Yas Txhaj Moulding Ntsiab Lus Xav

Txhua qhov kev txhaj tshuaj molding ua tiav yuav tsum tau siv ntau yam hauv ib zaug los txiav txim siab.

Xaiv Khoom Siv

Cov ntaub ntawv ua lub luag haujlwm tseem ceeb hauv kev txhaj tshuaj molding. Ib tus kws tshaj lij kev txhaj tshuaj molding tuaj yeem pab koj xaiv cov thermoplastic uas haum koj cov peev nyiaj thiab kev ua haujlwm. Vim tias cov molders feem ntau tau txais kev txo nqi ntawm cov qib thermoplastic ntau uas lawv yuav, lawv tuaj yeem xa cov nyiaj khaws cia rau koj.

Tolerance Variations

Txhua yam khoom tsim los ntawm kev txhaj tshuaj molding yuav tsum muaj kev zam tshwj xeeb kom haum rau lawv cov ntawv thov. Qee cov ntaub ntawv yuav nyuaj rau pwm lossis tuav kom yuav tsum tau ua siab ntev, thiab kev tsim cov cuab yeej kuj tuaj yeem cuam tshuam rau qhov kawg ntawm kev ua siab ntev. Ib txwm sib tham nrog koj qhov kev txhaj tshuaj molder qhov kev lees paub ntau yam rau cov khoom tshwj xeeb.

Barrel thiab Nozzle Temperatures

Moulders yuav tsum tswj lub chim tshwj xeeb thiab nozzle kub hauv kev txhaj tshuaj molding vim tias lawv cuam tshuam lub peev xwm ntawm cov resin ntws thoob plaws hauv pwm. Lub thoob thiab lub taub dej kub yuav tsum tau teem kom meej ntawm cov thermo-decomposition thiab melting kub. Txwv tsis pub, nws yuav ua rau cov dej ntws tawm, nyem, ntws qeeb, lossis tsis muaj qhov chaw.

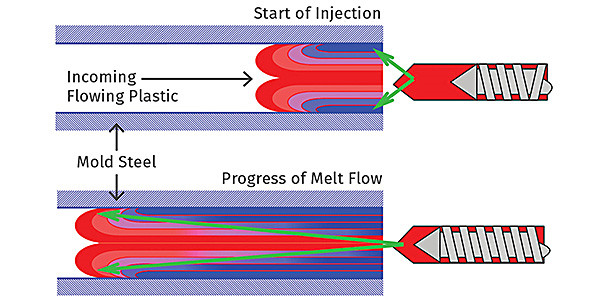

Thermoplastic Flow Rates

Moulders yuav tsum tswj xyuas qhov zoo txaus kom paub tseeb tias cov yas rhuab yog txhaj kom nrawm li sai tau rau hauv pwm kab noj hniav kom txog thaum nws yog 95% mus rau 99% tag nrho. Muaj tus nqi txaus txaus kom ntseeg tau tias cov yas khaws cov qib viscosity kom ntws mus rau hauv cov kab noj hniav.

Lwm yam tseem ceeb uas yuav tsum tau xav txog hauv kev txhaj tshuaj molding yog:

* Rooj vag qhov chaw

* Cov cim dab dej

* Lub kaum sab xis kaw

* Texturing

* Draft thiab kos duab lub kaum sab xis orientation

* Cov chaw ruaj ntseg steel

Rau qhov tseem ceeb hauv kev txhaj tshuaj molding txheej txheem

Cov txheej txheem txhaj tshuaj molding muaj rau XNUMX cov kauj ruam tseem ceeb, thiab cov teeb meem tuaj yeem tshwm sim ntawm ib qho ntawm cov theem no yog tias ua tsis tau zoo.

1. Clamping

Nyob rau hauv cov txheej txheem no, ob feem ntawm cov pwm yog nruj nreem kaw nrog ib tug clamping chav tsev, uas siv hydraulic zog los tsim kom muaj zog txaus los kaw lub pwm. Yog tsis muaj lub zog clamping txaus, cov txheej txheem tuaj yeem ua rau cov phab ntsa tsis sib xws, qhov hnyav tsis sib xws, thiab qhov sib txawv. Lub zog clamping ntau dhau tuaj yeem ua rau kev txhaj tshuaj luv luv, kub hnyiab, thiab gloss theem hloov.

2. Txhaj tshuaj

Moulders txhaj cov khoom siv thermoplastic yaj rau hauv pwm nrog cov cuab yeej ramming lossis ntsia hlau nyob rau hauv siab. Tom qab ntawd, ib feem yuav tsum tau tso cai kom txias ntawm tus nqi sib xws. Yog tias tsis yog, qhov kawg tuaj yeem muaj cov kab ntws lossis cov qauv tsis xav tau uas cuam tshuam rau nws qhov zoo nkauj.

3. Lub tsev siab

Thaum cov khoom siv thermoplastic tau txhaj rau hauv pwm, molders siv ntau lub siab los sau cov kab noj hniav kom puv. Lawv feem ntau tuav cov khoom siv thermoplastic molten kom txog thaum cov pwm lub rooj vag khov. Lub sijhawm nyob hauv tsev yuav tsum siv lub siab kom raug - tsawg dhau thiab nws tuaj yeem tso cov cim dab dej ntawm cov khoom tiav. Lub siab ntau dhau tuaj yeem ua rau burrs, qhov loj me, lossis teeb meem tso tawm ib feem ntawm cov pwm.

4. Cua txias

Tom qab lub tsev nyob, cov pwm tau ntim, tab sis nws tseem yuav kub dhau los tshem tawm ntawm pwm. Yog li ntawd, molders faib ib lub sijhawm rau cov pwm kom nqus cua sov los ntawm cov yas. Moulders yuav tsum tswj kom txaus, tsis tu ncua txias ntawm cov khoom siv thermoplastic los yog yuav muaj kev phom sij ntawm cov khoom kawg.

5. Pwm qhib

Cov phaj txav tau ntawm lub tshuab txhaj tshuaj pwm qhib. Qee cov pwm muaj huab cua blasting tswj los yog cov tub ntxhais rub tawm, thiab lub tshuab molding tswj cov qib quab yuam siv los qhib pwm thaum tiv thaiv ib feem.

6.Kev tshem tawm

Cov khoom kawg yog ejected los ntawm kev txhaj tshuaj pwm nrog lub mem tes los ntawm ejection system, rods, los yog robotics. Nano tso cov coatings ntawm cov pwm saum npoo pab tiv thaiv rips lossis kua muag thaum ejection.

Hom Moulding Defects tshwm sim los ntawm cov txheej txheem teeb meem

Muaj ntau ntau yam tsis xws luag cuam tshuam nrog kev txhaj tshuaj molding, xws li:

Warping: Warping yog deformation uas tshwm sim thaum ib feem ntsib qhov tsis sib xws. Nws nthuav tawm raws li qhov tsis xav tau khoov lossis twisted duab.

Dav hlau: Yog tias cov thermoplastic txhaj tshuaj qeeb dhau thiab pib teeb tsa ua ntej cov kab noj hniav puv, nws tuaj yeem ua rau jetting ntawm cov khoom kawg. Jetting zoo li lub dav hlau dav hlau ntws ntawm qhov chaw.

Sink marks: Cov no yog cov kev nyuaj siab saum npoo uas tshwm sim nrog qhov tsis sib xws los yog thaum molders tsis tso cai rau lub sij hawm txaus rau qhov txias, ua rau cov ntaub ntawv me me rau sab hauv.

Weld kab: Cov no yog cov kab nyias uas feem ntau tsim nyob ib ncig ntawm qhov chaw nrog qhov. Raws li cov yas molten ntws nyob ib ncig ntawm lub qhov, ob qhov ntws sib ntsib, tab sis yog tias qhov kub tsis zoo, cov dej ntws tsis zoo. Qhov tshwm sim yog ib txoj kab weld, uas txo cov kav ntev thiab lub zog ntawm qhov kawg.

Tshem tawm cov cim: Yog hais tias ib feem yog ejected ntxov dhau los yog muaj zog ntau dhau, cov ejector rods tuaj yeem tawm cov qhab nia hauv cov khoom kawg.

Lub tshuab nqus tsev vacuum: Lub tshuab nqus tsev vacuum tshwm sim thaum lub hnab ntim cua nyob hauv qab ntawm qhov chaw. Lawv yog tshwm sim los ntawm uneven solidification ntawm sab hauv thiab sab nrauv ntawm ib feem.

Txhaj Moulding Services Los ntawm DJmolding

Lub DJmolding, lub ntim siab, kev cai txhaj tshuaj molding tshwj xeeb, muaj 13 xyoo ntawm kev txhaj tshuaj molding. Txij li DJmolding tsim, peb tau mob siab rau muab peb cov neeg siv khoom zoo tshaj plaws txhaj tshuaj molded qhov chaw muaj. Niaj hnub no, peb qhov tsis xws luag yog tsawg dua 1 feem ntawm ib lab.