Ob Xim Txhaj Moulding

Ob-xim txhaj tshuaj molding, los yog txhaj tshuaj molding, yog txheej txheem tsim khoom siv los tsim cov khoom yas nrog ob xim sib txawv lossis cov khoom siv. Cov txheej txheem no suav nrog kev txhaj ob lwm yam khoom rau hauv ib lub pwm los tsim lub luag haujlwm nrog ob lub suab tiav lossis cov khoom siv sib txawv. Ob-xim txhaj tshuaj molding muaj ntau daim ntawv thov nyob rau hauv ntau yam lag luam, xws li tsheb, kev kho mob, thiab cov neeg siv khoom. Kab lus no yuav qhia txog cov ntsiab lus ntawm ob-xim txhaj tshuaj molding, nws qhov zoo, kev txwv, thiab kev siv.

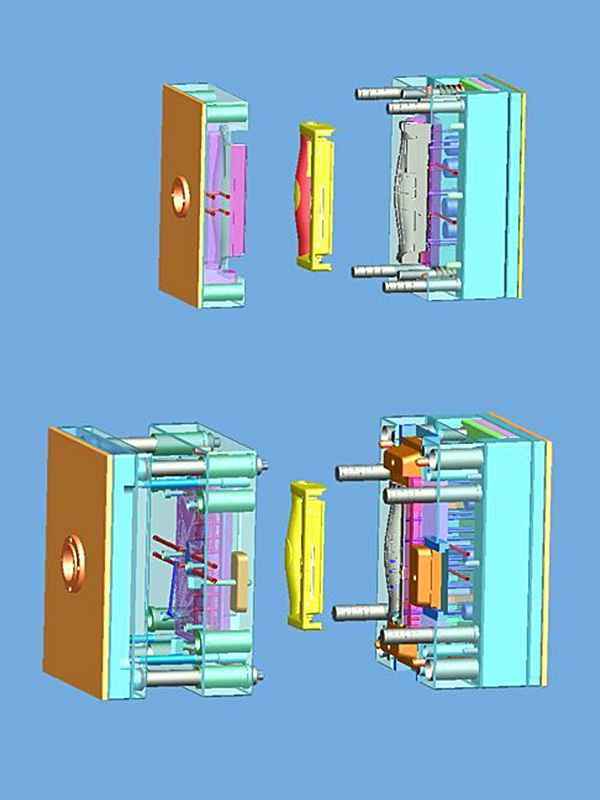

Ob-xim txhaj tshuaj molding txheej txheem

Ob txoj kev txhaj tshuaj molding txheej txheem muaj ob qho kev txhaj tshuaj sib txawv ntawm cov xim sib txawv. Thawj qhov kev txhaj tshuaj pwm ua rau lub hauv paus, thaum lub sijhawm txhaj tshuaj thib ob ua rau cov duab kawg thiab xim. Ob txoj kev txhaj tshuaj yog feem ntau ua nyob rau hauv tib lub tshuab, siv ob lub thoob thiab lub nozzles sib txawv.

Koj tuaj yeem rhuav tshem cov txheej txheem rau hauv cov kauj ruam hauv qab no:

- Cov pwm raug kaw, thiab thawj cov tshuaj txhaj tshuaj yog txhaj rau hauv lub pwm kab noj hniav kom tsim tau ib feem ntawm lub hauv paus.

- Tus neeg teb xov tooj qhib lub pwm thiab tig los yog txav thaj tsam mus rau qhov chaw nres tsheb thib ob.

- Qhov thib ob resin txhaj tshuaj yog txhaj rau hauv pwm kab noj hniav, tsim cov duab kawg thiab xim ntawm ib feem.

- Tus neeg teb xov tooj qhib lub pwm thiab tshem tawm ib feem.

Cov txheej txheem ob-xim txhaj tshuaj molding muaj ntau qhov zoo, suav nrog:

- Nce efficiency:Ob-xim txhaj tshuaj molding tshem tawm qhov xav tau rau kev ua haujlwm thib ob, xws li pleev xim lossis sib dhos, uas tuaj yeem txuag sijhawm thiab txo nqi.

- Txhim kho zoo nkauj: Lub peev xwm los tsim qhov chaw nrog ntau yam xim thiab cov qauv tsim sib txawv tuaj yeem txhim kho qhov zoo nkauj ntawm cov khoom kawg, ua kom pom kev zoo rau cov neeg siv khoom.

- Txhim kho kev ua haujlwm:Cov txheej txheem ob-xim txhaj tshuaj molding kuj tseem tuaj yeem txhim kho cov khoom kawg ntawm kev ua haujlwm, vim nws tso cai rau siv cov khoom sib txawv rau lwm qhov chaw.

Kuj tseem muaj qee qhov teeb meem cuam tshuam nrog ob-xim txhaj tshuaj molding txheej txheem, xws li:

- Tsim complexity: Cov txheej txheem yuav tsum tau tsim pwm tsim, ua rau nws nyuaj rau kev tsim thiab tswj.

- Khoom siv compatibility: Ob qhov sib txawv resins siv nyob rau hauv cov txheej txheem yuav tsum tau sib xws, los yog lawv yuav tsis ua raws li qhov zoo, ua rau muaj qhov tsis xws luag hauv cov khoom kawg.

- Tus nqi:Cov txheej txheem ob-xim txhaj tshuaj molding tuaj yeem kim dua li cov txheej txheem molding ib txwm vim qhov nyuaj ntawm cov pwm thiab cov khoom siv ntxiv yuav tsum tau ua.

Cov khoom siv hauv ob xim txhaj tshuaj molding

Xaiv cov khoom tsim nyog rau ob-xim txhaj tshuaj molding yog qhov tseem ceeb los tsim cov khoom zoo thiab ua haujlwm zoo. Cov ntawv blog no yuav tham txog cov ntaub ntawv uas feem ntau siv hauv ob xim txhaj tshuaj molding.

Thermoplastic elastomers (TPE)

TPEs yog nto moo rau ob-xim txhaj tshuaj molding vim hais tias lawv yog mos, saj zawg zog, thiab ua raws li zoo rau lwm yam ntaub ntawv. Lawv kuj tiv taus cov tshuaj thiab muaj peev xwm huab cua zoo. Cov neeg tsim khoom feem ntau siv TPEs rau kev tuav, tuav, thiab lwm qhov chaw uas xav tau qhov chaw xis nyob, tsis txhob plam.

Thermoplastic polyurethane (TPU)

TPU yog lwm cov khoom siv nrov rau ob-xim txhaj tshuaj molding vim nws qhov yooj yim thiab ua haujlwm ntev. TPU tuaj yeem tiv taus rov qab khoov thiab flexing, ua rau nws zoo tagnrho rau cov khoom xws li xov tooj, cov khoom siv kho mob, thiab cov khoom ua si. Nws kuj yog resistant rau roj thiab tshuaj.

Acrylonitrile butadiene styrene (ABS)

Cov neeg tsim khoom siv feem ntau siv ABS, cov thermoplastic nruj, hauv ob xim txhaj tshuaj molding. Nws muaj cov khoom siv zoo heev, muaj kev cuam tshuam zoo, thiab tuaj yeem ua raws li lwm cov ntaub ntawv. Cov neeg tsim khoom feem ntau siv ABS rau cov khoom siv tsheb, cov khoom siv hauv tsev, thiab cov khoom siv hluav taws xob.

Polypropylene (PP)

PP yog lub teeb yuag thiab nruj thermoplastic feem ntau siv hauv ob xim txhaj tshuaj molding. Nws nthuav tawm cov tshuaj zoo thiab qaug zog ua haujlwm thiab tso cai rau kev yooj yim molding rau hauv ntau yam duab. Cov neeg tsim khoom feem ntau siv PP rau ntim, ntim, thiab cov khoom siv tsheb.

Cov tshuaj polycarbonate (PC)

PC yog lub pob tshab thermoplastic feem ntau siv hauv ob xim txhaj tshuaj molding rau kev siv xws li cov khoom siv kho mob, cov khoom siv tsheb, thiab cov khoom siv hluav taws xob. Nws muaj kev cuam tshuam zoo heev, siab optical clarity, thiab tuaj yeem tiv taus qhov kub thiab txias. Cov neeg tsim khoom feem ntau siv PC rau lo ntsiab muag, teeb pom kev zoo, thiab npog.

Polyamide (PA)

PA, lub npe hu ua nylon, yog ntau yam thermoplastic feem ntau siv hauv ob xim txhaj tshuaj molding. Nws nthuav tawm cov khoom siv kho tshuab zoo, ua haujlwm zoo heev rau kev puas tsuaj thiab tshuaj lom neeg, thiab tso cai rau kev yooj yim molding rau hauv cov duab nyuaj. Cov neeg tsim khoom feem ntau siv PA rau lub zog, bearings, thiab cov khoom siv.

Qhov zoo ntawm ob-xim txhaj tshuaj molding

Kev txhaj tshuaj molding yog txheej txheem tsim khoom siv dav hauv cov ntaub ntawv yas yog yaj thiab txhaj rau hauv pwm los tsim cov txheej txheem nyuaj thiab meej. Ib qho ntawm cov kev hloov pauv ntawm cov txheej txheem no yog ob-xim txhaj tshuaj molding, uas tso cai rau kev tsim cov khoom nrog ob xim sib txawv lossis cov khoom siv hauv ib lub voj voog molding. Cov ntawv blog no yuav tham txog qhov zoo ntawm ob-xim txhaj tshuaj molding.

zoo

- Kev txuag nqi: Ib qho txiaj ntsig tseem ceeb ntawm ob-xim txhaj tshuaj molding yog kev txuag nqi. Hloov chaw ntawm kev tsim thiab sib sau ua ob ntu, cov txheej txheem no pib nrog ib feem nrog ob xim lossis cov khoom siv hauv ib lub voj voog molding. Txo qhov kev xav tau ntawm cov haujlwm sib dhos ntxiv ua rau tus nqi siab thiab txuag sijhawm.

- Txhim kho Design Flexibility:Ob-xim txhaj tshuaj molding muab kev tsim qauv yooj yim uas tsis tuaj yeem nrog lwm cov txheej txheem tsim khoom. Tsim ib feem nrog ob cov ntaub ntawv sib txawv lossis xim ua rau cov neeg tsim qauv ua kom tiav ntau dua thiab cov qauv tsim tshwj xeeb uas lwm cov txheej txheem tsis tuaj yeem ua tiav.

- Txhim kho cov khoom zoo nkauj: Ob-xim txhaj tshuaj molding muab cov khoom zoo nkauj zoo nkauj los ntawm kev tso cai rau kev tsim cov khoom nrog cov xim sib txawv lossis cov khoom siv. Cov khoom lag luam uas xav tau kev pom zoo, xws li cov khoom siv hluav taws xob, cov khoom siv kho mob, thiab cov khoom siv tsheb, tuaj yeem tau txais txiaj ntsig zoo los ntawm qhov no.

- Nce Durability: Ob-xim txhaj tshuaj molding tuaj yeem ua rau kom muaj zog ntawm ib feem. Los ntawm kev siv ob yam khoom sib txawv nrog cov khoom sib txawv, thaj av tuaj yeem muaj zog, yoog raws, lossis lwm yam khoom uas xav tau. Cov yam ntxwv no yooj yim rau cov khoom raug mob hnyav lossis muaj kev siv ntau zaus.

- Txhim kho Manufacturing Efficiency: Ob-xim txhaj tshuaj molding tseem tuaj yeem txhim kho kev tsim khoom los ntawm kev txo tus lej ntawm cov kauj ruam uas yuav tsum tau ua hauv cov txheej txheem ntau lawm. Los ntawm kev tshem tawm qhov xav tau rau kev ua haujlwm sib dhos ntxiv, ob-xim txhaj tshuaj molding tuaj yeem txo lub sijhawm thiab kev ua haujlwm uas yuav tsum tau ua los ua ib feem.

Kev txwv ntawm ob xim txhaj tshuaj molding

Ob-xim txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov uas tsim kom muaj kev zoo nkauj thiab zoo nkauj nrog ob lossis ntau xim. Thaum cov txheej txheem no muaj ntau qhov zoo, kuj tseem muaj qee qhov kev txwv rau kev txiav txim siab yog tias nws yog qhov kev xaiv zoo rau koj qhov project.

Ib qho kev txwv ntawm ob-xim txhaj tshuaj molding yog tus nqi. Cov khoom siv uas xav tau rau cov txheej txheem no feem ntau kim dua li cov khoom siv txhaj tshuaj molding. Tsis tas li ntawd, cov txheej txheem yuav tsum tau siv sijhawm ntau thiab kev ua haujlwm, uas tuaj yeem ua rau tus nqi nce.

Lwm qhov chaw rau kev txhim kho yog qhov nyuaj ntawm kev tsim. Kev txhaj tshuaj ob-xim tuaj yeem tsim cov qauv tsim nrog ntau xim, tab sis nws tsuas yog tsim nyog rau qee cov txheej txheem. Cov neeg tsim qauv yuav tsum ua tib zoo npaj cov qauv kom tsis txhob muaj xim los ntshav thiab ua kom cov khoom zoo kawg nkaus.

Nov yog qee qhov kev txwv los xav txog:

- Kev xaiv cov khoom siv tsawg:Ob-xim txhaj tshuaj molding feem ntau txwv rau cov ntaub ntawv tshwj xeeb, xws li cov thermoplastics. Kev txwv cov kev xaiv tuaj yeem cuam tshuam qhov kawg ntawm cov khoom zoo.

- Limited ntau lawm ntim:Cov neeg tsim khoom feem ntau siv ob xim txhaj tshuaj molding rau cov khoom me me. Ib txwm txhaj tshuaj molding yog tus nqi ntau dua yog tias xav tau ntau qhov chaw.

- Nyuaj nrog qhov sib dhos: Thaum tsim cov khoom nrog ntau cov xim, nws tuaj yeem nyuaj los kho cov xim kom raug. Kev ua tiav kev ua tiav hauv txoj haujlwm no yuav tsum tau ua tib zoo npaj thiab tswj kom raug ntawm cov txheej txheem txhaj tshuaj molding.

- Lub sijhawm voj voog ntev dua: Ob-xim txhaj tshuaj molding feem ntau xav tau lub voj voog ntev dua li kev txhaj tshuaj molding. Kev txwv tus nqi ntau lawm tuaj yeem ua rau tus nqi siab dua rau cov khoom kawg.

Txawm hais tias cov kev txwv no, ob-xim txhaj tshuaj molding tuaj yeem yog qhov kev xaiv zoo tshaj plaws rau cov haujlwm tshwj xeeb. Lub peev xwm los tsim cov qauv tsim nrog ntau xim tuaj yeem yog qhov zoo dua, tshwj xeeb tshaj yog nyob rau hauv kev lag luam xws li tsheb, cov khoom siv, thiab cov khoom siv kho mob.

Ua haujlwm nrog cov chaw tsim khoom paub txog uas nkag siab txog cov txheej txheem thiab nws cov kev txwv yog qhov tseem ceeb rau kev ua tiav ntawm ob qhov xim txhaj tshuaj molding project. Lawv tuaj yeem pab tsim, xaiv cov khoom siv, thiab txhaj tshuaj molding kom ntseeg tau tias cov khoom kawg ua tau raws li txhua qhov kev xav tau.

Tsim Kev xav rau ob-xim txhaj Moulding

Ib qho tseem ceeb xav txog yog qhov tsim ntawm qhov nws tus kheej. Cov neeg tsim qauv yuav tsum ua tib zoo npaj cov tswv yim los tiv thaiv cov xim los ntshav thiab xyuas kom meej tias cov khoom kawg yog qhov zoo. Nov yog qee qhov kev txiav txim siab tsim qauv kom nco ntsoov:

- Phab ntsa thickness: Lub thickness ntawm ib feem tuaj yeem cuam tshuam qhov kawg ntawm cov khoom zoo. Cov phab ntsa tuab tuaj yeem nyuaj rau pwm, ua rau cov xim tsis sib xws. Nws yog ib qho tseem ceeb kom sib npaug ntawm phab ntsa 'thickness nrog ib feem ntawm tag nrho cov tsim.

- Kev faib kab: Lub parting kab yog qhov twg ob halves ntawm pwm sib ntsib. Nws yog ib qho tseem ceeb uas yuav tsum ua tib zoo xav txog qhov chaw ntawm txoj kab sib cais kom ntseeg tau tias nws tsis cuam tshuam rau kev tsim ntawm ib feem lossis qhov zoo ntawm cov khoom kawg.

- Draft angles: Draft cov ces kaum pab txhawb qhov tso tawm ntawm cov pwm. Nrog rau cov qauv tsim kom zoo hauv kev tsim qauv yog qhov tseem ceeb los xyuas kom yooj yim tshem tawm thaj av ntawm cov pwm yam tsis muaj kev puas tsuaj.

- Kev ntxhib los mos:Kev ntxhib los mos ntawm ib feem tuaj yeem cuam tshuam rau qhov kawg tshwm sim ntawm thaj av. Nws yog ib qho tseem ceeb uas yuav tau xav txog qhov nto ntawm lub luag hauj lwm thiab yuav ua li cas nws cuam tshuam nrog ob xim thaum lub sij hawm txhaj tshuaj molding txheej txheem.

Lwm qhov kev txiav txim siab yog xaiv cov khoom siv. Ob-xim txhaj tshuaj molding feem ntau txwv rau cov ntaub ntawv tshwj xeeb, xws li thermoplastics. Xaiv cov ntaub ntawv uas tuaj yeem tswj cov txheej txheem txhaj tshuaj molding qhov kev ntxhov siab thiab muab cov khoom kawg qhov xav tau thiab kev ua haujlwm yog qhov tseem ceeb.

Nov yog qee qhov kev txiav txim siab ntxiv rau kev xaiv cov khoom:

- Xim compatibility:Yuav kom ua tiav cov txiaj ntsig zoo, cov neeg tsim qauv yuav tsum nquag xaiv cov xim uas qhia tau tias muaj kev sib raug zoo nrog ib leeg thiab cov khoom siv. Txhawm rau kom muaj qhov zoo sib xws ntawm cov khoom kawg, kev tiv thaiv cov xim los ntshav yog qhov tseem ceeb.

- Khoom siv compatibility:Ob yam khoom siv hauv kev txhaj tshuaj molding yuav tsum sib haum. Ua raws li cov txheej txheem no tuaj yeem zam cov teeb meem ntawm adhesion thiab lav qhov txiaj ntsig zoo.

- Cov khoom muaj nuj nqi:Cov khoom ntawm cov khoom siv hauv kev txhaj tshuaj molding tuaj yeem cuam tshuam rau qhov kawg ntawm cov khoom ua haujlwm. Nws yog ib qho tseem ceeb los xav txog cov khoom ntawm txhua yam khoom thiab lawv yuav cuam tshuam li cas thaum lub sij hawm txhaj tshuaj molding txheej txheem.

Cov khoom siv thiab cov cuab yeej siv rau ob xim txhaj tshuaj molding

Ob-xim txhaj tshuaj molding yog txheej txheem tsim khoom uas tso cai rau kev tsim cov khoom nrog ob lossis ntau xim. Cov txheej txheem no yuav tsum muaj cov cuab yeej tshwj xeeb thiab cov cuab yeej los xyuas kom meej tias qhov project ua tiav. Cov ntawv blog no yuav tham txog cov cuab yeej tsim nyog thiab cov cuab yeej siv rau kev txhaj tshuaj molding ob-xim.

Khoom

- Ob-txheej txhaj tshuaj molding tshuab: manufacturers tshwj xeeb tsim lub tshuab no rau ob-xim txhaj tshuaj molding. Nws muaj ob lub thoob thiab ob lub nozzles, tso cai rau kev txhaj tshuaj ntawm ob yam khoom sib txawv rau hauv tib lub pwm. Cov cuab yeej tseem muaj software tshwj xeeb uas tswj kev txhaj tshuaj ntawm ob cov ntaub ntawv.

- Pwm: Cov pwm yog qhov tseem ceeb tshaj plaws ntawm kev txhaj tshuaj molding txheej txheem ob-xim. Cov neeg tsim qauv yuav tsum xyuas kom meej tias tus qauv tsim tso cai rau kev txhaj tshuaj ntawm ob yam khoom sib txawv thiab kev sib raug zoo kom tsis txhob muaj xim los ntshav ntawm lawv. Cov pwm feem ntau yog ua los ntawm cov hlau thiab tuaj yeem kim heev.

- Robotics: Robotics feem ntau yog siv ob-xim txhaj tshuaj molding los automate cov txheej txheem thiab txhim kho efficiency. Robotics tuaj yeem txav qhov chaw ntawm lub tshuab txhaj tshuaj molding thiab cov kab sib dhos los yog tshem tawm cov khoom ntawm pwm.

Tooling

- Core pins: Core pins yog siv nyob rau hauv ob-xim txhaj tshuaj molding los tsim voids los yog qhov nyob rau hauv qhov kawg. Lawv feem ntau yog tsim los ntawm cov hlau thiab yuav tsum tau ua raws nraim kom ntseeg tau tias qhov kawg yog qhov zoo.

- Slides assemblies:Cov neeg tsim khoom siv cov swb sib dhos los tsim cov undercuts lossis lwm yam kev ua haujlwm hauv qhov kawg. Lawv feem ntau yog ua los ntawm cov hlau thiab tuaj yeem ua kom yuam kev.

- Kub khiav system: Cov neeg tsim khoom siv lub tshuab kub khiav los tswj qhov ntws ntawm ob yam khoom sib txawv hauv pwm. Nws muaj cov manifold, nozzles, thiab cov cua sov uas ua kom cov ntaub ntawv ntawm qhov kub thiab txias.

- Ejector pins: Cov neeg tsim khoom siv ejector pins tshem tawm qhov kawg ntawm cov pwm. Feem ntau, cov tuam ntxhab tsim lawv los ntawm cov hlau thiab kho lawv nrog kev ua kom zoo kom cov cheeb tsam tsis muaj kev puas tsuaj thaum ejection.

Ua haujlwm nrog cov chaw tsim khoom paub txog thaum siv ob xim txhaj tshuaj molding yog qhov tseem ceeb. Cov chaw tsim khoom yuav tsum muaj cov khoom siv thiab cov cuab yeej tsim nyog los tsim cov khoom zoo thiab muaj peev xwm coj tau lub cheeb tsam tsim, xaiv cov khoom siv, thiab cov txheej txheem txhaj tshuaj molding.

Qhov sib txawv ntawm ob xim txhaj tshuaj molding thiab tshaj molding

Ob-xim txhaj tshuaj thiab tshaj molding yog cov txheej txheem siv los tsim cov khoom nrog ntau yam khoom lossis xim. Thaum cov txheej txheem no qhia qee qhov sib xws, lawv kuj muaj ntau qhov sib txawv. Tsab ntawv blog no yuav tham txog qhov sib txawv ntawm ob-xim txhaj tshuaj molding thiab tshaj molding.

Ob-xim Txhaj Moulding

- Ob-xim txhaj tshuaj molding yuav tsum txhaj ob yam khoom sib txawv los yog xim rau hauv ib lub pwm kab noj hniav los tsim ib feem nrog ob lossis ntau xim.

- Cov neeg khiav dej num ua cov txheej txheem txhaj tshuaj los ntawm kev txhaj ob cov ntaub ntawv hauv ib qho kev txiav txim. Lawv txhaj cov khoom thib ob tom qab thawj cov khoom tau txias ib nrab thiab solidified.

- Cov txheej txheem yuav tsum muaj cov cuab yeej tshwj xeeb thiab cov cuab yeej siv, suav nrog ob lub tshuab txhaj tshuaj molding tshuab thiab pwm tsim los rau ob-xim txhaj tshuaj molding.

- Cov neeg tsim khoom feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom nrog cov duab lossis cov qauv tsim, xws li cov khoom siv tsheb thiab cov khoom siv.

Sib tshooj

- Overmolding yog molding ib yam khoom ntawm lwm yam khoom los yog substrate los tsim ib feem nrog ntau txheej los yog cov khoom.

- Cov txheej txheem feem ntau yog molding ib feem los yog substrate, ces molding ib tug thib ob cov ntaub ntawv nyob rau hauv lub hauv paus ib feem los tsim ib tug tiav piece nrog ntau txheej los yog cov khoom.

- Cov txheej txheem yuav tsum muaj cov cuab yeej tshwj xeeb thiab cov cuab yeej siv, suav nrog ntau lub tshuab txhaj tshuaj molding thiab cov pwm tsim los rau kev txhaj tshuaj ntau dhau.

- Cov neeg tsim khoom feem ntau siv ntau tshaj molding los tsim cov khoom nrog txhim kho kev tuav, kev nplij siab, lossis kev ua haujlwm ntev, xws li tuav rau cov cuab yeej hluav taws xob thiab cov khoom siv.

Txawv

- ntaub ntawv: Feem ntau, ob-xim txhaj tshuaj molding yuav siv ob yam khoom sib txawv, thaum over- molding yuav siv ib yam khoom raws li lub hauv paus thiab ib tug thib ob raws li lub overmold.

- Kev txiav txim ntawm kev txhaj tshuaj:Nyob rau hauv ob-xim txhaj tshuaj molding, cov neeg ua hauj lwm txhaj cov ntaub ntawv nyob rau hauv ib tug tshwj xeeb kev txiav txim, whereas nyob rau hauv over- molding, lawv thawj pwm lub hauv paus ib feem thiab ces ntxiv cov overmold.

- Khoom siv thiab cuab yeej: Ob xim txhaj tshuaj molding thiab tshaj molding xav tau cov cuab yeej sib txawv thiab cov cuab yeej, nrog ob-xim txhaj tshuaj molding yuav tsum tau txhaj tshuaj molding tshuab thiab pwm tsim los rau ob-xim txhaj tshuaj molding, thiab over-molding yuav tsum tau txhaj tshuaj ntau ntau. moulding tshuab thiab pwm tsim rau over- molding.

- Daim ntaub ntawv:Cov neeg tsim khoom feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom uas muaj cov duab lossis cov qauv tsim, thaum lawv nquag siv ntau tshaj molding los tsim cov cheeb tsam nrog kev tuav, kev nplij siab, lossis kev ua haujlwm ntev.

Kev siv ob-xim txhaj tshuaj molding hauv kev lag luam automotive

Ob-xim txhaj tshuaj molding yog ntau yam txheej txheem tsim khoom uas tau txais cov koob npe nrov hauv kev lag luam tsheb vim nws muaj peev xwm tsim cov khoom zoo, ntau xim nrog cov qauv tsim. Cov ntawv blog no yuav tham txog qee qhov kev siv ntawm ob-xim txhaj tshuaj molding hauv kev lag luam tsheb.

- Cov khoom siv sab hauv:Cov neeg tsim khoom siv dav siv ob-xim txhaj tshuaj molding los tsim cov khoom siv hauv tsheb, xws li cov twj paj nruag, qhov rooj vaj huam sib luag, thiab qhov chaw nruab nrab. Cov khoom no feem ntau xav tau ntau yam xim lossis cov khoom siv kom ua tiav qhov zoo nkauj thiab txhim kho lub tsheb qhov zoo nkauj tag nrho.

- Cov khoom siv sab nrauv: Cov neeg tsim khoom kuj tseem siv ob xim txhaj tshuaj molding los tsim cov khoom siv tsheb sab nraud, xws li cov grilles pem hauv ntej, headlamp bezels, thiab lub teeb lub teeb. Cov khoom siv no yuav tsum muaj kev ua haujlwm siab thiab ua haujlwm ntev kom tiv taus qhov hnyav sab nraum zoov, thiab ob-xim txhaj tshuaj molding muaj cov tshuaj zoo tshaj plaws kom ua tiav ob qho tib si.

- Functional Cheebtsam: Cov neeg tsim khoom kuj tseem tuaj yeem siv ob-xim txhaj tshuaj molding los tsim cov khoom xyaw hauv lub tsheb, xws li lub qhov cua, lub khob tuav, thiab cov pob qhov rooj. Cov khoom no xav tau kev sib xyaw ntawm cov khoom siv nrog cov khoom sib txawv, xws li rigidity thiab saj zawg zog, los ua lawv txoj haujlwm zoo. Ob-xim txhaj tshuaj molding tso cai rau kev tsim cov duab nyuaj thiab tsim qauv thaum koom nrog lwm cov ntaub ntawv kom ua tiav cov khoom xav tau.

- Branding thiab customization: Ob-xim txhaj tshuaj molding yog ib qho cuab yeej zoo heev rau kev tsim khoom lag luam thiab kev hloov kho hauv kev lag luam tsheb. Los ntawm kev sib txuas cov logos lossis cov qauv tsim tshwj xeeb rau hauv qhov chaw, cov tuam txhab tsim khoom tuaj yeem txhim kho cov cim npe ntawm lawv lub tsheb thiab tsim kom muaj txiaj ntsig zoo thiab zoo siab. Tsis tas li ntawd, ob-xim txhaj tshuaj molding tso cai rau tsim kev cai tshwj xeeb rau txhua lub tsheb, muab tus kheej kov rau cov neeg siv khoom.

Qhov zoo ntawm ob-xim txhaj tshuaj molding hauv kev lag luam automotive

- Muab cov qauv tsim kom yooj yim los tsim cov duab thiab cov qauv tsim

- Pab kom siv ntau yam khoom thiab xim hauv ib feem

- Txo lub sij hawm sib dhos thiab tus nqi los ntawm kev sib txuas ntau yam hauv ib qho

- Txhim kho tag nrho cov tsos thiab zoo nkauj ntawm lub tsheb

- Txhim kho kev ua haujlwm los ntawm kev sib xyaw cov ntaub ntawv nrog cov khoom sib txawv

Kev siv ob-xim txhaj tshuaj molding hauv kev kho mob kev lag luam

Ob-xim txhaj tshuaj molding yog ntau yam txheej txheem tsim nrog ntau yam kev siv hauv ntau yam kev lag luam, suav nrog kev lag luam kho mob. Cov ntawv blog no yuav tham txog qee qhov kev siv ntawm ob-xim txhaj tshuaj molding hauv kev lag luam kho mob.

- Cov cuab yeej kho mob:Cov neeg tsim khoom siv dav siv ob xim txhaj tshuaj molding los tsim cov khoom siv kho mob xws li cov koob txhaj tshuaj, tshuaj nqus pa, thiab cov ntsuas ntshav qabzib. Cov cuab yeej no yuav tsum tau ntsuas qhov tseeb thiab raug thiab feem ntau xav tau ntau yam ntaub ntawv kom ua tiav qhov kev xav tau.

- Implants: Cov neeg tsim khoom kuj tseem siv ob-xim txhaj tshuaj molding los tsim cov kev kho mob implants xws li hniav hniav, orthopedic implants, thiab pob ntseg. Cov implants no yuav tsum tau siab precision thiab durability, thiab ob-xim txhaj tshuaj molding tso cai rau kev tsim ntawm complex duab thiab designs thaum koom nrog cov khoom sib txawv kom ua tau raws li qhov xav tau.

- Cov cuab yeej kuaj mob: Ob-xim txhaj tshuaj molding tuaj yeem tsim cov cuab yeej kuaj mob xws li cov khoom siv kuaj thiab cov khoom siv kho mob. Cov khoom no xav tau kev sib xyaw ntawm cov khoom siv nrog cov khoom sib txawv, xws li pob tshab thiab rigidity, los ua lawv cov haujlwm zoo.

- Drug delivery systems:Ob-xim txhaj tshuaj molding yog qhov zoo tagnrho rau kev tsim cov tshuaj xa khoom xws li lub tshuab nqus pa, cov koob txhaj tshuaj, thiab cov cwj mem insulin. Cov tshuab no xav tau kev ua haujlwm siab thiab qhov tseeb kom xa cov tshuaj noj kom raug, thiab ob-xim txhaj tshuaj molding ua rau kev tsim cov duab nyuaj thiab tsim qauv thaum sib xyaw cov khoom sib txawv kom ua tiav cov khoom xav tau.

Qhov zoo ntawm ob-xim txhaj tshuaj molding hauv kev kho mob kev lag luam

- Muab cov qauv tsim kom yooj yim los tsim cov duab thiab cov qauv tsim

- Pab kom siv ntau yam khoom thiab xim hauv ib feem

- Txo lub sij hawm sib dhos thiab tus nqi los ntawm kev sib txuas ntau yam hauv ib qho

- Txhim kho kev ua haujlwm los ntawm kev sib xyaw cov ntaub ntawv nrog cov khoom sib txawv

- Txhim kho tag nrho kev nyab xeeb thiab kev ua tau zoo ntawm cov cuab yeej kho mob

Kev siv ob-xim txhaj tshuaj molding hauv kev lag luam khoom siv

Cov txheej txheem no yuav tsum tau txhaj ob yam khoom sib txawv rau hauv tib lub pwm, tsim ib feem nrog ob xim lossis ntaub. Cov neeg siv khoom lag luam kev lag luam tau txais txiaj ntsig zoo los ntawm cov thev naus laus zis no, vim nws tso cai rau kev tsim cov khoom zoo nkauj dua, ua haujlwm zoo, thiab cov khoom siv tau zoo. Cov ntawv blog no yuav tshawb txog cov ntawv thov ntawm ob-xim txhaj tshuaj molding hauv kev lag luam khoom siv.

- Aesthetically pleasing designs: Ob-xim txhaj tshuaj molding tso cai rau cov tuam txhab tsim cov khoom lag luam nrog cov qauv tsim kom pom tseeb uas sawv tawm ntawm cov txee. Nrog lub peev xwm los ua ke ob qho xim sib txawv los yog cov khoom siv hauv ib lub voj voog molding, cov tuam txhab tsim khoom tuaj yeem tsim cov khoom nrog cov qauv tsim thiab cov qauv sib txawv, xws li cov xov tooj, cov tswj kev ua si, thiab cov khoom siv hauv tsev. Cov thev naus laus zis no tseem tso cai rau cov tuam txhab tsim cov khoom lag luam nrog cov khoom lag luam thiab cov logos kos rau hauv cov qauv tsim, tsim cov khoom tshwj xeeb thiab lees paub.

- Enhanced functionality: Ob-xim txhaj tshuaj molding tuaj yeem txhim kho kev ua haujlwm ntawm cov khoom los ntawm kev tso cai rau kev sib koom ua ke ntawm ntau yam khoom siv rau hauv ib feem. Piv txwv li, lub rooj plaub xov tooj tuaj yeem tsim nrog cov khoom siv yooj yim thiab mos, muab kev tiv thaiv thiab kev poob siab. Tsis tas li ntawd, cov tuam ntxhab tuaj yeem siv ob-xim txhaj tshuaj molding los tsim cov khoom uas muaj ntau dua molded grips, txhim kho cov neeg siv kev nplij siab thiab tuav ntawm cov khoom xws li txhuam hniav, rab chais, thiab cov cuab yeej.

- Txo cov nqi tsim khoom:Kev siv ob-xim txhaj tshuaj molding tuaj yeem ua rau kev txuag nqi tseem ceeb hauv kev tsim cov khoom siv. Los ntawm kev sib xyaw ob cov ntaub ntawv rau hauv ib feem, cov tuam ntxhab tuaj yeem tshem tawm cov kauj ruam sib dhos ntxiv, txo cov nqi zog thiab kev xav tau rau lwm yam khoom siv. Lub tshuab no tseem tuaj yeem txo cov khoom pov tseg los ntawm kev siv cov khoom tsim nyog hauv kev tsim khoom nkaus xwb.

- Txhim kho cov khoom durability: Ob-xim txhaj tshuaj molding tuaj yeem txhim kho cov kav ntev thiab lub neej ntawm cov neeg siv khoom los ntawm kev tsim cov khoom nrog ntau yam khoom. Piv txwv li, lub raj mis dej tuaj yeem tsim nrog lub plhaub tawv tawv thiab cov ntaub mos, hloov tau yooj yim hauv ob sab phlu, muab ob qho tib si durability thiab yooj yim ntawm kev siv. Cov cuab yeej no tseem tuaj yeem tsim cov khoom lag luam nrog cov khoom siv los tiv thaiv, xws li cov khoom siv hauv chav ua noj thiab da dej lev.

- Kev xaiv kev xaiv:Ob-xim txhaj tshuaj molding tso cai rau customization xaiv yav tas los tsis tau nrog ib txwm raug txheej txheem. Cov neeg tsim khoom tuaj yeem tsim cov khoom lag luam nrog cov qauv tsim tshwj xeeb thiab xim, tso cai rau cov neeg siv khoom tsim lawv cov khoom. Piv txwv li, cov khoom ua si xws li golf clubs thiab tennis rackets tuaj yeem tsim nrog kev cai tuav cov xim, muab tus kheej kov rau cov khoom.

Tus nqi txiav txim siab rau ob xim txhaj tshuaj molding

Ob-xim txhaj tshuaj molding yog txheej txheem uas tso cai rau kev tsim cov khoom siv yas, ntau xim xim hauv ib qho kev ua haujlwm. Cov txheej txheem no suav nrog kev siv ob qhov sib txawv ntawm cov khoom siv thermoplastic txhaj rau hauv pwm, txhua qhov sib txawv ntawm cov khoom kawg. Thaum cov txheej txheem no tuaj yeem tsim cov txiaj ntsig zoo, nws muaj qee qhov kev txiav txim siab tus nqi tshwj xeeb. Cov ntawv tshaj tawm blog no yuav tshawb txog qee qhov kev xav txog tus nqi no thiab yuav ua li cas lawv tuaj yeem cuam tshuam rau tag nrho cov nqi ntawm ob-xim txhaj tshuaj molding.

Cov nqi khoom siv

Cov ntaub ntawv 'tus nqi yog ib qho ntawm qhov pom tseeb tshaj plaws kev txiav txim siab rau ob-xim txhaj tshuaj molding. Cov txheej txheem suav nrog kev siv ob cov ntaub ntawv, thiab cov neeg tsim qauv yuav tsum ua tib zoo xaiv ob qho tib si kom ntseeg tau tias muaj kev sib raug zoo thiab zoo. Nws yog ib qho tseem ceeb los xaiv cov ntaub ntawv uas yuav ua haujlwm zoo ua ke thiab ua tau raws li qhov xav tau ntawm cov khoom kawg. Nyob ntawm cov ntaub ntawv xaiv, tus nqi ntawm cov khoom siv raw tuaj yeem yog ib feem tseem ceeb ntawm qhov project tus nqi tag nrho.

Tus nqi cuab yeej

Tus nqi cuab yeej xav tau rau ob-xim txhaj tshuaj molding yog lwm qhov kev txiav txim siab tseem ceeb. Ob yam khoom sib txawv yuav xav tau ob lub pwm cais, thiab cov neeg tsim qauv yuav tsum tsim cov pwm no los ua haujlwm ua ke hauv kev tsim cov khoom kawg. Tus nqi siv rau ob-xim txhaj tshuaj molding yog siab dua li cov txheej txheem txhaj tshuaj molding. Tsis tas li ntawd, qhov nyuaj ntawm kev tsim pwm yuav cuam tshuam rau cov cuab yeej siv, vim tias cov pwm nyuaj yuav xav tau ntau lub sijhawm thiab siv zog los tsim.

Kev Siv Nyiaj Ua Haujlwm

Cov nqi ua haujlwm cuam tshuam nrog ob-xim txhaj tshuaj molding tuaj yeem siab dua li cov txheej txheem txhaj tshuaj molding. Txoj hauj lwm no yuav tsum muaj kev txawj ntse thiab qhov tseeb kom ua tau zoo. Tsis tas li ntawd, cov txheej txheem tuaj yeem siv sijhawm ntau dua li cov neeg ua haujlwm yuav tsum tau ua tib zoo txhaj tshuaj thiab pwm ob cov ntaub ntawv los tsim cov khoom kawg. Cov nqi zog ntau dua rau qhov project yuav yog qhov tshwm sim.

Kev Tswj Tus Nqi Zoo

Kev tswj kom zoo yog qhov tseem ceeb rau txhua txoj kev tsim khoom thiab tseem ceeb rau ob-xim txhaj tshuaj molding. Vim tias cov txheej txheem muaj ob yam khoom sib txawv, ua kom cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb. Qhov tseem ceeb no tuaj yeem xav tau kev sim thiab tshuaj xyuas ntxiv, ntxiv rau qhov project tus nqi tag nrho.

Ob xim txhaj tshuaj molding tuaj yeem yog cov txheej txheem kim dua li kev txhaj tshuaj molding. Txawm li cas los xij, cov txiaj ntsig ntawm cov txheej txheem no - suav nrog kev muaj peev xwm los tsim qhov nyuaj, ntau xim hauv ib qho kev ua haujlwm - tuaj yeem ua rau muaj txiaj ntsig zoo. Los ntawm kev ua tib zoo xav txog cov nqi uas tau teev tseg saum toj no, cov tuam txhab lag luam tuaj yeem txiav txim siab seb puas yog ob-xim txhaj tshuaj molding yog qhov kev xaiv zoo rau lawv qhov project.

Qee qhov kev txiav txim siab tseem ceeb rau kev txhaj tshuaj molding ob xim muaj xws li hauv qab no:

- Cov nqi ntawm cov khoom siv, raws li ob yam khoom sib txawv, yuav raug siv thiab yuav tsum tau ua tib zoo xaiv kom tau raws li qhov yuav tsum tau ua.

- Cov nqi cuab yeej nce ntxiv vim tias cov neeg tsim khoom yuav tsum tsim thiab tsim ob lub pwm los tsim cov khoom kawg.

- Cov nqi ua haujlwm, raws li cov txheej txheem yuav tsum muaj kev txawj ntse thiab kev paub dhau los ntawm tus neeg teb xov tooj thiab tuaj yeem siv sijhawm ntau dua.

- Cov nqi tswj kev ua tau zoo, xws li kev sim thiab tshuaj xyuas ntxiv, yuav tsum tau ua kom ntseeg tau tias cov khoom kawg ua tau raws li qhov yuav tsum tau ua.

Los ntawm kev ua tib zoo xav txog cov nqi no, cov neeg tsim khoom tuaj yeem txiav txim siab seb puas yog ob-xim txhaj tshuaj molding yog qhov kev xaiv zoo rau lawv qhov project.

Kev tswj xyuas zoo hauv ob xim txhaj tshuaj molding

Kev tswj kom zoo yog qhov tseem ceeb rau txhua txoj kev tsim khoom thiab tseem ceeb rau ob-xim txhaj tshuaj molding. Hauv tsab ntawv blog no, peb yuav tshawb txog qee qhov tseem ceeb ntawm kev tswj kom zoo hauv ob-xim txhaj tshuaj molding.

Xaiv Khoom Siv

Kev xaiv cov khoom siv yog ib qho tseem ceeb tshaj plaws ntawm kev tswj kom zoo hauv ob-xim txhaj tshuaj molding. Cov neeg tsim qauv yuav tsum ua tib zoo xaiv cov ntaub ntawv kom ntseeg tau tias muaj kev sib raug zoo thiab zoo. Nws yog ib qho tseem ceeb los xaiv cov ntaub ntawv uas yuav ua haujlwm zoo ua ke thiab ua tau raws li qhov xav tau ntawm cov khoom kawg. Cov neeg tsim qauv tseem yuav tsum xaiv cov ntaub ntawv nrog lub qhov muag kom txo qhov kev pheej hmoo ntawm qhov tsis xws luag, xws li warping lossis xim los ntshav.

Pwm Tsim thiab Kev Tsim Kho

Kev tsim thiab kev tsim cov pwm siv hauv ob-xim txhaj tshuaj molding kuj tseem ceeb heev kom ua tau zoo. Cov neeg tsim qauv yuav tsum tsim thiab tsim cov pwm meej kom ntseeg tau tias nws tuaj yeem tsim cov khoom ua tau raws li qhov xav tau tshwj xeeb thiab ua haujlwm nrog cov khoom siv. Cov neeg tsim qauv tseem yuav tsum tsim cov pwm kom txo qis kev pheej hmoo ntawm qhov tsis xws luag, xws li cov kab sib cais, flashing, lossis cov cim dab dej.

Txhaj Moulding txheej txheem

Cov txheej txheem txhaj tshuaj molding yog lwm qhov tseem ceeb ntawm kev tswj kom zoo hauv ob-xim txhaj tshuaj molding. Cov neeg ua haujlwm yuav tsum ua tib zoo tswj cov txheej txheem txhawm rau txhaj cov khoom sib txawv ntawm qhov raug thiab ntawm qhov kub thiab txias. Txoj haujlwm xav kom tus neeg teb xov tooj muaj ob qho tib si precision thiab kev txawj ntse ntawm qib siab. Ib qho kev sib txawv ntawm cov txheej txheem tsim nyog tuaj yeem ua rau muaj qhov tsis xws luag hauv cov khoom kawg.

Kev tshuaj xyuas thiab kuaj

Thaum kawg, kev tshuaj xyuas thiab kev sim yog qhov tseem ceeb ntawm kev tswj kom zoo hauv ob-xim txhaj tshuaj molding. Cov neeg ua haujlwm yuav tsum ua tib zoo tshuaj xyuas cov khoom kawg kom ntseeg tau tias nws ua tau raws li qhov xav tau tshwj xeeb hais txog nws lub cev qhov ntev thiab nws cov tsos zoo nkauj. Cov txheej txheem no yuav xav tau kev kuaj pom, ntsuas, thiab ntsuas. Cov neeg ua haujlwm yuav tsum txheeb xyuas thiab daws qhov teeb meem ua ntej xa khoom mus rau tus neeg siv khoom.

Qee qhov tseem ceeb ntawm kev tswj xyuas zoo hauv ob xim txhaj tshuaj molding suav nrog:

- Kev xaiv cov ntaub ntawv los xyuas kom meej compatibility thiab zoo

- Pwm tsim thiab kev tsim kho kom paub meej thiab txo qhov tsis xws luag

- Txhaj tshuaj molding txheej txheem tswj xyuas kom meej txhaj cov ntaub ntawv

- Kev tshuaj xyuas thiab kev ntsuam xyuas kom ntseeg tau tias cov khoom kawg ua tau raws li qhov xav tau tshwj xeeb.

Kev daws teeb meem tshwm sim hauv ob xim txhaj tshuaj molding

Zoo li txhua txoj kev tsim khoom, ntau qhov teeb meem tuaj yeem tshwm sim thaum ob xim txhaj tshuaj molding. Hauv no blog ncej, peb yuav tham txog qee qhov teeb meem uas cov tuam txhab lag luam ntsib thaum lub sij hawm ob-xim txhaj tshuaj molding thiab muab qee cov lus qhia rau kev daws teeb meem cov teeb meem.

Ua tsis tiav

Ib qho ntawm feem ntau cov teeb meem manufacturers ntsib thaum lub sij hawm ob-xim txhaj molding yog tsis tiav sau. Thaum cov tshuaj txhaj rau hauv pwm tsis sau nws, nws tsim cov khoom uas ploj lawm lossis tsis tiav. Muaj ntau ntau yam ua rau ua tsis tiav, suav nrog:

- Kev txhaj tshuaj tsis txaus

- Lub qhov rooj loj lossis qhov chaw tsis raug

- Kev ua pa tsis zoo

- Tsis txaus lossis tsis sib npaug ntawm cov pwm

Cov neeg tsim khoom yuav tsum nquag kho qhov kev txhaj tshuaj siab los daws qhov teeb meem no thiab xyuas kom cov pwm puv tag. Lawv kuj yuav tsum nquag xyuas lub rooj vag loj thiab qhov chaw thiab xyuas kom lawv ua kom cov pwm tsim nyog. Tsis tas li ntawd, cov neeg ua haujlwm yuav tsum xyuas kom meej tias lawv ua kom sov cov pwm sib npaug thiab siv cov khoom tsim nyog rau pwm thiab cov txheej txheem.

Tsov rog

Lwm qhov teeb meem uas cov tuam txhab lag luam ntsib thaum ob xim txhaj tshuaj molding yog warping. Ib feem tuaj yeem ua tsis zoo lossis tsis zoo thaum lub sijhawm lossis tom qab txheej txheem molding, ua rau nws tsis tsim nyog rau kev siv lossis tsis zoo nkauj. Muaj ntau ntau yam ua rau warping, suav nrog:

- Kev txias txias tsis sib xws

- Pwm tsim tsis zoo

- Kev xaiv cov khoom siv tsis raug

- Kev ua tsis raug

Txhawm rau daws teeb meem warping, cov tuam txhab lag luam yuav tsum nquag xyuas kom lawv tsim cov pwm kom raug thiab siv cov khoom tsim nyog. Lawv kuj yuav tsum tau kho cov txheej txheem txias kom ntseeg tau tias qhov chaw txias txias thiab maj mam. Thaum kawg, lawv yuav tsum xyuas kom meej tias cov kev ua haujlwm tsis raug, suav nrog qhov ntsuas kub, siab, thiab lub sijhawm voj voog.

Xim Ntshav

Ib qhov teeb meem thib peb uas cov tuam txhab lag luam ntsib thaum lub sij hawm ob-xim txhaj tshuaj molding yog xim los ntshav. Thaum cov xim hauv cov khoom sib xyaw ua ke, nws tuaj yeem ua rau nws tsis zoo nkauj lossis ua rau nws tsis muaj txiaj ntsig. Muaj ntau ntau qhov ua rau muaj xim los ntshav, suav nrog:

- Kev xaiv cov khoom tsis zoo

- Kev sib xyaw ntawm cov khoom siv tsis raug

- Kev ua tsis raug

- Pwm tsim tsis zoo

Txhawm rau daws cov xim los ntshav, cov tuam txhab tsim khoom yuav tsum xyuas kom meej tias cov ntaub ntawv siv tau sib xws thiab tsim nyog. Lawv kuj yuav tsum nquag xyuas kom meej tias lawv sib xyaw cov ntaub ntawv thiab teeb tsa cov txheej txheem ua kom raug. Thaum kawg, lawv yuav tsum xyuas kom meej tias cov pwm tsim tsim nyog rau cov txheej txheem thiab cov ntaub ntawv raug txhaj rau hauv qhov kev txiav txim kom raug thiab raws sijhawm.

Kev sib piv ntawm ob-xim txhaj tshuaj molding nrog lwm cov txheej txheem molding

Thaum ob xim txhaj tshuaj molding muaj qee qhov tshwj xeeb zoo, nws yog qhov tseem ceeb kom nkag siab tias nws piv rau lwm cov txheej txheem molding. Hauv tsab ntawv blog no, peb yuav sib piv ob-xim txhaj tshuaj molding nrog lwm cov txheej txheem molding thiab sib tham txog cov txiaj ntsig thiab kev txwv ntawm txhua tus.

Ob-xim Txhaj Moulding vs. Ib Xim Txhaj Moulding

Ib qho xim txhaj tshuaj molding yog hom ntau tshaj plaws, qhov twg ib qho khoom siv yog txhaj rau hauv pwm los tsim ib feem. Piv rau ob-xim txhaj tshuaj molding, ib leeg-xim txhaj tshuaj molding muaj qee qhov zoo, suav nrog:

- Cov txheej txheem yooj yim dua

- Cov nqi qis dua

- Cov sijhawm hloov nrawm dua

Txawm li cas los xij, ib leeg-xim txhaj tshuaj molding yog txwv rau kev tsim ntau xim lossis ntau yam khoom. Ob-xim txhaj tshuaj molding tso cai rau tsim kom yooj yim tsim thiab tsim ntau qhov chaw nrog ntau xim lossis cov ntaub ntawv.

Ob-xim Txhaj Moulding vs. Overmolding

Overmolding yog ib qho txheej txheem uas koom nrog molding ib qho khoom mus rau lwm tus los tsim ib feem nrog ntau yam khoom lossis cov khoom. Piv rau ob-xim txhaj tshuaj molding, over-molding muaj qee qhov zoo, suav nrog:

- Muaj peev xwm pwm rau qhov chaw uas twb muaj lawm

- Tus nqi qis rau kev khiav me me

- Cov cuab yeej yooj yim dua

Txawm li cas los xij, over-molding tuaj yeem txwv tsis pub ua qhov nyuaj nrog cov qauv tsim thiab ntau xim. Ob-xim txhaj tshuaj molding tso cai rau tsim kom yooj yim tsim thiab tsim ntau qhov chaw nrog ntau yam xim lossis cov ntaub ntawv.

Ob-xim Txhaj Moulding vs. Ntxig Moulding

Insert molding yog txheej txheem uas muaj molding nyob ib ncig ntawm ib qho kev ntxig los yog cov khoom siv los tsim ib feem nrog ntxiv kev ua haujlwm lossis cov khoom. Piv rau ob-xim txhaj tshuaj molding, ntxig molding muaj qee qhov zoo, suav nrog:

- Muaj peev xwm sib xyaw cov khoom siv ua haujlwm

- Tus nqi qis rau kev khiav me me

- Cov cuab yeej yooj yim dua

Txawm li cas los xij, ntxig molding tuaj yeem raug txwv hauv kev tsim cov khoom nrog cov qauv tsim thiab ntau xim. Ob-xim txhaj tshuaj molding tso cai rau tsim kom yooj yim tsim thiab tsim ntau qhov chaw nrog ntau yam xim lossis cov ntaub ntawv.

Sustainability thiab ib puag ncig cuam tshuam ntawm ob-xim txhaj tshuaj molding

Raws li kev txhawj xeeb ib puag ncig txuas ntxiv zuj zus, cov tuam ntxhab yuav tsum xav txog lawv cov txheej txheem tsim khoom 'kev ruaj ntseg thiab kev cuam tshuam ib puag ncig. Ob-xim txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov uas muaj ntau yam txiaj ntsig, tab sis nws tseem yog qhov tseem ceeb kom nkag siab txog nws qhov kev cuam tshuam ib puag ncig thiab muaj peev xwm rau kev ruaj khov. Cov ntawv tshaj tawm blog no yuav tshawb txog kev ruaj khov thiab kev cuam tshuam ntawm ecological ntawm ob-xim txhaj tshuaj molding.

Sustainability nyob rau hauv Ob-xim Txhaj Molding

Ob-xim txhaj tshuaj molding muaj qee lub peev xwm rau kev ruaj khov vim nws muaj peev xwm tsim cov khoom nrog ntau yam khoom thiab cov khoom. Cov txheej txheem no tuaj yeem ua rau cov khoom tsim tau zoo dua qub, tsis muaj pov tseg, thiab kev siv zog ntau dua. Tsis tas li ntawd, ob-xim txhaj tshuaj molding tuaj yeem muab qee cov txiaj ntsig kev ruaj ntseg:

- Lawv txo qis qhov xav tau ntawm kev sib dhos ntxiv lossis cov txheej txheem tiav, uas tuaj yeem txo cov khoom pov tseg thiab siv zog.

- Kev siv cov khoom siv rov ua dua tshiab hauv cov txheej txheem molding tuaj yeem txo cov khoom pov tseg thiab txuag cov peev txheej.

- Lawv txo qis cov khoom seem tsim tawm thaum lub sij hawm molding, uas tuaj yeem txo cov khoom pov tseg thiab txuag cov peev txheej.

Ib puag ncig cuam tshuam ntawm Ob-xim Txhaj Moulding

Thaum ob-xim txhaj tshuaj molding muaj qee lub peev xwm rau kev ruaj khov, nws tseem ceeb heev kom nkag siab txog nws qhov kev cuam tshuam ib puag ncig. Cov kev cuam tshuam ecological ntawm ob-xim txhaj tshuaj molding tuaj yeem suav nrog cov hauv qab no:

- Kev siv hluav taws xob thaum lub sij hawm molding tuaj yeem ua rau lub tsev cog khoom emissions thiab kev hloov pauv huab cua.

- Cov khib nyiab tsim thaum lub sij hawm molding, nrog rau cov khoom seem thiab ntim cov khib nyiab.

- Kev siv cov khoom siv tshuaj lom lossis phom sij hauv molding tuaj yeem ua rau muaj kev pheej hmoo rau cov neeg ua haujlwm thiab ib puag ncig.

Txhawm rau daws cov kev txhawj xeeb ntawm ib puag ncig no, cov tuam txhab lag luam tuaj yeem ua ob peb kauj ruam los txo qhov cuam tshuam ecological ntawm ob-xim txhaj tshuaj molding, suav nrog:

- Siv cov cuab yeej siv hluav taws xob thiab cov txheej txheem los txo kev siv hluav taws xob thaum lub sij hawm molding txheej txheem.

- Siv cov kev txo cov khib nyiab thiab rov ua dua tshiab kom txo cov khoom pov tseg thaum lub sij hawm molding.

- Siv cov ntaub ntawv zoo ib puag ncig thiab zam cov khoom siv tshuaj lom lossis phom sij hauv molding.

Yav tom ntej tiam sis nyob rau hauv ob-xim txhaj molding

Raws li thev naus laus zis txuas ntxiv mus, ob peb lub neej yav tom ntej hauv kev txhaj tshuaj molding yog tsim nyog tshawb nrhiav. Cov ntawv tshaj tawm blog no yuav tham txog qee qhov kev tshwm sim thiab kev nce qib hauv ob-xim txhaj tshuaj molding.

Nce Automation

Ib qho tseem ceeb tshaj plaws nyob rau hauv ob-xim txhaj tshuaj molding yog kev siv automation nce. Automation tuaj yeem txhim kho kev ua haujlwm tau zoo thiab txo qhov kev pheej hmoo ntawm tib neeg kev ua yuam kev, uas ua rau cov nqi qis dua thiab txhim kho zoo. Qee txoj hauv kev uas cov tuam ntxhab siv automation hauv ob xim txhaj tshuaj molding suav nrog:

- Automated ib feem tshem tawm thiab ntim

- Tsis siv neeg cov khoom tuav thiab sib tov

- Automated pwm hloov

Advanced ntaub ntawv

Lwm qhov kev tshwm sim tshwm sim hauv ob xim txhaj tshuaj molding yog siv cov khoom siv siab heev. Cov ntaub ntawv qib siab tuaj yeem muab kev ua tau zoo dua qub, kev ua haujlwm ntev, thiab kev ua haujlwm, uas tuaj yeem pab sib txawv cov khoom lag luam hauv khw. Qee cov tuam txhab lag luam tau siv cov ntaub ntawv qib siab hauv ob xim txhaj tshuaj molding, suav nrog:

- Kev ua haujlwm siab thermoplastics

- Biodegradable thiab compostable cov ntaub ntawv

- Liquid silicone roj hmab (LSR) thiab thermoplastic elastomers (TPE)

Ntse Raug

Kev tsim ntse ntse yog lwm txoj kev cuam tshuam rau yav tom ntej ntawm ob-xim txhaj tshuaj molding. Kev tsim khoom ntse suav nrog kev siv cov thev naus laus zis siab thiab cov ntaub ntawv tshuaj ntsuam xyuas txhawm rau txhim kho cov txheej txheem tsim khoom thiab txhim kho cov khoom zoo. Cov neeg tsim khoom siv kev tsim khoom ntse hauv ntau txoj hauv kev hauv ob xim txhaj tshuaj molding, suav nrog:

- Real-time xyuas thiab analytics ntawm molding tsis

- Predictive txij nkawm thiab kev daws teeb meem

- Kev koom ua ke nrog lwm cov cuab yeej ntse, xws li robotics thiab automation

sustainability

Sustainability yog ib qho kev nthuav dav thoob plaws txhua qhov kev lag luam; ob-xim txhaj tshuaj molding yog tsis muaj kev zam. Cov neeg tsim khoom tau tsom mus rau kev txo cov pov tseg, txuag cov peev txheej, thiab txo qhov cuam tshuam ib puag ncig. Cov neeg tsim khoom tau nquag hais txog kev ruaj ntseg hauv ob xim txhaj tshuaj molding los ntawm ntau txoj hauv kev, suav nrog:

- Kev siv cov khoom siv rov ua dua tshiab

- Optimization ntawm molding tsis tau los txo cov khib nyiab thiab siv zog

- Kev siv cov tshuab kaw-loop rov ua dua tshiab

Cov ntaub ntawv tshawb fawb ntawm ob-xim txhaj tshuaj molding tej yaam num

Ob-xim txhaj tshuaj molding yog cov txheej txheem tsim khoom nrov uas muaj kev tsim qauv yooj yim, txhim kho kev ua haujlwm, thiab cov kev xaiv zoo nkauj tshwj xeeb. Hauv tsab ntawv blog no, peb yuav tshawb txog qee qhov kev tshawb fawb ntawm ob-xim txhaj tshuaj molding project los qhia txog kev siv ntau yam thiab ua tau zoo ntawm cov txheej txheem no.

Automotive Kev Lag Luam: Ob-xim Steering Log

Kev lag luam tsheb feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom nrog ob qho tib si pom thiab ua haujlwm. Ib qho piv txwv yog ob-xim lub kauj tsheb uas siv cov khoom siv nruj rau lub hauv paus thiab cov ntaub mos muag rau kev tuav. Qhov kev tsim no muab ob qho tib si kev nplij siab thiab ua haujlwm ntev rau tus neeg tsav tsheb. Cov txheej txheem ob-xim molding tseem tso cai rau cov khoom lag luam lossis cov qauv tsim kom muaj kev sib txuas ncaj qha rau hauv lub kauj.

Kev lag luam kho mob: Ob-xim syringe

Kev lag luam kho mob feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom uas muaj kev ua haujlwm tshwj xeeb thiab kev nyab xeeb. Ib tug ob-xim syringe tsim muaj peev xwm muab ib tug tawv txheej txheej rau kev tiv thaiv thiab ib tug mos puab txheej rau kev yooj yim ntawm kev siv. Ntxiv mus, cov txheej txheem ob-xim molding tso cai rau cov tuam txhab tsim lub qhov rais ntshiab ntawm lub koob txhaj tshuaj, qhia tau zoo txog cov kua dej uas lawv tau xa tawm.

Consumer Electronics Industry: Ob-xim xov tooj Case

Cov neeg siv khoom siv hluav taws xob kev lag luam feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom nrog ob qho tib si zoo nkauj thiab kev ua haujlwm. Lub rooj plaub xov tooj ob xim tsim tuaj yeem suav nrog txheej txheej tawv tawv rau kev tiv thaiv thiab cov txheej sab hauv mos rau kev poob siab. Cov txheej txheem ob-xim molding kuj tso cai rau cov khoom lag luam lossis cov qauv tsim kom muaj kev sib txuas ncaj qha rau hauv rooj plaub xov tooj.

Kev Lag Luam Khoom Siv Hauv Tsev: Txhuam Txhuam Txhuam Txhuam Txhuam

Kev lag luam khoom siv hauv tsev feem ntau siv ob-xim txhaj tshuaj molding los tsim cov khoom nrog cov qauv tsim tshwj xeeb thiab kev ua haujlwm. Tus neeg tsim qauv tuaj yeem tsim cov txhuam hniav ob xim nrog cov txheej txheej tawv tawv kom ruaj khov thiab cov txheej hauv cov mos mos rau kev nplij siab. Cov txheej txheem ob-xim molding kuj tso cai rau kev tsim cov qauv bristle thiab xim kom haum rau cov khoom lag luam lossis tsim cov txhuam hniav.

Kev lag luam kev ua si: Ob-xim tsheb kauj vab kaus mom hlau

Kev lag luam kev ua kis las feem ntau siv ob-xim txhaj tshuaj molding los tsim qhov chaw nrog kev ua haujlwm thiab kev zoo nkauj. Cov neeg tsim qauv tsim muaj peev xwm tsim ob lub kaus mom tsheb kauj vab uas muaj txheej txheej tawv tawv rau kev tiv thaiv thiab ib txheej mos mos rau kev nplij siab. Cov txheej txheem ob-xim molding kuj tso cai rau kev sib koom ua lag luam lossis tsim cov ntsiab lus rau hauv lub kaus mom hlau.

Kev cob qhia thiab ntawv pov thawj rau ob-xim txhaj tshuaj molding

Kev cob qhia thiab cov ntawv pov thawj tau dhau los ua nrov rau cov tib neeg uas xav ua haujlwm tshwj xeeb hauv daim teb no. Cov ntawv tshaj tawm blog no yuav tshawb txog qhov tseem ceeb ntawm kev cob qhia thiab ntawv pov thawj rau ob-xim txhaj tshuaj molding thiab qee qhov kev pabcuam muaj.

Vim li cas kev cob qhia thiab ntawv pov thawj tseem ceeb?

Kev cob qhia thiab ntawv pov thawj yog qhov tseem ceeb rau cov tib neeg hauv kev lag luam ob xim txhaj tshuaj molding. Kev cob qhia kom raug ua kom cov tib neeg muaj kev txawj ntse thiab kev txawj ntse los ua haujlwm cov tshuab kom muaj kev nyab xeeb thiab ua tau zoo thiab tsim cov khoom zoo. Cov ntawv pov thawj muab kev ntsuas tus qauv ntawm kev txawj ntse thiab ua kom pom kev cog lus rau kev txhim kho kev ua haujlwm tsis tu ncua.

Qee qhov txiaj ntsig ntawm Kev Kawm thiab Ntawv Pov Thawj suav nrog:

- Txhim kho kev nyab xeeb:Kev cob qhia kom raug thiab ntawv pov thawj tuaj yeem pab txo qis kev pheej hmoo ntawm kev raug mob thiab kev raug mob los ntawm kev ua kom cov tib neeg paub txog kev siv tshuab zoo tshaj plaws thiab kev saib xyuas.

- Nce Productivity:Cov tib neeg uas tau txais kev cob qhia thiab ntawv pov thawj feem ntau ua haujlwm tau zoo thiab muaj txiaj ntsig zoo hauv lawv lub luag haujlwm, ua rau txhim kho cov khoom tsim tau thiab cov khoom tsim tawm.

- Txhim khu kev ua tau zoo:Kev cob qhia kom raug thiab ntawv pov thawj tuaj yeem pab xyuas kom cov khoom ua tau raws li cov qauv tsim nyog thiab cov lus qhia tshwj xeeb.

Kev cob qhia thiab ntawv pov thawj muaj

- Manufacturers:Ntau lub tuam txhab tsim khoom muaj kev cob qhia rau lawv cov tshuab tshwj xeeb. Cov kev pabcuam no feem ntau suav nrog kev ua haujlwm ntawm lub tshuab, kev saib xyuas, kev daws teebmeem, thiab kev nyab xeeb.

- Cov Tsev Kawm Ntawv Lag Luam:Qee lub tsev kawm lag luam muaj ob chav xim txhaj tshuaj molding uas npog cov ntaub ntawv, tsim, thiab kev siv tshuab. Cov kev kawm no kuj tseem yuav suav nrog kev cob qhia tes.

- Cov koom haum muab ntawv pov thawj: Qee lub koom haum muab cov ntawv pov thawj rau cov tib neeg hauv kev lag luam ob-xim txhaj tshuaj molding. Cov kev kawm no feem ntau suav nrog kev sau ntawv thiab cov kev xeem ua pov thawj kom ua tau zoo.

Ob-xim txhaj tshuaj molding rau prototyping

Cov txheej txheem ob-xim txhaj tshuaj molding yog siv dav hauv kev tsim khoom los tsim cov khoom siv nrog ntau yam xim lossis cov khoom siv. Txawm li cas los xij, nws tuaj yeem yog qhov kev xaiv zoo tshaj plaws rau kev tsim qauv. Hauv tsab ntawv blog no, peb yuav tshawb nrhiav cov txiaj ntsig ntawm kev siv ob-xim txhaj tshuaj molding rau kev tsim qauv.

Cov txiaj ntsig ntawm Ob-xim Txhaj Moulding rau Prototyping

- Tus nqi-Siv tau: Kev txhaj tshuaj ob xim tuaj yeem yog qhov kev xaiv zoo rau kev tsim qauv vim tias nws tso cai rau tsim cov khoom nrog ntau xim lossis cov khoom siv hauv ib lub pwm. Los ntawm kev txo cov pwm xav tau, cov tuam ntxhab tuaj yeem txo tus nqi.

- High-Quality Parts:Ob-xim txhaj tshuaj molding ua cov khoom zoo nrog nruj tolerances thiab zoo heev nto finishes. Ib qho tseem ceeb ntawm prototyping yog tsim cov khoom uas muaj kev cuam tshuam cov khoom kawg.

- Faster Turnaround Sijhawm:Kev siv ob-xim txhaj tshuaj molding rau prototyping tuaj yeem ua rau lub sijhawm luv luv vim tias nws tso cai rau tsim qhov nyuaj hauv ib qho pwm. Los ntawm kev tshem tawm qhov xav tau los sib sau ua ke ntau yam, cov tuam ntxhab tuaj yeem txo lub sijhawm xav tau rau kev tsim qauv.

- Tsim Flexibility:Ob-xim txhaj tshuaj molding muab cov qauv tsim tau yooj yim, tso cai rau kev tsim cov khoom nrog cov geometry nyuaj thiab cov yam ntxwv sib txawv. Ua kom muaj tseeb sawv cev ntawm cov khoom kawg yog qhov tseem ceeb hauv kev tsim qauv.

- Kev xaiv khoom siv:Ob-xim txhaj tshuaj molding tso cai rau cov khoom sib txawv hauv ib feem, uas yog qhov tseem ceeb hauv kev tsim qauv vim tias nws yuav pab ntsuas cov khoom sib txawv thiab kev sib xyaw ua ke.

Daim ntawv thov ntawm Ob-xim Txhaj Moulding hauv Prototyping

- Tus neeg siv khoom:Cov neeg tsim khoom tuaj yeem siv ob xim txhaj tshuaj molding los tsim cov qauv ntawm cov neeg siv khoom xws li cov khoom ua si, khoom siv, thiab khoom siv hluav taws xob. Kev tsim cov khoom nrog ntau xim lossis cov khoom siv hauv ib lub pwm yog qhov tshwj xeeb tshaj yog siv hauv kev lag luam no.

- Automotive Kev Lag Luam: Ob-xim txhaj tshuaj molding tuaj yeem tsim cov qauv ntawm cov khoom siv hauv tsheb xws li tha xim sab hauv, lub kauj log, thiab cov pob qhov rooj ua haujlwm. Kev tsim cov khoom nrog sib txawv textures thiab tiav yog qhov tseem ceeb hauv kev lag luam no.

- Cov cuab yeej kho mob:Ob-xim txhaj tshuaj molding tuaj yeem tsim cov qauv ntawm cov khoom siv kho mob xws li tes tuav, khawm, thiab cov keyboards. Kev tsim khoom nrog cov khoom sib txawv yog qhov tseem ceeb hauv kev lag luam no, qhov twg biocompatibility thiab sterilization zog yog qhov tseem ceeb.

Xaiv tus khub zoo rau koj qhov project txhaj tshuaj molding ob-xim

Xaiv tus khub zoo rau koj qhov project txhaj tshuaj molding ob-xim yog qhov tseem ceeb rau kev ua tiav ntawm koj qhov project. Nws yuav pab tau yog tias koj pom tus khub uas muaj kev txawj ntse, kev paub dhau los, thiab muaj peev xwm ua tau raws li koj cov kev xav tau tshwj xeeb. Cov ntawv tshaj tawm blog no yuav tshawb txog qee yam tseem ceeb los xav txog thaum xaiv tus khub zoo rau koj qhov project txhaj tshuaj molding ob-xim.

Tej yam yuav tsum tau xav txog thaum xaiv ib tus khub rau koj ob-xim Txhaj Moulding Project:

- kev txawj ntse:Xaiv ib tus neeg koom tes nrog kev txawj ntse hauv ob xim txhaj tshuaj molding yog qhov tseem ceeb. Lawv yuav tsum muaj kev nkag siab tob txog cov txheej txheem thiab muaj peev xwm muab cov lus qhia thiab kev taw qhia txog kev tsim thiab tsim khoom ntawm koj qhov chaw.

- kev:Kev paub yog qhov tseem ceeb thaum xaiv tus khub rau koj qhov project txhaj tshuaj molding ob xim. Nrhiav ib tus neeg koom tes nrog cov ntaub ntawv pov thawj ntawm kev ua tiav uas tsim cov khoom zoo nrog kev ua siab ntev thiab kev ua tiav zoo heev.

- Peev Xwm:Xav txog lub hwj chim ntawm tus khub uas koj tab tom xav txog. Lawv puas muaj cov cuab yeej tsim nyog, cov peev txheej, thiab cov neeg ua haujlwm los tswj koj qhov project? Lawv puas tuaj yeem tuav cov ntim loj thiab qhov nyuaj? Xyuas kom koj tus khub muaj peev xwm ua tau raws li koj cov kev xav tau tshwj xeeb.

- Kev Tswjhwm Zoo: Kev tswj kom zoo yog qhov tseem ceeb hauv kev txhaj tshuaj molding ob xim. Xyuas kom koj tus khub muaj kev tswj xyuas zoo kom ntseeg tau tias cov khoom lawv tsim tau raws li koj cov lus qhia thiab cov qauv.

- Kev Sib Txuas Lus: Kev sib txuas lus yog qhov tseem ceeb rau txhua qhov haujlwm ua tiav. Xyuas kom koj tus khub teb thiab sib txuas lus thoob plaws tag nrho cov txheej txheem. Lawv yuav tsum qhia rau koj paub txog tej teeb meem lossis kev nyuaj siab thiab ua haujlwm hauv kev nrhiav kev daws teeb meem.

- Tus nqi: Tus nqi yog ib qho kev txiav txim siab thaum xaiv tus khub rau koj qhov project ob-xim txhaj tshuaj molding. Txawm li cas los xij, nws yog ib qho tseem ceeb kom nco ntsoov tias tus nqi qis tshaj tsis yog ib txwm txhais tau tias tus nqi zoo tshaj. Nrhiav tus khub uas muab cov nqi sib tw thaum tseem muab cov khoom zoo thiab cov kev pabcuam zoo heev.

- Muaj caij nyoog:Sustainability tau dhau los ua qhov tseem ceeb hauv kev tsim khoom. Xav txog kev koom tes nrog ib lub tuam txhab cog lus rau kev ruaj ntseg thiab txo lawv cov kev cuam tshuam ib puag ncig.

xaus

Ob-xim txhaj tshuaj molding yog ntau yam thiab nrov tsim cov txheej txheem uas muaj ntau yam zoo, xws li kev tsim kho kom yooj yim, txo lub sij hawm sib dhos, thiab txhim kho kev ua haujlwm. Thaum nws muaj nws cov kev txwv thiab cov kev sib tw, nws tuaj yeem tsim cov khoom zoo ntawm tus nqi sib tw nrog rau kev txiav txim siab tsim nyog, khoom siv, thiab cov khoom siv. Ob-xim txhaj tshuaj molding muaj cov ntawv thov nyob rau hauv ntau yam lag luam, thiab raws li kev siv technology tshiab, peb tuaj yeem cia siab tias yuav pom ntau yam tshiab hauv daim teb no. Ua hauj lwm nrog ib tus neeg koom tes txhim khu kev qha thiab paub txog uas tuaj yeem muab cov kev txawj ntse, khoom siv, thiab cov peev txheej uas xav tau yog qhov tseem ceeb rau kev ua tiav ntawm koj qhov project txhaj tshuaj molding ob-xim.