Nyaya muAustralia:

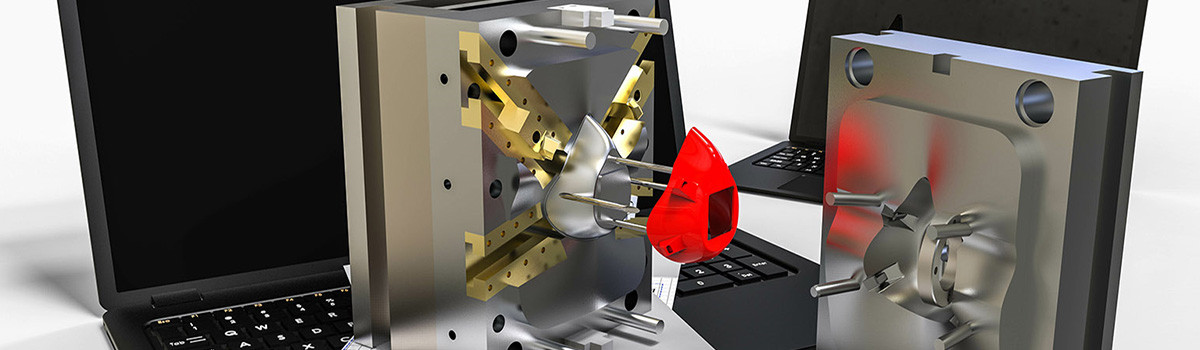

Sei Makambani eAustralia Anoburitsa Injection Injection Kuumba Ku DJmolding

Bhizinesi ndere kudzikisa mitengo. Kune nguva dzose kutsvaga nzira dzekuchengetedza mari uye kuwedzera purofiti mubhizinesi rega rega, zvisinei nehukuru hwayo. Nzira yakajairika yekuita izvi nhasi ndeye outsourcing.

Zvichiwedzera, makambani ari kuendesa kugadzira kwavo kumafekitori eChina nekuda kwekukurumidza kwavo, kushanda nesimba, uye mitengo yakaderera. Kugadzirwa kwavanoda nemutengo wavanokwanisa kutenga kwakatoendeswa kuChina nemakambani ekuAustralia.

Vamwe vanogadzira kubva kuAustralia, nekuda kwechikonzero chimwe chete, vaive vaburitsa majekiseni avo epurasitiki kuDJmolding.

Injection Molding Mari pa DJmolding

Zvichienzaniswa nedzimwe nyika, China ine mutengo wakaderera wevashandi uye zvigadzirwa, ndicho chimwe chezvikonzero zvinoita kuti makambani abudise majekiseni kwavari. DJmolding purofiti inogona kuwedzerwa nekudzikisa mitengo yekugadzira.

Makambani ane hunyanzvi mukugadzira mavhoriyamu akakwira uye kutsvaga kuchengetedza mutengo ndiwo anogona kunyanya kubatsirwa kubva pane izvi. Huwandu hwehuwandu hweChina hunorevawo kuti kune vashandi vanowanikwa nyore nyore vanogona kuzadzisa zvinodiwa nekambani yako. DJmolding inogona kubatsira kuderedza mutengo wekudzidzisa uye kuwedzera chibereko.

Hunhu By DJmolding injeciton supply

DJmolding yakaisa mari mumidziyo yekugadzira yepamberi uye vakadzidzisa vashandi vavo hunyanzvi hwekugadzira, izvo zvinogona kubatsira kuvandudza mhando yezvigadzirwa zvavo. DJmolding yakaisawo mari yakawanda mukutsvagisa nekusimudzira, zvichireva kuti DJmolding inokwanisa kuwana matekinoroji epamusoro anogona kuvabatsira kugadzira zvigadzirwa zvitsva. Izvi ndezvechokwadi kunyanya kumakambani ane hunyanzvi mukugadzira tekinoroji yepamusoro senge aerospace, zvemagetsi uye zvinhu zvemotokari.

Nguva dzekutungamira:

Kuburitsa kune DJmolding kazhinji kunogona kutungamirira kunguva pfupi dzekutungamira zvichienzaniswa nekugadzirwa kwemumba kweAustralia, nekuda kweiyo yakagadziridzwa zvivakwa uye chokwadi chekuti China iri padyo neakawanda emisika mikuru muAsia.

Iko kumhanya kweiyo DJmolding maitiro ekugadzira kwakakosha zvakare, tinogona kushandura zvigadzirwa mumavhiki mashoma. Izvi zvinogona kunyanya kubatsira kumabhizinesi ari kutsvaga kuburitsa zvigadzirwa zvitsva kana kuunza mitsara yemwaka, kuve nechokwadi chekupihwa kwakakwana zuva rekuburitswa risati rasvika.

Chiitiko che DJmolding Injection Molding Indasitiri:

DJmolding inozvikudza ine hunyanzvi muchikamu chekugadzira, ichipa huwandu hwakakwana hwesevhisi dzinosanganisira dhizaini, prototyping, kugadzira mold, jekiseni rekuumba, uye assembly.Mawoko edu-pachiitiko chakakosha kumakambani ekutanga kutsvaga fekitori inogona kupa gwara. Uyezve, vazhinji vatengesi veChinese vane hukama hwakasimba nevapeji venzvimbo, zvichiita kuti vakwanise kubatanidza vatengi nemafekitori akasarudzika emasevhisi akaita sekupakura uye kutumira.

Heino nhanho-ne-nhanho gwara pane DJmolding jekiseni molding maitiro:

1.Gadzira mold: Izvi zvinosanganisira kugadzira 3D modhi (dhizaini softwares: solidworks, ug, pro-e…) yechigadzirwa uye mold, uchifunga nezvezvinhu zvakaita sezvinhu (PP, PE, ABS, PA…), ukobvu hwemadziro, saizi yegedhi, uye nguva yekutonhora.

2.Gadzira mold: Iyo mold inowanzo gadzirwa nesimbi kana aluminiyamu uye inofanirwa kugadzirwa kuti iite zvakatemwa. Rondedzero yesimbi dzepurasitiki mold ine kuoma:

*P20 Simbi - 28-32 HRc

*420 Simbi - 48-52 HRc

*H13 Simbi - 48-52 HRc

*S7 Simbi - 45-49 HRc

*NAK55 Simbi - 50-55 HRc

*NAK80 Simbi - 38-43 HRc

*DC53 Simbi - 50-58 HRc

*A2 Simbi - 60-64 HRc

*D2 Simbi - 60-64 HRc

Ongorora: HRc inoreva Rockwell kuomarara chiyero, chinoyera kuoma kwechinhu.

3.Isa mold: Iyo mold inoiswa pamushini wekuumba jekiseni uye yakasungirirwa pakati pemahwendefa maviri pamushini.

4.Rodha zvinhu zvepurasitiki: Zvinhu zvepurasitiki zvinoiswa muhopper yemuchina wekuumba jekiseni kuburikidza negiravhiti uye imwe hopper inoedza zvinhu zvepurasitiki uku kuumbwa kwejekiseni kuripo.

5. Nyusa plastiki: Iyo yepurasitiki zvinhu inonyungudutswa nekupisa uye kumanikidza mukati medhiramu yemuchina wekuumba jekiseni.

6.Baya purasitiki muforoma: Plastiki yakanyungudutswa inomhanya mumold kuburikidza nenozzle uye sprue pasi pekumanikidzwa kwakanyanya, uye enda nemumhanyi, gedhi wozozadza mold cavities.

7.Cool uye simbisa: Iyo mold yakatonhodzwa kuti ibvumire purasitiki kusimba mukati megomba kwechinguva, uye nguva zhinji, nguva yekutonhora ingave 2/3 yenguva yese yekutenderera.

8.Vhura mold: Iyo mold inovhurwa uye chigadzirwa chakaumbwa chinobviswa kubva mukuumbwa, ipapo mold inovhara uye kutenderera kunotevera kunotanga.

Zvinodiwa maturusi uye zvinhu: jekiseni rekuumba muchina, mold, epurasitiki zvinhu, yekuomesa muchina, tembiricha controller (yepamusoro uye inotonhora zvakanyanya zvinodiwa zvekuumba jekiseni)

Chikamu chakaumbwa chinogona kutambudzika nenyaya dzakasiyana siyana kusanganisira yakawandisa zvinhu kumicheto (Flash), izvo zvinogona kukonzera kushaya simba chimiro. Warping kana kukanganisa kunogona kuitika kana chikamu chakaumbwa chikasachengeta chimiro chayo kana saizi nekuda kwekutonhora kusina kuenzana. Mavara matema pachikamu chakaumbwa imhaka yehurombo hwekugadzirisa zvinhu kana kusvibiswa. Kupera kwakashata kwepamusoro, kunoratidzwa nekusaenzana kwemavara kana kushata, kunogona kukonzerwa nekugadzira mold isina kunaka kana kusarudzwa kwezvinhu. Sink marks, indentations muchikamu chakaumbwa, inogona kukonzerwa nekuzadza zvisina kunaka kwe mold kana kusakwana kumanikidza panguva yekuumbwa. Pamusoro pezvo, chikamu chakaumbwa chinogona kunetsa kuburitsa, zvichitungamira mukudzikira kwekugadzira uye kuwedzera mitengo, kana inogona kukuvara panguva yejection.

Kukosha kwematanho ekuchengetedza hakugone kuwedzeredzwa mukuita jekiseni molding process. Kuti vadzivise kukuvara, vashandi vanofanirwa kushandisa midziyo yekudzivirira senge magirovhosi uye magirazi ekuchengetedza sezvo purasitiki yakanyungudutswa inosvika pakupisa kwakanyanya, dzimwe nguva kusvika ku300 madhigirii, uye ine mukana wekupwanya. Izvo zvakakosha kuti vashandisi vagamuchire kudzidziswa kwakaringana nezvemaitiro akachengeteka ekushanda.

Tora woenda nazvo

Izvo zvakakosha kuti unyatso tarisa zvese zvinosanganisirwa mukuendesa kunze kuChina, zvinosanganisira Logistics, mutengo wekutumira, uye zvinogona kuitika pane chako cheni.

Kushanda nemunhu ane mukurumbira uye ane ruzivo wekutsvaga shamwari, DJmoldnig inogona kubatsira kambani yako kuti ive nechokwadi chakatsiga uye chakabudirira chekuburitsa ruzivo.