Injection Mold Manufacturing

Plastiki chinhu chinowanzoshandiswa kune zvigadzirwa kune akasiyana maindasitiri. Matoyi, zvinhu zvemotokari, zvishandiso zvekurapa, maturusi, uye nezvimwe zvese zvinogadzirwa kubva kupurasitiki. Zvizhinji zvezvinhu zvepurasitiki kana zvatinosangana nazvo muhupenyu hwedu hwemazuva ese zvinogadzirwa nekushandura resin yakanyunguduka kuita yakatsanangurwa dhizaini ine maitiro ekugadzira anonzi epurasitiki jekiseni molding. Iyi nzira inoshanda zvakanyanya inogona kugadzira zvikamu muhukuru hwakawanda uye maumbirwo uye inogona kudzokorora chikamu chimwechete kakawanda uchishandisa mold imwechete. Pamwoyo pekuita uku ndiko kuumbwa, kunozivikanwawo sekushandisa. Iyo yepamusoro-yemhando yekugadzira mold yakakosha kugadzira zvikamu zvemhando yepamusoro uchichengetedza mutengo unoshanda. Chikamu chemhando chinokwira uye mutengo wepurojekiti yose uchadzika kana uchidyara mukugadzirwa kwemhando yepamusoro.

Injection Molding Process Matanho

Jekiseni molding ndeimwe yeakajairika nzira yekugadzira inoshandiswa kugadzira zvinhu zvepurasitiki. Iyo inzira yekudiwa kwepamusoro inogona kubereka chikamu chimwe chete zviuru zvenguva. Maitiro acho anotanga neComputer Aided Design (CAD) faira ine kopi yedhijitari yechikamu. Iyo CAD faira inobva yashandiswa seti yemirairo yekubatsira mukugadzira mold process. Iyo mold, kana chishandiso, chinowanzo gadzirwa kubva kuzvidimbu zviviri zvesimbi. Gomba riri muchimiro chechikamu chinochekwa murutivi rumwe norumwe rwe mold. Iyi mold inowanzogadzirwa kubva kualuminium, simbi, kana alloy.

Mushure mekugadzira mold, nhanho inotevera ndeyekusarudza iyo yakakodzera plastiki zvinhu. Kusarudzwa kwezvinhu kuchaenderana nekuti chikamu chekupedzisira chichashandiswa sei. Zvigadzirwa zvepurasitiki zvine maitiro akasiyana-siyana ekufunga. Izvi zvinosanganisira pamusoro pese kutaridzika uye kunzwa, pamwe nekuramba makemikari, kupisa, uye abrasion. Taura nenyanzvi dzepaDJmolding kuti udzidze zvakawanda nezvezvinhu zvepurasitiki zviripo zvekuumba jekiseni.

Zvinhu zvakasarudzwa zvinotanga sepurasitiki pellet inodyiswa muhopi pamushini wekuumba jekiseni. Mapellets anopinda nemukamuri inopisa umo anonyungudutswa, akatsikirirwa, obva aiswa jekiseni mugomba. Kana chikamu chatonhora, mahafu maviri e mold anovhura kuti abvise chikamu. Muchina wacho unobva wagadzirisa zvakare kuti utange maitiro zvakare.

Chii Chinoshandiswa Kugadzira Molds?

Kugadzira mold kunoitwa nesimbi, aluminium, kana alloy. DJmolding inoshandisa simbi yemhando yepamusoro kugadzira mold. Kugadzirwa kwesimbi mold kunodhura zvishoma pane kushandisa aluminium kana alloy. Mutengo wepamusoro unowanzo kuderedzwa nehupenyu hurefu hwehupfu hwesimbi. Aluminium molds, kunyange yakachipa kugadzira, haigare kwenguva yakareba sesimbi uye inofanirwa kutsiviwa kazhinji. Simbi molds inozogara zvakanaka kupfuura zana rezviuru zvema cycles. Aluminium molds inoda kutsiviwa kakawanda. Kugadzirwa kwesimbi mold kunogona kupa zvigadziriso zvakaomarara zvisingawanikwe nealuminium. Simbi molds inogona zvakare kugadziriswa kana kuchinjwa newelding. Aluminium molds inozoda kugadzirwa kubva pakatanga kana mold yakanganiswa kana kugadzirisa shanduko. Masimbi emhando yepamusoro anogona kushandiswa zviuru, mazana ezviuru, uye dzimwe nguva anosvika miriyoni kutenderera.

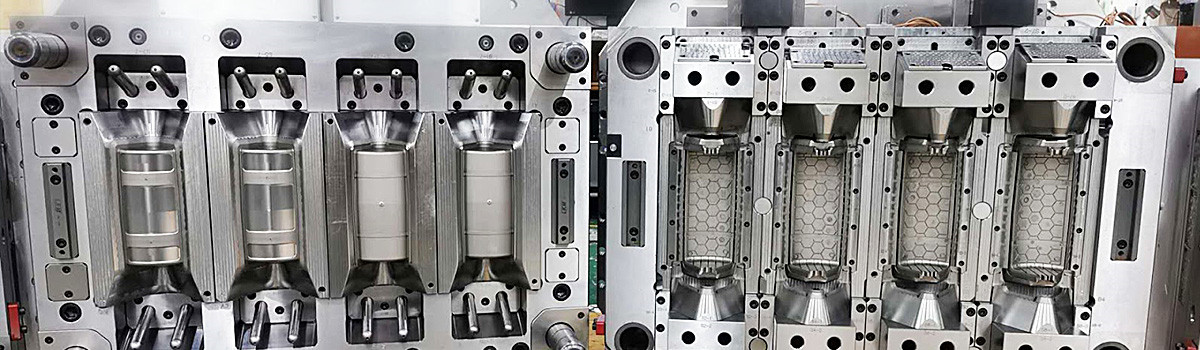

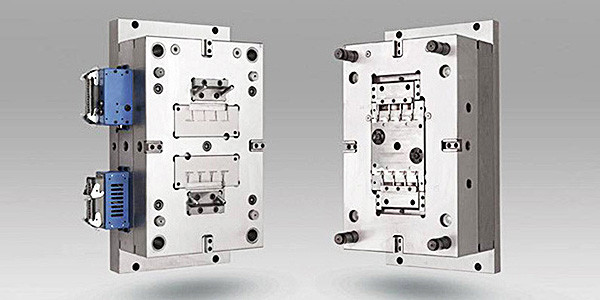

Jekiseni Mold Zvikamu

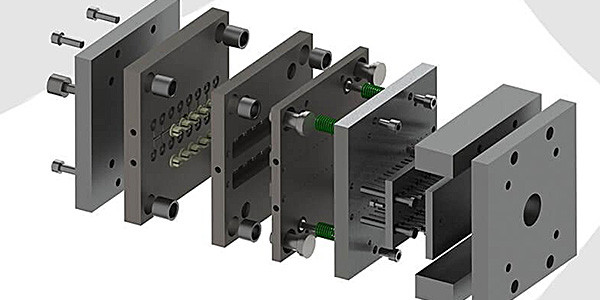

Majekiseni akawanda anoumbwa nezvikamu zviviri - A side neB side, kana mhango nepakati. Rutivi rwegoviti ndiyo yakaringana divi asi imwe hafu, iyo musimboti, ichange iine kumwe kusakwana kwekuona kubva kumapini ejector anosundira chikamu chakapedzwa kubva muforoma. Iyo jekiseni mold inosanganisirawo mahwendefa ekutsigira, ejector bhokisi, ejector bar, ejector mapini, ejector mahwendefa, sprue bushing, uye mhete yekuwana.

Injection molding inzira yekugadzira ine zvidimbu zvakawanda zvinofamba. Pazasi pane rondedzero yematemu anotsanangura akawanda ezvimedu zvinodiwa pakugadzira mold uye jekiseni rekugadzira. Chishandiso chacho chine mahwendefa akawanda esimbi mukati mefuremu. Iyo mold frame inoiswa mujekiseni-kuumba muchina uye inobatwa panzvimbo ine machira. Kuchekwa kwejekiseni mold inotariswa kubva padivi ingangoita sangweji ine akawanda akasiyana layer. Tarisa yedu Injection Molding Glossary kune yakazara runyorwa rwematemu.

Mold Frame kana Mold Base: Yakateedzana mahwendefa esimbi anobata zvikamu zve mold pamwechete, kusanganisira cavities, cores, runner system, kutonhora system, uye ejection system.

Plate: Imwe hafu yesimbi mold. Ndiro iyi haina zvikamu zvinofamba. Inogona kunge ine mhango kana pakati.

B ndiro: Imwe hafu yesimbi mold. Iyo ndiro ine zvikamu zvinofamba kana nzvimbo yekubvumira zvikamu zvinofamba kuti zvibatane nechikamu chakapedzwa - kazhinji mapini ejector.

Mahwendefa ekutsigira: Simbi mahwendefa mukati mold frame inopa kugadzikana panguva yekuumba.

Ejector Bhokisi: Iine ejector system inoshandiswa kusunda chikamu chapera kubva muforoma.

Ejector Plates: Indiro yesimbi ine ejector bar. Iyo ejector ndiro inofamba ichibvisa chigadzirwa chakapedzwa mushure mekuumbwa.

Ejector Bar: Chikamu che ejector plate. Mapini ejector akabatanidzwa kune ejector bar.

Ejector Pini: Mapini esimbi anobata chikamu chakapedzwa uye ochisundira kunze kweforoma. Ejector pini mamaki anoonekwa pane zvimwe zvinhu zvakaumbwa-jekiseni, kazhinji denderedzwa rakadhindwa rinowanikwa kuseri kwechikamu.

Sprue Bushing: Chidimbu chekubatanidza pakati pe mold nejekiseni-molding muchina uko resin yakanyungudutswa inopinda mugomba.

Sprue: Nzvimbo iri pafuremu yemold panopinda muto wemold.

Locator Ring: Metal mhete inovimbisa kuti muromo wejekiseni-wekuumba muchina unopindirana nemazvo nesprue bushing.

Cavity kana Die Cavity: Concave impression in mold, kazhinji ichigadzira kunze kwechikamu chakaumbwa. Molds dzinosarudzwa segomba rimwe chete kana kuti-multi-cavity zvichienderana nehuwandu hwekuora mwoyo kwakadaro.

Core: Convex impression mu mold, kazhinji ichigadzira mukati mechikamu chakaumbwa. Ichi chikamu chakasimudzwa che mold. Ndiyo inverse yemhango. Resin yakanyungudutswa inogara ichisundirwa mugomba, ichizadza nzvimbo. Iyo resin yakanyungudutswa ichaumba yakatenderedza core yakasimudzwa.

Runner kana Runner System: Zvigero mukati mesimbi mold inobvumira resin yakanyunguduka kuyerera kubva kusprue-ku-cavity kana mhango-ku-cavity.

Gedhi: Magumo emumhanyi apo resin yakanyunguduka inopinda mugomba re mold. Kune akasiyana gedhi magadzirirwo ekushandisa kwakasiyana. Mhando dzemagedhi dzinowanzo shandiswa dzinosanganisira pini, kutaura, feni, mupendero, dhisiki, fan, tunnel, bhanana kana cashew, uye chisel. Kugadzirwa kwegedhi uye kuiswa kwakakosha kufunga usati watanga nzira yekugadzira mold.

Kutonhora System: Nhepfenyuro yematanho ari kunze kwegoko re mold. Idzi nzira dzinotenderedza mvura kuti ibatsire kutonhora. Zvikamu zvakatonhodzwa zvisina kufanira zvinogona kuratidza zvakasiyana-siyana zvepamusoro kana zvimiro zvakakanganisika. Iyo yekutonhodza maitiro inowanzoita iyo yakawanda yejekiseni molding kutenderera. Kuderedza kutonhora nguva kunogona kuvandudza zvakanyanya mold kushanda uye kuderera mutengo. Fathom inopa Conformal Kutonhodza kune akawanda majekiseni-kuumba maapplication ayo anozowedzera kugona kwe mold kusvika 60%

DJmolding Mold Manufacturing for Different Molding Processes

Iyo yepurasitiki jekiseni molding process inogona kugadziridzwa kuti igare zvakasiyana uye zvakaoma zvinodikanwa. Kunyange yakanakira kugadzira mavhoriyamu akakura ezvikamu zvepurasitiki zvakapfava, inogona zvakare kushandiswa kugadzira zvikamu zvakaomarara zvine majeometri akaomarara kana magungano.

Multi-Cavity kana Mhuri Mold -Ichi mold chine matinji akawanda mune imwe mold furemu inoburitsa akati wandei akafanana kana ane hukama nejekiseni rega rega. Iyi inzira yakanaka yekuwedzera mavhoriyamu ekumhanya uye kudzikisa iyo yega-chidimbu-mutengo.

Kukundikana -Iyi jekiseni rekuumba nzira inoshandiswa kugadzira zvikamu zvakagadzirwa nemhando mbiri dzakasiyana dzepurasitiki. Muenzaniso wakanaka weiyi ungave unotakurika muviri wekuboora kana mutambo wemutongi ane goko rakaomarara rekunze rine nyoro, rinobata rubberized. Chikamu chakamboumbwa chinoiswazve muforoma yakagadzirwa. Iyo mold yakavharwa uye chikamu chechipiri chepurasitiki yakasiyana chinowedzerwa pamusoro pechikamu chepakutanga. Iyi inzira yakanaka kana maumbirwo maviri akasiyana achidiwa.

Isa Molding -Ijekiseni yekuumba maitiro inobvumira kubatanidzwa kwesimbi, ceramic, kana zvidimbu zvepurasitiki muchikamu chekupedzisira. Simbi kana zvidimbu zveceramic zvinoiswa muforoma uyezve mapurasitiki akanyunguduka anopinzwa muforoma kugadzira chidimbu chisina musono chakagadzirwa nezvinhu zviviri zvakasiyana. Insert molding yakanakira maapplication emotokari sezvo iri nzira itsva yekudzikisa huremu uye kuderedza zvinhu zvinodhura sesimbi. Panzvimbo pekugadzira chidimbu chose kubva musimbi, zvidimbu zvekubatanidza chete zvinoda kuva simbi asi chimwe chinhu chichaitwa kunze kwepurasitiki.

Co-Injection Molding -Mapolymeri maviri akasiyana anoiswa sequentially kana panguva imwe chete mugomba. Iyi nzira inogona kushandiswa kugadzira zvikamu neganda reimwe mhando yepurasitiki ine musimboti weimwe.

Thin-Wall Molding -Chimiro chekuumbwa kwejekiseni chinotarisa pane ipfupi kutenderera nguva uye yakakwirira chigadzirwa kugadzira dzakatetepa, dzakareruka, uye dzakachipa epurasitiki zvikamu.

Rubber Jekiseni - Rubha inobaiwa muforoma uchishandisa maitiro akafanana neakaita jekiseni repurasitiki. Zvikamu zverabha zvinoda kudzvanywa kwakawanda kwekubudirira jekiseni kuumba.

Ceramic Jekiseni -Jekiseni kuumba maitiro uchishandisa ceramic zvinhu. Ceramic chinhu chakasikwa chakaoma, chemikemikari inert zvinhu zvinoshandiswa mumaindasitiri akasiyana siyana. Ceramic jekiseni inoda akati wandei mamwe matanho; kusanganisira sintering kana kurapa zvikamu zvichangobva kuumbwa kuti tive nechokwadi chekugara kwenguva refu.

Low-Pressure Plastic Injection Molding - Zvikamu zvepurasitiki zvinogadzirwa padiki kudzvinyirira. Izvi zvinonyanya kubatsira kumabasa anoda kuvharidzirwa kwezvikamu zvakatetepa, semagetsi.

Bata DJmolding kuti uwane rumwe ruzivo nezve epurasitiki jekiseni molding. Chikwata chedu chenyanzvi chinogona kukubatsira neyako jekiseni repurasitiki rakaumbwa purojekiti.