High Volume Injection Molding

Yakakwira vhoriyamu jekiseni kuumba (Yakakwira-Volume Kugadzirwa): Plastic Injection Molding

Nekupfuura zviuru zvemajekiseni epurasitiki ekuumba uye mapurasitiki ekugadzira zvivakwa zvekusarudza kubva pamusoro peshoko, ndehupi humwe hunhu hwepamusoro hunoita kuti kambani yekuumba ionekwe? Pakusarudza mupi, zvinhu zvakawanda zvinofanirwa kutariswa; kusanganisira kugona, kuvimbiswa kwemhando, mukurumbira wekambani, mutengo, uye nguva yekuendesa. Kutsvaga chaiyo jekiseni remajekiseni epurasitiki kuti rikwane zvaunoda kungaite sekudyira nguva asi kutanga kuona zvakaderera uye zvakakwirira-vhoriyamu zvaunoda uye kuti vangachinja sei nekufamba kwenguva, zvichabatsira kudzikisa sarudzo dzako.

DJmolding's High-Volume Injection Molding Service

PaDJmolding, nzvimbo yedu yekugadzira ndeyepamusoro-magumo, inoshanda inoshanda ine akati wandei michina uye vane hunyanzvi vanoshanda. Nekuda kwemidziyo yedu yakasiyana, tinokwanisa kubata mabasa akasiyana siyana ayo anosiyana zvakanyanya mumaindasitiri avo, mhando yepurasitiki, uye huwandu hwezvidimbu zvinogadzirwa. Yakaderera uye yakakwira-mavhoriyamu, kubva pakugadzira kuburikidza nekugadzira, inogona kupedzwa mukati meimba iyo inopa vatengi vedu nemakwikwi mabhenefiti mumutengo, mhando, uye nguva dzekutungamira.

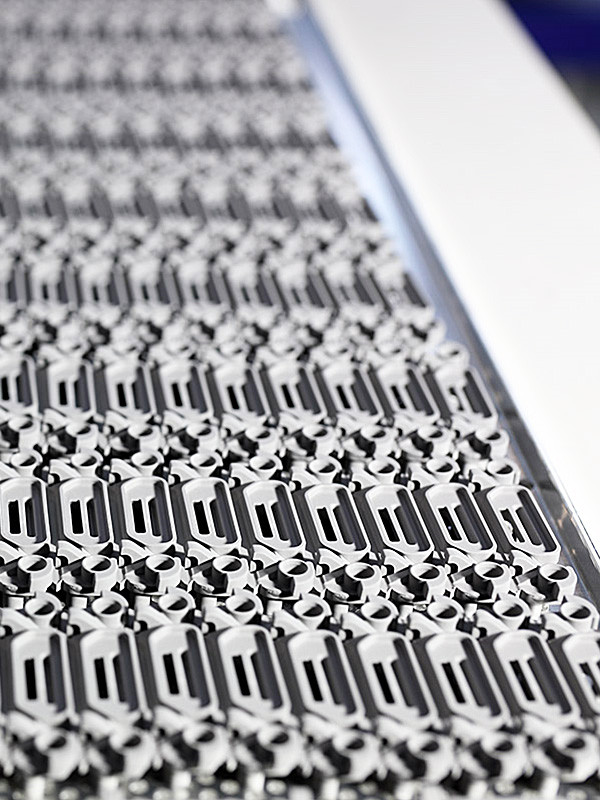

DJmolding's jekiseni molding inzira yakasimbiswa yakakwira-vhoriyamu yekugadzira maitiro. Iri ibasa rakasarudzika rinopa zvizere zvekugadzira-mhando zvikamu mumavhoriyamu anosvika mamirioni ezvimedu pamwedzi. Yakakwira-vhoriyamu jekiseni repurasitiki kuumba inobvumira yakakwirira-kushivirira chaiyo, yakaderera kurashikirwa, uye mari yekuchengetedza.

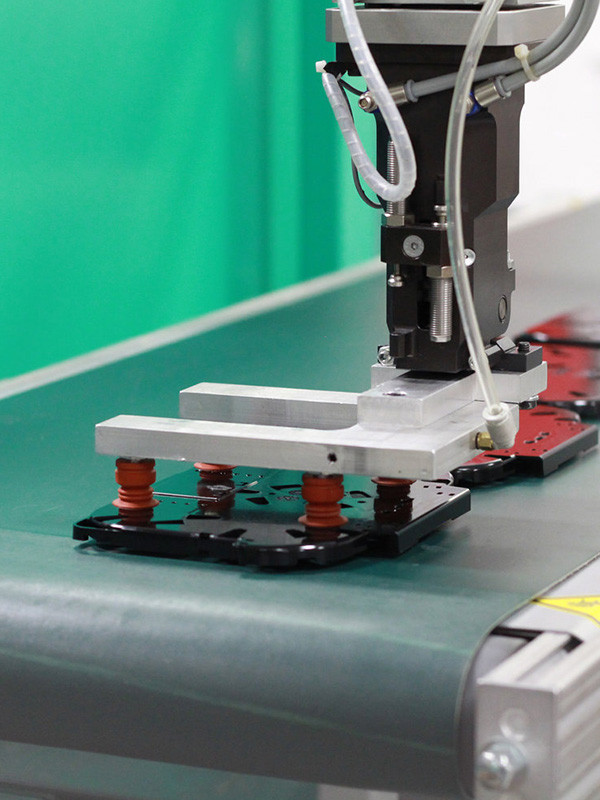

Mazhinji emidziyo yedu yekuumba yakakwira-vhoriyamu ndeyekombuta uye inoshandisa masisitimu emuchina kuwedzera mashandiro uye kuchengetedza mhando. Ita shuwa yekuona yedu "Quality Control System" kuti uone mabatiro atinoita kudzora kwemhando inobatanidzwa mune ese akakwira-vhoriyamu kugadzirwa. Rudzi urwu rwekugadzira rwakanakira mabhizinesi epakati uye akakura-hukuru kana kugadzirwa kwakawanda.

DJmolding's High-Volume Injection Molding Advantages

*Inogadzira zvimwe zvikamu nekukurumidza

* Deredza mutengo weyuniti uye kutenderera nguva yemugadziri

* Yakarurama uye inowirirana, yemhando yepamusoro kugadzirwa kwezvikamu

*Kugadzira kunogona kazhinji kuve otomatiki nemichina yakasimba, yakavimbika, kunyangwe panguva isiri yebasa

*Minime post-kugadzirwa basa

Customized High Volume Molding (Plastic jekiseni Prodtucts)

DJmolding's tsika molds uye yakakwirira vhoriyamu kuumba inosanganisira zvese kubva kune prototypes kusvika kuzere kugadzirwa huwandu. Yedu yepamusoro vhoriyamu molds, ingave ipfupi-run, yakakwira-vhoriyamu, kana yakawanda-cavity, inotariswa uye inodzorwa kuitira kuti iwe uve nechokwadi chezvese maficha ekugadzira mold uye kuvaka. Uku kutarisisa kweruzivo rwekugadzira kunosimbisa zvibodzwa, zvinangwa, uye preset mhedzisiro yepurojekiti iri pahurongwa muchikamu chimwe nechimwe chemaitiro. Yese yakakwira vhoriyamu kuumba, kubva padhizaini kuburikidza nekugadzira, inopedzwa mumba uye inopa vatengi vedu mukana wemakwikwi mumutengo, mhando, uye nguva dzekutungamira.

DJmolding inoshanda nemutengi kugadzira uye mainjiniya zvigadzirwa, kugadzira anonyanya kushanda akakwira vhoriyamu molds kuti mutengo ushande. Isu tinopa yakanakisa mhando yepamusoro vhoriyamu molds yakasarudzika kune epurasitiki jekiseni rekugadzira indasitiri, ichipa akasiyana masevhisi. Kubva pakushomeka kwevhoriyamu yakaderera, kuisa kuumba, uye kudhinda padhi, PTI, Inc.

DJmolding prototype zvikamu zvevatengi mundima dzakasiyana senge yekurapa, yemagetsi, ruoko chishandiso, kutaurirana, uye maindasitiri emotokari. Kusanganisira jekiseni uye kudzvanya mashini kubva pa85-500 Ton, yakawanda yeDJmolding yakakwira vhoriyamu yekugadzira michina yekombuta uye inoshandisa michina masisitimu kuwedzera mashandiro uye kuchengetedza mhando. Pa DJmolding tinotora maitiro ekudyidzana pane ese maitirwo, tichiunza makore eruzivo rwekugadzira jekiseni repurasitiki uye hunyanzvi hwehunyanzvi munzvimbo yakagadzirirwa kupa yakazara purasitiki jekiseni rekuumba ruzivo.

Chivakwa chepamusoro vhoriyamu mold chinoda musanganiswa wetekinoroji, zvishandiso uye vanokwanisa mold vavaki kuti vagadzire majekiseni mold nekukurumidza neinenge isina muganhu geometry yezvikamu zvepurasitiki.

Kubva padhizaini kusvika pakuendesa, DJmolding inogona kurongedza yako yese chirongwa chekuvaka maturusi kubva pakutanga kusvika pakupedzisira. Ichibatsirwa nehurongwa hwayo hwekuvimbisa mhando, chinangwa chePTI ndechekupa zvigadzirwa zvakaumbwa zvinozadzisa kana kudarika zvinodiwa uye zvinotarisirwa nevatengi vayo. Kambani manejimendi yakazvipira kuenderera mberi kwemhando yepamusoro. Kuti uwane emhando yepamusoro uye inoshanda yakakwira vhoriyamu yekuumba masevhisi, bata DJmolding. nhasi.

Makambani mazhinji haakwanise kupa kutanga kwakazara kwekupedzisa kugadzira mold ruzivo. Kunyangwe iwe uchitsvaga mashoma anokurumidza prototypes, zviuru zvemusika-akagadzirira vatengi mapurasitiki, kana miriyoni yekugadzira zvikamu, DJmolding inogona kupa zvaunoda. Yakaderera uye yakakwira-vhoriyamu, isu tinodada tinosimbirira kuti odha yega yega ndeyeyemwe nhanho yemhando. Bata nyanzvi dzedu nhasi.

Kubva padhizaini kusvika pakuendesa, DJmolding inogona kurongedza yako yese chirongwa chekuvaka maturusi kubva pakutanga kusvika pakupedzisira. Zvemhando yepamusoro uye masevhisi anoshanda, Kumbira A Quote nekutumira ruzivo rwako kune info@jasonmolding.com

Iyo yekugadzira maitiro epamusoro vhoriyamu jekiseni molding inoburitsa akawanda akafanana epurasitiki zvikamu. Iyi nzira yakakurumbira nekuti inodhura-inoshanda, inoshanda, uye inopa inowirirana, yemhando yepamusoro zvidimbu. Iyi blog positi inoongorora zvese zvaunoda nezve yakakwira vhoriyamu jekiseni kuumba, kusanganisira zvakanakira, zvayakaipira, maapplication, nezvimwe.

Chii chinonzi High Volume Injection Molding?

Yakakwira-vhoriyamu jekiseni molding inzira yekugadzira iyo inoburitsa akawanda akafanana epurasitiki zvikamu. Maitiro acho anosanganisira kubaya zvinhu zvepurasitiki zvakanyungudutswa mugomba pakumanikidzwa kukuru uye tembiricha, zvichiita kuti itonhore uye igosimba muchimiro chaunoda. Iyi yakanyanyisa otomatiki maitiro inogona kuburitsa zviuru kana kunyange mamirioni ezvikamu zvakafanana mukumhanya kumwe chete.

Nzira yekugadzira inoshanda zvakanyanya ndiyo kiyi yekubudirira yakakwira-vhoriyamu jekiseni molding. Maitiro acho anosanganisira kushandisa yakakwira-kumhanya majekiseni ekuumba michina uye otomatiki masisitimu anogonesa kukurumidza uye kwakaringana kugadzirwa kwezvikamu. Pamusoro pezvo, vagadziri vanogona kuona kuti vanogadzira chinhu chimwe nechimwe kune zvakatemwa nekushandisa emhando yepamusoro mold uye nekushandisa chaiwo jekiseni paramita.

Imwe yemabhenefiti akakosha epamusoro vhoriyamu jekiseni kuumba kugona kwayo kuburitsa huwandu hukuru hwezvikamu zvakafanana nekukurumidza uye zvine mutengo. Maitiro ekugadzira akakwana kune mota, zvinhu zvevatengi, zvigadzirwa zvekurapa, uye maindasitiri emagetsi.

Imwe mukana weiyo yakakwira vhoriyamu jekiseni kuumba kugona kugadzira zvikamu zvakaoma zvine kushivirira kwakasimba. Iyo jekiseni yekuumba maitiro ndeyechokwadi uye inowirirana, zvichikonzera kuomesesa zvinhu zvine musiyano mudiki pakati pezvimedu.

Pasinei nezvakawanda zvakanakira, yakakwira vhoriyamu jekiseni kuumba ine zvimwe zvinogumira. Semuenzaniso, panogona kunge paine sarudzo dziri nani dzekugadzira zvikamu zvakakura kwazvo kana zvidiki, sezvo mutengo uye kuoma kwezviumbwa zvinodiwa zvinogona kurambidza. Pamusoro pezvo, mavhoriyamu epurasitiki akakwira anogona kuve nekukanganisa kwezvakatipoteredza, zvichiita kuti zvive zvakakosha kuti vagadziri vatarise kusimba uye kuedza kudzokorodza.

Yakakwira-vhoriyamu jekiseni molding inzira inoshanda uye inoshanda yekugadzira iyo inogona kuburitsa huwandu hwakakura hwezvikamu zvepurasitiki zvakafanana nekukurumidza uye zvine mutengo. Iyo isarudzo yakakodzera kune akasiyana maindasitiri, uye iko kurongeka kwayo uye kuenderana kunoita kuti ive sarudzo yakakurumbira yekugadzira zvikamu zvakaoma zvine kushivirira kwakasimba. Kunyange iine zvimwe zvinogumira, mabhenefiti eiyo yakakwira vhoriyamu jekiseni molding inoita kuti ive chishandiso chakakosha kune vagadziri vari kutsvaga kugadzira akawanda emhando yepamusoro zvikamu zvepurasitiki.

Yepamusoro Volume Injection Molding Inoshanda Sei?

Maitiro acho anosanganisira akati wandei matanho akakosha, imwe neimwe yakakosha mukugadzira zvikamu zvemhando yepamusoro. Iyi blog post inotsanangura kuti yakakwira vhoriyamu jekiseni kuumba inoshanda sei, kusanganisira ayo akakosha matanho uye kufunga.

Mold Design uye Kugadzirira

Nhanho yekutanga mukuumba yakakwira vhoriyamu jekiseni kugadzira uye kugadzirira mold ichashandiswa nevagadziri kugadzira zvikamu. Kubatana nemugadziri we mold kunodiwa kuti ugadzire dhizaini chaiyo inosangana nezvose zvakakosha zvekugadzira zvikamu zvinodiwa. Kazhinji, vagadziri vanogadzira mold kubva kusimbi kana aluminium uye vanoigadzira kuti imirisane nekumanikidza kwakanyanya uye tembiricha yekuumba jekiseni.

Kugadzirira Kwezvinhu

Nhanho inotevera ndeyekuti vagadziri vagadzirire zvinhu zvepurasitiki zvavachashandisa kugadzira zvikamu. Kusarudza rakakodzera resin yepurasitiki yakakosha kugadzira izvo zvinodiwa, sezvo mhando yeresin inoshandiswa zvinoenderana nezvinodiwa chaizvo. Iyo resin inozoiswa mumushini wekuumba jekiseni, inopisa, uye inonyungudutswa kuita mvura.

Jekiseni Molding Process

Iyo jekiseni yekuumba maitiro inotanga apo iyo yakanyungudutswa yepurasitiki zvinhu inopinzwa mugomba rekuumbwa nekumanikidza kwakanyanya uye tembiricha. Iyo mold inobatwa yakavharwa pasi pekumanikidzwa kusvikira purasitiki yatonhora uye yakasimbiswa; panguva ino, mold inovhurwa, uye chikamu chinobudiswa.

Quality Control

Kana zvikamu zvave zvagadzirwa, ivo vanoenda kune yakaomesesa yemhando yekudzora maitiro kuti ave nechokwadi chekuti vanosangana nezvinodiwa. Izvi zvinogona kusanganisira kuongorora kwekuona, kuyerwa, uye kuyedza kuona kuti chikamu chimwe nechimwe chinopindirana muhukuru, chimiro, uye mhando.

Mafungiro eHigh-Volume Injection Molding

Pane akati wandei mafungidziro anofanirwa kuchengetwa nevagadziri kana vachishandisa yakakwira vhoriyamu jekiseni kuumba, kusanganisira:

- Kusarudzwa kwemichina: Makina ekuumba majekiseni akakwira-anomhanya anowanzo shandiswa kumhanyisa-vhoriyamu yekugadzira inomhanya, sezvo ichikwanisa kukurumidza uye nemazvo kuburitsa zvikamu.

- Mold Design: Iyo mold dhizaini yakakosha pakubudirira kweiyo jekiseni molding process, sezvo ichifanirwa kuve chaiyo uye ichikwanisa kumirisana nekumanikidza kwakanyanya uye tembiricha yemaitiro.

- Kusarudzwa Kwezvinhu: Sarudzo yepurasitiki resin inogona kukanganisa kunaka uye kushanda kwezvikamu zviri kugadzirwa, zvichiita kuti zvive zvakakosha kusarudza zvinhu zvakakodzera zvebasa racho.

- Mariro: Nepo kuumbwa kwejekiseni repamusoro-soro iri nzira yekugadzira inodhura, kuchine mari ine chekuita nekugadzira mold, kusarudzwa kwezvinhu, uye kugadzirwa kunofanirwa kutariswa.

Zvakanakira High Volume Injection Molding

Kuumbwa kwejekiseni repamusoro-vhoriyamu kwakashandura indasitiri yekugadzira nekugonesa kugadzirwa kwezvikamu zvepurasitiki zvakafanana muhuwandu hukuru nekumhanya kusingaenzaniswi uye kushanda nesimba. Maitiro aya awana mukurumbira muzvikamu zvakasiyana nekuda kwezvakawanda zvakanakira, zvichiita kuti ive nzira yekugadzira yemakambani ari kutsvaga kuderedza mitengo, kuderedza marara, uye kuwedzera kugadzirwa.

- Kugadzirwa Kusingadhuri: Yakakwira-vhoriyamu jekiseni molding inoshanda zvakanyanya uye inozviitira, zvichiita kuti iite mari-inoshanda kana ichienzaniswa nemamwe maitiro ekugadzira. Kana mold yangogadzirwa uye kugadzirirwa, maitiro ekugadzira anogona kuenderera mberi, achigadzira zviuru kana mamirioni ezvikamu zvakafanana zvine mashoma evashandi kana mari yezvinhu.

- Yakagadzirwa-Yakakwirira Kubuda: Nemakina ekuumba majekiseni anomhanya-mhanya, vagadziri vanogona kugadzira huwandu hukuru hwezvikamu chaizvo munguva pfupi. Izvi zvinoreva kuti kugadzirwa kwekugadzirwa kunogona kukurumidza kuwedzera kana kuderera kuti zvizadzise kuchinja kudiwa.

- Hunhu Hunoenderana: Iko kurongeka uye kuenderana kweyakakwira-vhoriyamu jekiseni molding inoita kuti ive yakanakira kugadzira zvikamu zvine kushivirira kwakasimba uye zvakaoma kunzwisisa. Iyo nzira inobvumira mwero wepamusoro wekururama, kuve nechokwadi chekuti chikamu chimwe nechimwe chinogadzirwa chakafanana kune chimwe.

- Kusiyana-siyana muChikamu Dhizaini: Kuumbwa kwejekiseni repamusoro-vhoriyamu kunogona kuburitsa zvikamu zvine huwandu hwakasiyana hwemagadzirirwo uye maumbirwo, kusanganisira ayo ane yakaoma geometries. Izvi zvinoreva kuti vagadziri vanogona kuve nemaitiro anoenderana nezvinodiwa nevatengi uye anogona kugadzirisa zviri nyore kugadzira kana shanduko yechigadzirwa.

- Yakaderedzwa Marara: Iko kushandiswa kwemhando yepamusoro mold uye chaiyo jekiseni paramita mune yakakwira vhoriyamu jekiseni molding inoderedza huwandu hwezvakaraswa kana tsvina inogadzirwa panguva yekugadzira. Izvi zvinoreva kuti vagadziri vanogona kugadzira zvikamu zvine kushomeka kwemarara, kuderedza mutengo uye kukanganisa kwezvakatipoteredza.

- Kuwedzera Kubudirira Kwekugadzira: High-volume jekiseni molding inogadzirwa zvakanyanya, zvinoreva kuti inoda basa shoma uye inogona kumhanya ichienderera nekupindira kushoma. Izvi zvinotungamira mukuwedzera kushanda kwekugadzira, sezvo vagadziri vanogona kugadzira zvikamu nekukurumidza uye zvine hungwaru pasina kudiwa kwebasa remaoko kana kutarisisa.

Zvakaipa zveHigh-Volume Injection Molding

Yakakwira-vhoriyamu jekiseni molding inowanzoshandiswa-inoshandiswa kugadzira maitiro ekugadzira huwandu hukuru hwezvikamu zvepurasitiki zvakafanana nekukurumidza uye zvine mutengo. Kunyange zvazvo iine zvakawanda zvakanakira, zvakadai sekudhura-kushanda uye kuwirirana kwehutano, kunewo zvipingamupinyi. Iyi blog positi inoongorora zvimwe zvekuipa kweiyo yakakwira vhoriyamu jekiseni molding.

- High Initial Investment: Imwe yezvakanyanya kuipa kweiyo yakakwira vhoriyamu jekiseni molding ndiko kuwedzera kwekutanga kwekudyara kunodiwa kugadzira nekugadzira mold. Mutengo uyu unogona kuve wakakosha, kunyanya kumabhizinesi madiki kana ayo anoda akagadziridzwa mold kune chaiwo zvikamu.

- Nguva Yekutungamira Yakareba:Maitiro ekugadzira uye kugadzira molds yeakakwira-vhoriyamu jekiseni kuumba inogona kutora akati wandei mavhiki kana kunyange mwedzi, zvichikonzera nguva refu yekutungamira. Izvi zvinogona kuve kukanganisa kumakambani anoda kuburitsa zvikamu nekukurumidza kana kupindura kune shanduko mukudiwa.

- Zvishoma Zvisarudzo Zvezvinhu: Nepo marudzi mazhinji epurasitiki resin aripo kune yakakwira vhoriyamu jekiseni kuumba, iyo sarudzo inogona kushomeka zvichienderana neiyo chaiyo application. Mamwe maresheni epurasitiki anogona kunge asina kukodzera kugadzirwa kwakakwira nekuda kwezvivakwa zvawo, izvo zvinogona kudzora sarudzo dzezvinhu.

- Yakaganhurirwa Dhizaini Kuchinjika: High-volume jekiseni molding inzira chaiyo inoda kuti mold dzigadzirwe nemadimikira chaiwo. Izvi zvinoreva kuti panogona kuve nekupikiswa padhizaini yezvikamu zvinogadzirwa kuburikidza nemaitiro aya, kunyanya kana chinzvimbo chacho chiine ma geometries akaoma kana zvimwe zvakasiyana dhizaini zvinodiwa.

- Kugadzirisa kwakakwirira uye Kugadzirisa Mari: Iyo mold inoshandiswa mukuumbwa kwejekiseni yakakwira-vhoriyamu inofanirwa kuchengetedzwa uye kugadziriswa nguva nenguva kuti ive nechokwadi chekushanda kwakakwana. Mutengo wekugadzirisa nekugadzirisa unogona kuve wakakosha, kunyanya kana mold ichishandiswa kazhinji kana kwenguva yakareba.

Zvisinei nekuipa uku, kuumbwa kwejekiseni repamusoro-soro rinoramba riri rakakurumbira uye rinoshanda rekugadzira nzira yekugadzira huwandu hukuru hwezvikamu zvepurasitiki zvakafanana. Nekunyatso tarisa zvakanakira nekuipira kweichi chirongwa, vagadziri vanogona kuita sarudzo dzine ruzivo nezve kana iri sarudzo chaiyo yezvavanoda kugadzira.

Zvishandiso Zvinoshandiswa muHigh-Volume Injection Molding

Kusarudza zvinhu zvakakodzera zvekuumba majekiseni epamusoro-soro kwakakosha kuti uve nechokwadi chemhando uye kushanda kwechigadzirwa chekupedzisira. Ichi chinyorwa chinotarisa mumidziyo inoshandiswa mukuumba majekiseni epamusoro, zvimiro zvavo, uye mashandisiro azvo.

Polypropylene (PP)

Polypropylene inowanzoshandiswa thermoplastic polymer mukuumbwa kwejekiseni repamusoro-soro nekuda kwekudhura kwayo, simba-ku-huremu reshiyo, uye kusimba. PP inogoneka kune mota, kurongedza, uye kugadzirwa kwezvinhu zvevatengi. Zvakanakira kushandisa PP mukuumba jekiseni zvinosanganisira huremu hwayo, makemikari kuramba, uye kugadzikana kwedimensional, izvo zvinoita kuti ive yakakodzera kune chaiyo zvikamu.

Acrylonitrile Butadiene Styrene (ABS)

ABS ndeye thermoplastic polymer inozivikanwa nekuomarara kwayo, kukanganisa kupikisa, uye kupenya kwakanyanya. Ichi chinyorwa chinowanzoshandiswa mumatoyi, zvikamu zvemotokari, uye dzimba dzemagetsi. Kupikisa kweABS kunoita kuti ive yakakodzera kune ruzivo rwakaiswa pasi pekukanganiswa kana kuvhunduka. Iyo zvakare iri nyore kugadzirisa uye ine yakanakisa kupedzisa kwepamusoro, ichiita kuti ive yakanaka kune yakakwira-vhoriyamu yekugadzira inomhanya.

Polycarbonate (PC)

Polycarbonate is thermoplastic polymer iyo inopesana zvakanyanya, inopenya yakajeka, uye isingadziviriri kupisa. Icho chinhu chakakurumbira chemotokari, aerospace, uye zvemagetsi maindasitiri. Mabhenefiti ePC anosanganisira yakanakisa kukanganisa kupikisa, kujeka kwemaziso, uye kupisa kupisa, zvichiita kuti ive yakakodzera kune yakakwirira-tembiricha yekushandisa, lenzi, uye zviratidziro.

Polyethylene (PE)

Polyethylene ndeye thermoplastic polymer inochinjika, yakasimba, uye inodzivirira kemikari. Inowanzoshandiswa kugadzira zvinhu zvekurongedza, mabhegi epurasitiki, uye mafirimu ekurima. PE's chemical resistance, kushanduka, uye huremu hunhu hunoita kuti ive yakanakira michina yekugadzira makemikari, kurongedza kwemakemikari, uye maapplication anoda kuti zvikamu zvikotame kana kuchinjika.

Polyethylene Terephthalate (PET)

PET ndeye thermoplastic polymer ine yakakwira simba-ku-huremu reshiyo, kujeka, uye zvipingamupinyi zvivakwa. Inogadzira mabhodhoro ezvinwiwa, midziyo yekudya, uye zvekurongedza. Mabhenefiti ePET anosanganisira simba-ku-huremu chiyero, kujeka, uye zvipingamupinyi zvinoita kuti ive yakanakira maapplication panodiwa simba, senge mabhodhoro ezvinwiwa uye kurongedza uko zviri mukati zvinofanirwa kuchengetedzwa kubva kunyoro uye oksijeni.

Polystyrenes (PS)

Polystyrene ndeye thermoplastic polymer iyo isingaremi, inodhura-inoshanda uye ine yakanaka yekudzivirira zvivakwa. PS inowanzoshandiswa kugadzira makapu anoraswa, zvinhu zvekurongedza, uye insulation, uye zvakanakira zvayo zvinosanganisira mutengo wakaderera, huremu hunhu, uye yakanaka yekuvharisa zvivakwa.

Mhando dzeJekiseni Molding Machines Anoshandiswa Kwepamusoro Vhoriyamu Kugadzira

Maitiro acho anosanganisira kubaya mapurasitiki akanyungudutswa mugomba, umo anoomesa uye kutora chimiro cheforoma. Majekiseni ekuumba michina inouya mumhando dzakasiyana, uye imwe neimwe inokodzera rudzi rwakati rwekugadzira. Heano mhando huru dzemajekiseni ekuumba machina anoshandiswa pakakwirira vhoriyamu kugadzirwa:

- Hydraulic Injection Molding Machines: Michina iyi inoshandisa hydraulic pressure kufambisa mold uye kubaya purasitiki yakanyungudutswa mugomba. Ivo vanozivikanwa nekukwira kwavo kwekugadzirwa kwepamusoro asi zvakare vane inononoka kutenderera nguva, vachidzikamisa kushandiswa kwavo kwepamusoro uye nekumhanya-mhanya kwekushandisa.

- Magetsi Majekiseni Anoumba Michina: Michina iyi inoshandisa magetsi servo motors kutyaira jekiseni unit uye mold. Ivo vanopa kurongeka kwakanyanya uye nekumhanya, zvichiita kuti ive yakanakira maindasitiri epamusoro-soro semidziyo yekurapa nemagetsi.

- Hybrid Injection Molding Machines: Michina iyi inosanganisa zvakanakisa zvepasirese. Ivo vanoshandisa hydraulic nemagetsi masisitimu kutyaira iyo jekiseni unit uye mold. Injini dzeHybrid dzinoshanda uye dzinokurumidza, iine yakakwira kugadzirwa, ichiita kuti ive yakanakira kugadzirwa kwakakwira.

- Michina Yekuumba Majekiseni maviri: Michina iyi inogadzira zvikamu zvakaoma zvinoda zvinhu zviviri zvakasiyana kana mavara. Chishandiso chine majekiseni maviri ejekiseni anoshanda pamwechete kugadzira chidimbu chekupedzisira. Michina yekugadzira majekiseni maviri-kupfura yakanakira kugadzira zvigadzirwa zvemhando yepamusoro zvine akawanda mazvikamu.

- Multi-Material Injection Molding Machines:Michina iyi inogadzira zvikamu zvakagadzirwa nezvinhu zvakasiyana. Vane majekiseni akawanda anovabvumira kushandisa zvimwe zvinhu panguva imwe chete. Multi-material jekiseni rekugadzira michina yakanakira kugadzira zvimedu zvinoda zvakasiyana zvivakwa, sesimba, kusimba, uye kuchinjika.

- Liquid Jekiseni Molding Machines: Michina iyi inoshandiswa kugadzira zvikamu zvakagadzirwa zvemvura silicone rubber (LSR). Muchina uyu unopinza LSR mugomba re mold, umo inoomesa uye inotora chimiro che mold. Liquid jekiseni rekuumba michina yakanakira kugadzira zvikamu zvinoda kunyatsojeka uye kusimba, senge michina yekurapa uye zvikamu zvemotokari.

Jekiseni Molding Maitiro Matanho ePamusoro-Volume Kugadzirwa

Maitiro acho anosanganisira kubaya mapurasitiki akanyungudutswa mugomba, umo anoomesa uye kutora chimiro cheforoma. Heano matanho anosanganisirwa mukuita jekiseni molding maitiro epamusoro vhoriyamu kugadzirwa:

- Kusarudzwa Kwezvinhu: Nhanho yekutanga mune jekiseni molding process ndeyekusarudza iyo yakakodzera zvinhu zvekugadzira chikamu. Izvo zvinhu zvakasarudzwa zvinofanirwa kunge zvine zvivakwa zvinodikanwa, senge simba, kusimba, uye kuchinjika, uye zvichifambirana nemuchina wekuumba jekiseni.

- Mold Design: Nhanho inotevera ndeyekugadzira mold kana zvinhu zvasarudzwa. Iyo mold inofanira kugadzirwa maererano nezvinodiwa chaizvo zvechikamu chiri kugadzirwa, kusanganisira chimiro, ukuru, uye maitiro. Iyo mold inofanirwawo kufunga nezve rudzi rwejekiseni rekugadzira muchina uri kushandiswa uye izvo chaizvo zvinodikanwa zvekugadzira maitiro.

- Machine Setup: Mushure mekunge mold yagadzirwa, muchina wekuumba jekiseni unomiswa. Izvi zvinosanganisira kubatanidza mold kumudziyo, kuseta tembiricha yakakodzera uye kudzvanywa, uye kuona kuti zvese zvinoshanda nemazvo.

- Jekiseni: Maitiro ejekiseni anotanga kana iyo yakanyungudutswa yepurasitiki inobaiwa mugomba rekuumbwa. Izvi zvinoitwa uchishandisa high-pressure injection unit iyo inomanikidza zvinhu kuti zvipinde muforoma pane imwe chiyero uye kumanikidza.

- Kutonhora:Mushure mekunge zvinhu zvepurasitiki zvakanyungudutswa zvaiswa mugomba reforoma, zvinofanirwa kubvumidzwa kutonhora nekuomesa. Izvi zvinoitwa nekutenderedza mhepo inotonhorera kana mvura kuburikidza negomba rekuumba kuderedza kupisa kwechinhu.

- Ejection: Kana zvinhu zvepurasitiki zvatonhora uye zvaoma, mold inovhurwa, uye chikamu chacho chinobudiswa. Iyo ejection process inosanganisira kushandisa mechanical kana hydraulic system kusundira chikamu kunze kwe mold cavity.

- Quality Control: Mushure mokunge chikamu chacho chabviswa, chinotarisa cheki chekutonga kuti ive nechokwadi chokuti inosangana nezvinodiwa. Izvi zvinogona kusanganisira kuongorora kwekuona, kuyerwa, uye kuyedzwa kuona kuti chikamu chacho ndechepamusoro-soro uye chisina hurema.

Dhizaini Yekufunga Kwepamusoro-Volume Injection Molding

Kugadzira chikamu chepurasitiki chepamusoro vhoriyamu jekiseni kuumbwa kunoda kunyatsotarisisa zvinhu zvakati wandei kuti ive nechokwadi chekuti chidimbu chinogona kugadzirwa nemazvo uye zvinodhura. Heano mamwe ekugadzirisa magadzirirwo epamusoro vhoriyamu jekiseni molding:

- Kuomarara Kwemadziro: Ukobvu hwemadziro echikamu chepurasitiki chinhu chakakosha chekufungisisa pakuumba jekiseni. Ukobvu hwemadziro hunofanira kunge hwakafanana kudzivirira kutonhora kusina kuenzana uye kubvongodza kwechidimbu. Madziro matete akanakira kugadzirwa kwakakwira-vhoriyamu sezvo achidzikisa kushandiswa kwezvinhu uye kutenderera nguva, nepo madziro akakora akakodzera zvikamu zvinoda simba rakawedzerwa.

- Chikamu Saizi uye Chimiro: Saizi uye chimiro chechikamu chinozokanganisa maitiro ekuumba jekiseni. Zvinhu zvakakura zvakanyanya kana zvakaoma zvinogona kuda nguva refu yekutenderera kana hunyanzvi hwekushandisa, zvichiwedzera mutengo wekugadzira. Yakareruka, maumbirwo ejometri akanyanya kunaka kugadzirwa kwevhoriyamu.

- Draft Angles: Kudhirowa angle ndiyo kona ye mold cavity wall inobvumira kuburitsa nyore kwechikamu. KusanganisiraKusanganisira dhizaini angles muchikamu dhizaini kwakakosha kuti ive nechokwadi chekuti chidimbu chinogona kukurumidza kuburitswa kubva mukuumbwa. Huwandu husina dhizaini angles hunogona kukonzera kudhura kwezvinhu zvekugadzira zvakaita sekutsemuka kana deformation.

- Gedhi Nzvimbo uye Saizi:Nzvimbo uye saizi yegedhi, panopindwa nepurasitiki yakanyungudutswa mugomba rekuumbwa, ndiyo yakakosha dhizaini yekutarisisa yekuumba jekiseni. Nzvimbo yegedhi inofanira kuiswa munzvimbo isingakanganisi chikamu chechimiro chechimiro. Saizi yegedhi inofanira kunge yakakura zvakakwana kuitira kuti zvinhu zvifambe nemazvo asi kwete zvakanyanya zvekuti zvinokonzeresa zvirema.

- Kusarudzwa Kwezvinhu: Kusarudzwa kwezvinhu zvakakosha kuti uone kuti chikamu chinogona kugadzirwa zvakanaka uye zvinodhura. Kusarudzwa kwezvinhu kunofanirwa kuenderana nezvinodiwa zvechidimbu, kusanganisira simba, kusimba, uye kuchinjika.

- Surface Kupera: Iyo chikamu chepamusoro pekupedzisira chinhu chakakosha chekufungisisa pakuumbwa kwejekiseni. Kupera kwepamusoro kwehuwandu kunofanirwa kuve kwakatsetseka uye kusina hurema, senge warping kana sink marks. Kuiswa kwegedhi kwakaringana, dhizaini yekuumbwa, uye kusarudzwa kwezvinhu zvinogona kuwana kutsetseka kwepamusoro kupera.

- kubvumidza: Kushivirira ndiwo mwero wekusiyana unobvumidzwa muzvikamu zvechikamu. Kushivirira kunofanirwa kutariswa panguva yechikamu chekugadzira chikamu kuve nechokwadi chekuti chidimbu chinogona kugadzirwa nemazvo uye nemazvo.

Hunhu Kudzora Matanho mune Yakakwira-Volume Injection Molding

Kudzora kwemhando kwakakosha kune yakakwira vhoriyamu jekiseni kuumbwa, sezvo ichiva nechokwadi chekuti zvikamu zvinogadzirwa zvinosangana nezvinodiwa uye hazvina hurema. Heano mamwe emhando yekudzora matanho anoshandiswa mune yakakwira vhoriyamu jekiseni molding:

- Kuongorora panguva Yekugadzira Maitiro: Kuongororwa nguva dzose panguva yekugadzira kunogona kubatsira kuona kukanganisa nekukurumidza uye kudzivirira kubva pakuva nyaya dzakakosha. Izvi zvinogona kusanganisira kuongorora kwekuona, kuyerwa, uye kuyedza kuona kuti chikamu chiri kugadzirwa nemazvo.

- Statistical process Control (SPC): SPC inzira yenhamba inoshandiswa kutarisa uye kutonga maitiro ekugadzira. Inosanganisira kuunganidza data pamaitiro ekugadzira uye kuiongorora kuti uone mafambiro uye mapatani anogona kuratidza nyaya nemaitiro. SPC inogona kubatsira kuona nekugadzirisa matambudziko asati aunza zvikamu zvakakanganisika.

- Kushandisa Automated Equipment: Zvishandiso zveotomatiki, senge marobhoti uye masensa, zvinogona kubatsira kuvandudza kuenderana uye kurongeka kwemaitiro ekugadzira. Mechanical midziyo inogona zvakare kuderedza njodzi yekukanganisa kwevanhu, zvichikonzera hurema hushoma.

- Kuchengetedza Mold:Kuchengetedza kwakakodzera mold kwakakosha pakuona kuti zvikamu zvinogadzirwa ndezvemhando yepamusoro. Izvi zvinosanganisira kuchenesa mold nguva nenguva uye kugadzira chero kunodiwa kugadzirisa kana kutsiva kuve nechokwadi chekuti mold iri kushanda nemazvo.

- Kuongorora kwePashure-Kugadzirwa: Mushure mekunge zvikamu zvagadzirwa, zvinoongororwa kwekupedzisira kuona kuti zvinosangana nezvinodiwa. Izvi zvinogona kusanganisira kuongorora kwekuona, kuyerwa, uye kuyedzwa kuona kuti zvikamu hazvina hurema.

- Kudzidzisa uye Dzidzo: Kudzidziswa kwakakodzera uye dzidzo yevashandi inogona kuvandudza kunaka kwemaitiro ekugadzira. Vashandi vanofanirwa kudzidziswa pamaitiro ekugadzira akakodzera uye matanho ekudzora hunhu kuti vaone kuti vanokwanisa kuona nekugadzirisa nyaya padzinomuka.

- Kuramba Kuvandudza: Kuenderera mberi kwekuvandudza kwakakosha pakudzora kwemhando yepamusoro-vhoriyamu jekiseni molding. Nekugara uchiongorora maitiro ekugadzira uye kuona nzvimbo dzekuvandudza, vagadziri vanogona kuderedza kuremara uye kugadzirisa mhando yezvikamu zvinogadzirwa.

Mutengo Ongororo yeHigh-Volume Injection Molding

High-volume jekiseni molding inzira yekugadzira inodhura-inoshanda yekugadzira huwandu hukuru hwezvikamu zvepurasitiki. Nekudaro, mutengo wekugadzira zvikamu kuburikidza nekuumbwa kwejekiseni unogona kusiyana zvichienderana nezvakati wandei zvinhu. Heano mamwe emitengo yekuongorora yekutarisa yakakwira vhoriyamu jekiseni molding:

- Mutengo Wezvinhu: Mutengo wezvishandiso ndechimwe chezvinhu zvakakosha zvinokanganisa mutengo wekuumba jekiseni. Rudzi uye kunaka kwezvinhu zvinoshandiswa zvinokanganisa mutengo, uye zvimwe zvinhu zvichidhura kupfuura zvimwe. Vagadziri vanofanira kusarudza zvinhu zvakakodzera zvichienderana nezvinodiwa zvechikamu.

- Mutengo Wekushandisa: Mutengo wekushandisa, kusanganisira mold uye zvimwe midziyo inodiwa pakuumba jekiseni, chimwe chinhu chakakosha chinokanganisa mutengo wekugadzira. Mutengo wekushandisa unogona kusiyana zvichienderana nekuoma kwechikamu, saizi ye mold, uye huwandu hwemakomba ari mu mold.

- Mutengo Webasa: Mari yevashandi chinhu chakakosha mukuumbwa kwejekiseni, sezvo maitiro achida vashandi vane hunyanzvi kuti vashandise michina uye vatarise maitiro ekugadzira. Mari yevashandi inogona kusiyana zvichienderana nenzvimbo uye ruzivo rwevashandi.

- Overhead Cost: Mutengo wepamusoro, unosanganisira zvekushandisa, rendi, uye zvimwe zvinodhura, zvinogonawo kukanganisa mutengo wekuumba jekiseni. Mari iyi inogona kusiyana zvichienderana nenzvimbo yekugadzira uye saizi yekushanda.

- Inzwi rekugadzira: Huwandu hwekugadzira chinhu chakakosha chinokanganisa mutengo wekuumba jekiseni. Mavhoriyamu ekugadzira epamusoro anogona kukonzera kuderera kwemitengo pachikamu nekuda kwehupfumi hwechiyero.

- Chikamu Dhizaini: Iyo dhizaini inogona zvakare kukanganisa mutengo wekuumba jekiseni. Zvinhu zvakaoma kana zvinoda hunyanzvi michina zvinogona kuwedzera mutengo wekugadzira.

- Quality Control: Mutengo wematanho ekudzora emhando, kusanganisira kuongorora uye kuyedzwa, unogona zvakare kukanganisa mutengo wekugadzira. Aya matanho anodiwa kuve nechokwadi chekuti zvikamu zvinogadzirwa zvinosangana nezvinodiwa uye hazvina hurema.

Maindasitiri Anoshandisa Yakakwira Volume Injection Molding

Yakakwira-vhoriyamu jekiseni molding inzira inoshandiswa zvakanyanya yekugadzira iyo inokwanisa kugadzira huwandu hukuru hwezvikamu zvepurasitiki nekukurumidza uye nemazvo. Heano mamwe maindasitiri anovimba zvakanyanya nepamusoro vhoriyamu jekiseni molding:

- Indasitiri yemotokari: Indasitiri yemotokari ndeimwe yevanonyanya kukosha vashandisi vepamusoro vhoriyamu jekiseni molding. Maitirwo acho anogadzira akasiyana epurasitiki zvinhu senge dashboard zvikamu, zvibato zvegonhi, uye zvemukati zvimedu zvekucheka.

- Consumer Goods Industry: Yakakwira-vhoriyamu jekiseni molding inogadzira zvinhu zvakasiyana zvevatengi, zvinosanganisira midziyo yemumba, matoyi, uye zvemagetsi. Iyo nzira inosarudzwa nekuti inobvumira vagadziri kugadzira zvikamu zvakakura zvakachipa.

- Indasitiri yezvokurapa: Indasitiri yezvokurapa inoda zvemhando yepamusoro uye chaiyo zvepurasitiki zvemidziyo yakasiyana-siyana yekurapa, senge michina yekuongorora, zvekuvhiya, uye zvekuraswa zvekurapa. Yakakwira-vhoriyamu jekiseni molding inofarirwa nekuti inogona kuburitsa zvikamu izvi nemazvo uye nguva dzose.

- Industry:Indasitiri yekurongedza inotsamira zvakanyanya pane yakakwira-vhoriyamu jekiseni kuumba kugadzira akasiyana emidziyo yepurasitiki, zvivharo, uye kuvhara. Iyo nzira inodhura-inoshanda uye inobvumira vanogadzira kugadzira akasiyana maumbirwo uye saizi nekukurumidza.

- Indasitiri yeAerospace: Indasitiri yezvemuchadenga inoda mapurasitiki epamusoro-soro anokwanisa kumira zvakanyanya, senge tembiricha yakanyanya uye kudzvanywa. High-volume jekiseni molding inogadzira izvi zvikamu, zvinosanganisira mukati uye kunze kwendege zvikamu, avionics, uye zvemagetsi.

- Indasitiri yekuvaka: Indasitiri yekuvaka inoshandisa yakakwira vhoriyamu jekiseni kuumba kugadzira akasiyana epurasitiki zvinhu, zvinosanganisira mahwindo mafuremu, pombi, uye insulation. Iyo nzira inosarudzwa nekuti inobvumira kugadzirwa kwehuwandu hukuru hwezvikamu zvinogara uye zvinopesana nemamiriro ekunze.

- Indasitiri yeMitambo neKutandara: Yakakwira-vhoriyamu jekiseni kuumba inogadzira akasiyana epurasitiki zvikamu zvemitambo uye indasitiri yevaraidzo, zvinosanganisira ngowani, giya rekudzivirira, uye matoyi. Iyo nzira inosarudzwa nekuti inobvumira kugadzira zvireruke, zvinogara, uye zvinoyevedza zvikamu.

Benefits of High-Volume Jekiseni Molding nokuda Medical Indasitiri

Indasitiri yezvokurapa nderimwe remaindasitiri makuru uye ari kukurumidza kukura pasi rose. Nekufambira mberi mune tekinoroji uye kuwedzera kuri kudiwa kwemidziyo yekurapa nemidziyo, panodiwa maitiro ekugadzira ane hunyanzvi anogona kuburitsa emhando yepamusoro zvinhu. Yakakwira-vhoriyamu jekiseni molding ndeimwe maitiro akadaro anopa akati wandei mabhenefiti kuindasitiri yekurapa. Ngationgororei mamwe mabhenefiti epamusoro vhoriyamu jekiseni molding muindasitiri yezvokurapa.

- Zvinodhura-zvinobudirira: High-volume jekiseni molding inzira inodhura-inoshanda yekugadzira iyo inogadzira huwandu hukuru hwezvikamu zvepurasitiki pamutengo wakaderera pane imwe unit.

- Kubatana: Yakakwira vhoriyamu jekiseni kuumba inobvumira kugadzira zvikamu zvine yakakwira viscosity uye kunyatsoita, kuve nechokwadi chekuti chidimbu chimwe nechimwe chinosangana nezvinodiwa.

- Customization: Iyo nzira inobvumira kugadziridzwa kwezvinhu kuti zvienderane nezvinodiwa chaizvo, zvinosanganisira ruvara, magadzirirwo, uye zvinhu.

- Kuteerera: Yakakwira vhoriyamu jekiseni kuumba inobvumira kukurumidza kugadzirwa kwezvinzvimbo, kuderedza nguva yekutungamira uye kuwedzera kushanda zvakanaka.

- Quality: Iyo yepamusoro-vhoriyamu jekiseni molding process inoburitsa emhando yepamusoro zvikamu zvinosangana neyakaomarara miyero inodiwa pamidziyo yekurapa.

- Kubereka: Maitiro acho anoitwa munzvimbo isina hutachiona, kuve nechokwadi chekuti zvikamu zvinogadzirwa hazvina kusvibiswa uye zvakachengeteka kune zvekurapa.

- Durability: Zvikamu zvinogadzirwa uchishandisa yakakwira-vhoriyamu jekiseni molding zvinogara uye zvinogona kumira nharaunda dzakaomarara, kuve nechokwadi kuti zvinogara kwenguva yakareba uye kuderedza kudiwa kwekutsiva. Kugara kwakakosha muindasitiri yezvokurapa, uko zvishandiso nemidziyo zvinofanirwa kushingirira kushandiswa nguva dzose uye mukana wekusangana nemakemikari nezvimwe zvinhu zvakaomarara.

- Kunzwisisa: Iyo yakakwirira-vhoriyamu jekiseni molding process inobvumira kugadzirwa kwezvikamu zvakaoma neakaomesesa magadzirirwo, kuve nechokwadi chekuti michina yekurapa inogona kugadzirwa kuti isangane nezvinodiwa chaizvo zvekurapa kwemazuva ano. Maitiro acho akanakira kugadzira zvinhu zvakaomarara zvine akasiyana maficha uye magadzirirwo akakosha kumidziyo yekurapa nemidziyo.

- Versatility: Yakakwira vhoriyamu jekiseni molding inogona kugadzira zvikamu zvakasiyana-siyana zvine maumbirwo akasiyana uye saizi, zvichiita kuti ive yakanakira kugadzira zvinhu mumhando dzakasiyana dzekurapa.

Yakakwira Vhoriyamu Injection Molding yeMotokari Indasitiri

Jekiseni molding inzira yekugadzira inosanganisira kubaya purasitiki yakanyungudutswa mugomba rekuumba kugadzira akasiyana epurasitiki zvikamu. Maitiro aya anoshandiswa zvakanyanya muindasitiri yemotokari kugadzira akawanda zvikamu senge mapaneru emagonhi, dashboards, mapaneru emidziyo, emukati matrim, uye ekunze nhengo dzemuviri. Yakakwira-vhoriyamu jekiseni molding inzira yakasarudzika inoita kuti vagadziri vakurumidze kuburitsa huwandu hukuru hwezvikamu zvakafanana.

Yakakwira-vhoriyamu jekiseni kuumba inonyatso inoshanda kugadzira nzira inopa akati wandei mabhenefiti kuindasitiri yemotokari. Zvimwe zvezvibatsiro izvi zvinosanganisira:

- Kuderedzwa kwemitengo yekugadzira - Maitiro acho anogadzirwa zvakanyanya, izvo zvinoderedza mutengo wevashandi, uye mold inobvumira vagadziri kugadzira zvikamu zvakafanana nemutengo wakaderera.

- Kuvandudzwa kwechikamu kuenderana - Yakakwira-vhoriyamu jekiseni molding inobvumira kugadzirwa kwezvikamu zvakafanana, kuderedza kusiyanisa uye kugadzirisa magadzirirwo mukugadzira maitiro.

- Inokurumidza nguva dzekugadzira - Iyo nzira inogadzirwa zvakanyanya, iyo inoita kuti vagadziri vagadzire huwandu hukuru hwezvikamu nekukurumidza, kuderedza nguva yekutungamira.

- Zvikamu zvemhando yepamusoro- Kushandiswa kwezviumbwa kunovimbisa kuti zvikamu zvinogadzirwa ndezvemhando yepamusoro, zvisingabatsiri uye zvisingaenderani.

- Dhizaini inochinjika -Jekiseni molding inobvumira kukurumidza kugadzira maumbirwo akaomarara uye dhizaini, ichipa vagadziri kuchinjika kukuru muzvirongwa zvavo.

Jekiseni molding inzira yakanaka yekugadzira yeindasitiri yemotokari, sezvo ichipa akawanda mabhenefiti anovandudza mashandiro, kuderedza mutengo, uye kugadzirisa chikamu chemhando. Yakakwira-vhoriyamu jekiseni molding, kunyanya, inzira yakasarudzika inoita kuti vagadziri vagadzire huwandu hukuru hwezvikamu zvakafanana nekukurumidza uye nemazvo.

Indasitiri yemotokari inotsamira zvakanyanya pakuumbwa kwejekiseni kugadzira zvakasiyana siyana zvemotokari nemotokari. Kubva panhengo dzemuviri dzekunze kusvika kune zvemukati zvigadziriso uye madhibhodhi, jekiseni kuumbwa kwave kwakakosha kugadzira maitiro muindasitiri yemotokari. Nekuumbwa kwejekiseni repamusoro, vagadziri vanogona kuburitsa huwandu hukuru hwezvikamu zvakafanana nemutengo wakaderera, nekuenderana uye mhando.

Yakakwira Vhoriyamu Injection Molding yeConsumer Goods Indasitiri

Yakakwira-vhoriyamu jekiseni molding inzira yekugadzira inotambirwa zvakanyanya neindasitiri yezvinhu zvevatengi nekuda kwekugona kwayo kugadzira akawanda emhando yepamusoro zvikamu zvine humbowo uye kuenderana. Iyi nzira inowanzo shandiswa mukugadzira zvinhu zvevatengi zvakaita sematoyi, kitchenware, uye zvekurongedza zvinhu, pakati pezvimwe. Iyi blog positi ichaongorora mabhenefiti epamusoro vhoriyamu jekiseni kuumba kune yevatengi zvinhu indasitiri.

Zvakanakira High Volume Injection Molding:

- Zvinodhura-zvinobudirira: Imwe yemabhenefiti ekutanga epamusoro vhoriyamu jekiseni kuumbwa ndeyekuti inzira inodhura yekugadzira huwandu hukuru hwezvikamu. Iyo nzira inogadzirwa zvakanyanya, iyo inoderedza mutengo wevashandi, uye molds inogona kushandiswa zvakare, izvo zvinoderedza mari yezvinhu.

- Kuenderana uye kurongeka:Jekiseni molding inopa yakanakisa kurongeka uye kuenderana mukugadzira zvikamu. Izvi zvinodaro nekuti ma mold akagadzirwa kune izvo chaizvo zvakatemwa zvezvinhu, kuve nechokwadi chekuti chidimbu chega chega chemhando nehukuru hwakafanana.

- Kugadzirwa nekukurumidza:High-volume jekiseni molding inzira yekukurumidza, uye huwandu hukuru hwezvikamu zvinogona kugadzirwa nekukasira. Izvi zvinoita kuti ive yakanakira kugadzira zvinhu zvevatengi zvinoda kukurumidza kuchinja nguva.

- Customization: Jekiseni molding inobvumira kugadzirisa kwezvikamu uchishandisa zvakasiyana zvinhu, mavara, uye pamusoro pekupedzisira. Uku kuchinjika kunoita kuti zvikwanise kugadzira zvikamu zvinosangana nezvinodiwa nevatengi uye zvinodiwa.

Zvishandiso zveHigh Volume Injection Molding muIndasitiri Yezvinhu Zvevatengi:

- Kavha zvinhu:Jekiseni molding inoshandiswa zvakanyanya kugadzira zvinhu zvekurongedza semabhodhoro epurasitiki, zvirongo, uye midziyo.

- Toys: Jekiseni molding inzira yakakurumbira yekugadzira matoyi sezvo ichibvumira kukurumidza kugadzira huwandu hukuru hwezvikamu.

- Kitchenware: Jekiseni molding inogadzira zvinhu zvakasiyana-siyana zvekicheni zvakadai semakapu, ndiro, uye midziyo.

- Electronics: Jekiseni molding inoshandiswa kugadzira zvakasiyana-siyana zvemagetsi senge dzimba, mabhatani, uye switch.

Yakakwira Vhoriyamu Injection Molding yeAerospace Indasitiri

Indasitiri yezvemuchadenga inoda zvemhando yepamusoro uye zvikamu zvakaringana kuti ive nechokwadi chekuchengetedza uye kugona kwendege. Kuumbwa kwejekiseni repamusoro-vhoriyamu kwave kuita kwakakosha kuindasitiri yezvemuchadenga sezvo ichipa mhinduro inodhura yekugadzira huwandu hukuru hwemhando yepamusoro-soro nemhando inowirirana. Iyi blog post ichakurukura yakakwira vhoriyamu jekiseni kuumbwa kweiyo aerospace indasitiri.

Mabhenefiti eHigh Volume Injection Molding yeAerospace Indasitiri:

Indasitiri yezvemuchadenga inoda zvinhu zvisingaremi, zvinogara zvinoshingirira tembiricha yakanyanyisa uye kumanikidza. Yakakwira-vhoriyamu jekiseni molding inopa akawanda mabhenefiti ekugadzira zvinhu zvakadaro, zvinosanganisira:

- Kugadzirwa Kusingadhuri: High-volume jekiseni molding inogona kuburitsa huwandu hukuru hwezvikamu nekukurumidza, zvichikonzera kudzikiswa kwemitengo yekugadzira.

- Hunhu Hunoenderana: Iyo otomatiki maitiro inova nechokwadi chekuti chikamu chimwe nechimwe chinogadzirwa ndechemhando yepamusoro, izvo zvakakosha pakuchengetedza uye kuvimbika kwezvikamu zvendege.

- Complex Geometries: Iyo jekiseni yekuumba maitiro inoburitsa akaomesesa zvimiro uye geometries, izvo zvingave zvakaoma kuwana nenzira dzechinyakare dzekugadzira.

- Kusarudzwa Kwezvinhu: Yakakwira-vhoriyamu jekiseni molding inogona kugadzirisa zvakasiyana-siyana zvezvinhu, kusanganisira macomposites, ayo akanakira aerospace application.

- Yakaderedzwa Marara: Iyo yakakwira mwero we otomatiki uye nemazvo mukuumbwa kwejekiseni inokonzeresa kutambisa zvinhu zvishoma uye zviraswa, izvo zvinogona kutungamira kune yakakosha mari yekuchengetedza uye mabhenefiti ezvakatipoteredza.

Zvishandiso zveHigh Volume Injection Molding muIndasitiri yeAerospace:

Yakakwira-vhoriyamu jekiseni molding inoshandiswa zvakanyanya muindasitiri yeaerospace kugadzirwa kwezvinhu zvakasiyana siyana, zvinosanganisira:

- Air ducts uye ventilation systems

- Zvikamu zvemukati nekunze zvendege

- Zvimiro zvezvinhu zvakaita semabhuraketi, zvikwambo, uye dzimba

- Magetsi uye wiring zvikamu

- Zvisimbiso uye gaskets

Zvakajairwa Kukanganisa muHwaya-Volume Jekiseni Molding

Nekudaro, senge chero maitiro ekugadzira, kuumbwa kwejekiseni dzimwe nguva kunogona kukonzera kukanganisa kunogona kukanganisa kunaka kwechigadzirwa chekupedzisira. Iyi blog positi ichakurukura dzimwe zvikanganiso zvakajairika mukuumbwa kwejekiseni repamusoro uye kuti dzingadzivirirwe sei.

- Sink Marks: Sink marks idepressions kana indentations inogona kuitika pamusoro pechikamu chakaumbwa. Izvo zvinokonzerwa nekuderera kwezvinhu zvepurasitiki sezvazvinotonhora, zvichikonzera kugovera kusina kuenzana kwezvinhu. Kuti udzivise sink mamaki, kugadzirisa dhizaini yechikamu uye kuve nechokwadi chekuti madziro emadziro mukati mechikamu chose chinodiwa.

- Warping:Warping ndiko deformation yechikamu chakaumbwa nekuda kwekutonhora kusina kuenzana kwezvinhu zvepurasitiki. Zvinokonzera chikamu chakamonyoroka kana chakakombama chisingaenderane nezvinodiwa. Warping inogona kudzivirirwa nekuona kuti tembiricha ye mold inowirirana uye nekubatanidza madhizaini anoderedza kushushikana pachikamu panguva yekutonhora.

- Flash: Flash chinhu chakawandisa chinobuda kubva mujoini ye mold uye chinogona kuitika kana mold isina kurongeka zvakanaka kana kusungirirwa. Flash inogona kudzivirirwa nekuona kuti mold yakanyatsoenderana uye kuti clamping force yakakwana kubata mold yakavharwa panguva yejekiseni.

- Short Shots: Mapfuti mapfupi anoitika kana zvinhu zvepurasitiki zvisingazadzi iyo mold cavity, zvichikonzera chikamu chisina kukwana. Izvi zvinogona kukonzerwa nekusakwana jekiseni pressure, low melt tembiricha, kana gedhi rakavharika. Mapfuti mapfupi anogona kudzivirirwa nekugadzirisa majekiseni paramita uye nekuona kuti gedhi rakagadzirwa nemazvo uye rakamiswa.

- Weld Lines: Weld mitsetse inoitika kana maviri kana anopfuura mafambiro ekuyerera asangana uye akasimba, zvichikonzera mutsara unooneka kana musono pane yakaumbwa chikamu. Weld mitsetse inogona kudzivirirwa nekugadzirisa mold dhizaini uye jekiseni paramita kuti ive nechokwadi chekuti zvinhu zvepurasitiki zvinoyerera zvakaenzana uye zvakanaka kuburikidza negomba.

Troubleshooting Tips for High-Volume Injection Molding

Yakakwira-vhoriyamu jekiseni molding inzira yakaoma inoda kutarisisa kune zvakadzama uye kunyatsotarisisa kuona kuti chigadzirwa chekupedzisira ndechemhando yepamusoro. Nyaya dzinoverengeka dzakajairika dzinogona kumuka panguva yekuumbwa kwejekiseni, izvo zvinogona kutungamira kune hurema muchigadzirwa chekupedzisira. Iyi positi ichaongorora mamwe eakajairika matipi ekugadzirisa matambudziko epamusoro vhoriyamu jekiseni kuumba.

- Tarisa iyo Injection Molding Machine Settings: Chimwe chezvinhu zvekutanga kutarisa kana uchigadzirisa yakakwira vhoriyamu jekiseni kuumba marongero pamushini wekuumba jekiseni. Ita shuwa kuti tembiricha, kudzvanywa, uye nguva yekutenderera zvese zvakagadzirirwa nemazvo kune chaiwo zvinhu zvinoshandiswa.

- Tarisa kune Material Flow Issues: Material flow issues ndiyo imwe nyaya yakajairika ine yakakwira vhoriyamu jekiseni molding. Zvinhu zvinoverengeka, kusanganisira zvisizvo zvigadziriso pamushini kana kuvharika mumushini wekuumba jekiseni, zvinogona kukonzera izvi. Ita shuwa kuti zvinhu zvinoyerera zvakanaka kuburikidza nemudziyo uye kuti hapana zvinovharika mumushini wekuumba jekiseni.

- Tarisa Warping uye Shrinkage: Warping uye shrinkage inyaya dzakajairika panguva yepamusoro vhoriyamu jekiseni kuumba. Idzi nyaya dzinowanzo kukonzerwa nekutonhodza kusina kuenzana kwechinhu, izvo zvinogona kutungamirira kuhondo kana kuderera kwechigadzirwa chekupedzisira. Ita shuwa kuti nguva yekutonhodza yaiswa nemazvo kune chaiyo zvinhu zviri kushandiswa uye system inoshanda nemazvo.

- Tarisa kune Mhepo Traps: Mhepo misungo ndiyo imwe nyaya yakajairika panguva yepamusoro vhoriyamu jekiseni kuumba. Izvi zvinoitika kana mhepo ikavharirwa mugomba re mold, izvo zvinogona kukonzera voids kana mabhubhu muchigadzirwa chekupedzisira. Ita shuwa kuti mold yakanyatso kufefeterwa kudzivirira zvisungo zvemhepo kuti zvisaitike.

- Tarisa Maitiro: Chekupedzisira, kunyatsotarisisa maitiro ekuumba jekiseni kwakakosha kuti uve nechokwadi chekuti chero nyaya dzinobatwa uye kugadziriswa nekukurumidza. Izvi zvinogona kuitwa nekutarisa marongero emuchina, kuyerera kwezvinhu, uye kutonhora maitiro. Nekunyatsotarisisa maitiro, chero nyaya dzinogona kuzivikanwa uye kugadziriswa dzisati dzatungamira mukukanganisa muchigadzirwa chekupedzisira.

Maintenance Zvinodiwa Majekiseni Molding Machines

Majekiseni ekuumba michina zvidimbu zvakakosha zvemidziyo muindasitiri yekugadzira. Izvo zvinoshandiswa kugadzira zvigadzirwa zvakasiyana-siyana, kubva kune zvikamu zvepurasitiki kusvika kune zvigadzirwa zvesimbi. Nekudaro, senge chero mumwe muchina, majekiseni ekuumba majekiseni anoda kugara achigadziriswa kuti ave nechokwadi chekushanda kwakakwana uye kudzivirira kuparara kunodhura. Iyi posvo inoongorora zvimwe zvezvinodikanwa zvekugadzirisa zvemajekiseni ekuumba michina.

- Kubatanidzwa: Kuzora kwakakodzera ndechimwe chezvinhu zvakakosha zvejekiseni molding muchina kugadzirisa. Zvikamu zvinofamba zvemuchina, zvakaita sejekiseni uye mayunitsi ekusunga, zvinofanirwa kuzorwa nguva nenguva kudzivirira kukwenya uye kusakara. Kushandisa iyo chaiyo lubricant mhando uye kutevedzera kurudziro yemugadziri wenguva yekuzora kwakakosha.

- Kuchenesa: Chimwe chinhu chakakosha chekugadzirisa jekiseni rekugadzira muchina kuchenesa nguva dzose. Muchina uyu unofanirwa kucheneswa nguva nenguva kubvisa chero huruva, marara, kana masara epurasitiki anogona kuungana pazvikamu zvawo. Izvi zvichabatsira kudzivirira kuvharika kwemazino emuchina uye mafirita, ayo anogona kukonzera nyaya dzekuita kana kukuvadza injini.

- Inspection: Kuongororwa nguva dzose kunodiwa zvakare kuti mushini uri muchimiro chakanaka. Kuongorora kunofanirwa kusanganisira kutarisa chero zviratidzo zvekusakara uye kubvaruka, senge makatsemuka kana zvidimbu zvakatyoka. Izvo zvikamu zvemagetsi, senge ma sensors uye switch, zvinofanirwawo kuongororwa nguva nenguva kuti zviite kuti zvinoshanda nemazvo.

- Kuchengetedza: Majekiseni ekuumba michina inodawo calibration kuti ive nechokwadi chekuti inoshanda mukati meiyo chaiyo paramita. Izvi zvinosanganisira kutarisa tembiricha yemuchina, kudzvanywa, uye masisitimu ekumhanyisa kuona kuti zviri mukati mezvido zvemugadziri. Calibration inofanirwa kuitwa nguva nenguva kuti ive nechokwadi chekuti mudziyo uri kushanda padanho rayo.

- Kutsiviwa Kwezvikamu Zvakasakara: Pakupedzisira, kutsiva chero nhengo dzakasakara kana dzakakuvadzwa nekukurumidza sezvinobvira kunokosha. Izvi zvinogona kubatsira kudzivirira kumwe kukuvara kwemuchina uye kuderedza njodzi yekuparara kunodhura. Zvikamu zvinotsiviwa zvinofanirwa kunge zviri zvemhando imwechete sezvikamu zvekutanga uye zvakaiswa nevano hunyanzvi.

Sustainability uye High Volume Injection Molding

Sustainability yave iri kuwedzera kukosha kunetseka muindasitiri yekugadzira mumakore achangopfuura. Sezvo nyika yakawedzera kuziva nezve maindasitiri maitiro 'maitiro ezvakatipoteredza, makambani ari kutsvaga nzira dzekudzikisa nharaunda yavo yekutsika uku vachichengetedza kugadzirwa uye pundutso. Yakakwira-vhoriyamu jekiseni molding ndiyo imwe nzvimbo uko kusimba kunogona kuita yakakosha kukanganisa.

Pane nzira dzinoverengeka idzo kusimba kunogona kuiswa mune yakakwira vhoriyamu jekiseni molding:

- Kusarudzwa kwezvinhu:Kusarudza zvinhu zvakakodzera kwakakosha kuti uwane kusimba mukuumba jekiseni. Sarudzo dzakawanda dzinosanganisira bioplastics, mapurasitiki akadzokororwa, uye bio-based materials. Nekusarudza zvinhu zvine hushamwari kwezvakatipoteredza uye zvine yakaderera kabhoni tsoka, vagadziri vanogona kuderedza zvakanyanya kukanganisa kwavo kune zvakatipoteredza.

- Simba remagetsi High-volume jekiseni molding inoda simba guru kuti rishande. Vagadziri vanogona kuderedza kushandiswa kwesimba uye kuderedza kabhoni emissions kuburikidza nekushandisa-simba rinoshanda maitiro nemidziyo. Izvi zvinogona kuwanikwa nekushandisa michina inoshanda nesimba, optimize kugadzirwa kwemaitiro, uye nekudyara mune inodzokororwa magetsi masosi.

- Kuderedza tsvina: Jekiseni molding inogona kuburitsa marara akakosha, kunyanya epurasitiki yakawandisa. Nekushandisa nzira dzekudzikisa marara, vagadziri vanogona kudzikisa huwandu hwemarara anogadzirwa nekuvandudza kuchengetedzwa kwavo. Izvi zvinogona kuwanikwa kuburikidza nekudzokorodza, kushandisazve zvinhu, uye kugadzirisa maitiro ekugadzira kuderedza marara.

- Hupenyu cycle analysis: Kuita ongororo yekutenderera kwehupenyu kunogona kubatsira vagadziri kuti vanzwisise kukanganisa kwezvakatipoteredza kwezvigadzirwa zvavo mukati mehupenyu hwavo hwese. Ongororo iyi inogona kubatsira kuona nzvimbo dzinogona kuvandudzwa uye kutungamira kuita sarudzo kugadzira zvimwe zvigadzirwa zvine hushamwari.

Pfungwa Dzokutanga:

- Kusarudzwa kwezvinhu kunoita basa rakakosha mukubudirira mukuumba jekiseni.

- Matanho-anoshanda nesimba uye michina inogona kuderedza kushandiswa kwesimba uye kuderedza kabhoni emissions.

- Mazano ekuderedza marara, akadai sekudzokorodza uye kushandisazve zvinhu, anogona kuderedza huwandu hwemarara anogadzirwa.

- Hupenyu kutenderera kuongorora kunogona kubatsira kuona nzvimbo dzinogona kuvandudzwa.

- Kubatanidza kusimba mune yakakwira vhoriyamu jekiseni kuumba kunogona kubatsira vagadziri nekudzikisa mutengo uye kukwezva kune vatengi vanoziva zvakatipoteredza.

- Ramangwana reHigh-Volume Injection Molding

Kuumbwa kwejekiseni repamusoro kwave kuri kwakakosha kugadzira kwemaindasitiri mazhinji kwemakumi emakore, uye inoramba ichiita basa rakakosha mukugadzira akawanda ezvigadzirwa zvepurasitiki. Sezvo tekinoroji ichifambira mberi uye kudiwa kwevatengi kunochinja kune zvigadzirwa zvinogoneka uye zvinogoneka, ramangwana repamusoro-vhoriyamu jekiseni rekuumbwa rinotaridzika kupenya. Heano mamwe emaitiro uye hunyanzvi huri kuumba kupera kweindastiri iyi.

- Sustainability: Nekuwedzera kudiwa kwevatengi kune zvigadzirwa zvine hushamwari kwezvakatipoteredza, kugadzikana kwave kwakakosha mukukwirira-vhoriyamu jekiseni molding. Vagadziri vari kuongorora zvinhu zvitsva, senge bioplastics uye bio-based zvinhu, uye kushandisa nzira dzekudzikisa tsvina kuti vaderedze kukanganisa kwezvakatipoteredza kwezvigadzirwa zvavo.

- Customization: Vatengi vari kutsvaga zvigadzirwa zvinosangana nezvavanoda zvakasiyana uye zvavanoda, uye yakakwirira vhoriyamu jekiseni kuumba inonyatso inokodzera kuzadzisa ichi chinodikanwa. Kufambira mberi mune tekinoroji, senge 3D kudhinda, kuri kuita kuti zvive nyore uye zvisingadhuri kugadzira zvikamu zvakagadziridzwa uye zvigadzirwa mumavhoriyamu makuru.

- Automation: Otomatiki iri kuramba ichiwanda muindasitiri yekugadzira, uye yakakwira vhoriyamu jekiseni kuumbwa hakuna mutsauko. Otomatiki maitiro, senge robhoti maoko uye dhizaini-inobatsirwa nekombuta, inogona kuvandudza hunyanzvi hwekugadzira uye kuderedza mitengo.

- Indasitiri 4.0: Shanduko yechina yemaindasitiri, Indasitiri 4.0, iri kushandura indasitiri yekugadzira nekubatanidza matekinoroji epamberi senge artificial intelligence, iyo Internet yezvinhu (IoT), uye hombe data analytics. Aya matekinoroji anoita kuti zvive nyore kune vagadziri kukwidziridza maitiro ekugadzira uye kugadzirisa mhando yechigadzirwa.

- Indasitiri yezvokurapa:High-volume jekiseni molding yakanyatsokodzera kugadzira michina yekurapa nemidziyo nekuda kwekurongeka kwayo uye kuenderana. Iko kudiwa kwezvigadzirwa zvekurapa kunotarisirwa kukura, zvichiita kuti iyi ive nzvimbo yakakosha kune indasitiri yekuumba jekiseni.

- Motokari dzemagetsi:Iko kuchinjika kuenda kumota dzemagetsi kunogadzira mikana mitsva yeakakwira-vhoriyamu jekiseni rekuumba indasitiri. Zvikamu zvepurasitiki, zvakaita sedzimba dzemabhatiri uye zvinobatanidza magetsi, zvakakosha kumotokari dzemagetsi, uye kudiwa kwezvikamu izvi kunotarisirwa kukura sezvo mota dzemagetsi dzichiwanda.

mhedziso:

High-volume jekiseni kuumba kwakakosha pakugadzira huwandu hukuru hwezvikamu zvepurasitiki. Nekunzwisisa zvakanakira, zvisingabatsiri, zvekushandisa, michina, nzira, magadzirirwo ekufunga, nhanho dzekudzora mhando, uye mashandisirwo epamusoro vhoriyamu jekiseni kuumba, mabhizinesi anogona kukwirisa maitiro avo ekugadzira, kuderedza mitengo, uye kugadzirisa mhando yezvigadzirwa zvavo. Kunyangwe iwe uri muindasitiri yezvokurapa, yemotokari, yevatengi, kana indasitiri yemuchadenga, kuumbwa kwejekiseni repamusoro kunogona kubatsira bhizinesi rako nekupa zvikamu zvinoenderana, zvemhando yepamusoro pamutengo usingadhuri.