Yas Txhaj Tshuaj Moulding

Yas txhaj tshuaj molding yog txheej txheem tsim khoom uas muaj cov yas pellets yaj thiab txhaj rau hauv cov pwm kab noj hniav los tsim cov khoom peb sab. Cov txheej txheem no pib nrog ntau yam khoom, los ntawm cov khoom me me mus rau cov khoom tseem ceeb hauv tsheb. Yas txhaj tshuaj molding muaj ntau qhov zoo dua lwm cov txheej txheem tsim khoom, suav nrog cov nqi tsim khoom siab, tsim kev yooj yim, thiab kev ua tau zoo. Phau ntawv qhia no yuav saib qhov tob ntawm cov yas txhaj tshuaj molding thiab tshawb xyuas nws ntau yam kev siv, cov txiaj ntsig, thiab kev txwv.

Keeb kwm ntawm Kev Txhaj Tshuaj Molding

Yas txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten yas rau hauv pwm kab noj hniav kom tsim tau cov duab tshwj xeeb. Cov keeb kwm ntawm kev txhaj tshuaj molding tuaj yeem taug qab rov qab mus rau lub sijhawm xyoo 1800s thaum celluloid, ib hom yas, tau tsim thawj zaug. Txawm li cas los xij, nws yog nyob rau xyoo 1940 uas cov yas txhaj tshuaj molding tau siv dav los ua cov txheej txheem tsim khoom.

Thaum Ntiaj Teb Tsov Rog Zaum II, qhov kev thov rau cov khoom siv yas ntau lawm tau nce, thiab cov tuam txhab pib tshawb nrhiav txoj hauv kev tshiab thiab muaj txiaj ntsig zoo los tsim lawv. Xyoo 1946, James Watson Hendry, tus neeg tsim khoom Asmeskas, tau tsim thawj lub tshuab txhaj tshuaj molding tshuab, uas tau hloov pauv kev lag luam yas txhaj tshuaj molding. Lub tshuab no tso cai rau kev tswj cov txheej txheem kev txhaj tshuaj ntau dua thiab zoo ib yam, ua rau tsim cov khoom yas ntau dua thiab siv tau zoo.

Thoob plaws xyoo 1950 thiab 1960, kev nce qib hauv cov tshuab yas txuas ntxiv los txhim kho cov txheej txheem yas txhaj tshuaj molding. Kev taw qhia txog cov ntaub ntawv tshiab, xws li polystyrene thiab polyethylene, tsim cov khoom yas ntau dua thiab ruaj khov. Tsis tas li ntawd, kev txhim kho hauv tshuab molding tshuab, suav nrog kev siv tshuab hydraulic, ua rau cov txheej txheem txhaj tshuaj molding txawm ntau npaum li cas thiab tus nqi zoo.

Niaj hnub no, kev txhaj tshuaj yas molding yog cov txheej txheem uas siv tau los tsim ntau yam khoom yas, los ntawm cov khoom ua si thiab cov khoom siv mus rau cov khoom siv tsheb thiab cov khoom siv kho mob. Nrog rau txoj kev loj hlob ntawm cov ntaub ntawv tshiab thiab thev naus laus zis, cov txheej txheem yas txhaj tshuaj molding txuas ntxiv txhim kho thiab txhim kho, kom ntseeg tau tias nws yuav tseem yog cov txheej txheem tsim khoom tseem ceeb rau ntau xyoo.

Lub hauv paus ntawm Kev Txhaj Tshuaj Molding

Yas txhaj molding yog txheej txheem tsim los tsim cov khoom thiab cov khoom tsim los ntawm cov ntaub ntawv yas. Cov txheej txheem cuam tshuam nrog kev txhaj tshuaj molten yas rau hauv pwm, uas ua kom txias thiab khov kho kom tsim tau cov duab uas xav tau.

Cov kauj ruam yooj yim koom nrog hauv cov txheej txheem yas txhaj tshuaj molding yog raws li hauv qab no:

- Pwm tsim: Thawj kauj ruam hauv cov txheej txheem yog tsim cov pwm uas yuav siv los tsim qhov xav tau. Cov pwm feem ntau yog tsim los ntawm cov hlau thiab yuav tsum tau npaj rau tus account rau lub shrinkage raws li cov yas txias thiab solidifies.

- Kev npaj cov khoom siv: Cov khoom siv yas siv rau hauv cov txheej txheem txhaj tshuaj tuaj yeem ua cov pellets lossis granules, uas yuav tsum tau yaj thiab npaj rau kev txhaj tshuaj rau hauv pwm. Qhov no feem ntau yog ua nyob rau hauv lub hopper, qhov twg cov yas yog rhuab mus rau ib tug tshwj xeeb kub thiab melted mus rau hauv lub xeev kua.

- Txhaj Tshuaj: Thaum cov yas yog yaj, nws raug txhaj rau hauv pwm siv lub tshuab tshwj xeeb txhaj tshuaj molding. Lub tshuab siv lub siab rau lub molten yas, yuam nws mus rau hauv lub pwm kab noj hniav, qhov twg nws yuav siv sij hawm qhov zoo ntawm cov pwm.

- Txias thiab solidification: Tom qab cov yas txhaj rau hauv pwm, nws tuaj yeem txias thiab khov. Qhov no tuaj yeem siv nyob qhov twg los ntawm ob peb feeb mus rau ob peb feeb, nyob ntawm qhov loj thiab qhov nyuaj ntawm ntu.

- Ejection: Thaum cov yas tau txias thiab khov kho, cov pwm qhib, thiab ib feem yog ejected. Txoj hauj lwm yuav xav tau kev ua tiav ntxiv, xws li trimming lossis sanding, kom tshem tawm cov yas ntau dhau los yog cov npoo ntxhib.

Yas txhaj tshuaj molding yog cov txheej txheem tseeb thiab rov ua dua, ua rau nws zoo tagnrho rau cov khoom tsim tawm thiab cov khoom lag luam zoo ib yam. Nws kuj muaj ntau yam, vim nws tuaj yeem tsim cov khoom thiab cov khoom hauv ntau qhov ntau thiab tsawg, duab, thiab complexities. Qee qhov kev siv ntau tshaj plaws ntawm cov yas txhaj tshuaj molding muaj xws li kev tsim cov khoom ua si, cov khoom siv, cov khoom siv tsheb, thiab cov khoom siv kho mob.

Yas Txhaj Molding Txheej Txheem: Step-by-Step

Yas txhaj tshuaj molding yog ib tug complex txheej txheem uas muaj ob peb kauj ruam. Ntawm no yog ib daim ntawv qhia ib kauj ruam rau cov txheej txheem txhaj tshuaj molding:

- Tsim Mould: Thawj kauj ruam yog tsim cov pwm siv los tsim ib feem. Cov pwm feem ntau yog ua los ntawm cov hlau los yog txhuas thiab yuav tsum tau npaj kom haum rau cov khoom yas shrinkage thaum nws txias.

- Tsim Mould: Thaum cov pwm tsim tiav, nws yog tsim los siv computer-aided design (CAD) software thiab computer-aided manufacturing (CAM) machinery. Cov pwm yuav tsum tau ua tib zoo machined thiab polished los xyuas kom meej cov khoom kawg qhov tseeb thiab tiav.

- Kev xaiv cov khoom siv: Cov khoom siv yas siv rau cov txheej txheem txhaj tshuaj molding yuav tsum raug xaiv raws li qhov yuav tsum tau ua, xws li nws lub zog, hloov tau, xim, thiab kev ntxhib los mos.

- Kev Npaj Khoom Siv: Cov khoom siv yas xaiv tau muab tso rau hauv qhov kub thiab txias rau hauv cov kua. Cov khoom yog ces txhaj rau hauv lub tshuab molding lub hopper.

- Txhaj Moulding: Cov khoom siv yas molten yog txhaj rau hauv pwm kab noj hniav siv lub tshuab tshwj xeeb txhaj tshuaj molding. Lub tshuab siv lub siab rau cov khoom siv yas, yuam nws mus rau hauv lub pwm kab noj hniav, qhov twg nws yuav siv sij hawm qhov zoo ntawm cov pwm.

- Txias: Thaum cov pwm kab noj hniav puv nrog cov yas, nws tuaj yeem txias thiab khov. Lub sij hawm txias yog txiav txim siab los ntawm cov khoom siv yas, qhov loj thiab tuab ntawm qhov, thiab pwm kub.

- Ejection: Tom qab cov yas tau solidified, pwm qhib, thiab ib feem yog ejected los ntawm pwm siv ejector pins.

- Kev Ua tiav: Qhov ejected yuav xav tau kev ua tiav ntxiv, xws li kev txiav, xuab zeb, lossis pleev xim, kom tshem tawm cov yas ntau dhau lossis cov npoo ntxhib.

- Kev Tswjhwm Zoo: Qhov ua tiav tau ua tiav kev tshuaj xyuas kom ua tau raws li qhov xav tau tshwj xeeb thiab cov qauv zoo.

Yas txhaj tshuaj molding tuaj yeem tsim ntau qhov chaw thiab cov khoom hauv ntau qhov ntau thiab tsawg, duab, thiab complexities. Cov txheej txheem no tau siv dav hauv ntau lub lag luam, suav nrog tsheb, kev kho mob, khoom siv, thiab hluav taws xob.

Hom Yas Siv Hauv Txhaj Molding

Ntau hom yas tuaj yeem siv rau hauv kev txhaj tshuaj molding. Kev xaiv ntawm cov khoom siv yas yuav nyob ntawm seb qhov yuav tsum tau ua ntawm cov khoom lossis ib feem uas raug tsim, xws li lub zog, yooj, durability, thiab tsos. Nov yog qee yam ntawm cov yas siv ntau tshaj plaws hauv kev txhaj tshuaj molding:

- Polyethylene (PE): PE yog cov khoom siv dav siv hauv cov khoom siv yas uas paub txog nws lub zog thiab yoog raws. Nws yog siv los tsim ntau yam khoom, nrog rau cov khoom ntim, cov khoom ua si, thiab cov khoom siv kho mob.

- Polypropylene (PP): PP yog cov khoom siv sib sib zog nqus thiab ruaj khov uas feem ntau siv hauv kev lag luam tsheb rau sab hauv, xws li dashboards thiab qhov rooj vaj huam sib luag. Nws kuj tsim cov khoom ntim, xws li ntim thiab lub raj mis.

- Polycarbonate (PC): PC yog cov khoom yas thiab pob tshab uas feem ntau siv los tsim cov khoom siv hluav taws xob, xws li khoos phis tawj thiab xov tooj. Nws kuj yog siv rau headlamp lo ntsiab muag thiab dashboard Cheebtsam hauv kev lag luam tsheb.

- Acrylonitrile Butadiene Styrene (ABS): ABS yog ntau yam khoom siv yas paub txog nws lub zog, ua haujlwm ntev, thiab ua haujlwm kub. Nws yog feem ntau siv los tsim cov khoom siv tsheb, xws li dashboards, fender flares, cov khoom ua si, thiab cov khoom siv.

- Polyamide (PA): PA, tseem hu ua nylon, yog cov khoom siv yas uas muaj zog thiab lub teeb yuag uas feem ntau siv los tsim cov khoom siv tsheb, xws li lub cav npog thiab lub tshuab nqus tsev. Nws kuj tsim cov khoom ua si, xws li khau boots thiab ntaus pob tesniv.

- Polystyrene (PS): PS yog cov khoom siv yas hnyav thiab nruj uas feem ntau siv los tsim cov khoom ntim, xws li khob, tais, thiab ntim khoom noj. Nws kuj tsim cov khoom siv, xws li cov khoom ua si thiab cov khoom siv hluav taws xob.

- Polyethylene Terephthalate (PET): PET yog cov khoom yas uas muaj zog thiab pob tshab uas feem ntau siv los tsim cov khoom ntim, xws li lub raj mis thiab ntim. Nws kuj tseem siv rau hauv kev lag luam textile los tsim fibers thiab fabrics.

Cov no tsuas yog ob peb yam ntawm cov yas feem ntau siv hauv kev txhaj tshuaj molding. Muaj ntau lwm yam khoom siv yas, txhua tus muaj cov khoom tshwj xeeb thiab cov yam ntxwv. Kev xaiv ntawm cov khoom siv yas yuav nyob ntawm seb qhov kev xav tau tshwj xeeb ntawm ib feem lossis cov khoom tsim tawm.

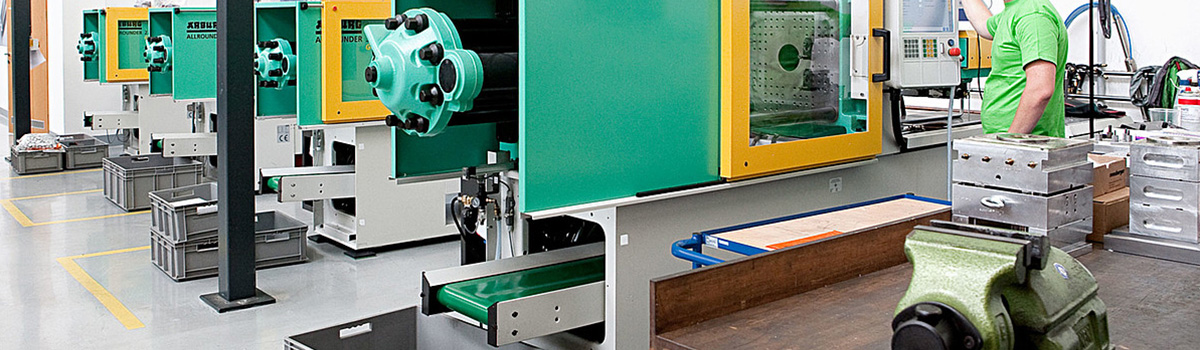

Hom Txhaj Moulding Tshuab

Txhaj tshuaj molding tshuab tuaj ntau hom thiab ntau thiab tsawg, txhua tus tsim los ua kom tau raws li cov kev tsim khoom tshwj xeeb. Nov yog qee yam ntawm ntau hom kev txhaj tshuaj molding tshuab:

- Hydraulic Txhaj Moulding Tshuab: Lub tshuab no siv lub zog hydraulic los tsim kom muaj lub zog los txhaj cov yas rau hauv pwm. Cov tshuab hydraulic feem ntau yog siv rau ntau qhov tseem ceeb uas yuav tsum tau muaj zog clamping siab.

- Hluav taws xob Txhaj Moulding Tshuab: Cov tshuab hluav taws xob siv hluav taws xob siv hluav taws xob los ua lub zog rau lub tshuab txhaj tshuaj thiab lub tshuab clamp. Lawv paub txog lawv cov high precision thiab lub zog efficiency, ua rau lawv nto moo rau ua me me, intricate qhov chaw.

- Hybrid Txhaj Moulding Tshuab: Hybrid cov cav tov muab cov txiaj ntsig ntawm cov khoom siv hydraulic thiab hluav taws xob, siv ob qho tib si hydraulic thiab hluav taws xob los tsim kom muaj qhov tsim nyog thiab lub zog. Hybrid cov cav tov muab qhov sib npaug zoo ntawm kev ceev, precision, thiab lub zog ua haujlwm.

- Vertical Txhaj Moulding Tshuab: Vertical machines tsim cov khoom uas yuav tsum tau ntxig molding los yog tshaj molding. Lawv muaj qhov ntsug clamping chav tsev uas tso cai rau kev nkag mus tau yooj yim rau cov pwm, ua rau lawv zoo tagnrho rau kev tsim cov khoom me me los yog complex.

- Ob-Shot Txhaj Moulding Tshuab: Ob lub tshuab txhaj tshuaj tsim cov khoom siv sib txawv lossis xim. Cov cuab yeej muaj ob chav txhaj tshuaj, txhua tus muaj peev xwm txhaj cov khoom txawv teb chaws rau hauv pwm. Hom tshuab no feem ntau yog siv los tsim cov khoom siv tsheb, xws li cov tes tuav thiab pob qhov rooj.

- Multi-Shot Txhaj Moulding Tshuab: Ntau lub tshuab txhaj tshuaj tsim cov khoom nrog ntau tshaj ob yam khoom lossis xim. Cov cuab yeej muaj ntau qhov kev txhaj tshuaj, txhua tus muaj peev xwm txhaj cov khoom sib txawv rau hauv pwm. Hom tshuab no feem ntau yog siv los tsim cov khoom siv, xws li txhuam hniav thiab rab chais.

- Txhua-Electric Txhaj Moulding Tshuab: Txhua lub tshuab hluav taws xob siv hluav taws xob siv hluav taws xob los siv lub zog txhaj tshuaj, lub tshuab clamp, thiab pwm. Lawv paub txog lawv cov precision siab, ceev, thiab lub zog efficiency, ua rau lawv nto moo rau ua me me, high-precision qhov chaw.

Cov no tsuas yog ob peb hom kev txhaj tshuaj molding tshuab. Txhua lub tshuab muaj cov yam ntxwv tshwj xeeb thiab qhov zoo, ua rau nws tseem ceeb los xaiv cov cuab yeej tsim nyog rau kev tsim khoom tshwj xeeb.

Ib feem ntawm Kev Txhaj Tshuaj Molding Tshuab

Txhaj tshuaj molding tshuab muaj ntau qhov chaw uas tsim cov khoom yas los ntawm cov khoom siv raw. Nov yog cov khoom tseem ceeb ntawm kev txhaj tshuaj molding tshuab:

Hopper: Lub reservoir tuav cov khoom yas raw ua ntej nws muab rau hauv lub tshuab txhaj tshuaj molding. Cov khoom yog feem ntau nyob rau hauv daim ntawv ntawm pellets los yog hmoov.

chim: Lub thoob yog qhov ntev, cylindrical ib feem ntawm lub tshuab txhaj tshuaj molding tshuab uas yog lub tsev cov ntsia hlau, uas melts thiab sib tov cov khoom yas.

Ntsia Hlau: Cov ntsia hlau yog cov khoom siv tig hauv lub thoob uas thawb cov khoom yas rau pem hauv ntej thiab yaj nws los ntawm kev sib txhuam thiab kub.

Kev Txhaj Tshuaj: Lub tshuab txhaj tshuaj suav nrog lub hopper, chim, thiab ntsia hlau thiab yog lub luag haujlwm rau melting thiab txhaj cov yas rau hauv pwm.

Clamping unit: Lub clamping unit yog lub luag haujlwm rau tuav cov pwm kom ruaj ntseg thiab siv lub siab tsim nyog thaum lub sijhawm txhaj tshuaj molding txheej txheem.

Pwm: Cov pwm yog cov cuab yeej tsim cov duab thiab qhov loj ntawm cov yas. Cov pwm feem ntau yog ua los ntawm cov hlau thiab muaj ob sab uas haum ua ke.

Nozzle: Lub nozzle yog ib feem ntawm chav txhaj tshuaj uas txuas lub tshuab txhaj tshuaj molding rau pwm. Cov khoom siv yas melted yog txhaj los ntawm lub nozzle thiab rau hauv pwm.

Txias qhov system: Lub tshuab ua kom txias yog lub luag haujlwm kom txias cov yas ib zaug txhaj rau hauv pwm. Qhov no ua kom cov khoom khov kho thiab tuaj yeem raug tshem tawm ntawm pwm yam tsis muaj kev puas tsuaj.

Tswj vaj huam sib luag: Cov tswj vaj huam sib luag yog lub interface uas tso cai rau tus neeg teb xov tooj saib xyuas thiab kho qhov chaw ntawm lub tshuab txhaj tshuaj molding, xws li kub, siab, thiab lub sijhawm voj voog.

Txhua qhov ntawm cov khoom no ua lub luag haujlwm tseem ceeb hauv cov txheej txheem txhaj tshuaj molding, thiab nws yog qhov tseem ceeb los tswj thiab ua kom zoo dua txhua daim kom ntseeg tau tias cov khoom zoo yog tsim tau zoo.

Txhaj Moulding Tooling: Tsim thiab tsim khoom

Kev txhaj tshuaj molding cuab yeej hais txog kev tsim thiab tsim cov pwm siv hauv kev txhaj tshuaj molding tshuab los tsim cov khoom yas. Qhov zoo thiab kev ua haujlwm ntawm cov pwm ncaj qha cuam tshuam rau qhov zoo thiab kev tsim khoom ntawm cov txheej txheem txhaj tshuaj molding. Nov yog cov kauj ruam tseem ceeb hauv kev tsim thiab tsim kev txhaj tshuaj molding tooling:

Cov khoom tsim: Thawj kauj ruam hauv kev txhaj tshuaj molding tooling yog tsim cov khoom tsim. Cov khoom tsim muaj xws li kev txiav txim siab qhov loj me, cov duab, thiab cov khoom siv, nrog rau txhua yam tshwj xeeb lossis cov kev xav tau.

Pwm tsim: Cov txheej txheem tsim pwm pib thaum cov khoom tsim tiav. Tus tsim pwm yuav txiav txim siab hom pwm zoo tshaj plaws, tus naj npawb ntawm cov kab noj hniav xav tau, thiab qhov loj thiab cov duab ntawm pwm.

Pwm tsim: Cov pwm yog tsim los ntawm cov pwm tsim, siv cov khoom zoo xws li hlau lossis txhuas. Cov pwm feem ntau yog ua nyob rau hauv ob halves, txhua tus muaj ib los yog ntau kab noj hniav.

Pwm sib dhos: Thaum cov pwm tsim, nws tau sib sau ua ke thiab kuaj xyuas qhov tseeb thiab ua haujlwm. Cov pwm yuav tsum tiv taus lub siab thiab kub ntawm cov txheej txheem txhaj tshuaj molding.

Pwm kuaj thiab siv tau: Tom qab cov pwm sib dhos, nws raug kuaj thiab siv tau los xyuas kom meej tias nws tsim cov khoom zoo uas ua tau raws li cov khoom specifications. Cov pwm yuav tsum tau hloov kho lossis hloov kho kom zoo dua qub.

Pwm tu: Kev tu thiab kho cov pwm tsis tu ncua yog qhov tseem ceeb los xyuas kom meej nws lub neej ntev thiab kev ua haujlwm. Qhov no suav nrog kev tu, lubricating, thiab hloov cov khoom hnav lossis puas.

Txhaj tshuaj molding cuab yeej yuav tsum tau precision thiab kev txawj ntse los tsim cov khoom zoo sib xws thiab ua tau zoo. Los ntawm kev ua raws li kev tsim thiab kev tsim ua tiav, cov tuam ntxhab tuaj yeem ua cov pwm uas ua tau raws li qhov tshwj xeeb ntawm lawv cov khoom thiab ua kom zoo dua lawv cov txheej txheem txhaj tshuaj molding.

Hom Txhaj Molding Tooling

Txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv los tsim cov khoom hauv ntau qhov ntau. Nws koom nrog kev txhaj tshuaj molten yas rau hauv pwm kab noj hniav thiab cia nws txias thiab khov rau hauv cov duab uas xav tau. Kev txhaj tshuaj molding cuab yeej yog txheej txheem ntawm kev tsim cov pwm siv hauv kev txhaj tshuaj molding. Muaj ntau ntau hom kev txhaj tshuaj molding cuab yeej, txhua tus muaj nws tus kheej zoo thiab qhov tsis zoo.

- Ob-Plate Moulds Ob-phaj pwm yog qhov yooj yim tshaj plaws ntawm kev txhaj tshuaj molding tooling. Lawv muaj ob daim hlau clamped ua ke los tsim ib kab noj hniav. Cov yas molten yog txhaj rau hauv lub qhov los ntawm lub rooj vag thiab tso cai rau txias thiab khov. Thaum ib feem yog tsim, ob daim hlau sib cais, thiab tus nqi yog ejected. Ob-phaj pwm feem ntau yog siv rau cov khoom me me rau nruab nrab nrog cov geometry yooj yim.

- Peb-Plate Moulds Peb-phaj pwm zoo ib yam li ob-phaj pwm, tab sis lawv muaj ib lub phaj ntxiv, hu ua stripper phaj, uas cais cov molded ib feem ntawm lub tshuab khiav. Lub tshuab khiav yog cov channel network uas xa cov yas molten mus rau pwm kab noj hniav. Peb-phaj pwm yog siv rau ntau qhov chaw tseem ceeb thiab ntau qhov geometry.

- Kub Khiav Pwm Nyob rau hauv kub khiav pwm, cov yas molten yog txhaj ncaj qha mus rau hauv pwm kab noj hniav los ntawm ib tug series ntawm rhuab raws es tsis yog los ntawm lub rooj vag. Qhov no txo cov khoom siv khib nyiab hauv lub tshuab khiav, ua rau muaj kev ua haujlwm zoo dua. Kub khiav moulds yog siv rau high-volume ntau lawm ntawm complex qhov chaw.

- Family Moulds Tsev neeg pwm tsim ntau yam hauv ib lub pwm. Lawv muaj ntau cov kab noj hniav npaj nyob rau hauv ib txoj kev uas tso cai rau zus tau tej cov domains ib txhij. Tsev neeg pwm feem ntau yog siv rau qhov chaw nrog me me mus rau nruab nrab-qhov loj me.

- Ntxig Moulds Ntxig pwm tsim cov khoom uas xav tau hlau lossis yas ntxig. Cov ntawv ntxig yog muab tso rau hauv pwm kab noj hniav ua ntej txhaj cov yas molten. Thaum cov yas tau txias thiab solidified, ib feem thiab cov ntxig yog sib txuas mus tas li. Ntxig pwm yog siv rau txoj haujlwm uas xav tau lub zog, durability, lossis zoo nkauj txaus nyiam.

- Overmolding Overmolding yog txheej txheem uas ib feem yog molded dua lwm tus. Nws yog feem ntau siv rau txoj haujlwm uas xav tau qhov muag muag lossis txhim kho tuav. Overmolding yuav tsum teem ib lub substrate los yog hauv paus ib feem ua ntej thiab ces molding ib tug thib ob cov ntaub ntawv rau nws. Cov khoom siv thib ob tuaj yeem yog cov khoom sib txawv ntawm cov yas, cov khoom zoo li roj hmab, lossis cov thermoplastic elastomer.

Hauv kev xaus, qhov kev xaiv ntawm kev txhaj tshuaj molding cuab yeej nyob ntawm seb hom ntawm cov khoom tsim, qhov xav tau ntim ntau lawm, thiab theem ntawm qhov nyuaj koom nrog hauv qhov tsim. Xaiv cov cuab yeej tsim nyog yog qhov tseem ceeb los xyuas kom meej tias cov txheej txheem ua haujlwm tau zoo thiab raug nqi.

Txhaj Moulding Design Guidelines

Txhaj tshuaj molding yog cov txheej txheem siv dav siv los ua cov khoom yas. Kev tsim cov khoom siv rau kev txhaj tshuaj molding yuav tsum muaj kev nkag siab zoo txog cov txheej txheem, cov ntaub ntawv, thiab cov qauv tsim cov txheej txheem uas yuav tsum tau ua raws li cov lus qhia kom ua tiav. Nov yog qee qhov kev txhaj tshuaj molding tsim cov txheej txheem kom nco ntsoov:

Phab ntsa Thickness, Phab ntsa thickness ntawm ib feem yuav tsum zoo ib yam thiab nyias li sai tau thaum tuav lub zog thiab functionality. Qhov no pab txo qhov txias thiab lub sij hawm voj voog thiab txo qhov kev pheej hmoo ntawm warping thiab dab dej.

Ribs thiab Bosses Ribs thiab tus thawj coj tuaj yeem siv los ua kom muaj zog thiab nruj ntawm qhov. Ribs yuav tsum tsis pub ntau tshaj 60% ntawm nominal phab ntsa thickness, thiab cov thawj coj yuav tsum yog 1.5 npaug ntawm nominal phab ntsa thickness.

Draft Angle, Lub kaum sab xis ntawm qhov tsawg kawg yog 1-2 degrees yuav tsum tau siv rau ntawm txhua qhov chaw ntsug kom pab txhawb qhov ejection thiab tiv thaiv kev puas tsuaj rau pwm.

Cov fillets thiab Radii Sharp cov ces kaum thiab cov npoo yuav tsum zam kom tsis txhob muaj kev ntxhov siab, uas tuaj yeem ua rau tawg thiab ua tsis tiav. Hloov chaw, fillets thiab radii yuav tsum faib cov kev ntxhov siab thiab txhim kho lub zog ntawm ib feem.

Rooj vag thiab Runners Qhov chaw thiab tsim ntawm lub rooj vag thiab cov neeg khiav dej num yog qhov tseem ceeb rau kev ua tiav qhov zoo. Kev nkag yuav tsum yog tsawg li tsawg tau nyob rau hauv lub thickness ntawm ib feem. Cov neeg khiav dej num yuav tsum tau tsim los kom txo qis kev poob siab thiab ua kom txaus siab.

Surface Finish Qhov saum npoo ntawm qhov tiav yuav tsum tau teev tseg raws li daim ntawv thov. Qhov saum npoo siab dua tuaj yeem xav tau rau cov khoom pom, thaum lub ntsej muag qis dua tuaj yeem siv tau rau qhov chaw zais.

Kev Xaiv Cov Khoom Siv Cov khoom xaiv rau ib feem yuav tsum tsim nyog rau kev txhaj tshuaj molding thiab ua tau raws li qhov xav tau ntawm cov khoom siv, thermal, thiab tshuaj lom neeg.

Kev ua haujlwm thib ob hauv kev txhaj tshuaj molding

Txhaj tshuaj molding yog txheej txheem tsim khoom siv ntau yam siv los tsim ntau yam khoom yas. Ntxiv nrog rau cov txheej txheem molding thawj, ntau txoj haujlwm yuav tsum tau ua haujlwm thib ob kom ua tiav cov duab uas xav tau, ua tiav, lossis ua haujlwm. Nov yog qee qhov kev ua haujlwm thib ob niaj hnub hauv kev txhaj tshuaj molding:

- Trimming yog tshem tawm cov khoom ntau dhau ntawm qhov molded tom qab nws tau raug tshem tawm ntawm pwm. Qhov no feem ntau yog ua tiav siv lub tshuab txiav los yog lub tshuab CNC. Trimming feem ntau yuav tsum tau ua kom tiav cov duab kawg thiab qhov loj ntawm ib feem.

- Vuam muab ob los yog ntau tshaj cov khoom yas siv cov cua sov, siab, los yog ua ke ntawm ob qho tib si. Qhov no feem ntau yog siv los tsim cov yam ntxwv loj lossis ntau dua uas tsis tuaj yeem tsim hauv ib qho pwm.

- Kho kom zoo nkauj yog cov txheej txheem ntawm kev ntxiv qhov pom lossis kev ua haujlwm rau saum npoo ntawm qhov molded. Qhov no tuaj yeem suav nrog kev pleev xim, luam ntawv, sau ntawv, lossis siv qhov zoo nkauj lossis qauv.

- Kev sib dhos yog cov txheej txheem ntawm kev koom nrog ntau qhov chaw los tsim cov khoom tiav. Qhov no tuaj yeem ua tiav siv cov fasteners, nplaum, lossis lwm yam kev koom ua ke.

- Insert Molding Insert molding yog molding yas nyob ib ncig ntawm lub pre-tsim hlau los yog yas insert. Qhov no feem ntau yog siv los tsim cov khoom nrog qib siab ntawm lub zog los yog kav ntev.

- Overmolding Overmolding yog txheej txheem ntawm molding ib tug thib ob khoom tshaj ib tug pre-tsim ib feem. Qhov no tuaj yeem ntxiv qhov muag muag, txhim kho tuav, lossis tsim ob lub suab lossis ntau yam khoom.

- Cov txheej txheej siv cov txheej txheem nyias rau ntawm qhov chaw kom txhim kho nws cov tsos, durability, lossis lwm yam khoom. Qhov no tuaj yeem suav nrog cov txheej txheem xws li chrome, npib tsib xee, lossis hmoov txheej.

Kev Zoo ntawm Kev Txhaj Tshuaj Yas Molding

Yas txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv los tsim cov khoom yas nrog cov neeg siab, sib xws, thiab zoo. Nws koom nrog kev txhaj tshuaj molten yas rau hauv pwm kab noj hniav thiab cia nws txias thiab khov. Nov yog qee qhov zoo ntawm cov yas txhaj tshuaj molding:

- High Efficiency thiab Productivity Yas txhaj tshuaj molding yog cov txheej txheem ua haujlwm tau zoo thiab ua haujlwm zoo uas tuaj yeem tsim cov khoom loj ntawm qhov sib xws thiab zoo. Nrog rau kev siv tshuab thev naus laus zis siab heev, lub sijhawm tsim khoom lag luam tuaj yeem raug txo mus rau vib nas this, uas tso cai rau cov khoom ntim ntau ntawm cov khoom sib txawv thiab sib txawv.

- High Accuracy thiab Precision Txhaj tshuaj molding ua rau kom raug thiab precision nyob rau hauv ua complex thiab intricate qhov chaw. Kev tswj hwm lub tshuab computer thiab cov software siab heev pab kom nruj kam rau ua nrog siab rov ua dua thiab raug.

- Versatility Txhaj tshuaj molding yog txheej txheem ntau yam uas tuaj yeem tsim ntau yam yas ntawm qhov sib txawv, cov duab, thiab qhov nyuaj. Cov txheej txheem tuaj yeem siv los ua txhua yam los ntawm cov khoom me me nrog cov ntsiab lus sib txawv mus rau cov nyiaj loj nrog cov geometry nyuaj.

- Cov Khoom Siv Flexibility Txhaj tshuaj molding tuaj yeem siv ntau yam ntawm cov ntaub ntawv yas, nrog rau cov thermoplastics, thermosets, thiab elastomers. Qhov no tso cai rau tsim cov khoom nrog ntau yam khoom siv, thermal, thiab tshuaj lom neeg.

- Low Waste Production Txhaj tshuaj molding yog cov txheej txheem tsim khoom pov tseg tsawg vim nws tsim cov khoom pov tseg tsawg heev thaum tsim khoom. Txhua yam khoom siv ntau dhau tuaj yeem siv tau yooj yim thiab rov siv dua hauv kev tsim khoom, ua rau kev tsim khoom zoo ib puag ncig.

- Txo Cov Nqi Ua Haujlwm Cov qib siab ntawm automation hauv kev txhaj tshuaj molding txo qhov kev xav tau ntawm cov txheej txheem siv zog, txo cov nqi zog. Qhov no kuj txo qhov kev pheej hmoo ntawm tib neeg kev ua yuam kev, txhim kho qhov kawg ntawm cov khoom zoo thiab sib xws.

- Txo cov kev ua haujlwm tom qab kev tsim khoom Txhaj tshuaj molding tsim cov khoom nrog cov neeg siab thiab sib xws, txo cov kev xav tau tom qab tsim khoom xws li trimming, drilling, lossis milling. Qhov no txo cov sij hawm tsim khoom thiab tus nqi ntawm cov khoom kawg.

- Consistency thiab Zoo Txhaj tshuaj molding tsim cov khoom nrog ib theem siab ntawm kev sib xws thiab zoo. Cov cuab yeej siv thev naus laus zis thiab tshuab computer tswj xyuas kom ntseeg tau tias txhua qhov kev nthuav dav zoo ib yam ntawm cov duab, qhov loj me, thiab zoo.

- Tsim Flexibility Txhaj tshuaj molding muaj qib siab ntawm kev tsim qauv yooj yim, raws li nws tso cai rau kev tsim cov khoom nrog cov geometry nyuaj, undercuts, thiab cov ntsiab lus sib txawv. Qhov no yuav ua rau cov neeg tsim qauv tsim cov khoom nrog cov duab tshwj xeeb thiab cov haujlwm uas tsis tuaj yeem ua los ntawm lwm cov txheej txheem tsim khoom.

- Nqi-zoo rau High-Volume Production Txhaj molding yog tus nqi-zoo rau kev tsim cov khoom yas. Tus nqi pib cov cuab yeej tuaj yeem siab, tab sis tus nqi ib feem txo qis vim qhov ntim ntawm ntau lawm nce. Qhov no ua rau nws yog ib qho txheej txheem zoo tshaj plaws rau kev tsim cov khoom loj.

Yas txhaj molding muaj ntau yam zoo, ua rau nws yog ib qho kev xaiv nrov rau kev tsim cov khoom yas. Nws cov kev ua haujlwm siab, qhov tseeb, ntau yam, cov khoom siv tau yooj yim, cov khoom siv pov tseg tsawg, txo cov nqi zog, thiab kev sib xws thiab kev ua haujlwm zoo ua rau nws ua cov txheej txheem zoo rau ntau yam kev siv. Lub peev xwm los tsim cov complex thiab intricate qhov chaw nrog siab tsim yooj thiab nqi-zoo rau high-ntim ntau lawm ua rau nws ib tug heev nrhiav-tom qab manufacturing txheej txheem.

Qhov tsis zoo ntawm Kev Txhaj Tshuaj Molding

Yas txhaj tshuaj molding yog ib txoj kev tsim khoom siv dav siv uas koom nrog kev txhaj tshuaj molten yas rau hauv pwm kab noj hniav kom tsim tau ntau yam ntawm cov yas thiab cov khoom. Txawm hais tias kev txhaj tshuaj yas molding muaj ntau yam txiaj ntsig, kuj tseem muaj ntau qhov tsis zoo. Nov yog qee qhov tsis zoo ntawm cov yas txhaj tshuaj molding:

- Cov cuab yeej siv siab: Tus nqi tsim thiab tsim cov pwm rau cov yas txhaj tshuaj molding tuaj yeem siab heev. Qhov no yog vim cov pwm yuav tsum tau ua los ntawm cov ntaub ntawv zoo thiab precision machined los tsim qhov xav tau. Tsis tas li ntawd, tus nqi ntawm kev tsim thiab tsim cov pwm tuaj yeem txwv tsis pub ua haujlwm me me, ua rau cov yas txhaj tshuaj molding tsis tshua muaj nqi rau cov khoom ntim tsawg.

- Lub sij hawm txhuas ntev: Cov txheej txheem ntawm kev tsim thiab tsim cov pwm rau cov yas txhaj tshuaj molding tuaj yeem siv sijhawm ntev, uas tuaj yeem ncua sijhawm ntawm cov khoom yas. Qhov no tuaj yeem muaj teeb meem tshwj xeeb rau cov lag luam uas yuav tsum tau teb sai sai rau kev hloov pauv hauv kev xav tau ntawm kev lag luam lossis tsim cov khoom tshiab sai sai.

- Txwv tsis pub yooj yim: Thaum cov pwm tsim thiab tsim, nws yooj yim dua thiab pheej yig dua los hloov tus tsim lossis hloov cov txheej txheem ntau lawm. Qhov no tuaj yeem txwv qhov hloov pauv ntawm cov yas txhaj tshuaj molding thiab ua rau nws tsis tsim nyog rau kev tsim cov khoom lag luam lossis ib qho ntawm cov khoom lag luam.

- Kev txhawj xeeb txog ib puag ncig: Kev txhaj tshuaj yas yas tso siab rau ntau cov yas, uas tuaj yeem muaj kev cuam tshuam ecological tsis zoo. Cov khib nyiab yas yog qhov teeb meem loj ntawm ib puag ncig, thiab kev txhaj tshuaj yas tuaj yeem ua rau muaj qhov teeb meem no. Tsis tas li ntawd, cov txheej txheem ntawm kev tsim cov khoom yas yuav tsum siv lub zog thiab cov khoom siv ntuj tsim, uas tuaj yeem cuam tshuam rau ib puag ncig ntxiv.

- Cov khoom siv siab heev: Cov yas txhaj tshuaj molding tuaj yeem tsim cov khoom siv tseem ceeb, uas tuaj yeem kim pov tseg lossis rov ua dua tshiab. Tsis tas li ntawd, kev tsim cov khoom seem tuaj yeem ua rau tag nrho cov nqi tsim khoom thiab txo cov txheej txheem tsim khoom.

- Kev xaiv cov khoom siv tsawg: Cov yas txhaj tshuaj molding feem ntau yog siv los tsim cov khoom thiab cov khoom siv los ntawm cov khoom siv thermoplastic, uas muaj cov khoom siv tsawg piv rau lwm cov ntaub ntawv xws li hlau lossis ceramics. Qhov no tuaj yeem ua rau cov yas txhaj tshuaj molding tsis haum rau cov ntawv thov uas xav tau lub zog siab, kub tsis kam, lossis lwm yam khoom siab heev.

Kev txwv ntawm Kev Txhaj Tshuaj Molding

Thaum cov yas txhaj tshuaj molding muaj ntau qhov zoo, qee qhov kev txwv kuj tseem cuam tshuam nrog cov txheej txheem. Nov yog qee qhov kev txwv ntawm kev txhaj tshuaj yas molding:

High Initial Tooling Nqi: Tus nqi pib ntawm kev tsim thiab tsim cov pwm tuaj yeem nce ntxiv. Cov pwm yuav tsum yog qhov tseeb thiab ruaj khov kom tiv taus cov txheej txheem txhaj tshuaj molding, thiab qhov no tuaj yeem xav tau kev nqis peev ntau, tshwj xeeb tshaj yog rau cov pwm loj lossis cov pwm loj.

Lub Sijhawm Lead: Lub sijhawm ua haujlwm ntawm cov pwm tuaj yeem yog qhov tseem ceeb, txij li lub lis piam mus rau hli, nyob ntawm qhov nyuaj thiab qhov loj ntawm cov pwm. Qhov no tuaj yeem ua rau ncua sij hawm ntau lawm, tshwj xeeb tshaj yog rau lub sijhawm ua haujlwm.

Kev txwv tsim: Kev txhaj tshuaj molding muaj qee yam kev txwv tsim uas yuav tsum tau xav txog. Piv txwv li, kev ua tiav cov phab ntsa tuab tuab thoob plaws hauv ib feem yog qhov tseem ceeb los xyuas kom meej qhov ntim thiab txias. Tsis tas li ntawd, cov kaum sab xis yuav tsum tau rau ntawm qhov chaw ntsug kom yooj yim ejection los ntawm pwm.

Kev txwv qhov loj me: Kev txhaj tshuaj molding yog qhov tsim nyog tshaj plaws rau kev tsim cov khoom me me rau nruab nrab. Cov khoom loj tuaj yeem xav tau cov cuab yeej tshwj xeeb thiab cov pwm loj, ntxiv rau cov nqi thiab qhov nyuaj.

Kev xaiv cov khoom siv: Thaum txhaj tshuaj molding tso cai rau ntau yam ntawm cov ntaub ntawv yas, kev xaiv ntawm cov khoom tseem txwv piv rau lwm cov txheej txheem tsim khoom. Cov ntaub ntawv uas muaj cov ntsiab lus melting siab lossis cov yam ntxwv tsis zoo yuav tsis haum rau kev txhaj tshuaj molding.

Surface Finish: Cov txheej txheem txhaj tshuaj molding tuaj yeem ua rau pom pom cov kab los yog cov kab sib cais ntawm qhov chaw. Ua kom tiav qhov zoo ntawm qhov chaw tiav tuaj yeem nyuaj, thiab lwm txoj hauv kev, xws li polishing lossis txheej, yuav tsum tau ua.

Limited Undercuts: Undercuts yog cov yam ntxwv lossis cov ntsiab lus ntawm ib feem uas tiv thaiv kom tsis txhob raug tshem tawm ntawm pwm. Undercuts tuaj yeem cuam tshuam cov txheej txheem ejection thiab xav tau cov pwm ntxiv lossis kev ua haujlwm thib ob kom ua tiav qhov xav tau ntawm geometry.

Cov Kev Kho Kho Txwv Txwv: Yog tias pwm puas lossis xav tau kev hloov kho, nws tuaj yeem raug nqi thiab siv sijhawm los kho lossis hloov cov pwm uas twb muaj lawm. Qee zaum, cov pwm tshiab yuav tsum tau tsim, ua rau cov nqi ntxiv thiab ncua sijhawm.

Txawm hais tias cov kev txwv no, cov yas txhaj tshuaj molding tseem muaj ntau yam thiab siv dav siv los tsim cov khoom yas. Los ntawm kev ua tib zoo xav txog cov kev txwv no thaum lub sij hawm tsim thiab kev npaj tsim khoom, nws muaj peev xwm txo tau lawv cov kev cuam tshuam thiab ua kom muaj txiaj ntsig zoo ntawm kev txhaj tshuaj molding.

Kev siv cov yas txhaj tshuaj molding

Yas txhaj tshuaj molding yog ntau yam txheej txheem tsim khoom uas tuaj yeem tsim ntau yam khoom yas. Nov yog qee qhov kev siv ntawm cov yas txhaj tshuaj molding:

- Cov Khoom Siv Khoom Siv: Kev txhaj tshuaj molding yog dav siv los tsim ntau yam khoom, xws li cov khoom ua si, chav ua noj, thiab khoom siv hluav taws xob. Cov txheej txheem tuaj yeem tsim cov khoom zoo nrog cov geometries intricate thiab meej qhov ntev, ua rau nws zoo tagnrho rau cov khoom uas yuav tsum tau nruj tolerances thiab complex duab.

- Automotive Parts: Ntau yam khoom siv hauv tsheb, xws li cov khoom siv dashboard, qhov rooj tuav, thiab teeb pom kev zoo, yog tsim los ntawm kev txhaj tshuaj molding. Cov txheej txheem tso cai rau cov khoom ntim ntau thiab zoo ib yam, ua rau nws muaj txiaj ntsig zoo rau cov tuam txhab tsheb.

- Cov Khoom Siv Kho Mob: Kev txhaj tshuaj molding feem ntau yog siv los tsim cov cuab yeej kho mob, xws li cov koob txhaj tshuaj, tshuaj nqus pa, thiab cov cuab yeej kuaj mob. Cov txheej txheem tuaj yeem tsim cov khoom siv nrog kev ua haujlwm siab thiab sib xws, kom ntseeg tau qhov zoo thiab kev ntseeg siab ntawm cov khoom siv.

- Ntim: Kev txhaj tshuaj molding yog dav siv los tsim cov ntim yas, xws li ntim, hau, thiab kaus mom. Cov txheej txheem tuaj yeem muaj qhov sib xws nrog qhov ntev thiab ua tiav zoo, ua rau nws zoo tagnrho rau kev ntim khoom nrog lub ntsej muag zoo nkauj thiab ruaj ntseg haum.

- Aerospace thiab Kev Tiv Thaiv: Txhaj tshuaj molding tsim ntau yam aerospace thiab tiv thaiv cov khoom, xws li dav hlau sab hauv, teeb pom kev zoo, thiab kev sib txuas lus. Cov txheej txheem tuaj yeem muaj cov khoom siv nrog lub teeb yuag, cov khoom siv ruaj khov, ua rau lawv haum rau cov ntawv thov uas xav tau lub zog-rau-hnyav sib piv.

- Kev tsim kho: Kev txhaj tshuaj molding tuaj yeem tsim ntau yam khoom siv, xws li cov vuas yas, vov tsev, thiab sab hauv. Cov txheej txheem tuaj yeem muaj qhov sib xws nrog qhov ntev thiab ua tiav zoo, ua rau nws muaj kev xaiv zoo rau cov tuam txhab tsim kho.

- Kev Ua Si thiab Kev Ua Si: Kev txhaj tshuaj molding yog siv dav hauv kev tsim cov khoom siv kis las, xws li golf clubs, tennis rackets, thiab cov khoom siv tsheb kauj vab. Cov txheej txheem tuaj yeem tsim cov khoom siv nrog cov khoom hnyav thiab cov geometries meej, kom ntseeg tau tias kev ua tau zoo thiab ua haujlwm ntev ntawm cov khoom siv.

Zuag qhia tag nrho, yas txhaj tshuaj molding yog ntau yam thiab dav siv cov txheej txheem tsim khoom uas tuaj yeem tsim cov khoom yas zoo rau ntau yam kev siv. Cov txheej txheem tuaj yeem tsim kho kom tau raws li cov qauv tsim tshwj xeeb thiab cov kev xav tau ntau lawm, ua rau nws muaj kev xaiv zoo rau cov tuam ntxhab hauv ntau qhov kev lag luam.

Automotive Kev Lag Luam thiab Yas Txhaj Moulding

Kev lag luam tsheb yog ib qho tseem ceeb ntawm cov neeg siv cov yas txhaj tshuaj molding tshuab. Cov txheej txheem ntawm cov yas txhaj tshuaj molding tau hloov pauv kev tsim cov khoom siv hauv tsheb thiab cov khoom siv, ua rau nws tuaj yeem tsim cov duab nyuaj nrog kev ua haujlwm siab thiab raug. Nov yog qee qhov kev txhaj tshuaj yas molding siv hauv kev lag luam tsheb:

- Cov khoom siv sab hauv: Yas txhaj tshuaj molding ua ntau yam hauv, nrog rau cov khoom siv dashboard, lub qhov rooj vaj huam sib luag, trim daim, thiab lwm yam. Cov khoom no tuaj yeem tsim nrog cov duab sib txawv thiab textures thiab kho kom haum rau txhua lub tsheb qauv cov qauv thiab kev ua haujlwm.

- Cov khoom siv sab nrauv: Yas txhaj tshuaj molding kuj yog siv los tsim ntau yam sab nrauv, nrog rau cov pob, cov hniav nyiaj hniav kub, sab iav, thiab lwm yam. Cov khoom no tuaj yeem tsim los tiv thaiv huab cua huab cua thiab ua rau ntau xim thiab ua tiav.

- Cov Cheebtsam hauv qab-the-hood: Yas txhaj tshuaj molding ua rau ntau yam hauv qab-hood, nrog rau cov npog cav, cua nkag tshuab, thiab cov khoom cua txias. Cov khoom siv no yuav tsum muaj qhov kub thiab txias thiab tshuaj tiv thaiv, uas tuaj yeem ua tiav nrog cov ntaub ntawv thermoplastic.

- Cov khoom siv hluav taws xob thiab hluav taws xob: Yas txhaj tshuaj molding ua rau ntau yam khoom siv hluav taws xob thiab hluav taws xob, nrog rau cov khoom sib txuas, vaj tse, thiab cov sensors. Cov khoom siv no yuav tsum muaj kev ua haujlwm siab thiab kev ntseeg siab, uas tuaj yeem ua tiav nrog qhov tseeb thiab sib xws ntawm cov yas txhaj tshuaj molding.

- Lightweighting: Yas txhaj tshuaj molding feem ntau yog siv los tsim cov khoom hnyav uas pab txo qhov hnyav tag nrho ntawm lub tsheb, txhim kho roj efficiency thiab txo cov emissions. Lub teeb hnyav kuj tuaj yeem txhim kho kev tuav thiab kev ua haujlwm ntawm lub tsheb.

Kev lag luam kev kho mob thiab yas txhaj tshuaj molding

Yas txhaj tshuaj molding yog siv dav hauv kev lag luam kho mob los tsim ntau yam khoom siv kho mob thiab cov khoom siv. Cov txheej txheem ntawm kev txhaj tshuaj yas molding tso cai rau kev tsim cov duab nyuaj nrog kev ua haujlwm siab thiab raug, ua rau nws txoj kev tsim khoom zoo tshaj plaws rau ntau daim ntawv thov kev kho mob. Nov yog qee txoj hauv kev siv cov yas txhaj tshuaj molding hauv kev lag luam kho mob:

- Cov khoom siv kho mob: Yas txhaj tshuaj molding tsim ntau yam khoom siv kho mob, suav nrog cov cuab yeej phais, cov cuab yeej kuaj mob, cov tshuab xa tshuaj, thiab lwm yam. Cov cuab yeej no feem ntau xav tau qhov tseeb thiab raug, thiab cov yas txhaj tshuaj molding tuaj yeem ua tau raws li cov kev cai no.

- Kev cog hniav: Cov yas txhaj tshuaj molding kuj tseem siv los tsim ntau yam kev cog qoob loo, suav nrog kev sib koom ua ke, kev cog hniav, thiab lwm yam. Cov implants no tuaj yeem tsim kom haum tus neeg mob lub cev thiab ua nrog cov khoom siv biocompatible.

- Cov khoom siv hauv chav kuaj: Yas txhaj tshuaj molding ua cov pipettes, microplates, thiab cov raj kuaj. Cov Cheebtsam no xav tau kev ua haujlwm siab thiab raug kom ntseeg tau tias muaj txiaj ntsig zoo.

- Ntim: Yas txhaj tshuaj molding yog siv los tsim cov ntim khoom siv kho mob, suav nrog cov txheej txheem tsis muaj menyuam thiab kev ntim khoom rau tus kheej. Cov kev daws teeb meem no tuaj yeem pab tswj cov cuab yeej kho mob kom tsis muaj menyuam thiab kev ncaj ncees.

- Cov cuab yeej siv ib leeg: Cov yas txhaj tshuaj molding feem ntau tsim cov khoom siv ib leeg xws li cov koob txhaj tshuaj, koob, thiab catheters. Cov cuab yeej no tuaj yeem ua rau hauv qhov ntim siab ntawm tus nqi qis thiab tuaj yeem pab tiv thaiv kev kis kab mob hauv chaw kho mob.

Cov khoom siv thiab cov yas txhaj tshuaj molding

Yas txhaj tshuaj molding yog dav siv nyob rau hauv kev tsim khoom ntawm cov neeg siv khoom vim nws versatility, efficiency, thiab nqi-zoo. Cov txheej txheem ntawm kev txhaj tshuaj molding tso cai rau kev tsim cov duab nyuaj nrog kev ua haujlwm siab thiab raug, ua rau nws txoj kev tsim khoom zoo tshaj plaws rau ntau cov neeg siv khoom. Nov yog qee txoj hauv kev siv cov yas txhaj tshuaj molding hauv kev tsim cov khoom siv:

- Cov Khoom Ua Si: Yas txhaj tshuaj molding ua ntau yam khoom ua si, los ntawm cov duab me me mus rau cov playsets loj. Cov txheej txheem tso cai rau tsim cov qauv tsim thiab cov ntsiab lus sib txawv thiab ua cov khoom ua si hauv ntau yam xim thiab cov ntaub ntawv.

- Cov khoom siv hauv tsev: Cov yas txhaj tshuaj molding ua ntau yam khoom siv hauv tsev, nrog rau cov khoom siv hauv tsev, cov thawv ntim khoom, thiab cov khoom siv tu. Cov khoom siv no tuaj yeem tsim kom muaj zog, hnav, thiab siv tau yooj yim.

- Electronics: Yas txhaj tshuaj molding ua ntau yam khoom siv hluav taws xob, nrog rau cov tsev hauv computer, rooj plaub xov tooj, thiab chargers. Qhov tseeb thiab qhov tseeb ntawm cov txheej txheem ua kom ntseeg tau tias cov khoom no yog tsim los nrog cov qib siab sib xws thiab kev ntseeg tau.

- Cov khoom siv tu tus kheej: Cov yas txhaj tshuaj molding tsim cov khoom tu tshwj xeeb, suav nrog cov txhuam hniav, rab chais, thiab txhuam hniav. Cov khoom no xav tau kev ua haujlwm siab thiab raug los xyuas kom yooj yim ntawm kev siv thiab kev nyab xeeb.

- Automotive accessories: Yas txhaj tshuaj molding tsim ntau yam khoom siv hauv tsheb, suav nrog cov khoom siv dashboard, lub khob tuav, thiab lwm yam. Cov khoom siv no tuaj yeem tsim los ua lub teeb yuag, ruaj khov, thiab tiv taus qhov hnav thiab tsim kua muag ntawm kev siv txhua hnub.

Environmental Considerations hauv Plastic Txhaj Molding

Yas txhaj tshuaj molding yog ib txoj kev tsim khoom siv dav siv tab sis muaj qhov cuam tshuam rau ib puag ncig. Nov yog qee qhov kev txiav txim siab ecological hauv kev txhaj tshuaj molding:

- Kev xaiv cov khoom siv: Kev xaiv cov khoom siv yas siv hauv kev txhaj tshuaj molding tuaj yeem cuam tshuam rau ib puag ncig. Qee cov ntaub ntawv yog biodegradable lossis recyclable, thaum lwm tus tsis yog. Siv cov khoom siv biodegradable lossis recyclable tuaj yeem pab txo qhov cuam tshuam ib puag ncig ntawm cov yas txhaj tshuaj molding.

- Kev siv hluav taws xob: Yas txhaj tshuaj molding yuav tsum muaj lub zog tseem ceeb los yaj cov yas thiab txhaj rau hauv pwm. Cov cuab yeej siv hluav taws xob thiab cov txheej txheem, xws li cov tshuab hluav taws xob thiab cov tshuab kaw, tuaj yeem txo cov kev siv hluav taws xob thiab kev cuam tshuam ib puag ncig.

- Kev tswj cov khib nyiab: Cov yas txhaj tshuaj molding tsim cov khoom pov tseg los ntawm cov khoom siv ntau dhau, qhov tsis zoo, thiab ntim khoom. Kev tswj cov khoom pov tseg kom zoo, xws li rov ua dua tshiab thiab rov siv cov khoom pov tseg, tuaj yeem pab txo qis kev cuam tshuam ib puag ncig ntawm cov yas txhaj tshuaj molding.

- Kev siv tshuaj lom neeg: Qee cov tshuaj hauv cov yas txhaj tshuaj molding, xws li cov pwm tso tawm thiab cov kuab tshuaj ntxuav, tuaj yeem ua rau ib puag ncig. Kev siv lwm txoj hauv kev zoo rau ib puag ncig lossis txo qis kev siv cov tshuaj no tuaj yeem pab txo qhov cuam tshuam ib puag ncig.

- Kev txiav txim siab kawg ntawm lub neej: Cov khoom yas uas tsim los ntawm kev txhaj tshuaj molding feem ntau xaus rau hauv qhov chaw pov tseg, uas tuaj yeem siv ntau pua xyoo kom degrade. Tsim cov khoom siv rov ua dua tshiab lossis biodegradability tuaj yeem txo qhov cuam tshuam ib puag ncig ntawm cov yas txhaj tshuaj molding.

Yav tom ntej ntawm Yas Txhaj Molding

Lub neej yav tom ntej ntawm kev txhaj tshuaj yas molding zoo li kev cog lus, raws li kev nce qib hauv kev siv tshuab thiab cov ntaub ntawv yuav tsum ua kom cov txheej txheem ua haujlwm tau zoo dua, muaj txiaj ntsig zoo, thiab ruaj khov. Nov yog qee qhov kev hloov pauv thiab kev txhim kho uas yuav ua rau lub neej yav tom ntej ntawm kev txhaj tshuaj yas molding:

- Additive manufacturing: Additive manufacturing, tseem hu ua 3D luam ntawv, yog ib tug tshiab technology uas muaj peev xwm hloov cov yas txhaj tshuaj molding. Los ntawm kev siv 3D luam ntawv los tsim pwm, cov tuam txhab lag luam tuaj yeem txo lub sijhawm thiab tus nqi cuam tshuam nrog cov txheej txheem pwm tsim.

- Kev tsim khoom ntse: Kev tsim khoom ntse, uas suav nrog automation, kev txheeb xyuas cov ntaub ntawv, thiab kev kawm tshuab, xav kom hloov pauv cov yas txhaj tshuaj molding. Cov neeg tsim khoom tuaj yeem txhim kho kev ua tau zoo, txo cov khoom pov tseg, thiab ua kom cov khoom tsim tau los ntawm kev siv cov sensors thiab cov ntaub ntawv txheeb xyuas los ua kom zoo dua cov txheej txheem.

- Sustainable cov ntaub ntawv: Cov khoom siv ruaj khov, xws li bioplastics thiab cov khoom siv rov ua dua tshiab, tau dhau los ua neeg nyiam hauv kev lag luam yas txhaj tshuaj molding. Cov ntaub ntawv no muab cov txiaj ntsig ib puag ncig thiab tuaj yeem pab cov tuam txhab ua kom tau raws li cov hom phiaj kev ruaj ntseg.

- Micro molding: Micro molding, uas koom nrog kev tsim cov khoom me me nrog kev ua haujlwm siab, tau dhau los ua qhov tseem ceeb hauv kev lag luam xws li kev kho mob thiab hluav taws xob. Kev nce qib hauv thev naus laus zis thiab cov khoom siv yuav tsum ua kom micro molding nkag tau yooj yim dua thiab siv tau zoo.

- Customization: Raws li cov neeg siv khoom xav tau cov khoom lag luam tus kheej ntau dua, cov yas txhaj tshuaj molding yuav tsum ua kom yooj yim dua thiab kho tau. Kev nce qib hauv thev naus laus zis, xws li kev tawm tswv yim ntawm lub sijhawm tiag tiag thiab kev kawm tshuab, yuav ua rau cov tuam txhab tsim khoom tsim khoom sai thiab ua tau zoo.

xaus:

Yas txhaj tshuaj molding yog ib qho kev siv ntau yam thiab muaj txiaj ntsig kev tsim khoom uas tau hloov pauv kev tsim khoom ntawm ntau yam khoom. Los ntawm cov khoom siv kho mob mus rau cov khoom siv hauv tsheb, cov yas txhaj tshuaj molding muaj ntau qhov zoo dua lwm cov txheej txheem tsim khoom, suav nrog cov nqi tsim khoom siab, tsim qauv yooj yim, thiab cov nqi siv tau zoo. Nrog kev nce qib hauv cov thev naus laus zis thiab cov khoom siv tas mus li, lub neej yav tom ntej ntawm kev txhaj tshuaj yas molding zoo li ci ntsa iab, thiab cov txheej txheem no yuav zoo li ua lub luag haujlwm tseem ceeb hauv kev tsim khoom hauv xyoo tom ntej.