Kukundikana

Overmolding inzira yekugadzira umo substrate kana chigadziko chikamu chinosanganiswa nechimwe kana zvimwe zvinhu kugadzira chigadzirwa chekupedzisira chine mashandiro akavandudzwa, kusimba, uye aesthetics. Iyi nzira yakawana mukurumbira mumakore achangopfuura nekuda kwekugona kwayo kuwedzera kunaka uye kuita kwezvigadzirwa uku ichideredza mitengo uye kurerutsa maitiro egungano. Overmolding inowana zvikumbiro mumaindasitiri akasiyana siyana, akadai semotokari, zvemagetsi, zvishandiso zvekurapa, uye zvigadzirwa zvevatengi. Kuti unzwisise zvizere maitiro aya, chinyorwa ichi chinotarisa mune akawanda maficha ekuwedzeredza, kusanganisira maitiro ayo, zvigadzirwa, uye mashandisiro.

Tsanangudzo uye Nheyo dzeKuwedzeredza

Kuwedzeredza kuumba chimwe chinhu pamusoro pechimwe, kazhinji kushandisa thermoplastic elastomers (TPE) kana thermoset rabha. Iyi nzira inogadzira chikamu chimwe chete chine maviri kana anopfuura zvinhu, imwe neimwe iine yakasarudzika zvivakwa zvinobatira chinangwa chaicho.

Nheyo dzeKuwedzeredza

Pane misimboti mitatu yekutanga yekuwedzeredza iyo vagadziri vanofanirwa kufunga nezvayo:

- Kuenderana kwezvinhu:Zvishandiso zvinoshandiswa mukuwedzeredza zvinofanirwa kuenderana, uye zvigadzirwa zvinofanirwa kunge zvichikwanisa kusungirirana kugadzira chinhu chakasimba uye chakabatana. Iko kunamatira pakati pezvishandiso kwakakosha kuti uve nechokwadi chekuti chinhu chine zvinhu zvinodiwa.

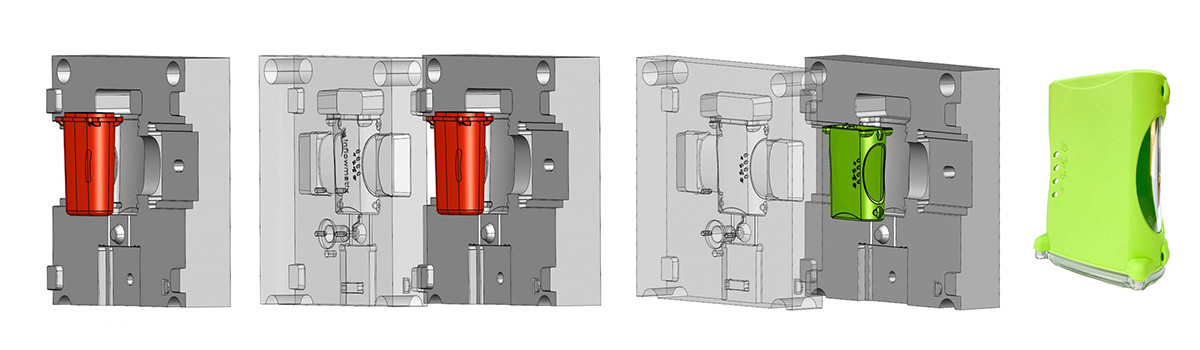

- Dhizaini yekuwedzeredza:Usati wawedzera, munhu anofanira kunyatsofungisisa nzira yechikamu. Iyo dhizaini inofanirwa kufambisa kuumba yechipiri zvinhu pamusoro pekutanga pasina kukanganisa. Dhizaini yemutsara wekuparadzanisa, panosangana zvinhu zviviri izvi, inofanira kunyatsoona kuti hapana mapeji kana voids pakati pezvinhu zviviri izvi.

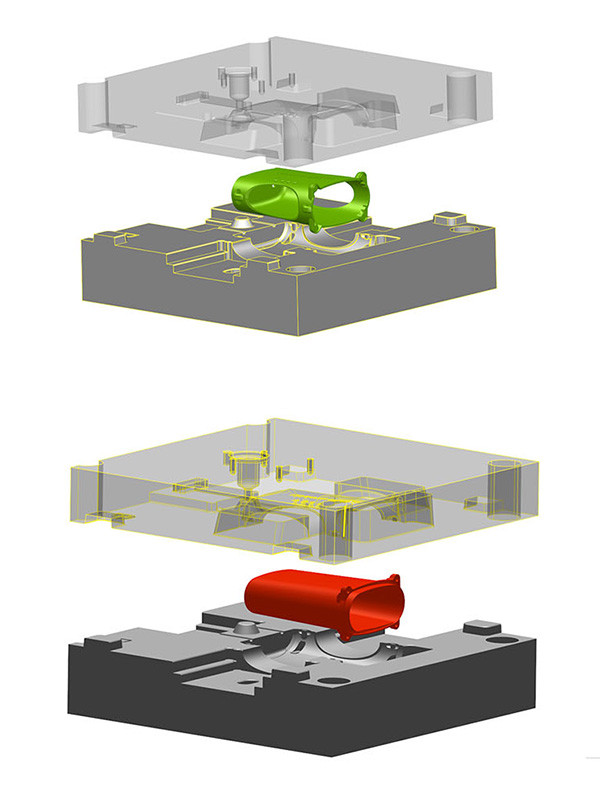

- Kugadzira Maitiro:Overmolding inoda yakasarudzika nzira yekugadzira inosanganisira kuumba chimwe chinhu pamusoro pechimwe. Mutoo wacho unoshandisa mold mbiri kana kupfuura, uko yekutanga mold inogadzira chinhu chekutanga, uye chechipiri ichigadzira chechipiri pane yekutanga. Zvadaro, tinobatanidza zviumbwa zviviri pamwechete kuti tigadzire chikamu chimwe chete.

Zvakanakira Overmolding

Kuwedzeredza kunopa akati wandei mabhenefiti anoita kuti ive sarudzo yakakurumbira kune vakawanda vanogadzira, kusanganisira:

- Enhanced Durability:Kuwedzeredza kunogona kuvandudza kusimba kwechikamu nekuwedzera chidziviriro chekudzivirira chinogona kuramba kupera uye kubvaruka.

- Yakavandudzwa Aesthetics: Overmolding inogona kuvandudza aesthetics yechikamu nekuwedzera ruvara kana kuumbwa kumusoro.

- Enhanced Functionality:Kuwedzeredza kunogona kuvandudza mashandiro echinhu nekuwedzera maficha akadai sekubata, mabhatani, kana switch.

Zvikumbiro zve Overmolding

Vagadziri vanowanzo shandisa overmolding kugadzira zvigadzirwa zvemagetsi senge mbozha nhare, maremote control, uye komputa peripherals. Iyo ine zvakare michina yekurapa, zvinhu zvemotokari, uye zvigadzirwa zvevatengi.

Jekiseni Molding vs. Overmolding: Ndeupi Musiyano?

Jekiseni kuumba uye overmolding anowanzo shandiswa kugadzirwa maitiro muzvikamu zvepurasitiki. Nepo nzira mbiri idzi dzichisanganisira kuumbwa kwepurasitiki, dzine misiyano yakasiyana. Iyi blog post ichakurukura mutsauko uripo pakati pejekiseni kuumba uye overmolding.

Kubaya jekiseni

Jekiseni molding inzira yekugadzira iyo inosanganisira kunyungudutsa epurasitiki pellets uye kubaya purasitiki yakanyungudutswa mugomba rekuumbwa. Purasitiki yacho inobva yatonhodzwa uye yobudiswa muforoma, zvichiita kuti pave nechikamu chepurasitiki chakasimba. Vagadziri vanoshandisa jekiseni molding senzira chaiyo uye inoshanda kugadzira mavhoriyamu akawanda ezvikamu zvepurasitiki. Zvimwe zvakakosha zvekugadzira jekiseni zvinosanganisira:

Inogadzira chikamu chimwe chezvinyorwa

- Mumwe anopinza zvinhu mugomba rekuumbwa nenhanho imwe chete.

- Maitiro acho anowana kushandiswa mukugadzira mavhoriyamu akawanda ezvikamu.

- Mutengo pachikamu chimwe nechimwe unodzikira sezvo huwandu hwekugadzira hunowedzera.

Kukundikana

Overmolding inzira yekugadzira inosanganisira kuumba chimwe chinhu pamusoro pechimwe chinhu. Maitiro acho anowanzo anowedzera yakapfava, yakaita rabha-sechinhu pamusoro pechikamu chepurasitiki chakaomarara kuti chiwedzere kusimba kwayo uye aesthetics. Zvimwe zvakakosha zve overmolding zvinosanganisira:

Inogadzira chikamu chezvinhu zviviri

- Kutanga, isu tinoumba yekutanga zvinhu, uyezve yechipiri zvinhu pamusoro pekutanga.

- Iyo nzira inowedzera kusimba uye aesthetics yechinhu.

- Mutengo pachikamu wakakwira pane jekiseni kuumba nekuda kweiyo yakawedzerwa tekiniki yekuumba yechipiri pane yekutanga.

- Musiyano pakati peJekiseni Molding uye Overmolding

Misiyano yekutanga pakati pejekiseni molding uye overmolding ndeiyi:

- Nhamba Yezvinhu:Jekiseni molding inoburitsa chinhu chimwe chete chikamu, ukuwo overmolding ichiburitsa maviri-materi chikamu.

- Process:Jekiseni rekugadzira rinopinza purasitiki yakanyungudutswa mugomba reforoma nhanho imwe, ukuwo kuwandisa kunosanganisira kuumba chinhu chekutanga kutanga uyezve kuumba chinhu chechipiri pamusoro pechinhu chekutanga.

- Chinangwa: Vagadziri vanoshandisa jekiseni kuumba kugadzira mavhoriyamu akawanda ezvikamu zvepurasitiki, nepo ivo vachishandisa overmolding kuti vawedzere kusimba uye kunaka kwechidimbu chepurasitiki.

- Mariro: Jekiseni molding rinowanzo kudhura pachikamu pane overmolding, nekuda kwekuwedzera maitiro ekuumba chinhu chechipiri pamusoro pekutanga.

Zvishandiso zveJekiseni Molding uye Overmolding

Vagadziri vanowanzo shandisa jekiseni kuumba kugadzira zvinhu zvevatengi, zvinhu zvemotokari, uye michina yekurapa. Ivo zvakare vanowanzo shandisa overmolding kuti iwedzere kusimba uye aesthetics mune zvemagetsi zvigadzirwa senge mbozha nhare uye kure zvinodzora.

Kaviri-Kupfurwa Kuwedzeredza: Iyo Yakakurumbira Tekinoroji

Kaviri-pfuti overmolding, inozivikanwawo sembiri-pfuti kuumba kana kuwanda-pfuti kuumba, inzira yakakurumbira inoshandiswa mukugadzira zvikamu zvepurasitiki. Iyi nzira inosanganisira kuumba zvinhu zviviri pane mumwe nemumwe kugadzira chigadzirwa chapera. Iyi blog positi ichakurukura izvo zvekutanga-kupfura-kupfurwa overmolding uye mabhenefiti ayo.

Mabhenefiti eTwo-Shot Overmolding

Kaviri-pfuti overmolding inopa akawanda mabhenefiti pamusoro pechinyakare overmolding matekiniki, anosanganisira:

- Enhanced Aesthetics: Kaviri-pfuti overmolding inobvumira kugadzirwa kwakaomarara zvikamu zvine akawanda mavara kana maumbirwo. Kushandisa zvinhu zvakasiyana-siyana kunogona kutungamira kuchigadzirwa chekupedzisira chinoyevedza kupfuura chakagadzirwa kubva pane chimwe chinhu.

- Mashandiro akavandudzwa: Kaviri-pfuti overmolding inogona zvakare kuwedzera kushanda kwechigadzirwa. Semuyenzaniso, kubata-bata kwakapfava pamusoro pepurasitiki yakasimba inogona kuvandudza ergonomics yechigadzirwa uye ruzivo rwemushandisi.

- Mari dzakaderedzwa:Kaviri-pfuti overmolding inogona kubatsira kudzikisa mutengo nekubvisa kudiwa kwechipiri maoperation senge pendi kana kukoira. Kuita izvi kunogona kutungamira kune nekukurumidza kugadzira maitiro uye kuderedza mari.

- Kuwedzera Kusimba: Kaviri-pfuti overmolding inogona zvakare kuvandudza kusimba kwechigadzirwa. Nokushandisa chigadziko chepurasitiki chakaoma ne-soft-touch grip, somuenzaniso, chigadzirwa hachikwanisi kuputika kana kuputsika kana chadonha.

Zvishandiso zveTwo-Shot Overmolding

Maindasitiri akasiyana anowanzo kushandisa maviri-pfuti overmolding, kusanganisira:

- Automotive: Kaviri-pfuti overmolding inogadzira zvikamu zvemotokari, senge dashboard zvikamu uye zvemukati zvimedu zvekucheka.

- Consumer Goods:Kaviri-pfuti overmolding inogadzira bhurasho remazino, reza, uye zvigadzirwa zvemagetsi.

- Midziyo yekurapa:Kaviri-pfuti overmolding inogadzira michina yekurapa yakadai semidziyo yekuvhiya nemidziyo yekuendesa zvinodhaka.

Insert Molding: Kubatanidza Zvikamu Zviviri Zvakasiyana

Insert molding inzira yekugadzira inosanganisira kuumba chikamu chepurasitiki chakatenderedza chiya chagara chiripo kana substrate. Iyo yekuisa inowanzo gadzirwa nesimbi kana epurasitiki uye inogona kuve yekuisa shinda, waya, kana dhinda redunhu. Iyi blog post ichakurukura izvo zvekutanga zvekuisa molding uye mabhenefiti ayo.

Insert Molding Inoshanda Sei?

Insert molding idanho rematanho maviri rinosanganisira zvinotevera:

- Isu tinoisa iyo yekuisa mu mold.

- Purasitiki inobaiwa yakatenderedza iyo inopinza, ichigadzira chikamu chepurasitiki chakaumbwa icho chakanyatsonamirwa kune chinoiswa.

- Iyo inopinza inowedzera simba uye kugadzikana kune yakapedzwa chikamu, ichiita kuti ive yakakodzera kune akasiyana mafomu.

Zvakanakira Insert Molding

Insert molding inopa akawanda mabhenefiti pamusoro pechinyakare kuumba matekiniki, anosanganisira:

- Simba Rakavandudzwa: Insert molding inogadzira imwe yakasimba uye yakagadzikana yakapedzwa chigadzirwa, sezvo iyo yekuisa inosungirirwa zvakasimba kune chikamu chepurasitiki. Kuvandudza kusimba uye hupenyu hwechigadzirwa zvinogoneka neizvi.

- Yakaderedzwa Nguva yeGungano: Insert molding inobatsira kuderedza nguva yegungano uye mutengo wevashandi nekubatanidza zvikamu zvakawanda kuita chikamu chimwe chakaumbwa.

- Kuwedzera Dhizaini Kuchinjika:Insert molding inogonesa kugadzirwa kwezvikamu zvakaomarara zvine akawanda zvinhu, maumbirwo, uye mavara, zvichikonzera mhedzisiro inotaridzika zvirinani.

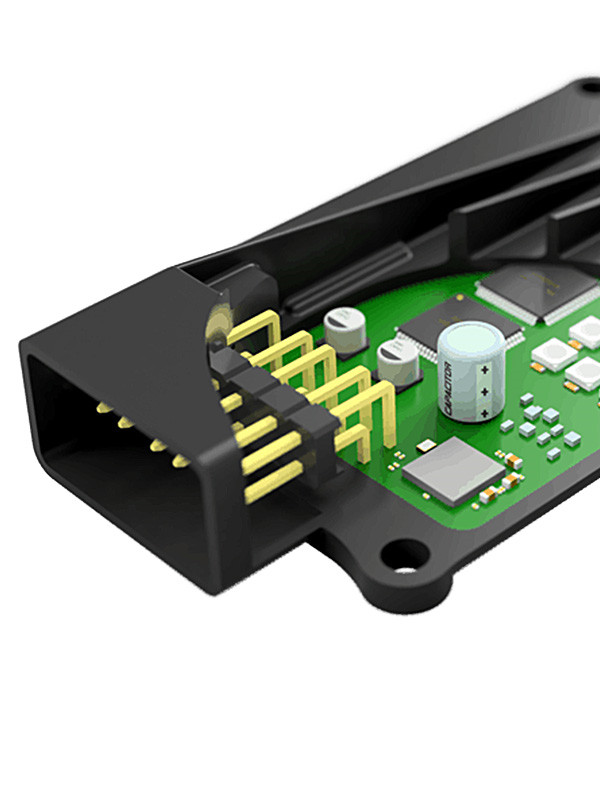

- Enhanced Functionality: Nekushandisa kuisa molding, vagadziri vanogona kuvandudza mashandiro echigadzirwa nekubatanidza maficha senge shinda inopinza kana magetsi madhiri.

Zvishandiso zve Insert Molding

Insert molding inowanzoshandiswa mumaindasitiri akasiyana siyana, kusanganisira:

- Automotive: Insert molding inogadzira zvikamu zvemotokari senge zvinobatanidza, masensa, uye switch.

- Electronics: Insert molding inogadzira zvinhu zvemagetsi senge zvinobatanidza, dzimba, uye switch.

- Midziyo yekurapa:Insert molding inogadzira catheter, connectors, uye sensors.

Soft Overmolding: Kuvandudza Kubata uye Kunyaradza

Soft overmolding inzira inoshandiswa mukugadzira kuwedzera chinhu chakapfava, chinochinjika pane chakaomarara base material. Iyo tekinoroji inobvumira kuwedzera mutsetse wekunyaradza uye kubata kune chigadzirwa, nekudaro ichivandudza mashandiro ayo uye aesthetics. Iyi blog positi ichakurukura izvo zvekutanga zvekupfava kuwedzeredza uye mabhenefiti ayo.

Ko Soft Overmolding Inoshanda Sei?

Soft overmolding inhanho mbiri-nhanho inosanganisira zvinotevera:

- Isu tinoumba iyo rigid base material.

- Chinhu chakapfava, chinochinjika chinoiswa jekiseni chakatenderedza chigadziko chakaumbwa, chichigadzira nzvimbo yakasununguka uye inobatika.

- Kazhinji, vagadziri vanogadzira zvinhu zvakapfava kubva kune thermoplastic elastomers (TPE) kana silicone. Chigadzirwa chinoguma chine nzvimbo yakatsetseka, yakasununguka inopa kubata zviri nani uye inovandudza kubata.

Zvakanakira Soft Overmolding

Soft overmolding inopa akati wandei mabhenefiti pamusoro pechinyakare kuumba matekiniki, kusanganisira:

- Nyaradzo Yakavandudzwa: Kuwedzeredza kwakapfava kunopa nzvimbo yakagadzika iyo inosimudzira ruzivo rwemushandisi. Iyo yakapfava zvinhu inoenderana nechimiro cheruoko rwemushandisi, ichidzikisa mapoinzi uye kugadzirisa kubata.

- Enhanced Grip: Iyo yakapfava inoshandiswa mukupfava yakapfava inopa kubata kuri nani, kuderedza mukana wekudonha kana kurasikirwa nechigadzirwa. Kuvandudza matanho ekuchengetedza kunogona kuderedza njodzi yekukuvara kwechigadzirwa.

- Aesthetically Inonakidza: Kuwedzeredza kwakapfava kunogona kuvandudza kutaridzika kwechigadzirwa, zvichiita kuti chiwedzere kunakidza. Iyo yakapfava zvinhu inogona kugadziridzwa kuti ienderane nemuvara uye kugadzirwa kwechigadzirwa, ichigadzira kutaridzika kwakabatana.

- Zvinogara: Yakapfava yakapfava inogadzira chigadzirwa chakasimba chinogona kumira kushandiswa nguva dzose uye kupfeka. Iyo yakapfava zvinhu inopa yakawedzera dziviriro kubva kune zvinokanganisa uye zvikweshwa, zvichideredza mukana wekukuvadza kune chigadzirwa.

Zvishandiso zveSoft Overmolding

Maindasitiri akasiyana anowanzo shandisa nyoro overmolding, kusanganisira:

- Consumer Electronics: Soft overmolding inogadzira zvigadzirwa zvemagetsi zvakaita seremote control, mahedhifoni, uye zvinodzora zvemitambo.

- Zvemitambo: Vagadziri vanoshandisa overmolding yakapfava kugadzira zvinhu zvemitambo zvakaita semabatiro emakirabhu egorofu, tenisi rackets, uye zvibato zvebhasikoro.

- Midziyo yekurapa: Kuwedzeredza kwakapfava kunogadzira michina yekurapa yakadai semidziyo yekuvhiya uye zvekunzwa.

Yakaoma Kuwedzeredza: Kuwedzera Dziviriro uye Kusimba

Kuwedzeredza kwakaoma kunowedzera yakaomarara yepurasitiki layer pamusoro pezvinhu zviripo, senge rabha kana silicone, kugadzira imwe yakasimba uye inodzivirira nzvimbo. Mhedzisiro yacho chigadzirwa chinogona kumira nharaunda dzakaomarara, kuramba abrasion, uye kushingirira kudzokorora kushandiswa.

Heano mamwe emabhenefiti ekushandisa yakaoma overmolding mukugadzirwa kwechigadzirwa:

- Kuwedzera kusimba: Kuwedzeredza kwakaoma kunopa imwe yakawedzera yekudzivirira iyo inogona kuwedzera hupenyu hwechigadzirwa. Kuchengetedza zvinhu zvepasi kubva pakusakara uye kubvaruka kunoita kuti mhedzisiro isanyanya kutyora kana kukundikana.

- Kubata kwakavandudzwa:Nekuwedzera hunyengeri hwepurasitiki layer kune yakapfava zvinhu, senge rabha kana silicone, vagadziri vanogona kugadzira zvirinani kubata kune vashandisi. Izvo zvakakosha kuti titarise chinhu ichi, kunyanya kune zvigadzirwa zvinoshandiswa munzvimbo inonyorova kana inotsvedza.

- Kurwisana nemamiriro ekunze:Kuwedzeredza kwakaoma kunogona kuchengetedza zvigadzirwa kubva pakufumurwa nechiedza chezuva, makemikari, uye zvimwe zvakatipoteredza zvinogona kukonzera kukanganisa nekufamba kwenguva. Kuwedzeredzwa uku kunonatsiridza kugona kwechigadzirwa kuchinjika uye kumirisana nenzvimbo dzakasiyana siyana.

- Aesthetic kukwezva: Kuwedzeredza kwakaoma kunogonawo kuvandudza kutaridzika kwechigadzirwa. Nekuwedzera chidimbu chepurasitiki chinonyengera, vagadziri vanogona kugadzira chimiro chakapfava, chakakwenenzverwa chisingabviri nechinhu chimwe chete.

- Customization: Nekushandisa dhizaini yakaoma, makambani anogona kugadzirisa zvigadzirwa zvavo nekuwedzera marogo, mavara, uye zvimwe zvinhu zvekugadzira kumusoro. Iyi branding zano inobatsira kuwedzera kuoneka mumusika.

Vagadziri vanoshandisa zvakaomesesa overmolding muzvigadzirwa zvakasiyana, kubva kumaindasitiri emidziyo kusvika kune zvemagetsi zvevatengi. Heino mienzaniso mishoma:

- Midziyo inobatwa nemaoko: Midziyo yakawanda inobatwa nemaoko, senge mbozhanhare uye mahwendefa, inoshandisa kuomarara kwepamusoro kugadzira chidziviriro chakatenderedza mudziyo. Iyi ficha inobatsira kuchengetedza mudziyo kubva mukukuvadzwa kunokonzerwa nemadonhwe uye kukanganisa.

- Zvishandiso zvemagetsi:Zvishandiso zvemagetsi zvinowanzosangana nemhoteredzo dzakaoma, dzakadai seguruva nemarara. Kushandisa hard overmolding kunogona kuchengetedza maturusi aya kubva mukukuvadzwa uye kuwedzera hupenyu hwavo.

- Zvishandiso zvekurapa Zvishandiso zvekurapa zvinoda kusimba kwakanyanya uye kuramba kune zvakatipoteredza zvinhu. Hard overmolding inogona kuchengetedza zvishandiso izvi uye kuona kuti zvinoshanda nemazvo.

Thermoplastic Elastomers (TPEs): Iyo Inofarirwa Material Yekuwedzeredza

Kana zvasvika pakuwedzeredza, kune zvakawanda zvekushandisa zvekusarudza kubva, asi hapana anozivikanwa kupfuura Thermoplastic Elastomers (TPEs). TPEs zvinhu zvakasiyana-siyana zvinopa akawanda mabhenefiti kana zvasvika pakuwedzeredza. Heano zvimwe zvezvikonzero nei TPEs ari iwo akasarudzika zvinhu zvekuwedzeredza:

- Versatility:Vagadziri vanogona kushandisa TPEs kupfutidza zvinhu zvakasiyana siyana, zvinosanganisira simbi, mapurasitiki, uye rubber. Vagadziri vanogona kuzvishandisa muzvigadzirwa zvakasiyana-siyana zvakagadzirwa kubva kune zvakasiyana zvinhu, zvichiita kuti zvive sarudzo inoshanduka.

- Kupfava uye kuchinjika: TPEs ine yakapfava uye inochinjika mameseji, ichiita kuti ive yakakodzera kune yakawandisa zvigadzirwa zvinoda kugadzika kubata. Vanogona zvakare kugadzira zvigadzirwa zvinoda kukotama kana kuchinjika pasina kutyora.

- Kupokana nemakemikari uye UV mwaranzi:TPEs inodzivirira zvakanyanya kumakemikari uye UV mwaranzi, ichiita kuti ive yakakodzera kune zvigadzirwa zvakafumurwa kune hutsinye nharaunda.

- Durability: TPEs dzakasimba zvakanyanya uye dzinoshingirira kupfeka uye kubvarura, dzichiita kuti dzive dzakanakira zvigadzirwa zvinogara zvichishandiswa kana kushandiswa zvakanyanya.

- Zvinodhura-zvinobudirira: MaTPEs anodhura-achienzanisa nezvimwe zvinhu zvinoshandiswa pakuwedzeredza, zvichiita kuti ive sarudzo inokwanisika kune vanogadzira.

- Zviri nyore kugadzirisa:MaTPE anogona kukurumidza kugadziriswa uchishandisa jekiseni rekugadzira, zvichiita kuti ive sarudzo yakakurumbira kune vanogadzira vanoda kugadzira akawanda ezvigadzirwa nekukasira uye nemazvo.

Mimwe mienzaniso yezvigadzirwa zvinoshandisa maTPE ekuwedzeredza zvinosanganisira:

- Mabatiro ezvishandiso zvemaoko: Vagadziri vanowanzo shandisa TPEs kuwedzeredza kubata kwezvishandiso zvemaoko, senge pliers uye screwdriver. TPEs 'yakapfava uye inochinjika mameseji inoita kuti ive yakanaka yekugadzira yakagadzika grip isingatsvedze.

- Midziyo yemitambo: Vagadziri vanowanzo shandisa maTPE kuwedzeredza midziyo yemitambo, senge gorofu kirabhu grips uye tenisi racket mibato. TPEs 'yakapfava uye inochinjika mameseji inoita kuti ive yakanaka yekugadzira yakagadzika grip isingatsvedze.

- Zvigadzirwa zvemagetsi: MaTPE anowanzo wedzera midziyo yemagetsi senge maremote control uye nharembozha. TPEs 'yakapfava uye inochinjika mameseji inoita kuti ive yakanakira kugadzira yekudzivirira yakatenderedza mudziyo isingazokwenya kana kukuvadza pamusoro.

Silicone Overmolding: Yakanakira Medical Devices uye Consumer Products

Silicone overmolding inzira inosanganisira jekiseni remvura silicone zvinhu pamusoro pe substrate zvinhu. Iyi nzira inogona kugadzira zvigadzirwa zvakasiyana siyana zveindasitiri asi inonyanya kubatsira kune zvekurapa zvishandiso uye zvigadzirwa zvevatengi. Iyi blog post inoongorora zvakanakira silicone overmolding kune aya maindasitiri.

Zvakanakira Silicone Overmolding nokuda Medical Devices

- Biocompatibility:Zvishandiso zvekurapa zvinosangana nenyama yemunhu zvinoda zvinhu zvakachengeteka zvemuviri. Silicone ndeye biocompatible zvinhu izvo zvisiri chepfu kana kukuvadza kune mhenyu tishu. Kushandisa zvinhu izvi mumidziyo yekurapa kunobatsira zvikuru.

- Mbereko: Midziyo yekurapa inofanirwa kuvharirwa isati yashandiswa kuti ive nechokwadi chekuti haina mabhakitiriya uye zvimwe zvinosvibisa zvinosvibisa. Vashandi vehutano vanogona kushandisa nzira dzakasiyana-siyana kugadzirisa silicone, kusanganisira chiutsi, mwaranzi, uye kugadzirwa kwemakemikari. Zvishandiso zvekurapa zvinogona kubatsirwa kubva mukusiyana-siyana kwechinhu ichi.

- Flexibility: Silicone yakakwira kuchinjika inobvumira kuiumba kuita akasiyana maumbirwo uye saizi. Kugona kwechinyorwa kuenderana nechimiro chemuviri kunoita kuti ive yakakwana kumidziyo yekurapa.

- Durability: Silicone chinhu chakasimba chakasimba chinogona kumira kushandiswa kakawanda uye kuratidzwa kumakemikari ane hutsinye. Kugara kwayo uye kugona kutsungirira kushandiswa kwakadzokororwa uye kuchenesa kunoita kuti ive chinhu chakakodzera chemidziyo yekurapa.

Zvakanakira Silicone Overmolding kune Consumer Zvigadzirwa

- Nyaradzo: Silicone chinhu chakapfava uye chinochinjika icho chakasununguka kupfeka chinopesana neganda. Zvigadzirwa zvevatengi zvinosangana nemuviri, senge maearbuds, wachi, uye fitness trackers, zvakanakira zvinhu zvakaita seizvi.

- Kurwisa Kwemvura: Silicone chinhu chinodzivirira mvura chinogona kumira kuratidzwa kune unyoro pasina kushatisa kana kurasikirwa chimiro. Zvigadzirwa zvevatengi zvinoshandiswa munzvimbo dzakanyorova, senge gogi rekushambira uye matauriro asingapindi mvura, anogadzirwa zvakanaka kubva pane izvi.

- Design Flexibility: Silicone inogona kuumbwa kuita akasiyana maumbirwo uye saizi, ichibvumira vagadziri kuti vagadzire zvakasiyana uye zvigadzirwa zvitsva. Ichi chivakwa chinoita silicone yakanakira zvigadzirwa zvevatengi zvinoda maumbirwo akaomarara uye magadzirirwo.

- Durability:Silicone chinhu chakasimba chakasimba chinogona kumira kuratidzwa nemwaranzi yeUV, tembiricha yakanyanyisa, uye makemikari ane hutsinye. Iyi ficha inoita kuti ive yakakodzera kune zvigadzirwa zvevatengi zvinoda kusimba uye zvinokwanisa kumira kwakasiyana mamiriro ekunze.

Polyurethane Overmolding: Yakasiyana-siyana uye Yakasimba

Polyurethane overmolding inzira yekugadzira iyo ichangobva kuwana mukurumbira nekuda kwekusiyana kwayo uye kusimba. Kuita uku kunosanganisira kuisa mutsetse we polyurethane zvinhu pamusoro peiyo substrate iripo, kugadzira isina musono, inodzivirira coating inosimudzira iyo yepakutanga kusimba, kusimba, uye kushanda.

Kuwedzeredza ne polyurethane kunopa akawanda mabhenefiti, zvichiita kuti ive inoyevedza sarudzo kune vanogadzira pane akasiyana maindasitiri. Hezvino zvimwe zvakakosha zvakanakira:

Kusiyanisa

Vagadziri vanogona kushandisa maitiro akasiyana-siyana e polyurethane overmolding neakawanda substrates, kusanganisira mapurasitiki, simbi, uye macomposites.

Izvi zvakasiyana-siyana zvinoita kuti polyurethane overmolding ive yakanakira mhinduro yezvishandiso zvinoda kusanganisa zvinhu zvakasiyana kuita chikamu chimwe chete.

mukurumari

Polyurethane chinhu chakasimba chakasimba chinogona kumirisana nemamiriro akasiyana siyana ezvakatipoteredza, kusanganisira tembiricha yakanyanyisa, makemikari ane hutsinye, uye kupera kunorema uye kubvaruka. Zvishandiso zvinoda kushanda kwakadzikama uye dziviriro zvinogona kubatsirwa nekusarudza iyi seyavo yakanaka sarudzo.

Customization

Vagadziri vanogona kuwana yakakwira dhigirii yekushongedza ne polyurethane overmolding, ichivabvumira kugadzira maumbirwo akaomarara uye magadzirirwo. Ichi chimiro chinoita kuti ive sarudzo yakakwana yezvinhu zvinoda kutaridzika kwakasiyana kana maitiro anoshanda.

Mutengo-Unoshanda

Polyurethane overmolding inogona kuve inodhura-inoshanda mhinduro kana ichienzaniswa nedzimwe nzira dzekugadzira, senge jekiseni kuumba kana machining. Inogona zvakare kuderedza nhamba yezvikamu zvinodiwa kune yakapihwa application, kuderedza nguva yegungano uye mutengo.

Yakavandudzwa Kubata uye Kunyaradza

Polyurethane overmolding inogona kusimudzira kubata uye kunyaradza kwezvigadzirwa, senge maturusi nemabatiro, nekupa isina-inotsvedza nzvimbo iri nyore kubata uye kugadzikana kubata.

Polyurethane overmolding inogona kushandiswa mumhando dzakasiyana dzekushandisa, kusanganisira:

- Automotive:zvemukati nekunze, sezvibatiso zvegonhi, zvikamu zvedashboard, uye zvimedu zvekuchekesa.

- Electronics:yekudzivirira zvinhu zvemagetsi zvine hunyoro kubva mukukuvadzwa kwezvakatipoteredza.

- Zvekurapa: kugadzira midziyo yekurapa yakasimba uye ine hutsanana, semabatiro emidziyo yekuvhiya.

- Consumer Goods: yekugadzira zvigadzirwa zvetsika zvine dhizaini yakasarudzika uye mashandiro akakwenenzverwa, senge zvinhu zvemitambo nemidziyo yemumba.

Kuwedzeredza kweMotokari Zvishandiso: Kuwedzera Aesthetics uye Basa

Muindasitiri yemotokari, kuwandisa kwave kuwedzera kukurumbira pakuvandudza aesthetics uye kushanda kwezvikamu zvemotokari. Iyi nzira yekugadzira inogadzira akasiyana emotokari zvikamu, senge mabatiro, grips, uye mapfundo. Pano, isu tichakurukura kuti overmolding inoshandiswa sei mumashandisi emotokari kusimudzira aesthetics uye kushanda.

Kuvandudza Aesthetics

Imwe yemabhenefiti ekutanga ekuwedzeredza muindasitiri yemotokari kugona kwayo kuvandudza aesthetics. Overmolding inobvumira vagadziri kugadzira maumbirwo akaomarara uye magadzirirwo ayo angave akaoma kuwana nemaitiro echinyakare ekugadzira. Hedzino dzimwe nzira kuwedzeredza kunowedzera kunaka kwekukwezva kwezvikamu zvemotokari:

- Customization: Overmolding inobvumira kugadzirisa, zvichiita kuti zvive nyore kugadzira zvikamu zvine akasiyana dhizaini uye musanganiswa weruvara unoenderana nemukati memotokari kana kunze.

- Mavara: Kuwedzeredza kunogona kugadzira nzvimbo dzakasiyana-siyana, kubva kunyoro-kubata kusvika kumusoro-kubata, kugadzirisa chikamu chekunzwa kwese.

- Kutengesa:Vagadziri vanogona kushandisa overmolding kuti ibatanidze zvinhu zvechiratidzo, senge marogo kana mazita emhando, mudhizaini.

- Quality: Overmolding inogadzira zvikamu zvepamusoro-soro zvine kupera kunoenderana, kuvandudza kutaridzika kwese uye kunzwa.

Kuvandudza Kushanda

Pamusoro pekuvandudza aesthetics, kuwandisa kunogona kuwedzera mashandiro emotokari zvinhu. Hedzino dzimwe nzira idzo vagadziri vanoshandisa overmolding kuwedzera kushanda:

- Kubata: Kuwedzeredza kunogona kugadzira nzvimbo isiri-inotsvedza inovandudza kubata, zvichiita kuti zvikamu zvive nyore kushandisa uye zvakachengeteka kune vatyairi nevafambi.

- Durability: Overmolding inogona kuwedzera kusimba kwezvikamu nekudzivirira kubva pakusakara uye kubvaruka uye kuratidzwa kune yakaoma mamiriro ezvakatipoteredza.

- Kuderedza ruzha: Kuwedzeredza kunogona kuderedza ruzha nekugadzira inonyorovesa mhedzisiro inoderedza kudedera uye inobata ruzha.

- Kudzivirirwa:Kuwedzeredza kunogona kudzivirira zvikamu kubva mukukuvadzwa kunokonzerwa nekukanganisa kana abrasion, izvo zvinobatsira kuwedzera hupenyu hwavo.

Zvishandiso zveKuwedzeredza muIndasitiri Yemotokari

Vagadziri vanoshandisa overmolding mumhando dzakasiyana dzemotokari dzekushandisa, kusanganisira:

- Interior components:Overmolding inogadzira mapfundo, switch, uye zvibatiso zvemukati maficha akadai semadhibhodhi, mapaneru emagonhi, uye mareti emaoko.

- Exterior components: Overmolding inogadzira ekunze maficha akadai segrill inoisa, headlight kutenderedza, uye magirazi anovhara.

- Pasi pehodhi: Overmolding inogadzira zvikamu zvakaita semakumisikidza enjini, masensa, uye mabhuraketi anofanirwa kumira tembiricha yakakwira uye mamiriro akaomarara.

Overmolding yeMagetsi: Kuvandudza Kuita uye Kuvimbika

Muindasitiri yemagetsi, overmolding yakawedzera mukurumbira nekuda kwekugona kwayo kuvandudza mashandiro uye kuvimbika kwezvikamu zvemagetsi. Pano, isu tichakurukura kuti overmolding inoshandiswa sei mumagetsi kusimudzira kuita uye kuvimbika.

Kuvandudza Kuita

Imwe yemabhenefiti ekutanga ekuwedzeredza muindasitiri yemagetsi kugona kwayo kuvandudza mashandiro. Kuwedzeredza kunogona kusimudzira kushanda kwezvikamu zvemagetsi nenzira dzinoverengeka:

- Kudzivirira mvura:Overmolding inogonesa kudzivirira mvura kwezvikamu zvemagetsi, zvichiita kuti zvive zvakakosha kune maapplication apo chikamu chinogona kusangana nehunyoro kana zvimwe zvinwiwa.

- Vibration Resistance: Kuwedzeredza kunogona kugadzira chipingamupinyi chinobatsira zvinhu zvemagetsi kuramba kuzunguzika, izvo zvakakosha mumashandisirwo apo chikamu chinogona kunge chiri pasi pekuvhunduka kana kudedera.

- Thermal Management: Overmolding inobatsira kubvisa kupisa kure nemagetsi, nekudaro kunowedzera kuita kwavo uye kuwedzera hupenyu hwavo.

- Magetsi Insulation:Overmolding inogona kugadzira insulating layer inodzivirira zvikamu zvemagetsi kubva pakukanganiswa kwemagetsi, izvo zvinogona kubatsira kuvandudza mashandiro avo.

Kuvandudza Kuvimbika

Pamusoro pekuvandudza mashandiro, kuwandisa kunogonawo kuwedzera kuvimbika kwezvikamu zvemagetsi. Heano dzimwe nzira idzo overmolding inovandudza kuvimbika:

- Kudzivirirwa kubva Kukuvadzwa: Kuwedzeredza kunogona kuchengetedza zvinhu zvemagetsi kubva mukukuvadzwa kwemuviri, sekukanganisa kana abrasion, izvo zvinogona kubatsira kuwedzera hupenyu hwavo.

- Chemical Nemishonga:Kuwedzeredza kunogona kuchengetedza zvikamu zvemagetsi kubva kumakemikari anogona kukonzera ngura kana kumwe kukuvadza, izvo zvinogona kubatsira kuvandudza kuvimbika kwavo.

- Yakaderedzwa Ngozi yekukundikana: Kuwedzeredza kunogona kubatsira kudzikisa njodzi yekutadza nekudzivirira zvinhu zvemagetsi kubva kune zvakatipoteredza zvakaita sehunyoro, vibration, uye tembiricha yakanyanyisa.

Zvishandiso zveKuwedzeredza muIndasitiri yeMagetsi

Akasiyana-siyana emagetsi ekushandisa anoshandisa overmolding, kusanganisira:

- Connectors:Overmolding inogadzira isingapindi mvura uye inodzivirira-vibration zvinongedzo zvinowana maapplication mumhando dzakasiyana dzemagetsi.

- Circuit Boards:Overmolding inogona kuchengetedza mabhodhi edunhu kubva kunyoro, vibration, uye zvimwe zvakatipoteredza izvo zvinogona kukonzera kukanganisa kana kutadza.

- Sensors: Kuwedzeredza kunogona kuchengetedza masensa kubva mukukuvadzwa kunokonzerwa nekuratidzwa kune hutsinye makemikari kana zvimwe zvakatipoteredza.

- Handheld Devices:Kuwedzeredza kunogadzira makesi akasimba uye asingapindi mvura emidziyo inobatwa nemaoko, senge nharembozha, makamera, uye GPS zvishandiso.

Kuwedzeredza kweMishonga Yezvokurapa: Kuve nechokwadi Chekuchengetedza uye Kunyaradza

Overmolding yave kuwedzera mukurumbira muindasitiri yezvokurapa yekuvandudza kuchengetedzwa uye kunyaradza kwemidziyo yekurapa. Pano, isu tichakurukura kuti overmolding inoshandiswa sei mumidziyo yekurapa kuve nechokwadi chekuchengetedza uye kunyaradza.

Kuchengetedza Kuchengetedza

Imwe yemabhenefiti ekutanga ekuwedzeredza muindasitiri yekurapa kugona kwayo kuve nechokwadi chekuchengetedza. Kuwedzeredza kunogona kuwedzera kuchengetedzeka kwemidziyo yekurapa munzira dzinoverengeka:

- Biocompatibility: Overmolding inogonesa kugadzirwa kwebiocompatible michina yekurapa, kuve nechokwadi chekuchengetedza kwavo kushandiswa mumuviri wemunhu pasina kukonzera kukanganisa.

- Mbereko: Kuwedzeredza kunogona kugadzira zvishandiso zvekurapa zviri nyore kuti zvibate, izvo zvakakosha pakudzivirira kupararira kwehutachiona munzvimbo dzehutano.

- Ergonomics: Kuwedzeredza kunogonesa kusikwa kwezvishandiso zvekurapa zvakagadzirirwa ergonomically, izvo zvinogona kubatsira kuderedza njodzi yekudzokorora kukuvara kwekunetseka uye kumwe kusagadzikana kwemusculoskeletal pakati pevashandi vehutano.

- Durability: Kuwedzeredza kunogona kugadzira michina yekurapa inogara yakasimba, iyo inogona kubatsira kuderedza njodzi yekutadza kana kusashanda panguva yekushandiswa.

Kuvimbisa Nyaradzo

Pamusoro pekuchengetedza kuchengetedzwa, kuwandisa kunogonawo kuwedzera kunyaradza kwemidziyo yekurapa. Hedzino dzimwe nzira idzo overmolding inopa nyaradzo:

- Mavara: Overmolding inogona kugadzira michina yekurapa ine textured surface inopa kubata zviri nani uye inovandudza kunyaradza.

- Flexibility: Overmolding inogona kugadzira michina yezvokurapa iyo inonyanya kushanduka, iyo inogona kubatsira kuvandudza kunyaradza uye kuderedza dambudziko rekukuvara kana kusagadzikana panguva yekushandiswa.

- Customization: Overmolding inobvumira kugadzirisa chimiro uye dhizaini yemidziyo yekurapa kuti ienderane nezvinodiwa zvakasiyana zvevarwere vega zviri nani, kuwedzera kunyaradza uye kuderedza njodzi yematambudziko.

Zvishandiso zveKuwedzeredza muIndasitiri Yezvokurapa

Mhando dzakasiyana dzekurapa dzinoshandisa overmolding, kusanganisira:

- Nzira Dzokuvhiya: Kuwedzeredza kunogona kugadzira zviridzwa zvekuvhiya zvine kugadzikana kubata, zvirinani ergonomics, uye yakagadziridzwa kusimba.

- Anodyara:Kuwedzeredza kunogona kugadzira biocompatible implants iyo yakanyanya kugadzikana kune varwere uye isinganyanyi kukonzera matambudziko.

- Diagnostic Devices: Kuwedzeredza kunogona kugadzira michina yekuongorora iyo iri nyore kubata, yakasimba, uye yakasununguka kune varwere.

- Zvipfeko Overmolding inogonesa kugadzirwa kwezvishandiso zvekurapa zvinopfekwa zvinopa nyaradzo yakawedzerwa uye kuchinjika, zvichiita kuti zvive nyore kune varwere kupfeka nekushandisa.

Kuwedzeredza kweZvigadzirwa zveVatengi: Kuwedzera Kukosha uye Kukwidza

Pano, tichakurukura kuti overmolding inoshandiswa sei muzvigadzirwa zvevatengi kuwedzera kukosha uye kukwezva.

Kuvandudza Aesthetics

Imwe yemabhenefiti ekutanga ekuwandisa muindasitiri yechigadzirwa chevatengi kugona kwayo kuvandudza aesthetics. Kuwedzeredza kunogona kuwedzera kutaridzika uye kunzwa kwezvigadzirwa zvevatengi munzira dzinoverengeka:

- Design Flexibility:Overmolding inobvumira kuchinjika kukuru kwedhizaini, zvichiita kuti kugadzira zvigadzirwa zvine maumbirwo akasiyana uye maumbirwo zvive nyore.

- Kugadzirisa Kwemavara: Overmolding inogonesa mavara akawanda muchigadzirwa chimwe chete, ichigadzira dhizaini inobata maziso inomira pasherufu.

- Soft-Touch Feel:Kuwedzeredza kunogona kugadzira zvigadzirwa zvine nyoro-kubata kunzwa, kuvandudza iyo yakazara mushandisi ruzivo uye kukwezva.

Kuwedzera Kushanda

Pamusoro pekuvandudza aesthetics, kuwandisa kunogona kuwedzera kushanda kune zvigadzirwa zvevatengi. Hedzino dzimwe nzira idzo overmolding inowedzera kukosha:

- Yakavandudzwa Kubata: Overmolding inobvumira kugadzirwa kwezvigadzirwa nekubata zviri nani, kunowedzera kusununguka kwekushandisa uye kunyaradza kana uchizvibata.

- Enhanced Durability:Kuwedzeredza kunogona kugadzira zvigadzirwa zvinogara zvakanyanya, kuvandudza hupenyu hwavo uye kukosha kwese.

- Kudzivirira mvura: Overmolding inogonesa kugadzirwa kwezvigadzirwa zvisingapinde mvura, zvichiwedzera kuita kwavo kwakasiyana-siyana uye kukwezva kune vatengi.

Zvishandiso zveKuwedzeredza muIndasitiri yeVatengi

Yakasiyana-siyana yevatengi chigadzirwa application inoshandisa overmolding, kusanganisira:

Electronics: Overmolding inogona kugadzira yakashongedzwa uye yakasimba makesi emidziyo yemagetsi senge mafoni uye mahwendefa.

Zvombo Zvemitambo: Kuwedzeredza kunogona kugadzira michina ine yakagadziridzwa kubata uye kusimba, senge bhasikoro zvibato uye tenisi racket grips.

Kitchenware: Overmolding inogona kugadzira kitchenware ine nyoro-yekubata inonzwa uye yakagadziridzwa kubata, senge midziyo yekubikira uye mibato yepoto nemapani.

Personal Care Products: Kuwedzeredza kunogona kugadzira zvigadzirwa zvekuchengeta wega zvine chitarisiko chakasarudzika uye kunzwa, senge bhurasho remazino uye reza.

Kuwedzeredza Dhizaini Kufunga: Kubva Prototyping kusvika Kugadzirwa

Kuwedzeredza kunosanganisira kubaya chinhu chechipiri pamusoro pechinhu chakafanoumbwa, kugadzira chigadzirwa chakabatana. Kuwedzeredza kunogona kupa zvakakosha mabhenefiti, akadai sekuvandudzwa kweaesthetics, kuwedzera kushanda, uye kusimba kwakasimba. Nekudaro, kugadzira nekugadzira zvikamu zvakawandisa zvinoda kunyatsotariswa kuti uve nechokwadi chekubudirira.

Heano mamwe akakosha dhizaini ekufunga kune yakawandisa zvikamu:

Kuenderana kwezvinhu: Izvo zvinhu zvinoshandiswa mukuwedzeredza zvinofanirwa kuenderana kuti ive nechokwadi chisungo chakasimba. Kubatana pakati pezvinhu zviviri zvakakosha pakuita kwechikamu. Zvishandiso zvine maitiro akafanana uye kunyunguduka tembiricha zvakanakira overmolding.

Chikamu dhizaini: Magadzirirwo echikamu chekare-chakaumbwa anofanira kufunga nezvehukuru, chimiro, uye nzvimbo yenzvimbo yakafukidzirwa. Chikamu chakanyatsogadzirwa chichava nehupamhi hwemadziro eunifomu uye pasina undercuts kuti ive nechokwadi chekuchinja kwakanaka pakati pezvinhu.

Tooling design: The tooling for overmolding yakaoma pane yechinyakare jekiseni molding. Iyo dhizaini yedhizaini inofanirwa kubata iyo pre-yakaumbwa chikamu munzvimbo panguva yekuwedzeredza maitiro, ichibvumira iyo yechipiri zvinhu kuyerera ichitenderera nepamusoro pechikamu.

Mugadziri anofanirawo kugadzira chishandiso kuderedza kupenya uye kuve nechokwadi chekubatana pakati pezvinhu.

Process optimization: Iyo yekuwedzeredza maitiro inosanganisira akawanda nhanho, kusanganisira kuumba iyo pre-yakaumbwa chikamu, kutonhora, uyezve jekiseni yechipiri zvinhu. Injiniya inofanirwa kukwirisa maitiro kuti ive nechokwadi chekubatana kwakanakisa pakati pezvinhu zviviri izvi uye kuderedza hurema hwakaita se warping kana sink mamaki.

Paunenge uchifamba kubva ku prototyping kuenda kukugadzira, pane zvimwe zvekufunga zvekuchengeta mupfungwa:

Volume uye mutengo: Overmolding inogona kudhura kupfuura yechinyakare jekiseni kuumba nekuda kwekuoma kwemaitiro uye mutengo wekushandisa. Sezvo vhoriyamu ichiwedzera, mutengo pachikamu unogona kudzikira, zvichiita kuti kuwandisa kuwedzere mari-inoshanda kune makuru ekugadzira anomhanya.

Kuraira kwehutano: Kuwedzeredza kunoda matanho akasimba kuti ave nechokwadi chekuenderana chikamu chemhando uye kudzivirira kukanganisa. Chikwata chekudzora mhando chinofanirwa kuita ongororo uye kuyedza padanho rega rega rekugadzira maitiro kuti ive nechokwadi chekuti chikamu chinosangana nezvinodiwa.

Sarudzo yemupi: Kusarudza mupi akakodzera wekuwandisa kwakakosha pakubudirira kweprojekiti. Tsvaga mutengesi ane ruzivo mukuwedzeredza uye rekodhi rekodhi yekugadzira zvikamu zvemhando yepamusoro. Mutengesi anofanirawo kukwanisa kupa rubatsiro rwekugadzira, kugadzirisa maitiro, uye matanho ekudzora emhando.

Kugadzira Kunodhura Nekuwedzeredza

Overmolding inzira yekugadzira inosanganisira kubaya chinhu chechipiri pamusoro pechikamu chakafanoumbwa kugadzira chimwe chigadzirwa chakabatana. Iyi nzira inogona kupa zvakakosha mabhenefiti, akadai sekuvandudzwa kweaesthetics, kuwedzera kushanda, uye kusimba kwakasimba. Overmolding inogona zvakare kuve inodhura-inoshanda mhinduro kune chaiyo zvigadzirwa.

Hedzino dzimwe nzira dzekuti overmolding inogona kubatsira kuderedza mutengo wekugadzira:

Yakaderedzwa nguva yekubatanidza: Overmolding inogona kubvisa kudiwa kwezvikamu zvakasiyana uye nzira inopedza nguva yekuzviunganidza. Kuwedzeredza kunogona kuderedza nguva yegungano uye mutengo wevashandi nekugadzira chigadzirwa chakabatana.

Yakaderedzwa tsvina yezvinhu: Yechinyakare jekiseni kuumba kazhinji inoburitsa akakosha marara nekuda kwemasprues uye anomhanya anodiwa kuzadza mold. Overmolding inogona kuderedza marara nekushandisa iyo pre-yakaumbwa chikamu seyakanyanya uye kubaya chinhu chechipiri chete pazvinenge zvichidikanwa.

Kuvandudza chikamu chekuita: Kuwedzeredza kunogona kuvandudza kuita kwechikamu uye kusimba, kuderedza kudiwa kwekugara kuchitsiva kana kugadzirisa. Kuderedza nguva yekudzikira uye mari yekugadzirisa kunogona kukonzera kuchengetedza kwakakosha kwenguva refu.

Yakaderedzwa mari yekushandisa: Overmolding inogona kudhura kupfuura yechinyakare jekiseni kuumba nekuda kwekuoma kwemaitiro uye mutengo wekushandisa. Nekudaro, mune zvimwe zviitiko, kuwedzeredza kunogona kuderedza mutengo wekushandisa nekubvisa kudiwa kweakasiyana mold kune chimwe nechimwe chikamu. Overmolding inogona kurerutsa maitiro ekugadzira, kunyanya kune zvidiki uye zvakaoma zvikamu.

Mari yekufambisa yakaderedzwa: Overmolding inoderedza mari yekufambisa nekubvisa kukosha kwekutakura uye kuunganidza zvikamu zvakasiyana gare gare. Nekuita izvi, pachava nekuderedzwa kwengozi yekukuvadza panguva yekufambisa, zvichiita kuti kuderera kwezvikamu zvakarambwa uye tsvina.

Paunenge uchifunga nezvekuwedzeredza kwekugadzira-inodhura-inoshanda, zvakakosha kuchengeta zvinotevera zvinhu mupfungwa:

Kusarudzwa kwezvinhu: Izvo zvinhu zvinoshandiswa mukuwedzeredza zvinofanirwa kuenderana kuti ive nechokwadi chisungo chakasimba. Zvishandiso zvine maitiro akafanana uye kunyunguduka tembiricha zvakanakira overmolding. Kusarudza zvinhu zvakakodzera kunogonawo kukanganisa mari yenguva refu yekuchengetedza nekuvandudza chikamu chekuita uye kuderedza mari yekugadzirisa.

Process optimization: Iyo yekuwedzeredza maitiro inosanganisira akawanda nhanho, kusanganisira kuumba iyo pre-yakaumbwa chikamu, kutonhora, uyezve jekiseni yechipiri zvinhu. Iyo process optimization timu inofanirwa kukwirisa maitiro kuti ive nechokwadi chepamusoro chisungo pakati pezvinhu zviviri uye kuderedza hurema hwakadai se warping kana sink mamaki. Kugadzirisa maitiro kunogona kukonzera kukurumidza kutenderera nguva uye kuwedzera kushanda zvakanaka, kuderedza mutengo wekugadzira.

Sarudzo yemupi: Kusarudza mupi akakodzera wekuwandisa kwakakosha pakubudirira kweprojekiti. Tsvaga mutengesi ane ruzivo mukuwedzeredza uye rekodhi rekodhi yekugadzira zvikamu zvemhando yepamusoro. Mutengesi anofanirawo kukwanisa kupa rubatsiro rwekugadzira, kugadzirisa maitiro, uye matanho ekudzora emhando.

Environmental Sustainability uye Overmolding

Overmolding inzira yakakurumbira yekugadzira inosanganisira kuumba chimwe chinhu pamusoro pechimwe kugadzira chigadzirwa chimwe chete. Iyi nzira inopa huwandu hwemabhenefiti, kusanganisira yakagadziridzwa aesthetics, yakawedzera mashandiro, uye kuwedzera kusimba. Asi zvakadini netapuro dzayo pamhoteredzo? Kuwandisa inzira yekugadzira inochengetedza zvakatipoteredza here?

Hedzino dzimwe nzira dzekuti overmolding inogona kuve yakachengetedza nharaunda yekugadzira maitiro:

Yakaderedzwa tsvina yezvinhu: Overmolding inogona kuderedza marara nekushandisa iyo pre-yakaumbwa chikamu seyakanyanya uye kubaya chinhu chechipiri chete pazvinenge zvichidikanwa. Kushandisa zvinhu zvishoma mukugadzira kunoderedza huwandu hwemarara anogadzirwa zvachose.

Kuderedza kushandiswa kwesimba: Overmolding inogona kuita simba rakawanda kupfuura maitiro ekugadzira echinyakare nekuti kuumba chigadzirwa chimwe chete kunoda simba shoma pane kugadzira zvikamu zvakasiyana uye kuzviunganidza gare gare.

Kushandiswa kwezvinhu zvakadzokororwa: Zvizhinji zvekuwedzeredza zvinhu zvinogona kudzokororwa, kuderedza marara mumarara. Kushandisa zvinhu zvakadzokororwa zvakare kunogona kuderedza kudiwa kwezvinhu zvemhandara, kuchengetedza zviwanikwa uye kuderedza kushandiswa kwesimba.

Hurefu hwehupenyu hwechigadzirwa: Overmolding inogona kuvandudza kuita kwechikamu uye kusimba, zvichikonzera zvigadzirwa zvinogara kwenguva refu uye zvinoda zvishoma zvinotsiviwa. Kuderedza tsvina inogadzirwa mukati mehupenyu hwechigadzirwa kunogona kuderedza zvakanyanya kukanganisa kwayo kwezvakatipoteredza.

Chekufambisa chadzikira: Nekubvisa kudiwa kwekufamba kwakasiyana uye gare gare kusangana kwezvikamu, kuwandisa kunogona kuderedza mari yekufambisa. Kudzikisa huwandu hwemafuta anoshandiswa mumotokari kunogona kuderedza kukanganiswa kwezvakatipoteredza uye kuderera kwakabatana nekubuda.

Nekudaro, zvakakosha kuti uzive kuti overmolding haisi nguva dzose inochengetedza nharaunda yekugadzira maitiro. Hezvino zvimwe zvekufunga nezvazvo:

Kusarudzwa kwezvinhu: Izvo zvinhu zvinoshandiswa mukuwedzeredza zvinofanirwa kunyatsosarudzwa kuti ive nechokwadi chekuti zvine hushamwari. Semuyenzaniso, zvimwe zvinhu zvinogona kunetsa kudzokorodza kana kuti zvingada kushandiswa kwesimba kwakakosha kugadzira.

Process optimization: Overmolding inofanira kuvandudzwa kuderedza kushandiswa kwesimba uye kutambisa. Imwe nzira yekudzikisira kutambisa zvinhu ndeyekusimudzira muchina kana kunatsa nzira yekuumba kuti inyatsoshanda.

Mafungiro ekuguma kwehupenyu: Pavanenge vachifunga nezvekuguma kweupenyu hwechigadzirwa, vanhu kana masangano vanofanira kufunga kuti vachachibvisa sei. Zvigadzirwa zvakawandisa zvinogona kunetsa kudzokorodza kana kuti zvingada simba rakawanda rekurasa kupfuura zvigadzirwa zvechinyakare.

Kuwedzeredza uye Indasitiri 4.0: Zvitsva uye Mikana

Overmolding inzira yekugadzira inosanganisira kuumba chinhu pane chimwe chinhu kana substrate. Maindasitiri emotokari, ekurapa, uye emagetsi anoshandisa zvakanyanya. Nekuuya kweIndasitiri 4.0, kuwandisa kwave kutonyanya kugadzira uye kushanda zvakanaka. Pano, isu tichaongorora hutsva uye mikana yekuwedzeredza muIndasitiri 4.0 nguva.

Innovations in Overmolding

Kubatanidza Indasitiri 4.0 tekinoroji senge otomatiki, hungwaru hwekugadzira, uye Internet yezvinhu (IoT), yakashandura maitiro ekuwedzeredza. Hezvino zvimwe zvezvitsva zvakabuda:

- Smart Molds: Aya ma mold akashongedzerwa nema sensors uye anogona kutaurirana nemichina kugadzirisa maitiro ekuumba. Vanogonawo kuona hurema uye kuzivisa vashandisi kuti vatore matanho ekugadzirisa.

- Robotic:Kushandisa marobhoti mukuwedzeredza kwakawedzera kushanda zvakanaka uye kudzikisa mutengo wevashandi. Marobhoti anogona kubata anodzokorodza mabasa akadai sekurodha uye kuburitsa zvinhu, kuderedza njodzi yekukanganisa kwevanhu.

- 3D Kudhinda:Kudhinda kwe 3D kwakagadzira mold dzakaoma dzaive dzisingaite kugadzira. Iyo yakawedzera dhizaini inoshanduka yakakonzera kuderedzwa kwekutungamira nguva.

- Predictive Maintenance:Predictive maintenance inzira inoshandisa ongororo yedata kufanotaura kuti michina ichada riini kugadzirisa. Iyi nzira inogona kubatsira kudzivirira kuderera uye kuderedza mari yekugadzirisa.

Mikana muOvermolding

Overmolding ine mikana yakawanda muIndasitiri 4.0, inosanganisira:

- Lightweighting:Kuwedzeredza kunogona kugadzira zvikamu zvisingaremi nekuumba chidimbu chakatetepa chechinhu pane yakareruka substrate. Kuderedza huremu hwechigadzirwa chekupedzisira kunovandudza kushanda kwemafuta uye kunoderedza kuburitsa.

- Customization: Overmolding inobvumira kugadzirisa kwezvikamu nekushandisa zvinhu zvakasiyana uye mavara. Mumaindasitiri ezvekurapa uye evatengi emagetsi, zvinotaridzika zvine basa zvakanyanya, uye zvakakosha kufunga nezve ichi chinhu.

- Sustainability:Overmolding inogona kubatsira kuderedza marara nekushandisa zvinhu zvakadzokororwa sema substrates. Nekudzikisa kukanganisa kwezvakatipoteredza kwekugadzira, makambani haangogone kuvandudza chimiro chavo chemhando uye kubatsira kune ramangwana rakagadzikana.

- Mari Kuchengetedza: Otomatiki, marobhoti, uye kufembera kugadzirisa kunogona kuderedza mutengo wevashandi uye kuwedzera kushanda zvakanaka, zvichiita kuti mugadziri achengetedze mutengo.

Overmolding Matambudziko uye Solutions

Nekudaro, kuwandisa kunouyisa mamwe matambudziko ayo vagadziri vanofanirwa kukunda kuti vagadzire zvemhando yepamusoro zvikamu zvakaputirwa. Muchikamu chino, tinoongorora mamwe ematambudziko akawandisa uye mhinduro.

matambudziko

- Kunamatira: Kuwedzeredza kunoda kuti zvinhu zviviri zvinoshandiswa zvinonamira kune mumwe nemumwe, uye kusanamatira kusinganamate kunotungamira mukudonhedza, kutsemuka, kana kudhindwa kwechinhu chakawandisa.

- Warping:Munguva yekuwedzeredza maitiro, iyo substrate inogona kukanganisa nekuda kwekupisa kwakanyanya uye kudzvanywa kwakaiswa. Warping inokanganisa zvakanyanya kunaka kwechikamu.

- Kuenderana kwezvinhu:Izvo zvinhu zvinoshandiswa mukuwedzeredza zvinofanirwa kuenderana kuti ive nechokwadi chekunamatira kwakanaka uye kudzivirira warping. Zvinhu zvisingaenzaniswi zvinogona kutungamirira kuhutano husina kunaka uye kukundikana kwezvinhu.

- Mutsara wekuparadzanisa: Mutsetse wekuparadzanisa ndipo panosangana zvinhu zviviri. Yakashata yekuparadzanisa mutsara dhizaini inogona kutungamira kune isina simba mapoinzi muchigadzirwa chakapedzwa uye kuderedzwa kusimba.

- Kuyerera kwezvinhu: Iyo yekuwedzeredza maitiro inoda iyo yechipiri zvinhu kuti iyerere yakatenderedza substrate, ichizadza yega yega. Kuyerera kwezvinhu zvisina kunaka kunogona kutungamira kune isina kukwana kufukidzwa, voids, kana isina simba mapoinzi.

Solutions

- Kugadzirira kwepamusoro: Kugadzirira iyo substrate pamusoro kwakakosha kuti uwane kunamatira kwakanaka. Nzvimbo yacho inofanira kunge yakachena, yakaoma, uye isina zvinosvibisa zvakaita semafuta nemarara. Pre-kurapa iyo substrate nevanonamatira vanosimudzira inogona zvakare kuvandudza kubatana.

- Yakakodzera tooling dhizaini: Dhizaini inofanirwa kufunga nezvezvinhu zvinoshandiswa uye chikamu geometry kudzivirira warping uye kuve nechokwadi chekuyerera kwakanaka kwezvinhu. Kushandisa yakasarudzika maturusi, senge ekuisa molding, inogona zvakare kunatsiridza kusimba kwechikamu uye simba.

- Kusarudzwa kwezvinhu: Zvishandiso zvinoshandiswa mukuwedzeredza zvinofanirwa kuenderana nekuwana yakanaka bonding uye kudzivirira warping. Kushandisa zvinhu zvine zvakafanana thermal kuwedzera coefficients kunogona kuderedza kushushikana kwechikamu panguva yekuumbwa.

- Kupatsanura mutsara dhizaini: Paunenge uchigadzira chigadzirwa, zvakakosha kuti utarise mutsara wekuparadzanisa kuti uve nechokwadi chekusimba kwayo. Kushandisa mitsara yekuparadzana yakatenderedzwa kunokurudzirwa zvakanyanya kudzivirira kushushikana mupfungwa.

- Injection molding process optimization: Kugadzirisa maitiro kunogona kuvandudza kuyerera kwezvinhu uye kudzivirira voids kana isina simba mapoinzi. Kudzora tembiricha, kudzvanywa, uye kumhanya kwejekiseni kwakakosha kuti uwane mhedzisiro yakanaka.

Nhepfenyuro Yemberi Yekuwedzeredza: Emerging Trends uye Technologies

Overmolding, maitiro anosanganisira kuumba chimwe chinhu pane chimwe, yanga iri nzira yakakurumbira muindasitiri yekugadzira kwemakumi emakore. Nekudaro, nekufambira mberi mune tekinoroji uye tarisiro huru pakusimudzira, kuwandisa kwave kuita kuwedzera kukurumbira. Pano, isu tichakurukura mafambiro emangwana ekuwedzeredza, kusanganisira ari kubuda maitiro uye matekinoroji.

Trends in Overmolding:

Sustainability: Sustainability chinhu chinonyanya kukosha kumakambani mazhinji, uye kuwandisa kunogona kubatsira kuderedza marara nekuvandudza kushanda zvakanaka mukugadzira maitiro. Kushandisa zvinhu zvakadzokororwa uye biodegradable polymers mukuwedzeredza kuri kuwedzera kuwanda, zvichideredza kukanganisa kwezvakatipoteredza.

Miniaturization: Sezvo tekinoroji ichishanduka, kudiwa kwezvinhu zvidiki, zvakareruka, uye zvakanyanya kuomarara zviri kuwedzera. Kuwedzeredza kunobvumira kugadzirwa kwezvidiki, zvakanyanya kuomarara zvikamu zvinogara uye zvinoshanda, zvichiita kuti ive sarudzo yakanaka kune iyo miniaturization maitiro.

Customization: Vatengi vari kuda zvimwe zvigadzirwa zvemunhu, uye kuwandisa kunopa kugona kugadzirisa zvigadzirwa zvine mavara akasiyana, maumbirwo, uye zvinhu. Sezvo kugadzirisa kunowedzera kuwanikwa uye kuchikwanisika, isu tinotarisira kuti maitiro aya akure.

Tekinoroji muOvermolding:

In-Mold Decoration (IMD): In-Mold Decoration ndiyo tekinoroji inogadzira yakashongedzwa pamusoro panguva yekuwedzeredza. Iyi tekinoroji inogonesa kugadzirwa kwezvigadzirwa zvine akaomesesa dhizaini uye mapatani, zvichiita kuti ive yakanakira maitiro ekugadzirisa.

Isa Molding: Insert molding inosanganisira kuwandisa chikamu chakagara chiripo kana chikamu. Iyi tekinoroji yakanakira miniaturization sezvo ichigadzira zvidiki, zvakanyanya kuoma maficha.

Multi-Shot Overmolding: Multi-shot overmolding inosanganisira kushandisa akawanda zvinhu kugadzira chikamu chimwe chete kana chigadzirwa. Iyi tekinoroji inobvumira zvigadzirwa zvekugadzira zvine akasiyana maumbirwo, mavara, uye zvinhu, zvichiita kuti ive yakanakira maitiro ekugadzirisa.

Co-Injection Molding: Co-injection molding inosanganisira kubaya zvinhu zviviri kana kupfuura muforoma imwe chete. Iyi tekinoroji inobvumira kugadzira zvigadzirwa zvine musanganiswa wezvivakwa, senge simba uye kuchinjika.

Zvakanakira Overmolding:

Yakaderedzwa Marara: Overmolding inobvisa kudiwa kwezvikamu zvakasiyana uye zvikamu, zvichitungamira kune inoshanda uye inogoneka kugadzira maitiro.

Yakavandudzwa Kusimba: Overmolding inopa kuwedzera kusimba uye simba kune zvigadzirwa, zvichiita kuti zvirambe zvichinyanya kupfeka uye kubvaruka.

Zvinodhura-Zvinoshanda: Kuwedzeredza kunogona kuve imwe nzira inodhura kune yechinyakare nzira dzekugadzira, kunyanya kana uchigadzira zvidiki, zvakanyanya kuoma zvikamu.

Kuwedzeredza Masevhisi uye Vanopa: Kusarudza Yakakodzera Partner

Nekudaro, kuwana iyo chaiyo overmolding mupi webasa kunogona kuve kwakaoma, kunyanya kupihwa akasiyana siyana evanopa uye masevhisi aripo. Pano, isu tichakurukura zvinhu zvakakosha zvekufunga nezvazvo pakusarudza overmolding service provider.

Zvinhu Zvokufunga nezvazvo:

Experience: Tsvaga mupi webasa ane rekodhi yakasimbiswa mukuwedzeredza. Tarisa pane portfolio yemupi kuti uone kana vaine ruzivo rwekushanda pamapurojekiti akafanana neako.

Unyanzvi: Ita shuwa kuti mupi anogona kuzadzisa zvaunoda chaizvo, kusanganisira kusarudzwa kwezvinhu, sarudzo dzekugadzirisa, uye huwandu hwekugadzira.

Quality: Hunhu hwakakosha mukuwedzeredza, sezvo kunyangwe zvirema zvidiki zvinogona kutungamira mukukundikana kwechigadzirwa. Tarisa mupi ane yakasimba yemhando yekudzora system yakasimbiswa neakakodzera masangano anodzora.

Mariro: Kuwedzeredza kunogona kudhura, saka kusarudza anokwikwidza mupi wemitengo pasina kukanganisa kunaka kwakakosha.

Kukurukurirana: Tsvaga mupi anokoshesa kutaurirana kwakajeka uye kwakajeka. Mupi wacho anofanira kunge achipindura kumibvunzo yako uye kukuchengetedza iwe uchiziva panguva yese yekugadzira.

Lead Time: Funga nezvenguva yekutungamira yemupi, sezvo kunonoka kunogona kukanganisa chirongwa chako chekugadzira. Ita shuwa kuti mupi anogona kuzadzisa nguva yako yaunoda.

Location: Kusarudza mupi wenzvimbo padyo nebhizinesi rako kunogona kuderedza mutengo wekufambisa uye nguva dzekutungamira.

Mabatiro evatengi: Sarudza mupi anokoshesa basa revatengi uye achashanda newe kugadzirisa chero nyaya.

Vanopa Sevhisi:

Makambani eJekiseni Molding: Makambani mazhinji ekuumba majekiseni anopa masevhisi ekuwedzeredza sechimwe chinopa. Aya makambani ane mukana weruzivo mukuumba jekiseni uye anogona kupa huwandu hwakazara hwesevhisi, kusanganisira kusarudzwa kwezvinhu uye sarudzo dzekugadzirisa.

Makondirakiti Manufacturing Makambani: Makambani ekugadzira makondirakiti anopa masevhisi ekugadzira kune akasiyana maindasitiri. Aya makambani anowanzo kuve neruzivo rwakakura mukuwedzeredza uye anogona kupa zvinodhura mhinduro kune yakakura vhoriyamu yekugadzira inomhanya.

Specialty Providers: Specialty vanopa vanotarisa pane chaiwo maficha ekuwedzeredza, senge tooling kana kusarudzwa kwezvinhu. Ava vanopa vanogona kupa hunyanzvi hunyanzvi hunogona kuve hwakakosha kumapurojekiti akaomarara kana akasiyana.

mhedziso

Overmolding inzira inosiyana-siyana uye inoshanda inogona kusimudzira kushanda kwechigadzirwa, kusimba, uye aesthetics mumaindasitiri akasiyana. Nehuwandu hwezvinhu, matekinoroji, uye mashandisirwo, kuwandisa kunopa mikana yakawanda kune vagadziri kugadzira zvigadzirwa zvemhando yepamusoro zvinosangana nezvinodiwa uye zvido zvevatengi. Vagadziri vanogona kuita sarudzo dzine ruzivo uye kuramba vachikwikwidza mumusika wanhasi nekufunga nezve dhizaini, mutengo, kusimudzira, uye hunyanzvi zvinhu zvekuwedzeredza. Kunyangwe iwe uri mugadziri wechigadzirwa, mainjiniya, kana muridzi webhizinesi, kunzwisisa iyo pfungwa yekuwedzeredza kunogona kukubatsira kuendesa zvigadzirwa zvako kune inotevera nhanho.