Maviri Mavara Injection Molding

Maviri-mavara jekiseni molding, kana maviri-pfuti jekiseni kuumba, inzira yekugadzira inoshandiswa kugadzira zvikamu zvepurasitiki zvine mavara maviri akasiyana kana zvinhu. Kuita uku kunosanganisira kubaya zvimwe zvinhu zviviri muforoma imwe chete kugadzira basa rine maviri-toni kupedzisa kana akasiyana maitiro ekushanda. Maviri-mavara jekiseni molding ane akawanda maapplication mumaindasitiri akasiyana, anosanganisira emotokari, ekurapa, uye zvigadzirwa zvevatengi. Ichi chinyorwa chichaongorora zvakadzama nezve maviri-mavara jekiseni molding, zvakanakira, zvisingakwanisi, uye mashandisirwo.

Maviri-mavara jekiseni molding process

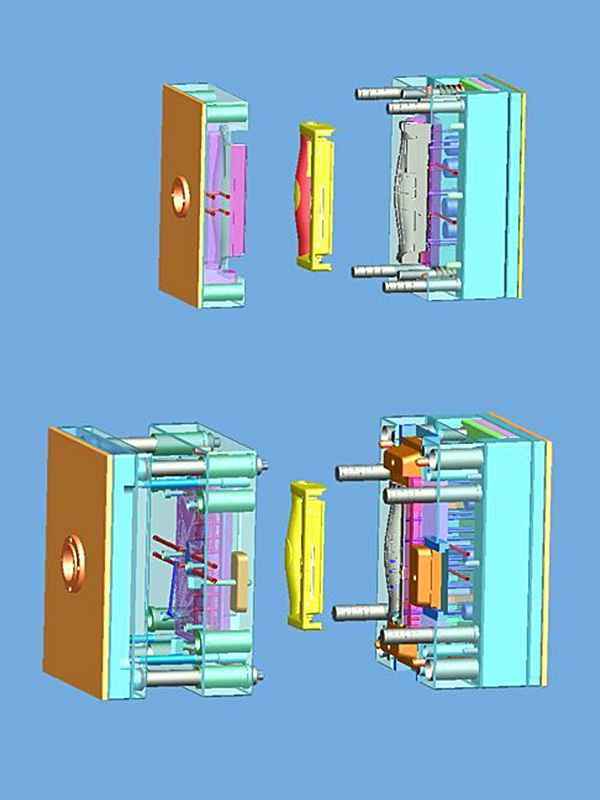

Iyo miviri-mavara jekiseni yekuumba maitiro inosanganisira maviri akapatsanurwa majekiseni eakasiyana mavara resin. Jekiseni rekutanga rinoumba hwaro hwechikamu, ukuwo jekiseni rechipiri rinoumba chimiro chekupedzisira uye ruvara. Majekiseni maviri aya anowanzoitwa mumuchina mumwechete, uchishandisa madhiramu maviri akasiyana uye nozzles.

Iwe unogona kupatsanura maitiro kuita matanho anotevera:

- Iyo mold inovharwa, uye jekiseni rekutanga resin rinopinzwa mugomba rekugadzira kugadzira hwaro hwechikamu.

- Mushandi anovhura mold uye anotenderera kana kufambisa dunhu kuenda kune yechipiri chiteshi.

- Yechipiri resin jekiseni inobaiwa mugomba rekuumbwa, ichigadzira chimiro chekupedzisira uye ruvara rwechikamu.

- Mushandi anovhura mold uye anoburitsa chikamu.

Iyo miviri-mavara jekiseni yekuumba maitiro ane akati wandei mabhenefiti, anosanganisira:

- Kuwedzera kushanda zvakanaka:Maviri-mavara jekiseni molding inobvisa kudiwa kwechipiri mavhisi, sekupenda kana kubatanidza, izvo zvinogona kuchengetedza nguva uye kuderedza mutengo.

- Aesthetics yakavandudzwa: Kugona kugadzira zvikamu zvine mavara akawanda uye zvigadziriso zvakaomarara zvinogona kuvandudza aesthetics yechigadzirwa chekupedzisira, zvichiita kuti chiwedzere kutaridzika kune vatengi.

- Kuvandudza kushanda:Iyo miviri-mavara jekiseni yekuumba maitiro inogona zvakare kuwedzera mashandiro echigadzirwa chekupedzisira, sezvo ichibvumira kushandisa zvinhu zvakasiyana kune zvimwe zvikamu.

Kune zvakare mamwe matambudziko ane chekuita neaviri-mavara jekiseni molding maitiro, akadai se:

- Dhizaini yakaoma: Iyo nzira inoda yakaoma mold dhizaini, zvichiita kuti zvinyanye kunetsa kugadzira nekuchengetedza.

- Kuenderana kwezvinhu: Iwo maviri akasiyana resin anoshandiswa mukuita anofanirwa kuenderana, kana anogona kusamira nemazvo, zvichikonzera kukanganisa muchigadzirwa chekupedzisira.

- Mariro:Iyo miviri-mavara jekiseni yekuumba maitiro anogona kudhura kupfuura echinyakare ekuumba maitiro nekuda kwekuoma kwe mold uye mimwe michina inodiwa.

Zvishandiso zvinoshandiswa mukuumbwa kwejekiseni-mavara maviri

Kusarudza zvinhu zvakakodzera zvemavara-mavara jekiseni kuumba kwakakosha kugadzira emhando yepamusoro uye anoshanda zvikamu. Iyi blog positi ichakurukura zvinhu zvinowanzo shandiswa mune maviri-mavara jekiseni molding.

Thermoplastic elastomers (TPE)

MaTPE ane mukurumbira wekuumba majekiseni maviri-mavara nekuti akapfava, anochinjika, uye anonamira zvakanaka kune zvimwe zvinhu. Izvo zvakare zvinoshingirira kumakemikari uye zvine kugona kwakanaka kwemamiriro ekunze. Vagadziri vanowanzo shandisa maTPE ekubatisa, zvibato, uye zvimwe zvikamu zvinoda nzvimbo yakagadzika, isina-inotsvedza.

Thermoplastic polyurethane (TPU)

TPU chimwe chinhu chakakurumbira chemavara maviri-majekiseni ekuumba nekuda kwekuchinjika kwayo kwakanyanya uye kusimba. TPU inogona kumira kudzokororwa kupeta uye kuchinjika, ichiita kuti ive yakanakira zvikamu zvakaita sekesi dzenhare, zvishandiso zvekurapa, uye zvemitambo. Iyo zvakare inopokana nemafuta nemakemikari.

Acrylonitrile butadiene styrene (ABS)

Vagadziri vanowanzo shandisa ABS, yakaoma thermoplastic, mune maviri-mavara jekiseni kuumba. Iyo ine yakanakisa mechaniki zvivakwa, yakakwirira simba kuramba, uye inogona kunamatira zvakanaka kune zvimwe zvinhu. Vagadziri vanowanzo shandisa ABS yezvikamu zvemotokari, midziyo yemumba, uye midziyo yemagetsi.

Polypropylene (PP)

PP yakareruka uye yakaoma thermoplastic inowanzoshandiswa mukuumba majekiseni maviri-mavara. Iyo inoratidza yakanaka makemikari uye kuneta kuramba uye inobvumira kuumba nyore mumhando dzakasiyana siyana. Vagadziri vanowanzo shandisa PP yemidziyo, kurongedza, uye zvikamu zvemotokari.

Polycarbonate (PC)

PC ndeye thermoplastic inoonekera inowanzoshandiswa mukuumbwa kwejekiseni remavara maviri ezvishandiso zvakaita semidziyo yekurapa, zvikamu zvemotokari, uye zvinhu zvemagetsi. Iyo ine yakanakisa kukanganisa kupikisa, yakakwira optical kujeka, uye inogona kumira tembiricha yakakwira. Vagadziri vanowanzo shandisa PC yemalenzi, madhairekitori emwenje, uye anovhara.

Polyamide (PA)

PA, inozivikanwa se nylon, inoshandiswa zvakasiyana-siyana thermoplastic inowanzoshandiswa mukuumba jekiseni remavara maviri. Iyo inoratidza yakanaka michina zvimiro, yakanakisa kuramba kune abrasion uye makemikari, uye inobvumira kuumba nyore kuita maumbirwo akaomarara. Vagadziri vanowanzo shandisa PA yemagiya, mabhengi, uye zvikamu zvezvimiro.

Zvakanakira maviri-mavara jekiseni molding

Jekiseni molding inzira inoshandiswa zvakanyanya yekugadzira iyo zvinhu zvepurasitiki zvinonyungudutswa uye zvinobayiwa muforoma kugadzira zvikamu zvakaoma uye chaizvo. Imwe yemisiyano yeiyi maitiro ndeye maviri-mavara jekiseni molding, iyo inobvumira kugadzirwa kwezvikamu zvine mavara maviri akasiyana kana zvinhu mune imwechete yekuumba kutenderera. Iyi blog post ichakurukura zvakanakira maviri-mavara jekiseni molding.

Advantages

- Mari Kuchengetedza: Imwe yeakakosha mabhenefiti maviri-mavara jekiseni molding ndiko kuchengetedza mutengo. Panzvimbo pekugadzira uye kuunganidza zvikamu zviviri, izvi zvinotanga nechikamu chine mavara maviri kana zvinhu mune imwe yekuumbwa kutenderera. Kuderedza kudiwa kwemamwe mabasa egungano kunoguma nemutengo wakakwirira uye kuchengetedza nguva.

- Yakavandudzwa Dhizaini Flexibility:Maviri-mavara jekiseni molding inopa dhizaini kuchinjika izvo zvisingagoneke nemamwe maitiro ekugadzira. Kugadzira chikamu nezvinhu zviviri zvakasiyana kana mavara kunoita kuti vagadziri vakwanise kuwana mamwe akaomarara uye akasiyana madhizaini ayo mamwe matekiniki asingakwanisi kuita.

- Enhanced Product Aesthetics: Maviri-mavara jekiseni molding inopa yakagadziridzwa chigadzirwa aesthetics nekubvumira kugadzirwa kwezvikamu zvine mavara akasiyana kana zvinhu. Zvigadzirwa zvinoda kukwezva zvinoonekwa, zvakaita semagetsi evatengi, midziyo yekurapa, uye zvikamu zvemotokari, zvinogona kubatsira zvakanyanya kubva pane ichi.

- Kuwedzera Kusimba: Maviri-mavara jekiseni molding anogona zvakare kuwedzera kusimba kwechikamu. Nekushandisa zvinhu zviviri zvakasiyana zvine zvimiro zvakasiyana, dunhu rinogona kuwedzera simba, kuchinjika, kana zvimwe zvinodiwa. Iyi ficha yakanakira zvigadzirwa zvakafumurwa kune yakaoma mamiriro kana kugara uchishandiswa.

- Kuvandudza Kubudirira Kwekugadzira: Maviri-mavara jekiseni molding anogona zvakare kuvandudza kugadzirwa kwekuita nekudzikisa huwandu hwematanho anodiwa mukugadzira maitiro. Nekubvisa kudiwa kwemamwe mavhisi egungano, maviri-mavara jekiseni molding anogona kuderedza nguva uye basa rinodiwa kugadzira chikamu.

Kuganhurirwa kwemavara-mavara jekiseni molding

Maviri-mavara jekiseni molding inzira yakakurumbira yekugadzira iyo inogadzira yakaoma uye inoyevedza zvikamu zvine maviri kana anopfuura mavara. Nepo maitiro aya aine akawanda mabhenefiti, pane zvakare zvimwe zvipimo zvekufunga kana iri iyo sarudzo yakanaka yeprojekiti yako.

Chimwe chinodzivirirwa chemavara maviri-mavara jekiseni kuumba ndiwo mutengo. Midziyo inodiwa pakuita uku kazhinji inodhura pane yechinyakare yekuumba jekiseni. Pamusoro pezvo, maitiro acho anoda nguva yakawanda uye kushanda, izvo zvinogona kukwidza mitengo.

Imwe nzvimbo yekuvandudza ndiyo yakaoma yekugadzira. Maviri-mavara majekiseni ekuumba anogona kugadzira akaomesesa dhizaini ane akawanda mavara, asi angangove akakodzera kune mamwe maitiro. Vagadziri vanofanira kunyatsoronga chimiro kudzivirira kubuda kwemavara uye kuve nechokwadi chemhando yepamusoro yekupedzisira chigadzirwa.

Heano zvimwe zvipimo zvekufunga nezvazvo:

- Kusarudzwa kwezvinhu zvishoma:Maviri-mavara majekiseni ekuumba anowanzo kuganhurirwa kune chaiwo zvinhu, senge thermoplastics. Kuganhurira sarudzo kunogona kukanganisa kunaka kwechigadzirwa chekupedzisira.

- Huwandu hwekugadzira hushoma:Vagadziri vanowanzo shandisa maviri-mavara jekiseni molding kune madiki ekugadzira anomhanya. Traditional jekiseni molding inodhura-inoshanda kana zvikamu zvakawanda zvichidikanwa.

- Kunetsa nekumisikidza chikamu: Paunenge uchigadzira zvikamu zvine mavara mazhinji, zvinogona kuve zvakaoma kurongedza mavara nemazvo. Kuwana budiriro mubasa iri kunoda kuronga zvine hungwaru uye kutonga kwakaringana kwekuita jekiseni rekuumba.

- Nguva refu yekutenderera: Kuumbwa kwejekiseni-mavara-mavara kazhinji kunoda mitsetse yakareba kupfuura yechinyakare jekiseni kuumba. Kudzikamisa mwero wekugadzira kunogona kutungamirira kumitengo yakakwira yechigadzirwa chekupedzisira.

Kunyangwe izvi zvisingakwanisi, maviri-mavara jekiseni kuumba inogona kuve yakanakisa sarudzo yemapurojekiti chaiwo. Iko kugona kugadzira dhizaini yakaoma ine mavara akawanda inogona kuve yakakosha mukana, kunyanya mumaindasitiri akadai semotokari, zvinhu zvevatengi, uye zvigadzirwa zvekurapa.

Kushanda nemugadziri ane ruzivo anonzwisisa maitiro uye zvaasingakwanisi kwakakosha pakubudirira kweaviri-mavara jekiseni molding purojekiti. Ivo vanogona kubatsira nekugadzira, kusarudzwa kwezvinhu, uye jekiseni kuumba kuti ive nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvose zvinodiwa.

Dhizaini Yekufunga kune maviri-mavara jekiseni Molding

Imwe pfungwa inokosha ndeyekugadzirwa kwechikamu chacho pachacho. Vagadziri vanofanira kunyatsoronga zano rekudzivirira kubuda ropa uye kuona kuti chigadzirwa chekupedzisira chiri chemhando yepamusoro. Heano mamwe maitiro ekugadzira ekufunga nezvawo:

- Rusvingo kuwanda: Kukora kwechikamu kunogona kukanganisa kunaka kwechigadzirwa chekupedzisira. Madziro akakora anogona kuoma kuumba, zvichikonzera kusaenzana kwemavara. Izvo zvakakosha kuenzanisa madziro 'ukobvu nechikamu chese dhizaini.

- Mutsara wekuparadzanisa: Mutsetse wekupatsanura ndipo panosangana zvidimbu zviviri zveforoma. Izvo zvakakosha kuti unyatso tarisa nzvimbo yemutsara wekuparadzanisa kuti uve nechokwadi chekuti haikanganisi dhizaini yechikamu kana kunaka kwechigadzirwa chekupedzisira.

- Draft angles: Draft angles inobatsira mukubatsira zvikamu kuburitswa kubva muforoma. Kusanganisira akakodzera dhizaini angles mudhizaini kwakakosha kuti uve nechokwadi chekubvisa dunhu kubva mukuumbwa pasina kukanganisa.

- Mavara:Chimiro chechikamu chinogona kukanganisa kutaridzika kwekupedzisira kwenharaunda. Izvo zvakakosha kuti titarise pamusoro peiyo basa uye kuti ichabatana sei nemavara maviri panguva yekuumba jekiseni.

Imwe fungidziro ndeyekusarudzwa kwezvinhu. Maviri-mavara majekiseni ekuumba anowanzo kuganhurirwa kune chaiwo zvinhu, senge thermoplastics. Kusarudza zvinhu zvinokwanisa kubata majekiseni ekuumba kushushikana uye kupa chigadzirwa chekupedzisira chimiro chinodikanwa uye kushanda kwakakosha.

Heano mamwe ekuwedzera ekufunga nezvekusarudza zvinhu:

- Kuenderana nemavara:Kuti uwane mhedzisiro yakanaka, vagadziri vanofanirwa kushingaira kusarudza mavara anoratidza kuenderana kune mumwe nemumwe uye zvinhu zvinoshandiswa. Kuti uve nechokwadi chekutaridzika kunoenderana kwechigadzirwa chekupedzisira, kudzivirira kubuda kwemavara kunokosha.

- Kuenderana kwezvinhu:Izvo zvinhu zviviri zvinoshandiswa mukuumbwa kwejekiseni zvinofanirwa kuenderana. Kutevera maitiro aya kunogona kudzivirira matambudziko ekunamatira uye kuvimbisa mhedzisiro yakanaka.

- Zvinhu zvemidziyo:Zvimiro zvezvinhu zvinoshandiswa mukuita jekiseni molding zvinogona kukanganisa kushanda kwechigadzirwa chekupedzisira. Izvo zvakakosha kuti utarise zvimiro zvechinyorwa chimwe nechimwe uye mabatiro avachaita panguva yekuumba jekiseni.

Equipment uye tooling maviri-mavara jekiseni molding

Maviri-mavara jekiseni molding inzira yekugadzira inobvumira kugadzirwa kwezvikamu zvine maviri kana anopfuura mavara. Iyi nzira inoda hunyanzvi hwekushandisa uye zvishandiso kuti purojekiti ibudirire. Iyi blog positi ichakurukura inodiwa michina uye midziyo yekuumba maviri-mavara jekiseni.

midziyo

- Kaviri-pfuti jekiseni molding muchina: vagadziri vanonyatso gadzira muchina uyu kune maviri-mavara jekiseni molding. Iyo ine madhiramu maviri uye maviri nozzles, ichibvumira jekiseni rezvinhu zviviri zvakasiyana muforoma imwechete. Chishandiso ichi zvakare chine nyanzvi software inodzora jekiseni rezvinhu zviviri izvi.

- Mold: Iyo mold ndiyo inonyanya kukosha chikamu chemavara maviri-mavara jekiseni molding process. Vagadziri vanofanirwa kuve nechokwadi chekuti dhizaini inobvumira jekiseni rezvinhu zviviri zvakasiyana uye kurongeka chaiko kudzivirira kubuda kweruvara pakati pavo. Iyo mold inowanzogadzirwa kubva kusimbi uye inogona kudhura zvakanyanya.

- Robotic: Marobhoti anowanzo shandiswa mune maviri-mavara jekiseni kuumba kuti otomatiki maitiro uye kunatsiridza mashandiro. Robhoti inogona kufambisa zvikamu pakati pemushini wekuumba jekiseni uye mutsara wegungano kana kubvisa zvinhu kubva mukuumbwa.

Tooling

- Core pins: Mapini epakati anoshandiswa mune maviri-mavara jekiseni kuumba kugadzira voids kana maburi muchikamu chekupedzisira. Iwo anowanzo kugadzirwa kubva kusimbi uye anofanirwa kunyatso kurongeka kuti ave nechokwadi chekuti chikamu chekupedzisira chemhando yepamusoro.

- Masiraidhi magungano:Vagadziri vanoshandisa masiraidhi maassemblies kugadzira undercuts kana zvimwe zvakaomarara muchikamu chekupedzisira. Iwo anowanzo gadzirwa kubva kusimbi uye anogona kuve akaomarara.

- Hot runner system: Vagadziri vanoshandisa inopisa mumhanyi system kudzora kuyerera kwezvinhu zviviri zvakasiyana mu mold. Inoumbwa nezvakawanda, ma nozzles, uye maheater anochengeta zvinhu zviri patembiricha chaiyo.

- Ejector pini: Vagadziri vanoshandisa ejector pini kuti vabvise chikamu chekupedzisira kubva mukuumbwa. Kazhinji, vagadziri vanoagadzira kubva kusimbi uye anoabatanidza iwo nemazvo kuti dunhu rirege kuchengetedza chero kukuvara panguva yejection.

Kushanda nemugadziri ane ruzivo paunenge uchishandisa maviri-mavara jekiseni molding kwakakosha. Mugadziri anofanirwa kuve nemidziyo uye zvekushandisa zvinodikanwa kugadzira zvikamu zvemhando yepamusoro uye kugona kutungamira dhizaini yedunhu, kusarudzwa kwezvinhu, uye jekiseni rekuumba maitiro.

Misiyano pakati pemavara maviri-mavara jekiseni molding uye pamusoro pekuumba

Ijekiseni remavara maviri uye pamusoro-kuumbwa maitiro anoshandiswa kugadzira zvikamu zvine akawanda zvinhu kana mavara. Nepo maitiro aya achigovana zvimwe zvakafanana, anewo misiyano yakati wandei. Iyi blog post ichakurukura mutsauko uripo pakati pemavara maviri-mavara jekiseni kuumba uye pamusoro-kuumbwa.

Mbiri-Ruvara Jekiseni Molding

- Kuumbwa kwejekiseni remavara maviri kunosanganisira kubaya zvinhu zviviri zvakasiyana kana mavara mugomba rimwe chete kugadzira chikamu chine mavara maviri kana anopfuura.

- Vashandi vanoita maitiro ejekiseni kuburikidza nekubaya zvinhu zviviri nenzira chaiyo. Vanopinza chinhu chechipiri mushure mekunge chinhu chekutanga chatonhodzwa zvishoma uye chaoma.

- Maitiro acho anoda hunyanzvi midziyo uye midziyo, kusanganisira maviri-pfuti jekiseni rekugadzira muchina uye mold yakagadzirirwa maviri-mavara jekiseni kuumba.

- Vagadziri vanowanzo shandisa majekiseni ane mavara maviri kugadzira zvikamu zvine zvimiro zvakaomarara kana dhizaini, senge zvinhu zvemotokari uye zvigadzirwa zvevatengi.

Kukundikana

- Kuwedzeredza kunosanganisira kuumba chimwe chinhu pamusoro pechimwe chinhu kana substrate kugadzira chikamu chine akawanda akaturikidzana kana zvikamu.

- Maitiro acho anowanzo sanganisira kuumba chikamu chepasi kana substrate, wobva wagadzira chimwe chinhu chechipiri pamusoro pechikamu chepasi kuti ugadzire chidimbu chakapedzwa chine akawanda akaturikidzana kana zvikamu.

- Maitiro acho anoda hunyanzvi midziyo uye midziyo, kusanganisira yakawanda-pfuti jekiseni rekugadzira muchina uye mold yakagadzirirwa kuumbwa-kupfuura.

- Vagadziri vanowanzo shandisa over-molding kuti vagadzire zvikamu zvine mabatiro akavandudzwa, anonyaradza, kana kusimba, senge mabatiro emidziyo yemagetsi uye zvigadzirwa zvevatengi.

Kusiyana

- Zvinhu: Kazhinji, maviri-mavara jekiseni kuumba kunosanganisira kushandisa zvinhu zviviri zvakasiyana, nepo kuumba-kuumbwa kunosanganisira kushandisa chinhu chimwe sehwaro uye chechipiri seyakanyanya.

- Order of injection:Mukugadzira jekiseni remavara maviri-mavara, vashandisi vanobaya majekiseni mune yakarongeka, nepo mukuumbwa-pamusoro, vanotanga vaumba chikamu chegadziko vozowedzera iyo overmold.

- Equipment uye tooling: Kuumbwa kwejekiseni remavara maviri-mavara uye kudarika-kuumba kunoda midziyo yakasiyana-siyana uye midziyo, ine mavara maviri-mavara ejekiseni anoda maviri-pfuti jekiseni rekuumba uye mold yakagadzirirwa kuumba-mavara-majekiseni ekuumba, uye kudarika-kuumbwa kunoda jekiseni remajekiseni akawanda. molding muchina uye mold yakagadzirirwa pamusoro-kuumbwa.

- Applications:Vagadziri vanowanzo shandisa majekiseni ane mavara maviri kugadzira zvikamu zvine maumbirwo akaomarara kana dhizaini, nepo ivo vanowanzo shandisa over-molding kugadzira matunhu ane yakagadziridzwa kubata, kunyaradza, kana kusimba.

Zvishandiso zvemavara-mavara jekiseni kuumba muindasitiri yemotokari

Maviri-mavara jekiseni molding inzira inosiyana-siyana yekugadzira iyo yakawana mukurumbira muindasitiri yemotokari nekuda kwekugona kwayo kugadzira emhando yepamusoro, ane mavara mazhinji ane madhizaini akaomarara. Iyi blog positi ichakurukura mamwe mashandisirwo emavara-mavara jekiseni kuumba muindasitiri yemotokari.

- Interior components:Vagadziri vanoshandisa zvakanyanya-mavara-mavara jekiseni kuumba kugadzira zvinhu zvemukati zvemotokari, senge mapaneru emidziyo, mapaneru emasuo, uye epakati consoles. Izvi zvikamu zvinowanzoda akawanda mavara kana zvinhu kuti zviwane kutaridzika kwekutanga uye kuwedzera kunaka kwemotokari.

- Exterior components: Vagadziri vanoshandisawo maviri-mavara jekiseni kuumba kugadzira ekunze zvinhu zvemotokari, senge magrille epamberi, mwenje wemarambi, uye miswe remwenje lenzi. Izvi zvikamu zvinoda kunyatsojeka uye kusimba kutsungirira mamiriro ekunze akaomarara, uye maviri-mavara jekiseni kuumbwa kunopa mhinduro yakakwana yekuzadzisa zvese.

- Zvinoshanda zvikamu: Vagadziri vanogona zvakare kushandisa maviri-mavara jekiseni kuumba kugadzira inoshanda zvinosanganisa mota, senge mhepo inopinza, zvibatiso zvemikombe, uye mapfundo. Izvi zvikamu zvinoda musanganiswa wezvinhu zvine zvinhu zvakasiyana, zvakadai sekuoma uye kushanduka, kuita mabasa avo zvinobudirira. Maviri-mavara jekiseni molding inobvumira kugadzirwa kweakaomesesa maumbirwo uye magadzirirwo uku uchibatanidza zvimwe zvinhu kuti uwane izvo zvinodiwa.

- Branding uye kugadzirisa: Maviri-mavara jekiseni kuumba chishandiso chakanakisa chekumaka uye kugadzirisa muindasitiri yemotokari. Nekubatanidza marogo kana akasiyana madhizaini muzvikamu, vagadziri vanogona kusimudzira rudzi rwemotokari dzavo uye kugadzira kutaridzika uye kunzwa kwekutanga. Pamusoro pezvo, maviri-mavara jekiseni kuumba inobvumira kugadzira tsika maficha akasarudzika kune yega yega mota, ichipa yakasarudzika kubata kune vatengi.

Zvakanakira maviri-mavara jekiseni molding muindasitiri yemotokari

- Inopa dhizaini kuchinjika kugadzira yakaoma maumbirwo uye magadzirirwo

- Inogonesa kushandiswa kwezvinhu zvakawanda uye mavara muchikamu chimwe chete

- Inoderedza nguva yegungano uye mutengo nekubatanidza zvikamu zvakawanda kuita chimwe

- Inovandudza kutaridzika kwese uye kunaka kwemotokari

- Inovandudza kushanda nekubatanidza zvinhu zvine zvinhu zvakasiyana

Zvishandiso zvemavara-mavara jekiseni molding muindasitiri yezvokurapa

Maviri-mavara jekiseni molding ibasa rekugadzira rakasiyana-siyana rine akasiyana mashandisirwo mumaindasitiri akasiyana, kusanganisira indasitiri yekurapa. Iyi blog post ichakurukura zvimwe zvekushandisa kwemavara-mavara jekiseni molding muindasitiri yezvokurapa.

- Zvishandiso zvekurapaVagadziri vanoshandisa zvakanyanya-mavara-majekiseni ekuumba kugadzira michina yekurapa yakaita sejekiseni, inhalers, uye ropa glucose metres. Midziyo iyi inoda kuyerwa kwakaringana uye kwakaringana uye kazhinji inoda zvinhu zvakawanda kuti uwane basa rinodiwa.

- Anodyara: Vagadziri vanoshandisawo majekiseni ane mavara maviri kuti vagadzire ma implants ekurapa akadai sekorona yemazino, ma implants emapfupa, uye zvinoyamura kunzwa. Aya ma implants anoda kurongeka kwepamusoro uye kusimba, uye maviri-mavara jekiseni molding inobvumira kugadzirwa kweakaomesesa maumbirwo uye magadzirirwo uku uchibatanidza zvinhu zvakasiyana kuti uwane izvo zvinodiwa.

- Diagnostic equipment: Maviri-mavara majekiseni ekuumba anogona zvakare kugadzira michina yekuongorora senge matest kits nemidziyo yekufungidzira yekurapa. Izvi zvikamu zvinoda musanganiswa wezvinhu zvine hunhu hwakasiyana, sekujeka uye kuomarara, kuita mabasa avo nemazvo.

- Maitiro ekuunza zvinodhaka:Kuumbwa kwejekiseni remavara maviri kwakanakira kugadzira masisitimu ekutumira zvinodhaka senge inhalers, majekiseni, uye mapeni e insulin. Aya masisitimu anoda kurongeka kwepamusoro uye kurongeka kuendesa iyo chaiyo mushonga dosage, uye maviri-mavara jekiseni molding inogonesa kugadzirwa kweakaomesesa maumbirwo uye magadzirirwo uku uchibatanidza zvinhu zvakasiyana kuti zvibudirire zvinodiwa.

Zvakanakira maviri-mavara jekiseni molding muindasitiri yezvokurapa

- Inopa dhizaini kuchinjika kugadzira yakaoma maumbirwo uye magadzirirwo

- Inogonesa kushandiswa kwezvinhu zvakawanda uye mavara muchikamu chimwe chete

- Inoderedza nguva yegungano uye mutengo nekubatanidza zvikamu zvakawanda kuita chimwe

- Inovandudza kushanda nekubatanidza zvinhu zvine zvinhu zvakasiyana

- Inowedzera kuchengetedzwa kwese uye kushanda kwemidziyo yekurapa

Zvishandiso zve-mbiri-mavara jekiseni molding muvatengi zvigadzirwa indasitiri

Iyi nzira inosanganisira kupinza zvinhu zviviri zvakasiyana muforoma imwe chete, kugadzira chikamu chimwe chete chine mavara maviri kana machira. Indasitiri yezvigadzirwa zvevatengi yakabatsirikana zvakanyanya kubva kune tekinoroji iyi, sezvo ichibvumira kugadzirwa kwezvinhu zvinoyevedza, zvinoshanda, uye zvinodhura. Iyi blog positi inoongorora mashandisirwo emavara-majekiseni ekuumba muindasitiri yezvigadzirwa zvevatengi.

- Aesthetically inonakidza madhizaini: Kuumbwa kwejekiseni remavara maviri kunobvumira vagadziri kugadzira zvigadzirwa zvine dhizaini inoyevedza inomira pachena pamasherufu. Nekugona kusanganisa mavara maviri akasiyana kana zvinhu muchikamu chimwe chete chekuumba, vagadziri vanogona kugadzira zvigadzirwa zvine dhizaini yakaoma uye mapatani, senge kesi dzefoni, zvidzori zvemitambo, uye zvinhu zvemumba. Iyi tekinoroji inobvumirawo vanogadzira kugadzira zvigadzirwa zvine branding uye marogo akaiswa mudhizaini, kugadzira yakasarudzika uye inozivikanwa chigadzirwa.

- Enhanced functionality: Maviri-mavara jekiseni molding anogona kuvandudza mashandiro ezvigadzirwa nekubvumira kubatanidzwa kwezvinhu zvakawanda muchikamu chimwe chete. Semuenzaniso, kesi yefoni inogona kugadzirwa nezvinhu zvakaoma uye zvakapfava, zvinopa dziviriro uye kuvhunduka kubatwa. Pamusoro pezvo, vagadziri vanogona kushandisa majekiseni emavara maviri kugadzira zvikamu zvine mabatiro akawandisa, kuvandudza kugadzikana kwevashandisi uye kubata pane zvigadzirwa zvakaita sebhurasho remazino, reza, uye maturusi.

- Yakaderedzwa mari yekugadzira:Kushandisa maviri-mavara jekiseni kuumba kunogona kutungamira kune yakakosha mari yekuchengetedza mukugadzira zvigadzirwa zvevatengi. Nekubatanidza zvinhu zviviri kuita chikamu chimwe chete, vagadziri vanogona kubvisa mamwe matanho egungano, kuderedza mutengo wevashandi uye kudiwa kwemimwe michina. Iyi tekinoroji inogona zvakare kuderedza marara emidziyo nekushandisa chete izvo zvinodiwa mukugadzira.

- Kuvandudzwa kwechigadzirwa kusimba: Maviri-mavara majekiseni ekuumba anogona kuwedzera kusimba uye hupenyu hwezvigadzirwa zvevatengi nekugadzira zvikamu zvine akawanda zvinhu. Semuenzaniso, bhodhoro remvura rinogona kugadzirwa neganda rekunze rakaoma uye rakapfava, rinoshanduka remukati, rinopa zvose kusimba uye nyore kushandisa. Iyi tekinoroji inogona zvakare kugadzira zvigadzirwa zvine anti-slip properties, senge midziyo yekubikira uye mabheti ekugezera.

- Maitiro ekugadzirisa:Maviri-mavara jekiseni molding inobvumira kugadzirisa sarudzo kare zvaisaita nemaitiro echinyakare ekugadzira. Vagadziri vanogona kugadzira zvigadzirwa zvine akasiyana dhizaini uye mavara, zvichibvumira vatengi kuti vagadzirise zvigadzirwa zvavo. Semuenzaniso, midziyo yemitambo yakadai semakirabhu egorofu uye tenisi rackets inogona kugadzirwa neyakajairwa grip mavara, ichipa yakasarudzika kubata kune chigadzirwa.

Mari inotariswa yekuumbwa kwejekiseni remavara maviri

Maviri-mavara jekiseni molding inzira inobvumira kugadzirwa kweakaomesesa, ane mavara akawanda epurasitiki zvikamu mukushanda kumwe chete. Kuita uku kunosanganisira kushandisa zvinhu zviviri zvakasiyana zvethermoplastic zvinoiswa muforoma, imwe neimwe ichigadzira nhurikidzwa yakasiyana yechigadzirwa chekupedzisira. Kunyange zvazvo iyi nzira inogona kuunza migumisiro inofadza, ine mamwe maitiro akasiyana emitengo. Iyi blog positi ichaongorora mamwe eaya mafungidziro emitengo uye maitiro avanogona kukanganisa mutengo wakazara wekuumbwa kwemajekiseni maviri-mavara.

Mari Yezvinhu

Mutengo wemidziyo ndeimwe yezvinonyanya kuoneka mutengo wekutarisa kune maviri-mavara jekiseni kuumba. Maitiro acho anosanganisira kushandisa zvinhu zviviri, uye vagadziri vanofanira kunyatsosarudza zvese kuti vaone kuenderana uye kunaka. Zvakakosha kusarudza zvinhu zvinozoshanda pamwe chete zvakanaka uye zvinosangana nezvinodiwa zvechigadzirwa chekupedzisira. Zvichienderana nemidziyo yakasarudzwa, mutengo wezvigadzirwa zvinogona kuve chikamu chakakosha chemutengo weprojekiti.

Tooling Costs

Mutengo wekushandisa unodiwa kune maviri-mavara jekiseni kuumbwa ndeimwe yekutanga kufunga. Zvigadzirwa zviviri zvakasiyana zvinoda zviumbwa zviviri zvakasiyana, uye vagadziri vanofanirwa kugadzira mold idzi kuti dzishande pamwe mukugadzira chigadzirwa chekupedzisira. Mutengo wekushandisa wekuumbwa kwejekiseni-mavara maviri wakakwira pane echinyakare majekiseni ekuumba maitiro. Pamusoro pezvo, kuomarara kwekugadzira mold kuchakanganisa mutengo wekushandisa, sezvo mold dzakaomarara dzichida nguva yakawanda uye simba kugadzira.

Mari Yevashandi

Mari yebasa inobatanidzwa nembiri-mavara jekiseni molding inogona zvakare kukwira pane yechinyakare jekiseni kuumba maitiro. Iri basa rinoda hunyanzvi hwepamusoro uye huroyi hwekuita nemazvo. Pamusoro pezvo, maitiro anogona kutora nguva yakawanda sezvo vashandisi vanofanirwa kupinza zvine hungwaru nekuumba izvo zviviri zvigadzirwa kugadzira chigadzirwa chekupedzisira. Kukwira kwemitengo yebasa yepurojekiti inogona kunge iri mhedzisiro.

Quality Control Costs

Kudzora kwemhando kwakakosha kune chero nzira yekugadzira uye yakakosha kune maviri-mavara jekiseni molding. Nekuti maitiro anosanganisira zvinhu zviviri zvakasiyana, kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa. Izvi zvakakosha zvinogona kuda kumwe kuyedzwa uye kuongororwa, zvichiwedzera kumutengo weprojekiti yese.

Kuumbwa kwejekiseni remavara maviri kunogona kuve kudhura zvakanyanya pane yechinyakare jekiseni kuumba. Zvisinei, zvikomborero zvemuitiro uyu - kusanganisira kukwanisa kugadzira zvikamu zvakaoma, zvine mavara akawanda mukushanda kumwe chete - zvinogona kuita kuti ive yakakosha mari. Nekunyatsofunga nezve mutengo watsanangurwa pamusoro, vagadziri vanogona kusarudza kana maviri-mavara jekiseni kuumba iri sarudzo yakanaka yeprojekiti yavo.

Mamwe emitengo yakakosha yekufunga kwemavara maviri-mavara jekiseni anosanganisira anotevera:

- Mari yemidziyo, sezvinhu zviviri zvakasiyana, ichashandiswa uye inofanira kunyatsosarudzwa kuti isangane nezvinodiwa.

- Mari yekushandisa inokwira nekuti vagadziri vanofanirwa kugadzira uye kugadzira mold mbiri kugadzira chigadzirwa chekupedzisira.

- Mari yebasa, sezvo maitiro achida hunyanzvi uye ruzivo pane chikamu chemushandisi uye anogona kutora nguva yakawanda.

- Mari yekudzora mhando, senge yekuwedzera kuyedzwa uye kuongorora, inogona kudikanwa kuti ive nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa.

Nekunyatsofunga nezvezvinhu izvi zvinodhura, vagadziri vanogona kusarudza kana maviri-mavara jekiseni kuumba iri sarudzo chaiyo yeprojekiti yavo.

Kudzora kwehunhu mune maviri-mavara jekiseni molding

Kudzora kwemhando kwakakosha kune chero nzira yekugadzira uye yakakosha kune maviri-mavara jekiseni molding. Mune ino blog post, isu tichaongorora zvimwe zvakakosha zvemhando yekudzora mune maviri-mavara jekiseni molding.

Kusarudzwa Kwezvinhu

Kusarudzwa kwezvinhu ndechimwe chezvinhu zvinonyanya kukosha zvekutonga kwemhando mune maviri-mavara jekiseni molding. Vagadziri vanofanira kunyatsosarudza zvinhu kuti vave nechokwadi chekuenderana uye kunaka. Zvakakosha kusarudza zvinhu zvinozoshanda pamwe chete zvakanaka uye zvinosangana nezvinodiwa zvechigadzirwa chekupedzisira. Vagadziri vanofanirwawo kusarudza zvinhu zvine ziso rekudzikisa njodzi yekuremara, senge warping kana kubuda ropa.

Mold Dhizaini uye Kuvaka

Dhizaini uye kuvakwa kwe mold inoshandiswa mune maviri-mavara jekiseni molding yakakoshawo kuve nechokwadi chemhando yepamusoro. Vagadziri vanofanirwa kugadzira nekugadzira mold yacho chaizvo kuti ive nechokwadi chekuti inogona kuburitsa zvikamu zvinosangana nezvinodiwa uye kushanda nezvinhu zvinoshandiswa. Vagadziri vanofanirwawo kugadzira mold kuti ideredze njodzi yekuremara, senge mitsara yekuparadzanisa, kupenya, kana sink mamaki.

Jekiseni Molding Process

Iyo jekiseni yekuumba maitiro ndechimwe chinhu chakakosha chekutonga kwemhando mune maviri-mavara jekiseni kuumba. Vashandi vanofanira kunyatso kudzora maitiro ekubaya majekiseni maviri akasiyana muhuwandu chaihwo uye pakudziya kwakakodzera. Basa racho rinoda kuti mushandisi ave nezvose zvakanyatsojeka uye hunyanzvi padanho repamusoro. Chero kukanganisa kubva kune yakakodzera maitiro parameters kunogona kukonzera kukanganisa mune yekupedzisira chigadzirwa.

Kuongorora uye Kuedzwa

Chekupedzisira, kuongorora uye kuyedzwa zvinhu zvakakosha zvemhando yekudzora mune maviri-mavara jekiseni molding. Vashandi vanofanira kunyatsoongorora chigadzirwa chekupedzisira kuti vaone kuti chinosangana nezvinodiwa maererano nekukura kwayo uye kutaridzika kwayo. Iyi nzira inogona kuda kuongororwa kwekuona, kuyerwa, uye kuyedzwa. Vashandi vanofanira kuona uye kugadzirisa zvakakanganisika vasati vatumira chigadzirwa kumutengi.

Zvimwe zvezvinhu zvakakosha zvehutongi hwemhando mune maviri-mavara jekiseni molding anosanganisira:

- Kusarudzwa kwezvinhu kuve nechokwadi chekuenderana uye kunaka

- Mold dhizaini uye kuvaka kuve nechokwadi chechokwadi uye kuderedza hurema

- Injection molding process control kuti ive nechokwadi chejekiseni chaiyo yezvinhu

- Kuongorora uye kuyedzwa kuona kuti chigadzirwa chekupedzisira chinosangana nezvinodiwa.

Kugadzirisa matambudziko akajairika mune maviri-mavara jekiseni molding

Kufanana nechero nzira yekugadzira, nyaya dzinoverengeka dzinogona kumuka panguva mbiri-mavara jekiseni molding. Mune ino blog positi, isu tichakurukura mamwe ematambudziko akajairika anotarisana nevagadziri panguva yemavara-majekiseni ekuumba uye nekupa mamwe matipi ekugadzirisa nyaya idzodzo.

Kuzadza Kusina Kukwana

Imwe yenyaya dzinowanzosangana nevagadziri panguva mbiri-mavara jekiseni kuumba haina kukwana kuzadzwa. Kana chinhu chinobaiwa muforoma chikasachizadza, chinoburitsa zvidimbu zvisipo kana zvisina kukwana. Pane zvakati wandei zvinokonzeresa kusakwana kwekuzadza, kusanganisira:

- Kusakwana jekiseni pressure

- Saizi yegedhi isina kunaka kana nzvimbo

- Kutadza kufema zvakanaka

- Kupisa kusina kukwana kana kusaenzana kwe mold

Vagadziri vanofanira kushingaira kugadzirisa jekiseni kumanikidza kugadzirisa nyaya iyi uye kuona kuti mold inozadza zvizere. Ivo vanofanirwawo kushingairira kutarisa saizi yegedhi nenzvimbo uye voona kuti vanoburitsa zvakakwana mold. Pamusoro pezvo, vashandisi vanofanirwa kuona kuti vari kudziyisa mold zvakaenzana uye vachishandisa zvinhu zvakakodzera kuumbwa uye maitiro.

Warping

Imwe nyaya yakajairika iyo vagadziri vanotarisana nayo panguva mbiri-mavara jekiseni kuumbwa ndeye warping. Chikamu chinogona kukanganiswa kana kushambidzika panguva kana mushure mekuumbwa, zvichiita kuti risakodzere kushandiswa kana kusatarisika. Pane zvikonzero zvinoverengeka zvinogona kukonzera warping, kusanganisira:

- Kutonhora zvisina kuenzana

- Kutadza kugadzira mold

- Kusarudzwa kwezvinhu zvisina kunaka

- Zvisizvo zvekugadzirisa parameters

Kuti vagadzirise warping, vagadziri vanofanirwa kushingaira kuona kuti vanogadzira mold nemazvo uye kushandisa zvinhu zvakakodzera. Vanofanirawo kugadzirisa maitiro ekutonhora kuti vave nechokwadi chokuti chikamu chacho chinotonhora zvakafanana uye zvishoma nezvishoma. Chekupedzisira, ivo vanofanirwa kuona kuti maparamita ekugadzirisa akarurama, kusanganisira tembiricha, kudzvanywa, uye nguva yekutenderera.

Ruvara Kubuda ropa

Yechitatu nyaya yakajairika inosanganikwa nevagadziri panguva yemavara-majekiseni ekuumba kubuda kwemavara. Kana mavara ari muchigadzirwa akabatana, anogona kuita kuti chitaridzike chisingafadzi kana kutochirega chisingabatsiri. Pane zvakawanda zvinogona kukonzera kubuda ropa kwemavara, kusanganisira:

- Kusarudzwa kwezvinhu zvisina kunaka

- Kusanganiswa kwezvinhu zvisina kunaka

- Zvisizvo zvekugadzirisa parameters

- Kutadza kugadzira mold

Kugadzirisa kubuda ropa kwemavara, vagadziri vanofanirwa kuve nechokwadi chekuti zvinhu zvinoshandiswa zvinoenderana uye zvakakodzera. Ivo vanofanirwawo kushinga kuona kuti vanosanganisa zvinhu uye kuseta maparamita ekugadzirisa nemazvo. Chekupedzisira, ivo vanofanirwa kuve nechokwadi chekuti dhizaini ye mold inokodzera maitiro uye kuti zvinhu zvacho zvinobayiwa muhurongwa hwakakodzera uye panguva dzakakodzera.

Kuenzanisa kwemaviri-mavara jekiseni molding nemamwe maitiro ekuumba

Nepo maviri-mavara jekiseni kuumba kune mamwe akasiyana mabhenefiti, zvakakosha kuti unzwisise kuti inofananidzwa sei nemamwe maitiro ekuumba. Mune ino blog positi, isu tichafananidza maviri-mavara jekiseni kuumbwa nemamwe maitiro ekuumba uye kukurukura mabhenefiti uye zvipimo zveumwe neumwe.

Mbiri-Ruvara Jekiseni Molding vs. Single-Ruvara Jekiseni Molding

Single-ruvara jekiseni molding ndiyo yakajairika mhando, apo chinhu chimwe chete chinopinzwa muforoma kugadzira chikamu. Kuenzaniswa nemavara maviri-mavara jekiseni kuumba, imwe-ruvara jekiseni kuumba ine zvimwe zvakanakira, zvinosanganisira:

- Simpler process

- Mari shoma

- Faster kutenderera nguva

Nekudaro, imwe-ruvara jekiseni kuumba inogumira mukugadzira akawanda-mavara kana akawanda-material zvikamu. Maviri-mavara jekiseni molding inobvumira kuwedzera dhizaini kuchinjika uye kugadzirwa kwezvikamu zvakaomarara zvine akawanda mavara kana zvinhu.

Mbiri-Ruvara Jekiseni Molding vs. Overmolding

Overmolding inzira inosanganisira kuumba chimwe chinhu pane chimwe kugadzira chikamu chine zvinhu zvakawanda kana zvivakwa. Kuenzaniswa nemavara maviri-mavara jekiseni kuumba, pamusoro-kuumbwa kune zvimwe zvakanakira, zvinosanganisira:

- Kugona kuumba pazvikamu zviripo

- Mutengo wakaderera wekumhanya kudiki

- Simpler tooling

Nekudaro, pamusoro-kuumbwa kunogona kushomeka mukugadzira zvikamu zvakaoma zvine madhizaini akaomarara uye akawanda mavara. Maviri-mavara jekiseni molding inobvumira kuwedzera dhizaini kuchinjika uye kugadzirwa kwezvikamu zvakaomarara zvine mavara akasiyana kana zvinhu.

Mbiri-Ruvara Injection Molding vs. Insert Molding

Insert molding (Insert molding) chirongwa chinosanganisira kuumba kutenderedza chinhu chinoisa kana chikamu kuti chigadzire chikamu chine mashandiro akawedzerwa kana zvimiro. Kuenzaniswa nekuumbwa kwejekiseni-mavara maviri, kuisa kuumbwa kune zvimwe zvakanakira, zvinosanganisira:

- Kukwanisa kubatanidza zvikamu zvinoshanda

- Mutengo wakaderera wekumhanya kudiki

- Simpler tooling

Nekudaro, kuisa molding inogona kushomeka mukugadzira zvikamu zvine madhizaini akaomarara uye akawanda mavara. Maviri-mavara jekiseni molding inobvumira kuwedzera dhizaini kuchinjika uye kugadzirwa kwezvikamu zvakaomarara zvine mavara akasiyana kana zvinhu.

Sustainability uye zvakatipoteredza kukanganisa kwemaviri-mavara jekiseni molding

Sezvo zvinonetsa zvezvakatipoteredza zvichiramba zvichikura, vagadziri vanofanirwa kufunga nezvemaitiro avo ekugadzira 'kusimba uye kukanganisa kwezvakatipoteredza. Maviri-mavara jekiseni molding inzira yakakurumbira yekugadzira iyo inopa akati wandei mabhenefiti, asi zvakakoshawo kuti unzwisise maitiro ayo ezvakatipoteredza uye mukana wekusimudzira. Iyi blog positi ichaongorora kugadzikana uye ecological kukanganisa kwemavara-mavara jekiseni kuumba.

Sustainability muMbiri-Ruvara Jekiseni Molding

Maviri-mavara majekiseni ekuumba ane imwe mukana wekusimudzira nekuda kwekugona kwayo kugadzira zvikamu zvine akawanda zvinhu uye zvivakwa. Iyi nzira inogona kutungamira mukugadzira zvikamu zvine kusimba kuri nani, kushomeka kwemarara, uye hukuru hwesimba. Uye zvakare, maviri-mavara jekiseni kuumba anogona kupa mamwe mabhenefiti ekusimudzira:

- Vari kuderedza kudiwa kwekuwedzera kuunganidza kana kupedza maitiro, izvo zvinogona kuderedza marara uye kushandiswa kwesimba.

- Kushandisa zvinhu zvakadzokororwa mukugadzira nzira kunogona kuderedza marara uye kuchengetedza zviwanikwa.

- Vari kuderedza kuwanda kwezvinhu zvakasara zvinogadzirwa panguva yekuumbwa, izvo zvinogona kuderedza marara uye kuchengetedza zviwanikwa.

Environmental Impact of Mbiri-Ruvara Jekiseni Molding

Nepo maviri-mavara jekiseni kuumba kune imwe mukana wekusimudzira, zvakakoshawo kuti unzwisise maitiro ayo ezvakatipoteredza. Mhedzisiro yezvakatipoteredza yekuumbwa kwejekiseni-mavara maviri inogona kusanganisira zvinotevera:

- Kushandiswa kwesimba panguva yekuumbwa kunogona kubatsira mukubuda kwegreenhouse gasi uye shanduko yemamiriro ekunze.

- Tsvina inogadzirwa panguva yekuumbwa, kusanganisira zvimedu uye marara ekurongedza.

- Iko kushandiswa kunogona kuita zvinhu zvine chepfu kana zvine ngozi mukuumba kunogona kuisa njodzi kune vashandi uye nharaunda.

Kuti vagadzirise izvi zvinonetsa kwezvakatipoteredza, vagadziri vanogona kutora matanho akati wandei kuti vaderedze iyo ecological kukanganisa kwemavara maviri-mavara jekiseni kuumba, kusanganisira:

- Kushandisa simba-inoshanda midziyo uye maitiro ekuderedza kushandiswa kwesimba panguva yekuumba.

- Ita zvirongwa zvekudzikisa marara uye kudzokorodza zvakare kuderedza tsvina inogadzirwa panguva yekuumbwa.

- Kushandisa zvinhu zvine hushamwari kwezvakatipoteredza uye kudzivirira zvinhu zvine chepfu kana zvine njodzi mukuumba.

Mafambiro emangwana mune maviri-mavara jekiseni molding

Sezvo tekinoroji iri kuramba ichishanduka, akati wandei emangwana maitiro ekuumbwa kwemavara-mavara jekiseni akakodzera kuongororwa. Iyi blog positi ichakurukura mamwe emaitiro ari kubuda uye kufambira mberi mune maviri-mavara jekiseni kuumba.

Kuwedzera otomatiki

Imwe yeanonyanya kukosha maitiro mukuumbwa kwemavara-mavara jekiseni ndiko kuwedzera kwekushandisa otomatiki. Automation inogona kuvandudza kushanda zvakanaka uye kuderedza njodzi yekukanganisa kwevanhu, izvo zvinotungamira kumitengo yakaderera uye yakagadziridzwa mhando. Dzimwe nzira idzo vagadziri vari kushandisa otomatiki mune maviri-mavara jekiseni molding anosanganisira:

- Automated chikamu kubvisa uye kurongedza

- Otomatiki kubata zvinhu uye kusanganisa

- Automated mold inoshanduka

Advanced Materials

Imwe nzira iri kubuda mukuumbwa kwemavara-mavara jekiseni ndiko kushandiswa kwezvinhu zvepamberi. Zvishandiso zvepamberi zvinogona kupa kuvandudzwa kwekuita, kusimba, uye kushanda, izvo zvinogona kubatsira kusiyanisa zvigadzirwa mumusika. Vamwe vagadziri vari kushandisa zvigadzirwa zvepamberi mune maviri-mavara jekiseni molding, kusanganisira:

- High-performance thermoplastics

- Biodegradable uye compostable zvinhu

- Liquid silicone rubber (LSR) uye thermoplastic elastomers (TPE)

Smart Kugadzira

Kugadzira kwakangwara ndeimwe maitiro anokanganisa ramangwana remajekiseni-mavara maviri ekuumba. Kugadzira kwakangwara kunosanganisira kushandisa matekinoroji epamberi uye data analytics kukwirisa maitiro ekugadzira uye kugadzirisa mhando yechigadzirwa. Vagadziri vari kushandisa hungwaru kugadzira nenzira dzakasiyana-siyana mukuumba jekiseni-mavara maviri, kusanganisira:

- Chaiyo-nguva yekutarisa uye analytics yekuumba paramita

- Predictive kugadzirisa uye kugadzirisa matambudziko

- Kubatanidzwa nemamwe akangwara matekinoroji, senge marobhoti uye otomatiki

kuenderera

Sustainability chimiro chiri kukura mumaindasitiri ese; maviri-mavara jekiseni molding hazvisi izvo. Vagadziri vari kuwedzera kutarisisa kudzikisa tsvina, kuchengetedza zviwanikwa, uye kuderedza kukanganiswa kwezvakatipoteredza. Vagadziri vari kushingairira kugadzirisa mukuumbwa kwemavara-mavara jekiseni kuburikidza nenzira dzakasiyana siyana, kusanganisira:

- Kushandiswa kwezvinhu zvakashandiswa patsva

- Optimization of molding parameters kuderedza marara uye simba rekushandisa

- Kuitwa kweakavharika-loop recycling masisitimu

Case zvidzidzo zvembiri-mavara jekiseni molding mapurojekiti

Maviri-mavara jekiseni molding inzira yakakurumbira yekugadzira iyo inopa dhizaini kuchinjika, yakagadziridzwa mashandiro, uye yakasarudzika aesthetic sarudzo. Mune ino blog positi, isu tichaongorora zvimwe zviitiko zvemaviri-mavara majekiseni ekuumba mapurojekiti kuratidza kuita kwakasiyana-siyana uye kushanda kwemaitiro aya.

Indasitiri yeMotokari: Maviri-Mavara Steering Wheel

Indasitiri yemotokari inowanzoshandisa maviri-mavara jekiseni kuumba kugadzira zvikamu zvine zvese zvinoonekwa uye kushanda. Mumwe muenzaniso ndeye maviri-mavara chidhiraivho chinoshandisa chakaomarara zvinhu zvegadziko uye jira rakapfava rekubata. Iyi dhizaini inopa kunyaradza uye kusimba kwemutyairi. Iyo miviri-yemavara yekuumba maitiro zvakare inobvumira branding kana dhizaini zvinhu kuti zvibatanidzwe zvakananga mudhiraivha.

Indasitiri Yezvokurapa: Sirinji Yemavara-Maviri

Indasitiri yezvokurapa inowanzoshandisa maviri-mavara jekiseni molding kugadzira zvikamu zvine basa rakasiyana uye kuchengetedza maficha. Sirinji ine mavara maviri dhizaini inogona kubatanidza yakaoma yekunze layer yekudzivirira uye yakapfava yemukati layer kuitira nyore kushandisa. Uyezve, iyo miviri-mavara ekuumba maitiro inobvumira vagadziri kugadzira hwindo rakajeka pane sirinji, zvichinyatso kuratidza huwandu hwemvura yavanoburitsa.

Consumer Electronics Indasitiri: Maviri-Mavara Foni Nyaya

Indasitiri yemagetsi yevatengi inowanzoshandisa maviri-mavara jekiseni kuumbwa kugadzira zvikamu zvine zvese zvinoyevedza kukwezva uye kushanda. Iyo ine-mavara-mavara kese dhizaini inogona kusanganisira yakaomarara yekunze dhizaini yekudzivirira uye yakapfava yemukati layer yekuvhunduka kunyura. Iwo maviri-mavara ekuumba maitiro zvakare anobvumira branding kana dhizaini zvinhu kuti zviiswe zvakananga mukesi yefoni.

Indasitiri Yezvinhu Zvemumba: Bhurashi reZino rine Mavara maviri

Indasitiri yemidziyo yemumba inowanzoshandisa maviri-mavara jekiseni kuumba kugadzira zvikamu zvine akasiyana dhizaini maficha uye kushanda. Mugadziri anogona kugadzira bhurasho remazino rine mavara maviri rine dura rekunze rakaomarara uye rakapfava remukati rekunyaradza. Iyo miviri-yemavara molding process inobvumirawo kugadzirwa kwebristle mapatani uye mavara kuti aenderane nekumaka kana dhizaini yebhurasho rezino.

Indasitiri yeMitambo: Helmet Yemabhasikoro aneMavara maviri

Indasitiri yemitambo inowanzoshandisa maviri-mavara jekiseni kuumba kugadzira zvikamu zvine mashandiro uye aesthetic kukwezva. Vagadziri vanogona kugadzira ngowani yebhasikoro ine mavara maviri ane ganda rakaoma rekunze rekudzivirira uye rakapfava remukati rekunyaradza. Iwo maviri-mavara ekuumba maitiro anobvumirawo kusanganisa branding kana dhizaini zvinhu mungowani.

Kudzidziswa uye chitupa chemavara maviri-mavara jekiseni kuumba

Zvirongwa zvekudzidzisa uye zvitupa zvave kuwedzera mukurumbira kune vanhu vanoda kuita hunyanzvi mundima iyi. Iyi blog positi ichaongorora kukosha kwekudzidziswa uye chitupa chemavara maviri-mavara jekiseni kuumba uye zvimwe zviripo zvirongwa.

Sei Kudzidziswa uye Chitupa Kwakakosha?

Kudzidziswa uye certification kwakakosha kune vanhu vari mune maviri-mavara majekiseni ekuumba indasitiri. Kudzidziswa kwakaringana kunovimbisa kuti vanhu vane hunyanzvi uye ruzivo rwekushandisa michina zvakachengeteka uye nemazvo uye kugadzira zvigadzirwa zvemhando yepamusoro. Zvirongwa zvetifiketi zvinopa chiyero chakamisikidzwa chehunyanzvi uye kuratidza kuzvipira mukuenderera mberi kwehunyanzvi kusimudzira.

Mamwe Mabhenefiti Ekudzidziswa uye Certification anosanganisira:

- Kuchengetedzwa Kwakavandudzwa:Kudzidziswa kwakaringana uye chitupa kunogona kubatsira kuderedza njodzi yetsaona nekukuvara nekuona kuti vanhu vanoziva yakanakisa mashandiro emuchina uye maitiro ekugadzirisa.

- Kuwedzera Kubudirira:Vanhu vakagamuchira kudzidziswa uye certification vanowanzo shanda uye vanobudirira mumabasa avo, zvichitungamira mukuvandudza goho uye kubuda.

- Hunhu hwakawedzerwa:Kudzidziswa kwakaringana uye certification kunogona kubatsira kuona kuti zvigadzirwa zvinosangana nezvinodiwa zvemhando yepamusoro uye zvakatemwa.

Zvirongwa zvekudzidzisa uye zvetifiketi zviripo

- Varikugadzira:Vazhinji vagadziri vemidziyo vanopa zvirongwa zvekudzidzisa zvemichina yavo chaiyo. Aya mapurogiramu anowanzo vhara mashandiro emuchina, kugadzirisa, kugadzirisa matambudziko, uye kuchengetedza.

- Zvikoro Zvekutengeserana:Zvimwe zvikoro zvekutengesa zvinopa maviri-mavara jekiseni ekuumba makosi anovhara zvinhu, dhizaini, uye mashandiro emuchina. Aya mapurogiramu anogona zvakare kusanganisira maoko-pakudzidziswa.

- Masangano Ezvitupa: Mamwe masangano anopa zvirongwa zvekupa zvitupa zvevanhu vari muindasitiri yekugadzira jekiseni remavara maviri. Zvirongwa izvi zvinowanzo sanganisira zvese zvakanyorwa uye zvinoshanda bvunzo kuratidza hunyanzvi.

Maviri-mavara jekiseni molding ye prototyping

Iyo miviri-mavara majekiseni ekuumba maitiro anoshandiswa zvakanyanya mukugadzira kugadzira zvikamu zvakaoma nemavara akawanda kana zvinhu. Nekudaro, inogona zvakare kuve yakanakisa sarudzo ye prototyping. Mune ino blog post, isu tichaongorora mabhenefiti ekushandisa maviri-mavara jekiseni molding ye prototyping.

Mabhenefiti eTwo-Ruvara Injection Molding yePrototyping

- Zvinodhura-Zvinoshanda: Maviri-mavara majekiseni ekuumba inogona kuve inodhura-inoshanda sarudzo ye prototyping nekuti inobvumira kugadzira zvikamu zvine mavara akawanda kana zvinhu mune imwe mold. Nokuderedza nhamba yezviumbwa zvinodiwa, vagadziri vanogona kuderedza mari.

- High-Quality Parts:Maviri-mavara majekiseni ekuumbwa anoburitsa emhando yepamusoro zvikamu zvine kushivirira kwakasimba uye kupedzisa kwepamusoro kwepamusoro. Chinhu chakakosha che prototyping kugadzira zvikamu zvinonyatso kuratidza chigadzirwa chekupedzisira.

- Inokurumidza Kuchinja Nguva:Kushandisa maviri-mavara jekiseni molding ye prototyping inogona kutungamira kune ipfupi nguva yekutendeuka nekuti inobvumira kugadzira zvikamu zvakaomarara mune imwe mold. Nekubvisa kukosha kwekuunganidza akawanda maficha, vagadziri vanogona kuderedza nguva inodiwa ye prototyping.

- Design Flexibility:Maviri-mavara jekiseni kuumbwa kunopa yakakwira dhizaini kuchinjika, inobvumira kugadzirwa kwezvikamu zvine yakaoma geometries uye zvakaomarara maficha. Kugadzira inomiririra chaiyo yechigadzirwa chekupedzisira kwakakosha mu prototyping.

- Kusarudzwa Kwezvinhu:Maviri-mavara majekiseni ekuumba anobvumira zvinhu zvakasiyana muchikamu chimwe chete, izvo zvakakosha mu prototyping nekuti zvinogonesa kuongorora kwakasiyana siyana zvinhu uye musanganiswa.

Zvishandiso zveMaviri-Ruvara Injection Molding muPrototyping

- Zvigadzirwa zvevatengi:Vagadziri vanogona kushandisa maviri-mavara jekiseni kuumba kugadzira prototypes ezvigadzirwa zvevatengi zvakaita sematoyi, midziyo, uye zvemagetsi. Kugadzira zvikamu zvine mavara mazhinji kana zvinhu mune imwe mold kunonyanya kubatsira mune ino indasitiri.

- Indasitiri yemotokari: Maviri-mavara majekiseni ekuumba anogona kugadzira prototypes emidziyo yemotokari senge yemukati trim, mavhiri ekudhiraivha, uye giya shift shift. Kugadzira zvikamu zvine mavara akasiyana uye kupera kwakakosha mune ino indasitiri.

- Midziyo yekurapa:Kuumbwa kwemajekiseni maviri-mavara kunogona kugadzira prototypes emidziyo yekurapa senge zvibato, mabhatani, uye switch. Kugadzira zvikamu zvine zvinhu zvakasiyana kwakakosha muindasitiri ino, uko biocompatibility uye sterilization zvivakwa zvakakosha.

Kusarudza mudiwa akakodzera kune yako mbiri-mavara jekiseni rekugadzira purojekiti

Kusarudza mudiwa akakodzera kune yako mbiri-mavara jekiseni rekugadzira purojekiti yakakosha pakubudirira kweprojekiti yako. Zvingabatsira kana iwe ukawana mudiwa ane hunyanzvi, ruzivo, uye kugona kuzadzisa zvaunoda chaizvo. Iyi blog positi inoongorora zvimwe zvakakosha zvekufunga nezvazvo pakusarudza mudiwa akakodzera kune yako maviri-mavara jekiseni rekuumba purojekiti.

Zvinhu Zvokufunga nezvazvo Paunenge Uchisarudza Shamwari Yenyu Yemavara-Maviri Majekiseni Molding Project:

- Hunyanzvi:Kusarudza shamwari ine hunyanzvi mukuumbwa kwejekiseni remavara maviri kwakakosha. Vanofanira kuva nekunzwisisa kwakadzama kwemaitiro uye kukwanisa kupa mazano uye mazano pamusoro pekugadzira nekugadzirwa kwezvikamu zvako.

- Experience:Chiitiko chakakosha pakusarudza mudiwa kune yako maviri-mavara jekiseni rekugadzira purojekiti. Tsvaga wekushamwaridzana naye ane rekodhi rekodhi rekubudirira kugadzira zvikamu zvemhando yepamusoro zvine kushivirira kwakasimba uye kupedzisa kwepamusoro.

- Unyanzvi:Funga nezvemasimba emudiwa wauri kufunga. Vane midziyo inodiwa, zviwanikwa, uye vashandi vekubata basa rako here? Vanogona kubata mavhoriyamu makuru nezvikamu zvakaoma kunzwisisa here? Ita shuwa kuti mumwe wako ane hunyanzvi hwekuzadzisa zvaunoda chaizvo.

- Quality Control: Kudzora kwehunhu kwakakosha mune maviri-mavara jekiseni molding. Ita shuwa kuti mumwe wako ane yakasimba yemhando yekudzora system yekuona kuti zvikamu zvavanogadzira zvinosangana nezvako zvakatemwa uye zviyero.

- Kukurukurirana: Kukurukurirana chinhu chinokosha kune chero chirongwa chinobudirira. Ita shuwa kuti mumwe wako anoteerera uye anotaurirana mukati mese maitiro. Vanofanira kukuzivisa nezve chero matambudziko kana matambudziko uye kuve nehanya mukutsvaga mhinduro.

- Mariro: Mutengo unogara uchitariswa kana uchisarudza mudiwa kune yako maviri-mavara jekiseni rekugadzira purojekiti. Zvisinei, zvakakosha kuyeuka kuti mutengo wakaderera haurevi kukosha kwakanakisisa. Tsvaga wekufambidzana naye anopa kukwikwidza mitengo achiri kupa zvikamu zvemhando yepamusoro uye sevhisi yakanaka.

- Sustainability:Sustainability iri kuwedzera kukosha mukugadzira. Funga kudyidzana nekambani yakazvipira kusimudzira uye kudzikisira kukanganisa kwavo kwezvakatipoteredza.

mhedziso

Maviri-mavara majekiseni ekuumba inosiyana-siyana uye inowedzera kufarirwa nzira yekugadzira iyo inopa akawanda mabhenefiti, akadai sekuvandudza dhizaini kuchinjika, kuderedzwa nguva yegungano, uye kusimudzira kushanda. Kunyange iine painogumira uye zvinonetsa, inogona kugadzira zvikamu zvemhando yepamusoro nemutengo wakakwikwidzana nemafungiro akakodzera ekugadzira, zvishandiso, uye zvinhu. Maviri-mavara jekiseni molding ane maapplication mumaindasitiri akasiyana, uye sezvo tekinoroji inofambira mberi, tinogona kutarisira kuona humwe hutsva mundima iyi. Kushanda nemudiwa akavimbika uye ane ruzivo anogona kupa hunyanzvi, midziyo, uye zviwanikwa zvinodiwa zvakakosha kuti uve nechokwadi chekubudirira kweprojekiti yako yekuumba jekiseni remavara maviri.