Thermoplastic Injection Molding

Thermoplastic jekiseni molding inzira yakakurumbira yekugadzira inoshandiswa kugadzira akasiyana epurasitiki zvikamu zvemaindasitiri akawanda. Kuita uku kunosanganisira kunyungudusa maplastic pellets nekuapinza muforoma kuti abudise chimiro chetatu-dimensional. Thermoplastic jekiseni molding inoshanda zvakanyanya uye inodhura-inoshanda kugadzira mavhoriyamu makuru emhando yepamusoro zvikamu zvepurasitiki zvine kushivirira kwakasimba. Iri gwara rakazara rinoongorora zvakasiyana-siyana zve thermoplastic jekiseni molding, kusanganisira zvakanakira uye zvazvakaipira, mhando dze thermoplastics dzinoshandiswa, jekiseni rekuumba maitiro, dhizaini kufunga, uye zvimwe zvakawanda.

Nhoroondo yeThermoplastic Injection Molding

Nhoroondo ye thermoplastic jekiseni kuumba inotenderera pamusoro pezana ramakore rekufambira mberi kwetekinoroji, kusimukira kwezvinhu, uye maindasitiri ekushandisa. Kubva payakatanga yakazvininipisa seye celluloid molding process kusvika kune yazvino hunyanzvi tekinoroji, jekiseni rekugadzira rinoramba riri nzira yakakosha yekugadzira, kutyaira hunyanzvi uye kuumba maindasitiri akasiyana.

- Early Developments:John Wesley Hyatt nemukoma wake Isaiah vakagadzira yekutanga inoshanda jekiseni rekugadzira muchina, vachitsvaga mabviro ekuumbwa kwejekiseni rethermoplastic kumashure kusvika pakupera kwezana ramakore re19. Muna 1872, vakapa patent mudziyo wakashandisa plunger kubaya celluloid mugomba reforoma, kugadzira zvinhu zvakasimba. Kubudirira uku kwakaisa hwaro hwechimanjemanje chekuumba jekiseni.

- Kufambira mberi mune Zvishandiso:Mukutanga kwezana ramakore rechi20, kuunza mapolymer matsva ekugadzira kwakavhura mikana mitsva yekuumba jekiseni. Bakelite, phenolic resin, yakave yakakurumbira zvinhu zvekuumba nekuda kweakanakisa emagetsi ekudzivirira emagetsi. Muma1930s nema1940s, kufambira mberi kwepolymer chemistry kwakatungamira mukuvandudzwa kwemamwe thermoplastics, akadai sepolystyrene uye polyethylene, iyo yakawedzera kuwedzera huwandu hwezvinhu zvakakodzera kuumbwa kwejekiseni.

- Industrial Adoption: Kutorwa kwakapararira kweiyo thermoplastic jekiseni molding yakatanga muma1950s sezvo vagadziri vakaziva kukosha kwayo uye kuita kwakasiyana-siyana. Kuunza michina yekudzvanya yakakwira inobvumirwa kukurumidza kutenderera nguva uye kuwedzera mavhoriyamu ekugadzira. Nekuda kweizvozvo, kusarudzwa kwakasiyana-siyana kwezvigadzirwa zvezvese zvemunhu uye zvemaindasitiri zvakavapo. Izvi zvaisanganisira zvinhu zvemotokari, midziyo yemumba, uye zvekutamba.

- Technology Innovations:Kwemakumi emakore, tekinoroji yekuumba jekiseni yakaramba ichishanduka. Mumakore ekuma1960, michina inodzorwa nekombuta yakabuda, ichigonesa kutonga chaiko pamusoro pemaitiro ekuumba. Kuunzwa kweanopisa mumhanyi masisitimu muma1980s kwakaderedza marara uye kwakavandudza kushanda zvakanaka nekubvisa kudiwa kwevamhanyi nemasprues. Mumakore achangopfuura, otomatiki, marobhoti, uye 3D kufambira mberi kwekudhinda zvakawedzera kushandura indasitiri yekuumba jekiseni, zvichiita kuti dhizaini yakaoma uye kuderedza nguva yekugadzira.

- Sustainability uye Recycling:Nekukura kwekunetseka kwezvakatipoteredza, indasitiri yekugadzira jekiseni yakagamuchira matanho ekusimudzira. Vagadziri vakagadzira bio-based uye recycled thermoplastics, kuderedza kuvimba nefossil-yakavakirwa zvinhu. Pamusoro pezvo, matekinoroji akavandudzwa ekudzokorodza zvakare akagonesa kudzokororwa kwemarara ekupedzisira-mutengi uye epashure-maindasitiri, kuderedza kukanganiswa kwezvakatipoteredza kwekuumbwa kwejekiseni re thermoplastic.

- Ramangwana Tarisiro:Remangwana re thermoplastic jekiseni molding rinotaridzika kuvimbisa. Indasitiri iri kuongorora hunyanzvi hwakadai senge micro-injection molding yezvidiki zvikamu, akawanda-material uye overmolding matekiniki ezvikamu zvakaomarara, uye kubatanidza hungwaru matekinoroji ekutarisa maitiro uye optimization. Uyezve, vatsvakurudzi vanotarisira kufambira mberi kwezvinhu zvinoparara uye kugadzirwa kwekuwedzera kushandura munda, zvichiita kuti jekiseni rive rakasimba uye riite zvakawanda.

Zvakanakira zveThermoplastic Injection Molding

Thermoplastic jekiseni molding inopa akawanda mabhenefiti kune vanogadzira. Inopa dhizaini kuchinjika, ichibvumira kune yakaoma uye yakaoma dhizaini ine akasiyana maficha. Iyo nzira inodhura-inoshanda, ichidzikisa tsvina yezvinhu uye kudzikisa mutengo weyuniti. Thermoplastic jekiseni molding inotsigira akawanda zvinhu, ichipa versatility kune akasiyana maapplication.

- Design Flexibility:Thermoplastic jekiseni molding inobvumira dhizaini yakaoma uye yakaoma ine maficha akaita senge undercuts, madziro matete, uye akasiyana makobvu, achipa vanogadzira rusununguko rwakakura.

- Kubudirira Kwemari: Iyo nzira inoshanda zvakanyanya, inoderedza marara emidziyo uye kuderedza mutengo weyuniti. Kuumba panguva imwe chete yezvikamu zvakawanda uye kutenderera kwekugadzira nekukurumidza kunobatsira kuchengetedza mutengo.

- Material Versatility: Thermoplastic jekiseni molding inotsigira zvakasiyana-siyana zvezvishandiso, zvichiita kuti vagadziri vasarudze yakanyatsokodzera sarudzo yechishandiso chega chega, kusanganisira yakaomarara kana inochinjika, inoonekera kana opaque, uye zvinhu zvinopikisa makemikari.

- Simba uye Kugara:Jekiseni-yakaumbwa thermoplastics inogona kuratidza yakanakisa mechaniki zvivakwa, senge kusimba kwepamusoro, kuoma, uye kukanganisa kuramba. Sarudzo dzekusimbisa, senge girazi kana kabhoni fibers, inowedzera kuwedzera izvi zvivakwa.

- Kuenderana uye Hunhu:Jekiseni molding inovimbisa inowirirana chikamu-kune-chikamu kunaka uye dimensional kurongeka, kuendesa kushivirira kwakasimba uye zvigadzirwa zvakavimbika. Iyo nzira inopawo kutsetseka uye yunifomu kupedzisa kwepamusoro, kubvisa kudiwa kwekuwedzera kupedzisa mabasa.

- Scalability uye Mass Production:Jekiseni molding ino scalable kubva pasi kusvika pakakwirira mavhoriyamu, zvichiita kuti ive yakakodzera kugadzirwa kwehuwandu. Kana vagadziri vangogadzira mold, vanogona kuburitsa huwandu hukuru hwezvikamu zvakafanana zvine misiyano mishoma.

- Kubatanidzwa uye Gungano:Majekiseni-akaumbwa majekiseni anogona kubatanidza akawanda zvikamu muchidimbu chimwe, kuderedza kudiwa kwemamwe magungano maitiro. Kubatanidzwa uku kunowedzera kushanda kwechigadzirwa, kunoderedza nguva yegungano, uye kunoderedza mitengo.

- Sustainability:Indasitiri yekuumba jekiseni iri kuratidza kuwedzera kutarisa kwekusimba. Kuvepo kwezvigadzirwa zvebio-based uye zvakadzokororwa zvinobvumira kugadzira zvigadzirwa zvine hushamwari. Iko kunoshanda kwekushandisa kwezvinhu uye kudzokororwa kweiyo thermoplastics kunobatsira kune yakasvibira yekugadzira maitiro.

Aya mabhenefiti akaita kuti ive nzira yakagamuchirwa yekugadzira yakawanda mumaindasitiri akasiyana, ichipa emhando yepamusoro, inodhura-inoshanda, uye ine hushamwari mhinduro kune dzakaoma chigadzirwa zvinodiwa.

Zvakaipa zveThermoplastic Injection Molding

Nepo thermoplastic jekiseni molding ichipa akawanda mabhenefiti, kune zvakare akati wandei akashata. Vagadziri vanofanirwa kunyatso ongorora zvinhu izvi uye kuzviyera zvichienderana nemabhenefiti ekuona kukodzera kweiyo thermoplastic jekiseni molding kune yavo chaiyo maapplication.

- High Initial Investment: Kumisikidza thermoplastic jekiseni rekuumba mashandiro kunoda kukosha kwekutanga kudyara mukugadzira mold nekugadzira uye kutenga michina yakakosha. Mutengo une chekuita nekugadzira mold uye midziyo inogona kuve yakakura, kunyanya kune yakaoma uye yakaoma dhizaini.

- Dhizaini Zvisingakwanisi: Nepo thermoplastic jekiseni molding inopa dhizaini kuchinjika, zvimwe zvipimo zviripo. Semuenzaniso, kuwana yunifomu yemadziro ukobvu mukati mechikamu chose kunogona kuve kwakaoma, zvichitungamira kune mutsauko mukugovaniswa kwezvinhu uye zvinogona kuitika zvimiro kushaya simba. Pamusoro pezvo, kuvapo kwe undercuts kana yakaoma geometries kungangoda kushandiswa kwemamwe mold maficha kana chechipiri mashandiro, kuwedzera mari uye nguva yekugadzira.

- Nguva Yekutungamira Yakareba:Maitiro ekugadzira nekugadzira mold dzekuumba jekiseni anogona kutora nguva, zvichitungamira kunguva yakareba yekutungamira yekuvandudzwa kwechigadzirwa. Iyo dhizaini iteration process, kugadzirwa kwe mold, uye kuyedzwa kunogona kuwedzera yakakosha nguva kune yakazara kugadzirwa nguva, iyo inogona kunge isiri yakakodzera mapurojekiti ane nguva dzakasimba.

- Zvisungo zvekusarudza zvinhu:Kunyangwe thermoplastic jekiseni rekugadzira richitsigira huwandu hwakawanda hwezvinhu, pane zvimwe zvinogumira uye zvinomanikidza. Zvimwe zvekushandisa zvinogona kunge zvine zvakanangana kugadzirisa zvinodiwa kana kuwanikwa kushoma, zvichikanganisa sarudzo dzekugadzira uye kusarudzwa kwezvinhu zveimwe application.

- Chikamu Chekukura Kugumira:Majekiseni ekuumba emuchina ane saizi mipimo, zvese maererano nehukuru hwemuviri hwechishandiso uye saizi yezviumbwa zvavanogona kugara. Kugadzira zvikamu zvakakura zvinogona kuda michina yakasarudzika kana dzimwe nzira dzekugadzira.

- Environmental Impact:Ipo indasitiri iri kushanda kuti irambe ichienderera mberi, iyo thermoplastic jekiseni rekugadzira ichiri kugadzira tsvina, kusanganisira zvimedu uye sprues. Kurasa kwakaringana uye kudzokororwazve kwezvinhu izvi kunodiwa kuti kuderedze kukanganisa kwezvakatipoteredza.

- Iyo yakaoma yeProcess Optimization:Kuwana yakaringana maparamendi ekuumbwa kweiyo thermoplastic jekiseni inogona kuve yakaoma uye inopedza nguva. Vagadziri vanofanirwa kunyatso kudzora uye kukwidziridza tembiricha, kudzvanywa, kutonhora mitengo, uye nguva yekutenderera kuti ive nechokwadi chekuenderana chikamu chemhando uye kuderedza hurema.

Mhando dzeThermoplastics Inoshandiswa muInjection Molding

Iyi ingori mishoma mienzaniso ye thermoplastics inowanzoshandiswa mukuumba jekiseni. Chinhu chega chega chine zvimiro zvakasarudzika, zvichiita kuti chive chakakodzera kune chaiyo maapplication zvichienderana nesimba, kuchinjika, makemikari kuramba, pachena, uye mutengo. Vagadziri vanofanirwa kufunga nezveizvi zvivakwa uye zvinodiwa pakusarudza yakakodzera thermoplastic yemapurojekiti avo ekuumba jekiseni.

- Polypropylene (PP):Polypropylene ndeye thermoplastic inoshanda zvakasiyana-siyana inowanzoshandiswa mukuumba jekiseni. Iyo inopa yakanakisa makemikari kuramba, yakaderera density, uye yakanaka kukanganisa simba. PP (polypropylene) ine mashandisirwo akasiyana-siyana mukurongedza, zvinhu zvemotokari, midziyo yemumba, uye michina yekurapa.

- Polyethylene (PE):Polyethylene imwe inoshandiswa zvakanyanya thermoplastic mukuumba jekiseni. Inowanikwa nenzira dzakasiyana-siyana, dzakadai sepamusoro-density polyethylene (HDPE) uye yakaderera-density polyethylene (LDPE). PE inopa yakanaka makemikari kuramba, kusimba, uye kuchinjika, ichiita kuti ive yakakodzera mabhodhoro, midziyo, uye pombi.

- Polystyrene (PS):Polystyrene ndeye thermoplastic inoshanda zvakasiyana-siyana inozivikanwa nekujeka kwayo, kusimba, uye kugona. Inowana kushandiswa kwakajairika mukurongedza, zvinhu zvevatengi, uye zvigadzirwa zvinoraswa. PS (polystyrene) inobvumira kukurumidza kugadzirisa uye inopa yakanaka dimensional kugadzikana, asi inogona kunge isina brittle uye inotarirwa nekupwanya kushushikana kwezvakatipoteredza.

- Acrylonitrile Butadiene Styrene (ABS): ABS yakakurumbira thermoplastic inozivikanwa nekunaka kwayo kupikisa uye kusimba. Inobatanidza zvinhu zve acrylonitrile, butadiene, uye styrene kugadzira zvinhu zvakasiyana-siyana zvakakodzera zvikamu zvemotokari, dzimba dzemagetsi, uye matoyi.

- Polyvinyl Chloride (PVC): PVC inoshandiswa nevakawanda thermoplastic inozivikanwa nekunaka kwayo kemikari kuramba, kusimba, uye mutengo wakaderera. Inogona kuve yakaoma kana kuchinjika zvichienderana nekugadzirwa uye zvinowedzera zvinoshandiswa. PVC (polyvinyl chloride) inowana kushandiswa kwakajairwa mukuvaka, kuiswa kwemagetsi, zvigadzirwa zvehutano, uye kurongedza.

- Polycarbonate (PC): Polycarbonate inopenya thermoplastic ine zvinoshamisa maitiro uye yakakwirira kupisa kupisa. Inowana kushandiswa kwakajairika mumashandisirwo anoda kujeka kwemaziso, senge zvinhu zvemotokari, ngowani dzekuchengetedza, uye zviratidziro zvemagetsi.

- Naironi (Polyamide):Nylon ndeye yakasimba uye yakasimba thermoplastic inozivikanwa neayo akanakisa emuchina zvivakwa uye makemikari kuramba. Inowana kushandiswa kwakajairwa mumashandisirwo anoda simba rakawanda, senge zvikamu zvemotokari, zvikamu zveindasitiri, uye zvinhu zvevatengi.

- Polyethylene Terephthalate (PET):PET yakakurumbira thermoplastic yekugadzira mabhodhoro, midziyo, uye zvekurongedza zvinhu. Inopa kujeka kwakanaka, makemikari kuramba, uye zvipingamupinyi zvivakwa, zvichiita kuti ive yakakodzera kune chikafu uye chinwiwa application.

Zvivakwa zveThermoplastics Zvinoshandiswa muJekiseni Molding

Aya maficha e thermoplastics anoita basa rakakosha mukuona kukodzera kwavo kune chaiwo majekiseni ekuumba maapplication. Vagadziri vanofanirwa kutarisisa zvivakwa izvi uye vosarudza yakakodzera thermoplastic zvichienderana nekuita kwaunoda, mamiriro ekunze, uye mutengo zvinodiwa.

- Mechanical Properties:Thermoplastics inoshandiswa mukuumba jekiseni inogona kuratidza zvakasiyana-siyana zvemuchina, zvinosanganisira kusimba kwesimba, kupikisa kupikisa, uye kushanduka kwesimba. Izvi zvivakwa zvinotarisisa kugona kwechinhu kumirisana nemasimba akaiswa uye kusimba kwayo kwese mukushandisa kwakasiyana.

- Chemical Nemishonga:Mazhinji thermoplastics anoshandiswa mukuumba jekiseni ane kurwisa kunoshamisa kumakemikari, zvinonyungudutsa, uye oiri. Ichi chivakwa chakakosha kune maapplication anosanganisira kuratidzwa kune hutsinye nharaunda kana zvinhu zvinoparadza.

- Thermal Stability:Iko kugadzikana kwekupisa kwe thermoplastics kunoreva kugona kwavo kutsungirira tembiricha yakakwira pasina kuderera kwakanyanya. Mamwe ma thermoplastics anoratidza yakanakisa kupisa kupisa, achivabvumira kuchengetedza ma mechanic zvivakwa kunyangwe pakupisa kwakanyanya.

- Electrical Properties:Thermoplastics inoshandiswa mukuumba jekiseni inogona kuva nemagetsi chaiwo emagetsi, anosanganisira kuvharisa magetsi, conductivity, kana simba re dielectric. Izvi zvivakwa zvakakosha kune zvikumbiro mumaindasitiri emagetsi nemagetsi, uko zvinhu zvinofanirwa kupa yakavimbika magetsi kuita.

- Kujeka uye Kujeka:Mamwe thermoplastics, akadai sepolycarbonate uye PET, anopa kujeka uye kujeka kwakanakisa, zvichiita kuti ive yakakodzera kune zvikumbiro zvinoda optical properties. Vagadziri vanowanzo shandisa zvinhu izvi muzvigadzirwa zvakaita semahwindo akajeka, lenzi, uye zviratidziro.

- Flexibility uye Kuoma: Kuchinjika uye kuoma zvinhu zvakakosha zve thermoplastics inoshandiswa mumashandisirwo anoda kukanganisa kuramba uye kusimba. Mamwe thermoplastics, akadai seABS nenylon, anopa kusimba kwakanyanya, achivabvumira kutsungirira zvinodzokororwa zvinodzokororwa pasina kutyora.

- Dimensional Kugadzikana:Dimensional kugadzikana zvinoreva kugona kwe thermoplastic kuchengetedza chimiro nekukura kwayo pasi pemamiriro akasiyana, kusanganisira shanduko yekushisa. Zvishandiso zvine kugadzikana kwakanaka kwedimensional inova nechokwadi chezvikamu zvakaenderana, zvichideredza njodzi yekumisikidza kana kukanganisa.

- Kemikari Kuenderana:Iko kuenderana kwekemikari ye thermoplastics inoreva kugona kwavo kuramba kudzikisira kana kusangana nemakemikari akasiyana siyana, anosanganisira acids, mabhesi, uye zvinonyungudutsa. Kuti ive nechokwadi chekushanda kwakakwana, kusarudza thermoplastic inogona kumirisana neyakajeka kemikari nharaunda yaichasangana nayo mune yakarongwa application kwakakosha.

- Kuwandisa: Thermoplastics ine hukobvu hwakasiyana, hunogona kukanganisa huremu hwavo uye chikamu chese chikamu zvivakwa. Zvinhu zvakaderera-density, senge polyethylene, zvinopa zvigadziriso zvisingaremi, nepo zvakakwirira-density zvinhu, zvakaita sepolypropylene, zvinopa simba rakawedzerwa uye kusimba.

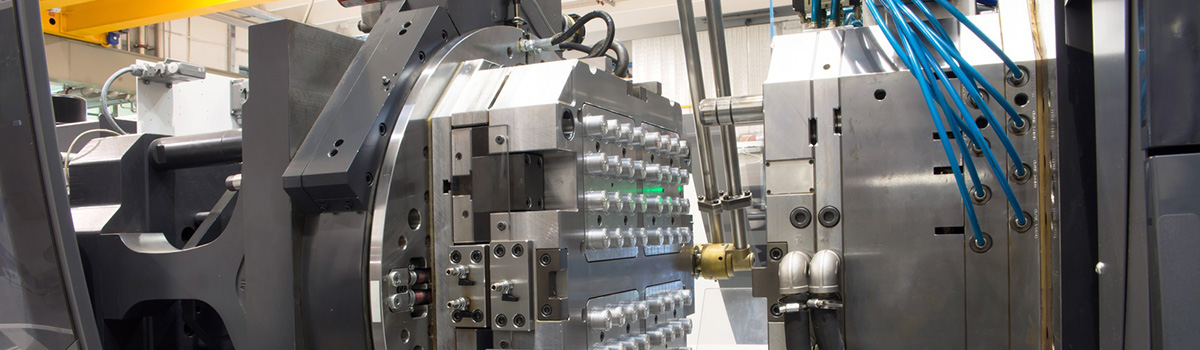

Jekiseni Molding Maitiro: Nhanho-ne-Nhanho

Iyo jekiseni yekuumba maitiro anotevera matanho aya, achibvumira kugadzirwa kwakanaka uye kwakaringana kwepamusoro-mhando thermoplastic zvikamu. Nhanho yega yega inoda kunyatso kudzora uye kutarisa kuti ive nechokwadi chinopindirana chikamu zviyero, zvivakwa zvezvinhu, uye huwandu hwese.

- Mold Dhizaini uye Kugadzirwa: Nhanho yekutanga mukuumbwa kwejekiseni ndiko dhizaini nekugadzira mold. Vagadziri vanofanirwa kugadzira iyo chaiyo uye yakadzama mold dhizaini kuti iwane inodiwa chikamu chakatemwa. Vagadziri vanobva vagadzira mold vachishandisa nzira dzakasiyana siyana, senge CNC kana magetsi ekuburitsa machining (EDM).

- Kugadzirira kwezvinhu: Nhanho inotevera ndeyekugadzirira kana mold yagadzirira. Thermoplastic pellets kana granules inosarudzwa zvichibva pane inodiwa zvinhu zvivakwa uye yakanyungudutswa mune hopper. Vashandi vanobva vadyisa zvinhu mubhodhoro remuchina wekuumba jekiseni, uko unonyungudika uye homogenization.

- Jekiseni:Munguva yechikamu chejekiseni, vashandisi vanobaya thermoplastic yakanyungudutswa mugomba rekuumbwa pasi pekumanikidzwa kukuru. Muchina wejekiseni remuchina unosundira zvinhu zvakanyunguduka nemumuromo uye mumold. Izvo zvinhu zvinozadza mold cavity, kutora chimiro chechikamu chinodiwa.

- Kutonhodza uye Solidification:Mushure mekuzadza mold, vashandi vanobvumira plastiki yakanyungudutswa kuti itonhore uye igosimba. Kutonhodza kwakakosha pakuwana kugadzikana kwedimensional uye kwakaringana kuumbwa kwechikamu. Vashandisi vanogona kudzora maitiro ekutonhodza nekutenderedza chinotonhodza kuburikidza nemachani mukati memukuvhute kana kushandisa marata ekutonhodza.

- Kuvhura Mold uye Ejection:Vashandi vanovhura mold uye vanobvisa chikamu kubva mumhango ye mold kana plastiki yaoma. Iyo ejection system mukati memuchina inoshandisa mapini, ejector mahwendefa, kana mhepo inoputika kubvisa dunhu kubva muforoma. Iyo mold inobva yagadzirira kutenderera kwejekiseni rinotevera.

- Post-Processing: Mushure me ejection, chikamu chinogona kuita post-processing Operations, sekucheka, kubvisa, kana kupera kwepamusoro. Matanho aya anobatsira kubvisa zvinhu zvakawandisa, mipendero yakatsetseka, uye kugadzirisa chimiro chekupedzisira chechikamu.

- Kuongorora kwakanaka: Danho rekupedzisira rinosanganisira kuongorora zvikamu zvakabaiwa zvemhando uye kuona kuti zvinozadzisa zvinodiwa. Matekinoroji akasiyana ekudzora emhando, anosanganisira kuyerwa kwedimensional, ongororo yekuona, uye mashandiro ekuyedza, anogona kushandiswa kuratidza kunaka kwechikamu uye kuperera.

- Kudzokorora uye Kushandisazve Zvinhu:Chero zvakawandisa kana zvimedu zvinogadzirwa panguva yekuumbwa kwejekiseni zvinogona kudzokororwa uye kushandiswa zvakare. Kuderedza kushandiswa kwezvinhu zvitsva zvethermoplastic kunobatsira kuderedza marara uye kuvandudza kuchengetedzwa.

Equipment Inoshandiswa muInjection Molding

Izvi midziyo yemidziyo inofambisa maitiro ekugadzira jekiseni, kubva pakunyunguduka uye kubaya iyo thermoplastic zvinhu kusvika pakuumbwa, kutonhora, uye kuburitsa chikamu chekupedzisira. Kushanda kwakaringana uye kuchengetedzwa kwezvishandiso izvi zvakakosha kuti uwane hunyanzvi, hwemhando yepamusoro jekiseni rekuumba kugadzirwa.

- Jekiseni Molding Machine:Iyo yekutanga midziyo mukuumba jekiseni ine basa rekunyungudutsa iyo thermoplastic zvinhu, kuipinza mu mold, uye kutonga maitiro.

- Mold: Iyo mold, yakasarudzika-yakagadzirirwa kugadzira yaidiwa chimiro uye maficha echikamu chepurasitiki, inosanganisira mahafu maviri, mhango uye musimboti. Vashandi vanoiisa pane clamping unit yemuchina wekuumba jekiseni.

- Hopper:Container inobata thermoplastic material mupellet kana granular form uye inoiisa mudhiramu remuchina wekuumba jekiseni kuti rinyunguduke uye jekiseni.

- Barrel uye Screw: Iyo dhiramu, cylindrical chamber, inonyunguduka uye inoita homogenize thermoplastic zvinhu sezvo screw inotenderera mukati mayo kunyunguduka, kusanganisa, uye kumisa zvinhu.

- Dziya uye Kutonhodza Systems:Majekiseni ekuumba majekiseni ane zvinhu zvekudziya, semagetsi emagetsi kana maheater anoshandisa mafuta anopisa, kusimudza tembiricha yedhiramu, uye kutonhora masisitimu, senge mvura kana kutenderera kweoiri, kutonhodza mold uye kuomesa chikamu chepurasitiki.

- Ejector System:Inobvisa chikamu chakaumbwa kubva mugomba mushure mekusimba, kazhinji uchishandisa ejector mapini, mahwendefa, kana kuputika kwemhepo panguva yekuvhura mold.

- Control System:Inotarisisa uye inodzora akasiyana ma paramita eiyo jekiseni molding process, ichibvumira vashandisi kuseta uye kugadzirisa ma paramita akadai sekumhanya kwejekiseni, tembiricha, kudzvanywa, uye nguva yekutonhora.

Injection Molding Machines: Mhando uye Hunhu

Imwe neimwe mhando yemuchina wekuumba jekiseni ine maitiro ayo uye zvakanakira, zvichibvumira vanogadzira kuti vasarudze yakanyatsokodzera mudziyo wezvavanoda zvekugadzira.

- Hydraulic Injection Molding Machines: Michina iyi inoshandisa hydraulic masisitimu kuti igadzire inodiwa yekupinza purasitiki yakanyungudutswa muforoma. Ivo vanozivikanwa nepamusoro pesimba ravo rekurovedzera, kutonga chaiko, uye kuita zvakasiyana mukubata akasiyana thermoplastics. Michina yeHydraulic inokodzera kugadzirwa kwakakura uye inogona kugamuchira mold dzakaoma.

- Magetsi Majekiseni Anoumba Michina:Michina yemagetsi inoshandisa magetsi servo motors pakushanda kwemuchina, kusanganisira jekiseni, clamping, uye ejector masisitimu. Ivo vanopa chaiyo kutonga, kushanda nesimba, uye nekukurumidza mhinduro nguva kupfuura hydraulic michina. Michina yemagetsi yakanakira kuumba maapplication ayo anoda yakakwira kudzokorora uye kunyatsoita.

- Hybrid Injection Molding Machines:Hybrid michina inosanganisa mabhenefiti eese ari maviri hydraulic nemagetsi zvishandiso. Ivo vanoshandisa musanganiswa we hydraulic uye yemagetsi servo masisitimu kuti vawane yakanyanya kurongeka, kushanda nesimba, uye mutengo-kubudirira. Hybrid michina inokodzera huwandu hwakawanda hwekushandisa, ichipa chiyero pakati pekuita uye mari yekushandisa.

- Michina Yemajekiseni Aviri-Platen: Michina-yeplateti miviri ine dhizaini yakasarudzika ine mahwendefa maviri akapatsanurwa ekusunga mold. Iyi dhizaini inopa kugadzikana kwakawedzera, yakagadziridzwa mold kuwiriranisa uye inobvumira yakakura mold saizi uye yakakwirira clamping masimba. Michina-maplateti maviri akakodzera zvikamu zvakakura uye zvakaoma zvinoda kuumbwa chaiko.

- Multi-Component Injection Molding Machines:Vagadziri vanogadzira michina iyi kugadzira zvikamu zvine akawanda zvinhu kana mavara mune imwechete yekuumba kutenderera. Vane majekiseni akasiyana-siyana uye molds, zvichiita kuti panguva imwe chete jekiseni rezvinhu zvakasiyana. Multi-component michina inopa kushanduka uye kushanda zvakanaka mukugadzira zvikamu zvakaoma zvine maitiro akasiyana.

- Micro-Injection Molding Machines:Yakagadzirirwa chaizvo kugadzira zvikamu zvidiki uye zvakaringana, michina yekugadzira majekiseni madiki inopa yakanyanyisa kurongeka uye nekurongeka. Ivo vanogona kuburitsa zvakaomesesa zvinhu zvine kushivirira kwakasimba uye kushomeka kwekutambisa zvinhu. Magetsi, midziyo yekurapa, uye ma micro-optics anowanzo shandisa micro-jekiseni yekuumba michina.

Mold Dhizaini Mafungiro eInjection Molding

Kungwarira dhizaini yekufunga kwakakosha pakubudirira kwekugadzira jekiseni rekugadzira.

- Chikamu Dhizaini:Iyo mold dhizaini inofanirwa kuenderana nezvinodiwa chaizvo zvechikamu, kusanganisira chimiro chayo, zviyero, uye zvinoshanda. Vagadziri vanofanirwa kunyatso funga maekiseni ekudhirowa, ukobvu hwemadziro, undercuts, uye chero chinhu chinodiwa kuve nechokwadi chekureruka kwejection uye chikamu chemhando.

- Mold Material: Iyo mold zvinhu kusarudzwa kwakakosha pakuwana durability, dimensional kugadzikana, uye kupisa kuramba. Zvakajairika mold zvinhu zvinosanganisira simbi alloys, aruminiyamu alloys, uye simbi yemidziyo. Sarudzo yezvinhu zvinoenderana nezvinhu zvakaita sehuwandu hwekugadzira, chikamu chakaoma, uye inotarisirwa hupenyu hwechishandiso.

- Kutonhora System:Kutonhodza kwakanaka kwakakosha kune kwakakodzera chikamu kusimba uye kuderedza kutenderera nguva. Iyo mold dhizaini inofanirwa kubatanidza nzira yekutonhodza kana yekumisikidza yakarongeka kuti ive nechokwadi chekutonhodza mold. Kutonhora kwakakodzera kunoderedza njodzi yewarpage, shrinkage, uye chikamu chakaremara.

- Kutengesa:Kufefetera kwakaringana kunodiwa kubvumira kupukunyuka kwemhepo nemagasi panguva yejekiseni. Kusapinda mhepo kwakakwana kunogona kutungamira kumisungo yegesi, mavanga ekupisa, kana kusakwana kwechikamu kuzadza. Vagadziri vanogona kuwana venting nekubatanidza venting grooves, mapini, kana mamwe maitiro mukugadzira mold.

- Ejection System:Iyo mold dhizaini inofanirwa kusanganisira inoshanda ejection system kuti ibvise zvakachengeteka uye zvinobudirira chikamu chakaumbwa kubva mugomba rekuumbwa. Iyo ejection system inogona kuve ne ejector pini, maoko, kana mamwe maitiro, akamisikidzwa zvine hungwaru kudzivirira kukanganiswa nebasa kana zvakakosha zvinhu.

- Gedhi Dhizaini:Gedhi ndipo panopinda purasitiki yakanyungudutswa mumhango yeforoma. Iyo dhizaini yegedhi inofanirwa kuve nechokwadi chekuzadza kwakaringana chikamu, kuderedza mitsetse yekuyerera, uye kudzivirira nguva isati yakwana kutonhora. Yakajairwa gedhi madhizaini anosanganisira magedhi ekumucheto, tunnel magedhi, uye inopisa mumhanyi masisitimu, zvichienderana nechikamu chinodiwa uye zvinhu zvenyama.

- Mutsara wekuparadzanisa:Iyo mold dhizaini inofanirwa kutsanangudza mutsara wakakodzera wekuparadzanisa, unova mutsara unouya mahafu maviri e mold. Kuiswa kwakaringana kwemutsara kunovimbisa kushomeka kwemwenje uye yekuparadzanisa mutsara kusawirirana uye inofambisa inonyatso gadzira mold.

- Kuchengetedza Mold uye Kushanda: Vagadziri vanofanira kufunga nezvekureruka kwekugadzirisa, kugadzirisa, uye kushandira mold. Zvikamu zveMould zvinofanirwa kuwanikwa nyore nyore pakuchenesa, kuongororwa, uye kutsiviwa. Kubatanidza maficha akadai sekukurumidza-kuchinja anoisa kana modular mold dhizaini inogona kunatsiridza mold service.

Mold Zvishandiso Zvinoshandiswa muInjection Molding

Kudyidzana nenyanzvi dzezvinhu zvekuumbwa uye kufunga nezve izvo zvinodikanwa zvechishandiso chekuumba zvinogona kubatsira kuona iyo yakanyanya kufanira zvinhu kuti uwane yakakwana mold kuita uye chikamu chemhando.

- Steel Alloys: Steel alloys, senge simbi yemidziyo (semuenzaniso, P20, H13) uye simbi isina tsvina, inowanzoshandiswa kugadzira majekiseni ekuumba mold nekuda kwekusimba kwazvo, kuramba kupisa, uye kusapfeka. Izvi zvinhu zvinokwanisa kumira tembiricha yakakwira uye kumanikidza mujekiseni rekuumba maitiro uye zvinopa yakanaka dimensional kugadzikana kwekugadzira emhando yepamusoro zvikamu.

- Aluminium Alloys:Aluminium alloys, akadai se7075 uye 6061, akareruka uye anopa yakanaka madhiraivha ekupisa, zvichiita kuti aenderane ne mold inoda kutonhora kwakanaka. Vagadziri vanowanzo shandisa aluminium molds ye prototyping, yakaderera-vhoriyamu kugadzirwa, kana maapplication uko kudzikisa huremu kwakakosha. Nekudaro, aluminium molds inogona kuve yakaderera kusimba kana ichienzaniswa nesimbi alloys.

- Copper Alloys:Copper alloys, senge beryllium mhangura, inoratidza yakakwirira yekupisa conductivity uye yakanaka machinability. Ivo vanowana kushandiswa mune mold inoda yakanakisa kupisa kupisa kuitira kutonhora kunoshanda. Copper alloys inogona kubatsira kuderedza nguva dzekutenderera nekukasira kubvisa kupisa kubva kune yakaumbwa chikamu, zvichikonzera kukurumidza kusimba.

- Tool Steels:Zvishandiso zvesimbi, zvinosanganisira H13, S7, uye D2, zvakagadzirirwa kushandiswa kwepamusoro-kushanda kwekushandisa. Idzi simbi dzinopa musanganiswa wekusimba kwepamusoro, kuomarara, uye kupfeka kuramba. Masimbi emidziyo anokodzera mold ane mavhoriyamu ekugadzira akakwira, zvinokurisa, kana mamiriro ekuumba anodiwa.

- Nickel Alloys:Nickel alloys, akadai seInconel neHastelloy, anozivikanwa nekusagadzikana kwawo kwekuora, kusimba kwepamusoro-tembiricha, uye kugadzikana kwekupisa. Vagadziri vanoshandisa aya alloys mu molds inobata zvinhu zvinoparadza kana zvinoda kuramba kutonhora kwakanyanya uye hukasha hwekuumba nharaunda.

- Composite Materials:Zvinhu zvakaumbwa, senge mapurasitiki akasimbiswa kana macomposites ane simbi inoiswa, dzimwe nguva anoshandiswa kune chaiwo ekuumba maapplication. Zvinhu izvi zvinopa kuenzana kwezvivakwa, senge simba repamusoro, kugadzikana kwekupisa, uye kuderedzwa uremu. Composite molds inogona kuva inodhura-inoshanda dzimwe nzira kune chaiyo kugadzirwa zvinodiwa.

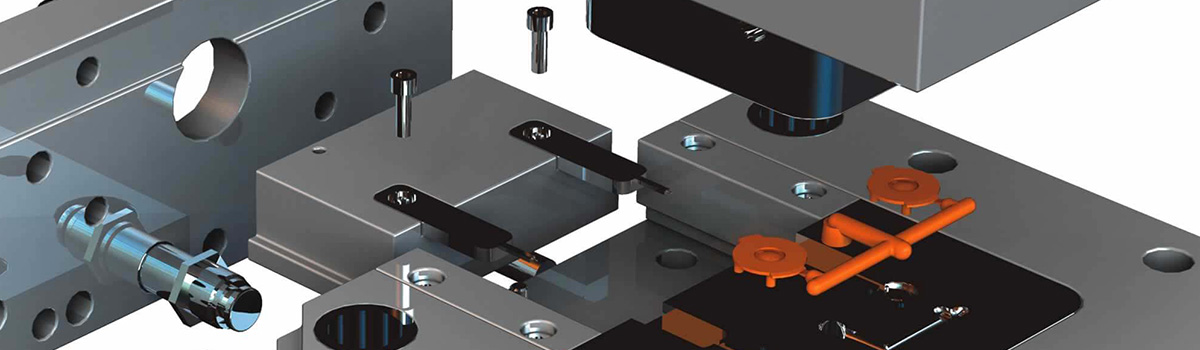

Mhando dzeJekiseni Molds

Jekiseni molding inosiyana-siyana uye inoshandiswa zvakanyanya kugadzira maitiro ezvikamu zvepurasitiki.

- Two-Plate Mold:Iyo mbiri-plate mold ndiyo inonyanya kuzivikanwa mhando yejekiseni mold. Inosanganisira mahwendefa maviri, ndiro yegomba, uye core plate, iyo inoparadzanisa kuti ibvumire kubuda kwechikamu chakaumbwa. Iyo paniti ndiro ine mhango yedivi re mold, nepo core plate inogara iyo yepakati side. Vagadziri vanoshandisa maviri-plate molds yekugadzira huwandu hwakasiyana hwezvikamu nekuda kwemaitiro avo ari nyore.

- Three-Plate Mold:Iyo yechitatu-plate mold ishanduro yepamusoro yembiri-plate mold. Inosanganisira imwe ndiro, mumhanyi, kana sprue plate. Iyo inomhanya ndiro inogadzira nzira yakaparadzana yesprue, vanomhanya, uye magedhi, zvichibvumira kubviswa nyore kwechikamu chakaumbwa. Vagadziri vanowanzo shandisa matatu-plate molds kune akaomesesa masisitimu emagedhi kana kudzivirira gedhi pachimedu chinodiwa.

- Hot Runner Mold:Iyo mumhanyi uye gedhi system inodziya mune inopisa mumhanyi molds, kubvisa kudiwa kwekusimba uye kunyungudukazve kwezvinhu panguva yega yega kutenderera. Iyo inopisa mumhanyi system ine inopisa manifolds uye nozzles inochengetedza yakanyungudutswa yepurasitiki. Anopisa anomhanya molds anopa zvakanakira senge yakaderedzwa kutenderera nguva, yakaderera marara emidziyo, uye yakagadziridzwa chikamu chemhando nekudzikisira magedhi.

- Cold Runner Mold: Cold runner molds ine chinyakare mumhanyi uye gedhi system apo purasitiki yakanyungudutswa inoyerera kuburikidza neinotonhora inomhanya inosimba nekutenderera kwega kwega. Vashandi vanobva vabvisa vamhanyi vakasimba, zvichiita kuti pave nemarara. Vagadziri vanowanzo shandisa maumbirwo akaomarara ekugadzira vhoriyamu yakaderera kana kana mari yezvinhu isinganyanyi kukosha nekuda kwedhizaini yavo yakatwasuka.

- Isa Mold:Isai molds inoisa simbi kana epurasitiki mugomba panguva yekuumba jekiseni. Insert inogona kufanoiswa mu mold kana kuiswa ne otomatiki maitiro. Iyi mold inobvumira kubatanidza zvimwe zvikamu kana kusimbisa zvinhu muchikamu chakaumbwa, kuwedzera kushanda kwayo kana simba.

- Overmold: Kuwedzeredza kunosanganisira kuumba chimwe chinhu pamusoro pechimwe, chinowanzo sunga simbi yepurasitiki substrate ine yakapfava elastomer kana thermoplastic. Iyi nzira inobvumira kugadzirwa kwezvikamu zvine akawanda zvinhu kana maumbirwo mune imwe mold, ichipa yakagadziridzwa kubata, cushioning, kana aesthetic maficha.

Zvinhu Zvinokanganisa Majekiseni Kuumba Mari

Kufunga nezvezvinhu izvi zvinogona kubatsira vagadziri kufungidzira uye kukwidziridza mutengo wekuumba jekiseni, kuve nechokwadi chekuenzanisa pakati pemhando, kushanda nesimba, uye mutengo-unoshanda kune avo chaiwo ekugadzira zvinodiwa.

- Chikamu Kuoma:Iyo yakaoma yechikamu dhizaini inoita basa rakakosha pakuona mutengo wekuumba jekiseni. Akaomesesa geometries, undercuts, madziro akatetepa, kana maficha akaomarara angangoda mamwe maturusi, nyanzvi mold, kana kureba kutenderera, zvichiwedzera mutengo wekugadzira.

- Kusarudzwa Kwezvinhu:Sarudzo ye thermoplastic zvinhu inokanganisa mutengo wekuumba jekiseni. Zvishandiso zvakasiyana zvine mitengo inosiyana pakirogiramu, uye zvinhu zvakaita sekuwanikwa kwezvinhu, zvivakwa, uye zvinodikanwa zvekugadzirisa zvinogona kukanganisa mutengo wezvinhu zvese.

- Tooling uye Mold Dhizaini: Mari yekutanga yekushandisa uye mold dhizaini yakakosha mumitengo yekuumba jekiseni. Zvinhu zvakadai sekuoma kwe mold, huwandu hwema cavities, mold size, uye mold zvinhu zvinobatsira pakushandisa uye kugadzira mold mari. Zvimwe zvakaoma molds kana mold inoda maficha epamberi anogona kuwedzera mari yekumberi.

- Inzwi rekugadzira: Iyo vhoriyamu yekugadzira inokanganisa zvakananga mutengo pachikamu mukuumbwa kwejekiseni. Mabhuku epamusoro anowanzo konzera hupfumi hwemwero, kuderedza mutengo pachikamu. Sezvineiwo, yakaderera-vhoriyamu yekugadzira inomhanya inogona kuunza machaji akakwira nekuda kwekuseta, zvishandiso, uye kutambisa zvinhu.

- Cycle Time: Iyo nguva yekutenderera, iyo inosanganisira kutonhora uye ejection zvikamu, inokanganisa huwandu hwekugadzira uye mutengo wakazara. Nguva refu yekutenderera inokonzeresa kuderedzwa kwekugadzirwa uye kukwira mitengo. Kugadzirisa dhizaini yekugadzira, kutonhora sisitimu, uye maparamendi ekuita anogona kuderedza nguva dzekutenderera uye kugadzirisa kushanda zvakanaka.

- Hunhu hunodiwa:Zvakasimba zvemhando zvinodiwa kana zvitupa zvakati zvinogona kukanganisa mutengo wekuumba jekiseni. Kusangana chaiko kushivirira, kupedzwa kwepamusoro zvinodiwa, kana kumwe kuyedzwa kungangoda zvimwe zviwanikwa, maitiro, kana kuongorora, zvichiwedzera kumutengo wakazara.

- Secondary Operations:Kana zvikamu zvakaumbwa zvinoda post-processing maoperation senge kuungana, kupenda, kana mamwe matanho ekupedzisa, aya mavhiya anogona kuwedzera kune iyo yakazara jekiseni yekuumba mutengo.

- Mutengesi uye Nzvimbo:Sarudzo yejekiseni molding mutengesi uye nzvimbo yavo inogona kukanganisa mutengo. Mutengo wevashandi, kuwanda, kutakura zvinhu, uye mari yekufambisa inosiyana zvichienderana nenzvimbo yemutengesi, zvichikanganisa mutengo wese wekugadzira.

Kudzora Hunhu muJekiseni Molding

Kuita akasimba emhando yekudzora matanho mukati mekuita jekiseni kuumba kunobatsira kuona uye kugadzirisa zvinogona kukanganisa, kutsauka, kana kusawirirana, kuve nechokwadi chekugadzirwa kwezvikamu zvemhando yepamusoro zvinosangana nezvinodiwa nevatengi.

- Process Monitoring: Kuenderera mberi nekutarisisa kweakakosha maitiro paramita, senge kunyunguduka tembiricha, jekiseni kumanikidza, nguva yekutonhora, uye nguva yekutenderera, inovimbisa kuenderana uye kudzokorora muchikamu chekugadzira. Real-time monitoring uye otomatiki masisitimu anogona kuona mutsauko kana kutsauka kubva kumiganho yakatarwa, ichibvumira kugadziridzwa nenguva uye kuchengetedza kugadzikana kwemaitiro.

- Kuongorora uye kuyerwa:Kugara uchiongorora uye kuyerwa kwezvikamu zvakaumbwa zvakakosha kuti uone kurongeka kwedimensional, chikamu chemhando, uye kuomerera kune zvakatemwa. Masevhisi edu anovhara nzira dzakasiyana dzekudzora mhando, sekuyeresa hukuru, kuongorora mhando yepamusoro, kuita ongororo yekuona, uye kuita bvunzo dzinoshanda. Nzira dzakasiyana-siyana dzekuongorora, dzakadai semashini ekuyeresa (CMM) uye optical uye ekuona ekuona masisitimu, anoshandirwa kuongororwa kwakaringana.

- Statistical process Control (SPC): SPC inosanganisira kuunganidza uye kuongorora maitiro data kutarisa uye kudzora jekiseni kuumba mhando. Nzira dzeStatistical, dzakadai sekutonga machati uye kuongorora kugona kwemaitiro, kubatsira kuona mafambiro, kuona misiyano yemaitiro, uye kuona kuti maitiro anoramba ari mukati memiganhu yakatsanangurwa yekudzora. SPC inogonesa kutarisisa kutariswa kwezvinhu uye kufambisa maitiro ekugadzirisa.

- Material Testing: Kuyedza zvigadzirwa, senge thermoplastics, additives, uye colorants, inova nechokwadi chemhando yavo uye kukodzera kwekuumbwa kwejekiseni. Kuyedzwa kwezvinhu kunogona kusanganisira kunyungudika kuyerera index (MFI) kuongororwa, michina zvivakwa, hunhu hwekupisa, uye kuumbwa kwezvinhu. Kuongorora mhando yezvinhu kunobatsira kudzivirira kukanganisa uye kusawirirana muzvikamu zvakaumbwa.

- Tooling Maintenance uye Kuongorora:Kugadzirisa kwakaringana uye kugara uchiongorora majekiseni molds kwakakosha pakuona mhando mukuumba jekiseni. Kugara kucheneswa, kukwirisa, uye kuongorora kwe mold kunobatsira kudzivirira kusakara, kukuvadzwa, kana kushatisa izvo zvinogona kukanganisa chikamu chemhando. Kugadziriswa nenguva kana kutsiva zvinhu zvakasakara kana zvakakuvadzwa mold kwakakosha kuti uchengetedze kuita kwakafanana kwekuumba.

- Zvinyorwa uye Traceability:Kuchengeta akazara magwaro uye traceability rekodhi kwakakosha pakutonga kwemhando mukuumba jekiseni. Izvo zvakakosha kurekodha maitiro paramita, mhedzisiro yekuongorora, ruzivo rwezvinhu, uye chero shanduko kana kugadzirisa kunoitwa panguva yekugadzira. Manyoro akakodzera anogonesa kuteedzera kwezvikamu, kufambisa midzi kuongororwa kwechikonzero, uye inovimbisa kuenderana mumhando.

- Kudzidzira uye Kuvandudza Unyanzvi: Kupa kudzidziswa kwakakwana uye zvirongwa zvekuvandudza hunyanzvi zvevashandisi, matekinoroji, uye vashandi vehutongi hwemhando inosimudzira kunzwisisa kwavo kwemajekiseni ekuumba maitiro, zvinodiwa zvemhando, uye maitiro ekuongorora. Vashandi vakanyatsodzidziswa vanogona kuona kukanganisa, kugadzirisa matambudziko, uye kuita matanho ekugadzirisa zvinobudirira, kuve nechokwadi chekugadzirwa kwemhando yepamusoro.

Yakajairwa Injection Molding Defects uye Maitiro eKuzvidzivirira

Kugara uchiongorora, kutarisa, uye kuongororwa kwemaitiro ekuumba jekiseni uye kugadzirisa kwakaringana uye kugadzirisa kwemidziyo uye mold kunogona kubatsira kuona uye kugadzirisa izvi zvinowanzoitika.

- Sink Marks:Sink marks idepressions kana indentations pamusoro pechikamu chakaumbwa chinokonzerwa nekutonhodza kusina kuenzana kana kupera. Mumwe anofanirwa kufunga nezvekwakakodzera gedhi nzvimbo uye dhizaini, dhizaini yekutonhodza system, uye yunifomu yemadziro ukobvu kugovera kudzivirira sink mamaki. Kuwedzera kudzvanywa kwejekiseni kana kugadzirisa nguva yekutonhora kunogonawo kubatsira kuderedza sink mamaki.

- Warpage:Warpage inoreva deformation kana kukotama kwechikamu chakaumbwa mushure me ejection nekuda kwekutonhodza kusina kuenzana kana kusaririra kushushikana. Kuchengetedza yunifomu yemadziro ukobvu, kushandisa nzira dzekutonhodza dzakakodzera, uye kuve nechokwadi chekuzadzwa kwakaringana uye kurongedza kwe mold kwakakosha kudzivirira warpage. Kukwirisa tembiricha yekuumbwa, kushandisa maekiseni akakodzera, uye kudzora tembiricha yezvinhu uye jekiseni kumhanya kunogona kubatsira kuderedza warpage.

- Flash:Kupenya kunoitika kana zvinhu zvakawandisa zvichiyerera mumutsara wekuparadzanisa, zvichikonzera kutetepa, kusingadiwe fungidziro kana zvimwe zvinhu pachikamu chekupedzisira. Munhu anogona kudzivirira kupenya nekuita dhizaini yakakodzera ye mold, kusanganisira kushandisa simba rakakwana rekusunga, kurongeka chaiko, uye kushandisa nzira dzakakodzera dzekufemesa. Kugadzirisa maparamendi akadai sekumanikidza jekiseni, tembiricha, uye nguva yekutenderera kunoderedza flash.

- Short Shot:Kurumidza kupfura kunoitika kana iyo jekiseni isingazadze mold, zvichikonzera chikamu chisina kukwana. Sarudzo yakafanira yezvinhu, kuve nechokwadi chekunyungudika kwakaringana tembiricha uye viscosity, uye kuchengetedza yakakodzera jekiseni kudzvanywa uye nguva zvakakosha kuti udzivise mafoto mapfupi. Pamusoro pezvo, kuonesa dhizaini ye mold yeanomhanya akakwana uye saizi yegedhi uye mhepo yakakodzera inogona kubatsira kudzivirira kukurumidza kupfura.

- Weld Lines:Weld mitsetse inoitika kana maviri kana anopfuura akanyungudutswa zvinhu zvinoyerera zvakasangana uye kusimba, zvichikonzera mutsara unooneka kana chiratidzo pane chikamu chepamusoro. Gedhi rakanaka uye dhizaini yekumhanya, yakanyanya kunyunguduka tembiricha, jekiseni kumhanya, uye kugadzirisa kuyerera kwezvinhu uye chikamu geometry inogona kuderedza weld mitsetse. Mold flow analysis uye gedhi rekuisa optimization rinogonawo kubatsira kudzivirira kana kuderedza weld mitsetse.

- Burn Marks:Burn marks idiscolorations kana mavara matema pamusoro pechikamu chakaumbwa chinokonzerwa nekupisa kwakanyanya kana kupisa kwechinhu. Kudzivirira tembiricha yekunyungudika yakanyanyisa, kushandisa nzira dzekutonhodza dzakakodzera, uye kugadzirisa nguva yekutenderera kunogona kubatsira kudzivirira mavanga ekupisa. Kupinda mhepo kwakaringana, dhizaini yakaringana yegedhi, uye kudzora tembiricha yeforoma zvinobetserawo kuderedza mavanga ekutsva.

Post-Molding Operations: Kupedzisa uye Gungano

Mushure mekuumbwa kwejekiseni, zvikamu zvakawanda zvakaumbwa zvinogona kuda kuwedzera kupedzisa uye kushanda kwegungano kuti uwane chigadzirwa chekupedzisira chinodiwa. Aya ma post-molding mashandiro anogona kusanganisira:

- Kugadzira:Bvisa chero chinhu chakawandisa kana kupenya kwakatenderedza chikamu chakaumbwa uchishandisa kucheka kana kucheka maturusi.

- Pamusoro Treatment:Kuvandudza kutaridzika kana kushanda kwechikamu chepamusoro uchishandisa hunyanzvi hwakasiyana sekupenda, kupeta, kana kutumira mameseji.

- Assembly:Kubatanidza zvikamu zvakaumbwa zvakawanda kana kuwedzera zvinhu zvakaita sezvisungo, zvekuisa, kana mavara kuti upedze chigadzirwa chekupedzisira.

- Kuedzwa:Kuongororwa kwechikamu chemhando uye mashandiro kuburikidza neakasiyana nzira dzekuyedza senge dimensional ongororo, kuyedza zvivakwa zvezvinhu, kana kuyedzwa kwekuita.

- Kavha uye Kutakura:Kurongedza kwakaringana uye kunyora kwechigadzirwa chakapedzwa kuti chitumire kune vatengi kana vashandisi vekupedzisira.

Kusarudzwa kwemashure-kuumbwa mashandiro kunoenderana neiyo chaiyo application uye inodiwa yekupedzisira chigadzirwa maitiro. Kudyidzana kwepedyo pakati penyanzvi dzekugadzira jekiseni, kupedzisa uye nyanzvi dzekuunganidza, uye mutengi akakosha kuti uwane iyo inodiwa yakakwana yechigadzirwa mhando uye kushanda. Kuronga kwakaringana uye kubatanidza mashandiro epashure-kuumbwa mukuita kwekugadzira kunogona kubatsira kuve nechokwadi chekugadzirwa kwakanaka uye nekuuya nenguva kwezvigadzirwa zvemhando yepamusoro.

Jekiseni Molding vs. Mamwe Plastic Manufacturing Maitiro

Imwe neimwe yepurasitiki yekugadzira maitiro ine zvakanakira uye zvisingakwanisi, zvichiita kuti ive yakakodzera kune akasiyana maapplication.

- Jekiseni Kuumbwa: Jekiseni molding ibasa rakasiyana-siyana uye rinoshandiswa zvakanyanya kugadzira kugadzira zvikamu zvepurasitiki. Inopa mabhenefiti akadai seyakanyanya kugadzirwa kunyatsoita, chaiyo chikamu kudzokorora, uye kugona kugadzira yakaoma geometries. Jekiseni molding inokodzera kukwirisa-vhoriyamu yekugadzira inomhanya uye inobvumira kushandiswa kwakasiyana-siyana kweiyo thermoplastic zvinhu. Iyo inopa yakanakisa dimensional kurongeka uye kupera kwepamusoro, zvichiita kuti ive yakakodzera kune akasiyana maindasitiri akadai semotokari, zvinhu zvevatengi, uye zvigadzirwa zvekurapa.

- Blow Molding: Blow molding inzira inoshandiswa kunyanya kugadzira mapurasitiki asina maburi, senge mabhodhoro, midziyo, uye zvinhu zvemotokari. Zvinosanganisira kunyungudutsa epurasitiki uye kuipinza mugomba remuvhu, kugadzira chimiro chaunoda. Blow molding inokodzera kugadzirwa kwepamusoro-soro uye inogona kugadzira zvikamu zvakakura, zvisingaremi zvine yunifomu yemadziro ukobvu. Nekudaro, inogumira maererano nekuoma kwechikamu uye kusarudzwa kwezvinhu zvichienzaniswa nekuumbwa kwejekiseni.

- Thermoforming:Thermoforming inzira inoshandiswa kugadzira zvikamu zvepurasitiki nekudziisa thermoplastic sheet uye kuigadzira uchishandisa mold kana vacuum kugadzira. Inowana kushandiswa kwakajairika mukurongedza, zvigadzirwa zvinoraswa, uye zvakakura-zvigadzirwa zvakaita sematireyi nemavharo. Thermoforming inopa inodhura-inoshanda kugadzirwa kwezvikamu zvakakura uye inobvumira kukurumidza prototyping. Nekudaro, ine zvinogumira maererano nekuoma kwechikamu, kusarudzwa kwezvinhu, uye kurongeka kwedimensional zvichienzaniswa nekuumbwa kwejekiseni.

- Extrusion:Extrusion inzira inoenderera yekugadzira epurasitiki profiles, mashiti, machubhu, uye mafirimu. Inosanganisira kunyungudusa resin yepurasitiki uye kuimanikidza kuburikidza nefa kuti igadzire chimiro chaunoda. Extrusion inokodzera kugadzira kureba, kuenderera kureba kwezvigadzirwa zvepurasitiki zvine muchinjiko unowirirana. Nepo extrusion ichipa yakakwira mareti ekugadzira uye mutengo-kushanda, inogumira maererano neakaomesesa chikamu geometries uye chaiyo dimensional kudzora zvichienzaniswa nekuumbwa kwejekiseni.

- Compression Molding:Kuomesa kuumbwa kunosanganisira kuisa pre-yakayerwa huwandu hweiyo thermosetting mugomba rinopisa uye nekuimanikidza pasi pekumanikidzwa kwakanyanya kusvika yapora. Inowana kushandiswa kwakajairwa mukugadzira zvikamu zvine simba repamusoro uye kugadzikana kwedimensional, senge zvinhu zvemotokari uye magetsi ekudzivirira. Compression molding inopa yakanaka chikamu kuenderana, yakakwirira kugadzirwa kwehunyanzvi, uye kugona kushandisa akawanda akasiyana ezvigadzirwa. Nekudaro, inogumira maererano nechikamu chakaoma uye kutenderera nguva ichienzaniswa nekuumbwa kwejekiseni.

Zvishandiso zveThermoplastic Injection Molding

Maindasitiri akasiyana anoshandisa zvakanyanya thermoplastic jekiseni rekuumbwa nekuda kwekusiyana-siyana, kushanda nesimba, uye mutengo-kushanda. Zvimwe zvekushandisa kwe thermoplastic jekiseni molding zvinosanganisira:

- Indasitiri yemotokari: Indasitiri yemotokari inoshandisa zvakanyanya thermoplastic jekiseni rekugadzira zvinhu zvakasiyana siyana, zvinosanganisira mukati nekunze trim, madhibhodhi, mapaneru emagonhi, mabumpers, uye magetsi ekubatanidza. Maitiro acho anobvumira chikamu chaicho kudzokorodza, yakaoma geometries, uye zviremera zvinhu, kuvandudza kushanda kwemafuta uye dhizaini inoshanduka.

- Consumer Goods:Jekiseni molding inowana mashandisirwo akawandisa mukugadzira zvinhu zvevatengi zvakaita semidziyo yemumba, midziyo yemagetsi, midziyo yekurongedza, uye matoyi. Iyo nzira inogonesa kugadzirwa kwakawanda kwezvakagara, zvemhando yepamusoro zvigadzirwa zvine zviyero zvinoenderana uye kupera kwepamusoro. Inobvumirawo kugadzirisa sarudzo uye nekukurumidza chigadzirwa iterations.

- Midziyo yekurapa:Jekiseni molding inoita basa rakakosha muindasitiri yezvokurapa mukugadzira zvakasiyana siyana zvemidziyo, zvinosanganisira majekiseni, zviridzwa zvekuvhiya, zvinoiswa zvinhu, uye masisitimu ekuendesa zvinodhaka. Maitiro acho anovimbisa kugadzirwa kweasina kuchena, chaiyo, uye biocompatible zvikamu zvinosangana nezvinoomesesa zvekutonga zvinodiwa zvebazi rezvehutano.

- Indasitiri yeMagetsi neMagetsi:Indasitiri yemagetsi inoshandisa jekiseni kuumba kugadzira majoini emagetsi, akavharirwa, switch, uye zvimwe zvinhu. Iyo nzira inopa yakakwira dimensional kurongeka, yakanakisa kupedzisa kwepamusoro, uye kugona kubatanidza zvinhu zvakaita sekuisa molding uye overmolding, zvichibvumira kugadzirwa kwakanaka kwemagungano akaomarara emagetsi.

- Packaging Indasitiri:Maindasitiri akasiyana-siyana, anosanganisira echikafu nechinwiwa, emishonga, uye nekuchengeta munhu, anowanzo shandisa jekiseni rekugadzira midziyo yepurasitiki yekurongedza, makepisi, kuvharwa, uye mabhodhoro. Maitiro acho anogonesa kugadzirwa kweakareruka, anogara, uye anoyevedza anoyevedza epakeji mhinduro ane hunyanzvi hwekugadzira mitsetse.

- Indasitiri yeAerospace:Iyo aerospace chikamu inoshandisa jekiseni kuumba yekugadzira isingaremi uye yakakwirira-inoita zvinhu zvakaita semhepo ducts, mabhuraketi, mukati mapaneru, uye zvimiro zvikamu. Maitiro acho anobvumira kushandisa zvigadzirwa zvepamberi uye zvakaomarara chikamu geometries, zvichibatsira mukuderedza uremu uye nekuvandudza kushanda kwemafuta.

Environmental Impact yeThermoplastic Injection Molding

Thermoplastic jekiseni molding inzira yakakurumbira yekugadzira nekuda kwemabhenefiti ayo mazhinji, asi zvakakoshawo kuti titarise maitiro ayo nharaunda. Heano mamwe mazano ekufunga:

- Kubudirira Kwezvinhu:Thermoplastic jekiseni molding inosimudzira kugona kwezvinhu nekuderedza marara. Iyo nzira inoshandisa chaiyo kutonga pamusoro pehuwandu hwezvinhu zvakaiswa mu mold, kuderedza kudiwa kwezvinhu zvakawandisa. Vagadziri vanogona zvakare kushandisa nzira dzekugaya uye kudzokorodza kushandisa zvakare zvimedu kana zvikamu zvakarambwa, zvichiwedzera kuderedza marara.

- Energy Kutora:Vagadziri vanogadzira majekiseni ekuumba majekiseni kuti ashande nesimba, aine mamodheru emazuva ano anosanganisira matekinoroji epamberi senge servo motors uye dhiraivha yekumhanya. Aya maficha anokwenenzvera mashandisirwo esimba nekudzikisira mashandisirwo emagetsi panguva yekuumbwa, zvichikonzera kuderera kwesimba rinodiwa uye kuderedzwa kwezvakatipoteredza.

- Kutakura Kutya:Ndichiri kuderedza marara, vagadziri vanofanirwa kuita nzira dzakafanira dzekutonga marara kubata zvakasara zvinhu, masprues, kana anomhanya. Vagadziri vanogona kumisa zvirongwa zvekudzokorodza kuunganidza uye kushandisa zvakare marara epurasitiki anogadzirwa panguva yekuumbwa kwejekiseni, nekudaro kuderedza marara anotumirwa kunoraswa.

- Kuderedza Emission: Thermoplastic jekiseni molding kazhinji inoburitsa yakaderera emissions pane mamwe maitiro ekugadzira. Vagadziri vanogona kuderedza kuburitswa nekushandisa eco-hushamwari zvinhu, kushandisa simba-inoshanda midziyo, uye kushandisa epamusoro ekubuditsa uye kusefa masisitimu kutora chero zvinobuda zvinoburitswa.

- Sustainable Material Sarudzo:Kusarudzwa kwezvinhu zve thermoplastic zvinogona kukanganisa zvakanyanya kuchengetedzwa kwezvakatipoteredza kwekuumba jekiseni. Kusarudzira biodegradable kana bio-based mapurasitiki, pamwe neanogona kudzokororwa kana kushandiswazve, zvinogona kubatsira kudzikisa iyo yakazara ecological tsoka yemaitiro.

Hupenyu Kutenderera Kufunga: Kufunga nezvese kutenderera kwehupenyu hwechigadzirwa chakaumbwa kwakakosha pakuongorora maitiro ezvakatipoteredza. Munguva yekugadzira uye nhanho dzekusarudza zvinhu, vagadziri vanofanirwa kufunga nezvezvinhu zvakaita sekusimba kwechikamu, kudzokorodza kwacho, uye mukana wekupera-kwehupenyu kurasa kana kushandiswazve.

Ramangwana reThermoplastic Injection Molding

Iyo remangwana re thermoplastic jekiseni rekuumbwa rinotaridzika kuvimbisa, nekuenderera mberi kufambira mberi muhunyanzvi uye nekuwedzera kudiwa kwemhando yepamusoro, zvikamu zvakaringana mumaindasitiri akasiyana. Zvimwe zvezviitiko zvakakosha zvinotarisirwa mumakore anotevera zvinosanganisira:

- Kuwedzera kushandiswa kweautomation uye marobhoti kuvandudza kushanda zvakanaka uye kuderedza mitengo.

- Kuedza kwakanangana nekugadzira zvinhu zvitsva uye maitiro ekuvandudza chikamu chekuita uye kugonesa maapplication matsva.

- Iko kukura kutorwa kwemaitiro akasimba, sekushandisa zvinhu zvakadzokororwa uye optimize mashandisirwo esimba, kuderedza kukanganiswa kwezvakatipoteredza kwekuumbwa kwejekiseni.

- Kubatanidzwa kukuru kwehunyanzvi hwedhijitari, senge 3D kudhinda uye simulation software, kuvandudza dhizaini nekugadzira maitiro.

Musika wepasi rose wejekiseni wekuumba uri kuwedzera, kunyanya mune hupfumi huri kusimukira, uchitungamirwa nekuwedzera kuri kuda kwezvigadzirwa zvepurasitiki mumaindasitiri akasiyana.

Kusarudza Yakakodzera Injection Molding Partner

Kusarudza jekiseni rakakodzera rekuumba mudiwa kwakakosha pakubudirira kweprojekiti yako. Tora nguva yekuongorora sarudzo dzakawanda, kushanya kwesaiti, uye kuita nhaurirano dzakakwana kuti uve nechokwadi chekudyidzana kunoenderana uye kunogara kwenguva refu.

- Unyanzvi uye Zvakaitika:Tsvaga mubatsiri wekuumba jekiseni ane ruzivo rwakakura uye ruzivo muindasitiri. Ivo vanofanirwa kuve nerekodhi rekodhi rekuunza zvigadzirwa zvemhando yepamusoro uye mhinduro kune vatengi muzvikamu zvakasiyana. Funga nezvekunzwisisa kwavo kwezvinhu zvakasiyana-siyana, magadzirirwo ekuumbwa, uye maitiro ekugadzira.

- Kukwanisa Kugadzira: Ongorora kugona kugadzira kweiyo jekiseni molding mudiwa. Ita shuwa kuti vane nzvimbo yakanyatsoshongedzerwa ine michina yemazuva ano uye matekinoroji ekubata zvaunoda purojekiti. Funga nezve kugona kwavo kugadzira, kugona kubata akasiyana mativi saizi uye kuoma, uye kugona kuzadzisa zvaunoda mavhoriyamu ekugadzira uye nguva.

- Quality Assurance:Hunhu hwakakosha mukuumba jekiseni. Ongorora maitiro ekudzora emhando uye zvitupa zveanogona kufambidzana naye. Tsvaga vanobatana vanoteedzera akasimba emhando zviyero, vane yakasimba yekuongorora maitiro, uye ita yakazara bvunzo kuti ive nechokwadi chechikamu chemhando uye kuenderana.

- Dhizaini uye Injiniya Tsigiro:Akavimbika jekiseni rekuumba mudiwa anofanirwa kupa dhizaini nerutsigiro rweinjiniya kukwirisa chikamu chako dhizaini yekugadzira. Ivo vanofanirwa kuve nemainjiniya ane hunyanzvi anogona kupa yakakosha yekuisa pakusarudza zvinhu, mold dhizaini, uye maitiro ekugadzirisa kusimudzira chikamu chemhando uye kushanda nesimba.

- Mutengo Kukwikwidza:Nepo mutengo usingafanire kunge uri iwo wega unosarudza, zvakakosha kuti uongorore mitengo uye kukwikwidza kwemutengo wemudiwa wekuumba jekiseni. Kumbira akadzama makotesheni uye funga nezvemitengo yekushandisa, mutengo wezvinhu, mutengo wevashandi, uye chero mamwe masevhisi avanopa.

- Kukurukurirana uye Kudyidzana:Kukurukurirana kunobudirira nekushandira pamwe kwakakosha pakudyidzana kunobudirira. Ita shuwa kuti mubatsiri wekuumba jekiseni ane nzira dzakanaka dzekutaurirana, anopindura kubvunza kwako, uye anogona kupa anogara achigadziridza chirongwa. Maitiro ekubatana achabatsira kuona kuti tazadzisa zvaunoda uye nekukasira kugadzirisa chero matambudziko.

- Mareferensi eVatengi uye Wongororo:Tsvaga mareferensi evatengi kana verenga wongororo / zvipupuriro kuti uwane ruzivo mune zvakaitika kune vamwe vatengi vane jekiseni rekuumba mudiwa. Kuwana ruzivo urwu kunogona kubatsira kuona kuvimbika kwavo, kukurumidza, uye huwandu hwese hwekugutsikana kwevatengi.

mhedziso

Thermoplastic jekiseni molding inzira inochinja-chinja uye inodhura-inoshanda yekugadzira zvikamu zvepurasitiki muhuwandu hukuru. Kugona kwayo kugadzira maumbirwo akaomarara nehupamhi hwepamusoro uye kuenderana kwave sarudzo yakakurumbira kune akasiyana maindasitiri, anosanganisira emotokari, ekurapa, zvemagetsi, uye zvinhu zvevatengi. Nekunzwisisa zvakasiyana-siyana zve thermoplastic jekiseni molding, kusanganisira zvayakanakira, zvayakaipira, uye dhizaini kufunga, unogona kuita sarudzo ine ruzivo nezve kusarudza akakodzera jekiseni rekuumba mudiwa kune zvaunoda bhizinesi.