Isitofu sePlastiki sokubumba Iingqwalasela eziphambili

Nayiphi na iprojekthi yokubumba eyimpumelelo yokutofa kufuneka ithathele ingqalelo izinto ezininzi ngaxeshanye.

Ukukhetha isixhobo

Izixhobo zidlala indima ebalulekileyo ekubumbeni inaliti. Umboneleli wokubumba isitofu onobuchule unokukunceda ukhethe i-thermoplastic ehambelana nohlahlo lwabiwo-mali kunye neemfuno zokusebenza. Ngenxa yokuba ababumbi bahlala befumana izaphulelo kumanani amakhulu amabakala e-thermoplastic abawathengayo, banokudlulisela ezo zonga kuwe.

Iiyantlukwano zokunyamezela

Yonke imveliso eyenziwe ngokubumba inaliti kufuneka ibe nonyamezelo oluthile ukuze ilingane nesicelo sayo. Izinto ezithile zinokuba nzima ukubumba okanye ukubamba ukunyamezela okufunekayo, kwaye uyilo lwesixhobo sinokuchaphazela ukunyamezela inxalenye yokugqibela. Soloko uxoxa ngesibumbi sakho senaliti ngoluhlu lokunyamezela ukwamkelwa kweemveliso ezithile.

Umphanda kunye nobushushu boMlomo

Iimolders kufuneka zigcine umphanda othile kunye nobushushu bombhobho ekubunjweni kwenaliti kuba zichaphazela ukukwazi kweresin ukuhamba kuyo yonke isikhunta. Amaqondo obushushu emgqomo kunye nombhobho kufuneka abekwe ngokuchanekileyo phakathi kwe-thermo-decomposition kunye namaqondo okunyibilika. Kungenjalo, kunokubangela ukuphuphuma, ukukhanya, ukuhamba kancinci, okanye iindawo ezingazaliswanga.

Amaxabiso okuHamba kweThermoplastic

Izinto zokubumba kufuneka zigcine umlinganiselo wokuqukuqela ungowona wokuqinisekisa ukuba iplastiki eshushu itofwa ngokukhawuleza kangangoko kunokwenzeka kwingxuma yokungunda de ibe yi-95% ukuya kuma-99%. Ukuba nesantya esifanelekileyo sokuhamba kuqinisekisa ukuba iplastiki igcina inqanaba le-viscosity elifanelekileyo lokungena emgodini.

Eminye imiba ekufuneka ithathelwe ingqalelo nakuwuphi na umsebenzi wokubumba inaliti zezi:

*Indawo yesango

*Sinki amanqaku

*Vala ii-engile

*Ukuthumela imiyalezo

*Idrafti kunye nedrafti yokuqhelaniswa ne-engile

* Iindawo ezikhuselekileyo zentsimbi

Amanyathelo amathandathu aPhambili kwiNkqubo yokuBumba ngokutofa

Inkqubo yokubumba inaliti ibandakanya amanyathelo amathandathu angundoqo, kwaye imiba inokuvela nakweliphi na lala manqanaba ukuba ayiqhutywa ngokufanelekileyo.

1.Ukubamba

Kule nkqubo, iziqingatha ezibini zokubumba zikhuselwe ngokuqinileyo kusetyenziswa iyunithi yokudibanisa, esebenzisa amandla oxinzelelo lwe-hydraulic ukwenza amandla aneleyo ukuvala ukubumba. Ngaphandle kwamandla aneleyo okubamba, inkqubo inokukhokelela kumacandelo angalinganiyo eludongeni, ubunzima obungahambelaniyo, kunye nobukhulu obahlukeneyo. Amandla okubamba ngokugqithisileyo anokubangela ukudubula okufutshane, ukutshisa, kunye notshintsho lwegloss level.

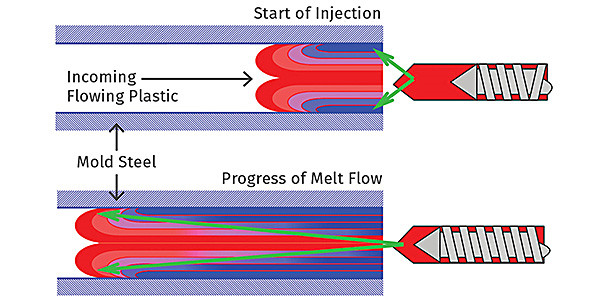

2.Ukutofa

Iimolders zifakela imathiriyeli enyibilikisiweyo ye-thermoplastic kwi-mold ngesixhobo seramming okanye isikrufu phantsi koxinzelelo oluphezulu. Emva koko, inxalenye kufuneka ivunyelwe ukuba ipholise kwizinga elifanayo. Ukuba akunjalo, inxalenye yokugqibela ingaba nemigca yokuhamba okanye iipateni ezingafunekiyo ezichaphazela ubuhle bayo.

3.Uxinzelelo lokuhlala

Emva kokuba i-thermoplastic imathiriyeli ifakwe kwi-mold, ii-molders zenza uxinzelelo olungakumbi lokuzalisa imingxuma ngokupheleleyo. Ngokuqhelekileyo babamba izinto ezityhidiweyo ze-thermoplastic de isango lokungunda libe ngumkhenkce. Ixesha lokuhlala kufuneka lifake uxinzelelo oluchanekileyo-oluphantsi kakhulu kwaye lunokushiya amanqaku e-sink kwimveliso egqityiweyo. Uxinzelelo olugqithisileyo lunokubangela i-burrs, imilinganiselo eyandisiweyo, okanye ingxaki yokukhulula inxalenye ekubumbeni.

4.Ukupholisa

Emva kokuhlala, ukungunda kuyazaliswa, kodwa kusenokwenzeka ukuba kuseshushu kakhulu ukuba kungasuswa kubumba. Ngoko ke, ababumbi banika ixesha elithile lokuba umngundo ufunxe ubushushu kwiplastiki. Iimolders kufuneka zigcine ngokwaneleyo, ukupholisa okufanayo kwesixhobo se-thermoplastic okanye kuya kuba sengozini yokulwa nemveliso yokugqibela.

5.Ukuvula uMngundo

Iipleyiti ezihambayo zomatshini wokutofa ngundo ziyavuleka. Ezinye iimbumba zinolawulo lokuqhuma umoya okanye i-core pulls, kwaye umatshini wokubumba ulawula inqanaba lamandla asetyenziselwa ukuvula ukubumba ngelixa ukhusela inxalenye.

6.Ukususwa kwenxalenye

Imveliso yokugqibela ikhutshwa kwimold yokutofa nge-pulse ephuma kwinkqubo yokukhupha, iirods, okanye iirobhothi. I-Nano yokukhulula iingubo kwindawo yokubumba inceda ukukhusela ukukrazula okanye iinyembezi ngexesha lokukhupha.

Iziphene zokubumba eziqhelekileyo ezibangelwa ziingxaki zeNkqubo

Kukho iziphene ezininzi zokubumba ezinxulumene nesitofu sokubumba, njengale:

Warping: I-Warping yi-deformation eyenzekayo xa inxalenye ifumana ukushwabana okungalinganiyo. Iveza njengeemilo ezigobileyo ezingacetywanga okanye ezijijekileyo.

Ukubhabha: Ukuba i-thermoplastic itofwe ngokucothayo kwaye iqala ukuseta ngaphambi kokuba i-cavity igcwale, inokubangela ukujeziswa kwemveliso yokugqibela. Ijethi ijongeka ngathi yijethi ejikelezayo kumphezulu wenxalenye.

Amanqaku esinki: Oku kukudandatheka komphezulu okwenzeka ngokupholisa okungalinganiyo okanye xa izibumba zingavumeli ixesha elaneleyo lokuba inxalenye iphole, nto leyo ebangela ukuba imathiriyeli ishwabene ngaphakathi.

Imigca yeWeld: Le yimigca ebhityileyo edla ngokujikeleza iindawo ezinemingxuma. Njengoko iplastiki etyhidiweyo ihamba ijikeleze umngxuma, ukuqukuqela kubini kuyadibana, kodwa ukuba iqondo lobushushu alilunganga, ukuqukuqela akuyi kudibana kakuhle. Isiphumo singumgca we-weld, onciphisa ukuqina kunye namandla enxalenye yokugqibela.

Khupha amanqaku: Ukuba inxalenye ikhutshwe ngokukhawuleza okanye ngamandla amaninzi, iirodi ze-ejector zinokushiya amanqaku kwimveliso yokugqibela.

Vacuum voids: Vacuum voids zenzeka xa iipokotho zomoya zivaleleke ngaphantsi kwendawo. Zibangelwa kukuqiniswa okungalinganiyo phakathi kwamacandelo angaphakathi nangaphandle kwenxalenye.

Iinkonzo zokuBumba isitofu ukusuka kwi-DJmolding

I-DJmolding, umthamo ophezulu, ingcali yokubumba i-injection yesiko, ineminyaka eyi-13 yamava okubumba inaliti. Ukusukela oko kwasekwa i-DJmolding, sizinikele ekuboneleleni abathengi bethu ngezona ndawo zibunjiweyo zenaliti ezikumgangatho ophezulu ezikhoyo. Namhlanje, izinga lethu lesiphene lingaphantsi kwengxenye enye kwisigidi.