5 Yakajairwa Plastic Resins Anoshandiswa muInjection Molding

1 am chinyorwa nechigumbuso. Baya Edit bhatani kuchinja chinyorwa ichi. Lorem ipsum ja kugara amet, consectetur adipiscing elit. Ut elit elit, luctus nec ullamcorper mattis, dapibus Leo pulvinar.

Nemazana ezvigadzirwa uye marezeni einjiniya aripo pamusika nhasi, maitiro ekusarudza zvinhu epurasitiki jekiseni rekugadzira mabasa anogona kumboita seanonetsa pakutanga.

PaDJmolding, isu tinonzwisisa zvakasarudzika mabhenefiti uye zvivakwa zvemhando dzakasiyana dzemapurasitiki uye tinoshanda padhuze nevatengi kuti tiwane yakanyanya kukwana purojekiti yavo.

Chii chinonzi Plastic Resins?

Isu tinorarama munyika yakakomberedzwa nemarara epurasitiki. Nekuda kwezvivakwa zvavo zvakati wandei zvinodikanwa, maresheni epurasitiki anogona kuwanikwa mune zvese kubva kumabhodhoro uye midziyo kuenda kumotokari uye zvekurapa zvinhu nezvimwe zvakawanda. Plastic resins inosanganisira mhuri hombe yezvinhu izvo imwe neimwe ine yayo yakasarudzika midziyo inoita kuti ive yakanaka kune akasiyana maapplication. Paunosarudza resin yakakodzera yeprojekti yako, zvakakosha kuti unzwisise izvo mhando yega yega inofanirwa kupa.

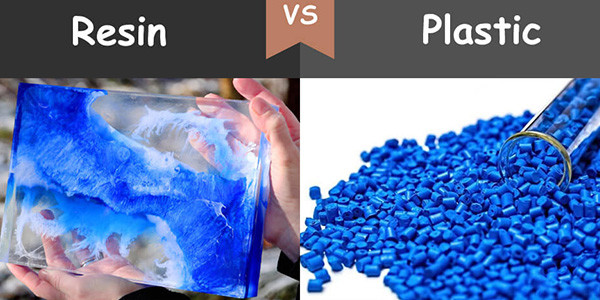

Ndeupi Musiyano pakati peResin nePlastiki?

Resin nepurasitiki zvese zvakakosha makomisheni, asi zvine misiyano yakakosha, kusanganisira:

*Kwakabva: Nepo marezeni achingoitika muzvirimwa, mapurasitiki anogadzirwa uye anowanzo kutorwa kubva petrochemicals.

* Tsanangudzo: Plastiki imhando yeanogadzira resin, nepo marezini ari amorphous makomisheni anogona kunge ari semi-solid kana kuomarara.

* Kugadzikana uye kusachena: Plastiki yakagadzikana kupfuura resin uye inoshaya tsvina. Ne resin, tsvina haigoni kudziviswa.

*Kuoma: Purasitiki yakaoma uye yakaoma, nepo resin ichiwanzoita gluey uye viscous zvinhu.

*Kukanganisa kwezvakatipoteredza: Sezvo resin iri yakasikwa, inopa imwe yakasarudzika nharaunda kune epurasitiki. Purasitiki inodzikisira zvishoma nezvishoma uye kazhinji ine muchetura zvinowedzera izvo zvinogona kutungamira kusvibisa kwezvakatipoteredza.

Zvakajairwa Zvikumbiro zvePlastiki Resin Injection Molding

Plastic jekiseni molding inoenderana neyakasiyana siyana resin zvinhu. Paunosarudza resin chaiyo kune zvaunoda, zvakakosha kuti unzwisise zvinodikanwa zveimwe application yako. Zvishandiso zvakajairika zveakasiyana jekiseni molding resins anosanganisira:

ABS

Jekiseni-yakaumbwa ABS inoshandiswa mumhando dzakasiyana-siyana dzekushandisa, kusanganisira epurasitiki madziro mahwendefa emagetsi emagetsi, anodzivirira musoro, makiyi ekhibhodi, zvinhu zvemagetsi, uye zvinhu zvemotokari zvakaita senhengo dzemuviri, mavhiri anovhara, uye dashboard. Inoshandiswawo kune akasiyana maindasitiri ekugadzirisa, zvemitambo zvemitambo, uye zvinhu zvevatengi.

Celson (Acetal)

Nekuda kweiyo yakaderera coefficient yekukwesha, jekiseni-yakaumbwa Celson yakanakira mavhiri epulley, mabhandi ekutakura, magiya, uye mabhengi. Ichi chinyorwa chinogonawo kuwanikwa mune dzakasiyana-siyana dzepamusoro-injiniya zvikamu, makiyi masisitimu, pfuti, mafuremu egirazi remaziso, uye zvisungo.

Polypropylene

Injection-molding polypropylene inoshandiswa mumhando dzakasiyana siyana dzemaindasitiri, zvekutengesa, uye zvevatengi. Semuenzaniso, inogona kuwanikwa mumaturusi emagetsi maturusi, midziyo, yekurongedza, zvinhu zvemitambo, midziyo yekuchengetera, uye matoyi evana.

HIPS

Nekuti HIPS ine simba repamusoro rekuita, inogona kuwanikwa mumidziyo, michina yekutsikirira, zviratidzo, uye zvikamu zvemidziyo. Mamwe maapplication akajairika anosanganisira matoyi evana uye zvinhu zvemagetsi.

LDPE

Nekuda kwekuchinjika kwayo uye kuramba kunyorova uye makemikari, jekiseni-yakaumbwa LDPE inowanzoshandiswa pakushandisa zvinosanganisira zvekurapa, waya netambo insulators, mabhokisi emidziyo, uye matoyi evana.

Zvinhu Zvikuru Zvokufunga nezvazvo Paunenge Uchisarudza Injection Molding Material

Zvikamu zvepurasitiki zvetsika kubva kuDJmolding kuti uve nechokwadi chekuti unosarudza resin chaiyo yeprojekiti yako, ramba uchifunga zvinotevera:

*Impact simba - Mamwe maapplication anoda simba rakawanda kupfuura mamwe, saka resin's Izod simba rekuita rinofanira kutariswa kubva pakutanga.

*Kusimba simba -Kusimba kwekupedzisira kusimba, kana simba rekupedzisira, inoyera kuramba kweresin kune tension uye kugona kwayo kumirisana nemutoro wakapihwa pasina kupatsanura.

* Flexural modulus ye elasticity - Izvi zvinoreva dhigirii iyo chinhu chinogona kukotamiswa pasina kukuvara uye chinoramba chichidzokera kuchimiro chayo chepakutanga.

*Kudzora kupisa - Izvi zvakanyanya kukosha kune maapplication anoda insulating performance kana kushivirira kune akasiyana tembiricha.

*Kutorwa kwemvura — Izvi zvinoenderana nehuwandu hwemvura inotorwa nechinhu mushure memaawa makumi maviri nemana ekunyudzwa.

Tsika Yekusarudzwa kwezvinhu neDJmolding

Djmolding ipurasitiki inogadzira jekiseni rekugadzira, inogadzira zvikamu zvepurasitiki zvine acrylic (PMMA), acrylonitrile butadiene styrene (ABS), nylon (polyamide, PA), polycarbonate (PC), polyethylene (PE), polyoxymethylene (POM), polypropylene (PP), polystyrene (PS) uye zvichingodaro

Kusarudza izvo zvinhu zvakanaka kubva pakutanga hazvingokuchengetere nguva chete, uye mari, asi zvakare zvichava nechokwadi chekuita kwakakwana uye kugadzirwa. Tsvakurudza sarudzo dzako nekuchenjera, uye bvunza ane ruzivo rwepurasitiki jekiseni molder kuti ubatsire kuona sarudzo yakanaka.