Iyo Art yeDiki Batch Plastic Injection Molding: Kufambisa Kugadzirwa Nechokwadi

Iyo Art yeDiki Batch Plastic Injection Molding: Kufambisa Kugadzirwa Nechokwadi

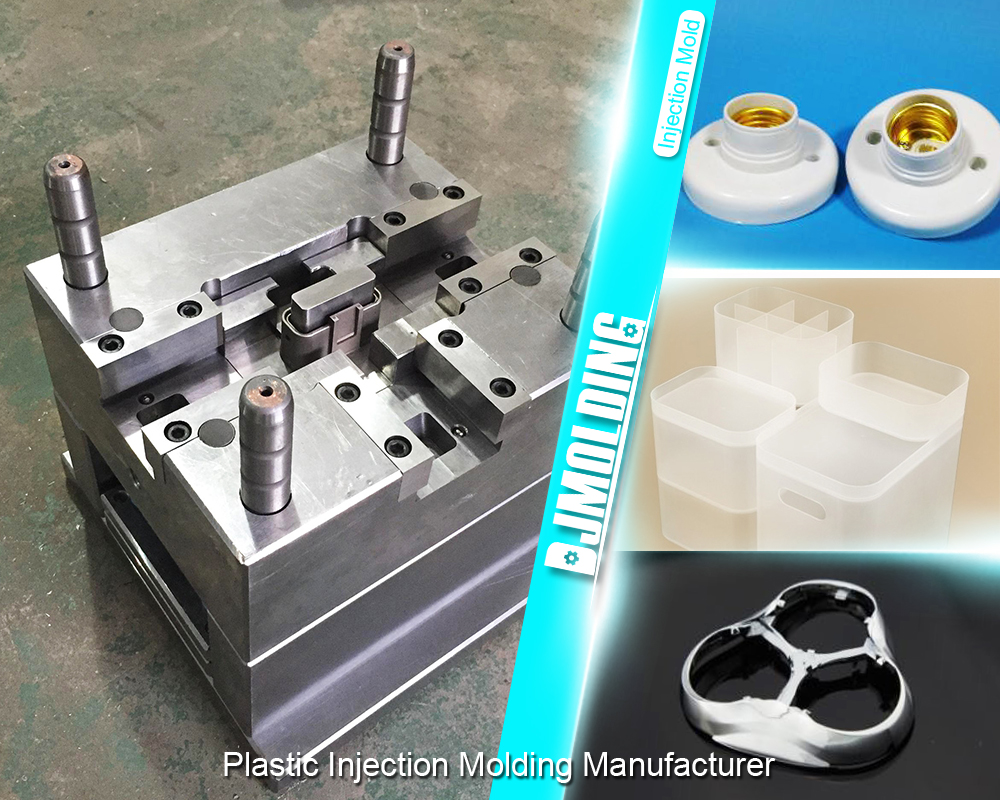

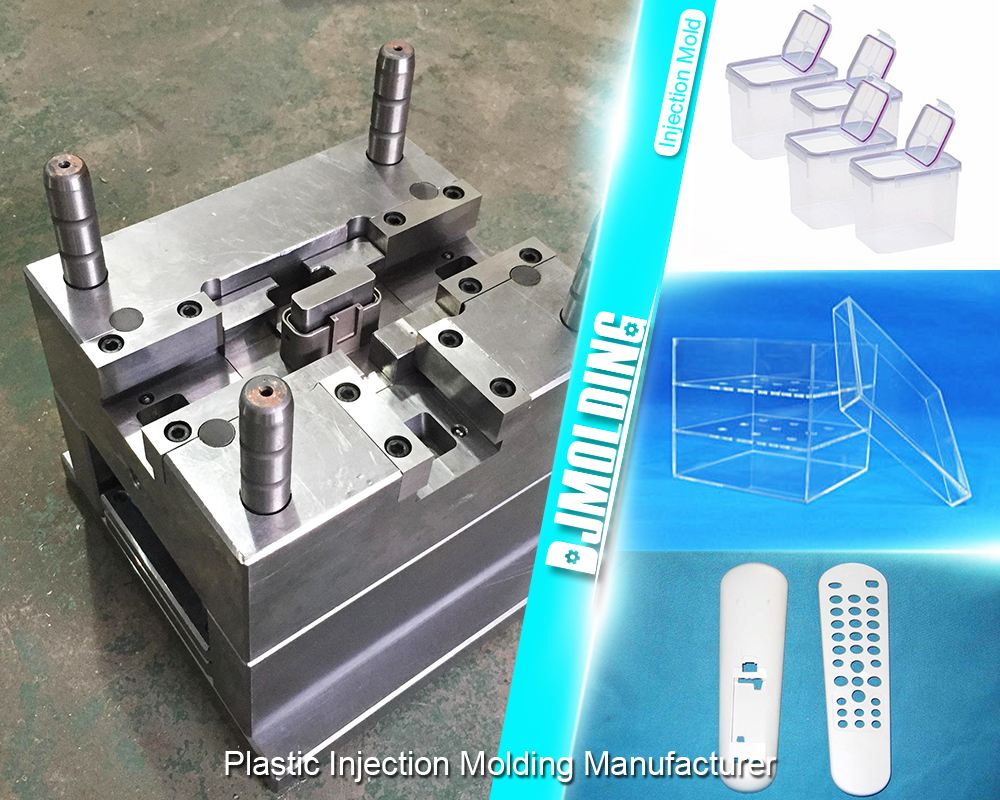

Plastic jekiseni Kuumbwa yabuda senzira yekuchinja-mutambo mune yanhasi inokurumidza kugadzira mamiriro. Kubatanidza kurongeka uye kushanda nesimba kunogonesa kugadzirwa kwakawanda kwezvinhu zvakaoma kunzwisisa zvepurasitiki. Ichi chinyorwa chinotarisa mukati mekuoma kwemajekiseni epurasitiki kuumba, kuratidza kukosha kwayo, zvakanakira, uye mashandisirwo mumaindasitiri akasiyana.

Kunzwisisa Diki Batch Plastic Injection Molding

Tsanangudzo uye Maitiro Ongororo

Plastic jekiseni molding inzira yekugadzira inosanganisira kubaya purasitiki yakanyungudutswa mugomba rekuumba kugadzira yakaoma uye chaiyo maumbirwo. Ichi chikamu chinotsanangura matanho ekutanga, kubva pakusarudza zvinhu kusvika pakushandisa zvakakosha senge molds, jekiseni mayunitsi, uye clamping masisitimu.

Mhando dzePlastiki Yakashandiswa

Kubudirira kwekuumbwa kwejekiseni repurasitiki kunoenderana nekushandisa mhando dzakasiyana dzemapurasitiki akagadzirirwa kune chaiwo maapplication. Pano, tinoongorora mapurasitiki anonyanya kushandiswa, kusanganisira thermoplastics uye thermosetting polymers. Nekunzwisisa hunhu hwavo hwakasiyana uye zvivakwa, vagadziri vanogona kukwidziridza maitiro ekuumba kune epamusoro mhedzisiro.

Mabhenefiti Akakosha ePlastiki Injection Molding

Plastic jekiseni molding inopa akawanda mabhenefiti pamusoro pedzimwe nzira dzekugadzira. Ichi chikamu chinotarisa mukudhura-kushanda, dhizaini kuchinjika, hukuru hwekugadzira hunyanzvi, uye kuenderana kwehutongi hwemhando. Mienzaniso yepasirese uye nyaya dzebudiriro dzinoratidzazve shanduko yekuumbwa kwejekiseni repurasitiki pamaindasitiri akasiyana.

Iyo Plastic Injection Molding process

Mold Design uye Kugadzirira

Mold design chinhu chakakosha che epurasitiki jekiseni Kuumbwa. Isu tinokurukura kukosha kwekugadzira molds kuti iite basa rakanyanya, kusimba, uye kugadzirwa kwakanaka. Pamusoro pezvo, isu tinobata pane zvakasiyana mold zvinhu uye zvimiro zvavo kuti tive nechokwadi chekusarudzwa kweiyo yakanyanya kufanirwa sarudzo yeprojekiti yega yega.

Injection Phase

Chikamu chejekiseni chinosanganisira kunyungudutsa zvinhu zvepurasitiki, kuchimanikidza, uye nekuchipinza mugomba reforoma. Pano, tinopa tsananguro yakadzama yechikamu ichi, tichisimbisa kukosha kwekunyatso uye kutonga. Vagadziri vanoongorora tembiricha, kudzvanywa, uye nguva yekutonhora kuti vawane mhando yechigadzirwa.

Kutonhodza uye Solidification

Chikamu chekutonhodza chinoita basa rakakosha mukugadzira jekiseni repurasitiki. Isu tinoongorora matekiniki ekutonhodza kuti tive nechokwadi chekusimbiswa kwepurasitiki, kusimudzira kutendeseka uye kuderedza kukanganisa. Nyanzvi dzinokurukura mazano akadai sekudzora tembiricha yekuumbwa, conformal kutonhora, uye nekukurumidza kutonhora nzira.

Ejection uye Kupedzisa

Iyo mold inobvisa chigadzirwa mushure mekusimba. Ichi chikamu chinotsanangura maitiro ejection uye chinosimbisa chechipiri mashandiro akadai sekucheka, kupukuta, uye kupedzisa kwepamusoro. Nekugadzirisa izvi zvekupedzisa kubata, vagadziri vanogona kusimudzira aesthetics yechigadzirwa, kushanda, uye kushambadzira.

Zvishandiso zvePlastiki Injection Molding

- Zvigadzirwa zvevatengi: Vagadziri vanonyanya kushandisa epurasitiki jekiseni kuumba kugadzira zvinhu zvevatengi. Vagadziri vanoshandisa nzira iyi kugadzira kitchenware, midziyo yemumba, matoyi, uye zvemagetsi. Iko kuita kwakasiyana-siyana kwekuumbwa kwejekiseni repurasitiki kunobvumira kugadzirwa kweakaomesesa dhizaini, mavara anopenya, uye zvigadzirwa zvinogara zvinosimudzira hupenyu hwedu hwemazuva ese.

- Indasitiri yemotokari: Indasitiri yemotokari inovimba zvakanyanya nekuumbwa kwejekiseni repurasitiki kugadzira zvinhu zvakasiyana. Kubva mukati ma trim uye dashboard mapaneru kuenda kunze senge mabumpers uye grilles, epurasitiki jekiseni molding inopa dhizaini kuchinjika, kuderedza huremu, uye mutengo-kubudirira. Iyo inogonesa iyo indasitiri yemotokari kuti iwane aesthetic kukwezva, kushanda kwekubatanidza, uye kuvandudzwa kwemafuta.

- Medical and Healthcare: Plastic jekiseni kuumba kwakakosha mune zvekurapa uye zvehutano zvikamu. Vagadziri vanoishandisa kugadzira michina yekurapa, midziyo, uye zvinodyiwa zvine hutsinye hwemhando yepamusoro uye kutevedza kwemitemo. Vagadziri vanogadzira zvinhu zvakaita semajekiseni, majekiseni eIV, zviridzwa zvekuvhiya, uye maimplants vachishandisa biocompatible zvinhu kuti ive nechokwadi chekuchengetedzwa kwemurwere uye kuita chaiko.

- Packaging Indasitiri: Plastic jekiseni molding inobatsira muindasitiri yekurongedza. Inogonesa kugadzirwa kwemidziyo yepurasitiki, mabhodhoro, zvivharo, uye kuvharwa kunoshandiswa muzvikamu zvakasiyana sechikafu nezvinwiwa, kutarisirwa kwevanhu, uye mishonga. Iko kugona kugadzira akagadziridzwa maumbirwo, saizi, uye maficha anoita epurasitiki jekiseni kuumba sarudzo yakasarudzika yekurongedza mhinduro.

- Electronics uye Magetsi Zvikamu: Plastic jekiseni molding inobatsira zvikuru indasitiri yemagetsi. Inofambisa kugadzirwa kwemakasi, majoini, switch, uye zvimwe zvakaomarara zvikamu zvinodiwa pamidziyo yemagetsi uye masisitimu emagetsi. Plastic jekiseni molding inovimbisa kunyatsoita, dimensional kugadzikana, uye dziviriro kubva kune zvakatipoteredza zvinhu zvemagetsi zvigadzirwa.

- Aerospace uye Dziviriro: Plastic jekiseni molding inowana maapplication muaerospace uye chikamu chekudzivirira. Vagadziri vanoshandisa epurasitiki jekiseni molding kugadzira kureruka, yakakwirira-simba zvinhu zvinosangana nekuita kwakaomarara uye kuchengetedza zvinodiwa. Mienzaniso inosanganisira zvemukati, mapaneru emidziyo, mabhuraketi, uye masisitimu emuchadenga ducting.

- Kuvaka uye Zvishandiso zvekuvaka: Kuumbwa kwejekiseni repurasitiki kunopa indasitiri yekuvaka nekugadzira zvinhu zvakaita sepombi, mafittings, insulation, uye zvinhu zvedenga. Kugara kwenguva refu, corrosion resistance, uye kudhura-kushanda kwezvigadzirwa zvemajekiseni epurasitiki zvinoita kuti zvive zvakanakira kushandiswa kwekuvaka.

- Mitambo Nevaraidzo: Plastic jekiseni molding inogadzira michina yemitambo, zvigadzirwa zvekuvaraidza, uye giya rekunze. Vagadziri vane zvinhu zvakaita sengowani, giya rekudzivirira, zvinhu zvebhora, uye zvibatiso zvemidziyo vachishandisa maitiro aya. Plastic jekiseni Kuumbwa inobvumira kugadzirwa kwezvakareruka, zvisingaite zvigadzirwa zvinosimudzira kuita uye kuchengetedzeka.

Kufambira mberi uye Mafambiro Amangwana

Technology Innovations

- Automation: Automation yakashandura kuumbwa kwejekiseni repurasitiki, kugadzirisa maitiro ekugadzira nekuvandudza kushanda zvakanaka. Otomatiki masisitimu anogona kubata kubata zvinhu, mold shanduko, uye kutonga kwemhando, kuderedza kukanganisa kwevanhu uye kuwedzera chibereko.

- 3D Kudhinda: Kubatanidza 3D yekudhinda tekinoroji nepurasitiki jekiseni molding yakavhura mikana mitsva yekukurumidza prototyping uye kugadzirisa. 3D-akadhindwa mold uye anoisa anogona kushandiswa padivi pechinyakare mold, achibvumira kukurumidza kudzokororwa uye inodhura-inoshanda diki-batch kugadzirwa.

- Njere yekuzvinyudza (AI): AI inoita basa rinowedzera kukosha mukuumba jekiseni repurasitiki. AI-powered software inogona kuongorora process data munguva chaiyo, optimize parameters senge tembiricha, kudzvanywa, uye kutonhora nguva yekuvandudza chikamu chemhando. Predictive AI-powered kugadzirisa masisitimu anogona zvakare kubatsira kudzivirira kusingatarisirwe kuderera uye kuderedza mari yekugadzirisa.

- Multi-Material Molding: Iko kugona kushandisa akawanda zvinhu mune imwechete jekiseni molding process iri kuwana traction. Vagadziri vanogona kushandisa epurasitiki jekiseni kuumba kugadzira zvikamu zvakaoma zvine zvinhu zvakasiyana siyana, sekubatanidza mapurasitiki akaoma uye anochinjika. Iyi tekinoroji yekugadzira inobvumira kunyatso kudzora pamusoro pemaitiro ekuumba, zvichiita kuti uwane huwandu hwakasiyana hwezvikamu zvekugadzira uye geometries zvinogoneka. Multi-material molding inowedzera dhizaini mikana uye inosimudzira mashandiro echigadzirwa.

- Micro-Injection Molding: Miniaturization inzira iri kukura mumaindasitiri, uye micro-jekiseni kuumba inogadzirisa kudiwa uku. Iyi tekinoroji inoburitsa yakakwirira-chaiyo diki, zvikamu zvakaomarara, kuvhura mikana muzvikamu zvakaita semagetsi, zvishandiso zvekurapa, uye microfluidics.

- Sustainable Materials: Sezvo kugadzikana kuchive chinhu chakakosha pamberi, indasitiri iri kutsvaga zvimwe zvekushandisa zvepurasitiki jekiseni kuumba. Biodegradable uye bio-yakavakirwa mapurasitiki anotorwa kubva kune anovandudzwa masosi ari kuwana mukurumbira. Pamusoro pezvo, kushandisa mapurasitiki akadzokororwa kunoderedza marara uye kunotsigira hupfumi hwedenderedzwa.

- Smart Manufacturing: Kubatanidza Internet yezvinhu (IoT) tekinoroji mupurasitiki jekiseni molding inobvumira kungwara kutarisa uye kutonga kwemaitiro ekugadzira. Sensors uye yekubatanidza inogonesa chaiyo-nguva yekuunganidza data, kuongorora, uye kure kutarisa. Kushandisa otomatiki matekiniki mukuumbwa kwejekiseni repurasitiki kunosimudzira kutonga kwemhando, kunoderedza nguva yekudzikira, uye kunonatsiridza mashandiro akazara. Aya maitiro anogona kusanganisira otomatiki kubata zvinhu, robhoti kubviswa chikamu, uye in-line yekuongorora masisitimu.

- Virtual uye Augmented Reality: Mukugadzira jekiseni repurasitiki, vagadziri uye mainjiniya vanoshandisa chaiwo uye augmented echokwadi matekinoroji kusimbisa dhizaini uye kugadzirisa maitiro. Vagadziri vanogona kuona zvingangoitika nyaya, kugadzirisa zvigadziriso, uye kuderedza nguva-ku-musika nekugadzira chaiwo prototypes uye kutevedzera maitiro ekuumba.

Uku kufambira mberi uye mafambiro emangwana mukuumbwa kwejekiseni repurasitiki kuri kuumba mamiriro eindasitiri, zvichiita kuti kugadzirwa kukurumidze, kushande, uye kune hushamwari. Nekumbundira otomatiki, kusimudzira kudhinda kwe3D uye AI, kuongorora zvinhu zvitsva, uye kutora hungwaru hwekugadzira maitiro, vagadziri vanogona kuramba vachikwikwidza uye kusangana nezvinoda kuitika zvemusika. Iko kuenderera mberi kwekutsvaga kwekuvandudza kunovimbisa kuti epurasitiki jekiseni molding inoramba iri pamberi pekugadzirwa kwemazuva ano.

mhedziso

Plastic jekiseni molding ibwe repakona rekugadzirwa kwemazuva ano, zvichiita kuti kugadzirwa kwakanaka kwezvinhu zvakaoma zvepurasitiki. Plastic jekiseni molding yakashandura zvigadzirwa nekushandura nhanho dzepakati pekuita, ichipa akasiyana mabhenefiti, nekutsvaga maapplication mumaindasitiri akawanda. Vagadziri vanogona kusangana nevatengi 'zvinoramba zvichikura zvinodiwa nekusimudzira kunyatsoita, dhizaini inoshanduka, uye mutengo-kubudirira. Indasitiri yekugadzira jekiseni repurasitiki yakagadzirira remangwana rizere nehunyanzvi uye mutoro wezvakatipoteredza sezvo kufambira mberi kwetekinoroji uye kuedza kwekusimudzira kuri kuramba kuchiiumba. Isu tinokoka vaverengi kuti vaongorore zvakare uye vawane mikana isingaverengeki iyo inopihwa epurasitiki jekiseni molding.

Nezvizhinji nezve diki batch epurasitiki jekiseni kuumba,unogona kushanyira Djmolding pa https://www.djmolding.com/injection-mould-manufacturing/ nokuti zvimwe info.