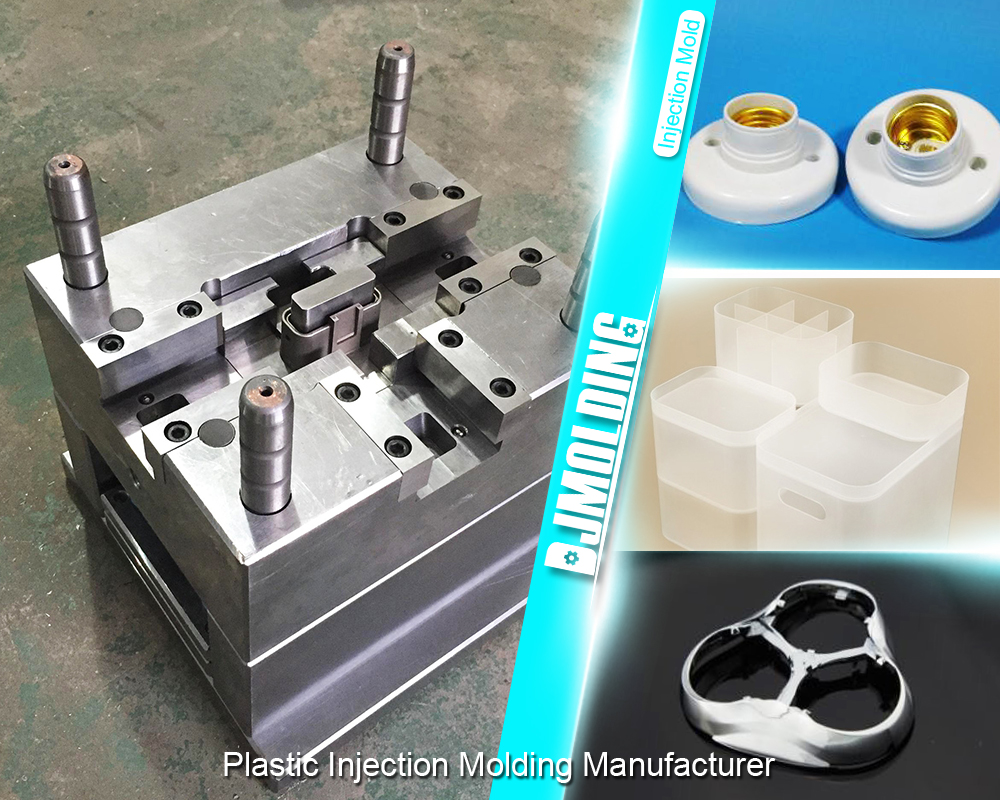

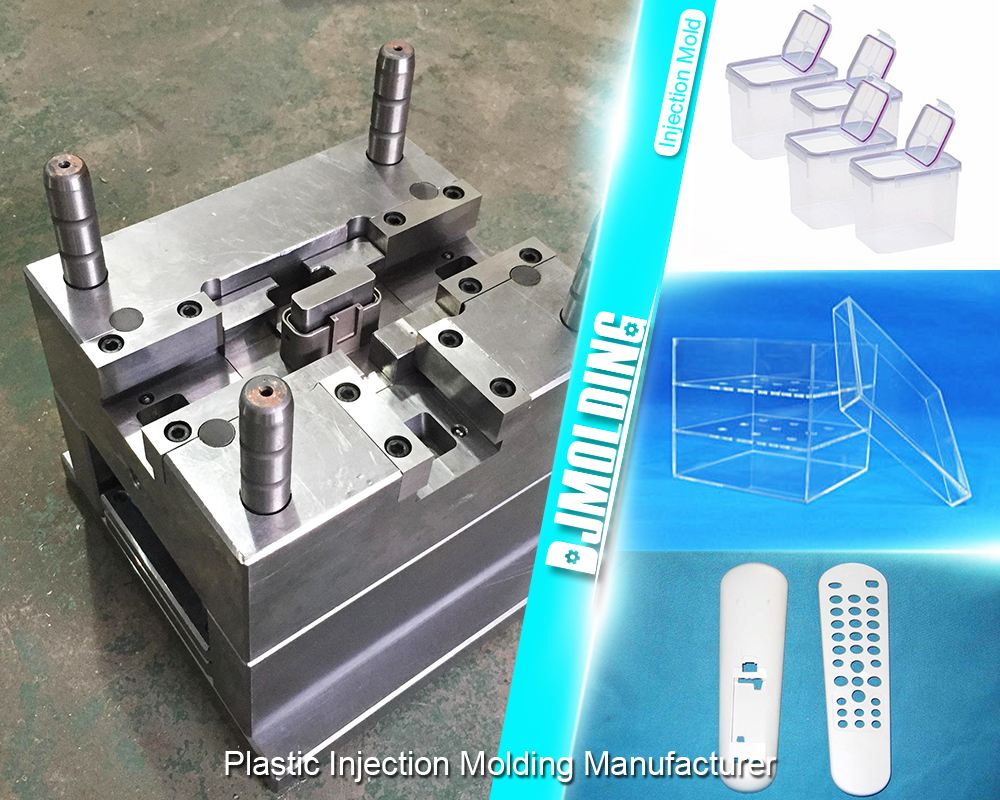

Kev kos duab ntawm Me me Batch Yas Txhaj Moulding: Streamlining Production With Precision

Kev kos duab ntawm Me me Batch Yas Txhaj Moulding: Streamlining Production With Precision

Yas txhaj molding tau tshwm sim raws li ib tug kev ua si-hloov txheej txheem nyob rau hauv niaj hnub no tus ceev-paced manufacturing toj roob hauv pes. Harnessing precision thiab efficiency enables lub loj ntau lawm ntawm intricate yas Cheebtsam. Kab lus no delves rau hauv intricacies ntawm kev txhaj tshuaj yas molding, qhia txog nws qhov tseem ceeb, qhov zoo, thiab kev siv thoob plaws ntau hom kev lag luam.

Nkag siab me me Batch Yas Txhaj Moulding

Txhais thiab txheej txheem txheej txheem

Yas txhaj tshuaj molding yog cov txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten yas rau hauv pwm kab noj hniav los tsim cov duab nyuaj thiab meej. Tshooj lus no piav qhia txog cov txheej txheem tseem ceeb, los ntawm kev xaiv cov khoom siv mus rau kev siv cov khoom tseem ceeb xws li pwm, txhaj tshuaj, thiab cov tshuab clamping.

Hom Plastics Siv

Txoj kev vam meej ntawm kev txhaj tshuaj molding yog nyob ntawm kev siv ntau hom yas uas haum rau cov kev siv tshwj xeeb. Ntawm no, peb tshawb nrhiav cov yas siv feem ntau, suav nrog cov thermoplastics thiab thermosetting polymers. Los ntawm kev nkag siab txog lawv cov yam ntxwv tshwj xeeb thiab cov khoom, cov tuam txhab tuaj yeem txhim kho cov txheej txheem molding kom zoo dua.

Cov txiaj ntsig tseem ceeb ntawm Kev Txhaj Tshuaj Molding

Yas txhaj molding muaj ntau qhov zoo dua lwm txoj kev tsim khoom. Tshooj lus no delves rau hauv nws cov nqi-zoo, tsim kev yooj yim, kev tsim khoom siab, thiab kev tswj xyuas zoo ib yam. Cov piv txwv tiag tiag hauv ntiaj teb thiab cov dab neeg ua tiav tau piav qhia ntxiv txog qhov kev hloov pauv ntawm cov yas txhaj tshuaj molding rau ntau qhov kev lag luam.

Txoj Kev Txhaj Tshuaj Molding

Pwm Tsim thiab Kev Npaj

Pwm tsim yog ib qho tseem ceeb ntawm qhov yas txhaj tshuaj molding. Peb tham txog qhov tseem ceeb ntawm kev tsim pwm rau kev ua haujlwm zoo, ua haujlwm ntev, thiab ua haujlwm tau zoo. Tsis tas li ntawd, peb kov cov khoom pwm sib txawv thiab lawv cov khoom kom ntseeg tau tias qhov kev xaiv zoo tshaj plaws rau txhua qhov project.

Txhaj Phaj

Lub sijhawm txhaj tshuaj yog melting cov khoom yas, nias nws, thiab txhaj rau hauv pwm kab noj hniav. Ntawm no, peb muab cov lus piav qhia ntxaws ntxaws ntawm theem no, hais txog qhov tseem ceeb ntawm kev txiav txim siab thiab kev tswj hwm. Cov neeg tsim khoom tshawb nrhiav qhov kub, siab, thiab lub sijhawm txias kom ua tiav cov khoom zoo.

Cooling thiab Solidification

Lub caij txias ua lub luag haujlwm tseem ceeb hauv cov txheej txheem yas txhaj tshuaj molding. Peb tshawb xyuas cov txheej txheem ua kom txias kom ntseeg tau tias cov yas khov kho kom zoo, txhim kho cov qauv kev ncaj ncees thiab txo qhov tsis xws luag. Cov kws tshaj lij sib tham txog cov tswv yim xws li pwm tswj qhov kub thiab txias, ua kom txias txias, thiab txoj kev ua kom txias sai.

Ejection thiab Finishing

Cov pwm ejects cov khoom tom qab solidification. Tshooj lus no piav qhia txog cov txheej txheem ejection thiab qhia txog cov haujlwm thib ob xws li trimming, polishing, thiab nto tiav. Los ntawm kev hais txog cov kev ua tiav no, cov tuam ntxhab tuaj yeem txhim kho cov khoom zoo nkauj, kev ua haujlwm, thiab kev ua lag luam.

Kev siv cov yas txhaj tshuaj molding

- Tus neeg siv khoom: Cov neeg tsim khoom siv dav siv cov yas txhaj tshuaj molding los tsim cov khoom siv. Cov neeg tsim khoom siv cov txheej txheem no los tsim cov khoom siv hauv chav ua noj, khoom siv hauv tsev, khoom ua si, thiab khoom siv hluav taws xob. Lub versatility ntawm yas txhaj tshuaj molding tso cai rau cov creation ntawm intricate designs, vibrant xim, thiab ruaj cov khoom uas txhim khu peb lub neej txhua hnub.

- Automotive Kev Lag Luam: Kev lag luam tsheb loj tso siab rau cov yas txhaj tshuaj molding los tsim ntau yam khoom. Los ntawm sab hauv trims thiab dashboard panels mus rau sab nrauv yam xws li bumpers thiab grilles, yas txhaj tshuaj molding muaj kev yooj yim tsim, yuag txo, thiab nqi-zoo. Nws ua rau kev lag luam automotive kom ua tiav kev zoo nkauj, kev sib koom ua ke, thiab txhim kho roj efficiency.

- Kev Kho Mob thiab Kev Kho Mob: Kev txhaj tshuaj yas molding yog qhov tseem ceeb hauv kev kho mob thiab kev kho mob. Cov neeg tsim khoom siv nws los tsim cov cuab yeej siv kho mob, khoom siv, thiab cov khoom siv nrog cov qauv zoo thiab kev tswj hwm. Cov neeg tsim khoom tsim cov khoom xws li cov koob txhaj tshuaj, IV connectors, cov cuab yeej phais, thiab cov khoom cog siv cov khoom siv biocompatible los xyuas kom cov neeg mob muaj kev nyab xeeb thiab ua haujlwm zoo.

- Kev Lag Luam Ntim: Yas txhaj tshuaj molding yog qhov tseem ceeb hauv kev lag luam ntim khoom. Nws tso cai rau kev tsim cov ntim yas, lub raj mis, lub kaus mom, thiab kaw siv hauv ntau yam xws li khoom noj thiab dej haus, kev saib xyuas tus kheej, thiab tshuaj. Lub peev xwm los tsim cov duab customized, qhov ntau thiab tsawg, thiab cov yam ntxwv ua rau cov yas txhaj tshuaj molding yog ib qho kev xaiv rau kev ntim cov kev daws teeb meem.

- Cov khoom siv hluav taws xob thiab hluav taws xob: Yas txhaj tshuaj molding ua tau txiaj ntsig zoo rau kev lag luam hluav taws xob. Nws pab txhawb kev tsim cov casings, connectors, keyboards, thiab lwm yam intricate qhov yuav tsum tau rau cov khoom siv hluav taws xob thiab hluav taws xob. Yas txhaj tshuaj molding ua kom precision, qhov ruaj khov, thiab tiv thaiv ib puag ncig yam khoom siv hluav taws xob.

- Aerospace thiab Defense: Yas txhaj tshuaj molding pom cov ntawv thov hauv aerospace thiab kev tiv thaiv sectors. Cov neeg tsim khoom siv cov yas txhaj tshuaj molding los tsim lub teeb yuag, lub zog muaj zog uas ua tau raws li kev ua tau zoo thiab kev nyab xeeb. Piv txwv muaj xws li cov khoom siv sab hauv, cov cuab yeej ntsuas, cov hlua khi, thiab cov tshuab aerospace ducting.

- Kev tsim kho thiab cov khoom siv hauv tsev: Yas txhaj tshuaj molding pab txhawb rau kev tsim kho kev lag luam los ntawm kev tsim cov khoom xws li cov kav dej, fittings, rwb thaiv tsev, thiab cov khoom siv vov tsev. Lub durability, corrosion kuj, thiab nqi-zoo ntawm cov yas txhaj tshuaj molded khoom ua rau lawv zoo tagnrho rau kev tsim kho daim ntawv thov.

- Kev Ua Si thiab Kev Ua Si: Yas txhaj tshuaj molding tsim cov khoom siv kis las, cov khoom ua si, thiab cov khoom siv sab nraum zoov. Cov neeg tsim khoom muaj cov khoom xws li cov kaus mom hlau, cov iav tiv thaiv, cov khoom siv pob, thiab cov khoom siv ua haujlwm siv cov txheej txheem no. Yas txhaj molding tso cai rau kev tsim cov khoom hnyav, cuam tshuam-resistant uas txhim khu kev ua haujlwm thiab kev nyab xeeb.

Kev nce qib thiab yav tom ntej Trends

Technology Innovation

- Automation: Automation tau revolutionized yas txhaj molding, streamlining txheej txheem ntau lawm thiab txhim kho efficiency. Cov tshuab tsis siv neeg tuaj yeem tuav cov khoom siv, hloov pwm, thiab kev tswj kom zoo, txo tib neeg kev ua yuam kev thiab ua kom cov khoom tsim tau.

- 3D Luam Ntawv: Kev koom ua ke 3D luam ntawv thev naus laus zis nrog cov yas txhaj tshuaj molding tau qhib qhov muaj peev xwm tshiab rau kev ua qauv sai thiab kev hloov kho. 3D-printed pwm thiab inserts tuaj yeem siv nrog cov pwm ib txwm siv, ua kom nrawm dua thiab raug nqi me me-batch ntau lawm.

- Artificial txawj ntse (AI): AI ua lub luag haujlwm tseem ceeb hauv kev txhaj tshuaj yas molding. AI-powered software tuaj yeem txheeb xyuas cov txheej txheem cov ntaub ntawv hauv lub sijhawm tiag tiag, txhim kho qhov tsis zoo xws li kub, siab, thiab lub sijhawm txias kom txhim kho qhov zoo. Predictive AI-powered txij nkawm tshuab kuj tuaj yeem pab tiv thaiv lub sijhawm poob qis thiab txo tus nqi kho.

- Multi-Material Moulding: Lub peev xwm los siv ntau yam ntaub ntawv hauv ib qho kev txhaj tshuaj molding yog tau txais traction. Cov neeg tsim khoom tuaj yeem siv cov yas txhaj tshuaj molding los tsim cov khoom sib txawv nrog cov khoom siv sib txawv, xws li kev sib txuas cov khoom siv tawv thiab hloov tau yooj yim. Cov txheej txheem tsim khoom no tso cai rau kev tswj xyuas meej ntawm cov txheej txheem molding, ua kom tiav ntau yam ntawm cov qauv tsim thiab geometry ua tau. Multi-material molding expands tsim possibilities thiab txhim khu cov khoom functionality.

- Micro-Injection Moulding: Miniaturization yog ib qho kev loj hlob thoob plaws hauv kev lag luam, thiab micro-txhaj tshuaj molding caters rau qhov kev thov no. Cov txheej txheem no tsim cov khoom me me, qhov sib txawv, qhib cov hauv kev xws li hluav taws xob, khoom siv kho mob, thiab microfluidics.

- Sustainable Materials: Raws li kev ruaj ntseg yog qhov tseem ceeb tshaj plaws, kev lag luam tab tom tshawb nrhiav lwm cov ntaub ntawv rau kev txhaj tshuaj yas molding. Biodegradable thiab bio-raws li plastics tau los ntawm cov khoom siv txuas ntxiv tau txais kev nyiam. Tsis tas li ntawd, siv cov yas rov ua dua tshiab txo cov khib nyiab thiab txhawb kev lag luam ncig.

- Smart Manufacturing: Kev koom ua ke Internet ntawm Yam (IoT) thev naus laus zis hauv kev txhaj tshuaj yas yas tso cai rau kev soj ntsuam thiab tswj cov txheej txheem ntau lawm. Sensors thiab kev sib txuas ua kom muaj kev sau cov ntaub ntawv hauv lub sijhawm, tsom xam, thiab saib xyuas tej thaj chaw deb. Siv cov txheej txheem automated hauv cov yas txhaj tshuaj molding txhim khu kev tswj kom zoo, txo lub sijhawm poob, thiab txhim kho kev ua haujlwm tag nrho. Cov txheej txheem no tuaj yeem suav nrog kev tuav cov khoom siv tsis siv neeg, kev tshem tawm neeg hlau, thiab kev tshuaj xyuas hauv kab.

- Virtual thiab Augmented Reality: Hauv kev txhaj tshuaj yas molding, cov tsim qauv thiab cov kws tsim qauv siv cov thev naus laus zis thiab kev muaj tiag tiag kom siv tau cov qauv tsim thiab txhim kho cov txheej txheem. Cov neeg tsim khoom tuaj yeem txheeb xyuas cov teeb meem muaj peev xwm, txhim kho cov qauv tsim, thiab txo lub sijhawm ua lag luam los ntawm kev tsim cov qauv virtual thiab simulating cov txheej txheem molding.

Cov kev nce qib no thiab cov qauv yav tom ntej hauv kev txhaj tshuaj yas molding yog shaping kev lag luam toj roob hauv pes, ua kev tsim khoom sai dua, muaj txiaj ntsig zoo, thiab ib puag ncig zoo. Los ntawm embracing automation, leveraging 3D printing thiab AI, tshawb nrhiav cov ntaub ntawv tshiab, thiab siv cov kev txawj ntse tsim, manufacturers muaj peev xwm nyob twj ywm kev sib tw thiab ua tau raws li cov kev xav tau ntawm lub lag luam. Kev nrhiav kev nruam txuas ntxiv ntawm kev tsim kho tshiab kom ntseeg tau tias cov yas txhaj tshuaj molding tseem nyob ntawm qhov ua ntej ntawm kev tsim khoom niaj hnub.

xaus

Yas txhaj molding yog lub hauv paus ntawm kev tsim khoom niaj hnub, ua kom muaj txiaj ntsig zoo ntawm cov khoom siv yas nyuaj. Yas txhaj tshuaj molding tau hloov cov khoom los ntawm kev hloov pauv cov txheej txheem tseem ceeb, muab ntau yam zoo, thiab nrhiav kev siv thoob plaws ntau qhov kev lag luam. Cov neeg tsim khoom tuaj yeem ua tau raws li cov neeg siv khoom xav tau ntau zuj zus los ntawm kev siv qhov tseeb, tsim kev yooj yim, thiab tus nqi-zoo. Kev lag luam yas txhaj tshuaj molding yog npaj rau lub neej yav tom ntej uas muaj kev tsim kho tshiab thiab lub luag haujlwm ib puag ncig raws li kev txhim kho thev naus laus zis thiab kev siv dag zog txuas ntxiv mus rau nws. Peb caw cov neeg nyeem los tshawb nrhiav ntxiv thiab tshawb pom qhov tsis muaj kev cia siab uas cov yas txhaj tshuaj molding muaj.

Rau ntxiv txog me me batch yas txhaj tshuaj molding, koj tuaj yeem them mus ntsib Djmolding ntawm https://www.djmolding.com/injection-mould-manufacturing/ yog xav paub ntau info.