Zvese Zvaunoda Kuziva Nezve Plastic Injection Molding

Zvese Zvaunoda Kuziva Nezve Plastic Injection Molding

Plastic jekiseni Kuumbwa inzira inoshandiswa zvakanyanya kugadzira kugadzira mapurasitiki akaomarara. Iyi blog positi ichakurukura izvo zvekutanga zvepurasitiki jekiseni kuumba, basa rayo, mashandisirwo, zvakanakira, uye zvazvakaipira.

Plastic jekiseni Molding:

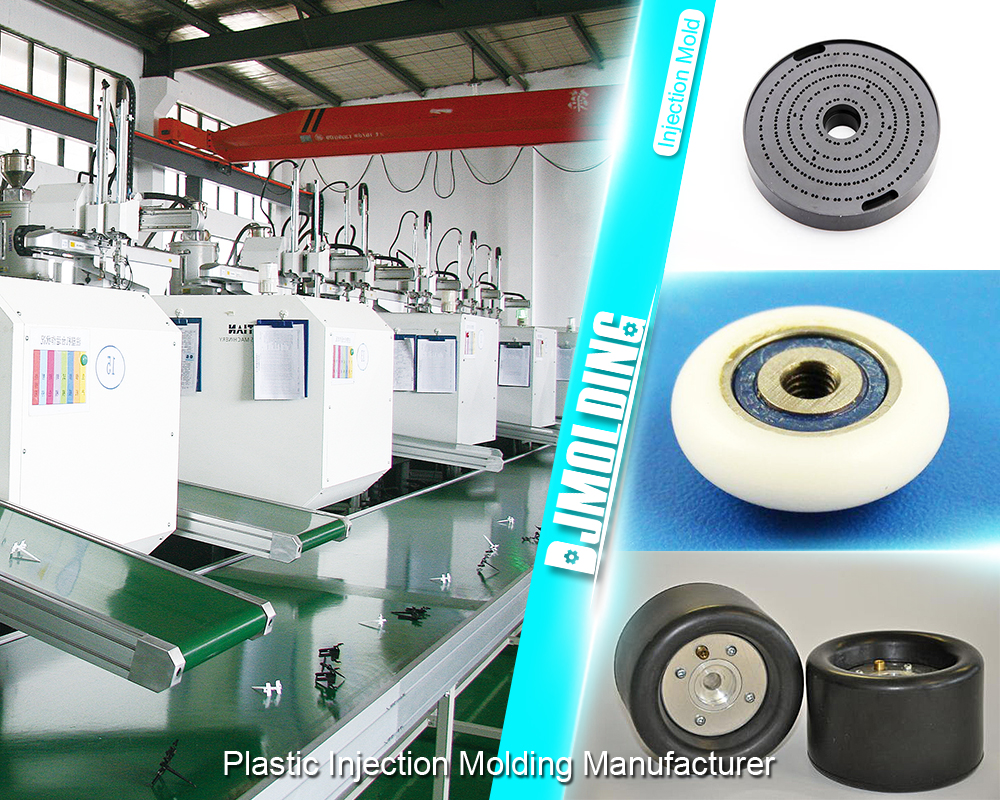

Plastic jekiseni molding ndeimwe yeanonyanya kufarirwa nzira dzekugadzira yekugadzira emhando yepamusoro zvigadzirwa zvepurasitiki muhuwandu hukuru. Maindasitiri akasiyana, akadai semotokari, ekurapa, ekurongedza, uye zvinhu zvevatengi, anoshandisa jekiseni molding kugadzira zvigadzirwa zvavo. Iyo nzira inosanganisira kunyungudutsa epurasitiki pellets uye kuapinza muforoma pasi pekumanikidzwa kwakanyanya. Purasitiki yacho inobva yatonhodza uye yooma, ichiita mhango ye mold. Mune ino blog positi, isu tichanyura mune iyo ruzivo rwepurasitiki jekiseni rekugadzira maitiro.

Iyo Plastic Injection Molding process

Plastic jekiseni molding inzira yakaoma iyo inosanganisira akawanda matanho. Heano matanho akakosha anosanganisirwa mune epurasitiki jekiseni molding process:

Muforoma Dhizaini

Nhanho yekutanga mukugadzirisa ndeyekugadzira mold. Nhanho yekutanga mukuita ndeyekugadzira mold uchishandisa komputa-inobatsira dhizaini (CAD) software, iyo inobatsira kugadzira 3D modhi yechikamu. Iyo mold inogadzirwa zvichienderana nedhizaini iyi uchishandisa simbi kana aluminium.

Kusarudzwa Kwezvinhu

Nhanho inotevera ndeyekusarudza zvinyorwa zvechikamu. Thermoplastics, iyo inogona kunyunguduka uye kugadziridza kakawanda, ndiyo inonyanya kushandiswa kuumba jekiseni repurasitiki. Zvinyorwa zvakasarudzwa zvinofanira kunge zvakakodzera kune chinangwa chekushandiswa.

Kupisa uye Kunyunguduka

Kana timu yekugadzira ikangogadzira mold uye inosarudza iyo yakakodzera zvinhu, jekiseni rekugadzira muchina unopisa uye unonyungudutsa mapurasitiki epurasitiki. Iyo jekiseni molding process inodzora tembiricha nekungwarira kuti ive nechokwadi chekunyungudika kwezvinhu.

Injection

Isu tinobva tabaya purasitiki yakanyungudutswa mugomba rekuumbwa pasi pekumanikidzwa kukuru. Kudzvinyirirwa kunovimbisa kuti zvinhu zvinozadza niche yose uye zvinotora chimiro che mold.

Kutonhodza uye Ejection

Ipurasitiki inozobvumirwa kutonhora uye kusimba, ichitora chimiro chemugodhi we mold. Kana plastiki yangotonhora, muchina wekugadzira jekiseni unovhura mold uye unoburitsa chikamu.

Zvishandiso zvePlastiki Injection Molding

Plastic jekiseni molding inoshandiswa mumaindasitiri akasiyana siyana kugadzira zvinhu zvakasiyana. Heano mamwe eanonyanya kushandiswa epurasitiki jekiseni molding:

- Indasitiri yeMotokari: Maindasitiri akasiyana anoshandisa epurasitiki jekiseni kuumba kugadzira akasiyana ezvikamu, senge mota dashboards, mabumpers, uye emukati matrim.

- Bazi rezvekurapa: Plastic jekiseni molding inogadzira michina yekurapa senge sirinji, inhalers, uye zvekuvhiya.

- Packaging Indasitiri: Plastic jekiseni molding inogadzira zvinhu zvekurongedza senge mabhodhoro caps, midziyo, uye kuvhara.

- Consumer Goods Industry: Plastic jekiseni molding inogadzira zvinhu zvakasiyana-siyana zvevatengi, zvakaita sematoyi, zvemagetsi, uye midziyo yemumba.

Zvakanakira Plastic jekiseni richigadzirisa

Plastic jekiseni Kuumbwa inzira inoshandiswa zvakanyanya yekugadzira iyo inopa akawanda mabhenefiti pamusoro pedzimwe nzira dzekugadzira. Maitirwo acho anosanganisira kubaya purasitiki yakanyungudutswa mugomba reforoma, iro rinotonhodza nokuoma kuita chinhu chemhando yepamusoro. Heano mamwe ezvakanakira epurasitiki jekiseni molding.

Kubudirira Kwepamusoro

Plastic jekiseni molding inzira inoshanda kwazvo inogona kukurumidza kuburitsa yakakwira mavhoriyamu ezvikamu. Iyo otomatiki maitiro ane mazana kana kunyange zviuru zvezvimiro nekukurumidza, zvichiita kuti ive yakanakira hukuru-hukuru hwekugadzira inomhanya. Pamusoro pezvo, maitiro acho anogona kuvandudzwa kuti aderedze kutenderera nguva, achiwedzera kuvandudza kushanda zvakanaka.

Kusawirirana uye Kururamisa

Plastic jekiseni molding inogadzira zvinhu zvinopindirana muhukuru uye chimiro nehupamhi hwepamusoro. Iyo mold cavity inovimbisa kuti muchina unogadzira chinhu nechiyero chaunoda uye kuti maitiro acho anodzokororwa zvakanyanya. Hunhu hunoenderana hunogadzirwa nepurasitiki jekiseni kuumbwa kwakakosha kune maapplication uko chaiwo kuyerwa kwakakosha, kuve nechokwadi chekuti zvinhu zvinogadzirwa zvichave nemhando inowirirana.

Kusiyanisa

Plastic jekiseni molding inogona kuburitsa zvikamu muhukuru hwakasiyana uye maumbirwo. Vagadziri vanogona kugadzira mold ine maficha ane yakaoma geometries, senge dzakatetepa-madziro mativi, ayo angave akaoma kana kusagoneka kugadzira uchishandisa dzimwe nzira. Pamusoro pezvo, maitiro anogona kushandisa akasiyana epurasitiki zvinhu, zvinosanganisira engineering-giredhi resins, iyo inogona kusarudzwa zvichibva pane inodiwa zvivakwa zvechikamu.

Mutengo-Unoshanda

Plastic jekiseni molding inzira inodhura-inoshanda yekugadzira yakakwira mavhoriyamu ezvikamu. Mari yekutanga yekugadzira uye kugadzira mold inogona kunge yakakwira, asi mutengo pachikamu chimwe nechimwe unodzikira sezvo huwandu hwekugadzira hunowedzera. Pamusoro pezvo, maitiro anogona kuve otomatiki, ayo anoderedza mutengo wevashandi uye anovandudza kushanda zvakanaka. Iyo shoma tsvina yemidziyo inobatsirawo kuderedza mitengo, sezvo chero chinhu chakawandisa chinogona kudzokororwa uye kushandiswa mune ramangwana rekugadzira rinomhanya.

Minimal Material Waste

Plastic jekiseni kuumba inoburitsa kushoma zvinhu marara, sezvo chero chinhu chakawandisa chinogona kudzokororwa uye kushandiswa mune ramangwana rekugadzira rinomhanya. Plastic jekiseni molding inoshanda zvakanyanya kupfuura dzimwe nzira dzekugadzira nekuti inonyunguduka uye inobaya chete huwandu hunodiwa hwezvinhu mugomba rekuumbwa, kuderedza marara. Chero zvinhu zvakawandisa zvinowanzounganidzwa uye kushandiswazve, izvo zvinoderedza marara uye zvinonatsiridza kuchengetedzwa.

Zvakanyanya kukosha kukanganisa

Vagadziri vanonyanya kushandisa epurasitiki jekiseni molding kune zvakanakira ayo asi vanofanirwa kufunga nezve zvimwe zvakakosha zvakaipira. Ichi chikamu chichakurukura zvakakosha zvakanyanya kuipa kwepurasitiki jekiseni molding.

High Initial Investment

Imwe yezvakanyanya kuipa kwepurasitiki jekiseni molding ndeye yakakwira yekutanga investimendi inodiwa kugadzira mold. Iyo mold dhizaini uye maitiro ekugadzira anogona kudhura, kunyanya kune yakaoma madhizaini kana hombe mold. Mutengo wefodya unogona kuve chipingamupinyi chekupinda kune mabhizinesi madiki kana kutanga, zvichiita kuti zvivaomere kukwikwidza nemakambani makuru anogona kubhadhara mari yakawanda.

Yakaganhurirwa Dhizaini Flexibility

Iyo mold inodzikamisa dhizaini yechikamu, zvinoreva kuti kuita shanduko kune iyo nzira inogona kuve yakaoma uye inodhura. Kuita shanduko kazhinji kune mold kunogona kuve kwakakosha kukanganisa sezvo kunoda imwe nguva uye mari yekushandurwa kwega kwega. Uku kudzikisira mukugadzirisa dhizaini kunogona kunyanya kunetsa kune zvigadzirwa zvinoda kugara uchigadziridzwa kana kugadzirisa.

Production Time

Chimwe chinokanganisa chekugadzira jekiseni repurasitiki ndechekuti maitiro anogona kutora mavhiki akati wandei, kubva pakugadzira kusvika pakugadzirwa. Iyo nguva inodiwa pakugadzira mold uye kugadzira, kugadzirira zvinhu, uye kugadzirwa kunogona kuita kuti zviome kusangana nekukurumidza kutendeuka nguva. Kugadzirisa mold inogona kukanganisa zvakanyanya kumakambani anoda nguva dzekukurumidza kugadzira kana kutarisana nehupenyu hupfupi hwechigadzirwa.

Kukanganisa kwezvakatipoteredza

Iyo yepurasitiki jekiseni molding process inogona kukuvadza nharaunda. Kuita uku kunoda kushandiswa kwemafuta ekupisa nekunyungudutsa purasitiki, zvichikonzera kuburitsa gasi regreenhouse. Pamusoro pezvo, maitiro acho anogona kuburitsa tsvina mupurasitiki yakawandisa uye kushandiswa kwesimba, kukuvadza nharaunda.

Chiverengwa

Mukupedzisa, epurasitiki jekiseni molding inzira yakavimbika uye inoshanda yekugadzira yekugadzira emhando yepamusoro zvigadzirwa zvepurasitiki. Mabhenefiti ayo, sekuenderana, kunyatsoita, uye mutengo-kubudirira, inoita kuti ive sarudzo yakakurumbira kune akasiyana maindasitiri. Nekudaro, zvayakaipira, senge yakakwira yekutanga kudyara uye kushomeka kwedhizaini kuchinjika, inofanirawo kutariswa. Plastic jekiseni molding ndiyo yakakosha tekinoroji yakashandura indasitiri yekugadzira. Sezvo tekinoroji ichifambira mberi, kuumbwa kwejekiseni repurasitiki kungangoramba kuchishanduka nekuvandudza, kuve kwakanyanya kushanda, kudhura, uye kushamwaridzana nenharaunda.

Nezvizhinji nezve epurasitiki jekiseni Kuumbwa,unogona kushanyira Djmolding pa https://www.djmolding.com/ nokuti zvimwe info.