Chii chinonzi plastic injection molding

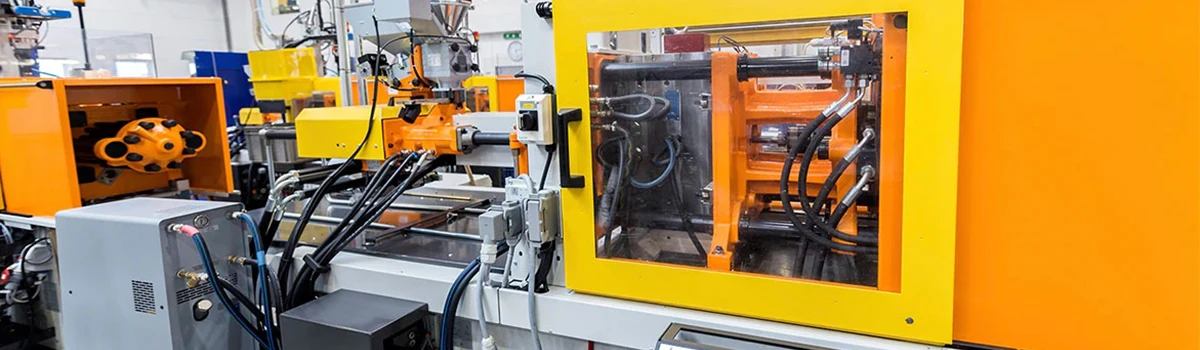

Thermoplastic jekiseni molding inzira yekugadzira yakakwirira-vhoriyamu zvikamu nezvinhu zvepurasitiki. Nekuda kwekuvimbika kwayo uye kuchinjika mumagadzirirwo esarudzo, jekiseni rekugadzira rinoshandiswa mumaindasitiri mazhinji, anosanganisira: kurongedza, mutengi & zvemagetsi, mota, zvekurapa, uye zvimwe zvakawanda.

Jekiseni molding ndeimwe yeanonyanya kushandiswa kugadzira maitiro munyika. Thermoplastics mapolymer anopfava uye anoyerera kana apiswa, uye anoomesa sezvaanotonhorera.

Applications

Jekiseni molding ndiyo yakajairika nzira yemazuva ano yekugadzira zvikamu zvepurasitiki; yakanakira kugadzira mavhoriyamu akakwirira echinhu chimwe chete. Jekiseni molding inoshandiswa kugadzira zvinhu zvakawanda, zvinosanganisira waya spools, kurongedza, mabhodhoro kepu, mota zvikamu uye zvikamu, mitambo yemitambo, mizinga yehomwe, zviridzwa zvemimhanzi, zvigaro nematafura madiki, midziyo yekuchengetera, michina michina, uye zvimwe zvakawanda zvigadzirwa zvepurasitiki.

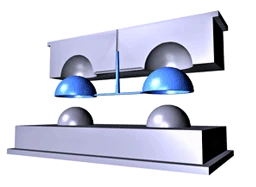

Mold design

Mushure mekunge chigadzirwa chagadzirwa muSoftware senge CAD package, molds inogadzirwa kubva kusimbi, kazhinji simbi kana aluminium, uye nemazvo-akagadzirwa kuti aumbe maficha echikamu chinodiwa. Iyo mold ine zvikamu zviviri zvakakosha, iyo jekiseni mold (A ndiro) uye ejector mold (B ndiro). Plastic resin inopinda mumold kuburikidza nesprue, kana gedhi, uye inoyerera ichipinda mumold kuburikidza nemachani, kana matani, ayo anogadzirwa kumeso kweA uye B mahwendefa.

Injection molding process

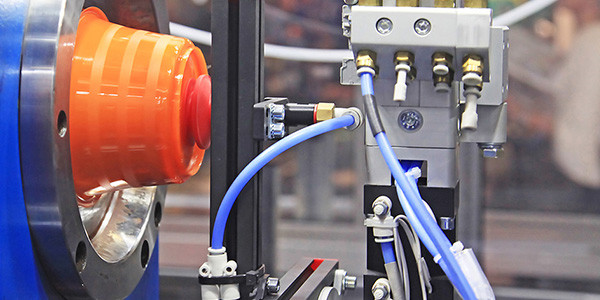

Kana thermoplastics ikaumbwa, kazhinji pelletized mbishi inodyiswa kuburikidza nehopi mudhiramu rinopisa rine screw inodzosera. Iyo screw inoendesa mbishi kumberi, kuburikidza necheki vharuvhu, kwainounganidza kumberi kwescuru kuita vhoriyamu inozivikanwa sepfuti.

Iyo pfuti ndiyo huwandu hweresin inodiwa kuzadza sprue, mumhanyi uye mhango dze mold. Kana zvinhu zvakakwana zvaungana, zvinhu zvinomanikidzwa pakumanikidzwa kukuru uye velocity muchikamu chinoumba mhango.

Injection Molding Inoshanda Sei?

Kana mapurasitiki azadza mold kusanganisira masprues ayo, anomhanya, masuwo, nezvimwewo, mold inochengetwa patembiricha yakatarwa kuti ibvumire kusimba kweyunifomu yechinhu muchikamu chechimiro. Kudzvanywa kwekubata kunochengetwa uku kuchitonhora kune ese kumisa kuyerera mudhiramu uye kuderedza kuderera kwemhedzisiro. Panguva ino, mamwe epurasitiki granules anowedzerwa kune hopper mukutarisira kunotevera kutenderera (kana kupfurwa). Kana yatonhodzwa, platen inovhura uye inobvumira chikamu chapera kuti chibudiswe, uye screw inodzoserwa kumashure zvakare, ichibvumira zvinhu kupinda mudhiramu uye kutanga maitiro zvakare.

Iyo jekiseni molding cycle inoshanda neichi chinoramba chiripo-kuvhara mold, kudyisa / kupisa mapurasitiki granules, kuamanikidza kupinda muforoma, kutonhora iwo muchikamu chakasimba, kuburitsa chikamu, uye kuvhara mold zvakare. Iyi sisitimu inobvumira kukurumidza kugadzirwa kwezvikamu zvepurasitiki, uye zvikamu zvepurasitiki zvinosvika zviuru gumi zvinogona kugadzirwa muzuva rekushanda zvichienderana nedhizaini, saizi, uye zvinhu.

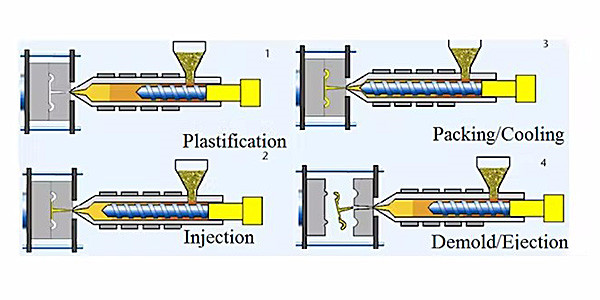

Jekiseni kuumba kutenderera

Iyo jekiseni yekuumba kutenderera ipfupi kwazvo, kazhinji pakati pe 2 masekonzi uye 2 maminetsi kureba. Pane matanho akati wandei:

1.Kurovera

Usati wapinza zvinhu mu mold, mahafu maviri emuumbi akavharwa, zvakachengeteka, nechikwata chekugadzirisa. Iyo hydraulically powered clamping unit inosundira mold halves pamwe chete uye inoshandisa simba rakakwana kuchengetedza mold yakavharwa apo zvinhu zvinobayiwa.

2.Jekiseni

Iine mold yakavharwa, iyo polymer pfuti inopinzwa mugomba rekuumbwa.

3.Kutonhorera

Kana mhango yazadzwa, kudzvanywa kwekubata kunoiswa kunobvumira kuti polymer yakawanda ipinde mugomba kutsiva kupera kwepurasitiki painotonhora. Zvichakadaro, sikururu inotendeuka yodyisa pfuti inotevera kune siruu yekumberi. Izvi zvinoita kuti screw idzoke sezvo pfuti inotevera inogadzirwa.

4.Ejection

Kana chikamu chacho chatonhora zvakakwana, mold inovhura, chikamu chinobudiswa, uye kutenderera kunotanga zvakare.

Advantages

1.Fast production; 2.Design flexibility; 3.Kururama; 4.Low mari yebasa; 5.Low tsvina