Plastic Jekiseni Kuumba Makiyi Mafungiro

Chero rakabudirira jekiseni rekugadzira purojekiti inofanirwa kutora akawanda zvinhu kamwechete mukufunga.

Kusarudzwa Kwezvinhu

Zvishandiso zvinoita basa rakakosha mukuumba jekiseni. A hunyanzvi jekiseni rekuumba mupi anogona kukubatsira iwe kusarudza thermoplastic inokodzera bhajeti rako uye kuita zvinodiwa. Nekuti ma molder anowanzo kuwana zvidzikiso pahuwandu hukuru hwemagiredhi ethermoplastic avanotenga, vanogona kupfuudza izvo zvakachengetwa kwauri.

Kushivirira Kusiyana

Chese chigadzirwa chinogadzirwa kuburikidza nekuumbwa kwejekiseni chinofanirwa kuve nekushivirira kwakanangana nekuenderana nechavanoda kushandisa. Zvimwe zvinhu zvinogona kunetsa kuumba kana kubatirira kune zvinodiwa kushivirira, uye dhizaini yemidziyo inogona kukanganisa kushivirira kwechikamu chekupedzisira. Gara uchikurukura neako jekiseni molder kubvuma kushivirira renji kune chaiwo zvigadzirwa.

Bharel uye Nozzle Temperature

MaMolders anofanirwa kuchengetedza chaiwo mbiya uye tembiricha yenozzle mukuumba jekiseni nekuti inokanganisa kugona kweresin kuyerera mukati me mold. Kupisa kwemudhiramu nenozzle kunofanirwa kunyatsoiswa pakati pe thermo-decomposition uye tembiricha yekunyungudika. Zvikasadaro, zvinogona kukonzera kufashukira, kupenya, kuyerera kunononoka, kana zvikamu zvisina kuzadzwa.

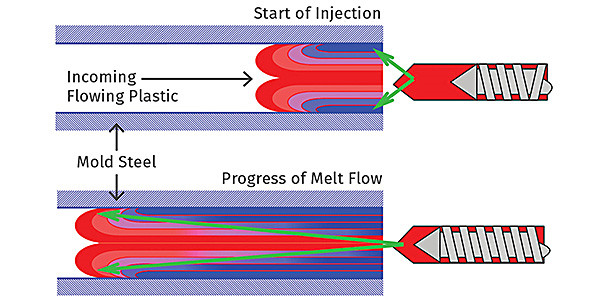

Thermoplastic Flow Rates

MaMolders anofanirwa kuchengetedza mwero wakakwana wekuyerera kuti ive nechokwadi chekuti purasitiki inodziya inobayiwa nekukurumidza sezvinobvira mugomba remold kusvika yazara 95% kusvika 99%. Kuve nekuyerera kwakaringana kunovimbisa kuti purasitiki inochengeta iyo chaiyo viscosity level kuti ipinde mugomba.

Zvimwe zvinhu zvinofanirwa kutariswa mune chero jekiseni molding operation ndezvi:

*Gedhi nzvimbo

*Sink marks

*Kudzima kona

*Kunyora

* Dhizaini uye dhizaini angle yekutarisa

*Simbi nzvimbo dzakachengeteka

Matanho Matanhatu Akakosha Mukuita Jekiseni Molding

Iyo jekiseni yekuumba maitiro inosanganisira nhanho huru nhanhatu, uye nyaya dzinogona kumuka pane chero yeaya matanho kana ikasaitwa nemazvo.

1.Kurovera

Mukuita uku, mahafu maviri e mold akachengetedzwa zvakasimba achishandisa clamping unit, iyo inoshandisa simba re hydraulic kushandisa simba rakakwana kuvhara mold. Pasina simba rakakwana rekusunga, maitiro anogona kutungamirira kune zvikamu zvisina kuenzana zvemadziro, huremu husingaenderane, uye hukuru hwakasiyana. Yakawandisa clamping simba inogona kukonzera kupfurwa mapfupi, kutsva, uye gloss level shanduko.

2.Jekiseni

Ma molder anopinza yakanyungudiswa thermoplastic zvinhu muforoma ne ramming mudziyo kana sikuruu pasi pekumanikidzwa kwakanyanya. Zvadaro, chikamu chacho chinofanira kubvumirwa kutonhora pamwero wakafanana. Kana zvisina kudaro, chikamu chekupedzisira chinogona kuve nemitsara yekuyerera kana mapatani asingadiwe anokanganisa kunaka kwayo.

3.Dwelling Pressure

Kana iyo thermoplastic material yave jekiseni mu mold, molders vanoita zvakanyanya kumanikidza kuzadza mhango zvizere. Kazhinji vanobata thermoplastic yakanyungudutswa kusvika gedhi reforoma raoma. Nguva yekugara inofanira kushandisa kudzvinyirirwa kwakarurama-yakanyanya kuderera uye inogona kusiya sink marks pachigadzirwa chakapedzwa. Kuwedzera kudzvinyirira kunogona kukonzera maburrs, hukuru hwakakura, kana kunetseka kuburitsa chikamu kubva mukuumbwa.

4.Kutonhorera

Mushure mekugara, mold inozadzwa, asi inogona kunge ichiri kupisa zvakanyanya kuti ibvise kubva muforoma. Naizvozvo, vanogadzira vanogovera imwe nguva yekuti mold itore kupisa kubva mupurasitiki. Molders dzinofanirwa kuchengetedza zvakakwana, yunifomu kutonhora kweiyo thermoplastic zvinhu kana kuti inozoisa panjodzi yekupokana kwechigadzirwa chekupedzisira.

5.Mold Kuvhura

Mahwendefa anofambika emushini wejekiseni remuvhu anovhurwa. Mamwe mold ane air blast control kana core pulls, uye muchina wekuumba unodzora mwero wesimba rinoshandiswa kuvhura mold uchidzivirira chikamu.

6.Chikamu Kubviswa

Chigadzirwa chekupedzisira chinoburitswa kubva mujekiseni mold ne pulse kubva ku ejection system, rods, kana marobhoti. Nano kuburitsa machira pane mold pamusoro anobatsira kudzivirira kubvaruka kana misodzi panguva yejection.

Typical Molding Defects Zvinokonzerwa neProcess Matambudziko

Kune akati wandei ekuumba kukanganisa kwakabatana nejekiseni molding, senge:

Warping: Warping is deformation inoitika kana chikamu chacho chikasangana nekuderera kusina kuenzana. Inopa sezvisingatarisirwi zvakakombama kana zvakamonyoroka zvimiro.

Jetting: Kana iyo thermoplastic ikabaiwa zvishoma nezvishoma uye ikatanga kugadzika mugodhi usati wazara, inogona kukonzera jetting yechigadzirwa chekupedzisira. Jetting inoita sewavy jet stream pamusoro pechikamu.

Sink marks: Aya ndiwo madhiri epamusoro anoitika nekutonhodza kusina kuenzana kana kana molders isingabvumire nguva yakakwana yekuti chikamu chitonhore, zvichiita kuti zvinhu zvidzikire mukati.

Weld mitsetse: Iyi mitsara mitete inowanzoita yakatenderedza zvikamu zvine maburi. Sezvo purasitiki yakanyungudutswa ichiyerera ichitenderedza gomba, mafambiro maviri aya anosangana, asi kana tembiricha isina kunaka, kuyerera hakubatanidze zvakanaka. Mhedzisiro ndeye weld line, iyo inoderedza kusimba uye kusimba kwechikamu chekupedzisira.

Eject marks: Kana chikamu chacho chikadzingwa kare kana nesimba rakawandisa, matanda ejector anogona kusiya mamakisi muchigadzirwa chekupedzisira.

Vacuum voids: Vacuum voids inoitika kana homwe dzemhepo dzakavharirwa pazasi pepamusoro pechikamu. Izvo zvinokonzerwa nekusimbiswa kusina kuenzana pakati pezvikamu zvemukati nekunze zvechikamu.

Jekiseni Molding Services From DJmolding

Iyo DJmolding, yakakwira vhoriyamu, yakajairwa jekiseni rekuumba nyanzvi, ine makore gumi nematatu echiitiko chekuumba jekiseni. Kubva DJmolding yakatangwa, isu takazvipira kupa vatengi vedu iwo emhando yepamusoro jekiseni akaumbwa zvikamu zviripo. Nhasi, mwero wedu wekuremara uri pasi pechikamu chimwe pamiriyoni.