Basics Of Plastic jekiseni Molding

Ongorora maitiro ekuumba jekiseni uye kuti anoshanda sei.

Plastic jekiseni molding inzira yakakurumbira yekugadzira iyo thermoplastic pellets inoshandurwa kuita mavhoriyamu akakwira ezvikamu zvakaoma. Iyo jekiseni yekuumba maitiro inokodzera akasiyana emidziyo yepurasitiki uye chinhu chakakosha chehupenyu hwazvino-makesi enhare, dzimba dzemagetsi, matoyi, uye kunyange zvikamu zvemotokari hazvigoneke pasina iyo. Ichi chinyorwa chichapwanya izvo zvekutanga zvekuumbwa kwejekiseni, tsanangura kuti jekiseni rekuumba rinoshanda sei, uye kuratidza kuti rakasiyana sei nekudhinda kwe3D.

Ndezvipi Zvinokosha zvePlastiki Injection Molding?

Izvo zvekutanga zvemajekiseni epurasitiki ekuumba maitiro anosanganisira kugadzira dhizaini yechigadzirwa, kugadzira dhizaini kuti ikwane dhizaini yechigadzirwa, kunyungudutsa epurasitiki resin pellets, uye kushandisa kumanikidza kubaya mapellets akanyunguduka muforoma.

Ona kupatsanurwa kwedanho rega rega pazasi:

1. Kugadzira Chigadzirwa Chekugadzira

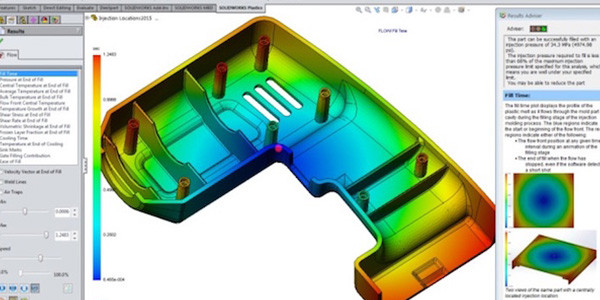

Vagadziri (mainjiniya, mabhizinesi ekugadzira mold, nezvimwewo) vanogadzira chikamu (muchimiro cheCAD faira kana imwe nzira inochinjika), vachitevera yakakosha dhizaini dhizaini yakanangana neiyo jekiseni rekuumba. Vagadziri vanofanirwa kuyedza kuisa zvinotevera maficha mumagadzirirwo avo kubatsira kuwedzera budiriro yepurasitiki jekiseni mold:

*Maboss ekuisa threaded/fasteners

*Anogara kana ari pedyo-anogara achikobvura madziro

*Smooth transitions pakati pekusiyana kwemadziro ukobvu

*Makomba makomba muzvikamu zvakakora

*Mipendero yakatenderedzwa

*Draft angles pamadziro akatwasuka

* Mbabvu dzezvitsigiro

*Friction inokodzera, snap-fit majoini, uye mamwe asina-fastener ekubatanidza maficha

*Mahinji ekugara

Pamusoro pezvo, vagadziri vanofanirwa kudzikisa zvinotevera maficha kudzikisa kuremara mumagadzirirwo avo:

*Asina-uniform madziro makobvu kana kunyanya matete/makobvu madziro

*Madziro akamira asina maekona ekudhirowa

*Kamwe kamwe geometrical shanduko (makona, maburi, nezvimwewo)

*Kugadzirwa kwembabvu zvisina kunaka

* Undercuts / overhangs

2. Kuita Tooling Mold kuti Ienderane neChigadzirwa Dhizaini

Vane hunyanzvi hwekugadzira machini uye vagadziri vezvishandiso, vachishandisa dhizaini yechigadzirwa, vanogadzira mold yemidziyo yemuchina wekuumba jekiseni. A tooling mold (inozivikanwawo sechingori chishandiso) moyo nemweya wemushini wekuumba jekiseni. Iwo akanyatso gadzirwa kuti ave neakashata gango rekugadzirwa kwechigadzirwa uye mamwe maficha akadai semasprues, anomhanya, magedhi, mamhepo, ejector masisitimu, kutonhora nzira, uye zvinhu zvinofamba. Matooling molds anogadzirwa nemagiredhi chaiwo esimbi nealuminium anokwanisa kumira makumi ezviuru (uye dzimwe nguva mazana ezviuru) zvekudziya nekutonhodza, se6063 aluminium, P20 simbi, H13 simbi, uye 420 simbi isina tsvina. Maitiro ekugadzira mold anotora anodarika mavhiki makumi maviri kuti apedze, kusanganisira kugadzira uye kubvumidzwa, zvichiita kuti nhanho iyi ive yakanyanya kurebesa yekuumba jekiseni. Icho zvakare chikamu chinodhura zvakanyanya chekugadzira jekiseni, uye kana mold yemidziyo yagadzirwa, haigone kuchinjwa zvakanyanya pasina kuunza imwe mari.

3. Kunyungudutsa Plastic Resin Pellets

Mushure mekunge vashandisi vawana mold yapera, inopinzwa mumushini wekuumba jekiseni, uye mold inovhara, kutanga jekiseni rekuumba kutenderera.

Plastic granules anodyiswa muhopper uye mudhiramu. Iyo screw inodzokororwa inodhonzwa kumashure, ichibvumira zvinhu kuti zvitsvedze munzvimbo iri pakati pescrew nedhiramu. Iyo sikuruu inobva yanyura kumberi, ichimanikidzira zvinhu mudhiramu uye pedyo nemabhandi ekudziya apo inonyunguduka kuita purasitiki yakanyungudutswa. Iyo tembiricha yekunyunguduka inochengetwa isingachinji sekuenderana nezvakatsanangurwa kuitira kuti pasave nekuora kunoitika mudhiramu kana muforoma pachayo.

4. Kushandisa Kumanikidza Kupinza Mapeti Akanyunguduka MuMould

Iyo screw inodzosera inomanikidza iyi purasitiki yakanyunguduka kuburikidza nemuromo, iyo inogara mukati mekuora mwoyo mu mold inozivikanwa se mold sprue bushing. Iyo inofambisa platen pressure inokodzera mold uye nozzle pamwechete zvakasimba, kuve nechokwadi kuti hapana plastiki inogona kutiza. Plastiki yakanyungudutswa inomanikidzwa nemaitiro aya, zvichiita kuti ipinde munzvimbo dzese dzemugodhi uye kutamisa mweya wegomba kunze kuburikidza nemold vents.

Jekiseni Molding Machine Zvikamu

Zvikamu zvemushini wekuumba jekiseni zvinosanganisira hopper, dhiramu, siruu inodzokorodza, heater (s), platen inofambiswa, muromo, mold, uye mold cavity.

Rumwe ruzivo pane yega yega jekiseni molding zvikamu mune runyorwa pazasi:

*Hopper: paburi rinopinzwa mapuranga epurasitiki mumushini.

*Barel: imba yekunze yemuchina wekuumba jekiseni, une siruu inodzokorodza uye magranules epurasitiki. Iyo dhiramu yakaputirwa mune akati wandei mabhandi ekudziya uye inonamirwa nemuromo unopisa.

*Kudzorera screw: iyo corkscrew component iyo inotakura uye inodzvinyirira zvinhu zvepurasitiki sezvainonyunguduka nemudhiramu.

* Heaters: Iyo inozivikanwawo semabhendi ekudziya, zvikamu izvi zvinopa simba rekupisa kune epurasitiki granules, achiashandura kubva pachimiro chakasimba kuenda kumvura. form.

*Plateni Inotakurika: Iyo inofambisa chikamu chakabatana neiyo mold core iyo inoshandisa kudzvanywa kuti ichengetedze mold halves isina mhepo uye zvakare inoburitsa iyo mold core pakuburitsa chikamu chakapedzwa.

*Nozzle: chikamu chinopisa chinopa muganho wekubuda kwepurasitiki yakanyungudutswa mugomba rekuumbwa, ichichengeta zvese tembiricha uye kudzvanywa kwakagadzikana sezvinobvira.

*Mould: chikamu kana zvikamu zvine mold mhango uye mamwe anotsigira mapini ejector mapini, mumhanyi migero, kutonhora migero, mhepo, etc. Pashoma, mold inoparadzaniswa kuita hafu mbiri: divi rakamira (pedyo nedhiramu) uye mold. musimboti (pane platen inofamba).

* Mold Cavity: iyo nzvimbo isina kunaka iyo, kana yazadzwa nepurasitiki yakanyungudutswa, inoigadzira kuita chikamu chekupedzisira chinodiwa pamwe nezvitsigiro, magedhi, vanomhanya, sprues, nezvimwe.

Injection Molding Inoshanda Sei?

Kana mapurasitiki azadza mold kusanganisira masprues ayo, anomhanya, masuwo, nezvimwewo, mold inochengetwa patembiricha yakatarwa kuti ibvumire kusimba kweyunifomu yechinhu muchikamu chechimiro. Kudzvanywa kwekubata kunochengetwa uku kuchitonhora kune ese kumisa kuyerera mudhiramu uye kuderedza kuderera kwemhedzisiro. Panguva ino, mamwe epurasitiki granules anowedzerwa kune hopper mukutarisira kunotevera kutenderera (kana kupfurwa). Kana yatonhodzwa, platen inovhura uye inobvumira chikamu chapera kuti chibudiswe, uye screw inodzoserwa kumashure zvakare, ichibvumira zvinhu kupinda mudhiramu uye kutanga maitiro zvakare.

Iyo jekiseni molding cycle inoshanda neichi chinoramba chiripo-kuvhara mold, kudyisa / kupisa mapurasitiki granules, kuamanikidza kupinda muforoma, kutonhora iwo muchikamu chakasimba, kuburitsa chikamu, uye kuvhara mold zvakare. Iyi sisitimu inobvumira kukurumidza kugadzirwa kwezvikamu zvepurasitiki, uye zvikamu zvepurasitiki zvinosvika zviuru gumi zvinogona kugadzirwa muzuva rekushanda zvichienderana nedhizaini, saizi, uye zvinhu.

Djmolding yakaderera vhoriyamu jekiseni kuumba makambani mu china.Our epurasitiki jekiseni kuumba muitiro unobudisa tsika prototypes uye kuguma-kushandisa kugadzirwa zvikamu ane mutobvu nguva nokukurumidza sezuva 1, yakaderera vhoriyamu epurasitiki jekiseni kuumba chikamu mugovera kusvika 10000 zvikamu pagore.