Plastic jekiseni kuumba tekinoroji uye kushandisa

Jekiseni molding inzira inoshandiswa kugadzira zvakasiyana-siyana zvemuchina. Iko kushandiswa kwakasiyana-siyana kweiyi nzira inogonesa hupamhi hwepamusoro, hushoma-mutengo, kukurumidza kugadzirwa kwezvikamu zvepurasitiki.

Ndeapi marudzi akajairika ekuita jekiseni molding process?

Thermoset jekiseni kuumba

Kuumba nezvinhu zve thermoset zvinoda kupisa kana kemikari nzira yekuyambuka-inobatanidza polymer cheni.

Kukundikana

Overmolding inzira yekuumba jekiseni apo chimwe chinhu chinoumbwa pamusoro pechimwe.

Gasi-inobatsira jekiseni molding

Inert gasi inounzwa, pakumanikidzwa kwakanyanya, kupinda mupolymer inonyungudika pakupera kwechikamu chejekiseni chekuumba.

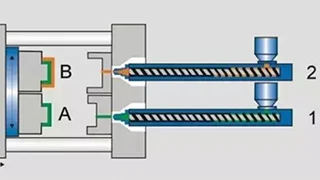

Co-jekiseni & Bi-jekiseni kuumba

Jekiseni rezvinhu zviviri zvakasiyana uchishandisa imwe chete kana nzvimbo dzakasiyana dzejekiseni.

Co-jekiseni & Bi-jekiseni kuumba

Jekiseni rezvinhu zviviri zvakasiyana uchishandisa imwe chete kana nzvimbo dzakasiyana dzejekiseni.

Powder injection molding (PIM)

Kugadzira nzira yekugadzira zvidiki diki uchishandisa hupfu, kazhinji ceramics (CIM) kana simbi (MIM), uye zvinosunga zvisungo.

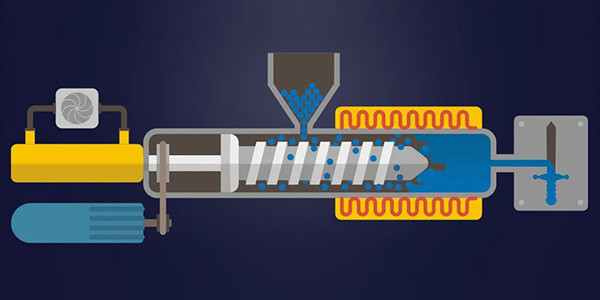

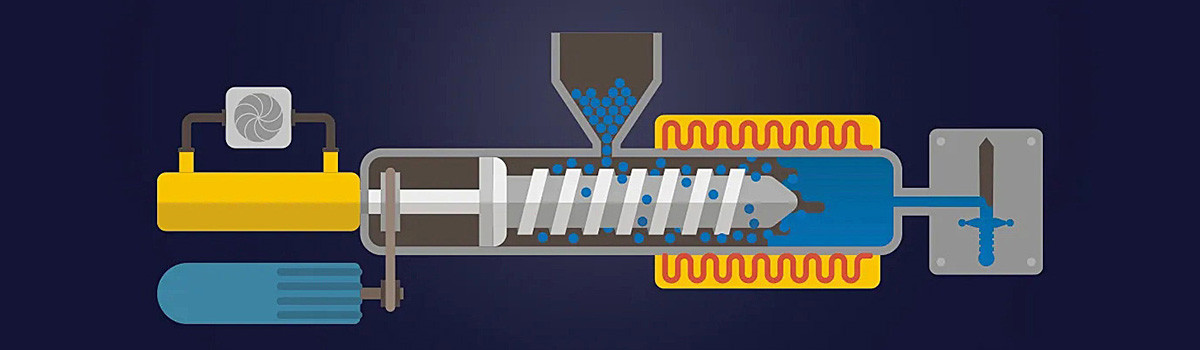

Chii chinonzi plastic injection molding

Thermoplastic jekiseni molding inzira yekugadzira yakakwirira-vhoriyamu zvikamu nezvinhu zvepurasitiki. Nekuda kwekuvimbika kwayo uye kuchinjika mumagadzirirwo esarudzo, jekiseni rekugadzira rinoshandiswa mumaindasitiri mazhinji, anosanganisira: kurongedza, mutengi & zvemagetsi, mota, zvekurapa, uye zvimwe zvakawanda.

Jekiseni molding ndeimwe yeanonyanya kushandiswa kugadzira maitiro munyika. Thermoplastics mapolymer anopfava uye anoyerera kana apiswa, uye anoomesa sezvaanotonhorera.

Chii chinonzi Cushion & nei ndichifanira kuibata

Jekiseni Molding ine akawanda emazwi asinganzwisisike ekurira. Zadza nguva, kumanikidzwa kumashure, saizi yepfuti, cushion. Kune vanhu vatsva kumapurasitiki kana kuumba jekiseni, mamwe emazwi aya anogona kunzwa kuremerwa kana kuita kuti unzwe usina kugadzirira. Chimwe chezvinangwa zvebhurogu yedu ndechekubatsira vatsva processors vane maturusi avanoda kuti vabudirire. Nhasi tichatarisa cushion. Chii, uye nei zvakakosha "kuchibata?"

Nheyo dzePlastiki Injection Molding

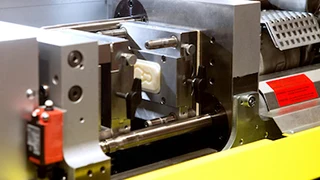

Plastic jekiseni molding inzira yakakurumbira yekugadzira iyo thermoplastic pellets inoshandurwa kuita mavhoriyamu akakwira ezvikamu zvakaoma. Iyo jekiseni yekuumba maitiro inokodzera akasiyana emidziyo yepurasitiki uye chinhu chakakosha chehupenyu hwazvino-makesi enhare, dzimba dzemagetsi, matoyi, uye kunyange zvikamu zvemotokari hazvigoneke pasina iyo. Ichi chinyorwa chichapwanya izvo zvekutanga zvekuumbwa kwejekiseni, tsanangura kuti jekiseni rekuumba rinoshanda sei, uye kuratidza kuti rakasiyana sei nekudhinda kwe3D.

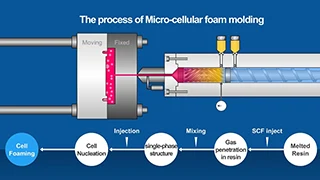

Zvitsva Zvitsva muPurasitiki Injection Molding

Plastic jekiseni molding senzira yekugadzira yave iripo kwemakumi emakore. Nekudaro, maitiro matsva ekuumba majekiseni ari kufambisa nzira iyi kumberi, achiunza mabhenefiti matsva uye asati amboitika kune makambani anozvisarudzira.

Tsvaga kuti maitiro matsva ekuumba jekiseni ndeapi emakore anouya uye kuti kambani yako ingabatsirike sei nekuashandisa.

Plastic Jekiseni Kuumba Makiyi Mafungiro

Zvishandiso zvinoita basa rakakosha mukuumba jekiseni. A hunyanzvi jekiseni rekuumba mupi anogona kukubatsira iwe kusarudza thermoplastic inokodzera bhajeti rako uye kuita zvinodiwa. Nekuti ma molder anowanzo kuwana zvidzikiso pahuwandu hukuru hwemagiredhi ethermoplastic avanotenga, vanogona kupfuudza izvo zvakachengetwa kwauri.

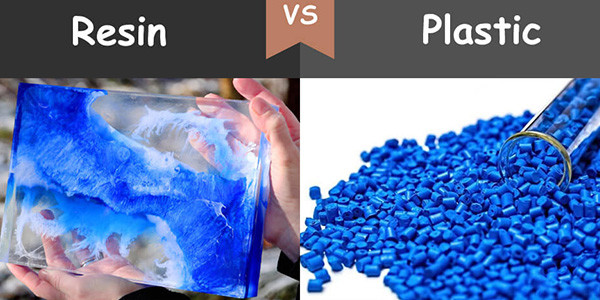

Maitiro Ekusarudza Izvo Zvakanakisa Plastic Zvishandiso ZvePlastiki Injection Molding

Kusarudza mapurasitiki akakodzera ekuumba jekiseni repurasitiki kunogona kuve kwakaoma-kune zviuru zvezvisarudzo mumusika zvaungasarudza kubva, mazhinji ayo asingashande kune chinangwa chakapihwa. Neraki, kunzwisisa kwakadzama kwezvinhu zvinodikanwa zvezvinhu uye chinangwa chekushandisa kuchabatsira kupfupisa rondedzero yezvaungagona kuita mune chimwe chinhu chinogoneka.

Maitiro ekusarudza iyo Yakanakisa Plastic yePlastiki Injection Molding

Nemazana ezvigadzirwa uye marezeni einjiniya aripo pamusika nhasi, maitiro ekusarudza zvinhu epurasitiki jekiseni rekugadzira mabasa anogona kumboita seanonetsa pakutanga.

PaDJmolding, isu tinonzwisisa zvakasarudzika mabhenefiti uye zvivakwa zvemhando dzakasiyana dzemapurasitiki uye tinoshanda padhuze nevatengi kuti tiwane yakanyanya kukwana purojekiti yavo.

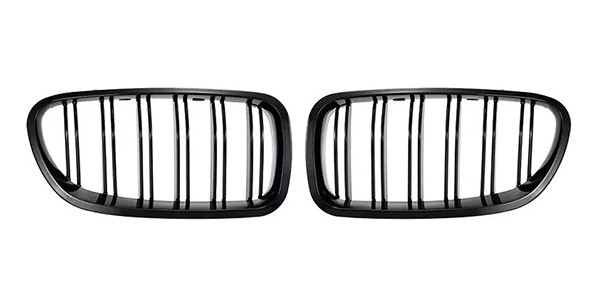

Innovative jekiseni Molding Solutions For The Automotive Indasitiri

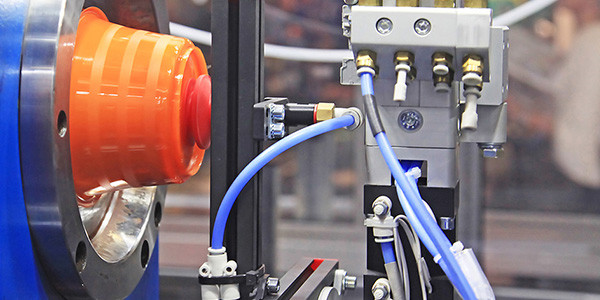

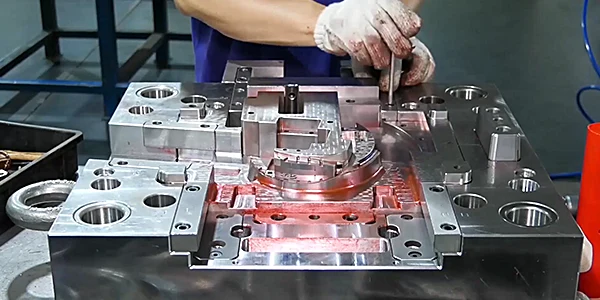

Kamwe kana maumbirwo akakodzera ezvigadzirwa awanikwa, icho chaicho chikamu cheakawanda-nhanho epurasitiki jekiseni kuumba maitiro anoitwa. Kutanga, ipurasitiki inonyungudutswa mumadhiramu anokosha; ipapo ipurasitiki inomanikidzwa uye inopinzwa mumhando dzakagadzirirwa kare. Nenzira iyi, zvakanyatsogadzirwa zvikamu zvinogona kugadzirwa nekukurumidza. Ichi ndicho chikonzero kukurumidza jekiseni kuumba kwave kwakakurumbira mumaindasitiri mazhinji, kusanganisira chikamu chemotokari.

Maitiro Ekutora Yakanaka Jekiseni Molding Kambani

Iwe uri mutengi wezvikamu zvepurasitiki here? Uri kunetsekana here kuwana mubatanidzwa nemuumbi akakosha? PMC (Plastiki Yakaumbwa Concepts) iri pano kuti ikubatsire. Isu tinonzwisisa kuzivisa kambani inoremekedzwa yekuumba kwakakosha pakubudirira kwekambani yako. Zvakakosha kuisa mberi nzira yekusarudza muumbi wakanaka. Ngationgororei mibvunzo mishoma inokubatsira mukutsvaga waunoshanda naye anobatsira kutsigira kuzvipira kwekambani yako kune mhando.

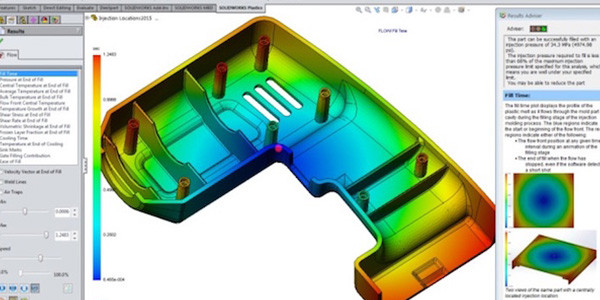

Solutions to Common Molding Defects of Injection Molding

Kukanganisa kwakajairika kana uchishandisa mold kugadzirisa majekiseni epurasitiki ekuumba zvikamu, uye izvi zvakanyanya kukanganisa mashandiro ekugadzirisa. Izvi zvinotevera zvinojairika kuumba kukanganisa uye mhinduro dzepurasitiki jekiseni mold zvikamu.