Tsawg Volume Manufacturing Service

Cov lag luam me feem ntau xav tau kev pab nrhiav kev tsim khoom tsim nyog uas tuaj yeem tsim cov khoom ntim tsawg yam tsis muaj nqi ntau. Cov lag luam me uas muaj peev txheej tsawg feem ntau yuav tsum tau kov yeej qhov teeb meem tseem ceeb vim qhov yuav tsum tau ua kom muaj txiaj ntsig zoo ntawm kev tsim cov khoom loj hauv cov qauv tsim khoom. Txawm li cas los xij, nrog qhov tshwm sim ntawm cov kev pabcuam ntim qis, cov lag luam me tam sim no tuaj yeem tsim cov khoom me me ntawm ib feem ntawm tus nqi ntawm cov qauv kev tsim khoom. Tsab ntawv xov xwm no yuav tshawb txog cov txiaj ntsig ntawm cov kev pabcuam tsim khoom ntim tsawg thiab yuav ua li cas lawv tuaj yeem pab cov lag luam me nyob hauv kev sib tw.

Low Volume Manufacturing yog dab tsi?

Kev tsim cov ntim tsawg yog hais txog kev tsim cov khoom me me, feem ntau yog los ntawm ob peb chav mus rau ob peb puas, siv cov txheej txheem tsim khoom thiab cov txheej txheem. Cov neeg tsim khoom tsim cov khoom ntim qis kom tau raws li cov kev xav tau tshwj xeeb ntawm cov lag luam me lossis kev pib ua lag luam, sib piv rau kev tsim khoom loj, uas tsom rau kev tsim cov khoom loj. Txoj hauv kev no tso cai rau cov tuam txhab kom zam dhau tus nqi siab thiab pheej hmoo ntawm kev tsim khoom loj. Cov kev pabcuam ntim tsawg siv cov kev txhaj tshuaj molding, CNC machining, 3D luam ntawv, thiab cov ntawv hlau tsim kom muaj txiaj ntsig zoo tsim cov khoom me me, ua rau nws yog ib qho kev daws teeb meem zoo tshaj plaws rau cov lag luam tab tom nrhiav rau cov nqi tsim khoom.

Cov txiaj ntsig ntawm Kev Tsim Nyog Tsawg rau Kev Lag Luam Me

Tsawg ntim kev tsim khoom muaj cov lag luam me ntau qhov zoo, muab cov nqi tsim khoom tsim tau raws li lawv cov kev xav tau tshwj xeeb. Nov yog cov txiaj ntsig tseem ceeb ntawm kev tsim khoom ntim tsawg:

- Kev txuag nqi:Cov lag luam me tuaj yeem zam cov nqi siab tshaj plaws cuam tshuam nrog cov khoom lag luam ib txwm muaj los ntawm kev xaiv cov khoom ntim qis. Nws ua rau lawv tsim cov khoom me me yam tsis muaj cov nqi teeb tsa ntau dhau lossis xav tau cov khoom lag luam tseem ceeb.

- Fast Turnaround Sijhawm:Cov kev pabcuam ntim khoom tsawg yog qhov tseem ceeb rau lub sijhawm hloov pauv sai, cia cov lag luam me tuaj yeem nqa lawv cov khoom lag luam sai. Qhov kev nrawm no ua rau lawv teb sai sai rau cov kev xav tau ntawm kev lag luam thiab siv peev nyiaj rau cov hauv kev tshwm sim.

- Flexibility nyob rau hauv Manufacturing txheej txheem:Nrog rau kev tsim khoom ntim tsawg, cov lag luam tuaj yeem xaiv los ntawm ntau cov txheej txheem tsim khoom raws li lawv cov khoom tshwj xeeb, tso cai rau lawv los kho qhov kev tsim khoom rau lawv cov kev xav tau tshwj xeeb. Ntau cov txheej txheem, suav nrog kev txhaj tshuaj molding, CNC machining, 3D luam ntawv, thiab ntawv hlau fabrication, muab qhov yooj yim xav tau kom tau raws li cov kev xav tau tshwj xeeb.

- High-Quality End Khoom:Tsawg-ntim raug tswj xyuas cov qauv zoo txawm tias tsim cov khoom me me. Cov neeg tsim khoom siv cov cuab yeej siv qib siab thiab kev txawj ntse los xyuas kom meej tias txhua yam khoom ua tau raws li qhov xav tau tshwj xeeb, ua rau cov khoom zoo kawg.

- Tsim rau Manufacturing (DFM):Cov kev pabcuam ntim tsawg feem ntau txhawb kev tsim kho kom zoo. Cov neeg tsim khoom koom tes nrog cov lag luam thaum lub sij hawm tsim qauv, muab cov lus pom zoo los txhim kho cov khoom lag luam, ua rau muaj txiaj ntsig zoo thiab muaj txiaj ntsig zoo.

- Prototyping Services:Ntau qhov kev tsim khoom ntim qis muaj peev xwm ua kom muaj peev xwm, ua rau cov lag luam me tuaj yeem rov ua dua ntawm lawv cov khoom tsim ua ntej kev tsim tawm tag nrho. Prototyping pab txheeb xyuas thiab daws qhov teeb meem tsim, ntsuas kev ua haujlwm, thiab sau cov lus qhia muaj txiaj ntsig rau kev kho kom zoo ntxiv.

- Khoom siv thiab txheej txheem xaiv:Cov kev pabcuam ntim ntim tsawg muaj ntau yam khoom siv thiab cov txheej txheem tsim khoom kom haum rau cov khoom siv sib txawv. Cov lag luam tuaj yeem xaiv cov kev xaiv tsim nyog raws li lub zog, durability, zoo nkauj, thiab tus nqi.

- Scalability:Tsawg ntim kev tsim khoom muab kev xaiv scalability rau cov lag luam me. Raws li qhov kev thov loj tuaj, cov tuam txhab tuaj yeem kho cov khoom ntim tau zoo yam tsis muaj kev nqis peev tseem ceeb lossis rov kho dua, ua kom muaj kev hloov pauv kom tau raws li kev xav tau ntawm kev lag luam.

- Txo Cov Khoom Muag Khoom Muag: Tsawg ntim kev tsim khoom txo qis cov khoom lag luam txaus ntshai rau cov lag luam me. Lawv tuaj yeem tsim cov khoom lag luam raws li qhov xav tau lossis tswj cov khoom lag luam lean, txo cov nqi thiab kev pheej hmoo cuam tshuam nrog cov khoom muag ntau dhau thiab muaj peev xwm ua tsis tiav.

Kev txuag nqi nrog cov khoom ntim tsawg

Tsawg ntim kev tsim khoom muaj ntau qhov txiaj ntsig txuag nyiaj rau kev lag luam, tshwj xeeb tshaj yog rau kev tsim khoom me me. Nov yog qee qhov txiaj ntsig tseem ceeb ntawm kev txuag nqi nrog cov khoom ntim qis:

- Txo cov nqi teeb tsa:Cov txheej txheem tsim khoom qub feem ntau suav nrog cov nqi teeb tsa siab, tshwj xeeb tshaj yog rau kev tsim khoom me me. Cov lag luam tuaj yeem zam cov nuj nqis ua ntej no los ntawm kev txhim kho cov txheej txheem tsim khoom me me los ntawm kev siv cov khoom ntim tsawg.

Tsis Muaj Yam tsawg kawg nkaus Order Quantity: Tsis zoo li kev tsim khoom loj ib txwm muaj, cov kev pabcuam ntim qis feem ntau tsis tas yuav tsum tau xaj kom tsawg kawg nkaus. Cov lag luam tuaj yeem txuag nyiaj ntawm cov khoom muag ntau dhau thiab pov tseg los ntawm tsuas yog tsim cov khoom tsim nyog.

- Tus nqi qis dua:Cov kev pabcuam ntim khoom siv tsawg siv cov cuab yeej thiab cov cuab yeej ua kom zoo rau cov khoom me me, txo tus nqi ntawm cov cuab yeej thiab txo qhov kev pheej hmoo ntawm kev ua tsis tiav.

- Cov nqi qis dua: Kev tsim khoom qub feem ntau xav tau kev yuav khoom ntau ntawm cov khoom, uas tuaj yeem ua rau cov khoom muag ntau dhau thiab pov tseg. Nrog rau kev tsim khoom ntim tsawg, cov lag luam tuaj yeem xaj cov khoom me me, txo cov khoom pov tseg thiab txo cov nqi khoom tsawg.

- Txo Cov Nqi Ua Haujlwm: Tsawg ntim kev tsim khoom feem ntau xav tau kev ua haujlwm tsawg dua li cov khoom siv ntau lawm, ua rau cov nqi ua haujlwm qis dua.

- Agile Manufacturing:Tsawg ntim kev tsim khoom muaj cov txheej txheem tsim agile, ua rau cov lag luam tuaj yeem pivot tawm sai sai raws li kev xav tau ntawm kev ua lag luam, txo qhov kev pheej hmoo ntawm kev tsim cov khoom muag ntau thiab pov tseg.

Fast Turnaround Sijhawm

Kev tsim khoom ntim tsawg yog hais txog kev tsim cov khoom me me, feem ntau tsawg dua 10,000 units. Hom kev tsim khoom no feem ntau yuav tsum tau tsim thaum tsim cov khoom tshiab, kuaj kev lag luam xav tau rau ib yam khoom tshwj xeeb, lossis tsim cov khoom uas muaj cov yam ntxwv tshwj xeeb uas tsis tshua muaj.

Lub sijhawm hloov pauv sai rau kev tsim cov ntim qis yog qhov tseem ceeb kom ua tau raws li kev xav tau ntawm kev lag luam, txo cov sij hawm ua cov hmoov txhuas, thiab ua kom lub sijhawm ua lag luam ntawm cov khoom tshiab. Nov yog qee cov tswv yim kom ua tiav lub sijhawm hloov pauv sai rau cov khoom ntim qis:

- Txhim kho cov txheej txheem tsim khoom: Cov txheej txheem yuav tsum txo qis lub sijhawm tsim khoom thiab ua kom muaj txiaj ntsig zoo. Qhov no suav nrog kev txheeb xyuas cov kab nrib pleb, ua kom yooj yim cov kauj ruam tsim khoom, thiab ua kom cov txheej txheem tsim khoom yog lean thiab agile.

- Siv cov thev naus laus zis tsim hluav taws xob: Kev tsim cov thev naus laus zis, xws li 3D luam ntawv, CNC machining, thiab txhaj tshuaj molding, tuaj yeem txo cov sij hawm tsim khoom thiab cov nqi. Cov thev naus laus zis no tso cai rau tsim cov khoom thiab cov khoom siv nrog kev ua haujlwm siab thiab raug, ua kom lub sijhawm hloov pauv sai.

- Ua haujlwm nrog cov chaw tsim khoom uas paub txog: Cov chaw tsim khoom lag luam yuav nkag siab tob txog cov txheej txheem tsim khoom thiab tuaj yeem muab kev nkag siab thiab cov lus pom zoo rau txo lub sijhawm tsim khoom. Lawv kuj yuav muaj cov kws tshaj lij thiab cov cuab yeej tsim nyog los tsim cov khoom lag luam zoo sai thiab ua tau zoo.

- Siv cov khoom siv hauv lub sijhawm (JIT) kev tsim khoom: JIT kev tsim khoom yog lub tswv yim tsim khoom uas tsuas yog tsim cov khoom thaum xav tau. Cov tswv yim no yuav pab txo qis cov khoom lag luam, txo cov sij hawm txhuas, thiab txhim kho kev tsim khoom.

- Siv cov kev coj ua lag luam agile: Agile manufacturing xyaum siv cov txheej txheem hloov tau yooj yim thiab thev naus laus zis los hloov kho sai sai rau kev hloov pauv kev lag luam. Txoj hauv kev no tso cai rau cov tuam txhab lag luam teb sai rau cov khoom lag luam tshiab thiab kev ua lag luam.

- Embrace automation: Automation technologies, xws li robotics thiab artificial txawj ntse, tuaj yeem pab txhim kho cov txheej txheem tsim khoom thiab txhim kho kev ua haujlwm. Cov thev naus laus zis no tuaj yeem ua cov haujlwm rov ua dua sai dua thiab raug dua li tib neeg, ua rau lub sijhawm hloov pauv sai dua.

- Siv cov khoom siv txhim khu kev qha: Cov neeg siv khoom ntseeg siab tuaj yeem muab cov khoom zoo thiab cov khoom siv rau lub sijhawm, txo qis hauv kev tsim khoom. Nws yog ib qho tseem ceeb los tsim kom muaj kev sib raug zoo nrog cov neeg muag khoom thiab xyuas kom lawv muaj peev xwm ua tau raws li qhov xav tau ntau lawm.

Cov txheej txheem tsim khoom yooj yim

Peb qhov kev cog lus rau kev ua tau zoo thiab cov neeg siv khoom txaus siab ua kom txhua yam khoom ua tau raws li koj xav tau.

- Peb lub tuam txhab tau cog lus los muab cov txheej txheem tsim khoom hloov tau yooj yim uas tuaj yeem hloov kho raws li kev hloov pauv ntawm peb cov neeg siv khoom. Peb nkag siab tias txhua qhov project yog qhov tshwj xeeb thiab yuav xav tau ntau txoj hauv kev, thiab peb tsim peb cov txheej txheem tsim khoom kom muaj ntau yam thiab hloov tau.

- Peb cov kws tshaj lij engineers thiab cov kws tshaj lij tuaj yeem tsim kho peb cov txheej txheem tsim khoom kom haum rau koj cov kev xav tau, txawm tias tsawg los yog siab ntim ntau lawm, ceev prototyping, los yog kev cai fabrication. Peb tuaj yeem tsim ntau yam khoom, los ntawm cov khoom me me intricate mus rau cov rooj sib txoos loj.

- Peb siv cov cuab yeej tshiab thiab cov cuab yeej siv los xyuas kom meej qhov siab tshaj plaws thiab kev ua haujlwm zoo hauv peb cov txheej txheem tsim khoom. Peb cov cuab yeej muaj software siab heev thiab automation muaj peev xwm, ua rau peb hloov pauv ntawm cov khoom sib txawv thiab cov khoom ntim tau sai.

- Peb muab ntau yam kev tsim khoom, suav nrog CNC machining, txhaj tshuaj molding, 3D luam ntawv, laser txiav, thiab lwm yam. Peb pab neeg tuaj yeem ua haujlwm nrog koj los txiav txim siab txoj kev tsim nyog tshaj plaws rau koj qhov project xav tau raws li cov khoom siv, tsim complexity, thiab ntim ntau lawm.

- Peb kuj tsim peb cov txheej txheem tsim khoom kom muaj peev xwm ua tau, ua kom peb tuaj yeem nce ntau lawm sai li sai tau raws li qhov xav tau nce. Nyob ntawm koj cov kev xav tau tshwj xeeb, peb tuaj yeem tsim cov khoom me me lossis cov khoom loj.

- Peb nkag siab tias lub sij hawm-rau-kev ua lag luam yog ib qho tseem ceeb rau ntau ntawm peb cov neeg siv khoom, thiab peb cov txheej txheem tsim khoom yooj yim ua rau peb muab cov qauv tsim sai thiab cov kev pabcuam tsim khoom. Nrog peb cov thev naus laus zis thiab kev txawj ntse, peb tuaj yeem tsim cov qauv zoo tshaj plaws sai thiab ua tau zoo, tso cai rau koj los kuaj thiab kho koj cov qauv ua ntej tsiv mus rau ntau lawm.

- Peb ua qhov tseem ceeb ntawm kev tswj hwm zoo thoob plaws hauv peb cov txheej txheem tsim khoom thiab ntiav cov txheej txheem kev sim thiab tshuaj xyuas kom ntseeg tau tias txhua yam khoom ua tau raws li peb cov neeg siv khoom xav tau. Peb pab neeg saib xyuas txhua kauj ruam ntawm cov txheej txheem, los ntawm kev xaiv cov khoom siv mus rau qhov kawg kev soj ntsuam thiab kev siv tau.

- Peb qhov kev cog lus rau kev hloov pauv tau dhau los ntawm peb cov txheej txheem tsim khoom. Peb muaj nuj nqis qhib kev sib txuas lus thiab kev koom tes nrog peb cov neeg siv khoom, cia peb nkag siab lawv cov kev xav tau thiab muab cov kev daws teeb meem. Peb pab neeg txhawb nqa cov neeg siv khoom teb yog ib txwm muaj los daws cov kev txhawj xeeb lossis cov lus nug tam sim.

High-Quality End Khoom

Peb lub tuam txhab tau cog lus tias yuav xa cov khoom zoo kawg uas ua tau raws li lossis tshaj peb cov neeg tau txais kev cia siab.

- Ntawm peb lub tuam txhab, peb ua ntej xa cov khoom zoo kawg nkaus kom tau raws li cov qauv ntawm peb cov neeg siv khoom. Peb nkag siab tias kev ua tau zoo yog qhov tseem ceeb tshaj plaws thiab siv zog ua kom dhau qhov kev cia siab los ntawm kev muab cov khoom lag luam zoo tshaj plaws ua kom kav ntev.

- Peb ntiav cov kev tswj xyuas nruj nruj thoob plaws hauv kev tsim khoom kom ntseeg tau tias txhua kauj ruam ua tau raws li cov qauv siab tshaj plaws. Los ntawm kev xaiv cov khoom siv rau kev tsim khoom thiab kev sib dhos, peb pab neeg ua haujlwm tau saib xyuas txhua theem kom lav qhov zoo thiab kev ncaj ncees ntawm cov khoom kawg.

- Peb ua haujlwm nrog lub network ntawm cov neeg muab kev ntseeg siab uas muab peb cov khoom zoo tshaj plaws uas ua tau raws li cov lus qhia zoo. Txawm hais tias nws yog hlau, yas, composites, los yog lwm yam khoom tshwj xeeb, peb tsuas yog los ntawm cov neeg muag khoom muaj koob npe los xyuas kom meej qhov zoo tshaj plaws hauv peb cov khoom.

- Peb ua peb cov txheej txheem tsim nrog precision thiab ua tib zoo saib kom meej. Peb siv cov thev naus laus zis thiab cov cuab yeej siv los xyuas kom meej qhov tseeb, sib xws, thiab rov ua dua tshiab hauv txhua yam khoom peb tsim. Peb cov kws tshaj lij thiab cov kws tshaj lij ua haujlwm saib xyuas kev tsim khoom kom paub thiab daws cov teeb meem muaj peev xwm lossis kev sib txawv ntawm qhov xav tau zoo.

- Peb nkag siab tias kev txaus siab ntawm cov neeg siv khoom tsis yog tsuas yog qhov zoo ntawm cov khoom kawg nkaus xwb tab sis kuj yog nws cov haujlwm thiab kev ua haujlwm. Peb ua cov txheej txheem kev sim thiab kev siv tau zoo los xyuas kom meej tias peb cov khoom ua tau raws li lossis tshaj tag nrho cov kev xav tau thiab kev ua tau zoo.

- Kev txhim kho txuas ntxiv yog lub hauv paus ntsiab lus tseem ceeb ntawm peb lub tuam txhab. Peb nquag nrhiav kev tawm tswv yim los ntawm peb cov neeg siv khoom thiab siv zog los koom nrog lawv cov kev nkag siab rau hauv peb cov txheej txheem tsim khoom. Los ntawm kev txhawb nqa kev kawm tas mus li thiab txhim kho kab lis kev cai, peb niaj hnub nce qhov zoo ntawm peb cov khoom kawg.

- Peb txoj kev mob siab rau kev xa cov khoom zoo kawg txuas mus rau ntau yam kev lag luam thiab kev lag luam. Txawm hais tias nws yog cov khoom siv, cov khoom siv tsheb, cov khoom siv hluav taws xob, lossis cov khoom siv hauv tsev, peb muaj kev txawj ntse thiab cov peev txheej kom ua tau raws li cov qauv zoo ntawm txhua qhov kev lag luam.

- Peb nkag siab qhov tseem ceeb ntawm kev xa khoom raws sijhawm yam tsis muaj kev cuam tshuam zoo. Peb cov txheej txheem ntau lawm thiab kev ua haujlwm tau zoo ua rau peb ua tau raws li cov sijhawm teem sijhawm thaum tswj hwm qib siab tshaj plaws ntawm kev tswj xyuas zoo.

- Peb txoj kev mob siab rau cov khoom zoo kawg tau txais peb lub koob npe nrov thiab muaj kev ntseeg siab rau cov neeg siv khoom. Peb txaus siab rau qhov kev txaus siab ntawm peb cov neeg siv khoom, thiab peb txoj kev mob siab rau kev ua tau zoo kom ntseeg tau tias txhua yam khoom tawm hauv peb qhov chaw yog qhov zoo tshaj plaws thiab kev ua haujlwm zoo.

Tsim rau Manufacturing (DFM)

Design for Manufacturing (DFM) yog ib qho kev sib koom ua ke uas tsom mus rau kev ua kom zoo rau kev tsim cov khoom lag luam los txhim kho nws cov khoom lag luam. DFM lub hom phiaj txo qis cov nqi tsim khoom, txo lub sijhawm sib dhos, thiab ua kom cov khoom zoo kawg nkaus los ntawm kev xav txog kev tsim cov txheej txheem thaum ntxov ntawm cov qauv tsim. Nov yog qee cov ntsiab lus tseem ceeb uas qhia txog qhov tseem ceeb thiab cov hauv paus ntsiab lus ntawm DFM:

- Simplified designs:DFM hais txog kev ua kom yooj yim cov qauv tsim khoom kom tshem tawm qhov tsis tsim nyog nyuaj, txo tus naj npawb ntawm cov khoom, thiab txhim kho cov txheej txheem sib dhos. Txoj hauv kev no pab txo cov nqi tsim khoom los ntawm kev txo cov khoom pov tseg, kev sib dhos tsis raug, thiab lub sijhawm tsim khoom.

- Kev xaiv cov khoom siv: Kev xaiv kom raug yog qhov tseem ceeb hauv DFM kom ntseeg tau tias muaj kev sib raug zoo nrog cov txheej txheem tsim khoom. Cov neeg tsim qauv yuav tsum xav txog yam xws li cov khoom muaj, nqi, lub zog, thiab yooj yim ntawm fabrication. Xaiv cov ntaub ntawv uas ua raws li kev tsim khoom muaj peev xwm tuaj yeem txhim kho tag nrho cov khoom siv tau zoo.

- Tsim rau kev sib dhos (DFA):DFA yog ib qho tseem ceeb ntawm DFM uas tsom rau kev tsim cov khoom lag luam rau cov pab pawg yooj yim thiab muaj txiaj ntsig. Nws suav nrog kev xav txog yam xws li kev taw qhia ib feem, kev tsim qauv ntawm cov khoom, thiab cov qauv tsim qauv. DFA txo cov nqi zog, txhim kho cov khoom zoo, thiab txo cov sij hawm ua cov khoom siv los ntawm kev txhim kho cov txheej txheem sib dhos.

- Tolerance thiab haum xav txog: Hauv DFM, cov neeg tsim qauv ua tib zoo xav txog kev zam thiab haum ntawm cov khoom kom ntseeg tau tias kev sib dhos thiab kev ua haujlwm zoo. Los ntawm kev txheeb xyuas qhov tsim nyog kam rau ua, cov neeg tsim qauv tuaj yeem txo qhov kev pheej hmoo ntawm cov teeb meem sib dhos, txhim kho kev sib hloov ntawm ib feem, thiab txo qis qhov xav tau ntawm kev rov ua haujlwm lossis hloov kho thaum tsim khoom.

Manufacturing txheej txheem compatibility: DFM txiav txim siab txog lub peev xwm thiab kev txwv ntawm cov txheej txheem tsim khoom xaiv. Txhawm rau kom muaj txiaj ntsig zoo, cov neeg tsim qauv yuav tsum nkag siab txog qhov txwv ntawm ntau yam kev tsim khoom, xws li kev txhaj tshuaj molding, machining, lossis casting, thiab tsim cov khoom tsim cov txheej txheem tsim tau sai.

- Tsim rau Testability (DFT):DFT yog ib qho tseem ceeb ntawm DFM uas tsom rau kev tsim cov khoom lag luam nrog cov yam ntxwv ua kom zoo rau kev sim thiab kev tswj kom zoo. Los ntawm kev koom ua ke cov yam ntxwv xws li cov ntsiab lus ntsuas, nkag mus rau kev sojntsuam, lossis kev kuaj tus kheej muaj peev xwm, DFT ua rau muaj kev sim ua tau zoo thaum lub sijhawm tsim khoom, txo qhov yuav ua rau cov khoom tsis raug mus txog lub khw.

Kev Pabcuam Prototyping

Cov kev pabcuam Prototyping muab cov kev daws teeb meem zoo rau cov tuam txhab thiab cov tib neeg tab tom nrhiav coj lawv cov tswv yim rau lub neej thiab ua kom lawv cov qauv tsim ua ntej ntau lawm. Cov kev pabcuam no suav nrog ntau lub peev xwm, tso cai rau kev tsim cov qauv kev ua haujlwm uas zoo ib yam li cov khoom kawg. Nov yog qee cov ntsiab lus tseem ceeb uas qhia txog qhov tseem ceeb thiab cov txiaj ntsig ntawm cov kev pabcuam prototyping:

- Irative tsim txheej txheem:Cov kev pabcuam Prototyping ua rau muaj kev tsim qauv rov ua dua, tso cai rau cov neeg tsim qauv kho kom zoo dua qub thiab txhim kho lawv cov tswv yim los ntawm ntau qhov kev rov ua dua. Los ntawm kev tsim thiab sim cov qauv sai sai, cov neeg tsim qauv tuaj yeem txheeb xyuas qhov tsis zoo ntawm cov qauv tsim, ua qhov tsim nyog hloov kho, thiab txhim kho cov khoom kawg ntawm kev ua haujlwm thiab kev zoo nkauj.

- Pov thawj ntawm lub tswvyim: Prototypes yog cov pov thawj pom tseeb ntawm lub tswv yim qhov ua tau thiab muaj peev xwm ua tiav. Los ntawm kev tsim cov qauv tsim ua haujlwm, cov neeg tsim khoom thiab cov neeg ua lag luam tuaj yeem ua kom pom qhov muaj txiaj ntsig ntawm lawv cov tswv yim rau cov tub ua lag luam, cov neeg muaj feem cuam tshuam, lossis cov neeg muaj peev xwm. Cov ntaub ntawv pov thawj ntawm lub tswv yim no tuaj yeem ua rau muaj feem ntau ntawm kev ruaj ntseg nyiaj txiag lossis tau txais kev txhawb nqa rau kev txhim kho ntxiv.

- Tsim validation thiab kuaj:Cov kev pabcuam Prototyping muab lub sijhawm los kuaj thiab siv tau cov khoom tsim ua ntej kev tsim ua tiav tag nrho. Cov qauv tsim ua haujlwm pub rau kev sim tiag tiag hauv ntiaj teb, cov neeg siv cov lus pom zoo, thiab kev ntsuas kev ua haujlwm. Los ntawm kev txheeb xyuas thiab daws qhov teeb meem ntawm kev tsim qauv thaum ntxov, cov kev pabcuam prototyping pab txo qis kev pheej hmoo, txo cov nqi, thiab txhim kho tag nrho cov khoom zoo kawg nkaus.

- Customization thiab personalization:Cov kev pabcuam Prototyping muab qhov yooj yim los tsim cov qauv tsim raws li kev cai tshwj xeeb. Txawm hais tias nws yog qhov tshwj xeeb zoo li, qhov loj me, lossis kev ua haujlwm, cov kev pabcuam no tso cai rau cov neeg tsim qauv los tshawb txog ntau yam kev ua tau zoo thiab tsim cov qauv tsim uas yog sawv cev rau lawv lub zeem muag. Qhov no customization nam pab txhawb innovation thiab txhawb txoj kev loj hlob ntawm tus kheej cov khoom.

- Lub sij hawm thiab tus nqi txuag:Kev siv cov kev pabcuam prototyping tuaj yeem ua rau lub sijhawm tseem ceeb thiab txuag nqi thaum tsim khoom. Prototypes pab tiv thaiv tus nqi rov ua dua thiab kho dua thaum lub sijhawm tsim khoom loj los ntawm kev txheeb xyuas cov teeb meem tsim tawm ntxov. Tsis tas li ntawd, cov txheej txheem prototyping sai, xws li 3D luam ntawv, ua kom lub sij hawm tig rov qab sai dua, txo lub sij hawm mus rau kev lag luam thiab tso cai rau kev rov ua dua sai dua.

- Kev sib koom tes thiab kev sib txuas lus:Prototypes yog cov cuab yeej siv sib txuas lus ntawm cov tsim qauv, engineers, thiab cov neeg muaj feem. Lawv muab ib qho kev sawv cev ntawm cov khoom lag luam, tso cai rau kev sib txuas lus pob tshab thiab kev sib koom tes zoo dua. Prototypes pab txhawb kev tsim tawm tswv yim, ua raws cov kev cia siab, thiab xyuas kom txhua tus neeg koom nrog muaj kev nkag siab txog qhov kawg ntawm cov khoom muag thiab kev ua haujlwm.

Cov ntaub ntawv thiab cov txheej txheem muaj rau cov khoom ntim qis

Peb lub tuam txhab muaj ntau yam khoom siv thiab cov txheej txheem rau kev tsim khoom ntim tsawg.

- Peb lub tuam txhab muaj ntau yam khoom siv thiab cov txheej txheem tshwj xeeb tsim rau kev tsim khoom ntim tsawg. Txawm hais tias koj xav tau cov khoom me me lossis kev tsim qauv, peb tuaj yeem ua tau raws li koj cov kev xav tau tshwj xeeb thaum tswj cov qauv zoo.

- Peb cov khoom xaiv muaj ntau yam kev xaiv tsim nyog rau kev tsim khoom ntim tsawg. Los ntawm cov hlau ib txwm muaj xws li txhuas thiab hlau mus rau cov khoom sib xyaw thiab cov yas, peb tuaj yeem ua raws li ntau yam ntawm cov khoom specifications thiab kev ua haujlwm.

- Ntxiv rau cov hlau thiab yas, peb tshwj xeeb hauv cov ntaub ntawv xws li ceramics, elastomers, thiab textiles, tso cai rau peb ua haujlwm rau ntau yam kev lag luam thiab kev siv. Peb cov kws tshaj lij cov ntaub ntawv tuaj yeem coj koj los xaiv cov ntaub ntawv tsim nyog tshaj plaws rau koj qhov project xav tau.

- Peb tsim peb cov txheej txheem tsim khoom ntim tsawg kom hloov tau thiab ua haujlwm tau zoo, ua kom cov nqi tsim khoom zoo yam tsis muaj kev cuam tshuam zoo. Peb siv cov txheej txheem siab heev xws li CNC machining, 3D luam ntawv, txhaj tshuaj molding, thiab lub tshuab nqus tsev casting kom ua tiav qhov tseeb thiab rov ua tau.

- CNC machining yog qhov tshwj xeeb zoo rau kev tsim khoom ntim tsawg vim nws muaj kev ua haujlwm siab thiab ntau yam. Nrog peb cov cuab yeej zoo tshaj plaws thiab cov kws tshaj lij tshuab, peb tuaj yeem ua tau zoo tsim cov khoom siv nrog nruj tolerances.

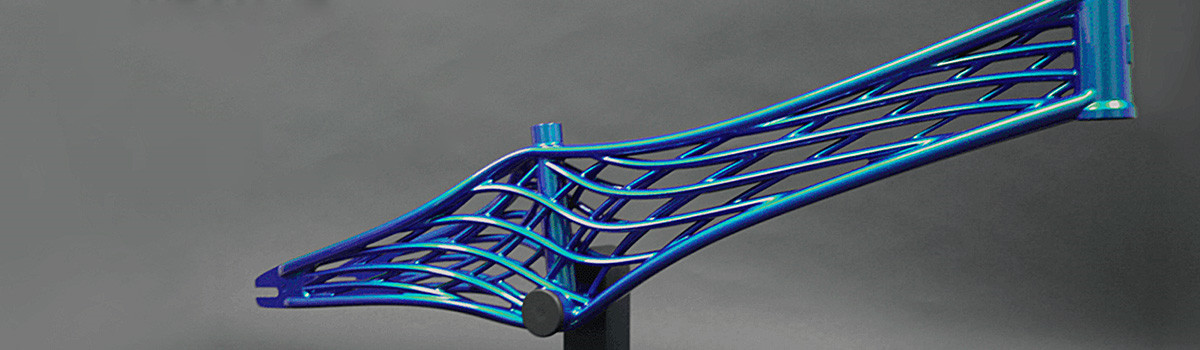

- 3D luam ntawv, lossis kev tsim khoom ntxiv, yog lwm qhov kev xaiv nrov rau cov khoom ntim qis. Nws tso cai rau prototyping sai thiab rov tsim kev hloov pauv, txo cov sij hawm txhuas thiab cov nqi. Peb siv ntau yam 3D luam ntawv thev naus laus zis, suav nrog kev xaiv laser sintering (SLS) thiab fused deposition modeling (FDM), kom ua raws li cov khoom sib txawv thiab qhov yuav tsum tau muaj.

- Kev txhaj tshuaj molding yog ib qho kev xaiv zoo tshaj plaws rau kev tsim cov khoom ntim yas tsawg. Los ntawm kev siv peb cov pwm tsim thiab cov cuab yeej txawj ntse, peb tuaj yeem tsim cov khoom zoo nrog qhov ntev thiab ua tiav.

- Lub tshuab nqus tsev casting yog ib qho txiaj ntsig zoo rau kev ua cov khoom me me ntawm cov qauv zoo los yog qhov kawg siv. Cov txheej txheem no tso cai rau siv ntau yam ntaub ntawv thiab tuaj yeem luam tawm cov ntsiab lus sib txawv thiab textures.

- Peb ua qhov tseem ceeb ntawm kev tswj xyuas qhov zoo thiab kev sim nruj me ntsis thoob plaws hauv cov txheej txheem tsim khoom ntim tsawg los xyuas kom meej tias txhua yam khoom ua tau raws li qhov koj xav tau. Peb pab neeg muaj kev paub dhau los saib xyuas txhua kauj ruam, los ntawm kev xaiv cov khoom siv thiab kev ua kom zoo tshaj plaws rau kev tshuaj xyuas zaum kawg thiab kev siv tau.

- Peb nkag siab txog cov kev sib tw tshwj xeeb thiab cov kev xav tau ntawm kev tsim khoom ntim tsawg, thiab peb pab neeg mob siab rau muab cov txiaj ntsig tshwj xeeb raws sijhawm thiab nyob rau hauv pob nyiaj siv. Txawm hais tias koj xav tau ob peb tus qauv lossis kev ua haujlwm tsawg, peb tsim peb cov ntaub ntawv thiab cov txheej txheem kom tau raws li koj cov kev xav tau tshwj xeeb thiab muab qib siab tshaj plaws ntawm cov neeg siv khoom txaus siab.

Txhaj Tshuaj Molding

Txhaj tshuaj molding yog ib txoj kev tsim khoom siv dav siv uas tsim cov khoom yas los ntawm kev txhaj tshuaj molten rau hauv pwm. Nws muaj ob peb qhov zoo, ua rau nws yog qhov kev xaiv nrov rau ntau lawm. Nov yog qee cov ntsiab lus tseem ceeb uas qhia txog qhov tseem ceeb thiab cov txiaj ntsig ntawm kev txhaj tshuaj molding:

- Ntau yam:Txhaj tshuaj molding muab tshwj xeeb versatility txog ib feem tsim thiab complexity. Nws tuaj yeem tsim cov khoom sib txawv thiab cov ncauj lus kom ntxaws nrog cov duab sib txawv, qhov ntau thiab tsawg, thiab cov yam ntxwv, suav nrog cov phab ntsa nyias, undercuts, thiab complex geometries. Qhov no versatility tso cai rau cov creation ntawm customized khoom kom tau raws li cov kev cai.

- Tus nqi tsim khoom:Kev txhaj tshuaj molding yog qhov ua tau zoo rau kev ua haujlwm loj. Thaum peb tsim cov pwm thawj zaug, ntau lawm ua sai dua thiab raug nqi ntau dua. Kev kub ceev ntau lawm thiab muaj peev xwm tsim tau ntau qhov chaw ib txhij txo qis tus nqi ib-unit, ua rau nws xaiv kev lag luam rau cov khoom ntim siab.

- Khoom siv ntau yam:Txhaj tshuaj molding txhawb ntau yam khoom siv thermoplastic thiab thermosetting, tso cai rau cov neeg tsim qauv xaiv cov khoom tsim nyog tshaj plaws rau lawv daim ntawv thov. Cov ntaub ntawv uas muaj ntau yam khoom, xws li yooj yooj yim, rigidity, pob tshab, los yog tsis kam mus rau tshav kub thiab tshuaj, tuaj yeem tsim cov khoom nrog ntau hom kev ua haujlwm.

- Consistency thiab zoo:Txhaj tshuaj molding ua kom muaj qhov zoo sib xws thiab qhov tseeb qhov tseeb. Lub automated xwm ntawm tus txheej txheem minimizes tib neeg kev ua yuam kev, uas ua rau ib tug zoo ib yam thiab repeatable ntau lawm. Tsis tas li ntawd, lub kaw pwm kaw qhov system muab kev tswj xyuas meej ntawm cov pwm pwm, tso cai rau kev tsim cov khoom zoo nrog kev ua siab ntev thiab qhov tsis xws luag.

- High ntau lawm efficiency:Txhaj tshuaj molding muaj cov voj voog ntau lawm, ua kom muaj cov khoom tsim tawm hauv lub sijhawm luv luv. Los ntawm kev sib txuas cov sij hawm ceev ceev nrog lub peev xwm los ua kom cov txheej txheem, cov lag luam tuaj yeem ua tiav cov khoom tsim tau thiab txhim kho tag nrho cov khoom siv tau zoo. Qhov kev ua tau zoo no ua rau kev txhaj tshuaj molding yog qhov kev xaiv zoo tshaj plaws rau kev ua kom tau raws li qhov xav tau sijhawm ntau lawm.

- Tsim rau manufacturing (DFM) compatibility:Kev txhaj tshuaj molding yog ua tau zoo nrog Tsim rau Kev Tsim Khoom (DFM) cov qauv. Ib qho kev xaiv zoo tshaj plaws rau DFM cov kev coj ua, nws lub peev xwm suav nrog tsim cov duab nyuaj, txhim kho kev siv cov khoom siv, thiab suav nrog cov yam ntxwv zoo li snap fits lossis nyob hinges. Cov neeg tsim qauv tuaj yeem siv cov peev txheej no los txhim kho kev tsim khoom, txo cov nqi, thiab txhim kho kev tsim khoom.

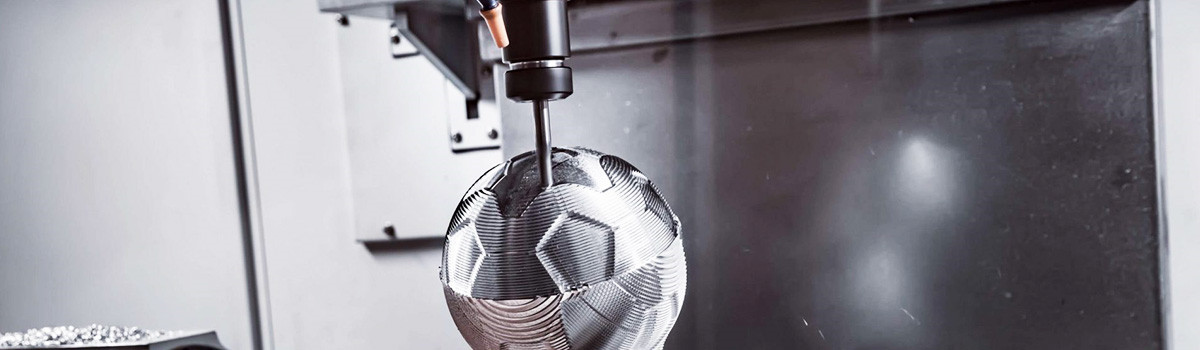

CNC Machining

CNC machining, los yog computer numerical control machining, yog txheej txheem siv los tsim cov khoom zoo thiab nyuaj los ntawm cov khoom siv raw xws li hlau, yas, lossis ntoo. Cov txheej txheem tsim khoom no suav nrog kev siv computer-aided tsim (CAD) software los tsim 3D qauv ntawm ib feem, uas tom qab ntawd hloov mus rau hauv tshuab code thiab siv los tswj lub tshuab CNC. CNC machining muaj ntau yam kev siv, los ntawm kev lag luam aerospace thiab automotive industries rau cov neeg siv khoom thiab cov khoom siv kho mob.

Cov txheej txheem ntawm CNC machining muaj ob peb kauj ruam, suav nrog:

- tsim: Thawj kauj ruam hauv CNC machining yog los tsim 3D qauv ntawm ib feem siv CAD software. Peb mam li hloov cov qauv no rau hauv tshuab code, uas peb siv los tswj lub tshuab CNC.

- Kev xaiv cov khoom siv: Cov khoom siv raw yog xaiv raws li cov khoom xav tau ntawm qhov kawg, xws li lub zog, durability, thiab kub tsis kam.

- Kev teeb tsa tshuab: Peb npaj lub tshuab CNC nrog lub tshuab code thiab ruaj ntseg cov khoom siv hauv lub tshuab.

- Machining: Lub tshuab CNC siv ntau yam cuab yeej, xws li kev xyaum, tshuab dhos, thiab mills, tshem tawm cov khoom siv raw khoom raws li lub tshuab code. Cov txheej txheem no yog qhov tseeb thiab tuaj yeem tsim cov duab thiab cov yam ntxwv.

- Tom qab ua: Thaum lub machining tiav, ib feem yuav xav tau tom qab ua tiav, xws li xuab zeb lossis polishing, kom ua tiav qhov xav tau thiab kev ntxhib los mos.

Qhov zoo ntawm CNC machining yog ntau, suav nrog:

- Precision: CNC machining yog qhov tseeb thiab tuaj yeem tsim qhov chaw nrog kev kam rau siab kom tsawg li 0.001 nti.

- efficiency: CNC machining yog cov txheej txheem tsim tau zoo heev uas tuaj yeem tsim cov khoom sai thiab raug.

- customization:CNC machining tuaj yeem tsim cov khoom lag luam customized raws li cov kev xav tau tshwj xeeb thiab nyiam.

- complexity:CNC machining tuaj yeem tsim cov duab ntau thiab cov qauv tsim uas yuav nyuaj lossis tsis tuaj yeem tsim los siv cov qauv tsim khoom.

- Zoo sib xws: CNC machining tsim cov khoom nrog cov qib siab sib xws, kom ntseeg tau tias txhua daim ua tau raws li cov lus qhia meej.

CNC machining muaj ntau yam kev siv thoob plaws ntau yam kev lag luam, suav nrog:

- Aerospace:Peb siv CNC machining los tsim aircraft cav, tis, thiab tsaws iav qhov chaw.

- Automotive: Peb siv CNC machining los ua qhov chaw rau lub cav, kis, thiab chassis.

- Kho mob: CNC machining ua cov cuab yeej phais, kev cog hniav, thiab prosthetics.

- Tus neeg siv khoom:Peb siv CNC machining los tsim txhua yam ntawm cov xov tooj smartphone mus rau cov khoom siv hauv chav ua noj.

- Architecture: Peb siv CNC machining los tsim cov khoom siv hauv tsev thiab cov khoom zoo nkauj.

3D Printing

3D luam ntawv, tseem hu ua additive manufacturing, yog ib tug revolutionary technology uas tsis ntev los no hloov lub manufacturing kev lag luam. Cov txheej txheem no suav nrog cov txheej txheem txheej txheej, feem ntau yog yas lossis hlau, nyob rau sab saum toj ntawm nws tus kheej kom txog thaum nws tsim cov duab uas xav tau, tsim cov khoom siv lub cev. 3D luam ntawv muaj ntau yam kev siv, los ntawm kev tsim qauv thiab kev tsim khoom mus rau kev tsim cov khoom siv kho mob thiab cov khoom siv kho mob.

Cov txheej txheem ntawm 3D luam ntawv muaj ob peb kauj ruam, suav nrog:

- tsim: Thawj kauj ruam hauv 3D luam ntawv yog tsim cov qauv digital ntawm cov khoom xav tau siv computer-aided design (CAD) software. Tom qab ntawd, peb xa cov qauv no mus rau lub tshuab luam ntawv 3D.

- Printing: Lub tshuab luam ntawv 3D pib txheej txheem luam ntawv los ntawm kev tsim cov txheej txheem nyias, feem ntau yog yas lossis hlau, thiab sib txuas nrog cov txheej txheem dhau los uas siv cov cua sov los yog nplaum. Peb rov ua cov txheej txheem no los ntawm txheej kom txog thaum peb tsim tag nrho cov khoom.

- Tom qab ua: Thaum luam ntawv tiav lawm, cov khoom yuav xav tau tom qab ua tiav, xws li xuab zeb lossis polishing, kom ua tiav qhov xav tau tiav thiab kev ntxhib los mos.

Qhov zoo ntawm 3D luam ntawv muaj ntau ntau, suav nrog:

- customization:3D luam ntawv tso cai rau peb los tsim cov khoom lag luam customized raws li cov kev xav tau tshwj xeeb thiab kev nyiam.

- Ceev:3D luam ntawv yog txheej txheem prototyping sai sai uas tuaj yeem tsim cov khoom siv lub cev los ntawm cov qauv digital.

- Nqi tsim nyog:3D luam ntawv tuaj yeem yog tus nqi tsim khoom, tshwj xeeb tshaj yog rau kev tsim khoom me me lossis cov khoom lag luam customized.

- complexity: 3D luam ntawv tuaj yeem tsim cov duab ntau thiab cov qauv tsim uas yuav nyuaj lossis tsis tuaj yeem tsim los siv cov qauv tsim khoom.

- Kev txo pov tseg: 3D luam ntawv minimizes pov tseg tsuas yog siv cov khoom tsim nyog los tsim cov khoom.

3D luam ntawv muaj ntau yam kev siv thoob plaws ntau yam kev lag luam, suav nrog:

- Raug: Peb tuaj yeem siv 3D luam ntawv rau prototyping, kev tsim khoom, thiab kev ua haujlwm me me.

- Kho mob: 3D luam ntawv tuaj yeem tsim cov khoom siv khomob, kev cog lus, thiab cov qauv phais rau kev npaj thiab kev cob qhia.

- Architecture: Peb tuaj yeem siv 3D luam ntawv los tsim cov qauv ntsuas thiab cov khoom tsim.

- zam: 3D luam ntawv tuaj yeem tsim tshwj xeeb, customized khaub ncaws thiab accessories.

- Education: 3D luam ntawv tuaj yeem siv rau hauv tsev kawm ntawv los qhia txog kev tsim thiab engineering.

Sheet Hlau Fabrication

Sheet hlau fabrication yog txheej txheem tsim khoom uas koom nrog kev tsim cov ntawv hlau rau hauv cov qauv sib txawv thiab cov khoom. Cov txheej txheem no muab cov txheej txheem txiav, khoov, xuas nrig ntaus, thiab vuam cov txheej txheem los hloov cov nplooj ntawv tiaj tus hlau mus rau ntau yam duab, qhov ntau thiab tsawg, thiab tsim. Ntau qhov kev lag luam, los ntawm kev tsim kho mus rau tsheb, siv cov ntaub ntawv hlau, thiab nws tseem ceeb heev rau kev tsim ntau yam khoom siv niaj hnub, nrog rau cov khoom siv hauv tsev thiab cov khoom siv hluav taws xob.

Cov txheej txheem ntawm cov ntawv hlau fabrication muaj ob peb kauj ruam, suav nrog:

- tsim:Thawj kauj ruam hauv cov ntawv hlau fabrication yog los tsim ib txoj kev npaj rau cov khoom uas xav tau. Cov lag luam tuaj yeem siv computer-aided technique (CAD) software kom ua tiav cov kev ntsuas thiab cov lus qhia tshwj xeeb.

- Txiav:Tom qab ua tiav cov qauv tsim, cov tuam txhab txiav cov ntawv hlau rau hauv qhov xav tau loj thiab cov duab siv ntau yam txuj ci, xws li laser lossis dej dav hlau.

- Dabtsi Yog Khoov: Cov kauj ruam tom ntej yog tig cov ntawv hlau rau hauv cov duab uas xav tau. Cov neeg tsim khoom siv cov cuab yeej tshwj xeeb xws li xovxwm nres los tsim cov kaum ntse ntse thiab nkhaus hauv cov hlau.

- Punching:Punching cov tswv yim yog siv los tsim cov qhov lossis lwm cov duab hauv cov hlau. Cov no tuaj yeem suav nrog stamping lossis drilling, nyob ntawm qhov nyuaj ntawm kev tsim.

Vuam: Thaum kawg, manufacturers weld ntau yam hlau ua ke los tsim cov khoom kawg. Los ntawm kev xa cov hlau mus rau qhov kub kub, peb yaj thiab fuse nws, tsim kom muaj kev ruaj khov thiab ruaj khov.

Sheet hlau fabrication muaj ntau qhov zoo dua lwm cov txheej txheem tsim khoom. Cov no suav nrog:

- Flexibility: Cov ntawv hlau tuaj yeem ua rau zoo li txhua yam duab lossis qhov loj me, ua kom muaj ntau yam rau ntau yam khoom.

- Zog:Sheet hlau muaj zog thiab ruaj khov, ua rau nws zoo tagnrho rau cov khoom uas yuav tsum tau muaj kev ruaj khov thiab kev ntseeg siab.

- Nqi tsim nyog: Sheet hlau yog qhov pheej yig, ua rau nws muaj kev xaiv pheej yig rau kev tsim khoom loj.

- Precision:Sheet hlau fabrication enables peb mus cuag cov kev ntsuas thiab specifications, xyuas kom meej peb ua txhua yam khoom mus rau cov qauv exacting.

Ntau yam kev lag luam siv cov ntawv hlau fabrication, suav nrog:

- Kev Siv: Cov tuam txhab siv cov ntawv hlau los tsim HVAC ducts, cov ntaub ntawv vov tsev, thiab lwm yam khoom siv hauv tsev.

- Automotive:Automotive manufacturers siv cov ntawv hlau los tsim lub cev tsheb, cov khoom siv cav, thiab lwm yam.

- Electronics: Cov neeg tsim khoom siv cov ntawv hlau los tsim cov rooj plaub hauv computer, cov xov tooj ntawm tes, thiab lwm yam khoom.

- Aerospace:Cov tuam txhab tsim dav hlau siv cov ntawv hlau los tsim cov khoom siv dav hlau thiab cov khoom siv.

Casting

Casting yog txheej txheem tseem ceeb hauv kev lag luam lom ze. Nws suav nrog xaiv cov neeg ua yeeb yam thiab lwm tus ua yeeb yam rau lub luag haujlwm hauv zaj duab xis, TV, ua yeeb yam, thiab lwm yam kev tshaj tawm. Tus thawj coj ua yeeb yam zoo tuaj yeem tsim lossis rhuav tshem ntau lawm, vim tias txoj cai cam tuaj yeem nqa cov ntawv rau lub neej thiab tsim kom muaj kev nco qab rau cov neeg tuaj saib. Hauv tsab ntawv blog no, peb yuav tshawb nrhiav qhov tseem ceeb ntawm casting thiab qhov tseem ceeb hauv kev txiav txim siab casting ua tiav.

Ua ntej thiab qhov tseem ceeb, lub luag haujlwm ntawm tus thawj coj ua yeeb yam yog nrhiav cov neeg ua yeeb yam zoo tshaj plaws rau txoj haujlwm. Cov txheej txheem ntawm kev ua yeeb yam nrog rau kev ntsuam xyuas tsis yog lawv lub peev xwm nkaus xwb tab sis kuj yog lawv lub sijhawm, qib kev tshaj lij, thiab tsim nyog rau ib feem. Tus thawj coj zoo tshaj plaws yuav ua haujlwm nrog tus thawj coj thiab cov neeg tsim khoom kom nkag siab txog lub zeem muag muaj tswv yim rau qhov project thiab nrhiav cov neeg ua yeeb yam uas tuaj yeem coj lub zeem muag mus rau lub neej.

Qee qhov tseem ceeb uas cov thawj coj saib xyuas xav txog thaum ntsuas cov neeg ua yeeb yam suav nrog:

- Kev muaj peev xwm ua yeeb yamyog qhov tseem ceeb tshaj plaws, vim tias qhov kev ua tau zoo heev tuaj yeem ua lossis tawg qhov project. Casting directors yuav nrhiav cov neeg ua yeeb yam los ua kom muaj kev ntseeg siab thiab muaj kev xav zoo siab.

- Lub cev zoo li: Cov tsos ntawm tus actor yog qee zaum tseem ceeb heev rau lub luag haujlwm. Piv txwv li, yog tias tus cwj pwm siab thiab daj ntseg daj, tus thawj coj ua yeeb yam yuav saib xyuas cov neeg ua yeeb yam uas phim cov lus piav qhia.

- muaj:Cov sijhawm ua yeeb yaj kiab tuaj yeem xav tau, yog li cov thawj coj ua yeeb yaj kiab yuav tsum xav txog tus neeg ua yeeb yam muaj ua ntej txiav txim siab. Yog tias tus neeg ua yeeb yam twb tau cog lus rau lwm qhov project, lawv yuav xav tau kev pab los ua lub luag haujlwm tshiab.

- Kev tshaj lij:Kev ua yeeb yam yog ib txoj haujlwm, thiab cov thawj coj ua yeeb yam yuav nrhiav cov kws tshaj lij thiab ntseeg tau. Cov tib neeg yuav tsum tuaj txog raws sijhawm, npaj kom txaus, thiab kho qhov project nrog kev saib xyuas kom pom tau tias muaj kev hwm rau qhov project.

Thaum kawg, kev txiav txim siab ua tiav tiav yuav tsum muaj kev sib xyaw ua ke ntawm cov xwm txheej no. Tus neeg ua yeeb yam yuav muaj peev xwm zoo kawg, tab sis yog tias lawv tsis muaj lossis tsis haum rau lub cev ntawm lub luag haujlwm, lawv yuav tsis yog qhov kev xaiv zoo tshaj plaws.

Ntxiv nrog rau kev xaiv cov neeg ua yeeb yam rau lub luag haujlwm tshwj xeeb, cov thawj coj ua yeeb yaj kiab kuj tseem ua lub luag haujlwm tseem ceeb hauv kev tsim cov cam khwb cia tag nrho ntawm kev tsim khoom. Thaum txiav txim siab, nws yog ib qho tseem ceeb uas yuav tau xav txog ntau yam, suav nrog:

- Chemistry: Qee qhov xwm txheej, kev sib raug zoo ntawm tus cwj pwm muaj txiaj ntsig zoo li kev ua yeeb yam ntawm tus kheej. Casting directors yuav nrhiav cov neeg ua yeeb yam uas muaj cov tshuaj lom neeg ntawm qhov screen.

- Ntau haiv:Kev sawv cev yog qhov tseem ceeb hauv kev lag luam kev lom zem, thiab cov thawj coj ua yeeb yam feem ntau siv zog los tsim cov yeeb yam sib txawv uas qhia txog lub ntiaj teb tiag.

- Hom kev lees paub: Qee qhov xwm txheej, kev ua yeeb yaj kiab uas muaj npe nrov tuaj yeem tsim cov suab nrov rau qhov project. Rau cov yeeb yaj kiab ywj pheej lossis cov khoom me me, kev nyiam tuaj yeem yog qhov tseem ceeb. Qhov ntawd yog qhov uas peb cov kev pab tuaj yeem ua ke.

Kev rho tawm

Extrusion yog txheej txheem tsim khoom uas suav nrog kev tsim cov khoom siv los ntawm kev thawb nws los ntawm kev tuag los tsim cov duab tshwj xeeb lossis profile. Cov neeg tsim khoom feem ntau siv cov txheej txheem no los ua cov khoom yas thiab hlau xws li cov kav dej, cov raj, thiab cov ntawv. Ntawm no, peb yuav tham txog extrusion, nws ua haujlwm li cas, thiab nws cov ntawv thov.

Extrusion ua haujlwm li cas?

Extrusion ua haujlwm los ntawm kev thawb cov khoom los ntawm kev tuag siv lub extruder. Lub extruder muaj lub hopper, ib tug ntsia hlau, thiab ib tug cua sov caij. Tus neeg teb xov tooj pub cov khoom siv raw rau hauv lub hopper, tom qab ntawd thauj nws mus rau qhov ntsia hlau. Cov ntsia hlau tig, thawb cov khoom los ntawm cov khoom cua sov, qhov twg nws yog melted thiab tov. Lub tshuab ua cov khoom molten los ntawm qhov tuag, qhov twg nws yuav siv sij hawm nyob rau hauv cov duab los yog profile. Cov khoom siv extruded ces txias thiab txiav mus rau qhov ntev uas xav tau.

Kev siv ntawm Extrusion

Extrusion muaj ntau daim ntawv thov hauv ntau yam kev lag luam, suav nrog:

- Kev Siv: Extrusion yog siv nyob rau hauv kev tsim kho kev lag luam los tsim cov yas thiab hlau kav, raj, thiab ntawv.

- Ntim:Extrusion yog siv nyob rau hauv lub ntim kev lag luam los tsim cov yas zaj duab xis thiab ntawv rau wrapping khoom.

- Automotive:Extrusion yog siv nyob rau hauv kev lag luam automotive los tsim cov khoom yas thiab hlau rau lub tsheb, xws li trim thiab weatherstripping.

- Khoom Noj thiab Haus Caw: Extrusion yog siv hauv kev lag luam khoom noj thiab dej haus los tsim cov thawv yas thiab hlau rau khaws cia thiab thauj khoom noj thiab dej haus.

Qhov zoo ntawm Extrusion

Extrusion muaj ntau yam zoo dua lwm cov txheej txheem tsim khoom, suav nrog:

- Nqi tsim nyog: Extrusion yog ib txoj kev tsim khoom raug nqi, tso cai rau cov khoom ntim ntau nrog cov khoom pov tseg tsawg.

- Ntau yam:Cov neeg tsim khoom tuaj yeem siv extrusion los tsim ntau yam ntawm cov duab thiab cov profiles, ua rau kev tsim khoom thoob ntiaj teb.

- Zoo sib xws: Extrusion ua tau zoo ib yam, kom ntseeg tau tias txhua yam khoom zoo ib yam.

- Ceev: Extrusion yog txheej txheem ceev, tso cai rau cov khoom ntim ntau hauv lub sijhawm luv luv.

- zoo: Extrusion ua cov khoom lag luam zoo nrog lub ntsej muag du.

Laser Txiav

Laser txiav yog cov txheej txheem tsim khoom nrov uas siv cov nqaj laser txiav cov ntaub ntawv rau hauv ntau yam duab thiab ntau thiab tsawg. Nws muaj ntau yam zoo dua li kev txiav ib txwm, xws li precision, ceev, thiab versatility. Cov ntawv blog no yuav tham txog kev txiav laser, nws ua haujlwm li cas, thiab qee qhov ntawm nws daim ntawv thov.

Laser txiav yog dab tsi?

Laser txiav yog cov txheej txheem tsim khoom siv lub laser beam txiav cov ntaub ntawv rau hauv ntau yam duab thiab ntau thiab tsawg. Nws yog ib txoj hauv kev nrov rau kev txiav cov khoom sib txawv, suav nrog hlau, ntoo, yas, thiab ntaub. Cov neeg ua haujlwm tuaj yeem tswj cov kab teeb laser kom txiav cov duab thiab cov qauv nrog cov khib nyiab tsawg.

Laser txiav ua haujlwm li cas?

Laser txiav ua hauj lwm los ntawm kev coj lub siab-powered laser beam mus rau cov khoom txiav. Lub laser resonator tsim lub teeb laser, tom qab ntawd tsom rau cov khoom siv los ntawm iav thiab lo ntsiab muag. Lub tsom laser beam melts, hlawv, los yog vaporizes cov ntaub, tsim ib tug huv si thiab meej txiav.

Kev siv ntawm Laser Txiav

Laser txiav muaj ntau daim ntawv thov nyob rau hauv ntau yam lag luam, xws li:

- Raug:Kev lag luam kev lag luam feem ntau siv laser txiav txiav thiab tsim cov khoom sib txawv. Xav txog kev sau lub suab nquag. Nws muaj txiaj ntsig zoo rau kev tsim cov duab sib txawv thiab cov qauv uas yuav nyuaj los yog tsis yooj yim sua kom ua tiav siv txoj kev txiav tsoos.

- Architecture: Laser txiav yog siv nyob rau hauv kev lag luam architecture los tsim cov vaj huam sib luag zoo nkauj, cov ntxaij vab tshaus, thiab lwm yam qauv tsim.

- Cov hniav nyiaj hniav kub:Laser txiav yog siv nyob rau hauv cov hniav nyiaj hniav kub kev lag luam los tsim intricate designs ntawm precious hlau.

- Automotive: Kev lag luam automotive siv laser txiav rau txiav thiab shaping hlau Cheebtsam.

- Electronics:Kev lag luam hluav taws xob siv laser txiav rau kev txiav thiab shaping Circuit Court boards thiab lwm yam nta.

Qhov zoo ntawm Laser Txiav

Laser txiav muaj ntau yam zoo dua li kev txiav ib txwm, suav nrog:

- Precision:Laser txiav ua kom raug txiav nrog cov khib nyiab tsawg, tso cai rau kev siv cov ntaub ntawv zoo dua.

- Ceev: Laser txiav yog nrawm dua li cov txheej txheem txiav ib txwm, tso cai rau lub sijhawm luv luv.

- Ntau yam:Laser txiav tuaj yeem txiav ntau yam khoom, suav nrog hlau, ntoo, yas, thiab ntaub.

- Zoo sib xws: Laser txiav ua cov txiaj ntsig zoo ib yam, kom ntseeg tau tias txhua qhov kev txiav yog tib yam.

- Automation: Laser txiav tuaj yeem ua haujlwm tsis siv neeg, tso cai rau cov khoom ntim siab nrog kev cuam tshuam rau tib neeg tsawg.

Xaiv Txoj Cai Tsawg Volume Manufacturing Service Provider

Kev tsim khoom ntim tsawg yog qhov tseem ceeb ntawm kev nqa koj cov khoom lag luam. Nws tso cai rau koj los tsim cov khoom me me ntawm koj cov khoom los kuaj kev ua lag luam thiab ua kom muaj kev hloov pauv tsim nyog ua ntej tsiv mus rau cov khoom loj. Xaiv qhov tsim nyog ntim khoom muab kev pabcuam yog qhov tseem ceeb rau kev ua tiav ntawm koj cov khoom. Hauv tsab ntawv tshaj tawm no, peb yuav tham txog qhov tseem ceeb ntawm kev xaiv cov khoom tsim khoom tsim khoom tsim nyog thiab qee cov lus qhia rau kev xaiv kom raug.

Vim li cas Xaiv Txoj Cai Tsawg Volume Manufacturing Service Provider tseem ceeb?

Xaiv qhov tsim nyog ntim khoom muab kev pabcuam yog qhov tseem ceeb rau ntau yam:

- Kev tswj kom zoo: Tus neeg muab kev pabcuam raug cai yuav ua kom koj cov khoom ua tau raws li koj cov qauv.

- Kev xa khoom raws sijhawm: Xaiv ib tus neeg muab kev pabcuam txhim khu kev qha tuaj yeem pab xyuas kom koj cov khoom siv tau yooj yim.

- Kev tswj tus nqi: Tus kws kho mob muaj npe nrov tuaj yeem pab koj tswj cov nqi los ntawm kev txheeb xyuas txoj hauv kev los txo cov nuj nqis.

- Nrhav:Xaiv ib tus neeg muab kev pabcuam nrog kev paub dhau los hauv koj txoj kev lag luam tuaj yeem pab koj txheeb xyuas cov sijhawm tshiab rau kev tsim kho tshiab thiab kev tsim khoom.

Lub tswv yim rau xaiv txoj cai qis Volume Manufacturing Service Provider

- Txheeb xyuas koj cov kev xav tau: Ua ntej xaiv qhov chaw tsim khoom lag luam tsawg, nws yog qhov tseem ceeb los txiav txim siab koj cov kev xav tau. Txhawm rau kom ua tiav cov khoom lag luam tsim tawm, nws yog ib qho tseem ceeb kom paub meej meej koj cov khoom specifications, lub hom phiaj kev lag luam, thiab lub sij hawm xa khoom.

- Tshawb nrhiav cov chaw muab kev pabcuam muaj peev xwmonline thiab tshawb xyuas lawv cov kev txheeb xyuas thiab kev ntaus nqi. Koj tseem tuaj yeem ncav cuag lwm cov lag luam hauv koj qhov kev lag luam kom pom zoo.

- Ntsuas kev paub thiab kev txawj ntse:Xaiv ib tus neeg muab kev pabcuam uas muaj kev paub dhau los hauv koj txoj kev lag luam thiab kev txawj ntse hauv cov khoom koj tsim. Nws yog ib qho tseem ceeb rau kev sib txuas lus koj cov kev xav tau kom meej kom cov khoom koj tau txais raws li qhov koj xav tau.

- Xav txog qhov chaw:Xaiv ib tus neeg muab kev pabcuam ze rau koj lub lag luam tuaj yeem pab txo tus nqi thauj khoom thiab xyuas kom lub sijhawm xa tuaj.

- Ntsuas tus nqi:Txawm hais tias tus nqi yuav tsum tsis yog qhov tseem ceeb hauv koj qhov kev txiav txim siab, kev ntsuas tus nqi ntawm kev ua haujlwm nrog cov neeg muab kev pabcuam sib txawv yog qhov tseem ceeb. Sib piv cov nqe lus thiab xaiv tus nqi sib tw thaum tseem ua tau raws li koj qhov kev xav tau zoo.

- Thov thov ib tus qauv: Ua ntej xaiv ib tus neeg muab kev pabcuam, thov ib qho piv txwv ntawm lawv txoj haujlwm. Kev ntsuas qhov ua tau zoo ntawm lawv txoj haujlwm tuaj yeem pab koj txiav txim siab seb lawv puas yog tus neeg sib tw tsim nyog rau koj qhov project.

- Sib tham txog koj cov kev xav tau:Kev sib txuas lus yog qhov tseem ceeb rau kev ua tiav kev koom tes nrog koj tus neeg muab kev pabcuam. Paub meej txog koj qhov kev cia siab thiab sib txuas lus txhua qhov kev hloov pauv lossis teeb meem thoob plaws hauv kev tsim khoom.

Kev sib txuas lus thiab kev sib koom tes nrog tus neeg tsim khoom

Kev sib txuas lus thiab kev koom tes nrog cov chaw tsim khoom yog qhov tseem ceeb ntawm kev ua tiav koj cov khoom lag luam. Tsim kom muaj kev sib raug zoo nrog koj cov chaw tsim khoom yog qhov tseem ceeb los xyuas kom meej tias koj cov khoom ua tau raws li qhov koj xav tau thiab xa tuaj raws sij hawm thiab hauv pob nyiaj siv. Cov ntawv tshaj tawm blog no yuav tham txog qhov tseem ceeb ntawm kev sib txuas lus thiab kev sib koom tes nrog cov chaw tsim khoom thiab qee cov lus qhia rau kev tsim kom muaj kev sib koom tes zoo.

Vim li cas kev sib txuas lus thiab kev koom tes nrog tus neeg tsim khoom tseem ceeb?

Kev sib txuas lus thiab kev koom tes nrog cov neeg tsim khoom yog qhov tseem ceeb rau ntau yam:

- Kev tswj kom zoo:Kev sib txuas lus zoo thiab kev sib koom tes nrog cov chaw tsim khoom tuaj yeem pab xyuas kom koj cov khoom zoo raws li qhov koj xav tau.

- Kev xa khoom raws sijhawm:Tsim kom muaj cov kab kev sib txuas lus meej tuaj yeem pab koj kom paub meej tias koj cov khoom xa tuaj raws sijhawm.

- Kev tswj tus nqi:Kev koom tes nrog cov chaw tsim khoom tuaj yeem pab koj tswj cov nqi los ntawm kev txheeb xyuas txoj hauv kev los txo cov nuj nqis.

- Nrhav:Kev koom tes nrog cov chaw tsim khoom tuaj yeem pab koj txheeb xyuas cov kev tsim kho tshiab thiab tsim khoom tsim khoom.

Lub tswv yim los tsim kom muaj kev koom tes zoo nrog tus neeg tsim khoom

- Tsim kom muaj kev cia siab meej:Nws yog ib qho tseem ceeb los tsim kom muaj kev cia siab meej rau koj cov khoom txij thaum pib. Kev txheeb xyuas koj cov khoom tshwj xeeb, lub hom phiaj kev lag luam, thiab lub sijhawm xa khoom yog tsim nyog los xyuas kom meej cov khoom xa tuaj.

- Saib xyuas cov kab kev sib txuas lus qhib:Kev sib txuas lus tsis tu ncua nrog cov chaw tsim khoom tuaj yeem pab tiv thaiv kev nkag siab yuam kev thiab xyuas kom meej tias qhov project tau ua tiav raws li tau npaj tseg. Teem caij mus xyuas thiab sib qhia cov kev hloov tshiab ntawm kev ua tiav yog qhov tseem ceeb kom txhua tus neeg nyob hauv tib nplooj ntawv.

- Txhim kho ib puag ncig kev sib koom tes: Kev koom tes nrog cov chaw tsim khoom yog qhov tseem ceeb rau kev tsim kom muaj kev sib koom tes zoo. Peb yuav tsum tau txais cov tswv yim tshiab thiab cov kev daws teeb meem thiab sib koom tes los nrhiav txoj hauv kev los txhim kho cov khoom.

- Tswj cov kev cia siab: Nws yog ib qho tseem ceeb los tswj cov kev cia siab thoob plaws hauv kev tsim khoom. Peb tau cog lus tias yuav qhib thiab ncaj ncees txog txhua qhov kev poob qis lossis teeb meem uas yuav tshwm sim thiab yuav ua haujlwm los nrhiav kev daws teeb meem los txo lawv cov teebmeem.

- Ua cov kev tswj xyuas zoo:Kev tswj xyuas kev tswj xyuas zoo thoob plaws hauv cov txheej txheem tsim khoom tuaj yeem pab txheeb xyuas txhua yam teeb meem thaum ntxov thiab tiv thaiv lawv los ntawm kev ua teeb meem tseem ceeb hauv kab.

Kev Tiv Thaiv Kev Txawj Ntse

Cov cuab yeej cuab tam (IP) yog hais txog kev tsim ntawm lub siab, xws li kev tsim khoom, kev tsim, thiab kev ua yeeb yam, tiv thaiv los ntawm txoj cai. Kev tiv thaiv IP yog qhov tseem ceeb rau cov lag luam thiab cov tib neeg los tiv thaiv lawv cov tswv yim thiab tiv thaiv lwm tus los ntawm kev siv lawv yam tsis tau tso cai. Cov ntawv tshaj tawm blog no yuav tham txog qhov tseem ceeb ntawm kev tiv thaiv kev txawj ntse thiab qee txoj hauv kev los tiv thaiv koj tus IP.

Vim li cas Kev Tiv Thaiv Kev Txawj Ntse yog qhov tseem ceeb?

Kev tiv thaiv IP yog qhov tseem ceeb rau ntau qhov laj thawj:

- Nws tiv thaiv koj lub lag luam kev sib tw kom zoo dua: Cov cuab yeej cuab tam muab cov tuam txhab muaj kev sib tw hauv kev lag luam. Piv txwv li, yog tias koj muaj patent rau cov khoom tshiab, koj tuaj yeem tiv thaiv lwm tus los ntawm kev tsim lossis muag cov khoom ntawd, muab koj lub lag luam muaj txiaj ntsig zoo.

- Nws pab koj tsim cov nyiaj tau los:Kev tiv thaiv IP tso cai rau koj tso cai rau koj cov cuab yeej kev txawj ntse rau lwm tus thiab tsim cov nyiaj tau los ntawm kev muaj cai.

- Nws txhawb innovation: Ikev tiv thaiv cov khoom ntiag tug txhawb kev tsim kho tshiab los ntawm kev txhawb nqa cov neeg tsim khoom thiab cov neeg tsim khoom los tsim cov tswv yim tshiab thiab cov khoom lag luam.

Txoj Kev Tiv Thaiv Koj Cov Khoom Muaj Peev Xwm

- Ua ib qho kev tshawb nrhiav dav:Ua ntej ua ntawv thov rau txhua hom kev tiv thaiv IP, nws yog ib qho tseem ceeb uas yuav tsum tau ua tib zoo tshawb xyuas kom ntseeg tau tias koj lub tswv yim yog qhov tshwj xeeb thiab tsis ua txhaum txoj cai ntawm lwm tus. Txhawm rau kom ntseeg tau tias muaj keeb kwm yav dhau los, kev tshawb nrhiav cov patents yav dhau los, cov cim lag luam, lossis cov cai uas twb muaj lawm yog qhov tsim nyog.

- Cov ntaub ntawv rau patents, trademarks, thiab copyrights: Nyob ntawm koj qhov kev tsim khoom lossis kev ua haujlwm muaj tswv yim, koj yuav tsum tau ua ntaub ntawv rau patents, cov cim lag luam, lossis cov cai. Lub patent tiv thaiv tus qauv tsim, lub cim lag luam tiv thaiv lub npe, thiab kev cai lij choj tiv thaiv kev ua haujlwm zoo. Kev thov rau cov ntaub ntawv tiv thaiv no tuaj yeem pab tiv thaiv lwm tus los ntawm kev siv lossis luam koj cov tswv yim.

- Siv cov ntawv cog lus tsis qhia tawm (NDAs):NDA yog daim ntawv cog lus raws cai uas tuaj yeem pab tiv thaiv koj tus IP thaum sib koom nrog lwm tus. Nws tsim kev sib raug zoo tsis pub lwm tus paub ntawm ob tog thiab tiv thaiv tus neeg txais kev pab los ntawm kev nthuav tawm koj lub tswv yim rau lwm tus yam tsis tau koj tso cai.

- Saib xyuas kev ua txhaum cai: Kev soj ntsuam rau kev ua txhaum cai suav nrog kev saib xyuas kev lag luam rau kev siv koj cov cuab yeej kev txawj ntse uas tsis raug tso cai. Nws yog ib qho tseem ceeb rau kev tshawb nrhiav online tsis tu ncua los tiv thaiv koj cov cuab yeej kev txawj ntse. Ib txoj hauv kev los tiv thaiv koj cov kev tsim khoom lossis cov haujlwm muaj tswv yim yog los ntawm kev tshawb nrhiav cov ntawv luam uas tsis raug tso cai thiab saib xyuas kev lag luam tawm rau txhua yam khoom ua txhaum cai ntawm koj cov cuab yeej kev txawj ntse.

- Tswj koj txoj cai:Yog tias koj pom tias ib tus neeg siv koj cov cuab yeej cuab tam yam tsis tau txais kev tso cai, nws yog qhov tseem ceeb uas yuav tsum tau ua. Ib tus tuaj yeem txiav txim siab ua kev cai lij choj lossis xa tsab ntawv tso tseg-thiab-tshem tawm los tiv thaiv kev ua txhaum cai.

Ua tiav cov txheej txheem tsim khoom thiab tau txais koj cov khoom

Thaum nqa cov khoom lag luam mus rau kev ua lag luam, ua tiav cov txheej txheem tsim khoom thiab tau txais cov khoom tiav yog ib qho kev zoo siab thiab tseem ceeb heev. Tam sim no yog lub sijhawm los saib cov txiaj ntsig ntawm koj txoj haujlwm nyuaj thiab kev npaj ua kom zoo. Txawm li cas los xij, muaj qee qhov kev txiav txim siab tseem ceeb uas yuav tsum nco ntsoov kom txhua yam mus zoo thiab koj cov khoom tuaj txog raws li qhov xav tau.

Nov yog qee cov lus qhia rau kev ua tiav cov txheej txheem tsim khoom thiab tau txais koj cov khoom:

- Muab ob npaug rau txhua yam ua ntej ua tiav qhov kev tsim khoom:Nws yog ib qho tseem ceeb kom ntseeg tau tias txhua yam nyob rau hauv kev txiav txim ua ntej muab lub teeb ntsuab rau cov khoom loj. Nws yog ib qho tsim nyog yuav tsum xyuas kom meej cov qauv tsim, cov khoom siv, thiab cov txheej txheem tsim khoom kom ntseeg tau tias muaj tseeb thiab kev ntseeg tau. Txhua yam teeb meem pom thaum lub sijhawm ua yeeb yam tuaj yeem kho tau kim, yog li daws cov teeb meem ua ntej yog qhov tseem ceeb.

- Nyob hauv kev sib txuas lus nrog koj cov chaw tsim khoom: Kev tuav qhib kev sib cuag nrog koj cov chaw tsim khoom yog qhov tseem ceeb kom ntseeg tau tias txhua yam ua haujlwm zoo. Kuv tau cog lus tias yuav qhia rau koj paub los ntawm kev muab cov kev hloov tshiab tsis tu ncua, teb koj cov lus nug, thiab daws cov kev txhawj xeeb uas koj muaj tam sim ntawd. Kev sib txuas lus zoo tuaj yeem pab ua kom cov txheej txheem ntau lawm du.

- Ua tau yooj yim nrog lub sijhawm: Cov sijhawm sijhawm ntau lawm tuaj yeem hloov pauv, yog li nws yog qhov tseem ceeb uas yuav tsum tau hloov pauv raws sijhawm. Nws yog qhov zoo dua kom tau txais cov khoom lag luam zoo ob peb hnub tom qab qhov kev xav tau tshaj li kom tau txais cov khoom tsis raug raws sijhawm. Xyuas kom tseeb tias koj muaj cov phiaj xwm xwm txheej nyob rau hauv qhov chaw rau txhua qhov kev ncua sij hawm tsis tau npaj tseg.

- Npaj rau kev kuaj cov khoom:Ua ntej xa koj cov khoom, nws yog ib lub tswv yim zoo los npaj rau kev kuaj cov khoom. Ib qho ntawm cov cheeb tsam uas peb npog yog kev sim rau kev tswj kom zoo, kev ua tau zoo, thiab kev nyab xeeb. Kev ntsuam xyuas tuaj yeem pab xyuas kom meej tias koj cov khoom ua tau raws li tag nrho cov qauv thiab cov cai.

- Xaiv ib txoj kev xa khoom txhim khu kev qha:Thaum xa koj cov khoom, xaiv txoj kev xa khoom txhim khu kev qha thiab kev ntseeg siab yog qhov tseem ceeb. Xaiv tus neeg nqa khoom uas muaj kev ntseeg siab, siv cov ntim khoom tsim nyog, thiab kev pov hwm txaus yog qhov tseem ceeb los xyuas kom meej tias txoj kev xa khoom zoo.

xaus

Cov kev pabcuam ntim khoom tsawg muab cov lag luam me ua kom muaj txiaj ntsig zoo rau kev tsim cov khoom me me uas tsis muaj nqi ntau. Cov kev pabcuam no muab sijhawm hloov pauv sai, cov txheej txheem tsim khoom yooj yim, cov khoom lag luam zoo kawg, thiab ntau yam ntaub ntawv thiab cov txheej txheem. Los ntawm kev xaiv cov khoom lag luam uas tsis tshua muaj nqi tsim khoom thiab sib txuas lus zoo nrog lawv, cov lag luam me tuaj yeem ua tiav lawv cov khoom lag luam thaum muaj kev sib tw hauv lawv txoj kev lag luam.