Liquid Silicone Rubber (LSR) Injection Molding

Chii chinonzi Liquid Silicone Rubber (LSR) Injection Molding?

Jekiseni molding yeLiquid Silicone Rubber (LSR) inzira inoshandiswa kugadzira zvidimbu zvinobatika, zvinogara muzvikamu zvakakwirira. Munguva yekuita, zvinhu zvakati wandei zvinodikanwa: jekiseni, metering unit, dhiramu rekupa, musanganiswa, muromo, uye mold clamp, pakati pevamwe.

Jekiseni molding yeLiquid Silicone Rubber (LSR) ndiyo yakajairika tekinoroji inoshandiswa kugadzira zvigadzirwa zvakasiyana zvekurapa nemagetsi zvikumbiro, pakati pezvimwe. Pamusoro pezvakazvarwa zvivakwa zvezvinhu, maparamita eiyo maitiro akakosha zvakare. LSR jekiseni molding inzira yakawanda inounzwa.

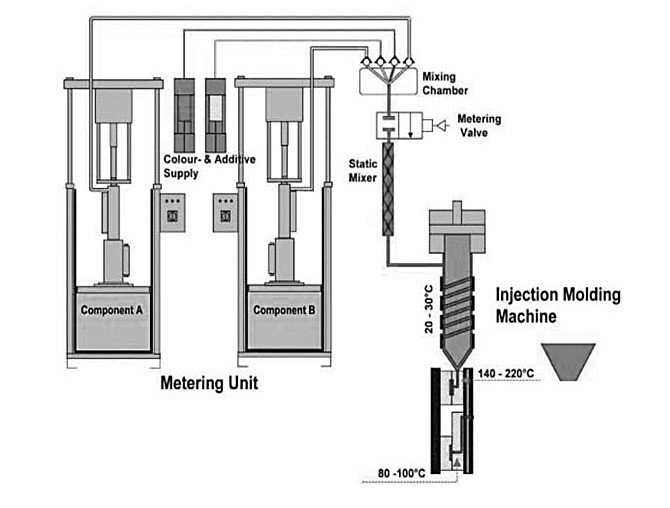

Nhanho yekutanga ndeyekugadzirira kwekusanganiswa. LSR inowanzo ine zvikamu zviviri, pigment, uye additives (mafirita semuenzaniso), zvichienderana nezvinodiwa zvechigadzirwa chekupedzisira. Mune ino nhanho, zvinongedzo zvemusanganiswa zvine homogenized uye zvinogona kusanganiswa neiyo tembiricha inodzikamisa sisitimu yekutonga kurinani kwesilicone tembiricha (ambient tembiricha kana silicone preheating).

Mazuva ano, huwandu hwemashandisirwo ezvigadzirwa zvesilicone rubha huri kuwedzera nekufara, uye LSR jekiseni rekugadzira ibasa rakakosha muindasitiri iyi.

Liquid Silicone Rubber Molding Inoshanda Sei?

LSR kuumbwa kunosiyana zvishoma kubva kune thermoplastic jekiseni molding nekuda kwekushanduka kwayo. Kufanana neyakajairwa aluminium chishandiso, LSR yekuumba chishandiso inogadzirwa uchishandisa CNC machining kugadzira yakanyanya-tembiricha chishandiso chakavakirwa kumirisana neLSR yekuumba maitiro. Mushure mekugaya, chishandiso chinokwenenzverwa neruoko kune zvakatemwa nevatengi, izvo zvinobvumira matanhatu akajairwa epamusoro pekupedzisira sarudzo.

Kubva ipapo, chishandiso chakapedzwa chinotakurwa mune yepamberi LSR-chaiyo jekiseni rekuumba muchina wakanyatsogadzirirwa kudzora kwakaringana saizi yepfuti kuti ibudise zvikamu zvinowirirana zveLSR. PaMold-Kugadzira, zvikamu zveLSR zvinobviswa nemaoko kubva mukuumbwa, sezvo majekiseni mapini anogona kukanganisa chikamu chemhando. LSR zvinhu zvinosanganisira akajairwa silicones uye chaiwo mamakisi kuti akwane akasiyana echikamu mashandisirwo uye maindasitiri sekurapa, mota, uye mwenje. Sezvo LSR iri thermosetting polymer, iyo yakaumbwa inogara zvachose-kana yangoiswa, haigone kunyungudutswa zvakare se thermoplastic. Kana kumhanya kwapera, zvikamu (kana yekutanga sampuli yekumhanya) inoiswa mabhokisi uye inotumirwa nguva pfupi pashure pacho.

Pano ngatizviongorore, kutanga, isu tinofanirwa kutaura nezve yemvura silicone rabha zvinhu, iwo mapoinzi makuru aunofanira kuziva seanotevera:

Liquid silicone rubber (LSR) yakanakisa insulation, yakakodzera yemhando yepamusoro kana yepamusoro-tech plug yemagetsi.

Liquid silicone rubber (LSR) zvinhu zvakakodzerwa kushandiswa mukupisa kwakanyanya kana kwakadzika-tembiricha nharaunda. Iyo yekudzivirira zvivakwa, michina zvivakwa, uye zvemuviri zvimiro zvezvinhu zvinoramba zvisina kuchinjika pa200 ℃ kana zvakaderera se -40 ℃.

Inopikisa gasification uye kuchembera, saka inokodzera kushandiswa kwekunze.

Liquid silicone rubber (LSR) inodzivirira mafuta, inogona kushandiswa muindasitiri yemugodhi wemafuta. Kune mhando mbiri: vertical double slide liquid silicone jekiseni rekuumba muchina, vertical single slide liquid silicone jekiseni muchina, inoshandiswa kugadzira marudzi ese emhando yepamusoro-inodiwa, yakakwirira-chaiyo silicone rubber zvigadzirwa; yakaderera silinda kona jekiseni muchina, ndiko kugadzirwa kweanosanganisa kuturika insulators, Post insulators uye echinyakare modhi yevanosunga.

Zvakanakira zveLSR Injection Molding (LIM).

Pane zvakawanda zvakanakira LSR Injection Molding (LIM). Inofananidzwa nesilicone compression molding.

Iyo yemvura silicone rubber (LSR) zvinhu zvakachengeteka, silicone gel ine chikafu giredhi kana yekurapa giredhi. Iyo LSR jekiseni molding (LIM) ine yakanyanya kurongeka, inogona kugadzira yakanyanya kurongeka silicone rubha zvikamu. Zvakare, ine mutsara wakatetepa wekuparadzanisa uye diki flash.

Zvakanakira LSR akaumbwa zvikamu

Limitless design -Inogonesa kugadzirwa kwechikamu geometri uye tekinoroji mhinduro hazvigoneke neimwe nzira

Inopesana -Inopa iyo yakanyanya kuenderana muhukuru hwechigadzirwa, humbowo uye huwandu hwemhando

kwakachena -Silicone ndeimwe yeakanyanya kuyedzwa biomaterials ane nhoroondo refu yekushandiswa zvakachengeteka

Nomazvo -Isina mwenje, isina tsvina dhizaini madhizaini ezvikamu zvinorema kubva pa0.002 magiramu kusvika kumazana akati wandei magiramu.

Kuvimbika -Kushandisa tekinoroji yazvino mumakina, zvishandiso uye otomatiki

Quality -Zero-defect quality level kuburikidza ne-in-process controls

zvinenge - Inogonesa kugadzirwa kwepamusoro-soro nekuda kwenguva pfupi kutenderera, kubva kuzviuru zvakati kusvika kumamirioni

zvakachena -Kushandisa nzira dzemazuva ano dzekugadzirisa uye kugadzira muKirasi 7 uye 8 dzimba dzakachena

Cost-inoshanda - Inopa yakaderera Yese Mutengo Wevaridzi (TCO)

LSR Injection Molding

Innovative tekinoroji inosangana nezvinodiwa nevatengi:

Liquid Silicone Rubber (LSR) inogona kugadziriswa mune yemvura jekiseni molding (LIM) maitiro. Iyo yemvura mbishi zvinhu inosanganiswa kubva kuzvikamu zviviri zvakasiyana muchiyero che1: 1 uye jekiseni kuburikidza neinotonhora-inomhanya-system mune inopisa mold. Kurapa kunoitika mukati memasekonzi, ichipa mukana wekumhanyisa bhasikoro uye kugadzirwa kwehuwandu hukuru.

Nekuda kwekushanduka-shanduka mukugadzira uye kushandisa, LSR jekiseni kuumba yakanakira kugadzira yakaoma geometries uye inogona kubatanidza akasiyana anoshanda maficha muchikamu chimwe chete. Inopawo zvakakosha zvakakosha maererano nekuvimbika kwechigadzirwa uye mutengo wakakwana wevaridzi.

LSR Liquid Silicone Rubber Injection Molding Process

DJmolding liquid silicone rabha jekiseni rekugadzira muchina inoita senge thermoplastic jekiseni rekuumba muchina. Mhando mbiri dzemichina dzinoshandisa zvikamu zvemuchina wakafanana, clamp unit, uye jekiseni rejekiseni.

Iyo LSR jekiseni rekugadzira muchina wekunamatira chikamu chakafanana kune yemvura silicone rabha uye thermoplastic michina. Iyo silicone jekiseni yekuumba michina inowanzo ine hydraulic gondohwe uye inogona kunge iine hydraulic toggle. Mimwe michina yakagadzirwa negondohwe remagetsi rine toggle. Kusiyana nemadzvinyiriro akanyanya anoshandiswa kuumba thermoplastic zvikamu, mvura silicone jekiseni kumanikidza iri mukati me800 PSI. Chinangwa chembambo ndechekuve nekuwedzera simba resilicone zvinhu, nekuchengeta mold yakavharwa sezvo silicone inopora.

Iyo jekiseni yejekiseni yesilicone yemvura inotonhorera nemvura yakatonhodzwa mbiya uye nozzle kudzivirira iyo yemvura silicone kubva pakupora. Thermoplastic jekiseni mayunitsi anomhanya nenzira yakapesana, anoda dhiramu nemuromo kuti zvipiswe kusvika 300F kana kudarika kuti zvinhu zvifambe. Liquid jekiseni rekugadzira mayuniti zvakare anomhanya nekudzika kwakadzika (pasi pe1,000 PSI), nepo iwo thermoplastic vamwe vavo vanomhanya kumakumi ezviuru zvePSI.

Liquid silicone inowanzo kupihwa mu5 gallon pail kana 55 galoni zvigubhu. Pane chikamu A uye Chikamu B. Colorants inouya nenzira yekupararira uye inowanzoita 1-3% nekurema kwesilicone yakasanganiswa. Iyo silicone dousing unit inopomba imwe chikamu A silicone uye imwe chikamu B silicone kuburikidza nehosi dzakaparadzana kune iyo static musanganiswa. Mukuwedzera, ruvara runopombwa kune static mixer kuburikidza neimwe hose. Izvo zvikamu zvakasanganiswa zvinobva zvadyiswa muhuro yejojo yekuumbwa kwejekiseni nenzira yevhavha yekuvhara.

DJmolding inyanzvi yemvura silicone rabha (LSR) jekiseni rekuumba uye yemvura silicone rubber zvikamu mugadziri kubva kuchina.

Liquid Silicone Rubber Injection Workshop

LSR Injection Prodcuts QC

LSR Zvigadzirwa

LSR Zvigadzirwa

Yedu liquid silicone rubber molding process inogadzira tsika prototypes uye magumo-ekushandisa ekugadzira zvikamu mumazuva gumi nemashanu kana mashoma. Isu tinoshandisa maaruminiyamu molds ayo anopa mutengo-unoshanda maturusi uye anokurumidza kugadzira kutenderera, uye stock akasiyana mamakisi uye durometers eLSR zvinhu.

Kupa kuenderana kwepamusoro-soro muhukuru, kunyatsoita, huwandu hwese.

Maitiro edu akazara eLiquid Silicone Rubber molding inotsamira pakubatana nevatengi kugadzira zvigadziriso zvakavakirwa pane zvakasarudzika uye zvinodiwa.

Liquid Silicone Rubber (LSR) Injection Molding inzira yekugadzira inosanganisira jekiseni remvura silicone rabha muforoma kugadzira zvigadzirwa zvakasiyana. LSR chinhu chakasiyana-siyana chave kuwedzera mukurumbira nekuda kwezvakasiyana zvivakwa, zvinosanganisira biocompatibility, kugadzikana kwemafuta, uye makemikari kuramba. Muchikamu chino, tichakurukura mabhenefiti eLSR jekiseni kuumba uye kuongorora akasiyana mashandisirwo eiyi tekinoroji.

Iyo LSR Injection Molding Inoshanda Sei?

LSR (Liquid Silicone Rubber) jekiseni rekugadzira inzira yekugadzira iyo inoburitsa yepamusoro-mhando, chaiyo silicone rubha zvikamu. Inobatsira pakugadzira maumbirwo akaomarara uye magadzirirwo ane ruzivo rwakanyanya uye kuenderana. Maitiro acho anosanganisira kubaya jekiseni resilicone rabha mugomba re mold, richiibvumira kurapa uye kusimba muchimiro chaunoda. Heino pfupiso pfupi yekuti LSR jekiseni molding inoshanda sei:

Kugadzirira Mold: Maitiro anotanga nekugadzira mold. Iyo mold inowanzo umbwa nehafu mbiri, jekiseni divi, uye divi rinosungirirana, rinokwana pamwechete kugadzira gomba resilicone. Mushure mekurapa, mold inocheneswa uye yakaputirwa neanoburitsa mumiriri kuti iite nyore kubvisa chikamu.

Kugadzirira kweSilicone: Liquid silicone rubber chinhu chine zvikamu zviviri zvine base silicone uye mumiririri wekurapa. Izvi zvikamu zvinosanganiswa pamwe chete muchiyero chaicho. Musanganiswa wacho wakasvibiswa kubvisa chero mabhuru emhepo anogona kukanganisa kunaka kwechikamu chekupedzisira.

Jekiseni: Iyo yakasanganiswa uye degassed liquid silicone rubber inoendeswa kune jekiseni unit. Iyo jekiseni unit inopisa zvinhu kune chaiyo tembiricha kuti ideredze viscosity yayo uye zviite nyore kuyerera. Izvo zvinhu zvinobayiwa mugomba remuvhu kuburikidza nemuromo kana sprue.

Kurapa: Kana iyo mvura silicone rabha ikaiswa mugomba reforoma, inotanga kupora. Maitiro ekurapa anowanzo kutangwa nekupisa, kunyangwe mamwe mold anogona kushandisa dzimwe nzira, senge UV mwenje. Iko kupisa kunokonzera iyo silicone kuyambuka-yakabatana uye kusimba, ichigadzira iyo mold cavity. Nguva yekurapa inosiyana zvichienderana nechikamu dhizaini uye silicone zvinhu.

Kutonhorera uye Chikamu Kubvisa: Mushure mekurapa maitiro, mold inotonhodzwa kubvumira iyo silicone kuti igadzirwe zvizere. Nguva yekutonhora inogona kusiyana asi kazhinji ipfupi pane yekurapa nguva. Kana yatonhodzwa, mold inovhurwa, uye chikamu chakapedzwa chinobviswa. Nzvimbo yacho inogona kuda mamwe matanho ekugadzirisa mushure, sekucheka zvinhu zvakawandisa kana kuongorora chero kukanganisa.

LSR jekiseni rekugadzira rinopa akati wandei mabhenefiti, anosanganisira kugadzira akaomarara uye akaomarara geometries, yakanakisa chikamu kuenderana, yakanyanya kurongeka, uye kuramba kutonhora kwakanyanya, makemikari, uye kuchembera. Inowanzoshandiswa mune dzakasiyana siyana zvekurapa, zvemotokari, zvemagetsi, uye zvevatengi zvigadzirwa maindasitiri.

Izvo zvakakosha kuti uzive kuti iyi itsananguro yakapfava yeLSR jekiseni rekuumba maitiro, uye iyo chaiyo mashandiro anogona kusiyana zvichienderana neiyo chaiyo midziyo, zvigadzirwa, uye chikamu chinodiwa.

Zvakanakira LSR Injection Molding

LSR (liquid silicone rubber) jekiseni rekuumba inzira inosiyana-siyana yekugadzira iyo inopa akawanda mabhenefiti pamusoro pechinyakare nzira dzekuumba. LSR jekiseni rekugadzira rinosanganisira kubaya jekiseni remvura silicone muforoma uye nekuriporesa kuita fomu yakasimba kugadzira chigadzirwa chapera. Heano mamwe emabhenefiti makuru eLSR jekiseni molding:

Kururamisa uye Kuenderana

LSR jekiseni rekugadzira rinopa kurongeka kwakasarudzika uye kuenderana mukugadzira yakaoma, yakaoma zvikamu zvine ruzivo rwakanaka. Iyo yemvura silicone inobaiwa muforoma iri pasi pekumanikidzwa kwakanyanya, ichizadza kunyangwe diki diki diki nemakona kugadzira zvikamu zvakaomarara. Pamusoro pezvo, kuumbwa kweLSR kunobvumira kuwirirana kukuru uye kudzokorora, kuderedza mukana wekuremara uye kusawirirana muchigadzirwa chekupedzisira.

High-Quality Parts

LSR jekiseni rekugadzira rinogona kuburitsa emhando yepamusoro, akasimba zvikamu zvinoramba kupfeka uye kubvarura, kupisa, uye UV mwaranzi. LSR zvinhu zvine zvakanakisa zvemuviri zvimiro, zvinosanganisira yakakwirira elasticity, yakaderera compression set, uye kuramba kutonhora kwakanyanya. Izvi zvinoita kuti LSR jekiseni rekuumba ive sarudzo yakanaka yekugadzira zvikamu zvinoda kunyatsojeka uye kusimba, senge michina yekurapa, zvinhu zvemotokari, uye zvigadzirwa zvevatengi.

Mutengo-Unoshanda

LSR jekiseni kuumba inogona kuva inodhura-inoshanda nzira yekugadzira yekugadzira zvikamu zvakakura. Maitiro ekuita kwepamusoro uye kuenderana kunobatsira kuderedza marara uye zvinhu zvakaraswa, nepo kushomeka kwevashandi uye nguva yekugadzira inoshanda inoderedza mutengo wekugadzira. Pamusoro pezvo, zvinhu zveLSR zvine hupenyu hurefu, zvichideredza kudiwa kwekudzokororwa kana kugadziriswa kwezvikamu.

Kusiyanisa

LSR jekiseni rekugadzira rinogona kuburitsa zvikamu zvakasiyana zvine hukuru hwakasiyana, maumbirwo, uye geometries. Iyo yemvura silicone inogona kuumbwa kuita yakaoma uye yakaoma maumbirwo ane ruzivo rwakanatswa, ichiita kuti ive yakanakira kugadzira zvikamu zvinoda kurongeka kwepamusoro uye huchokwadi. Pamusoro pezvo, LSR jekiseni rekugadzira rinogona kuve nemaitiro ane akasiyana madhigirii ekuomarara uye kupfava, zvichibvumira kuti iwedzere kushamisa chigadzirwa dhizaini uye basa rinoshanduka.

Yakaderedzwa Cycle Times

LSR jekiseni molding ine kukurumidza kutenderera nguva, inobvumira kuburitsa huwandu hukuru hwezvikamu munguva pfupi pfupi. Iyo yemvura silicone inobaiwa muforoma uye inoporeswa kuita yakasimba fomu mumasekonzi, zvichiita kuti ive sarudzo yakanaka kune yakakwira-vhoriyamu yekugadzira inomhanya.

Low Waste Generation

LSR jekiseni rekugadzira rinogadzira shoma shoma zvinhu, sezvo iyo silicone yemvura inobaiwa yakananga muforoma uye inorapwa kuti igadzire chimiro chaunoda. Izvi zvinopesana nemamwe maitiro ekugadzira, akadai sekugadzira kana kukanda, izvo zvinogadzira zvakakosha zvimedu. Pamusoro pezvo, zvinhu zveLSR zvinogona kudzokororwa uye kushandiswazve, kuderedza kudiwa kwezvinhu zvitsva uye kuderedza marara.

Kuvandudzwa Kwekuchengetedza

Zvishandiso zveLSR kazhinji hazvina makemikari anokuvadza senge phthalates, BPA, uye PVC, zvichiita kuti zvive zvakachengeteka kune vashandi nevatengi. Pamusoro pezvo, iyo yakaderera-tembiricha maitiro anoshandiswa muLSR jekiseni molding haidi zvinokuvadza zvinonyungudutsa kana mamwe makemikari, kuderedza njodzi yekusangana nezvinhu zvine njodzi.

Yakaderedzwa Nguva Yekutengesa

LSR jekiseni rekugadzira rinogona kuderedza nguva yekutengesa zvigadzirwa zvitsva, sezvo ichibvumira kukurumidza prototyping uye kukurumidza kugadzira inomhanya. Iyo maitiro ekurongeka kwepamusoro uye kuenderana kunobatsira kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa, kuderedza kudiwa kwemataundi akawanda e prototyping uye kuyedzwa.

kushandisa michina

LSR jekiseni rekugadzira rinogona kuve rakanyanya otomatiki, kuderedza kudiwa kwebasa remaoko uye kuderedza kushandiswa kwesimba. Pamusoro pezvo, otomatiki inogona kuvandudza kushanda zvakanaka, kuderedza mutengo wevashandi, uye kugadzirisa kuwirirana uye mhando yechigadzirwa chekupedzisira.

Zvakaipa zveLSR Injection Molding

Nepo LSR (liquid silicone rubber) kuumbwa kwejekiseni kunopa akawanda mabhenefiti, pane zvakare mashoma akashata ekufunga nezvazvo kana uchifunga kushandisa iyi nzira yekugadzira. Heano mamwe eakanyanya kuipa eLSR jekiseni molding:

High Initial Investment

Imwe yezvakanyanya kuipa kweLSR jekiseni molding ndeye yakakwira yekutanga investimendi inodiwa kumisikidza michina uye mold. LSR majekiseni ekuumba majekiseni uye zvishandiso zvinogona kudhura, kunyanya kune tsika mold kana madiki ekugadzira anomhanya. Izvi zvinogona kuita kuti LSR jekiseni rekuumbwa rishaye mutengo-rinoshanda kumakambani ane mabhajeti madiki kana zvigadzirwa zvine mashoma kudiwa.

Kusarudzwa Kwezvinhu Zvishoma

Nepo LSR zvinhu zvinopa zvakanakisa zvemuviri zvimiro, zvinogumira mukusarudza zvinhu. Kusiyana nechinyakare thermoplastics, nhamba shoma yesilicone-yakavakirwa zvinhu inowanikwa kuti ishandiswe muLSR jekiseni kuumba. Kutsvaga zvinhu zvakakodzera zvekushandisa chaiko kana zvigadzirwa zvinogona kuita kuti zviome.

Nguva Yakareba Yekupokana

LSR jekiseni kuumba inoda nguva refu yekurapa pane yechinyakare jekiseni kuumba maitiro. Iyo yemvura silicone inoda nguva yekurapa uye kusimba, izvo zvinogona kuguma kwenguva yakareba yekugadzira nguva uye kuderedzwa kushanda zvakanaka. Pamusoro pezvo, nguva refu yekuporesa inogona kuita kuti kugadzira zvimwe zvikamu zvine yakaoma kana yakaoma geometries zvinonetsa.

Specialized Skill Set Inodiwa

LSR jekiseni rekugadzira rinoda ruzivo rwehunyanzvi uye hunyanzvi, kusanganisira kunzwisisa kwakadzama kwezvivakwa uye maitiro emvura silicone. Izvi zvinogona kuita kuti zviome kumakambani kuwana vashandi vanokwanisa kuti vashande nekuchengetedza michina, kunyanya munzvimbo dzine LSR jekiseni rekugadzira risinganyanyi kuwanda.

Kuumba Matambudziko

LSR jekiseni kuumba inogona kupa mashoma matambudziko anofanirwa kugadziriswa kuti ave nechokwadi chekugadzirwa kwemhando yepamusoro zvikamu. Semuyenzaniso, liquid silicone inogona kuita kupenya kana maburrs, zvichikanganisa kunaka kwechigadzirwa chekupedzisira. Pamusoro pezvo, mold kuburitsa maajenti anogona kudiwa kuti abvise zvikamu kubva muforoma, izvo zvinogona kukanganisa kupera kwechigadzirwa chekupedzisira uye michina.

Yakaganhurirwa Surface Inopedza

LSR jekiseni rekugadzira rinogumira maererano nekupedza kwepamusoro, sezvo liquid silicone isingaenderane nemamwe machira kana kupera. Izvi zvinogona kuita kuti kuwana inodiwa inoyevedza kana inoshanda zvivakwa kune chaiwo zvigadzirwa kana maapplication kunetsa.

Zvishoma Muvara Sarudzo

LSR jekiseni kuumba zvakare inogumira mune zvemavara sarudzo, sezvo iyo yemvura silicone zvinhu inowanzo shanduka kana opaque. Nepo mamwe ekuwedzera emavara aripo, anogona kuve akaoma kubatanidza mune izvo pasina kukanganisa chimiro chemuviri kana kuenderana kwechigadzirwa chekupedzisira.

Inogona Kusvibisa Chikamu

LSR jekiseni rekugadzira rinogona kupa njodzi yekusvibiswa kana midziyo kana mold zvisina kuchengetedzwa zvakakwana kana kucheneswa. Kusvibiswa kunogona kukanganisa chimiro chekupedzisira chechigadzirwa, zvichikonzera kukanganisa kana kutadza nekufamba kwenguva.

Kurongeka uye Kururama muLSR Injection Molding

Kurongeka uye kurongeka zvinhu zvakakosha zveLSR (Liquid Silicone Rubber) jekiseni rekuumbwa, iro rinogadzira emhando yepamusoro silicone yerubha zvikamu zvine kushivirira kwakasimba uye zvakatemwa zvakatemwa. Heano zvimwe zvinhu zvakakosha izvo zvinopa kurongeka uye kurongeka muLSR jekiseni kuumba:

- Mold Dhizaini uye Kuvaka: Iyo mold chinhu chakakosha cheLSR jekiseni rekuumba maitiro, sezvo ichitarisa chimiro chekupedzisira uye zviyero zvechikamu. Iyo mold inofanirwa kugadzirwa uye kuvakwa chaizvo kuti ive nechokwadi chekuti chikamu chekupedzisira chinosangana nezvinodiwa. Iyo mold inofanirwa kugadzirwa yemhando yepamusoro uye yakavakirwa kune yakasimba kushivirira kuderedza zvikanganiso uye kuve nechokwadi.

- Injection Unit Kudzora: Iyo jekiseni unit inodzora kuyerera kweiyo liquid silicone rubber mu mold. Kunyatso kudzora kweiyo jekiseni unit kwakakosha kuti uwane yakarurama uye inowirirana zvikamu. Iyo jekiseni yuniti inofanirwa kuverengerwa uye kudzorwa kuti ive nechokwadi chekuti zvinhu zvakapinzwa mugomba rekuumbwa nekumhanya chaiko, kudzvanywa, uye vhoriyamu.

- Kudzora Kudzora: Kudzora tembiricha chinhu chakakosha muLSR jekiseni rekuumba maitiro, sezvo inokanganisa viscosity yezvinhu uye nguva yekurapa. Tembiricha inofanira kunyatsodzorwa kuti ive nechokwadi chekuti zvinhu zvinoyerera zvakanaka muforoma uye kuti kurapa kunoitika pamwero chaiwo.

- Hunhu Hwezvinhu: Hunhu hwezvinhu zveLSR hwakakosha kuti uwane kurongeka uye kurongeka muchikamu chekupedzisira. Kuti uve nechokwadi chekurapa kwakakodzera uye kuenderana, zvinhu zvacho zvinofanirwa kunge zvisina kusvibiswa uye zvakasanganiswa kune reshiyo chaiyo.

- Post-Processing: Kumashure-kugadzirisa matanho akadai sekucheka uye kuongorora kwakakosha kuti uwane kunyatso uye nekurongeka muLSR jekiseni molding. Chikamu chinofanirwa kuchekwa kusvika pachiyero chakakodzera uye kuongororwa kuti pane kuremara kana kusakwana.

LSR jekiseni rekugadzira rinopa yakanakisa kurongeka uye kurongeka, kubvumira kugadzirwa kwezvikamu zvine kushivirira kwakasimba uye zvakatemwa zvakatemwa. Inogona kuburitsa zvikamu zvine hunhu hunoenderana uye kushoma misiyano kubva pachidimbu kuenda kune zvakadzama. Izvi zvinoita kuti ive sarudzo yakanaka yezvishandiso uko kurongeka uye kurongeka kwakakosha, senge mumidziyo yekurapa, zvinhu zvemotokari, uye zvigadzirwa zvemagetsi.

Inokurumidza Kugadzira Nguva

Liquid silicone rubber (LSR) jekiseni rekuumbwa inzira yakakurumbira yekugadzira iyo inogadzira yakakwirira-mhando zvigadzirwa zvesilicone zvine zvinhu zvakanakisa senge makemikari kuramba, tembiricha kuramba, uye biocompatibility. Nekudaro, nguva dzekugadzira dzeLSR jekiseni rekugadzira dzimwe nguva dzinogona kunonoka, izvo zvinogona kunonoka kugadzira uye kuwedzera mutengo. Hedzino dzimwe nzira dzekuvandudza nguva dzekugadzira LSR jekiseni molding:

- Shandisa muchina wekugadzira jekiseni unoshanda: Kusarudza muchina wakakodzera kwakakosha kukurumidza kugadzirwa. Tsvaga chishandiso chinogona kubaya LSR nekukurumidza pasina kupira mhando. Funga kushandisa muchina wekumhanyisa jekiseni, kuderedza nguva yekutenderera uye nekuvandudza kugadzirwa kwakanaka.

- Gadzirisa dhizaini yekuumbwa: Iyo mold dhizaini zvakare chinhu chakakosha chinokanganisa nguva yekugadzira yeLSR jekiseni rekuumbwa. Gadzirisa iyo mold dhizaini kuti ive nechokwadi chekuti LSR inobaiwa zvinobudirira uye zvakafanana. Funga kushandisa mold ine yakakura gedhi saizi yekuvandudza kuyerera kweLSR uye kuderedza kutenderera nguva.

- Shandisa inopisa mumhanyi system: Inopisa mumhanyi system inogona kuvandudza kugona kweLSR jekiseni kuumba nekuchengeta LSR pane yakakodzera tembiricha mukati mekuita jekiseni. Izvi zvinogona kuderedza nguva yekutenderera uye kuvandudza kunaka kwechigadzirwa chekupedzisira.

- Preheat the LSR: Preheating the LSR before jekiseni kunogonawo kubatsira kuderedza nguva yekugadzira. Preheating iyo LSR inogona kuvandudza kuyerera kwayo uye kuderedza iyo jekiseni nguva, zvichitungamira kukurumidza kutenderera nguva uye nekuvandudza kugona.

- Deredza nguva yekurapa: Nguva yekurapa yeLSR inogona kuderedzwa nekuwedzera tembiricha yekurapa kana kushandisa inokurumidza kurapa mumiriri. Nekudaro, zvakakosha kuchengetedza kunaka kwechigadzirwa chekupedzisira uchidzikisa nguva yekurapa.

Mutengo-Unobudirira Manufacturing

Liquid silicone rubber (LSR) jekiseni rekuumbwa inzira yakakurumbira yekugadzira yekugadzira emhando yepamusoro silicone zvigadzirwa. Nekudaro, mutengo weLSR jekiseni rekugadzira unogona kunetseka vagadziri, kunyanya kana vachigadzira huwandu hukuru. Hedzino dzimwe nzira dzekuita LSR jekiseni kuumba zvakanyanya-inodhura:

- Gadzirisa dhizaini yechigadzirwa: Dhizaini yechigadzirwa inogona kukanganisa zvakanyanya mutengo weLSR jekiseni rekuumba. Nekugadzirisa dhizaini, vagadziri vanogona kuderedza huwandu hwezvinhu zvinoshandiswa, izvo zvinogona kudzikisa mutengo wakazara wekugadzira. Pamusoro pezvo, kurerutsa maitiro anogona kuderedza kuoma kwe mold, kuderedza mutengo wekushandisa.

- Shandisa otomatiki maitiro: Kushandisa otomatiki maitiro kunogona kuvandudza kugona kweLSR jekiseni kuumba uye kuderedza mutengo wevashandi. Otomatiki maitiro akadai sekubata marobhoti uye otomatiki kudyisa zvinhu zvinogona kuderedza kutenderera nguva uye kunatsiridza kugadzirwa kwese.

- Shandisa yemhando yepamusoro mold: Iyo yemhando yepamusoro mold inogona kuvandudza kugona kweLSR jekiseni kuumba uye kuderedza marara. Kushandisa mold yakasimba uye yakakwirira-chaiyo inogona kuderedza kudiwa kwekugadzirisa nguva dzose kana kuchinjwa, kuchengetedza mari munguva refu.

- Gadzirisa maitiro ekugadzira: Kugadzirisa maitiro ekugadzira kunogona kuderedza marara uye kunatsiridza kushanda zvakanaka, kuderedza mitengo. Izvi zvinogona kusanganisira optimize jekiseni moldings paramita, senge jekiseni kumhanya, tembiricha, uye kudzvanywa, kudzikisa kutambisa zvinhu uye kuderedza kutenderera nguva.

- Deredza tsvina yezvinhu: Kudzikisa tsvina yezvinhu kunogona kuderedza zvakanyanya mutengo weLSR jekiseni rekugadzira. Izvi zvinogona kuwanikwa kuburikidza nekushandisa chaiyo metering sisitimu yekudzora zvinhu zvinoshandiswa, kuve nechokwadi chekuti mold yakanyatsogadzirwa uye yakagadziridzwa kuti ideredze zvinhu zvakawandisa, uye kudzokorodza zvimwe zvinhu zvekushandisa mune ramangwana.

High-Quality Surface Inopedza

Liquid silicone rubber (LSR) jekiseni rekuumbwa inzira yakakurumbira yekugadzira zvigadzirwa zvemhando yepamusoro-silicone zvine zvimiro zvemhando yepamusoro senge tembiricha kuramba, makemikari kuramba, uye biocompatibility. Pamusoro pezvivakwa izvi, kuwana yepamusoro-yemhando yepamusoro kupedzisa kwakakosha kune akawanda maapplication. Hedzino dzimwe nzira dzekuwana yakakwirira-yemhando yepamusoro pekupedzisira muLSR jekiseni molding:

- Shandisa yemhando yepamusoro mold: Iyo yemhando yepamusoro mold yakakosha kuti uwane yemhando yepamusoro yekupedzisa. Iyo mold inofanirwa kugadzirwa kubva kumhando yepamusoro uye ine yakatsetseka pamusoro pekupedzisira. Pamusoro pezvo, mold inofanirwa kugadzirwa nemhepo yakaringana kudzivirira mabhuru emhepo kubva pakuumbwa, izvo zvinogona kukanganisa kupera kwepamusoro.

- Shandisa yepamusoro-mhando LSR zvinhu: Kushandisa yepamusoro-mhando LSR zvinhu zvinogona zvakare kugadzirisa pamusoro pekupedzisira. Zvinhu zvepamusoro-soro zveLSR zvinogadzirwa kuti zvive nechepasi viscosity, izvo zvinogona kuvandudza kuyerera kwezvinhu uye kuderedza kutaridzika kwekuyerera kwemavara uye kumwe kusakwana.

- Gadzirisa majekiseni ekuumba maparamendi: Kukwiridzira ma paramita akadai setembiricha, kumhanya kwejekiseni, uye kudzvanywa kunogonawo kugadzirisa kupera kwepasi. Iko kumhanya kwejekiseni kunofanirwa kuvandudzwa kudzivirira chero zvinhu zvekuvaka kana kutsika. Tembiricha uye kudzvanywa kunofanirwawo kunyatsodzorwa kudzivirira kushatisa kwezvinhu kana kuputika.

- Shandisa post-molding process: Post-molding maitiro akadai sekucheka, polishing, uye kupeta anogona zvakare kunatsiridza kupera kwepamusoro kwezvigadzirwa zveLSR. Cheka inogona kubvisa chero flash kana yakawandisa zvinhu kubva muchikamu. Kupenya kunogona kupfavisa kusakwana kupi zvako pamusoro. Iyo yekupfekedza inogona kupa imwe nhanho yekudzivirira uye kugadzirisa chimiro chechimiro.

- Ita gadziriso yenguva dzose yemuchina wekuumba jekiseni: Kugara uchigadzirisa kwakakosha kuti uve nechokwadi chekuenderana uye chemhando yepamusoro kugadzirwa. Chigadzirwa chacho chinofanira kucheneswa nguva dzose kudzivirira kusvibiswa, uye molds inofanira kuongororwa zviratidzo zvekusakara kana kukanganisa.

LSR Injection Molding for Medical Application

LSR jekiseni molding inzira yekugadzira inosanganisira jekiseni remvura silicone rabha (LSR) muforoma kugadzira chigadzirwa chekupedzisira. Iyi nzira inoshandiswa zvakanyanya muindasitiri yezvokurapa nekuda kweiyo yakasarudzika midziyo yeLSR, iyo inoita kuti ive chinhu chakakodzera chekushandisa kwekurapa.

LSR ndeye biocompatible uye hypoallergenic zvinhu izvo zvisina makemikari anokuvadza, zvichiita kuti ive yakachengeteka kumidziyo yekurapa uye maimplants. Iyo zvakare inoshingirira kukura kwebhakitiriya uye nyore kuuraya, izvo zvakakosha munzvimbo dzekurapa uko hutsanana uye kutonga kwehutachiona kwakakosha.

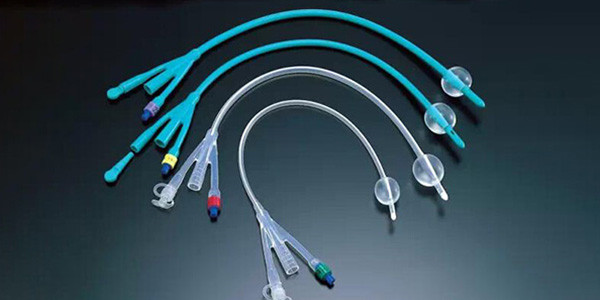

LSR jekiseni molding inzira chaiyo uye inoshanda inobvumira kugadzirwa kwezvakaoma uye zvakaomarara zvikamu zvekurapa zvine kushivirira kwakasimba. Izvi zvakakosha mumashandisirwo ekurapa uko kurongeka uye kurongeka kwakakosha, senge mukugadzira michina inodyarwa senge catheter, pacemaker components, uye artificial joints.

Pamusoro peiyo biocompatibility uye nemazvo, LSR ine yakanakisa mechaniki zvivakwa zvichiita kuti ive yakakodzera zvinhu zvekurapa zvikumbiro. LSR inoshingirira kupfeka uye kubvaruka, inoshingirira tembiricha yakanyanyisa, uye ine yakanakisa magetsi ekudzivirira zvivakwa. Izvi zvinhu zvinoita kuti LSR ive yakakurumbira zvinhu kune akasiyana siyana ekurapa maapplication, anosanganisira:

- Catheters uye tubing: LSR inowanzoshandiswa kugadzira catheter uye tubing nekuda kweiyo biocompatibility, flexibility, uye kink kuramba.

- Midziyo inodyarwa: LSR inowanzo shandiswa kugadzira midziyo inogoneka senge majoini ekugadzira, pacemaker components, uye maturusi ekuvhiya nekuda kwekugara kwayo uye biocompatibility.

- Zvisimbiso zvekurapa uye gaskets: LSR inowanzo shandiswa kugadzira nekuda kwekupokana kwayo nekupisa kwakanyanya uye kugona kuchengetedza zvimiro zvayo nekufamba kwenguva.

LSR jekiseni molding inzira inosiyana-siyana uye inoshanda yekugadzira michina yekurapa uye zvikamu. Hunhu hwayo hwakasiyana hunoita kuti ive chinhu chakakodzera kune akasiyana siyana ekurapa mashandisirwo, uye iko kurongeka kwayo uye kurongeka kwayo kunovimbisa kuti zvigadzirwa zvinosangana nemhando yepamusoro yemhando uye chengetedzo.

Kushandiswa kweLSR muIndasitiri Yemotokari

Liquid Silicone Rubber (LSR) iri kuwedzera kushandiswa muindasitiri yemotokari kune dzakasiyana siyana dzekushandisa nekuda kwezvakasiyana zvivakwa zvinoita kuti ive chinhu chakanakira zvikamu zvemotokari. LSR ndeye synthetic elastomer yakaumbwa kuburikidza nekuumbwa kwejekiseni, ichibvumira kurongeka kwepamusoro uye kurongeka mukugadzira zvinhu zvakaomarara uye zvakaomarara zvemotokari.

LSR ine yakanakisa mechanicha zvivakwa, ichiita kuti ive yakakodzera kune mota zvikamu zvinoda kusimba, yakakwirira-tembiricha kuramba, uye hupenyu hurefu hwebasa. LSR inoshingirira kune abrasion, kupfeka, uye kubvaruka, izvo zvinoita kuti ive yakanakira zvikamu zvemotokari zvinogara zvichinetsana, senge zvisimbiso, gaskets, uye O-mhete.

Imwe yemabhenefiti akanyanya kukosha eLSR muindasitiri yemotokari kugona kwayo kumirisana nekushisa kwakanyanya kusiyana. LSR inogona kushanda nemazvo munzvimbo dzepamusoro-uye dzakaderera-tembiricha, zvichiita kuti ive chinhu chakanakira zvikamu zvemotokari zvakafumurwa kune tembiricha yepamusoro, senge zvikamu zveinjini, masisitimu emhepo, uye hose dzeturbocharger.

Imwe bhenefiti yakakosha yeLSR muindasitiri yemotokari kugona kwayo kupa chisimbiso chakanakisa kurwisa mvura nemagasi. LSR chinhu chinopikisa zvakanyanya chinopa chisimbiso chakavimbika, kunyangwe pasi pekumanikidzwa kwakanyanya, zvichiita kuti ive yakanakira kushandiswa mumotokari gaskets uye zvisimbiso.

LSR zvakare ine yakanakisa magetsi ekudzivirira zvivakwa, izvo zvinoita kuti ive yakakodzera kushandiswa mumagetsi emagetsi muindasitiri yemotokari, senge majoini, masensa, uye masystem ekubatidza. LSR inokwanisa kumira kukwira kwemagetsi uye ine njodzi yakaderera yemagetsi arcing kana mapfupi maseketi, zvichiita kuti ive chinhu chakavimbika chekushandisa magetsi.

Pakazere, LSR ine akawanda mabhenefiti ayo anoita kuti ive chinhu chakanakira zvikamu zvemotokari, zvinosanganisira kusimba, kukwirisa-tembiricha kuramba, zvisimbiso zvekuvharisa zvakanaka, uye kuvharwa kwemagetsi. Kushandiswa kweLSR muindasitiri yemotokari kunotarisirwa kukura mumakore anouya sezvo vagadziri vachitsvaga kuvandudza kuvimbika, kuchengetedzeka, uye kuita kwezvigadzirwa zvavo uku vachideredza mitengo nekuvandudza hunyanzvi hwekugadzira.

Electronics Indasitiri Zvikumbiro zveLSR

Liquid Silicone Rubber (LSR) chinhu chinoshandiswa zvakanyanya muindasitiri yezvemagetsi nekuda kwekugadzikana kwayo kwemafuta, kuramba kwemakemikari, uye zvivakwa zvemagetsi. Inoshandiswa mumhando dzakasiyana siyana senge encapsulation, kuisa chisimbiso, uye potting yemagetsi zvikamu.

Imwe yemashandisirwo ekutanga eLSR muindasitiri yemagetsi iri mukuvharirwa kwezvinhu zvemagetsi, senge akasanganiswa maseketi (ICs), masensa, uye majoini. Encapsulation inodzivirira izvi zvikamu kubva kune hunyoro, guruva, uye zvimwe zvinosvibisa, izvo zvinogona kukonzera ngura uye kusvibisa kuita. LSR chinhu chakanakira encapsulation nekuda kweiyo yakaderera viscosity, yakakura kubvarura simba, uye yakanakisa kunamatira kune akasiyana substrates. Inopawo yakanaka dielectric properties, iyo inokosha mukushandiswa kwemagetsi.

LSR inovharawo zvikamu zvemagetsi kudzivirira kunyorova ingress uye zvimwe zvinosvibisa. Izvo zvinhu zvinogona kuumbwa kuita maumbirwo echinyakare uye saizi kuti ikwane akasiyana emagetsi zvikamu. LSR zvisimbiso zvinowanzo shandiswa munzvimbo dzakaoma, dzakadai semugungwa nemotokari kunyorera, uko dzinofanirwa kumira kutonhora kwakanyanya uye kuratidzwa kwemakemikari.

Potting ndeimwe yakakosha kushandiswa kweLSR muindasitiri yemagetsi. Kuputira kunosanganisira kuzadza gomba rakatenderedza chikamu nechinhu chemvura kuti chidzivirire kubva kune zvakatipoteredza zvinhu zvakadai sekuvhunduka, vibration, uye unyoro. LSR chinhu chakanakira kubikira nekuda kwekuderera kwayo viscosity, iyo inobvumira kuti ifambe zviri nyore kutenderedza maumbirwo akaomarara, uye kugadzikana kwayo kwepamusoro kwekushisa, iyo inovimbisa kuti chikamu chinoramba chakadzivirirwa pakupisa kwakanyanya.

LSR inoshandiswawo kugadzira makiyipadhi uye mabhatani, akajairwa zvikamu mumidziyo yemagetsi senge maremote control, Calculator, uye keyboards. Iyo yakanyanya customizable zvinhu inogona kuumbwa kuita akasiyana maumbirwo uye saizi ine akasiyana mameseji uye kuoma kwemazinga.

Aerospace Industry Applications yeLSR

Liquid Silicone Rubber (LSR) chinhu chinoshandiswa zvakanyanya muindasitiri yezvemuchadenga nekuda kwezvimiro zvayo zvakasiyana, senge kugadzikana kwekupisa kwekupisa, kuramba kwemakemikari, uye yakanakisa michina zvinhu. Inoshandiswa mune dzakasiyana siyana aerospace application sekuisa chisimbiso, bonding, uye potting zvemagetsi zvinhu uye kugadzira gaskets, O-mhete, uye zvimwe zvakakosha.

Imwe yemashandisirwo ekutanga eLSR muindasitiri yezvemuchadenga kuisa chisimbiso uye kubatanidza zvikamu zvendege. Izvo zvinhu zvinogona kuumbwa zviri nyore kuita zvimiro uye saizi yakaoma, zvichiita kuti ive yakakodzera kurongedza nekubatanidza matangi emafuta, zvikamu zveinjini, uye masisitimu emagetsi. LSR inopa yakanakisa kunamatira kune akasiyana substrates uye inogona kumirisana neyakaomarara mamiriro ezvakatipoteredza, senge tembiricha yakanyanyisa uye kuratidzwa kwemakemikari.

LSR inoshandiswawo mukugadzira midziyo yemagetsi mune zvemuchadenga application. Iyo yakaderera viscosity yezvinhu inoibvumira kuyerera zviri nyore kutenderedza maumbirwo akaomarara, ichipa yakanakisa dziviriro yeanonzwa emagetsi zvikamu kubva kune vibration, kuvhunduka, uye zvakatipoteredza zvinhu zvakaita sehunyoro uye tembiricha shanduko.

Chimwe chakakosha kushandiswa kweLSR muindasitiri yeaerospace kugadzira gaskets, O-mhete, uye zvimwe zvikamu zvekuisa chisimbiso. LSR inogona kugadzirwa kuti isangane nezvinodiwa chaizvo, senge tembiricha uye kumanikidza kuramba, uye inowanzo shandiswa mukushanda kwepamusoro-soro uko zvigadzirwa zverabha zvechinyakare zvingave zvisina kukodzera.

Pamusoro pekuisa chisimbiso nekubatanidza zvikumbiro, LSR inoshandiswawo kugadzira zvinhu zvinovheneka ndege, zvakaita semalenzi uye ma diffuser. Iyo yemidziyo yekuona zvimiro inoita kuti ive sarudzo yakanaka kune aya maapplication, ichipa yakanakisa kufambisa kwemwenje, nepo michina yayo inosimbisa kusimba uye kuramba kune zvakatipoteredza zvinhu senge UV radiation uye tembiricha kuchinja.

Chikafu-Giredhi LSR Injection Molding

Chikafu-Giredhi Liquid Silicone Rubber (LSR) chinhu chakasarudzika chinoshandiswa mune jekiseni rekugadzira zvigadzirwa zvinosangana nechikafu, senge midziyo yemukicheni, zvigadzirwa zvevana, uye kurongedza chikafu. Icho chinhu chakanyanya-kuchena zvinhu zvinosangana zvakaomesesa zvimiro zvekuchengetedza chikafu.

Imwe yemabhenefiti ekutanga eChikafu-Giredhi LSR kuramba kwayo kune tembiricha yakakwira, izvo zvinoita kuti ive yakakodzera kushandiswa mumidziyo yekubikira senge spatula, zvipunu, uye mold yekubheka. Inogona kumira tembiricha inosvika 450°F (232°C), ichiita kuti ive yakachengeteka pakubika nekubikisa maapplications.

Chikafu-Giredhi LSR inoshandiswawo kugadzira zvigadzirwa zvevana, senge pacifiers uye mazamu ebhodhoro. Zvigadzirwa izvi zvinofanirwa kusangana nemaitiro akasimba ekuchengetedza kuti ave nechokwadi chekuti zvakachengeteka kuvacheche. LSR chinhu chakanakira maapplication aya nekuda kwekunaka kwayo biocompatibility, kupfava, uye kusimba.

Kumwe kushandiswa kwakakosha kweChikafu-Giredhi LSR kuri mukutakura chikafu. Izvo zvinhu zvinogona kuumbwa kuita akasiyana maumbirwo uye saizi, zvichiita kuti ive yakakodzera kugadzira midziyo yekuchengetera chikafu, ice cube trays, uye zvimwe zvigadzirwa. LSR inoshingirira kumakemikari uye ine yakanakisa yekuvharisa zvivakwa, kuve nechokwadi chekuti zviri mukati mepakeji zvinoramba zviri zvitsva uye zvisina kusvibiswa.

Chikafu-Giredhi LSR inoshandiswawo kugadzira zvigadzirwa zvekurapa senge mazino ekuona zvinhu uye zvigadzirwa zveprosthetic. Iyo yezvinyorwa biocompatibility, kusimba, uye kugona kudzokorodza zvinhu zvakanaka zvinoita kuti ive sarudzo yakanaka kune izvi maapplication.

Pakazere, Chikafu-Giredhi LSR chinhu chakasarudzika chakanakira kugadzira zvigadzirwa zvinosangana nechikafu, senge midziyo yemukicheni, zvigadzirwa zvevana, uye kurongedza chikafu. Kupokana kwayo kune tembiricha yakakwira, biocompatibility, uye yakanakisa yekuisa chisimbiso zvivakwa zvinoita kuti ive chinhu chakanakira izvi maapplication. Izvo zvinhu zvinoshandiswa zvakare kugadzira zvigadzirwa zvekurapa nekuda kweiyo biocompatibility uye kugona kudzokorora zvinhu zvakanaka.

LSR Injection Molding yeZvigadzirwa Zvevana

LSR (Liquid Silicone Rubber) jekiseni rekuumba inzira yekugadzira inoshandiswa kugadzira akawanda ezvigadzirwa zvakagadzirwa nesilicone rabha. Imwe yeanonyanya kufarirwa mashandisirwo eLSR jekiseni molding ari mukugadzira zvigadzirwa zvevana, uye izvi zvinokonzerwa nemabhenefiti akawanda ayo LSR inopa kune zvigadzirwa zvevana, zvinosanganisira kuchengetedzeka, kusimba, uye nyore kuchenesa.

LSR jekiseni rekugadzira rinosanganisira jekiseni remvura silicone rabha muforoma, iyo inobva yaporeswa nekusimbiswa. Iyi nzira inobvumira kugadzirwa kwemaitiro akaoma uye magadzirirwo uye kushandiswa kwemavara akasiyana uye maitiro. Chigumisiro ndicho chigadzirwa chakapedzwa chakapfava, chinoshanduka, uye chinopesana nekupisa nemakemikari.

Imwe yemabhenefiti makuru ekuumbwa kweLSR jekiseni rezvigadzirwa zvevana kuchengetedza. Silicone rabha haina chepfu, hypoallergenic, uye haina makemikari anokuvadza akadai seBPA, phthalates, uye PVC. Izvi zvinoita kuti ive sarudzo yakakurumbira kune zvigadzirwa zvinosangana nevacheche, senge pacifiers, mhete dzemazino, uye mazamu ebhodhoro. LSR jekiseni molding inobvumirawo kugadzirwa kwezvigadzirwa zvisina mipendero yakapinza kana seam zvinogona kukuvadza ganda remwana rakapfava.

Durability imwe bhenefiti yeLSR jekiseni molding. Silicone rabha inoshingirira kupfeka uye kubvaruka, ichiita kuti ive yakakodzera kune zvigadzirwa zvinogara zvichishandiswa kana kubatwa zvine hukasha, senge pacifiers kana mazino mhete. Iyo yakapfava uye inoshanduka chimiro chechinhu chinoitawo kuti isanyanya kutsemuka kana kutsemuka kana yadonha, kuderedza njodzi yekukuvara kumwana.

LSR jekiseni rekugadzira rinopawo kuchenesa kuri nyore, izvo zvakakosha kune zvigadzirwa zvevana zvinofanirwa kucheneswa nguva zhinji. Silicone rabha haina porous uye inogona kucheneswa zviri nyore nesipo nemvura kana kuiswa mudhishi kuti inyatsocheneswa.

LSR Injection Molding yeSporting Goods

LSR (Liquid Silicone Rubber) jekiseni rekuumba inzira yakakurumbira yekugadzira zvigadzirwa zvakasiyana, kusanganisira zvemitambo. LSR jekiseni molding inopa akati wandei mabhenefiti ekugadzira zvinhu zvemitambo, zvinosanganisira kuchinjika, kusimba, uye kuramba kutonhora kwakanyanya uye mamiriro ekunze.

Imwe yemabhenefiti makuru eLSR jekiseni kuumbwa kwezvinhu zvemitambo kuchinjika. Silicone rabha chinhu chakapfava, chinobatika chinogona kuumbwa kuita akasiyana maumbirwo uye magadzirirwo. Izvi zvinobvumira kugadzirwa kwezvinhu zvemitambo zvakasununguka kushandisa uye zvinoenderana nemuviri, senge giya rekudzivirira kana kubata kwemidziyo.

Durability ndeimwe bhenefiti yeLSR jekiseni molding yezvinhu zvemitambo. Silicone rabha inoshingirira kupfeka uye kubvaruka, ichiita kuti ive yakakodzera kune zvigadzirwa zvinogara zvichishandiswa kana kubatwa zvine hukasha, senge mabhora, paddles, kana rackets. Izvo zvinhu zvinogonawo kumira zvakanyanya tembiricha uye mamiriro ezvakatipoteredza, sekuvhenekerwa nechiedza chezuva kana mvura, pasina kushatisa kana kuderera.

LSR jekiseni kuumba zvakare inobvumira kugadzira kwezvigadzirwa zvisingaenderane nekukanganisa uye abrasion. Iyo yakakwira yekubvarura simba uye kureba panguva yekuzorora inoita kuti ive yakanakira kugadzira giya rekudzivirira senge ngowani liner, muromo, uye shin magadhi. Mukuwedzera, LSR jekiseni molding inobvumira kugadzirwa kweasina-kutsvedza nzvimbo kana grips yemidziyo, senge mibato kana racquet grips.

Imwe bhenefiti yeLSR jekiseni rekugadzira zvinhu zvemitambo kugadzira zvigadzirwa zviri nyore kuchenesa nekuchengetedza. Silicone rabha haina porous uye inogona kupukuta nyore nyore nejira nyoro kana kuwachwa nesipo nemvura. Izvi zvinoita kuti ive chinhu chakanakira zvigadzirwa zvinowanzo shandiswa, senge gym midziyo kana yoga mats.

LSR Injection Molding yeZvinhu Zvemhuri

LSR jekiseni molding inzira yekugadzira inoshandisa Liquid Silicone Rubber (LSR) kugadzira zvikamu zvakaumbwa. Maitiro aya akanakira kugadzira zvinhu zvemhando yepamusoro zvemumba zvakaita semidziyo yemukicheni, zvigadzirwa zvevana, uye zvekugezera. LSR jekiseni rekugadzira rinopa zvikomborero zvakati wandei, zvinosanganisira kurongeka kwepamusoro, kusimba, uye kusimba, zvichiita kuti ive sarudzo yakanaka kune zvigadzirwa zvemumba zvinoda kushivirira kwakasimba uye kuita kwepamusoro.

Iyo LSR jekiseni yekuumba maitiro inosanganisira kubaya yemvura silicone zvinhu muforoma. Iyo mold inozopisa, uye iyo yemvura silicone zvinhu inorapa uye inoomesa muchimiro chaunoda. Maitiro acho akanyanya otomatiki, achibvumira kuenderana kugadzirwa kwezvikamu zvine kushivirira kwakasimba uye kupedzisa kwepamusoro kwepamusoro. Iyi nzira inobvumirawo kugadzira yakaoma geometries izvo zvingave zvakaoma kana zvisingagoneke kuwana nemamwe maitiro ekuumba.

Zvinhu zvemumba zvinowanzo gadzirwa pachishandiswa LSR jekiseni molding zvinosanganisira midziyo yemukicheni yakaita sema spatula nezvipunu zvekubikira, zvigadzirwa zvevana zvakadai semapacifiers nemabhodhoro mazamhu, nemidziyo yekugezera yakaita semashowerhead nebhurasho remazino. Zvigadzirwa izvi zvinoda kunyatso kuumbwa kuti zvisangane nekuchengetedza uye kuita zviyero, uye LSR jekiseni rekugadzira rinopa iyo chaiyo uye kuenderana kunodiwa kugadzira zvemhando yepamusoro zvinhu zvemumba zvinosangana nemazinga aya.

Imwe yemabhenefiti ekutanga eLSR jekiseni rekugadzira zvinhu zvemumba ndeyekugara kwayo. LSR zvinhu zvinoshingirira kune tembiricha yakakwira, UV mwaranzi, uye makemikari, zvichiita kuti zvive zvakanaka kune zvekugara kwenguva refu zvigadzirwa. Pamusoro pezvo, zvinhu zveLSR ndezve hypoallergenic, zvichiita kuti zvive zvakachengeteka kushandiswa muzvigadzirwa zvevana uye zvimwe zvinhu zvemumba zvinosangana neganda.

Imwe bhenefiti yeLSR jekiseni kuumba kugona kwayo kugadzira zvikamu zvine yakanakisa yepamusoro kupera. Iyo nzira inobvumira kugadzira maficha ane yakatsetseka, inopenya kupera isingaite kune zvikwambo uye scuffs. Izvi zvinoita kuti LSR jekiseni rekuumba ive sarudzo yakakwana yekugadzira zvinhu zvemumba zvinoda chitarisiko chinoyevedza, semidziyo yekubikira nemidziyo yekugezera.

Kuenzanisa nemamwe Marudzi eRubber Molding

LSR (Liquid Silicone Rubber) jekiseni rekuumbwa inzira yakakurumbira yekugadzira yekugadzira zvakasiyana siyana zvigadzirwa zverabha, uye inopa zvakati wandei zvakanakira pamusoro pemamwe marudzi ekugadzira rabha maitiro. Heano mamwe kuenzanisa pakati peLSR jekiseni kuumba uye akasiyana marudzi ekuumbwa kwerabha:

- Compression Molding: Compression molding inzira yakajairwa yekugadzira zvikamu zvakakura kana zvikamu zvine maumbirwo akaomarara. Mukumanikidza kuumbwa, chiyero chisati chayerwa cherubha chinoiswa muhutu hunopisa, uye kudzvanywa kunoshandiswa kusvikira rabha rapora. Kuenzaniswa neLSR jekiseni rekugadzira, kuumbwa kwekumanikidza inzira inononoka uye inogona kukonzera mutsauko muzvikamu zvezvikamu nekuda kwekusaenzana kwekugovera. LSR jekiseni kuumba, kune rumwe rutivi, inobvumira kunyatso kudzora kwezvikamu zvimiro uye inogona kuburitsa maumbirwo akaoma nekushivirira kwakasimba.

- Transfer Molding: Kutamisa kuumbwa kwakafanana nekumanikidza kuumbwa asi kunosanganisira kushandisa plunger kutamisa rabha kubva muhari jekiseni kuenda kuforoma. Transfer molding inogona kuburitsa zvidimbu zvine hupamhi hwepamusoro uye yakakodzera kugadzira zvikamu zvepakati-kati. Nekudaro, inogona kunonoka uye inodhura kupfuura LSR jekiseni kuumba.

- Jekiseni Molding: Jekiseni molding inzira inosanganisira kubaya jekiseni rabha rakanyungudutswa muforoma pakumanikidzwa kukuru. Jekiseni molding inogona kuburitsa zvikamu nekukurumidza uye nemazvo, asi inogona kunge isina kukodzera kugadzira zvikamu zvine madhizaini akaomarara kana ruzivo. Kuenzaniswa nekuumbwa kwejekiseni, LSR jekiseni kuumba inobvumira kugadzirwa kwezvikamu zvine ruzivo rwakakwana uye dhizaini yakaoma uye mapatani.

- Extrusion: Extrusion inzira inoshandiswa kugadzira zvikamu zvine inoenderera mberi-sectional profiles, senge hoses, seals, uye gaskets. Extrusion inzira inokurumidza uye inodhura, asi inogona kunge isina kukodzera kugadzira maumbirwo akaomarara kana zvikamu zvine kushivirira kwakasimba. LSR jekiseni rekugadzira, kune rumwe rutivi, rinogona kuva nezvikamu zvine zvimiro zvakaoma uye kushivirira kwakasimba, zvichiita kuti ive yakanakira kugadzira zvigadzirwa senge michina yekurapa, zvinhu zvemotokari, uye zvinhu zvevatengi.

Dhizaini Yekufunga kweLSR Injection Molding

Zvakati wandei zvakakosha zvinofanirwa kutariswa paunenge uchigadzira zvikamu zveLSR jekiseni rekugadzira kuti ive nechokwadi chekubudirira kugadzira maitiro. Izvi zvinotariswa zvinosanganisira kusarudzwa kwezvinhu, mold dhizaini, chikamu geometry, uye post-kuumba mashandiro.

Kusarudzwa kwezvinhu chinhu chakakosha kufunga paunenge uchigadzira zvikamu zveLSR jekiseni rekugadzira. Liquid silicone rubber zvinhu zvinouya mune akasiyana durometers, viscosities, uye mavara, uye kusarudza iyo yakakodzera zvinhu kwakakosha kuti uwane inodiwa zvimiro zvechigadzirwa chekupedzisira. Kusarudzwa kwezvinhu kunofanirwa kufunga nezvezvinodiwa zvekushandisa, senge tembiricha kuramba, makemikari kuramba, uye kusimba.

Mold dhizaini ndeimwe yakakosha kufunga kweLSR jekiseni kuumba. Iyo mold dhizaini inofanirwa kuvandudzwa kuti ibudise inodiwa chikamu geometry uye funga nezvekuyerera kwezvinhu, kutonhora, uye ejection. Iyo mold inofanirwa kugadzirwa neakakodzera gating uye venting masisitimu uye iine makabati akakwana kuti iwane yakakwira chiyero chekugadzira.

Chikamu geometry chakakoshawo pakugadzira zvikamu zveLSR jekiseni kuumba. Iyo chikamu geometry inofanirwa kuvandudzwa kuti iwane yekupedzisira chigadzirwa chinodiwa michina zvimiro uye aesthetics. Izvi zvinogona kusanganisira kushandisa dhizaini angles kufambisa ejection kubva muforoma, uchishandisa mbabvu kuwedzera kuomarara, nekuisa gating uye venting masisitimu kukwirisa kuyerera kwezvinhu.

Post-molding mashandiro anofanirwawo kutariswa paunenge uchigadzira zvikamu zveLSR jekiseni rekugadzira. Post-molding mashandiro anogona kusanganisira kucheka, kubvisa, uye sekondari gungano mashandiro. Mashandiro aya anofanirwa kuvandudzwa kuti aderedze marara uye kuderedza mari yevashandi.

Mamwe magadzirirwo ekufunga kweLSR jekiseni molding anogona kusanganisira kushandisa undercuts, kuiswa kwemapini ejector, uye kushandiswa kwemitsara yekuparadzanisa. Izvi zvinhu zvinofanirwa kutariswa panguva yekugadzira dhizaini kuti ive nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa uye chinogona kugadzirwa nemazvo.

Zvakatipoteredza uye Sustainability Benefits yeLSR Injection Molding

LSR jekiseni rekugadzira rinopa akati wandei kwezvakatipoteredza uye kusimudzira mabhenefiti pamusoro pechinyakare maitiro ekugadzira, zvichiita kuti ive sarudzo inokwezva kumakambani ari kutsvaga kudzikisa iwo ecological tsoka.

Imwe yemabhenefiti ekutanga ezvakatipoteredza eLSR jekiseni kuumba ndeye yakaderera tsvina chizvarwa. Maitiro acho anoburitsa marara mashoma, sezvo iyo yemvura silicone rabha inobaiwa yakananga muforoma uye inorapwa kuti igadzire chimiro chaunoda. Izvi zvinopesana nemamwe maitiro ekugadzira, akadai sekugadzira kana kukanda, izvo zvinogadzira zvakakosha zvimedu.

LSR jekiseni molding zvakare ine mukana wekudzikisa simba rekushandisa uye greenhouse gasi kubuda. Maitiro acho anogona kuve otomatiki zvakanyanya, kuderedza kudiwa kwebasa remaoko uye kuderedza kushandiswa kwesimba. LSR jekiseni molding inzira yakaderera-yekushisa inoda simba shoma pane mamwe maitiro ekuumba, senge jekiseni kuumba kana kuvhuvhuta. Izvi zvinogona kukonzera kukosha kwekuchengetedza simba uye kuderedzwa kwegreenhouse gasi kubuda.

Imwe bhenefiti yekusimudzira yeLSR jekiseni molding ndiko kugona kushandisa zvakadzokororwa zvinhu. Zvishandiso zveLSR zvinogona kudzokororwa uye kushandiswazve, kuderedza kudiwa kwezvinhu zvitsva uye kuderedza kugadzirwa kwemarara. Pamusoro pezvo, hupenyu hurefu hwezvigadzirwa zveLSR zvinoreva kuti zvinogona kushandiswa zvakare kana kudzokororwa, zvichiwedzera kudzikisa tsvina uye kuwedzera hupenyu hwechigadzirwa.

LSR jekiseni molding inogonawo kuderedza kushandiswa kwemakemikari anokuvadza mukugadzira. Zvishandiso zveLSR kazhinji hazvina makemikari ane muchetura senge phthalates, BPA, uye PVC, zvichiita kuti zvive zvakachengeteka kuvashandi nevatengi. Pamusoro pezvo, iyo yakaderera-tembiricha maitiro anoshandiswa muLSR jekiseni molding haidi zvinokuvadza zvinonyungudutsa kana mamwe makemikari.

Ramangwana reLSR Injection Molding

Ramangwana reLSR jekiseni rekugadzira rakajeka, nemaitiro acho achipa akati wandei mabhenefiti pamusoro pechinyakare nzira dzekugadzira. LSR jekiseni rekugadzira richawedzera kushanda zvakanaka, risingadhure, uye rine hushamwari kwezvakatipoteredza sezvo tekinoroji ichifambira mberi.

Imwe yenzvimbo dzinonyanya kuvimbisa yeramangwana reLSR jekiseni molding ndiko kushandiswa kwekuwedzera kugadzira nzira. Kugadzirwa kwekuwedzera, kunozivikanwawo se 3D kudhinda, kunobvumira kugadzirwa kweakaomesesa geometri uye akagadziridzwa zvikamu zvingave zvakaoma kana zvisingaite kugadzira uchishandisa echinyakare nzira dzekugadzira. Sezvo tekinoroji ichivandudza, LSR jekiseni rekugadzira richawedzera kubatanidzwa nekuwedzera kugadzira, zvichibvumira kuti zvakatonyanya kugadzirwa uye zvigadzirwa zvitsva.

Imwe nzvimbo yekuvandudza mune remangwana reLSR jekiseni molding kushandisa zvinhu zvepamberi. Sezvo zvinhu zvitsva zvichigadzirwa, LSR jekiseni rekugadzira rinogona kutora mukana weayo akasiyana zvivakwa, sekusimudzira kusimba, kuramba tembiricha, kana biocompatibility. Izvi zvinobvumidza kune zvakatonyanya hunyanzvi zvigadzirwa, senge maimplants ekurapa kana yepamusoro-inoshanda maindasitiri zvikamu.

Iko kuenderera mberi kwekubatanidzwa kwe otomatiki uye marobhoti muLSR jekiseni rekugadzira maitiro anogona zvakare kuve akakosha maitiro mune ramangwana. Automation inogona kuvandudza kushanda zvakanaka, kuderedza mutengo wevashandi, uye kugadzirisa kuwirirana uye kunaka kwechigadzirwa chekupedzisira. Sezvo tekinoroji ichivandudza, LSR jekiseni rekugadzira richawedzera otomatiki, nemarobhoti uye hungwaru hwekugadzira huchiita basa rakakosha mukugadzira.

Chekupedzisira, kugadzikana uye mutoro wezvakatipoteredza ungangoramba uri madhiraivha akakosha mune ramangwana reLSR jekiseni rekugadzira. Sezvo vatengi nemabhizinesi vachiwedzera kutarisa kudzikisa marara uye kuderedza maitiro avo ezvakatipoteredza, LSR jekiseni rekugadzira richava sarudzo inotonyanya kutaridzika yekugadzira zvigadzirwa zvemhando yepamusoro zvine yakaderera nharaunda tsoka. Kuvandudzwa kwezvinhu zvinogoneka, kudzokorodza uye kudzoreredza zvinhu, uye kushandisa simba rinogoneka rinogona kuita basa rakakosha mune ramangwana reLSR jekiseni rekuumbwa.

mhedziso:

Mukupedzisa, LSR jekiseni rekugadzira inzira yakavimbika uye inoshanda yekugadzira ine akawanda mabhenefiti kune akasiyana maindasitiri. LSR chinhu chakasiyana-siyana chine akasiyana maitiro ekuita, zvichiita kuti ive yakakodzera kune akawanda maapplication. Nekuenderera mberi kwekufambira mberi muhunyanzvi hweLSR uye kuwedzera kudiwa kwemaitiro ekugadzira akasimba, ramangwana reLSR jekiseni rekugadzira rakajeka.