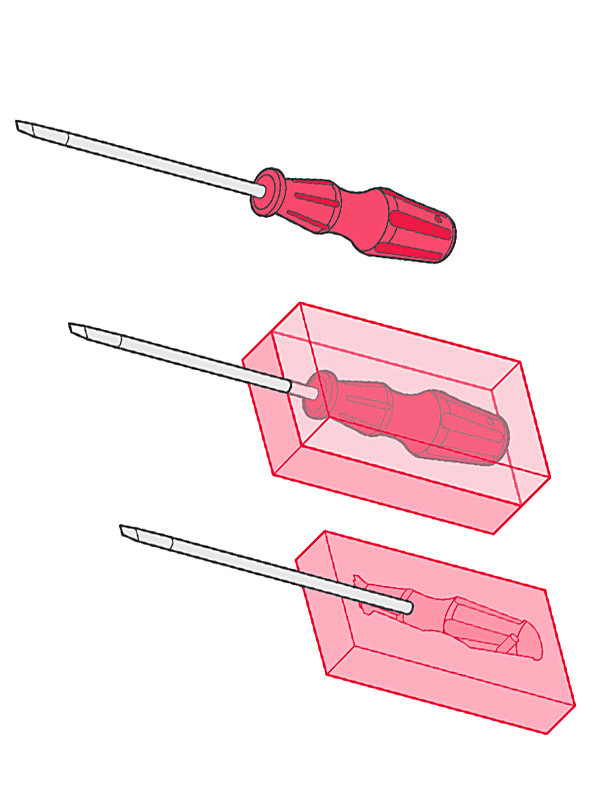

- Overmolded Inserts: Thaum lub sij hawm txhaj tshuaj molding txheej txheem, manufacturers pwm inserts rau hauv ib feem yas, uas yog hu ua over-molded inserts. Cov txheej txheem no suav nrog kev tsim thawj zaug txhaj tshuaj ntawm cov yas nyob ib ncig ntawm qhov ntxig thiab tom qab ntawd teeb tsa thib ob ntawm thawj zaug txhaj tshuaj los tsim ib qho, sib xyaw ua ke. Cov neeg tsim khoom feem ntau siv cov txheej txheem ntau dhau los tsim cov khoom sib xyaw ua ke, xws li muab cov hlau ntxig rau hauv cov khoom yas.

Hlau Inserts vs. Plastic Inserts

Cov txheej txheem suav nrog kev siv cov khoom ua ntej, lossis cov khoom ntxig, muab tso rau hauv pwm ua ntej cov txheej txheem yas txhaj tshuaj pib. Cov neeg tsim khoom tuaj yeem ua cov ntxig los ntawm ntau yam ntaub ntawv, suav nrog hlau thiab yas, thiab txhua hom nthuav tawm nws qhov tshwj xeeb zoo thiab qhov tsis zoo. Kab lus no yuav sib piv cov hlau thiab yas ntxig thiab pab koj txiav txim siab qhov kev xaiv zoo tshaj plaws rau koj daim ntawv thov.

Hlau ntxig

Cov neeg tsim khoom feem ntau siv hlau ntxig rau hauv molding vim lawv lub zog siab thiab ua haujlwm ntev. Lawv feem ntau yog ua los ntawm tooj dag, hlau, lossis txhuas thiab tuaj yeem ua threaded lossis unthreaded, nyob ntawm daim ntawv thov. Cov hlau ntxig feem ntau yog siv rau hauv kev txhaj tshuaj molding los muab lub zog ntxiv thiab ruaj khov rau cov khoom yas.

Qhov zoo ntawm Hlau Inserts

- Siab zog thiab durability

- Siv tiv taus thiab tsim kua muag

- Nws tuaj yeem muab kev ua haujlwm ntxiv los ntawm threading

- Qhov zoo tshaj plaws rau cov khoom uas muaj kev ntxhov siab siab lossis cov kev cai thauj khoom

Disadvantages ntawm Hlau Inserts

- Tus nqi siab dua li cov khoom siv yas

- Ntau nyuaj rau pwm dua li cov yas ntxig

- Hnyav, uas tej zaum yuav muaj kev txhawj xeeb hauv cov ntawv thov tshwj xeeb

Plastic Inserts

Yas inserts yog nrov rau molding vim lawv versatility thiab nqi-zoo. Cov neeg tsim khoom feem ntau ua rau lawv los ntawm cov ntaub ntawv xws li nylon, ABS, lossis polycarbonate, thiab lawv tuaj yeem yooj yim pwm rau hauv ntau yam duab thiab ntau thiab tsawg. Plastic inserts yog lub teeb yuag thiab tuaj yeem tsim qhov chaw nrog cov yam ntxwv tshwj xeeb, xws li kev sib txuas snap-haum lossis threaded qhov.

Qhov zoo ntawm Plastic Inserts

- Nqi-zoo

- khaub-ncaws nyias

- Yooj yim molded rau hauv ntau yam duab thiab ntau thiab tsawg

- Qhov zoo tshaj plaws rau cov khoom uas muaj kev ntxhov siab tsawg lossis cov kev xav tau ntawm cov kabmob

Qhov tsis zoo ntawm cov yas ntxig

- Tsawg zog dua cov hlau ntxig

- Tsis zoo tagnrho rau qhov chaw uas muaj kev ntxhov siab los yog cov kabmob load

- Nws tuaj yeem hnav thiab tsim kua muag ntau dua thaum lub sijhawm

Thaum xaiv Hlau Inserts

Hlau inserts excel nyob rau hauv qhov chaw uas xav tau siab zog thiab durability, raws li lawv tiv taus hnav thiab tsim kua muag thiab muab ntxiv functionality ntawm threaded. Hlau inserts kuj yog qhov zoo tagnrho rau kev ua haujlwm nrog kev ntxhov siab lossis kev thauj khoom hnyav. Txawm li cas los xij, lawv kim dua li cov yas ntxig thiab tej zaum yuav nyuaj rau pwm.

Cov ntawv thov uas yuav xav tau cov hlau ntxig muaj xws li

- Automotive thiab aerospace Cheebtsam

- Cov cuab yeej siv kho mob

- Muaj cov cuab yeej siv

- Neeg siv khoom hluav taws xob

Thaum xaiv cov yas ntxig

Plastic inserts yog tus nqi-zoo thiab muaj ntau yam rau qhov chaw uas muaj kev ntxhov siab tsawg lossis cov kev cai thauj khoom. Lawv pom cov yam ntxwv sib sib zog nqus; manufacturers tuaj yeem tsim lawv rau hauv ntau yam duab thiab ntau thiab tsawg. Plastic inserts kuj zoo tagnrho rau txoj haujlwm uas yuav tsum tau muaj cov yam ntxwv tshwj xeeb xws li kev sib txuas snap-haum lossis threaded qhov. Txawm li cas los xij, tej zaum lawv yuav xav tau kom haum rau cov ntsiab lus uas muaj kev ntxhov siab ntau lossis cov kev cai thauj khoom.

Cov ntawv thov uas yuav xav tau cov yas ntxig nrog

- Cov neeg siv khoom

- Cov cuab yeej siv hauv tsev

- Cov khoom ua si thiab ua si

- electronics

Cov txiaj ntsig ntawm Insert Injection Molding

Ntxig txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov uas muaj cov khoom ua ntej lossis cov ntxig tso rau hauv pwm ua ntej cov txheej txheem yas txhaj tshuaj molding pib. Cov txheej txheem no muaj ntau yam txiaj ntsig tshaj li cov txheej txheem molding ib txwm, ua rau nws muaj kev xaiv nrov rau ntau yam kev siv. Kab lus no yuav tham txog qee qhov txiaj ntsig tseem ceeb ntawm kev txhaj tshuaj molding.

- Nqi tsim nyog: Ntxig kev txhaj tshuaj molding tuaj yeem yog qhov kev tsim khoom raug nqi vim tias nws tshem tawm qhov xav tau rau kev sib dhos tom qab molding ntawm cov khoom sib cais. Los ntawm kev sib xyaw cov khoom siv thaum lub sij hawm molding, manufacturers tuaj yeem txo cov nqi zog thiab kev sib dhos thaum nce kev ua haujlwm ntau lawm.

- Txhim kho qhov muaj zog: Ntxig kev txhaj tshuaj molding tuaj yeem txhim kho lub zog thiab ruaj khov ntawm qhov chaw los ntawm kev siv cov khoom sib txawv hauv ntau qhov chaw ntawm daim. Cov yam ntxwv no tuaj yeem ua tau zoo tshwj xeeb rau cov ntawv thov uas xav tau cov ntsiab lus los tiv thaiv kev ntxhov siab lossis kev xav tau ntawm kev thauj khoom.

- Ua kom tsim tau yooj yim: Ntxig kev txhaj tshuaj molding muaj ntau dua kev tsim qauv yooj yim, vim nws tsim qhov nyuaj nrog ntau yam nta thiab ua haujlwm. Cov txheej txheem no yog qhov zoo rau cov qauv tsim thiab geometry, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntsiab lus zoo li no.

- Kev sib raug zoo thiab raug: Ntxig txhaj tshuaj molding muaj zoo sib xws thiab raug nyob rau hauv ib feem ntau lawm. Peb precisely tso lub preformed inserts rau hauv pwm, xyuas kom meej lawv raws nraim qhov yuav tsum tau ntawm txhua feem. Yog li ntawd, peb ua tiav qhov ntev ntev thiab kev tswj xyuas tshwj xeeb hauv cov khoom tsim.

- Txo lub sij hawm voj voog: Ntxig kev txhaj tshuaj molding tuaj yeem txo lub sijhawm voj voog los ntawm kev sib txuas ntau cov kauj ruam rau hauv ib txheej txheem. Txoj kev no tuaj yeem txuag lub sijhawm thiab txhim kho cov khoom tsim tau zoo, tshwj xeeb tshaj yog thaum cuam tshuam nrog cov ntim ntau lawm.

- Ntau yam ntawm cov ntaub ntawv: Kev txhaj tshuaj molding tuaj yeem siv nrog ntau yam ntaub ntawv, suav nrog yas, hlau, thiab ceramic. Tam sim no cov neeg tsim khoom tuaj yeem xaiv cov khoom tsim nyog tshaj plaws rau txhua daim ntawv thov los ntawm kev txiav txim siab lub zog, kav ntev, thiab tus nqi.

- Environmental txiaj ntsig: Ntxig txhaj tshuaj molding tuaj yeem muab cov txiaj ntsig ib puag ncig los ntawm kev txo cov khib nyiab thiab txo qis kev siv cov ntaub ntawv. Vim tias peb muab cov ntxig ntxig rau hauv pwm, peb muaj cov khoom pov tseg tsawg dua li cov txheej txheem molding. Kev ua raws li qhov no tuaj yeem ua rau muaj kev cuam tshuam ib puag ncig thiab txo cov nqi tsim khoom.

Tsim Kev xav rau Insert Molding

Ntxig molding yog txheej txheem tsim khoom nrov uas koom nrog kev sib koom ua ke ntawm preformed inserts rau hauv cov txheej txheem yas txhaj tshuaj molding. Cov txheej txheem no muaj ntau yam txiaj ntsig, suav nrog kev txhim kho ib feem ntawm lub zog, txo cov nqi sib dhos, thiab nce kev tsim kom yooj yim. Txawm li cas los xij, tsim qhov chaw rau kev ntxig molding yuav tsum tau ua tib zoo xav txog ntau yam kom ntseeg tau tias kev ua tiav thiab ua haujlwm tau zoo. Kab lus no yuav tham txog qee qhov tseem ceeb ntawm kev tsim qauv rau kev ntxig molding.

- Ntxig qhov chaw: Qhov chaw ntawm qhov ntxig rau hauv pwm yog qhov tseem ceeb rau kev ua tiav ntawm cov txheej txheem molding. Lub insert yuav tsum tau positioned precisely nyob rau hauv lub pwm los xyuas kom meej tias cov khoom yas tag nrho encapsulates nws thaum lub sij hawm molding txheej txheem. Cov neeg tsim qauv tseem yuav tsum xyuas kom meej tias qhov ntxig ntxig tsis cuam tshuam nrog cov khoom siv yas los yog ua rau muaj teeb meem ntawm txoj kab.

- Khoom Siv Tau Zoo: Kev xaiv cov ntaub ntawv rau ob qho tib si ntxig thiab cov khoom siv yas yog qhov tseem ceeb rau kev ua tiav ntawm cov txheej txheem molding. Cov ntaub ntawv yuav tsum tau sib xws los tiv thaiv cov teeb meem kev sib txuas lossis cov khoom siv tsis sib xws. Cov neeg tsim qauv yuav tsum ua tib zoo xav txog cov khoom siv, xws li cov ntsiab lus melting, shrinkage, thiab coefficient ntawm thermal expansion, kom ntseeg tau tias muaj kev vam meej molding.

- Ntu Geometry: Ib feem ntawm geometry yog lwm qhov tseem ceeb rau kev ntxig molding. Tus qauv tsim yuav tsum tso cai rau kom tsim nyog sau thiab ntim cov khoom yas nyob ib ncig ntawm lub ntxig kom paub meej tias nws tag nrho encapsulates. Ib feem geometry yuav tsum tau tso cai rau kom muaj cua txaus thiab txias kom tsis txhob muaj teeb meem nrog kev sib tsoo, shrinkage, lossis cov cim dab dej.

- Draft Angles thiab Undercuts: Lub xub ntiag ntawm cov kaum sab xis thiab cov undercuts tuaj yeem cuam tshuam qhov moldability ntawm ib feem hauv kev ntxig molding. Cov neeg tsim qauv yuav tsum ua tib zoo xav txog qhov kev tso kawm thiab cov duab geometry ntawm cov kaum sab xis thiab cov hauv qab kom ntseeg tau tias lawv tuaj yeem yooj yim tshem tawm cov ntxig los ntawm cov pwm yam tsis muaj kev puas tsuaj rau ib feem lossis pwm.

- Kev txiav txim siab ntawm Tooling: Cov cuab yeej xav tau rau kev ntxig molding tuaj yeem ua ntau dua li cov txheej txheem molding. Cov neeg tsim qauv yuav tsum ua tib zoo xav txog cov pwm tsim, nrog rau kev tso kawm thiab geometry ntawm qhov ntxig, lub rooj vag thiab qhov cua, thiab lwm yam kev ua haujlwm tsim nyog. Tsis tas li ntawd, cov cuab yeej yuav tsum muaj peev xwm tswj xyuas kom nruj kom ntseeg tau tias qhov kev tso tawm kom raug thiab tiv thaiv txhua yam teeb meem nrog rau qhov zoo.

Cov khoom siv hauv Insert Injection Molding

Ntxig txhaj tshuaj molding yog txheej txheem tshwj xeeb heev uas tsim cov khoom sib txuam ua tau zoo thiab tsis tu ncua. Cov txheej txheem no suav nrog kev siv cov khoom tsim ua ntej hu ua inserts, ntxig rau hauv pwm ua ntej txhaj tshuaj molding tshwm sim. Cov ntxig no tuaj yeem tsim los ntawm ntau yam ntaub ntawv, txhua tus muaj cov khoom tshwj xeeb thiab cov txiaj ntsig. Ntawm no peb yuav tham txog cov khoom siv feem ntau siv hauv kev txhaj tshuaj molding thiab lawv qhov zoo.

co

Kev txhaj tshuaj molding dav siv cov khoom siv los ntawm cov hlau xws li steel, aluminium, thiab tooj dag. Cov ntaub ntawv no muaj lub zog zoo thiab ua haujlwm ntev, ua rau lawv zoo tagnrho rau cov khoom uas yuav tsum tau hnav thiab tsim kua muag. Tsis tas li ntawd, cov hlau ntxig tuaj yeem tiv taus qhov kub thiab txias, ua rau lawv tsim nyog rau kev siv hauv kev thov xws li aerospace thiab automotive industries. Qee qhov tshwj xeeb zoo ntawm kev siv hlau ntxig hauv kev txhaj tshuaj molding suav nrog:

- Siab zog thiab durability

- Zoo heev kub tsis kam

- corrosion kuj

- Muaj peev xwm tiv taus siab thiab kev ntxhov siab

Yas

Plastic inserts kuj tseem siv rau hauv kev txhaj tshuaj molding, nrog rau cov ntaub ntawv xws li PEEK, PTFE, thiab UHMW yog cov kev xaiv nrov. Cov ntaub ntawv no muaj qhov kub thiab txias tsis kam, tshuaj lom neeg tsis kam, thiab tsis muaj kev sib txhuam. Cov khoom no yog qhov zoo rau kev siv hauv cov khoom siv kho mob thiab kev tsim khoom semiconductor vim lawv qhov siab thiab huv, uas yog qhov tseem ceeb hauv cov ntawv thov no. Qee qhov tshwj xeeb zoo ntawm kev siv cov yas ntxig rau hauv kev txhaj tshuaj molding muaj xws li:

- Cov tshuaj tiv thaiv siab

- Zoo heev kub kuj

- Kev sib txhuam tsawg

- Yooj yim rau tshuab thiab zoo li

ceramics

Hauv kev txhaj tshuaj molding, ceramic inserts pom siv vim lawv lub zog siab, hardness, thiab hnav tsis kam. Cov ntaub ntawv no zoo tagnrho rau siv rau hauv cov ntawv thov uas qhov yuav tsum tau tiv taus qhov kub thiab txias los yog ib puag ncig hnyav. Tsis tas li ntawd, ceramic inserts muab kev ruaj ntseg zoo heev, ua rau lawv haum rau precision engineering daim ntaub ntawv. Qee qhov tshwj xeeb zoo ntawm kev siv cov khoom siv ceramic hauv kev txhaj tshuaj molding muaj xws li:

- Siab zog thiab hardness

- Zoo heev hnav tsis kam

- Kev kub siab ua haujlwm

- Dimensional stability

Composites

Cov ntaub ntawv sib xyaw, xws li carbon fiber lossis fiberglass, yog siv rau hauv kev txhaj tshuaj molding rau lawv lub zog-rau-hnyav piv. Kev lag luam aerospace thiab automotive feem ntau siv cov ntaub ntawv no qhov kev txo qhov hnyav yog qhov tseem ceeb. Composite inserts muab siab tawv thiab lub zog, ua rau lawv zoo tagnrho rau cov cua turbines thiab cov khoom siv ua kis las ua haujlwm siab. Qee qhov tshwj xeeb zoo ntawm kev siv cov khoom sib xyaw hauv kev txhaj tshuaj molding suav nrog:

- Siab zog-rau-phaus piv

- Siab nruj thiab muaj zog

- Kev cuam tshuam zoo

- Tsawg thermal expansion coefficient

Roj hmab

Cov khoom siv roj hmab, xws li silicone lossis neoprene, yog siv rau hauv kev txhaj tshuaj molding rau lawv qhov yooj yim thiab sealing zog. Cov ntaub ntawv no feem ntau yog siv rau hauv kev kho mob thiab kev lag luam tsheb uas qhov kev sib khi thiab cushioning yog qhov tseem ceeb. Rubber inserts muab cov tshuaj tiv thaiv zoo heev rau cov tshuaj thiab qhov kub thiab txias, ua rau lawv zoo tagnrho rau kev siv hauv qhov chaw hnyav. Qee qhov tshwj xeeb zoo ntawm kev siv roj hmab ntxig hauv kev txhaj tshuaj molding suav nrog:

- Cov khoom sealing zoo heev

- Npaws yooj

- Tshuaj thiab kub tsis kam

- Zoo vibration damping

ua npuas ncauj

Cov ntaub ntawv ua npuas ncauj, xws li polyurethane lossis polystyrene, yog siv rau hauv kev txhaj tshuaj molding rau lawv cov khoom sib sib zog nqus thiab poob siab. Cov ntaub ntawv no feem ntau siv rau hauv kev ntim khoom thiab kev lag luam automotive qhov twg cushioning thiab cuam tshuam yog qhov tseem ceeb. Foam inserts muaj kev rwb thaiv tsev siab, ua rau lawv zoo tagnrho rau kev siv kub-rhiab heev. Qee qhov tshwj xeeb zoo ntawm kev siv cov npuas dej ntxig hauv kev txhaj tshuaj molding muaj xws li:

- Lub teeb thiab yoog raws

- Kev poob siab zoo heev

- Kev rwb thaiv tsev zoo

- Nws muaj peev xwm los pwm rau hauv cov duab complex

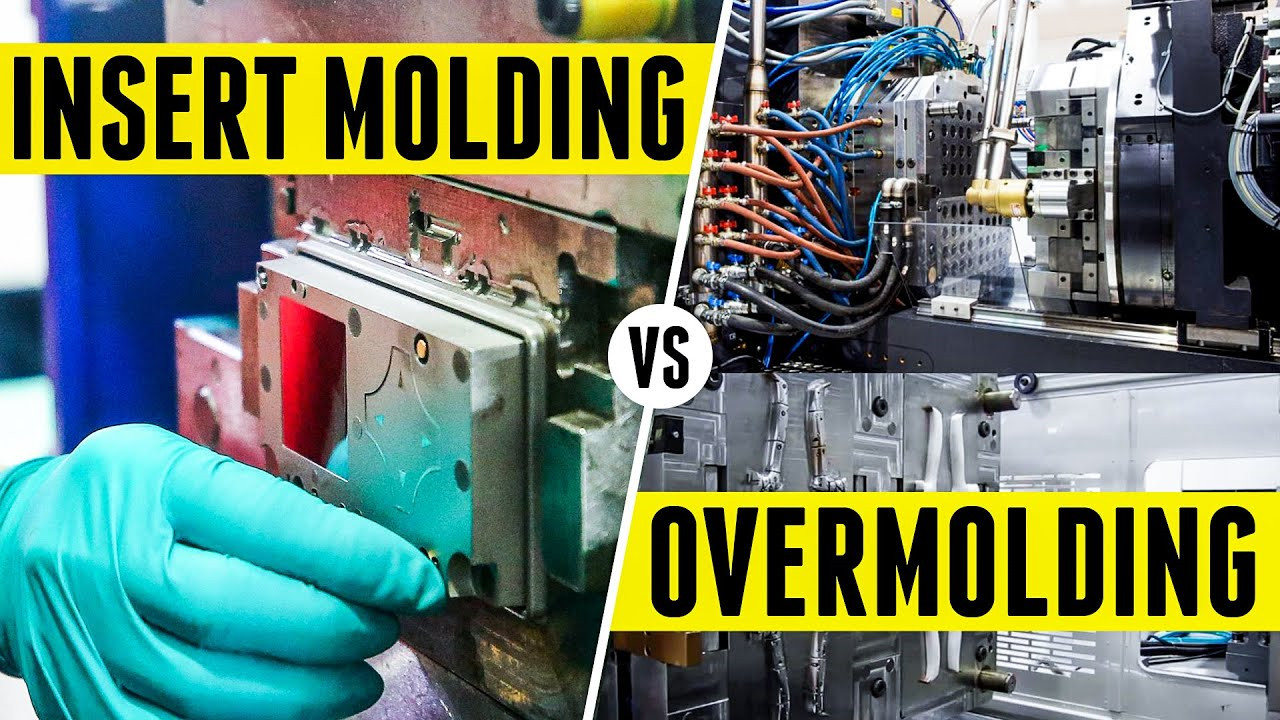

Ntxig Molding vs. Overmolding: Qhov txawv yog dab tsi?

Ntxig molding thiab overmolding yog ob txoj kev siv ntau hauv kev txhaj tshuaj molding uas muaj ntau yam ntaub ntawv. Txawm hais tias cov txheej txheem no yuav zoo sib xws, lawv muaj qee qhov sib txawv. Ntawm no peb yuav tham txog qhov sib txawv ntawm kev ntxig molding thiab over-molding.

Ntxig Moulding

Ntxig molding yog txheej txheem uas koom nrog kev ntxig ntawm cov khoom ua ntej, hu ua inserts, rau hauv pwm ua ntej txheej txheem txhaj tshuaj molding. Cov khoom siv yas yog tom qab ntawd txhaj ib ncig ntawm cov khoom ntxig, tsim cov khoom tiav uas sib txuas cov khoom ntawm cov ntxig thiab cov khoom yas. Cov txheej txheem no feem ntau yog siv rau hauv kev lag luam tsheb, kev kho mob, thiab kev lag luam aerospace los tsim cov khoom siv nrog cov qib siab ntawm qhov tseeb.

Qhov zoo ntawm insert molding

- High precision thiab raug

- Txhim kho ib feem lub zog thiab durability

- Txo lub sij hawm sib dhos thiab tus nqi

- Muaj peev xwm ua ke cov khoom siv nrog cov khoom sib txawv

Sib tshooj

Overmolding yog ib qho txheej txheem uas cuam tshuam nrog kev txhaj tshuaj molding ntawm cov khoom thib ob dhau ntawm qhov uas twb muaj lawm. Cov neeg tsim khoom siv cov txheej txheem no los tsim cov tes kov, tuav, thiab lwm yam khoom siv. Cov khoom siv molded feem ntau yog mos thiab zoo li roj hmab, muab kev tuav thiab kev nplij siab. Nyob ntawm ib feem ntawm qhov nyuaj, peb tuaj yeem ua dhau-moulding hauv ib qho kev txhaj tshuaj ib zaug lossis ob zaug txhaj tshuaj.

Qhov zoo ntawm over-molding

- Txhim kho ergonomics thiab zoo nkauj

- Txhim kho tuav thiab kev nplij siab

- Txo lub sij hawm sib dhos thiab tus nqi

- Muaj peev xwm ua ke cov khoom siv nrog cov khoom sib txawv

Qhov sib txawv ntawm kev ntxig molding thiab over-molding

- Ntxig molding yuav tsum tau ntxig cov khoom ua ntej-fabricated, thaum overmolding muaj kev txhaj tshuaj molding ntawm ib qho khoom thib ob dhau ntawm qhov uas twb muaj lawm.

- Peb siv cov txheej txheem molding los tsim cov khoom nrog cov qib siab ntawm qhov tseeb, thaum peb siv ntau tshaj molding los txhim kho ergonomics thiab zoo nkauj ntawm cov khoom.

- Ntxig molding koom nrog kev sib txuas cov ntaub ntawv nrog cov khoom sib txawv, thaum tshaj molding yuav siv cov khoom muag, zoo li roj hmab rau feem ntau molded.

- Ntxig molding feem ntau yog siv nyob rau hauv tsheb, kho mob, thiab aerospace kev lag luam, thaum over- molding yog feem ntau siv nyob rau hauv cov neeg siv khoom xws li cov cuab yeej, electronics, thiab cov khoom tu tus kheej.

Cov txheej txheem rau Insert Placement

Ntxig molding yog txheej txheem uas ua ntej ua ntej, los yog ntxig, muab tso rau hauv pwm ua ntej txheej txheem txhaj tshuaj molding tshwm sim. Cov khoom siv yas yog txhaj ib ncig ntawm cov khoom siv los tsim cov khoom tiav. Muab cov ntxig ntxig yog qhov tseem ceeb rau kev ua tiav ntawm cov txheej txheem molding. Ntawm no peb yuav tham txog qee cov tswv yim rau kev tso chaw tso.

- Kev tuav pov hwm: Tus neeg teb xov tooj manually tso cov ntxig rau hauv pwm hauv cov txheej txheem no. Cov neeg tsim khoom feem ntau siv cov txheej txheem no rau qhov me me lossis ncaj nraim uas yuav tsum tau tsuas yog ob peb qhov ntxig. Txawm li cas los xij, nws tuaj yeem siv sijhawm ntev thiab siv zog ua haujlwm, thiab muaj kev pheej hmoo siab dua ntawm kev ua yuam kev vim qhov kev tso kawm ntawm phau ntawv.

- Automated qhov chaw: Nyob rau hauv cov txheej txheem no, cov inserts yog muab tso rau hauv pwm siv lub computer system, xws li ib tug neeg hlau los yog ib tug pick-and-place machine. Cov txheej txheem no sai dua thiab muaj tseeb dua li kev muab tso rau hauv phau ntawv, ua rau nws zoo tagnrho rau kev tsim khoom loj los yog qhov chaw nyuaj. Txawm li cas los xij, nws yuav tsum tau nqis peev thawj zaug hauv cov cuab yeej siv thiab tej zaum yuav xav tau tus nqi ntau dua rau kev tsim khoom me me.

- Ntxig molding over-molding: Peb muab cov khoom tso rau hauv ib qho thib ob, tshaj-molded ib feem thiab tom qab ntawd muab tso rau hauv thawj pwm. Cov neeg tsim khoom feem ntau siv cov txheej txheem no rau kev thov nrog cov geometry nyuaj lossis thaj chaw nyuaj. Nws tseem tuaj yeem muab cov khoom sib txawv nrog cov khoom sib txawv, xws li cov yas ntxig ntxig nrog cov khoom muag muag.

- Adhesive-backed inserts:Nyob rau hauv cov txheej txheem no, peb pre-coated lub inserts nrog ib tug nplaum thaub qab, cia peb muab tso rau hauv lub pwm yam tsis tas yuav tsum tau phau ntawv los yog automated qhov chaw. Cov nplaum rov qab melts thaum lub sij hawm txhaj tshuaj molding, bonding lub ntxig rau cov khoom yas. Cov txheej txheem no feem ntau yog siv rau cov khoom me me, yooj yim thiab tuaj yeem txo cov sij hawm tsim khoom thiab tus nqi.

- Threaded inserts: Hauv cov txheej txheem no, threaded inserts yog muab tso rau hauv pwm thiab siv los tsim cov xov hauv cov khoom tiav. Cov neeg tsim khoom feem ntau siv cov txheej txheem no hauv kev tsim cov khoom lag luam uas yuav tsum tau ntxig cov ntsia hlau lossis ntsia hlau, xws li cov khoom siv hluav taws xob lossis cov khoom siv tsheb.

Hom Insert Txhaj Moulding Tshuab

Ib qho tseem ceeb ntawm cov txheej txheem txhaj tshuaj molding yog lub tshuab txhaj tshuaj molding. Cov tshuab no tuaj nyob rau hauv ntau hom, txhua tus muaj cov yam ntxwv tshwj xeeb thiab qhov zoo. Ntawm no peb yuav saib ntau hom kev txhaj tshuaj molding tshuab.

Ua ntej, cia peb txhais qhov kev txhaj tshuaj molding tshuab yog dab tsi. Lub tshuab txhaj tshuaj molding tshuab yog lub tshuab txhaj tshuaj molding uas tso cai rau kev nkag mus ntawm cov khoom siv ua ntej, xws li cov hlau lossis yas ntxig rau hauv pwm ua ntej txhaj cov khoom yas. Nrog rau qhov muaj peev xwm no, nws tuaj yeem ua tau los tsim cov khoom nyuaj uas yuav tsum tau muaj cov yam ntxwv ntxiv xws li cov xov qhib lossis cov hlau txhawb nqa.

Nov yog ntau hom kev txhaj tshuaj molding tshuab:

- Vertical txhaj tshuaj molding tshuab:Cov tshuab no muaj cov qauv kev taw qhia ntsug, qhov twg lawv mount lub pwm vertically. Lawv yog qhov zoo tagnrho rau kev ntxig molding vim lawv tso cai yooj yim ntawm cov ntxig rau hauv pwm los ntawm sab saum toj. Hom tshuab no kuj siv qhov chaw hauv pem teb tsawg dua thiab zoo dua rau kev ua haujlwm me me.

- Kab rov tav txhaj molding tshuab:Cov cav tov no muaj ib qho kev taw qhia tiaj tus, qhov twg lawv mount lub pwm horizontally. Lawv muab qhov zoo tshaj plaws haum rau kev ua haujlwm loj dua, thiab cov tuam ntxhab feem ntau siv lawv los tsim cov khoom tseem ceeb. Nrog cov tshuab kab rov tav, cov ntawv ntxig tuaj yeem thauj khoom los ntawm sab, ua rau nws yooj yim dua los xyuas kom muaj kev sib raug zoo.

- Rotary rooj txhaj tshuaj molding tshuab:Cov tshuab no muaj lub rooj sib hloov uas tso cai rau ntau yam pwm tuaj yeem txuas thiab tig mus rau hauv chav txhaj tshuaj rau kev tsim khoom. Hom tshuab no zoo tagnrho rau kev ntxig molding vim nws yuav ua kom muaj ntau yam ntxig rau hauv pwm, tsim ntau qhov chaw.

- Shuttle txhaj molding tshuab: Cov tshuab no muaj lub shuttle uas txav cov pwm rov qab los ntawm qhov chaw txhaj tshuaj thiab qhov chaw molding. Lawv yog qhov zoo tshaj plaws rau kev ua haujlwm me me thiab yog qhov zoo tagnrho rau kev ntxig molding vim lawv tso cai rau kev thauj khoom yooj yim thiab tshem tawm ntawm cov khoom siv.

Txheej txheem Parameter rau Insert Moulding

Cov khoom tsim tau muaj zog ntau dua thiab kav ntev dua piv rau kev txhaj tshuaj molding. Cov txheej txheem tsis zoo rau kev ntxig molding yog qhov tseem ceeb hauv kev ua tiav cov txiaj ntsig zoo thiab zoo ib yam. Ntawm no peb yuav saib cov txheej txheem tsis rau ntxig molding.

- Kev xaiv khoom siv: Kev xaiv cov khoom yog ib qho tseem ceeb ntawm cov txheej txheem rau kev ntxig molding. Cov khoom siv yas yuav tsum sib haum nrog cov khoom siv ntxig thiab daim ntawv thov. Compatibility ua kom ntseeg tau tias cov ntaub ntawv ntxig thiab cov khoom siv yas ua ke zoo, ua rau cov khoom muaj zog thiab ruaj khov.

- Kub: Kub ua lub luag haujlwm tseem ceeb hauv cov txheej txheem molding. Peb yuav tsum teem lub pwm kub kom raug los xyuas kom meej cov khoom yas ntws uniformly thiab puv lub kab noj hniav yam tsis muaj voids los yog deformations. Peb kuj yuav tsum xav txog qhov ntsuas kub kom ntseeg tau tias cov khoom siv yas ua raws li qhov zoo ntawm qhov ntxig tsis ua rau thermal puas.

- Txhaj Tshuaj: Kev txhaj tshuaj siab yog lwm qhov tseem ceeb rau kev ntxig molding. Peb yuav tsum tau teem lub nro kom raug kom peb uniformly thiab sai sai txhaj cov khoom yas rau hauv pwm kab noj hniav. Kev txhaj tshuaj siab tuaj yeem ua rau deformation ntawm cov ntxig lossis cov pwm, thaum qhov kev txhaj tshuaj tsawg tuaj yeem ua rau tsis tiav ntawm cov pwm kab noj hniav.

- Txhaj Ceev: Kev txhaj tshuaj nrawm kuj yog qhov tseem ceeb rau kev ntxig molding. Peb yuav tsum teeb tsa tus nqi kom raug txhawm rau xyuas kom cov khoom siv yas sib npaug ntawm cov pwm kab noj hniav yam tsis muaj voids lossis deformations. Kev txhaj tshuaj siab ceev tuaj yeem ua rau muaj kev kub ntxhov hauv cov khoom siv yas, ua rau muaj qhov tsis xws luag hauv cov khoom tiav.

- Lub sijhawm txias: Lub sijhawm txias yog xav tau rau cov khoom siv yas kom ruaj khov thiab tsim cov khoom kawg. Peb yuav tsum teem lub sijhawm txias kom raug los xyuas kom meej tias peb ua tiav cov duab thiab qhov loj me rau cov khoom tiav. Lub sij hawm txias dua tuaj yeem ua rau deformation lossis shrinkage, thaum lub sij hawm txias txias tuaj yeem ua rau lub sij hawm ntev dua thiab txo cov khoom tsim tau.

- Lub Sijhawm Ejection: Peb xav tau lub sij hawm ejection los eject cov khoom tiav los ntawm pwm. Peb yuav tsum teem lub sij hawm ejection kom raug tshem tawm cov khoom tiav yam tsis muaj kev puas tsuaj los yog deformation. Lub sij hawm ejection luv luv tuaj yeem ua rau tsis tiav ejection lossis kev puas tsuaj rau cov khoom, thaum lub sij hawm ejection ntev tuaj yeem ua rau lub sij hawm ntev dua thiab txo cov khoom lag luam.

Common Insert Molding Defects thiab yuav ua li cas kom tsis txhob lawv

Ntxig molding yog txheej txheem tsim khoom nrov uas suav nrog kev tso cov khoom ua ntej, xws li hlau lossis yas ntxig rau hauv pwm ua ntej txhaj cov khoom yas. Cov txheej txheem no ua rau muaj ntau yam khoom siv thiab ruaj khov dua li kev txhaj tshuaj molding. Txawm li cas los xij, zoo li txhua txoj kev tsim khoom, ntxig molding tuaj yeem muaj qhov tsis xws luag uas cuam tshuam rau qhov zoo thiab sib xws ntawm cov khoom kawg. Ntawm no peb yuav saib ze dua ntawm cov txheej txheem molding tsis xws luag thiab yuav ua li cas kom tsis txhob muaj lawv.

nyem: Flash yog qhov tsis xws luag uas tshwm sim thaum cov khoom yas ntau dhau los ntawm cov pwm thiab tsim cov txheej nyias nyias ntawm cov khoom tiav. Qhov kev tsis zoo no tuaj yeem cuam tshuam rau cov tsos thiab kev ua haujlwm ntawm cov khoom. Txhawm rau zam flash, koj tuaj yeem ua cov kauj ruam hauv qab no:

- Txo qhov kev txhaj tshuaj siab

- Ua kom cov pwm clamping quab yuam

- Siv cov pwm tso tawm tus neeg sawv cev

- Ua kom lub sijhawm txias

Short Shot: Kev txhaj tshuaj luv luv yog qhov tsis xws luag uas tshwm sim thaum cov khoom siv yas tsis tuaj yeem ua rau pwm kab noj hniav, ua rau cov khoom tsis tiav lossis cov khoom tsis zoo. Txhawm rau zam kev txhaj tshuaj luv luv, koj tuaj yeem ua cov kauj ruam hauv qab no:

- Ua kom lub zog txhaj tshuaj

- Nce qhov txhaj tshuaj ceev

- Ua kom cov khoom kub

- Ua kom pwm kub

Warpage: Warpage yog qhov tsis xws luag thaum cov khoom tiav ua deformed los yog twisted vim qhov txias txias los yog shrinkage. Txhawm rau zam Warpage, koj tuaj yeem ua cov kauj ruam hauv qab no:

- Ua kom pwm kub

- Ua kom lub sijhawm txias

- Ua kom lub ntim ntim siab

- Siv lub tshuab ua kom txias txias

Sink Marks: Sink marks yog kev nyuaj siab los yog indentations uas tshwm sim nyob rau saum npoo ntawm cov khoom tiav vim tsis txias txias los yog shrinkage. Txhawm rau zam cov cim dab dej, koj tuaj yeem ua cov kauj ruam hauv qab no:

- Ua kom pwm kub

- Ua kom lub sijhawm txias

- Ua kom lub ntim ntim siab

- Siv cov phab ntsa tuab los yog ribbing kom ntxiv dag zog rau cov khoom

Delamination: Delamination yog qhov tsis xws luag uas tshwm sim thaum cov khoom siv yas thiab cov khoom siv ntxig tsis sib raug zoo, ua rau kev sib cais lossis tev tawm. Txhawm rau kom tsis txhob delamination, koj tuaj yeem ua cov kauj ruam hauv qab no:

- Siv cov khoom siv yas sib xyaw thiab ntxig cov khoom siv

- Ua kom lub zog txhaj tshuaj thiab ceev

- Ua kom qhov kub thiab txias

- Ua kom pwm kub

Tom qab Molding Kev Ua Haujlwm rau Insert Molding

Txawm li cas los xij, tom qab ua tiav cov txheej txheem molding, peb yuav tsum ua ntau yam kev ua haujlwm tom qab molding kom ntseeg tau tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb. Ntawm no peb yuav saib ze dua ntawm kev ua haujlwm tom qab molding rau ntxig molding.

- Deflashing:Deflashing yog txheej txheem uas tshem tawm cov khoom siv ntau dhau, xws li flash lossis burrs, los ntawm cov khoom tiav. Cov txheej txheem no tuaj yeem ua tau manually lossis txiav, nyob ntawm qhov loj thiab qhov nyuaj ntawm cov khoom.

- Trimming:Trimming yog txheej txheem uas tshem tawm cov khoom siv ntau dhau los yog cov khoom tawm ntawm cov khoom tiav. Cov txheej txheem no tuaj yeem ua tau siv ntau yam cuab yeej txiav lossis cov txheej txheem, nyob ntawm seb cov duab thiab qhov loj ntawm cov khoom.

- Tu: Kev ntxuav yog ib qho txheej txheem uas tshem tawm cov av, cov khib nyiab, lossis cov kab mob ntawm cov khoom tiav. Cov txheej txheem no tuaj yeem ua tau los ntawm kev siv ntau yam tshuaj ntxuav lossis cov txheej txheem, nyob ntawm seb hom khoom siv hauv cov txheej txheem ntxig molding.

- los ua ke:Kev sib dhos yog txheej txheem uas koom nrog ntau yam khoom ua ke los tsim cov khoom tiav. Cov txheej txheem no tuaj yeem ua tau siv ntau txoj hauv kev, xws li ultrasonic vuam, kub stamping, lossis nplaum nplaum, nyob ntawm seb hom khoom siv thiab cov khoom kawg xav tau.

- Kev Xeem: Kev ntsuam xyuas yog txheej txheem uas ua kom cov khoom tiav tiav raws li qhov xav tau tshwj xeeb thiab cov qauv zoo. Cov txheej txheem no tuaj yeem suav nrog ntau yam kev sim, xws li tshuab, hluav taws xob, lossis kev kuaj pom, nyob ntawm seb hom khoom thiab nws qhov kev npaj siv.

Ntxiv rau cov kev ua haujlwm tom qab molding, kuj tseem muaj ntau yam yuav tsum tau xav txog thaum tsim cov txheej txheem molding uas yuav txo qis qhov xav tau ntawm cov txheej txheem tom qab molding. Cov no suav nrog:

- Xaiv cov khoom tsim nyog rau qhov ntxig thiab qhov molded

- Xyuas kom lub insert yog tsim nyog positioned thiab tuav nyob rau hauv qhov chaw thaum lub sij hawm molding txheej txheem

- Kho cov molding tsis, xws li kub thiab siab, kom txo tau qhov tsis xws luag thiab cov khoom ntau dhau

- Siv cov pwm zoo thiab cov cuab yeej siv los xyuas kom meej qhov sib xws thiab raug nyob rau hauv cov khoom tiav

Daim ntawv thov ntawm Insert Injection Molding

Ntxig txhaj molding yog cov txheej txheem tsim khoom siv ntau yam siv hauv ntau qhov kev lag luam los tsim cov khoom zoo, cov khoom siv nrog ntau lub zog thiab ua haujlwm ntev. Ntawm no peb yuav ua tib zoo saib cov ntawv thov ntawm kev txhaj tshuaj molding thiab nws cov txiaj ntsig rau kev lag luam sib txawv.

- Automotive Kev Lag Luam:Kev lag luam tsheb yog ib qho ntawm cov neeg siv tseem ceeb tshaj plaws ntawm kev txhaj tshuaj molding. Nws pom kev siv hauv kev tsim ntau yam khoom, suav nrog lub hnab airbag, siv lub rooj zaum, thiab cov khoom siv cav. Cov txheej txheem tso cai rau qhov tseeb thiab raug molding ntawm qhov chaw uas tuaj yeem tiv taus qhov hnyav ntawm kev siv tsheb.

- Electronics Kev Lag Luam:Kev lag luam hluav taws xob tseem cia siab ntau rau kev txhaj tshuaj molding los tsim cov khoom siv xws li smartphones, laptops, thiab lwm yam khoom siv hluav taws xob. Cov txheej txheem pom kev siv hauv kev tsim cov khoom xws li connectors, keyboards, thiab vaj tse rau cov khoom siv hluav taws xob. Cov txheej txheem muaj txiaj ntsig zoo thiab tuaj yeem tsim cov khoom ntim ntau sai thiab raug nqi zoo.

- Kev lag luam kho mob: Kev lag luam kho mob kuj tau txais txiaj ntsig zoo los ntawm kev txhaj tshuaj molding. Cov txheej txheem pom kev siv los tsim ntau yam khoom siv, suav nrog cov cuab yeej phais, cov khoom xa tshuaj, thiab cov khoom siv kho mob. Cov txheej txheem ua kom cov molding meej ntawm cov ntsiab lus uas tuaj yeem tiv taus qhov nruj ntawm kev siv tshuaj kho mob thiab tso cai rau kev tsim cov ntim loj.

- Aerospace Kev Lag Luam: Kev lag luam aerospace yog lwm qhov kev lag luam uas siv kev txhaj tshuaj molding feem ntau. Cov txheej txheem pom daim ntawv thov hauv kev tsim cov khoom xws li cov pa cua, cov hlua khi, thiab cov vaj tsev rau cov khoom siv dav hlau. Cov txheej txheem tso cai rau kev tsim cov khoom siv muaj zog uas tuaj yeem tiv taus qhov kev ntxhov siab thiab qhov kub thiab txias ntawm kev siv aerospace.

- Kev lag luam khoom siv: Kev lag luam cov khoom lag luam siv cov khoom siv txhaj tshuaj molding feem ntau los tsim ntau yam khoom xws li cov khoom ua si, cov khoom siv hauv tsev, thiab cov khoom ua si. Cov txheej txheem tso cai rau kev tsim cov khoom zoo, ruaj khov, lub teeb yuag, thiab cov khoom zoo nkauj txaus nyiam.

Ntxiv nrog rau cov kev lag luam no, kev txhaj tshuaj molding kuj tseem siv tau rau ntau yam kev siv, suav nrog:

- Kev Lag Luam Ntim: rau kev tsim cov kaus mom, kaw, thiab lwm yam ntim khoom

- Kev tsim kho kev lag luam: rau tsim cov kav dej, fittings, thiab lwm yam khoom siv

- Tub rog kev lag luam: rau kev tsim khoom rau cov tub rog tsheb thiab khoom siv

Automotive Industry Applications

Kev lag luam tsheb yog ib qho ntawm cov neeg siv khoom tseem ceeb tshaj plaws ntawm cov yas txhaj tshuaj molding, vim nws yog ib qho txiaj ntsig zoo thiab muaj txiaj ntsig zoo los tsim cov khoom siv hauv tsheb. Ntawm no peb yuav ua tib zoo saib ntau yam kev siv ntawm cov yas txhaj tshuaj molding hauv kev lag luam tsheb.

- Sab hauv Cheebtsam: Sab hauv ntawm lub tsheb muaj ntau yam khoom yas tseem ceeb rau kev zoo nkauj thiab kev ua haujlwm ntawm lub tsheb. Cov khoom no muaj xws li lub dashboard, lub qhov rooj vaj huam sib luag, cov cua txias qhov cua, thiab cov kauj tsheb kauj vab. Kev txhaj tshuaj molding ua rau kev tsim cov khoom ntawm cov khoom no hauv cov ntim siab sai thiab raug nqi zoo thaum tuav cov qib siab ntawm qhov raug.

- Sab nrauv Cheebtsam: Sab nrauv ntawm lub tsheb muaj ntau yam khoom siv yas, nrog rau cov npog npog, lub teeb taub hau, thiab cov teeb pom kev zoo. Txhaj tshuaj molding ua rau cov khoom no mus rau qib siab ntawm qhov tseeb, kom ntseeg tau tias lawv ua tau raws li cov qauv kev nyab xeeb thiab cov qauv zoo uas yuav tsum muaj hauv kev lag luam tsheb.

- Cav Cheebtsam: Kev txhaj tshuaj molding tseem pom siv los tsim ntau lub cav, suav nrog cov cua nkag manifolds, lub cav npog, thiab roj lim. Peb yuav tsum tsim cov khoom no kom nruj nruj thiab cov qauv, thiab kev txhaj tshuaj molding ua rau kev tsim cov khoom xyaw zoo uas ua tau raws li cov cai no.

- Hluav taws xob Cheebtsam: Cov khoom siv hluav taws xob hauv lub tsheb, xws li cov khoom sib txuas, cov keyboards, thiab cov khoom siv hluav taws xob, kuj yog tsim los ntawm kev txhaj tshuaj molding. Cov khoom no yuav tsum ua kom ntev thiab tiv taus kev ua haujlwm hnyav, thiab kev txhaj tshuaj molding tso cai rau tsim cov khoom xyaw zoo uas tuaj yeem tiv taus cov xwm txheej no.

- HVAC Cheebtsam:Kev txhaj tshuaj molding ua rau ntau yam khoom siv hauv HVAC system ntawm lub tsheb, suav nrog cov cua txias ducts thiab qhov cua. Cov khoom siv no yuav tsum tau tsim los ua kom muaj kev tiv thaiv zoo los xyuas kom muaj cua txaus thiab qhov cua hauv lub tsheb.

Ntxiv nrog rau cov ntawv thov no, cov tuam txhab siv kev txhaj tshuaj molding los tsim ntau yam khoom siv hauv tsheb, suav nrog roj, nres, thiab lub tshuab ncua.

Cov txiaj ntsig ntawm kev siv tshuaj molding hauv kev lag luam automotive muaj ntau, suav nrog:

- Siab Zoo:Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom zoo hauv cov ntim loj, txo cov sij hawm tsim khoom thiab cov nqi.

- Precision:Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom siv nrog cov neeg siab thiab sib xws, kom ntseeg tau tias lawv ua tau raws li cov qauv nruj.

- customization: Kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim, tso cai rau cov tuam txhab tsim kho cov khoom kom tau raws li cov qauv tsim tshwj xeeb.

Kev Siv Kho Mob Kev Lag Luam

Kev lag luam kev kho mob yog ib thaj chaw uas qhov tseeb thiab kev ntseeg siab yog qhov tseem ceeb, ua cov yas txhaj tshuaj molding txheej txheem tsim khoom zoo tshaj plaws los tsim cov khoom kho mob. Ntawm no peb yuav ua tib zoo saib ntau yam kev siv ntawm cov yas txhaj tshuaj molding hauv kev lag luam kho mob.

- Kev phais phais: Kev txhaj tshuaj molding tsim ntau yam cuab yeej phais, suav nrog forceps, clamps, thiab scalpels. Cov neeg tsim khoom yuav tsum tsim cov khoom no kom nruj nruj thiab cov qauv kom ntseeg tau qhov tseeb thiab qhov tseeb.

- Cov cuab yeej kho mob:Cov neeg tsim khoom kuj tseem siv kev txhaj tshuaj molding los tsim cov khoom siv kho mob, xws li catheters thiab cov khoom ua pa. Txhawm rau lav qhov kev nyab xeeb thiab kev cia siab ntawm cov neeg mob, cov neeg tsim khoom yuav tsum tsim cov khoom no raws li cov qauv nruj.

- Diagnostic Components: Cov neeg tsim khoom siv kev txhaj tshuaj molding los tsim ntau yam khoom siv hauv kev kuaj mob, xws li pipettes, syringes, thiab test tubes. Cov khoom siv no yuav tsum raug tsim los ua kom muaj kev tiv thaiv zoo kom ntseeg tau tias qhov kev xeem raug raug.

- Ntim: Kev txhaj tshuaj molding ua rau ntim rau cov khoom kho mob, xws li cov tais tsis muaj menyuam, cov thawv ntim khoom, thiab cov khoom ntim khoom. Cov khoom no yuav tsum raug tsim los rau cov qauv nruj kom ntseeg tau tias muaj menyuam tsis taus thiab kev nyab xeeb ntawm cov khoom siv kho mob.

- Cov Khoom Siv Kho Hniav: Kev txhaj tshuaj molding ua rau ntau yam khoom siv kho hniav, suav nrog lub qhov ncauj qhov ntswg, cov tais, thiab cov khoom orthodontic. Cov khoom siv no yuav tsum raug tsim los ua kom haum rau kev ua kom haum thiab kev nplij siab rau tus neeg mob.

Ntxiv nrog rau cov ntawv thov no, cov chaw tsim khoom siv kev txhaj tshuaj molding los tsim ntau yam khoom siv kho mob, suav nrog cov khoom siv dag zog, cov khoom siv hnov lus, thiab cov cuab yeej kuaj.

Cov txiaj ntsig ntawm kev siv tshuaj molding hauv kev lag luam kho mob muaj ntau, suav nrog:

- High Precision:Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom siv nrog cov qib siab ntawm qhov raug thiab sib xws, kom ntseeg tau tias lawv ua tau raws li cov qauv nruj.

- customization:Kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim, tso cai rau cov tuam txhab tsim kho cov khoom kom tau raws li cov qauv tsim tshwj xeeb.

- Tus nqi-Siv tau: Kev txhaj tshuaj molding yog cov txheej txheem tsim khoom tsim nyog uas tsim cov khoom zoo hauv cov ntim loj, txo cov sij hawm tsim khoom thiab cov nqi.

Electronic Industry Applications

Kev lag luam hluav taws xob yog ib thaj chaw uas vam khom ntau rau cov txheej txheem tsim khoom muaj txiaj ntsig thiab muaj txiaj ntsig. Yas txhaj tshuaj molding yog txheej txheem zoo tshaj plaws los tsim cov khoom siv hluav taws xob vim nws qhov tseeb, ntau yam, thiab ceev. Ntawm no peb yuav ua tib zoo saib ntau yam kev siv ntawm cov yas txhaj tshuaj molding hauv kev lag luam hluav taws xob.

- connectors: Kev txhaj tshuaj molding ua ntau yam khoom siv hauv kev lag luam hluav taws xob, suav nrog USB txuas, HDMI txuas, thiab lub suab jacks. Cov Cheebtsam no yuav tsum raug tsim los ua kom muaj kev sib haum xeeb kom ua tau raws li kev ua haujlwm thiab kev sib raug zoo.

- Housings thiab Enclosures: Kev txhaj tshuaj molding tsim cov vaj tsev thiab cov ntaub thaiv npog rau cov khoom siv hluav taws xob, suav nrog cov xov tooj ntawm tes, laptops, thiab lwm yam khoom siv hluav taws xob. Cov neeg tsim khoom yuav tsum tsim cov khoom no kom meej meej kom paub meej tias haum thiab ua haujlwm.

- Hloov: Kev txhaj tshuaj molding ua rau ntau hom kev tswj uas siv hauv cov khoom siv hluav taws xob, suav nrog cov keyboards rocker, laub-khawm keyboards, thiab swb keyboards. Cov khoom siv no yuav tsum raug tsim los ua kom muaj kev ua siab ntev kom ntseeg tau tias muaj nuj nqi.

- LED Cheebtsam:Kev txhaj tshuaj molding ua rau ntau yam khoom siv hauv LED teeb pom kev zoo, suav nrog cov lo ntsiab muag, cov tsom iav, thiab diffusers. Cov neeg tsim khoom yuav tsum tsim cov khoom siv no kom meej cov lus qhia kom ntseeg tau tias lub teeb pom kev zoo thiab ua haujlwm tau zoo.

- Cov Khoom Siv Hluav Taws Xob: Kev txhaj tshuaj molding ua rau ntau yam khoom siv hauv cov khoom siv hluav taws xob, suav nrog cov qhov (socket), plugs, thiab cable txuas. Cov khoom siv no yuav tsum raug tsim los ua kom muaj kev ua siab ntev kom muaj kev nyab xeeb thiab txhim khu kev qha.

Ntxiv nrog rau cov ntawv thov no, cov tuam txhab siv tshuaj molding los tsim ntau yam khoom siv hluav taws xob, suav nrog cov keyboards, cov nas hauv computer, thiab cov chaw taws teeb tswj.

Cov txiaj ntsig ntawm kev siv tshuaj molding hauv kev lag luam hluav taws xob muaj ntau, suav nrog:

- High Precision: Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom siv nrog cov qib siab ntawm qhov raug thiab sib xws, kom ntseeg tau tias lawv ua tau raws li cov qauv nruj.

- customization: Kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim, tso cai rau cov tuam txhab tsim kho cov khoom kom tau raws li cov qauv tsim tshwj xeeb.

- Ceev:Kev txhaj tshuaj molding yog txheej txheem tsim khoom sai thiab ua tau zoo uas tso cai rau kev tsim cov khoom zoo hauv cov ntim loj, txo cov sij hawm tsim khoom thiab cov nqi.

Aerospace Kev Lag Luam Kev Lag Luam

Kev lag luam aerospace yog ib qho kev lag luam uas yuav tsum muaj qib siab tshaj plaws ntawm qhov tseeb, qhov tseeb, thiab ua haujlwm ntev hauv tag nrho nws cov khoom. Yas txhaj tshuaj molding nyob rau hauv kev lag luam aerospace tau dhau los ua ntau dua vim nws muaj peev xwm tsim cov geometry nyuaj, txo qhov hnyav, thiab txhim kho kev ncaj ncees. Ntawm no peb yuav ua tib zoo saib ntau yam kev siv ntawm cov yas txhaj tshuaj molding hauv kev lag luam aerospace.

- Sab hauv Cheebtsam: Kev txhaj tshuaj molding ua rau ntau yam khoom siv sab hauv rau lub dav hlau, suav nrog lub rooj zaum nraub qaum, lub tais tais, thiab cov khoom siv sab hauv. Cov khoom no yuav tsum yog lub teeb yuag thiab ruaj khov, muaj peev xwm tiv taus kev ntxhov siab thiab hnav thiab tsim kua muag.

- Cov yam ntxwv ntawm tus qauv: Txhaj tshuaj molding tsim cov khoom siv rau lub dav hlau, nrog rau cov tis, cov plaub hau, thiab cov fuselage seem. Cov khoom no yuav tsum yog lub teeb yuag, muaj zog, thiab ruaj khov kom ntseeg tau tias muaj kev nyab xeeb thiab ua haujlwm ntawm lub dav hlau.

- Cav Cheebtsam:Kev txhaj tshuaj molding ua rau ntau yam khoom siv rau cov tshuab dav hlau, suav nrog cov turbine hniav, roj nozzles, thiab vaj tse. Cov khoom siv no yuav tsum raug tsim los ua kom cov lus qhia meej kom tiv taus qhov kub thiab txias, siab, thiab kev ntxhov siab.

- Hluav taws xob Cheebtsam: Kev txhaj tshuaj molding tsim cov khoom siv hluav taws xob rau cov dav hlau, suav nrog cov khoom sib txuas, cov keyboards, thiab cov hlua hlau. Cov khoom siv no yuav tsum raug tsim los ua kom muaj kev sib haum xeeb los xyuas kom muaj kev ua haujlwm zoo thiab kev ntseeg siab.

- Instrumentation Components:Txhaj tshuaj molding tsim cov cuab yeej ntsuas rau lub dav hlau, suav nrog cov tswj vaj huam sib luag thiab cov cuab yeej ntsuas vaj tsev. Cov khoom siv no yuav tsum muaj kev ruaj khov thiab tiv taus qhov kub thiab txias, siab, thiab kev vibrations.

Ntxiv rau cov ntawv thov no, cov chaw tsim khoom siv kev txhaj tshuaj molding los tsim ntau yam khoom siv rau kev lag luam aerospace, suav nrog cov hlua khi, cov hlua khi, thiab cov gaskets.

Cov txiaj ntsig ntawm kev siv tshuaj molding hauv kev lag luam aerospace muaj ntau, suav nrog:

- Qhov hnyav txo: Txhaj tshuaj molding tso cai rau kev tsim cov khoom sib sib zog nqus uas txo cov dav hlau qhov hnyav, ua rau txo qis roj noj thiab ua kom muaj zog.

- Precision:Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom nrog cov neeg siab thiab sib xws, kom ntseeg tau tias lawv ua tau raws li cov qauv nruj.

- customization:Kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim, tso cai rau cov tuam txhab tsim kho cov khoom kom tau raws li cov qauv tsim tshwj xeeb.

- Durability: Kuvnjection molding tsim cov khoom uas muaj kev ruaj khov thiab muaj peev xwm tiv taus kev ntxhov siab, kub, thiab siab, ua kom muaj kev nyab xeeb thiab kev ntseeg siab ntawm lub dav hlau.

Kev Siv Khoom Siv Khoom Siv Kev Lag Luam

Kev lag luam khoom noj khoom haus yog ib qho tseem ceeb tshaj plaws hauv kev lag luam thoob ntiaj teb. Cov khoom siv yog cov khoom uas tib neeg siv txhua hnub, suav nrog cov khoom siv hauv tsev, khoom siv hluav taws xob, khoom ua si, thiab cov khoom siv tu tus kheej. Yas txhaj tshuaj molding nyob rau hauv cov neeg siv khoom lag luam kev lag luam tau dhau los ua neeg nyiam vim nws muaj peev xwm tsim cov khoom lag luam zoo nrog qhov tseeb thiab raug. Ntawm no peb yuav ua tib zoo saib ntau yam kev siv ntawm cov yas txhaj tshuaj molding hauv kev lag luam khoom siv.

- Ntim: Kev txhaj tshuaj molding yog siv dav hauv kev tsim cov khoom ntim rau cov neeg siv khoom, suav nrog cov ntim khoom noj, lub raj mis dej haus, thiab cov thawv ntim tshuaj pleev ib ce. Kev txhaj tshuaj molding tso cai rau kev tsim cov duab thiab cov qauv tsim, kom ntseeg tau tias cov khoom ntim khoom siv tau zoo thiab pom kev zoo.

- Cov Khoom Hauv Tsev: Kev txhaj tshuaj molding ua rau ntau yam khoom siv hauv tsev, nrog rau cov khoom siv hauv chav ua noj, cov thawv ntim khoom, thiab cov khoom siv tu. Cov khoom no yuav tsum muaj zog, hnav, thiab siv tau txhua hnub.

- Cov khoom ua si: Kev txhaj tshuaj molding ua rau ntau yam khoom ua si, suav nrog cov duab ua yeeb yam, cov menyuam roj hmab, thiab cov board games. Cov khoom ua si no yuav tsum tau tsim kom muaj cov lus qhia meej kom ntseeg tau tias lawv muaj kev nyab xeeb thiab ruaj khov.

- Cov Khoom Siv Kho Tus Kheej: Kev txhaj tshuaj molding tsim cov khoom tu tshwj xeeb, suav nrog cov txhuam hniav, rab chais, thiab tshuaj zawv plaub hau. Cov khoom no yuav tsum ua kom zoo nkauj, ua haujlwm zoo, thiab tiv taus kev siv ntau zaus.

- Electronics: Kev txhaj tshuaj molding ua rau ntau yam khoom siv hluav taws xob, nrog rau cov rooj plaub, cov nyees khawm, thiab cov khoom sib txuas. Cov khoom siv no yuav tsum muaj zog, hnav, thiab tiv taus qhov kub thiab txias.

Ntxiv nrog rau cov ntawv thov no, cov tuam txhab siv tshuaj molding los tsim ntau yam khoom siv rau kev lag luam khoom siv, suav nrog cov khoom siv tsheb, cov khoom siv kho mob, thiab cov khoom siv hauv tsev.

Cov txiaj ntsig ntawm kev siv tshuaj molding hauv kev lag luam cov khoom siv yog ntau heev, suav nrog:

- Tus nqi-Siv tau:Kev txhaj tshuaj molding tso cai rau kev tsim cov khoom zoo ntawm tus nqi qis dua li lwm cov txheej txheem tsim khoom.

- Customization: Kuvnjection molding tso cai tsim cov ntsiab lus nrog cov duab thiab cov qauv tsim, tso cai rau cov tuam txhab tsim kho cov yam ntxwv kom tau raws li cov qauv tsim tshwj xeeb.

- Precision: Txhaj tshuaj molding muaj cov ntsiab lus tseeb thiab zoo ib yam uas ua tau raws li cov qauv zoo.

- Durability: Kev txhaj tshuaj molding ua rau qhov chaw ruaj khov thiab muaj peev xwm tiv taus qhov siab ntawm kev ntxhov siab, kub, thiab siab, ua kom muaj kev nyab xeeb thiab kev ntseeg siab ntawm cov khoom.

Yav tom ntej Trends hauv Insert Injection Molding

Raws li thev naus laus zis nce qib thiab cov neeg siv khoom xav tau hloov pauv, kev txhaj tshuaj molding kev lag luam tas li hloov zuj zus. Cov neeg tsim khoom ib txwm nrhiav txoj hauv kev los txhim kho kev ua tau zoo, txo cov nqi, thiab tsim cov khoom zoo dua. Ntawm no peb yuav saib qee qhov kev xav yav tom ntej hauv kev txhaj tshuaj molding.

- Automation: Automation tau dhau los ua neeg nyiam hauv kev lag luam tsim khoom, thiab kev txhaj tshuaj molding tsis muaj qhov tshwj xeeb. Cov tshuab tsis siv neeg tuaj yeem txo cov nqi zog, ua kom ntau lawm ceev, thiab txhim kho kev tswj kom zoo.

- Muaj caij nyoog: Nrog rau kev txhawj xeeb ib puag ncig zuj zus, manufacturers tab tom nrhiav txoj hauv kev los txo cov khib nyiab thiab txhim kho kev ruaj khov. Kev siv cov khoom siv rov ua dua tshiab thiab tsim cov khoom lag luam uas tuaj yeem siv tau yooj yim lossis rov siv dua tsuas yog ob peb txoj hauv kev uas cov tuam txhab daws qhov teeb meem no.

- 3D Luam Ntawv: Qee yam ntawm kev txhaj tshuaj molding twb siv 3D luam ntawv, tab sis nws muaj peev xwm ua tau ntau dua yav tom ntej. Lub peev xwm los tsim cov qauv tsim sai thiab tsim cov khoom siv kho kom haum tsuas yog ib qho zoo ntawm 3D luam ntawv.

- Advanced Materials: Cov kws tshawb fawb thiab cov chaw tsim khoom tab tom tsim cov ntaub ntawv tshiab uas tuaj yeem tiv taus ntau yam kub, kev kub ntxhov, thiab kev ntxhov siab.

- Smart Manufacturing:Kev tsim khoom ntse suav nrog kev siv thev naus laus zis los sau thiab txheeb xyuas cov ntaub ntawv hauv lub sijhawm tiag tiag, tso cai rau kev txiav txim siab sai dua thiab ua haujlwm tau zoo dua. Cov thev naus laus zis no tuaj yeem txhim kho kev tswj hwm zoo, txo qis sijhawm, thiab ua kom muaj txiaj ntsig zoo.

xaus

Ntxig txhaj tshuaj molding yog ntau yam thiab raug nqi tsim khoom uas tso cai rau kev tsim cov khoom siv nrog cov khoom sib xyaw. Nws qhov zoo dua li cov txheej txheem sib dhos ua ke ua rau nws nrov hauv ntau qhov kev lag luam, suav nrog tsheb, kho mob, hluav taws xob, aerospace, thiab cov khoom siv. Los ntawm kev nkag siab txog cov txheej txheem sib txawv, cov ntaub ntawv, thiab kev tsim cov kev txiav txim siab koom nrog hauv kev txhaj tshuaj molding, cov tuam txhab tuaj yeem txhim kho lawv cov txheej txheem tsim khoom thiab xa cov khoom zoo rau lawv cov neeg siv khoom. Raws li thev naus laus zis nce qib, peb tuaj yeem cia siab tias yuav pom ntau qhov kev siv tshiab ntawm kev txhaj tshuaj molding.