Plastic jekiseni Molding Services

Plastic jekiseni molding ndiyo maitiro ekuzadza mold chishandiso neamvura epurasitiki resin pasi pekumanikidzwa kukuru. Chishandiso chacho chinogona kuumba mhango imwe chete kana mazana emakomba kuitira kugadzira nhamba dzisingaperi dzezvikamu.

Pane zvakawanda zvakanakira epurasitiki jekiseni molding. Izvi zvinosanganisira kugona kugadzira mavhoriyamu mahombe ezvikamu nekukurumidza, yepamusoro yepamusoro mhando, akawanda maresi ekusarudza kubva, kuchinjika kwemavara, uye dura rekushandisa rinogona kugara kwemakore.

* Zviuru zvemaresheni ekusarudza kubva

* Hupfumi hwechiyero

* Yakagadzikana uye inodzokororwa

* Yakanakisa yepamusoro mhando

* Kuwedzeredza kune dzimwe sarudzo dzekugadzira

* Multi-cavity uye zvemhuri maturusi

Plastic jekiseni molding inzira yekugadzira inosanganisira kunyungudutsa epurasitiki pellets uye kuapinza mugomba rekugadzira kugadzira chinhu chine mativi matatu. Maitiro aya anotanga nezvigadzirwa zvakawanda, kubva kudiki diki diki kusvika kune zvakakosha zvikamu zvemotokari. Plastic jekiseni molding inopa akawanda mabhenefiti pamusoro pemamwe maitiro ekugadzira, anosanganisira akakwira ekugadzira mitengo, dhizaini inoshanduka, uye mutengo-kushanda. Gwaro iri rinotarisa zvakadzika pakuumbwa kwejekiseni repurasitiki uye kuongorora mashandisirwo ayo akasiyana-siyana, mabhenefiti, uye zvisingakwanisi

Custom Plastic jekiseni Molding

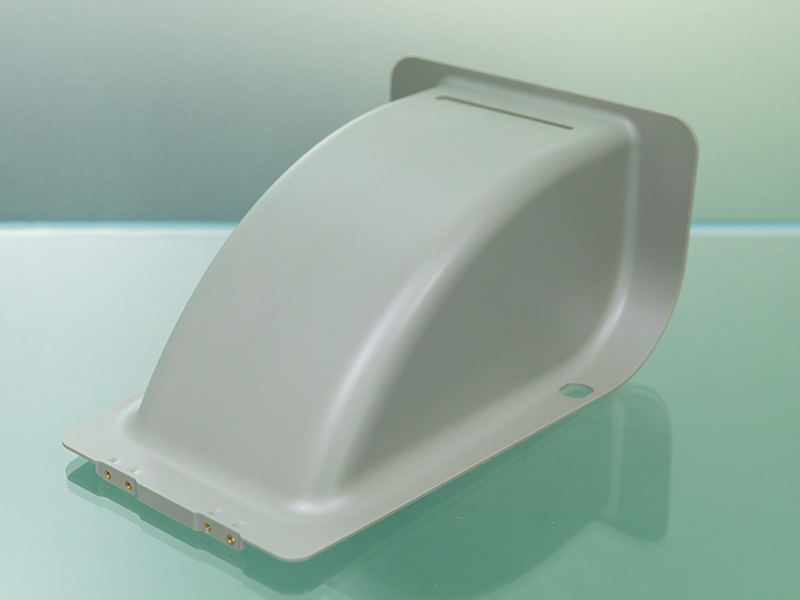

Zvikamu zvepurasitiki zvinogadzirwa zvinoenderana nezvako uye hazvina kupihwa kune chero mumwe mutengi. Izvi zvinogona kuve zvikamu zveinjiniya, makepisi, zvinhu zvekurongedza, zvikamu zvekurapa nezvimwe.

Liquid Silicone Rubber (LSR) Injection Molding

Jekiseni molding yeLiquid Silicone Rubber (LSR) inzira inoshandiswa kugadzira zvidimbu zvinobatika, zvinogara muzvikamu zvakakwirira. Munguva yekuita, zvinhu zvakati wandei zvinodikanwa: jekiseni, metering unit, dhiramu rekupa, musanganiswa, muromo, uye mold clamp, pakati pevamwe.

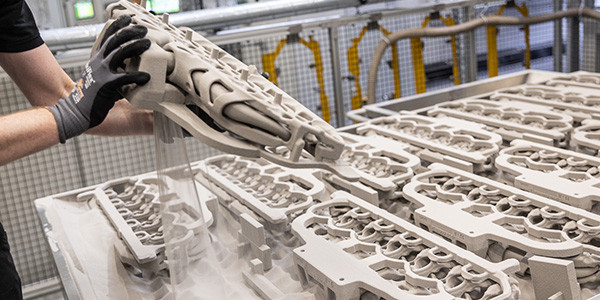

Inokurumidza Prototyping Service

Rapid prototyping ndiyo maitiro ekugadzira prototypes ezvigadzirwa nekukurumidza sezvinobvira. Prototyping chikamu chakakosha chekugadzirwa kwechigadzirwa. Ndiko uko zvikwata zvekugadzira zvinogadzira chigadzirwa chekuyedza kushandisa mazano avo.

Ndiyo maitiro ekugadzira prototypes nekukurumidza sezvinobvira kutevedzera yekupedzisira chigadzirwa dhizaini. Iri nhevedzano yematekiniki anoshandiswa kuenzanisa chiyero chechikamu chemuviri kana musangano uchishandisa CAD data.

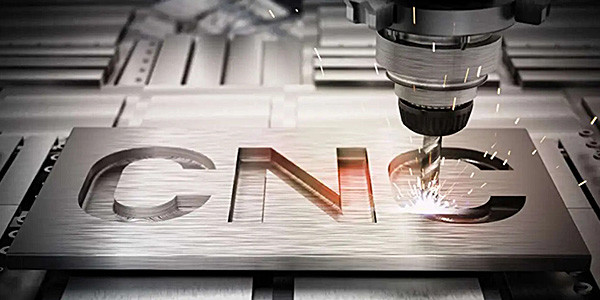

CNC inomirira komputa nhamba yekudzora, inova tekinoroji yekudzora maturusi emuchina otomatiki nekushandisa microcomputer yakasungirirwa pachishandiso. Michina yeCNCs yaizoshanda zvinoenderana nemirairo yakarongwa, sekufamba kwemichina, chiyero chekudya kwezvinhu, kumhanya, zvichingodaro. Iko hakuna kudikanwa kwevashandisi kudzora muchina nemawoko, nekudaro, CNC inobatsira kuvandudza mashandiro uye nemazvo kusvika pamwero mukuru.

Automotive Plastic Components Jekiseni Molding

Kuita kwepamusoro kwemotokari kunoda zvikamu zvinobata zvese. Mapurasitiki anoita kubva kunjini kuenda kune chassis; mukati memukati kusvika kunze. Mazuva ano mapurasitiki emota anoita 50% yevhoriyamu yemotokari nyowani asi isingasviki 10% yehuremu hwayo.

Isu takagadzira mold uye kuve nekugara kugadzirwa kweMotokari Plastiki Zvikamu zvinopa indasitiri yemotokari. Isu takabatira pamwe nevakawanda vanozivikanwa vagadziri vemotokari.

Recycled Plastic Injeciton Molding

Mapurasitiki akadzokororwa anoreva zvinhu zvepurasitiki zvinodzokororwa. Inogona kubva kune zvimwe zvigadzirwa zvepurasitiki kana tsvina inokonzerwa neplastic jekiseni molding process. Izvi zvinhu zvakadzokororwa zvinogona kuve zvechero mhando kana ruvara, uye kana ukazvishandisa kugadzira zvigadzirwa kuburikidza nejekiseni kuumba, hapana kurasikirwa mumhando.

Pa DJmolding, yedu pa-inodiwa, yakaderera-vhoriyamu yekugadzira inopa ine jekiseni molding-inoshandisa aluminium tooling-inokurumidza, inodhura nzira yekugadzira mazana ezviuru zvemagumo-ekupedzisira-akaumbwa zvikamu.

Low Volume Manufacturing Service

Mabhizinesi madiki anowanzoda rubatsiro kuwana zvinochipa zvekugadzira zvigadziriso zvinogona kuburitsa yakaderera mavhoriyamu ezvigadzirwa pasina kuunza mutengo wakakwira. Mabhizinesi madiki ane zviwanikwa zvishoma kazhinji anofanirwa kukunda chipingamupinyi chakakura nekuda kwemutengo-unoshanda unodiwa wekugadzira huwandu hukuru munzira dzechinyakare dzekugadzira. Nekudaro, nekubuda kweakaderera vhoriyamu yekugadzira masevhisi, mabhizinesi madiki anogona ikozvino kugadzira zvigadzirwa zvidiki pachikamu chemutengo wezvakajairwa nzira dzekugadzira. Ichi chinyorwa chichaongorora mabhenefiti eakaderera vhoriyamu yekugadzira masevhisi uye kuti vangabatsire sei mabhizinesi madiki kuti arambe achikwikwidza.

Nekupfuura zviuru zvemajekiseni epurasitiki ekuumba uye mapurasitiki ekugadzira zvivakwa zvekusarudza kubva pamusoro peshoko, ndehupi humwe hunhu hwepamusoro hunoita kuti kambani yekuumba ionekwe? Pakusarudza mupi, zvinhu zvakawanda zvinofanirwa kutariswa; kusanganisira kugona, kuvimbiswa kwemhando, mukurumbira wekambani, mutengo, uye nguva yekuendesa. Kutsvaga chaiyo jekiseni remajekiseni epurasitiki kuti rikwane zvaunoda kungaite sekudyira nguva asi kutanga kuona zvakaderera uye zvakakwirira-vhoriyamu zvaunoda uye kuti vangachinja sei nekufamba kwenguva, zvichabatsira kudzikisa sarudzo dzako.

Thermoplastic Injection Molding

Thermoplastic jekiseni molding inzira yakakurumbira yekugadzira inoshandiswa kugadzira akasiyana epurasitiki zvikamu zvemaindasitiri akawanda. Kuita uku kunosanganisira kunyungudusa maplastic pellets nekuapinza muforoma kuti abudise chimiro chetatu-dimensional. Thermoplastic jekiseni molding inoshanda zvakanyanya uye inodhura-inoshanda kugadzira mavhoriyamu makuru emhando yepamusoro zvikamu zvepurasitiki zvine kushivirira kwakasimba. Iri gwara rakazara rinoongorora zvakasiyana-siyana zve thermoplastic jekiseni molding, kusanganisira zvakanakira uye zvazvakaipira, mhando dze thermoplastics dzinoshandiswa, jekiseni rekuumba maitiro, dhizaini kufunga, uye zvimwe zvakawanda.

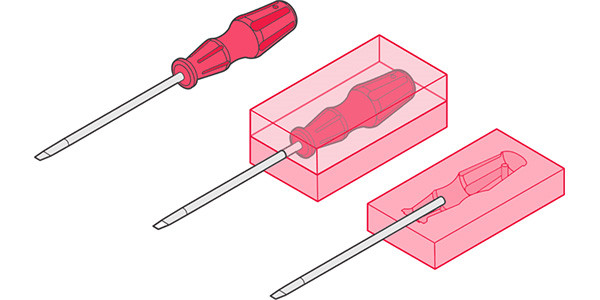

Insert jekiseni molding inzira inoshandiswa zvakanyanya kugadzira mukugadzira zvikamu zvepurasitiki zvakaoma zvine zvinhu zvakadzimirirwa. Iyi nzira inosanganisira kuisa simbi kana zvikamu zvepurasitiki mugomba rekuumbwa pamberi pekuita jekiseni. Iyo yakanyungudutswa inobva yayerera ichitenderedza chinhu chakaiswa, ichigadzira chisungo chakasimba pakati pezvinhu zviviri izvi. Insert jekiseni kuumbwa kunopa akati wandei mabhenefiti, anosanganisira yakagadziridzwa dhizaini kuchinjika, kuderedzwa nguva yegungano, uye kuwedzera chikamu mashandiro. Iri gwara rakazara rinoongorora akasiyana matekiniki, mabhenefiti, uye mashandisiro ekuisa jekiseni molding.

Overmolding inzira yekugadzira umo substrate kana chigadziko chikamu chinosanganiswa nechimwe kana zvimwe zvinhu kugadzira chigadzirwa chekupedzisira chine mashandiro akavandudzwa, kusimba, uye aesthetics. Iyi nzira yakawana mukurumbira mumakore achangopfuura nekuda kwekugona kwayo kuwedzera kunaka uye kuita kwezvigadzirwa uku ichideredza mitengo uye kurerutsa maitiro egungano. Overmolding inowana zvikumbiro mumaindasitiri akasiyana siyana, akadai semotokari, zvemagetsi, zvishandiso zvekurapa, uye zvigadzirwa zvevatengi. Kuti unzwisise zvizere maitiro aya, chinyorwa ichi chinotarisa mune akawanda maficha ekuwedzeredza, kusanganisira maitiro ayo, zvigadzirwa, uye mashandisiro.

Maviri Mavara Injection Molding

Maviri-mavara jekiseni molding, kana maviri-pfuti jekiseni kuumba, inzira yekugadzira inoshandiswa kugadzira zvikamu zvepurasitiki zvine mavara maviri akasiyana kana zvinhu. Kuita uku kunosanganisira kubaya zvimwe zvinhu zviviri muforoma imwe chete kugadzira basa rine maviri-toni kupedzisa kana akasiyana maitiro ekushanda. Maviri-mavara jekiseni molding ane akawanda maapplication mumaindasitiri akasiyana, anosanganisira emotokari, ekurapa, uye zvigadzirwa zvevatengi. Ichi chinyorwa chichaongorora zvakadzama nezve maviri-mavara jekiseni molding, zvakanakira, zvisingakwanisi, uye mashandisirwo.

Munyika yanhasi inokurumidza kukurumidza, kudiwa kwekuita uye kuchinjika mukugadzira kwawedzera. Pinda pane-inodiwa yekugadzira masevhisi, nzira yeshanduko inogadzirisa zvechinyakare kugadzirwa paradigms. Ichi chinyorwa chinonyura mukati meiyo pfungwa, mabhenefiti, mashandisiro, uye tarisiro ye-inodiwa yekugadzira masevhisi, ichijekesa maitiro avanoita maindasitiri pasi rese.

Kuti uzive zvakawanda nezve DJmolding epurasitiki zvigadzirwa uye masevhisi, ndapota taura nesu ne Email: info@jasonmolding.com